Dominican Larimar Mining—Current State and Future Prospects

Abstract

:1. Introduction

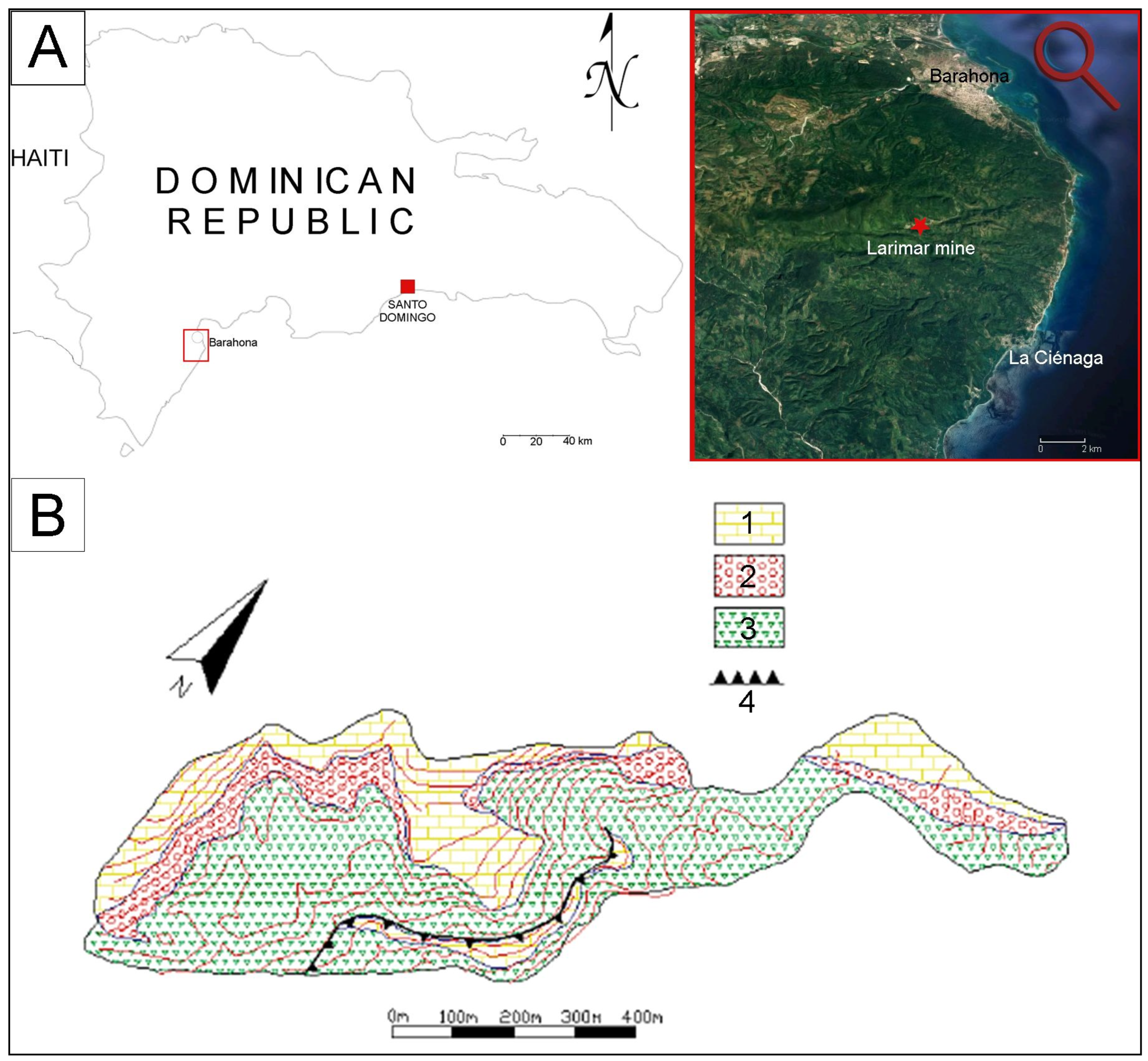

2. Geological Setting

3. Current Mineralogical and Petrological Data of the Rocks Hosting Larimar Deposit

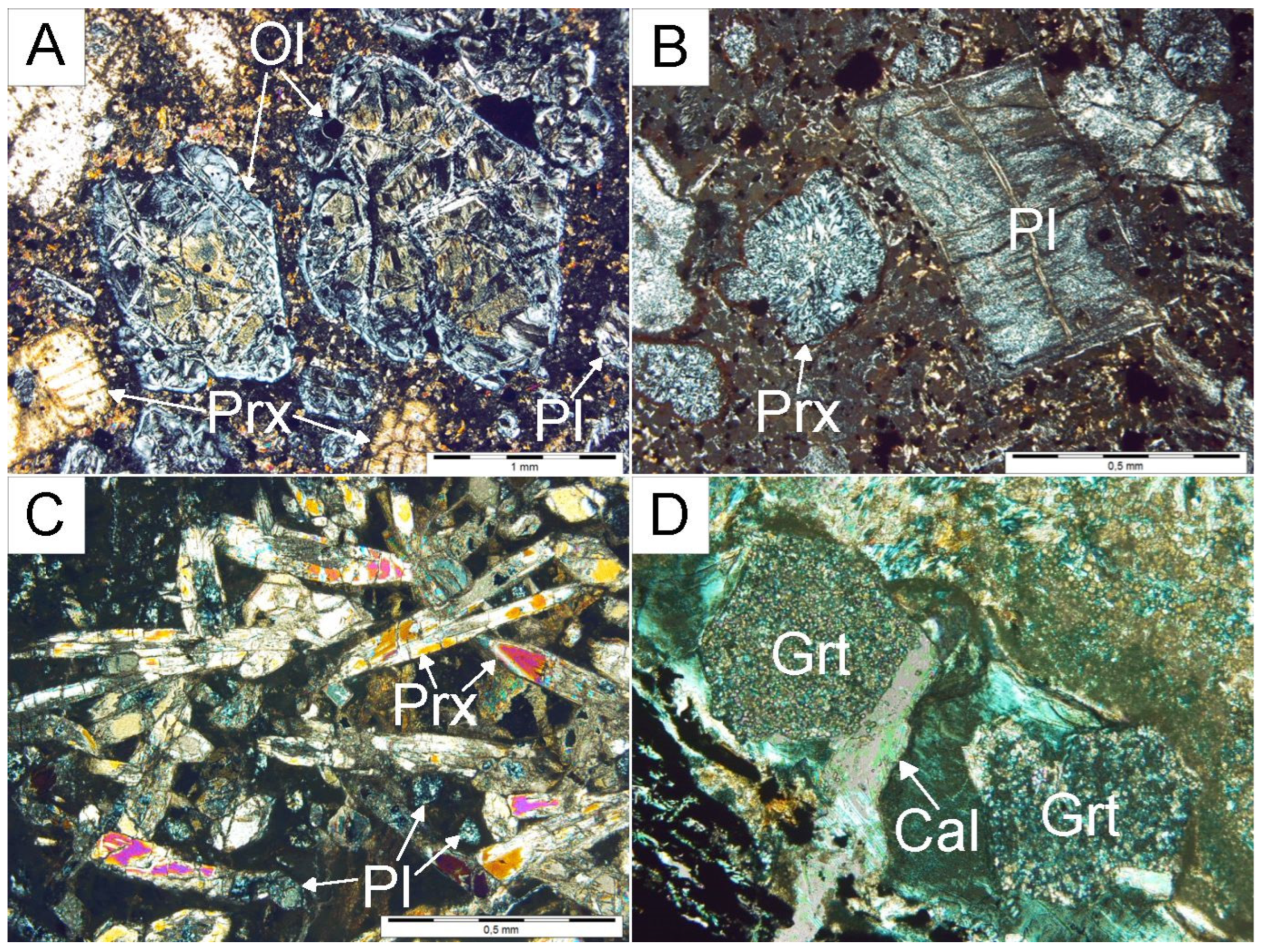

- Lithoclasts are represented by fragments of volcanics (basalts). In the groundmass, only pyroxenes are preserved a state that allows their primary nature (mainly orthopyroxenes, bronsite–hypersthene) to be determined. Some pyroxene grains show a lamellar structure resulting from exsolution of diopsides. In many places, they are accompanied by accumulations of pectolite and garnets. Plagioclase plates are almost completely altered. Many are filled with isotropic, usually irregular garnet grains. Sometimes they are intergrown with pyroxene prisms, which clearly indicate the order of crystallization of the different mineral phases. They are accompanied by numerous iron and titanium oxide clusters (e.g., magnetite, ilmenite, rutile), well visible on SEM images. Titanite grains are also quite numerous. Secondary products include calcite, serpentine group minerals, pectolite, pumpellyite, prehnite and garnets.

- Crystalloclasts are represented by pyroxenes (and possibly olivines) and plagioclases, they are all heavily altered.

- Vitroclasts (palagonite glass) are yellow-brownish; some of them are altered (chloritized).

4. Current State of Larimar Mining

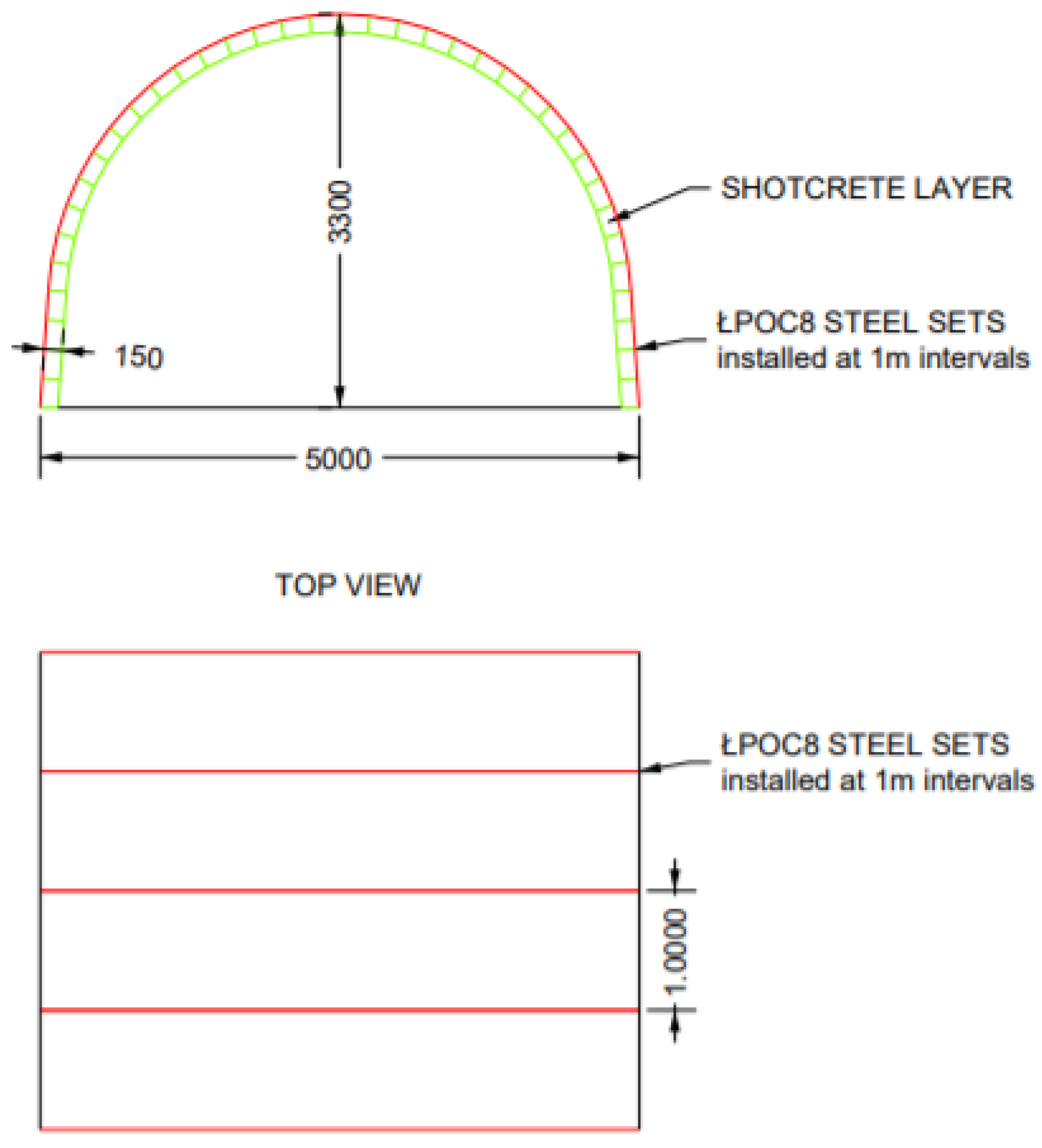

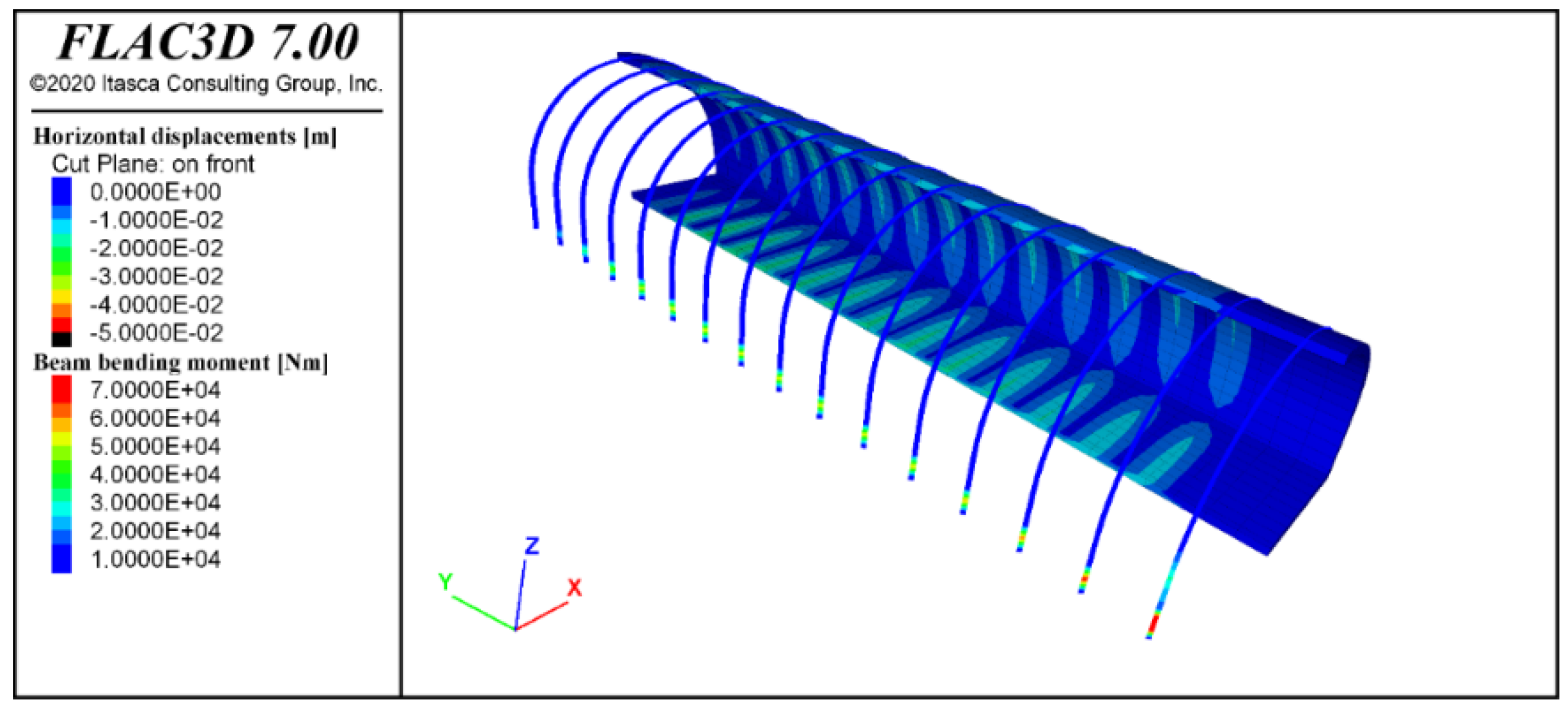

5. Perspectives for Future

- (1)

- Maximum main adit strain of 2% (ratio between opening width and observed displacement) [56];

- (2)

- Maximum bending moment observed in steel set <70 kNm.

6. Summary

- (a)

- The viability of implementing the design to be determined;

- (b)

- The design to be optimized in the future.

7. Conclusions

- The paper contains general assumptions of one of the variants of securing the main adit in the Las Filipinas Larimar Mine. To some extent the presented solution draws on the previous experience in the field of maintenance of the main works of this mine.

- The selection of the potentially most effective method of supporting the mining pits requires a series of geophysical and geotechnical surveys. The tests to be conducted will enable the preparation of design assumptions for the new deposit access structure and the planning of operating works. The option of increasing the role/share of vertical shafts in accessing the deposit is also being considered.

- A test site covering the entire field will be designed together with the Dominican side.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Alvarado, G.E.; Verdeja, E.; Rodriquez, J.; Barrantes, M. Conrtubution on the larimar host rock (Dominican Republic) and some notes about its origen. Bol. Geol. Min. 2007, 128, 767–782. [Google Scholar]

- Woodruff, R.E. Larimar beautiful, blue and baffling. Lap. J. 1986, 39, 26–32. [Google Scholar]

- Woodruff, R.E. The new caribbean gern. North South Net. Inc. 1987, 11, 7–59. [Google Scholar]

- Lizzadro, J. The Interesting Story of a New Blue Gemmaterial Called Larimar. Lizzadro Museum, Summer-Fall. January 1987; 13–14. [Google Scholar]

- Fuertes Marcuello, J.; Garcia Guinea, J. Caracterizaciὀn mineralὀgica e histὀrica del larimar de Barahona (Repứblica Dominicana). Bol. Inst. Gemol. Español 1990, 32, 6–12. (In Spanish) [Google Scholar]

- Kowalczyk, J.; Natkaniec-Nowak, L.; Wachowiak, J. Larimar—A Unique Pectolite Rock from the Dominican Republic. Geol. Geophys. Environ. 2015, 41, 101–102. [Google Scholar] [CrossRef] [Green Version]

- Sen, G.; Hickey-Vargas, D.G.; Waggnaer, E.; Maurrasse, F. Geochemistry of basalts from the Dumisseau Fromation, Southern Haiti: Implications for the origin of the Caribbean Sea crust. Earth Planet. Sc. Lett. 1988, 87, 423–437. [Google Scholar]

- Lewis, J.F.; Draper, G. Geological and Tectonic Evolution of the Northern Caribbean Margin: Decade of North American Geology; Geological Society of America: Boulder, CO, USA, 1990; Volume H, pp. 77–140. [Google Scholar]

- Révillon, S.; Hallot, E.; Arndt, N.; Chauvel, C.; Duncan, R.A. A complex history for the Caribbean Plateau: Petrology, geochemistry, and geochronology of the Beata Rigde, South Hispaniola. J. Geol. 2000, 108, 641–661. [Google Scholar] [CrossRef]

- Escuder-Viruete, J.; Joubert, M.; Abad, M.; Pérez-Valera, F.; Gabites, J. The basaltic volcanism of the Dumisseau Formation in the Sierra de Bahoruco, SW Dominican Republic: A record of the mantle plume-related magmatism of the Caribbean Large Igneous Province. Lithos 2016, 254, 67–83. [Google Scholar] [CrossRef]

- Kowalczyk, J.; George, C.; Nataniemc-Nowak, L.; Wachowiak, J.; Wagner, M. Larimarized fossil charcoal from Sierra de Bahoruco (Barahona Province, Dominican Republic). In Proceedings of the 1 er. Congreso International de Geologia Aplicada, Santo Domingo, Republica Dominicana, 15–17 March 2017; p. 34, In Resumenes Ponencias. [Google Scholar]

- Wagner, M.; Wachowiak, J.; Kowalczyk, J.; Natkaniec-Nowak, L.; Heflik, W.; Georges, C. Petrographic and mineralogical studies of fossil charcoal from Sierra de Bahoruco (Barahona Province, Dominican Republic). Int. J. Coal Geol. 2017, 173, 142–149. [Google Scholar] [CrossRef]

- De Leon, R.O. El Larimar: Origen y composición. Suplemento Listin Diario del Museo de Historia Natural. Rep. Dominic. Marzo 1986, 6–8. (In Spanish) [Google Scholar]

- Schaller, W.T. The pectolite-schizolite-serandite series. Am. Miner. 1955, 40, 1022–1031. [Google Scholar]

- Semenov, E.l.; Maksimyuk, L.E.; Arkangelskaya, V.N. Sobre los minerales del grupo serandita-pectolita. Azp. Vses. Min. Obshch. 1976, 104, 154–163. (In Russian) [Google Scholar]

- Hammer, V.M.F.; Libowitzky, E.; Rossman, G. Single-crystal IR spectroscopy of very strong hydrogen bonds in pectolite, NaCa2[Si3O8(OH)], and serandite, NaMn2[Si3O8(OH)]. Am. Miner. 1988, 83, 569–576. [Google Scholar] [CrossRef]

- Arakcheeva, A.; Pattison, P.; Meisser, N.; Chapuis, G.; Pekov, I.; Thélin, P. New insight into the pectolite—Serandite series: A single crystal diffraction study of Na(Ca1.73Mn0.27)[HSi3O9] at 293 and 100 K. Z. Krist. 2007, 222, 696–704. [Google Scholar] [CrossRef] [Green Version]

- Frost, R.L.; López, A.; Theiss, F.L.; Romano, A.W.; Scholz, R. Vibrational spectroscopic study of the silicate mineral pectolite—NaCa2Si3O8(OH). Spectrochim. Acta A Mol. Biomol. Spectrosc. 2015, 134, 58–62. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Woodruff, R.E.; Fritsch, E. Blue Pectolite from the Dominican Republic. Gems Gemol. 1989, 25, 216–225. [Google Scholar] [CrossRef]

- Kowalczyk-Szpyt, J. Mineralogical, Petrographical and Geochemical Study of the Larimar from the Sierra de Bahoruco Massif (Barahona Province, Dominican Republic); Faculty of Geology, Geophysics and Environmental Protection: Krakow, Poland, Unpublished; 155p. (In Polish)

- Kowalczyk, J.; Heflik, W.; Natkaniec-Nowak, L.; Wachowiak, J. Extrusive Basic Rocks from Sierra de Bahoruco (S-W Dominican Republic) with its Accompanying Processes of Transformation. In Proceedings of the Mineralogicko-Petrologická Konferencia Petros, Bratislava, Slovakia, 25 March 2017; pp. 28–29. [Google Scholar]

- Correcher, V.; Garcia Guinea, J.; Castillejo, M.; Oujja, M.; Rebollar, E.; Lopez-Arce, P. Laser-induced fluorescence and thermoluminescence response of a Na-Ca rich silicate. Radiat. Meas. 2006, 41, 971–975. [Google Scholar] [CrossRef]

- Kowalczyk, J.; Natkaniec-Nowak, L.; Wachowiak, J.; George, C. Preliminary Mineralogical and Petrographical Studies of the Larimar from Dominican Republic (Sierra de Bahoruco, Barahona Province). In Proceedings of the Polish Geological Congress, Wroclaw, Poland, 22 November 2016; pp. 167–168. [Google Scholar]

- Kraj, K. Mineralogical and Dendrological Studies of Mineralized Tree Trunks from Barahona Province (Dominican Republic); Faculty of Geology, Geophysics and Environmental Protection: Krakow, Poland, 2017; Unpublished work. (In Polish) [Google Scholar]

- Bente, K.; Thum, R.; Wannemacher, J. Colored Pectolites, so called “Larimar”, from Sierra de Bahoruco, Barahona Province, southern Dominican Republic. Neues Jahrb. Mineral. Monatsh. 1991, 1, 14–22. [Google Scholar]

- Espí, R.J.A. Singularidad del yacimiento mineral de la sierra de Bahoruco (República Dominicana) y su carácter patrimonial. De Re Met. Madr. 2007, 9, 41–52. (In Spanish) [Google Scholar]

- Espi, J.A.; Borrego, A.G. Petrographic Assessment of Organic Material Associated to Pectolite Deposits in Dominican Republic, Implications for its Genesis. In Proceedings of the International Conference for Coal and Organic Petrolology, Oviedo, Spain, 21–27 September 2008; The Society for Organic Petrology: Oviedo, Spain, 2008. [Google Scholar]

- Espi, J.A.; Pérez-Puig, C. El Proyecto Sobre el Estudio Geológico y Realización de Infraestructuras de Apoyo a la Minería del Larimar en la República Dominicana; Escuela de Minas de Madrid: Madrid, Spain, 2009. [Google Scholar]

- Sullasi, H.L.; Khoury, H.J.; Barros, V.; Libonati, R.; Guzzo, P.L.; Asfora, V.; De Araujo, R.E.; Capriles, M.; Reyes, J. Thermoluminescence response of the larimar rocks. Radiat. Meas. 2010, 45, 540–542. [Google Scholar] [CrossRef]

- Kloprogge, J.T.; Wood, B.J. X-ray Photoelectron Spectroscopy study of so-called “Larimar”, blue pectolite from the Dominican Republic. SDPR J. Earth Sc. Environ. Stud. 2016, 1, 1–5. [Google Scholar]

- Espi, J.A.; Pérez-Puig, C. Origin and model formation of the semi-precious Larimar stone in the Sierra de Bahoruco, Dominican Republic. Bol. Geol. Miner. 2017, 128, 803–828. [Google Scholar] [CrossRef]

- Bowin, C. The Geology of Hispaniola. In The Gulf of Mexico and the Caribbean; Nairn, A.E.M., Stehli, F.G., Eds.; Springer: Boston, MA, USA, 1975. [Google Scholar]

- Donnelly, T.W.; Beets, D.; Carr, M.J.; Jackson, T.; Klaver, G.; Lewis, J.; Maury, R.; Schellenckens, H.; Smith, A.; Wadge, G.; et al. History and tectonic setting of Caribbean magmatism. Geol. Soc. Am. 1990, 13, 339–374. [Google Scholar]

- Draper, G.; Mann, P.; Lewis, J.F. Hispaniola. In Caribbean Geology: An introduction; Donovan, S.K., Jackson, T.A., Eds.; University of the West Indies: Kingston, Jamaica, 1994; pp. 129–150. [Google Scholar]

- Sandoval Gutiérrez, M.I.; Baumgartner, P.; Escuder-Viruete, J.; Gabites, J.; de Lépinay, B. Late Cretaceous radiolarian biochronology of the Pedro Brand section, Tireo Group, eastern Central Cordillera, Dominican Republic: A contribution to the stratigraphy of the Caribbean Large Igneous Province. Rev. Micropaléontol. 2015, 58, 85–106. [Google Scholar] [CrossRef]

- Diebold, J.B.; Driscoll, N.W.; Team, E.W. New Insights on the Formation of the Caribbean Basalt Province revealed by multichannel seismic images of volcanic structures in the Venezuelan Basin, Caribbean basins. In Sedimentary Basins of the World; Mann, P., Ed.; Elsevier: Amsterdam, The Netherlands, 1999; pp. 561–589. [Google Scholar]

- Byrne, D.B.; Suarez, G.; Mccann, W.R. Muertos Trough subduction; microplate tectonics in the northern Caribbean? Nature 1985, 317, 420–421. [Google Scholar] [CrossRef]

- Masson, D.G.; Scanlon, K.M. The neotectonic setting of Puerto Rico. Geol. Soc. Am. Bull. 1991, 103, 144–154. [Google Scholar] [CrossRef]

- Mann, P.; McLaughlin, P.P.; Cooper, C. Geology of the Azua and Enriquillo basins, Dominican Republic; 2, Structure and Tectonics. In Geologic and Tectonic Development of the North America-Caribbean Plate Boundary in Hispaniola; Geological Society of America: Boulder, CO, USA, 1991; Volume 262, pp. 367–389. [Google Scholar]

- Mann, P.; Prentice, C.S.; Burr, G.; Pea, L.R.; Taylor, F.W. Tectonic geomorphology and paleoseismology of the Septentrional fault system. Bull. Seism. Soc. Am. 1998, 103, 144–154. [Google Scholar]

- Escuder-Viruete, J.; Hernaiz Huerta, P.P.; Draper, G.; Gutierrez, G.; Lewis, J.F.; Pérez-Estaún, A. Metamorfismo y estructura de la Formación Maimón y los Complejos Duarte y Río Verde, Cordillera Central Dominicana: Implicaciones en la estructura y la evolución del primitivo Arco Isla Caribeño—The metamorphism and structure of the Maimón Formation and Duarte and Rio Verde Complexes, Dominican Central Cordillera: Implications for the structure and evolution of the primitive Caribbean Island Arc. Acta Geol. Hisp. 2002, 37, 123–162. (In Spanish) [Google Scholar]

- Goldfinger, C. Submarine paleoseismology based on turbidite records. Ann. Rev. Mar. Sci. 2011, 3, 35–66. [Google Scholar] [CrossRef] [Green Version]

- Zoppis de Sena, R. Atlas Geológico y Mineralógico de la República Dominicana Mapa Geológico de la República Dominicana Escala 1: 50000; Servicio Geologico Nacional Republica Dominikana: Santo Domingo, Dominican Republic, 1988; p. 20. [Google Scholar]

- Mauffret, A.; Leroy, S. Seismic stratigraphy and structure of the Caribbean igneous province. Tectonophysics 1997, 283, 61–104. [Google Scholar] [CrossRef]

- Lapierre, H.; Bosch, D.; Dupuis, V.; Polvé, M.; Maury, R.; Hermandez, J.; Monié, P.; Yeghicheyan, D.; Jailland, E.; Tardy, M.; et al. Multiple plume events in the genesis of the peri-Caribbean Cretaceous oceanic plateau province. J. Geophys. Res. 2000, 105, 8403–8421. [Google Scholar] [CrossRef]

- Escuder-Viruete, J.; Pérez-Estaún, A.; Contreras, F.; Joubert, M.; Weis, D.; Ulrich, T.D.; Spadea, P. Plume mantle source heterogeneity through time: Insights from the Duarte Complex, Central Hispaniola. J. Geophys. Res. 2007, 112, 1–19. [Google Scholar]

- Escuder-Viruete, J.; Pérez-Estaún, A.; Joubert, M.; Weis, D. The Pelona-Pico Duarte basalts formation, Central Hispaniola. An on-land section of the Late Cretaceous volcanism related to the Caribbean large-igneous province. Geol. Acta 2011, 9, 1–22. [Google Scholar]

- Hastie, A.R.; Kerr, A.C.; Mitchell, S.F.; Millar, I.I.; James, K.H.; Lorente, M.A.; Pindell, J.I. Geochemistry and Tectonomagmatic Significance of Lower Cretaceous Island Arc Lavas from the Devils Racecourse Formation, Eastern Jamaica. The Origin and Evolution of the Caribbean Plate; The Geological Society of London: London, UK, 2009; Volume 328, pp. 339–360. [Google Scholar]

- Loeven, M.W.; Duncan, R.A.; Kent, A.J.R.; Krawl, K. Prolonged plume volcanism in the Caribbean Large Igneous Province: New insights from Curaçao and Haiti. Geoch. Geoph. Geosyst. 2013, 14, 4241–4259. [Google Scholar]

- Whattam, S.A.; Stern, R.J. Late Cretaceous plume-induced subduction initiation along the southern margin of the Caribbean and NW South America: The first documented example with implications for the onset of plate tectonics. Gondwana Res. 2015, 27, 38–63. [Google Scholar] [CrossRef]

- Escuder-Viruete, J.; Pérez-Estaún, A.; Weis, D. Geochemical constraints on the origin of the late Jurassic proto-Cretaceous oceanic crust in Hispaniola. Int. J. Earth Sci. 2010, 98, 407–425. [Google Scholar] [CrossRef]

- IGME-BRGM-INYPSA. Mapa geológico de la República Dominicana, escala 1: 50.000. La Ciénaga (5970-II); Informe inédito. Proyecto SYSMIN II-01-B; Servicio Geologico Nacional Republica Dominikana: Santo Domingo, Dominican Republic, 2010; p. 202. [Google Scholar]

- Huerta, P.P.; Díaz de Neira, J.A.; García-Senz, J.; Deschamps, I.; Lopera, E.; Escuder Viruete, J.; Ardévol Oró, L.I.; Granados, L.; Calvo, J.P.; Pérez-Estaún, A. La estratigrafía de la Sierra de Neiba (República Dominicana). Boletín Geológico Min. 2007, 118, 313–336. (In Spanish) [Google Scholar]

- Meznaric, M.; Hensold, G.; Karami, A. Instituto Canadiense de Recursos Internacionales Y Desarollo (CIRDI), Mina Larimar, Evaluación de peligros geotécnicos y opciones de Gestión—PROJECTO; Servicio Geologico Nacional Republica Dominikana: Santo Domingo, Dominican Republic, 2018; Unpublished Report. [Google Scholar]

- Geovértice. Galería de Exploración, Mina Larimar—Levantamiento Topográfico: Planta y Longitudinal; Geovértice: Santo Domingo, Dominican Republic, 2010. [Google Scholar]

- Karakaplan, E.; Basarir, H.; Wesseloo, J. Theoretical Investigation of the Effect of Stress on the Performance of Support Systems Based on Rock Mass Rating (RMR) Support Recommendations. In Proceedings of the Eighth International Symposium on Ground Support in Mining and Underground Construction, Luleå, Sweden, 12–14 September 2016. [Google Scholar]

- Bieniawski, Z.T. Engineering Rock Mass Classification: A Complete Manual for Engineers and Geologists in Mining, Civil and Petroleum Engineering; John Wiley & Sons: Hoboken, NJ, USA, 1989; 251p. [Google Scholar]

- Birid, K. Comparative Study of Rock Mass Deformation Modulus Using Different Approaches. In Proceedings of the 8th Asian Rock Mechanics Symposium, Sapporo, Japan, 14–16 October 2014; pp. 553–563. [Google Scholar]

- Galera, J.M.; Alvarez, Z.; Bieniawski, Z.T. Evaluation of the Deformation Modulus of Rock Masses: Comparison between Pressure Meter and Dilatometer Tests with RMR Predictions. In Proceedings of the ISP5-PRESSIO, Marne-la-vallée, France, 22–24 August 2005; Gambin, M., Mestat, P., Baguelin, F., Eds.; LCPC Publication: Paris, France, 2005. [Google Scholar]

- Kaiser, P.K.; Ming, C. Principle of rockbolting design. J. Rock Mech. Geotech. Eng. 2012, 4, 215–227. [Google Scholar] [CrossRef] [Green Version]

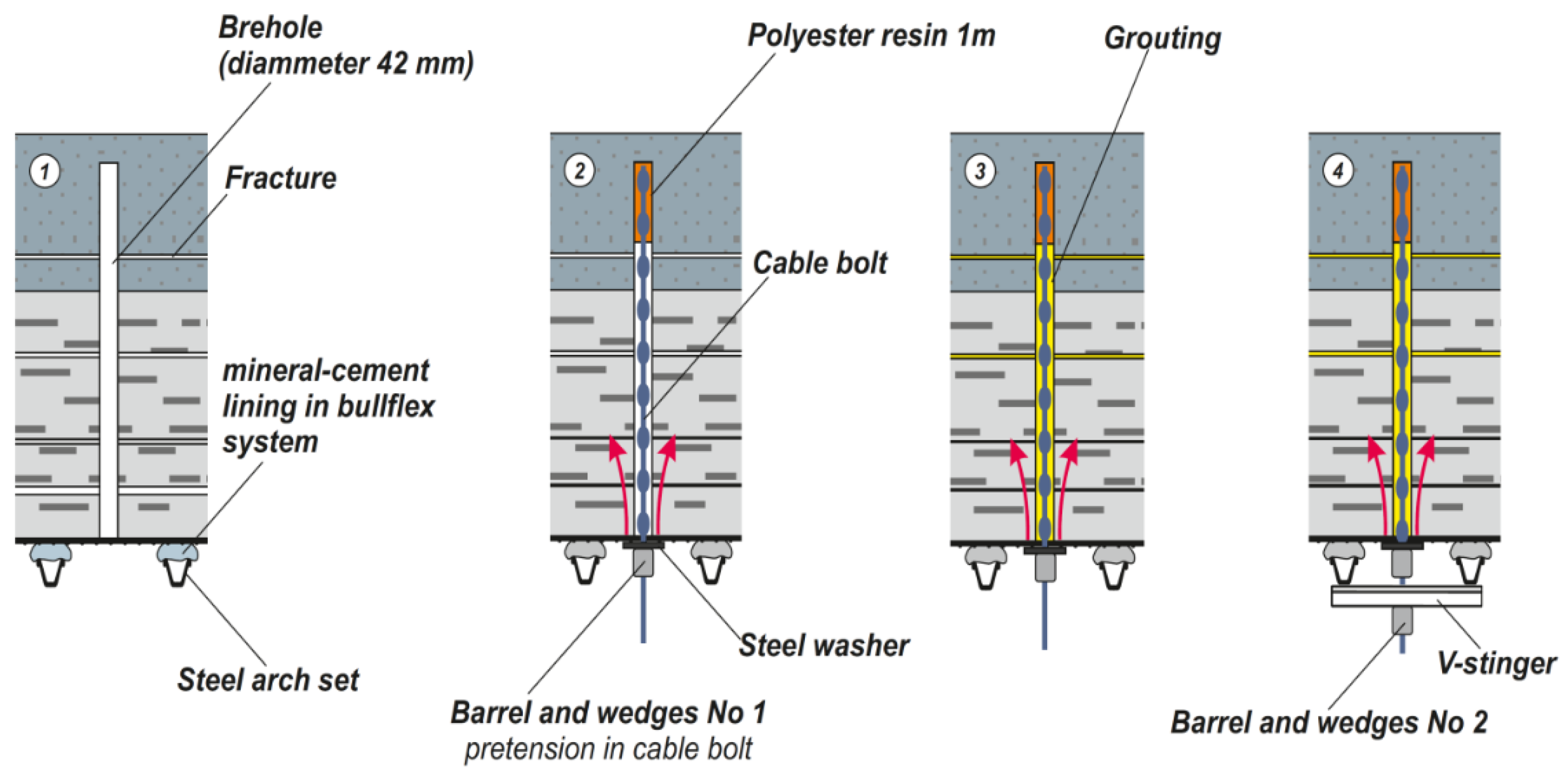

- Rak, Z.; Stasica, J.; Rawicki, Z. Selected problems in using roof bolting for the reinforcement of chock support in preparatory excavations. Occup. Saf. Environ. Prot. Min. 2016, 2, 3–13. (In Polish) [Google Scholar]

- Rak, Z.; Cieślik, J.; Stasica, J.; Dvorak, P. The importance of pre-tensioning cable bolts used to reinforce of arch yielding support. E3S Web Conf. 2018, 66, 03003. [Google Scholar] [CrossRef]

- Małkowski, P.; Rak, Z.; Stasica, J. Elements of constructing mechanical lining in the light of previous experience. Problemy Współczesnego Górnictwa 2011, 1/1, 316–326. (In Polish) [Google Scholar]

- Małkowski, P.; Rak, Z. Influence of mechanical lining on the state of stress around a gate drifted in weak carboniferous rocks. Problemy Współczesnego Górnictwa 2011, 1/1, 251–262. (In Polish) [Google Scholar]

- Stankus, J.; Li, X.; Giza, D.; Rutyna, M. Rock Anchoring and Grouting: Use of SUMO Cable Bolts in Western U.S. Longwall Recovery. In Proceedings of the XXI International Scientific and Technical Conference in the Mining Natural Hazards, Targanice, Poland, 4–7 November 2014; Series Natural Hazards Versus Safe and Effective Mines. pp. 35–37. (In Polish). [Google Scholar]

| Rock Mass Properties | |

|---|---|

| Rock Mass Rating (RMR) | 19 |

| Failure criterion | Mohr–Coulomb |

| Cohesion | 100 kPa |

| Angle of friction | 15° |

| Young’s modulus | 1664.4 MPa |

| Density | 2700 kg/m3 |

| Depth | 0–104 |

| Depth | Steel Set | Shotcrete | Floor Reinforcement |

|---|---|---|---|

| <30 m | 1 m interval | 10 cm | no |

| 30 < d < 50 m | 1 m interval | 15 cm | no |

| 50 < d < 104 m | 1 m interval | 15 cm | shotcrete 15 cm |

| Parameter | Titan | Sumo | IR-7/F |

|---|---|---|---|

| Capacity | 550 kN | 568 kN | >500 kN |

| Rod diameter | 28 mm | 28 mm | 28 mm |

| Cage diameter | Ø36 mm | Ø35 mm | Ø34 mm |

| Anchor hole diameter | Ø42 mm | Ø42 mm | Ø42 mm |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Broda, K.; Natkaniec-Nowak, L.; Rak, Z.; Stasica, J.; Heflik, W.; Mościcki, J.; Peña, M.; Muñoz, R.; George, C. Dominican Larimar Mining—Current State and Future Prospects. Minerals 2022, 12, 181. https://doi.org/10.3390/min12020181

Broda K, Natkaniec-Nowak L, Rak Z, Stasica J, Heflik W, Mościcki J, Peña M, Muñoz R, George C. Dominican Larimar Mining—Current State and Future Prospects. Minerals. 2022; 12(2):181. https://doi.org/10.3390/min12020181

Chicago/Turabian StyleBroda, Krzysztof, Lucyna Natkaniec-Nowak, Zbigniew Rak, Jerzy Stasica, Wiesław Heflik, Jerzy Mościcki, Miguel Peña, Rolando Muñoz, and Carlos George. 2022. "Dominican Larimar Mining—Current State and Future Prospects" Minerals 12, no. 2: 181. https://doi.org/10.3390/min12020181

APA StyleBroda, K., Natkaniec-Nowak, L., Rak, Z., Stasica, J., Heflik, W., Mościcki, J., Peña, M., Muñoz, R., & George, C. (2022). Dominican Larimar Mining—Current State and Future Prospects. Minerals, 12(2), 181. https://doi.org/10.3390/min12020181