Effect of Grinding Media Size on Ferronickel Slag Ball Milling Efficiency and Energy Requirements Using Kinetics and Attainable Region Approaches

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

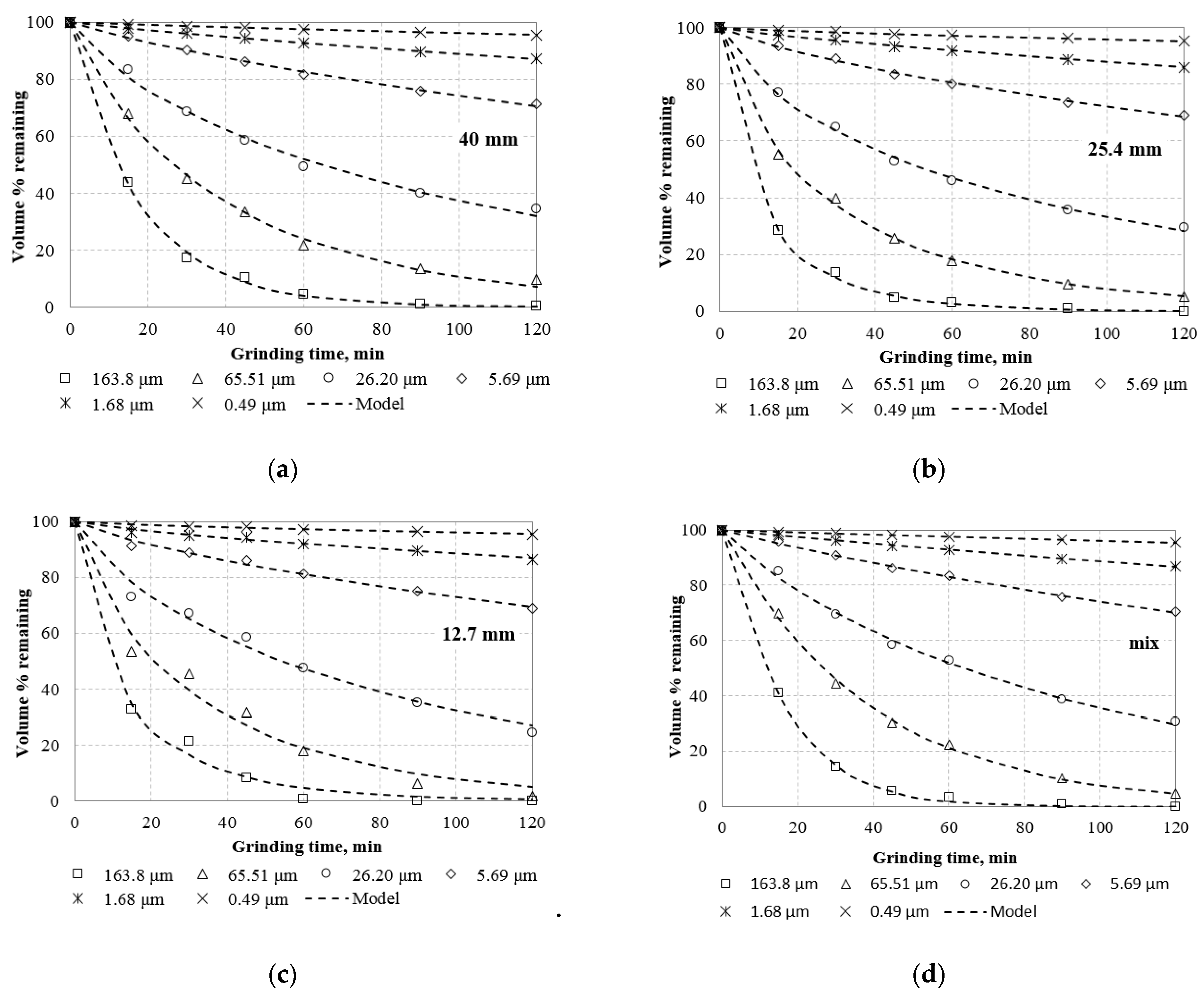

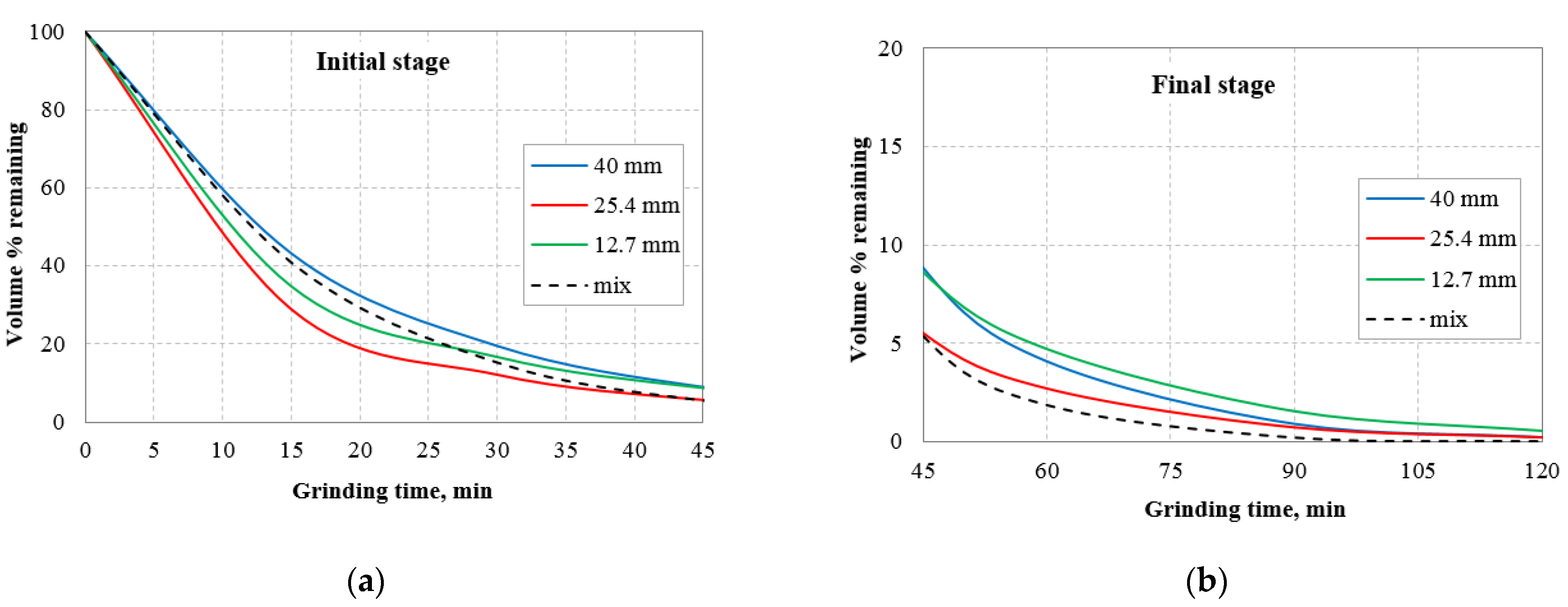

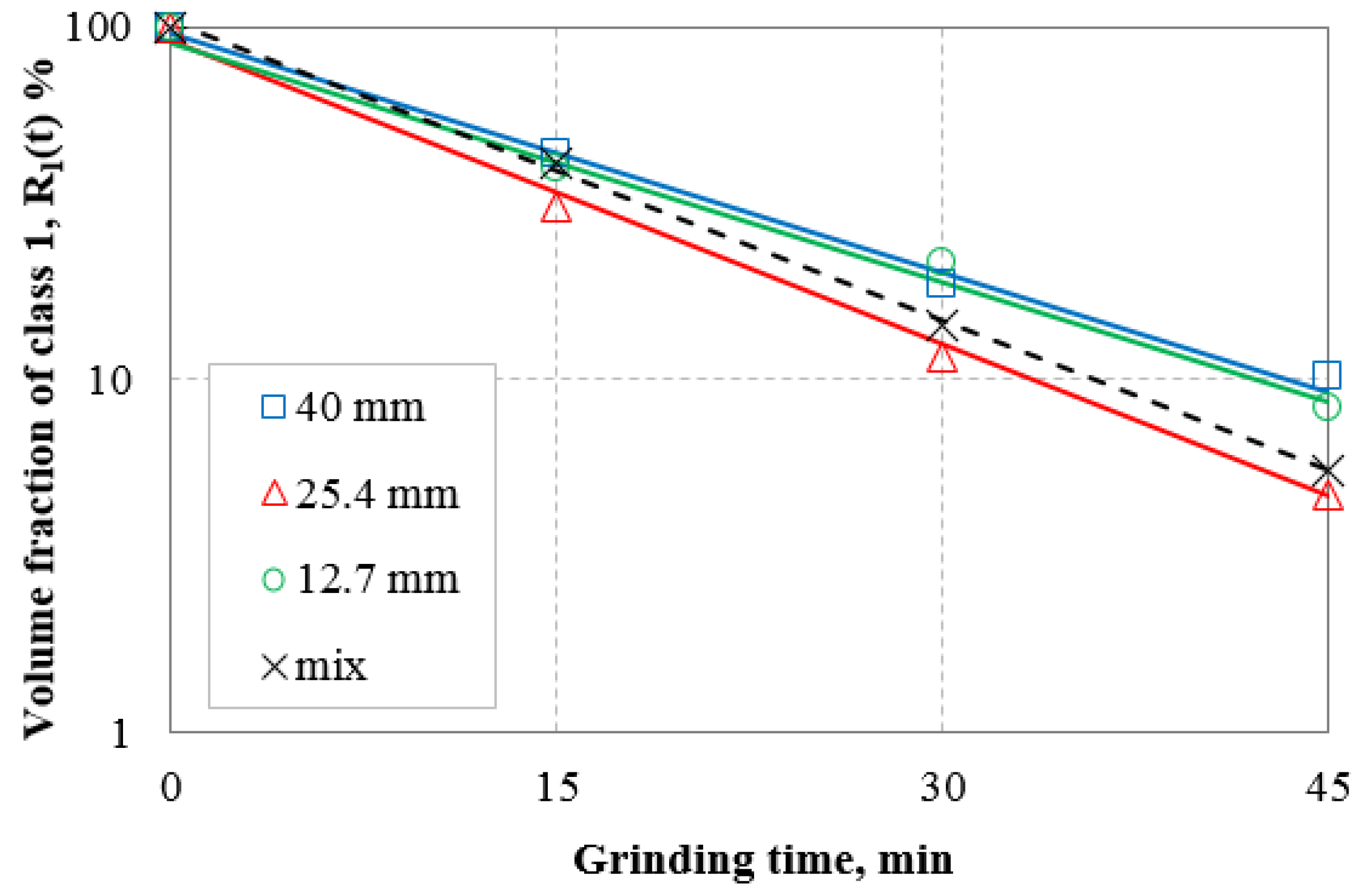

3.1. Grinding Kinetics

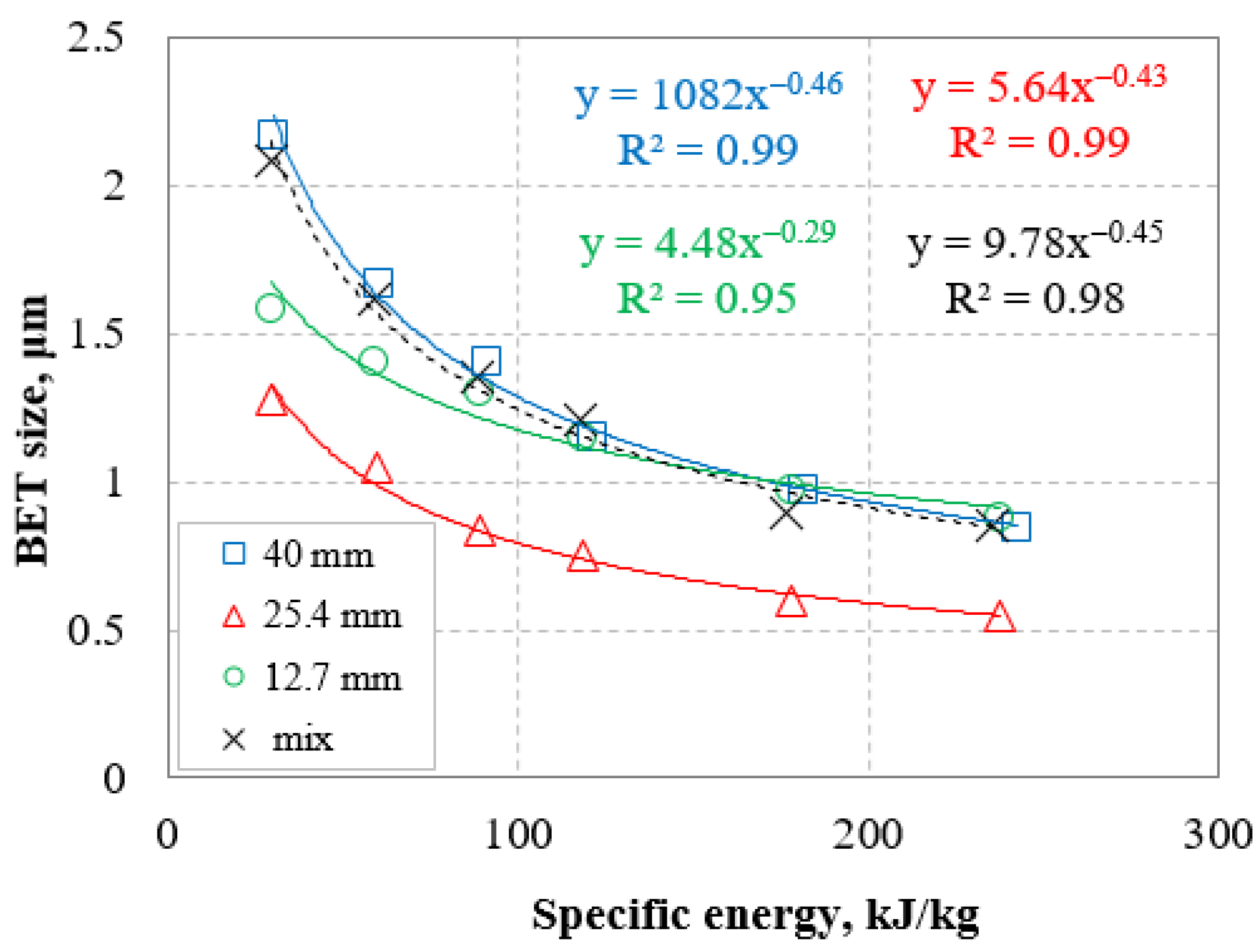

3.2. Particle Size and Specific Surface Area of Slag Products

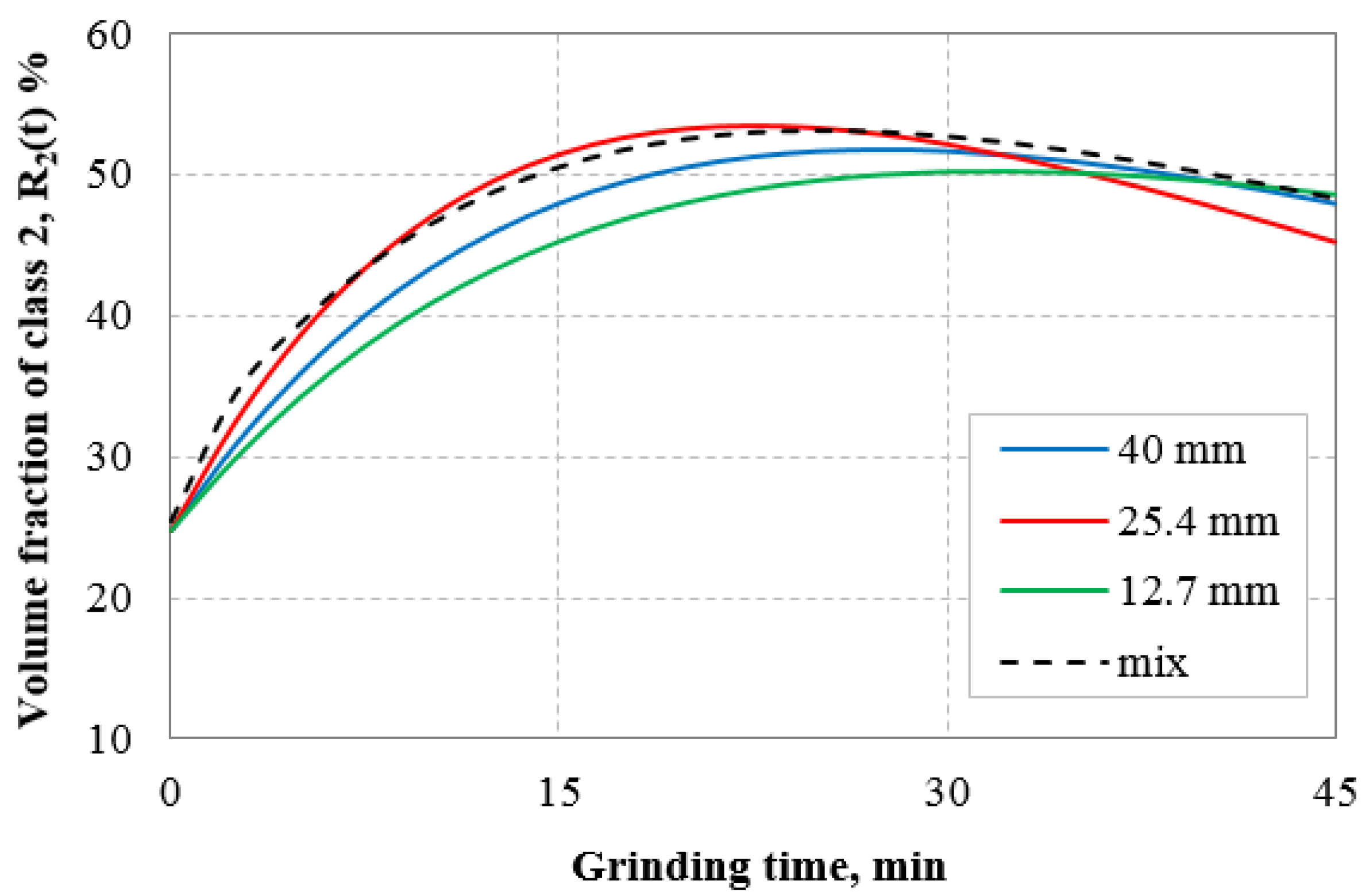

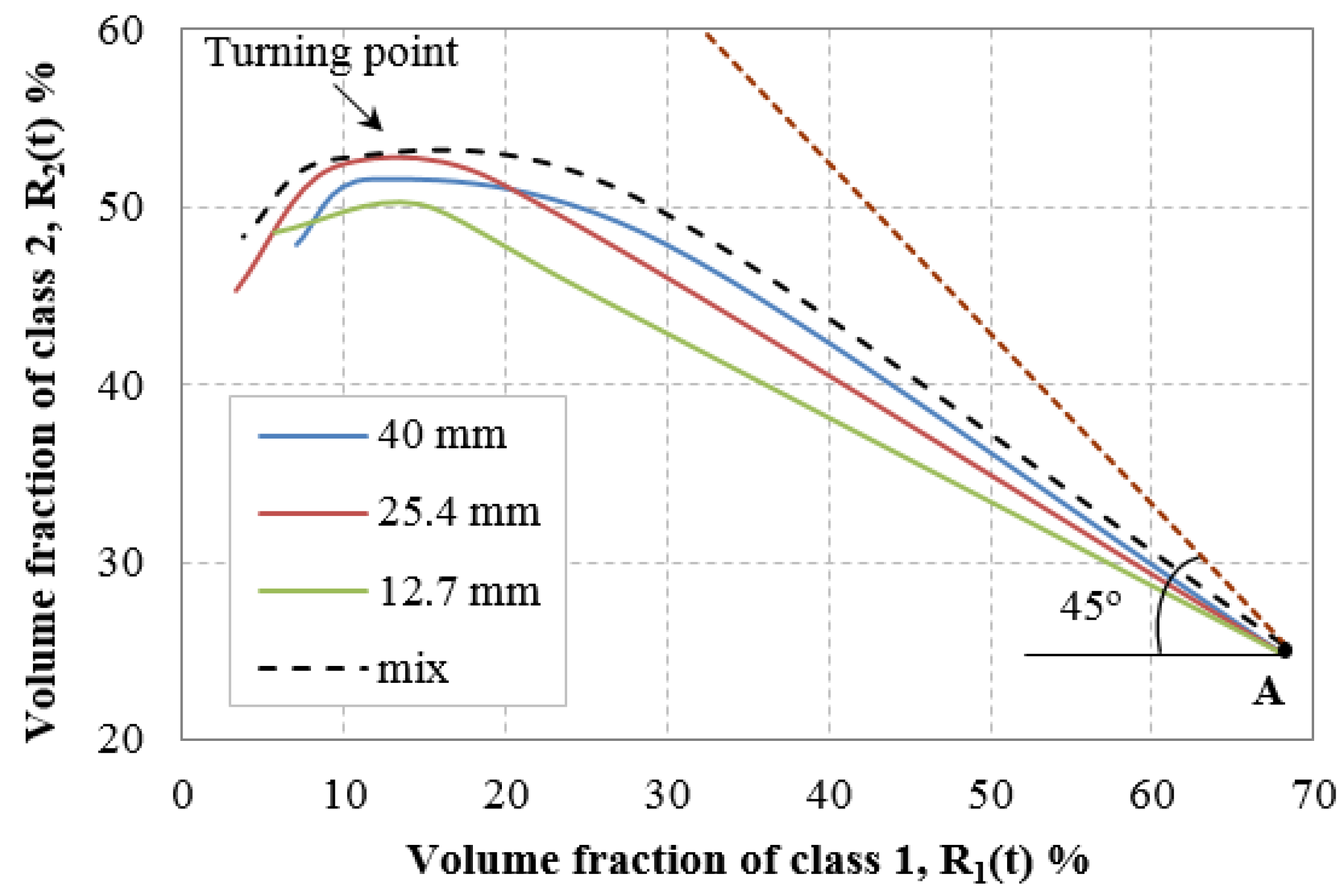

3.3. Analysis of the Attainable Region Technique

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sibanda, V.; Sipunga, E.; Danha, G.; Mamvura, T.A. Enhancing the flotation recovery of copper minerals in smelter slags from Namibia prior to disposal. Heliyon 2020, 6, e03135. [Google Scholar] [CrossRef] [Green Version]

- Sun, W.; Li, X.; Liu, R.; Zhai, Q.; Li, J. Recovery of Valuable Metals from Nickel Smelting Slag Based on Reduction and Sulfurization Modification. Minerals 2021, 11, 1022. [Google Scholar] [CrossRef]

- Gabasiane, T.S.; Danha, G.; Mamvura, T.A.; Mashifana, T.; Dzinomwa, G. Characterization of copper slag for beneficiation of iron and copper. Heliyon 2021, 7, e06757. [Google Scholar] [CrossRef]

- Piatak, N.M.; Parsons, M.B.; Seal, R.R., II. Characteristics and environmental aspects of slag: A review. Appl. Geochem. 2015, 57, 236–266. [Google Scholar] [CrossRef]

- Roy, S.; Datta, A.; Rehani, S. Flotation of copper sulphide from copper smelter slag using multiple collectors and their mixtures. Int. J. Miner. Process. 2015, 143, 43–49. [Google Scholar] [CrossRef]

- Guo, Z.; Zhu, D.; Pan, J.; Zhang, F. Innovative methodology for comprehensive and harmless utilization of waste copper slag via selective reduction-magnetic separation process. J. Clean. Prod. 2018, 187, 910–922. [Google Scholar] [CrossRef]

- Gao, F.; Huang, Z.; Li, H.; Li, X.; Wang, K.; Hamza, M.F.; Wei, Y.; Fujita, T. Recovery of magnesium from ferronickel slag to prepare hydrated magnesium sulfate by hydrometallurgy method. J. Clean. Prod. 2021, 303, 127049. [Google Scholar] [CrossRef]

- Komnitsas, K.; Zaharaki, D.; Perdikatsis, V. Effect of synthesis parameters on the compressive strength of low-calcium ferronickel slag inorganic polymers. J. Hazard. Mater. 2009, 161, 760–768. [Google Scholar] [CrossRef]

- Mehta, A.; Siddique, R. Sustainable geopolymer concrete using ground granulated blast furnace slag and rice husk ash: Strength and permeability properties. J. Clean. Prod. 2018, 205, 49–57. [Google Scholar] [CrossRef]

- Bartzas, G.; Komnitsas, K. Life cycle assessment of ferronickel production in Greece. Resour. Conserv. Recycl. 2015, 105, 113–122. [Google Scholar] [CrossRef]

- Komnitsas, K.; Bartzas, G.; Karmali, V.; Petrakis, E.; Kurylak, W.; Pietek, G.; Kanasiewicz, J. Assessment of alkali activation potential of a Polish ferronickel slag. Sustainability 2019, 11, 1863. [Google Scholar] [CrossRef] [Green Version]

- Gao, D.; Wang, F.-P.; Wang, Y.-T.; Zeng, Y.-N. Sustainable Utilization of Steel Slag from Traditional Industry and Agriculture to Catalysis. Sustainability 2020, 12, 9295. [Google Scholar] [CrossRef]

- Holmberg, K.; Kivikytö-Reponen, P.; Härkisaari, P.; Valtonen, K.; Erdemir, A. Global energy consumption due to friction and wear in the mining industry. Tribol. Int. 2017, 115, 116–139. [Google Scholar] [CrossRef]

- Jeswiet, J.; Szekeres, A. Energy Consumption in Mining Comminution. Procedia CIRP 2016, 48, 140–145. [Google Scholar] [CrossRef] [Green Version]

- Petrakis, E.; Komnitsas, K. Development of a Non-linear Framework for the Prediction of the Particle Size Distribution of the Grinding Products. Mining Metall. Explor. 2021, 38, 1253–1266. [Google Scholar] [CrossRef]

- Komnitsas, K.; Yurramendi, L.; Bartzas, G.; Karmali, V.; Petrakis, E. Factors affecting co-valorization of fayalitic and ferronickel slags for the production of alkali activated materials. Sci. Total Environ. 2020, 721, 137753. [Google Scholar] [CrossRef]

- Branca, T.A.; Colla, V.; Algermissen, D.; Granbom, H.; Martini, U.; Morillon, A.; Pietruck, R.; Rosendahl, S. Reuse and Recycling of By-Products in the Steel Sector: Recent Achievements Paving the Way to Circular Economy and Industrial Symbiosis in Europe. Metals 2020, 10, 345. [Google Scholar] [CrossRef] [Green Version]

- Stamboliadis, E. A contribution to the relationship of energy and particle size in the comminution of brittle particulate materials. Miner. Eng. 2002, 15, 707–713. [Google Scholar] [CrossRef]

- Austin, L.G.; Klimpel, R.R.; Luckie, P.T. Process Engineering of Size Reduction: Ball Milling; SME–AIME: New York, NY, USA, 1984. [Google Scholar]

- Wills, B.A.; Finch, J. Will’s Mineral Processing Technology. An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, 8th ed.; Butterworth-Heinemann: Oxford, UK, 2016. [Google Scholar]

- Faria, P.M.C.; Rajamani, R.K.; Tavares, L.M. Optimization of Solids Concentration in Iron Ore Ball Milling through Modeling and Simulation. Minerals 2019, 9, 366. [Google Scholar] [CrossRef] [Green Version]

- Deniz, V.; Onur, T. Investigation of the breakage kinetics of pumice samples as dependent on powder filling in a ball mill. Int. J. Miner. Process. 2002, 67, 71–78. [Google Scholar] [CrossRef]

- Chimwani, N.; Glasser, D.; Hildebrandt, D.; Metzger, M.J.; Mulenga, F.K. Determination of the milling parameters of a platinum group minerals ore to optimize product size distribution for flotation purposes. Miner. Eng. 2013, 43–44, 67–78. [Google Scholar] [CrossRef]

- Simba, K.P.; Moys, M.H. Effects of mixtures of grinding media of different shapes on milling kinetics. Miner. Eng. 2014, 61, 40–46. [Google Scholar] [CrossRef]

- Petrakis, E.; Stamboliadis, E.; Komnitsas, K. Identification of optimal mill operating parameters during grinding of quartz with the use of population balance modelling. KONA Powder Part. J. 2017, 34, 213–223. [Google Scholar] [CrossRef] [Green Version]

- Celik, M.S. Acceleration of breakage rates of anthracite during grinding in a ball mill. Powder Technol. 1988, 54, 227–233. [Google Scholar] [CrossRef]

- Rajamani, R.K.; Guo, D. Acceleration and deceleration of breakage rates in wet ball mills. Int. J. Miner. Process. 1992, 34, 103–118. [Google Scholar] [CrossRef]

- Bilgili, E.; Scarlett, B. Population balance modeling of nonlinear effects in milling processes. Powder Technol. 2005, 153, 59–71. [Google Scholar] [CrossRef]

- Deniz, V. The effect of mill speed on kinetic breakage parameters of clinker and limestone. Cem. Concr. Res. 2004, 34, 1365–1371. [Google Scholar] [CrossRef]

- Katubilwa, F.M.; Moys, M.H. Effect of ball size distribution on milling rate. Miner. Eng. 2009, 22, 1283–1288. [Google Scholar] [CrossRef]

- Deniz, V. The effects of ball filling and ball diameter on kinetic breakage parameters of barite powder. Adv. Powder Technol. 2012, 23, 640–646. [Google Scholar] [CrossRef]

- Shin, H.; Lee, S.; Suk Jung, H.; Kim, J.-B. Effect of ball size and powder loading on the milling efficiency of a laboratory-scale wet ball mill. Ceram. Int. 2013, 39, 8963–8968. [Google Scholar] [CrossRef]

- Olejnik, T.P. Selected mineral materials grinding rate and its effect on product granulometric composition. Physicochem. Probl. Miner. Proc. 2013, 49, 407–418. [Google Scholar]

- Mulenga, F.K.; Moys, M.H. Effects of slurry filling and mill speed on the net power draw of a tumbling ball mill. Miner. Eng. 2014, 56, 45–56. [Google Scholar] [CrossRef]

- Umucu, Y.; Altınigne, M.Y.; Deniz, V. The effects of ball types on breakage parameters of barite. J. Pol. Min. Eng. Soc. 2014, 15, 113–117. [Google Scholar]

- Harris, C.C. The Alyavdin-Weibull Plot of Grinding Data and the Order of Kinetics. Powder Technol. 1973, 7, 123–127. [Google Scholar] [CrossRef]

- Guo, W.; Han, Y.; Gao, P.; Li, Y.; Tang, Z. Effect of feed size on residence time and energy consumption in a stirred mill: An attainable region method. Powder Technol. 2021, 379, 485–493. [Google Scholar] [CrossRef]

- Horn, F. Attainable and non-attainable regions in chemical reaction technique. In Proceedings of the Third European Symposium on Chemical Reaction Engineering, Amsterdam, The Netherlands, 15–17 September 1964; Pergamon Press Ltd.: London, UK, 1964. [Google Scholar]

- Khumalo, N.; Glasser, D.; Hildebrandt, D.; Hausberger, B.; Kauchali, S. The application of the attainable region analysis to comminution. Chem. Eng. Sci. 2006, 61, 5969–5980. [Google Scholar] [CrossRef]

- Guo, W.; Gao, P.; Tang, Z.; Han, Y.; Meng, X. Effect of grinding media properties and stirrer tip speed on the grinding efficiency of a stirred mill. Powder Technol. 2021, 382, 556–565. [Google Scholar] [CrossRef]

- Petrakis, E.; Komnitsas, K. Modeling of bauxite ore wet milling for the improvement of process and energy efficiency. Circ. Econ. Sustain. 2021, 1–15. [Google Scholar] [CrossRef]

- Tsave, P.K.; Kostoglou, M.; Karapantsios, T.D.; Lazaridis, N.K. A Hybrid Device for Enhancing Flotation of Fine Particles by Combining Micro-Bubbles with Conventional Bubbles. Minerals 2021, 11, 561. [Google Scholar] [CrossRef]

- Egan, J.; Bazin, C.; Hodouin, D. Effect of particle size and grinding time on gold dissolution in cyanide solution. Minerals 2016, 6, 68. [Google Scholar] [CrossRef] [Green Version]

- Chimwani, N.; Mohale, T.M.; Bwalya, M.M. Tailoring ball mill feed size distribution for the production of a size-graded product. Miner. Eng. 2019, 141, 105891. [Google Scholar] [CrossRef]

- Metzger, M.J.; Glasser, D.; Hausberger, B.; Hildebrandt, D.; Glasser, B.J. Use of the attainable region analysis to optimize particle breakage in a ball mill. Chem. Eng. Sci. 2009, 64, 3766–3777. [Google Scholar] [CrossRef]

- Katubilwa, F.M.; Moys, M.H.; Glasser, D.; Hildebrandt, D. An attainable region analysis of the effect of ball size on milling. Powder Technol. 2011, 210, 36–46. [Google Scholar] [CrossRef]

- Mulenga, F.K.; Chimwani, N. Introduction to the use of the attainable region method in determining the optimal residence time of a ball mill. Int. J. Miner. Process. 2013, 125, 39–50. [Google Scholar] [CrossRef]

- Chimwani, N.; Mulenga, F.K.; Hildebrandt, D.; Glasser, D.; Bwalya, M.M. Use of the attainable region method to simulate a full-scale ball mill with a realistic transport model. Miner. Eng. 2015, 73, 116–123. [Google Scholar] [CrossRef]

- Kierczak, J.; Neel, C.; Puziewicz, J.; Bril, H. The Mineralogy and weathering of slag produced by the smelting of lateritic Ni ores, Szklary, Southwestern Poland. Can. Miner. 2009, 47, 557–572. [Google Scholar] [CrossRef]

- Petrakis, E.; Karmali, V.; Bartzas, G.; Komnitsas, K. Grinding kinetics of slag and effect of final particle size on the compressive strength of alkali activated materials. Minerals 2019, 9, 714. [Google Scholar] [CrossRef] [Green Version]

- Bond, F.C. Crushing and grinding calculations. Br. Chem. Eng. 1961, 6, 378–385; 543–548. [Google Scholar]

- Gupta, A.; Yan, D.S. Mineral Processing Design and Operations: An Introduction, 1st ed.; Elsevier: Amsterdam, The Netherlands, 2006. [Google Scholar]

- Li, M.; Wilkinson, D.; Patchigolla, K. Comparison of particle size distributions measured using different techniques. Part. Sci. Technol. 2005, 23, 265–284. [Google Scholar] [CrossRef]

- Ferraris, C.; Garboczi, E.J. Identifying improved standardized tests for measuring cement particle size and surface area. Transport. Res. Rec. 2013, 2342, 10–16. [Google Scholar] [CrossRef] [Green Version]

- Kuila, U.; Prasad, M. Specific surface area and pore-size distribution in clays and shales. Geophys. Prospect. 2012, 61, 341–362. [Google Scholar] [CrossRef]

- Kotake, N.; Daibo, K.; Yamamoto, T.; Kanda, Y. Experimental investigation on a grinding rate constant of solid materials by a ball mill—Effect of ball diameter and feed size. Powder Technol. 2004, 143–144, 196–203. [Google Scholar] [CrossRef]

- Erdem, A.S.; Ergun, S.L. The effect of ball size on breakage rate parameter in a pilot scale ball mill. Miner. Eng. 2009, 22, 660–664. [Google Scholar] [CrossRef]

- Magdalinovic, N.; Trumic, M.; Trumic, M.; Andric, L. The optimal ball diameter in a mill. Physicochem. Probl. Miner. Process. 2012, 48, 329–339. [Google Scholar]

- Cayirli, S. Influences of operating parameters on dry ball mill performance. Physicochem. Probl. Miner. Process. 2018, 54, 751–762. [Google Scholar]

- Petrakis, E.; Karmali, V.; Komnitsas, K. Factors affecting nickel upgrade during selective grinding of low-grade limonitic laterites. Miner. Process. Ext. Metall. 2021, 130, 192–201. [Google Scholar] [CrossRef]

- Petrakis, E.; Komnitsas, K. Effect of Energy Input in a Ball Mill on Dimensional Properties of Grinding Products. Mining Metall. Explor. 2019, 36, 803–816. [Google Scholar] [CrossRef]

- Cho, H.; Kwon, J.; Kim, K.; Mun, M. Optimum choice of the make-up ball sizes for maximum throughput in tumbling ball mills. Powder Technol. 2013, 246, 625–634. [Google Scholar] [CrossRef] [Green Version]

- Zhao, J.; Wang, D.; Yan, P.; Li, W. Comparison of grinding characteristics of converter steel slag with and without pretreatment and grinding aids. Appl. Sci. 2016, 6, 237. [Google Scholar] [CrossRef] [Green Version]

- Bouaziz, A.; Hamzaoui, R.; Guessasma, S.; Lakhal, R.; Achoura, D.; Leklou, N. Efficiency of high energy over conventional milling of granulated blast furnace slag powder to improve mechanical performance of slag cement paste. Powder Technol. 2017, 308, 37–46. [Google Scholar] [CrossRef] [Green Version]

- Gómez-Tena, M.P.; Gilabert, J.; Toledo, J.; Zumaquero, E.; Machí, C. Relationship between the specific surface area parameters determined using different analytical techniques. In Proceedings of the XIII World Congress on Ceramic Tile Quality, Castellon, Spain, 17–18 February 2014; pp. 1–10. [Google Scholar]

- Alderete, N.M.; Villagran Zaccardi, Y.; Coelho Dos Santos, G.S.; De Belie, N. Particle Size Distribution and Specific Surface Area of SCM’s Compared Through Experimental Techniques. In Proceeding of the Int. RILEM Conference on Materials, Systems and Structures in Civil Engineering—Segment on Concrete with Supplementary Cementitious Materials, Lungby, Denmark, 22–24 August 2016; Jensen, O.M., Kovler, K., De Belie, N., Eds.; RILEM: Paris, France, 2016; pp. 61–70. [Google Scholar]

- Cepuritis, R.; Garboczi, E.J.; Ferraris, C.F.; Jacobsen, S.; Sørensen, B.E. Measurement of particle size distribution and specific surface area for crushed concrete aggregate fines. Adv. Powder Technol. 2017, 28, 706–720. [Google Scholar] [CrossRef] [Green Version]

- Knieke, C.; Sommer, M.; Peukert, W. Identifying the apparent and true grinding limit. Powder Technol. 2009, 195, 25–30. [Google Scholar] [CrossRef]

- Tanaka, T. A new concept applying a final fineness value to grinding mechanism-grinding tests with frictional and impulsive force. Kagaku Kogaku 1954, 18, 160–171. [Google Scholar] [CrossRef] [Green Version]

- Choi, H.; Lee, W.; Kim, S. Effect of grinding aids on the kinetics of fine grinding energy consumed of calcite powders by a stirred ball mill. Adv. Powder Technol. 2009, 20, 350–354. [Google Scholar] [CrossRef]

- Gu, F.; Zhang, Y.; Peng, Z.; Su, Z.; Tang, H.; Tian, W.; Liang, G.; Lee, J.; Rao, M.; Li, G.; et al. Selective recovery of chromium from ferronickel slag via alkaline roasting followed by water leaching. J. Hazard. Mater. 2019, 374, 83–91. [Google Scholar] [CrossRef]

- Cao, R.; Jia, Z.; Zhang, Z.; Zhang, Y.; Banthia, N. Leaching kinetics and reactivity evaluation of ferronickel slag in alkaline conditions. Cem. Concr. Res. 2020, 137, 106202. [Google Scholar] [CrossRef]

| Fe2O3 | SiO2 | CaO | Al2O3 | Cr2O3 | MgO | NiO | K2O | TiO2 | MnO | Total |

|---|---|---|---|---|---|---|---|---|---|---|

| 40.62 | 30.18 | 13.00 | 7.60 | 1.98 | 1.80 | 0.95 | 0.89 | 0.69 | 0.28 | 97.99 |

| Item | Description | 1st Series | 2nd Series | 3rd Series | 4th Series |

| Steel Balls | Diameter, d (mm) | 40 | 25.4 | 12.7 | 40, 25.4, 12.7 |

| Number | 20 | 77 | 603 | 6, 28, 202 | |

| Weight (g) | 5239.2 | 5128.2 | 5122.9 | 1572.7, 1865.7, 1702.4 | |

| Density (g/cm3) | 7.85 | 7.85 | 7.85 | 7.85 | |

| Porosity (%) | 40 | 40 | 40 | 40 | |

| Ball filling volume, J (%) | 20 | 20 | 20 | 20 | |

| Item | Description | In All Series | |||

| Ball Mill | Diameter, D (cm) | 20.4 | |||

| Length, L (cm) | 16.6 | ||||

| Volume, V (cm3) | 5423 | ||||

| Operational speed, Ν (rpm) | 66 | ||||

| Critical speed, Νc (rpm) | 93.7 | ||||

| Feed | Bulk density (g/cm3) | 1.67 | |||

| Material filling volume, fc (%) | 4 | ||||

| Interstitial filling, U (%) | 50 | ||||

| Ball Size (mm) | Parameter | 163.8 μm | 65.51 μm | 26.20 μm | 5.69 μm | 1.68 μm | 0.49 μm |

|---|---|---|---|---|---|---|---|

| 40 | K | 0.0614 | 0.0370 | 0.0243 | 0.0054 | 0.0020 | 0.0008 |

| M | 0.966 | 0.891 | 0.803 | 0.872 | 0.886 | 0.853 | |

| R2 (adj.) | 0.999 | 0.997 | 0.992 | 0.996 | 0.999 | 0.999 | |

| 25.4 | K | 0.1546 | 0.0662 | 0.0361 | 0.0079 | 0.0028 | 0.0010 |

| M | 0.770 | 0.792 | 0.743 | 0.807 | 0.835 | 0.823 | |

| R2 (adj.) | 0.999 | 0.998 | 0.998 | 0.998 | 0.999 | 0.998 | |

| 12.7 | K | 0.1333 | 0.0534 | 0.0277 | 0.0078 | 0.0036 | 0.0017 |

| M | 0.765 | 0.837 | 0.806 | 0.802 | 0.763 | 0.682 | |

| R2 (adj.) | 0.999 | 0.998 | 0.998 | 0.998 | 0.982 | 0.977 | |

| mix * | K | 0.0485 | 0.0255 | 0.0168 | 0.0039 | 0.0015 | 0.0005 |

| M | 1.077 | 1.004 | 0.894 | 0.943 | 0.954 | 0.952 | |

| R2 (adj.) | 1.000 | 0.999 | 0.996 | 0.997 | 0.998 | 0.997 |

| Ball Size | Parameter | Grinding Period (min) | |||||

|---|---|---|---|---|---|---|---|

| (mm) | 15 | 30 | 45 | 60 | 90 | 120 | |

| 40 | d90 (μm) | 289.9 | 175.8 | 139.0 | 93.0 | 69.9 | 60.0 |

| d50 (μm) | 86.4 | 44.2 | 31.1 | 22.6 | 16.6 | 13.4 | |

| BET (m2/kg) | 894 | 1163 | 1378 | 1686 | 1999 | 2293 | |

| LD (m2/kg) | 213 | 301 | 388 | 489 | 631 | 750 | |

| 25.4 | d90 (μm) | 225.1 | 158.0 | 106.0 | 80.9 | 59.3 | 48.5 |

| d50 (μm) | 59.1 | 38.3 | 25.4 | 20.4 | 14.5 | 11.8 | |

| BET (m2/kg) | 1513 | 1852 | 2325 | 2569 | 3223 | 3547 | |

| LD (m2/kg) | 350 | 476 | 655 | 765 | 1001 | 1167 | |

| 12.7 | d90 (μm) | 254.6 | 196.6 | 127.7 | 80.1 | 53.1 | 40.0 |

| d50 (μm) | 55.3 | 39.2 | 28.4 | 21.7 | 15.2 | 11.2 | |

| BET (m2/kg) | 1065 | 1323 | 1485 | 1679 | 2000 | 2213 | |

| LD (m2/kg) | 271 | 341 | 392 | 511 | 631 | 764 | |

| mix * | d90 (μm) | 252.2 | 153.8 | 109.5 | 86.2 | 59.9 | 47.1 |

| d50 (μm) | 75.9 | 39.9 | 27.8 | 23.4 | 15.2 | 11.9 | |

| BET (m2/kg) | 930 | 1200 | 1435 | 1598 | 2160 | 2260 | |

| LD (m2/kg) | 221 | 316 | 416 | 486 | 682 | 780 | |

| Ball Size (mm) | Specific Energy | Time | SSA | k | BET Size |

|---|---|---|---|---|---|

| kJ/kg | min | m2/kg | kg/kJ | μm | |

| 40 | 507 | 258 | 2369 | 0.011 | 0.82 |

| 25.4 | 486 | 240 | 3596 | 0.013 | 0.54 |

| 12.7 | 357 | 180 | 2121 | 0.016 | 0.91 |

| mix * | 482 | 244 | 2376 | 0.012 | 0.81 |

| Ball Size (mm) | Equation (3) | Equation (5) | |||

|---|---|---|---|---|---|

| S1 (min−1) | Adj. R2 | S2 (min−1) | b21 | Adj. R2 | |

| 40 | 0.055 | 0.990 | 0.013 | 0.796 | 0.999 |

| 25.4 | 0.066 | 0.992 | 0.016 | 0.861 | 0.993 |

| 12.7 | 0.052 | 0.988 | 0.009 | 0.695 | 0.997 |

| mix * | 0.065 | 0.998 | 0.011 | 0.785 | 1.000 |

| Ball Size | Volume Fraction | Grinding Time | Specific Energy |

|---|---|---|---|

| mm | % | min | kJ/kg |

| 40 | 51.7 | 27.5 | 55.6 |

| 25.4 | 53.5 | 22.5 | 44.6 |

| 12.7 | 50.3 | 32.5 | 64.3 |

| mix * | 53.3 | 25.0 | 49.0 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Petrakis, E.; Komnitsas, K. Effect of Grinding Media Size on Ferronickel Slag Ball Milling Efficiency and Energy Requirements Using Kinetics and Attainable Region Approaches. Minerals 2022, 12, 184. https://doi.org/10.3390/min12020184

Petrakis E, Komnitsas K. Effect of Grinding Media Size on Ferronickel Slag Ball Milling Efficiency and Energy Requirements Using Kinetics and Attainable Region Approaches. Minerals. 2022; 12(2):184. https://doi.org/10.3390/min12020184

Chicago/Turabian StylePetrakis, Evangelos, and Konstantinos Komnitsas. 2022. "Effect of Grinding Media Size on Ferronickel Slag Ball Milling Efficiency and Energy Requirements Using Kinetics and Attainable Region Approaches" Minerals 12, no. 2: 184. https://doi.org/10.3390/min12020184

APA StylePetrakis, E., & Komnitsas, K. (2022). Effect of Grinding Media Size on Ferronickel Slag Ball Milling Efficiency and Energy Requirements Using Kinetics and Attainable Region Approaches. Minerals, 12(2), 184. https://doi.org/10.3390/min12020184