Process Mineralogy of the Tailings from Llallagua: Towards a Sustainable Activity

Abstract

1. Introduction

2. Materials and Methods

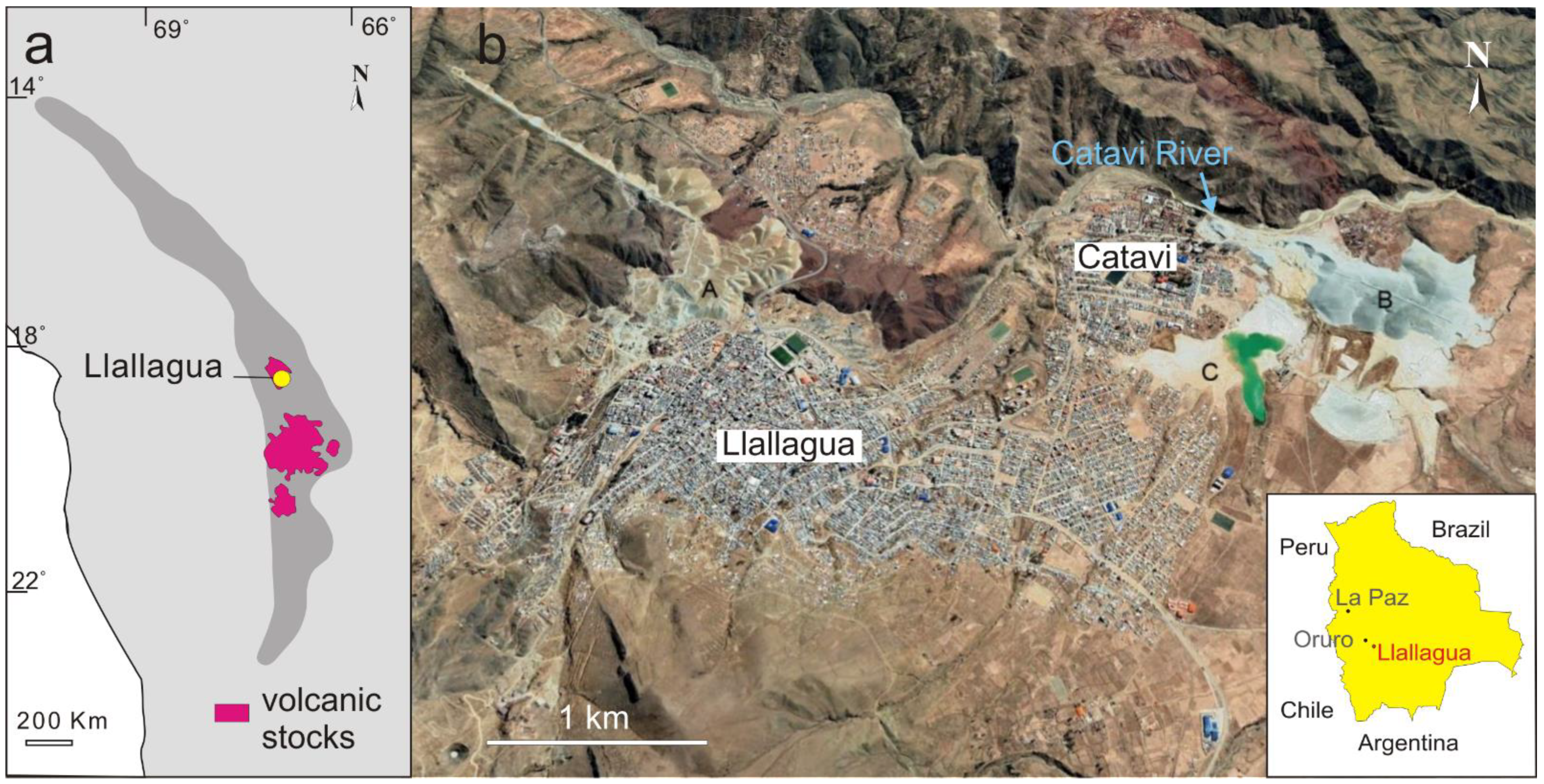

2.1. Materials

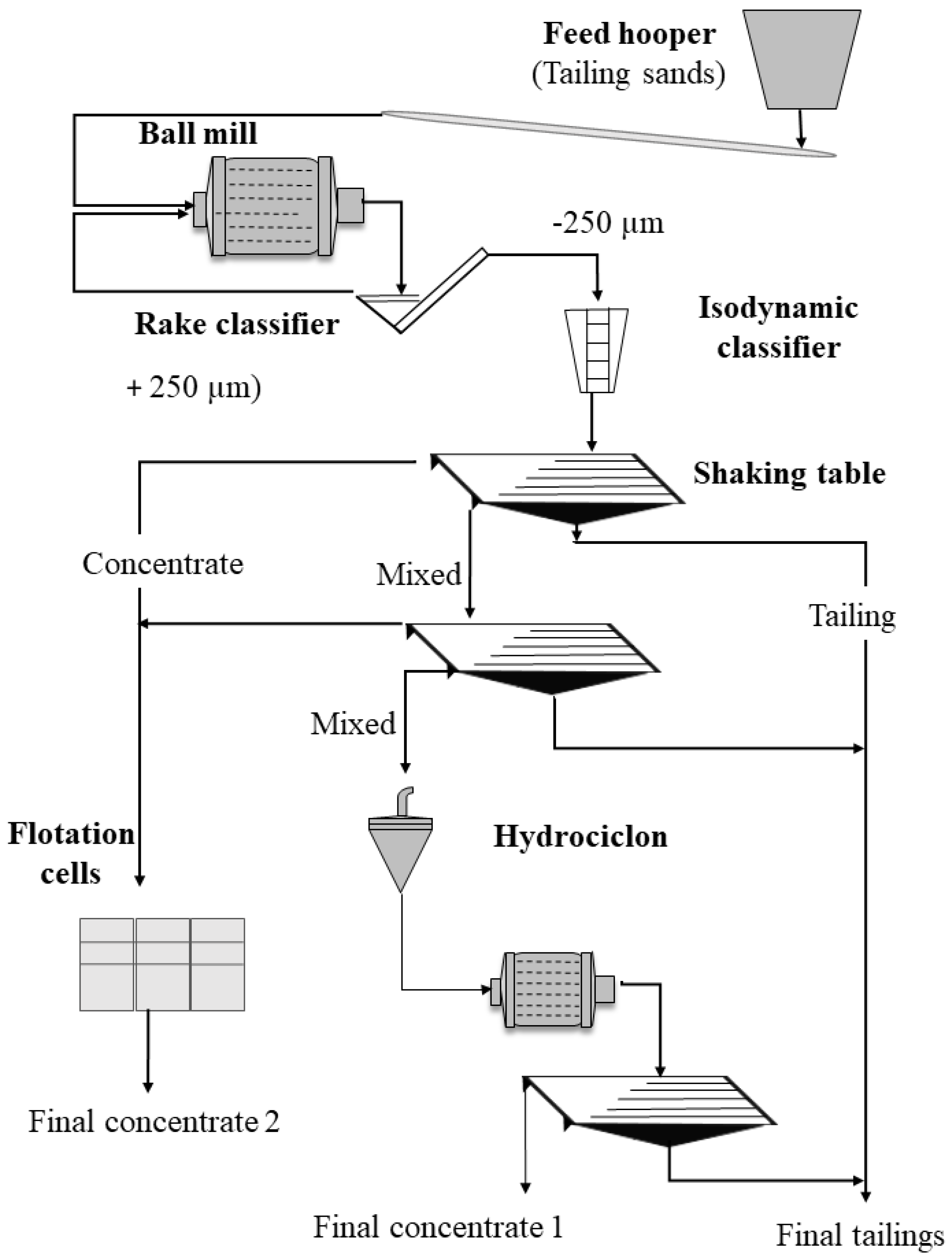

2.2. Methods

3. Results

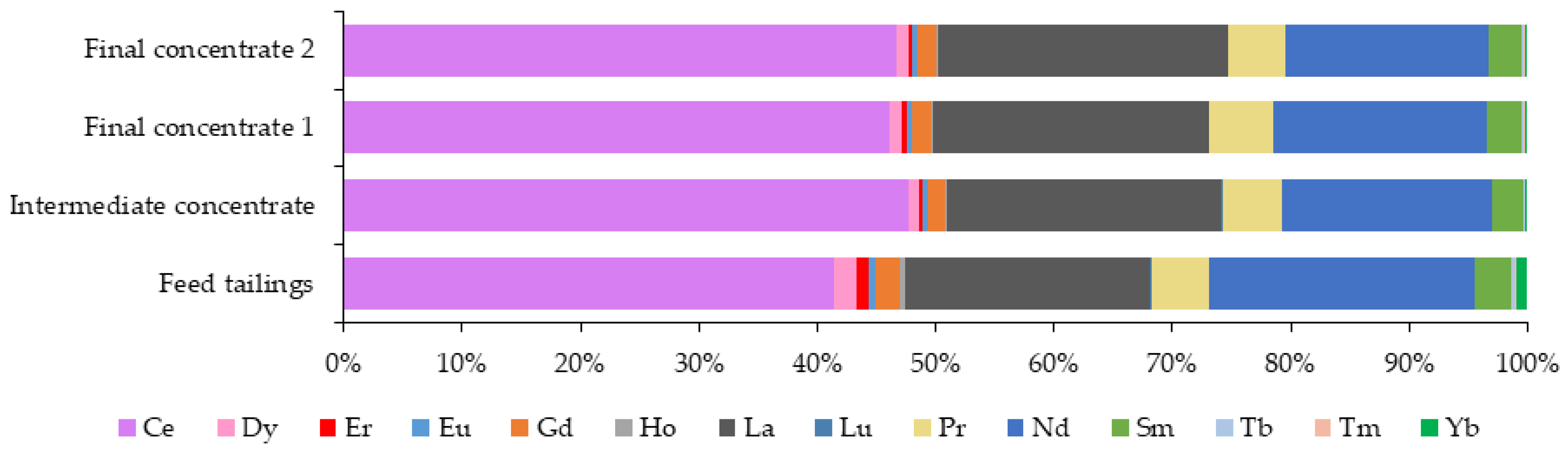

3.1. Chemical Composition

3.2. Mineralogy

3.2.1. Major Minerals: XRD

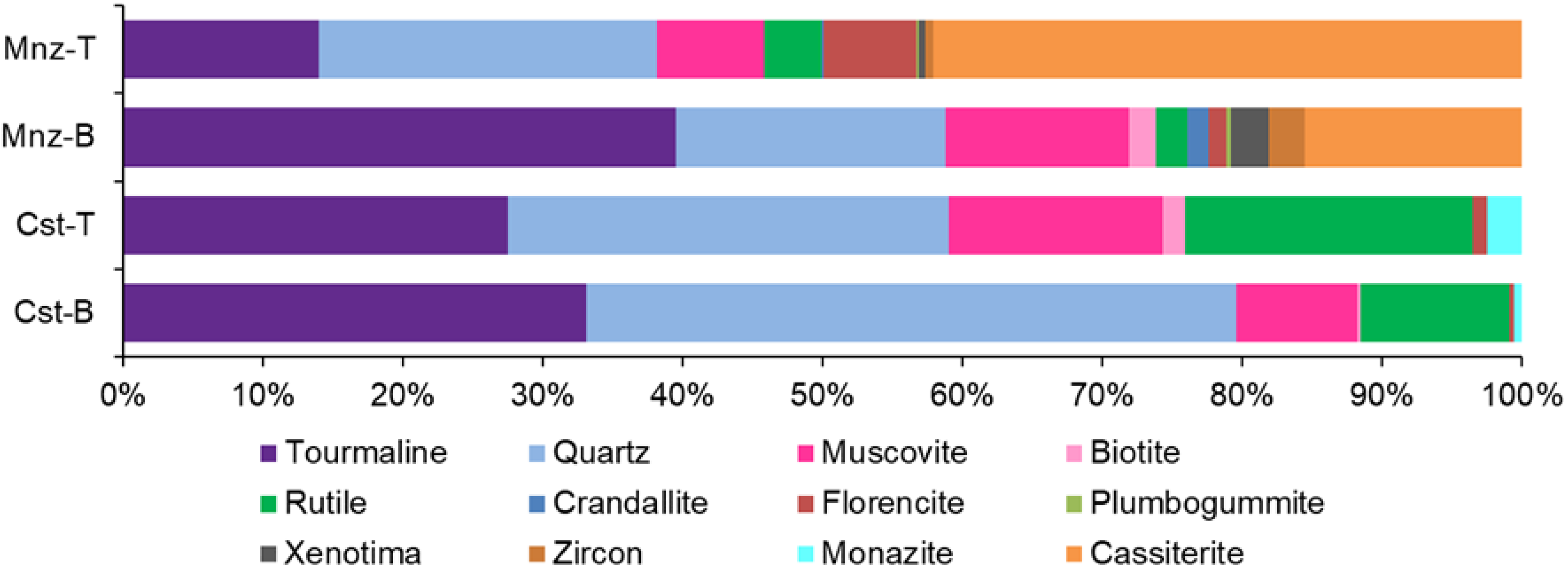

3.2.2. Modal Mineralogy of the Concentrate

3.3. Particle Size Distribution

3.4. Mineral Liberation

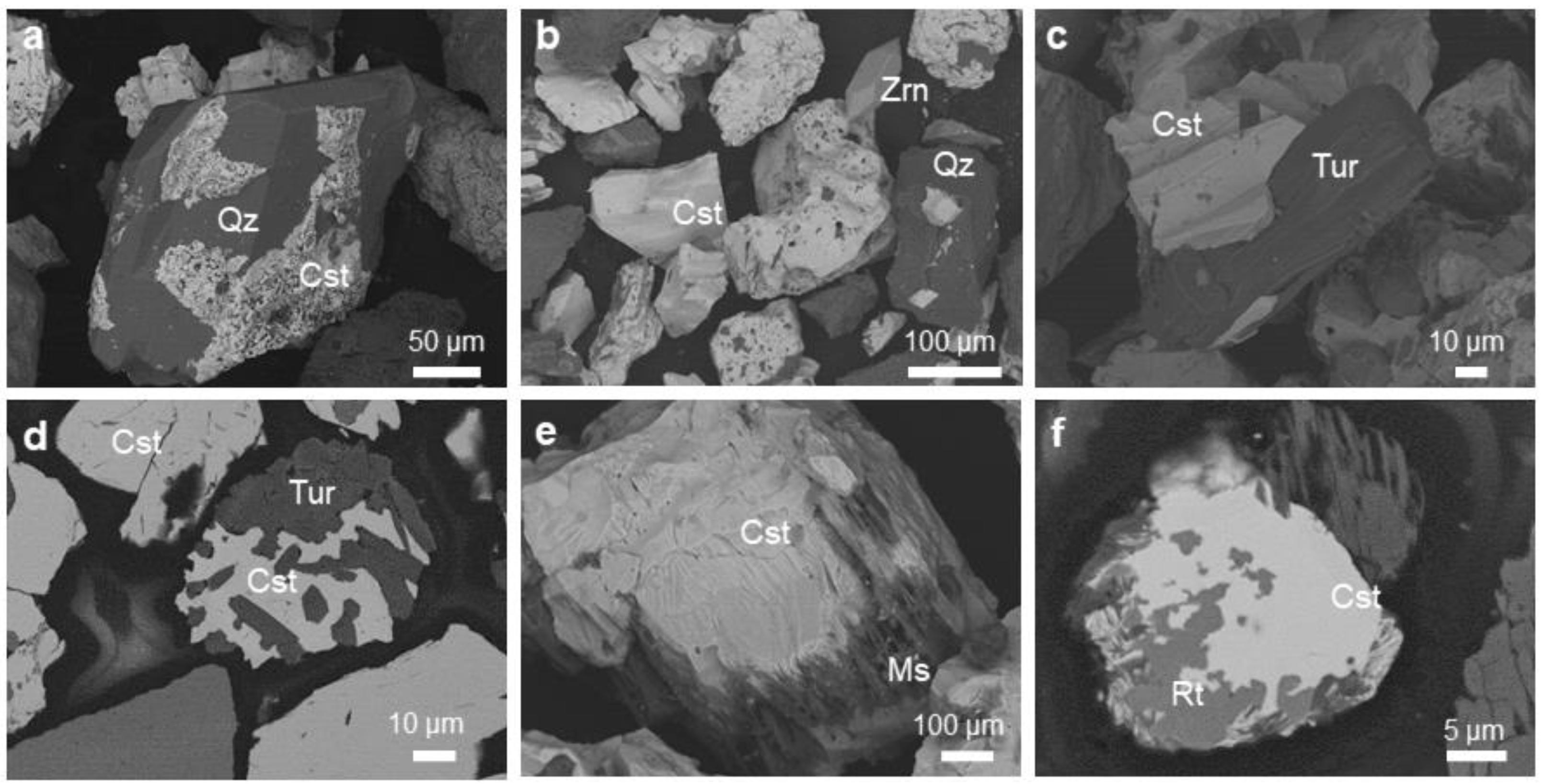

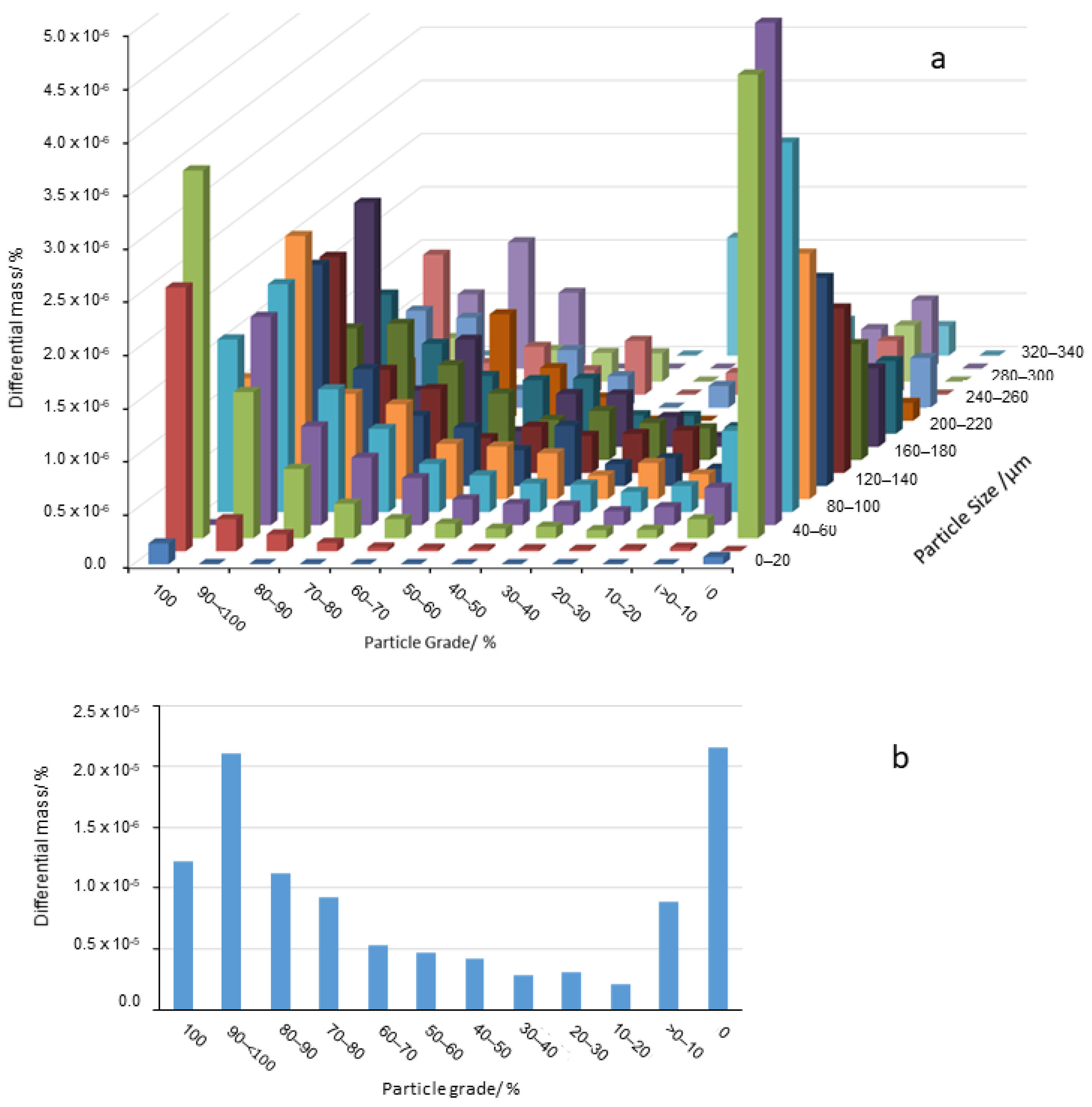

3.4.1. Cassiterite

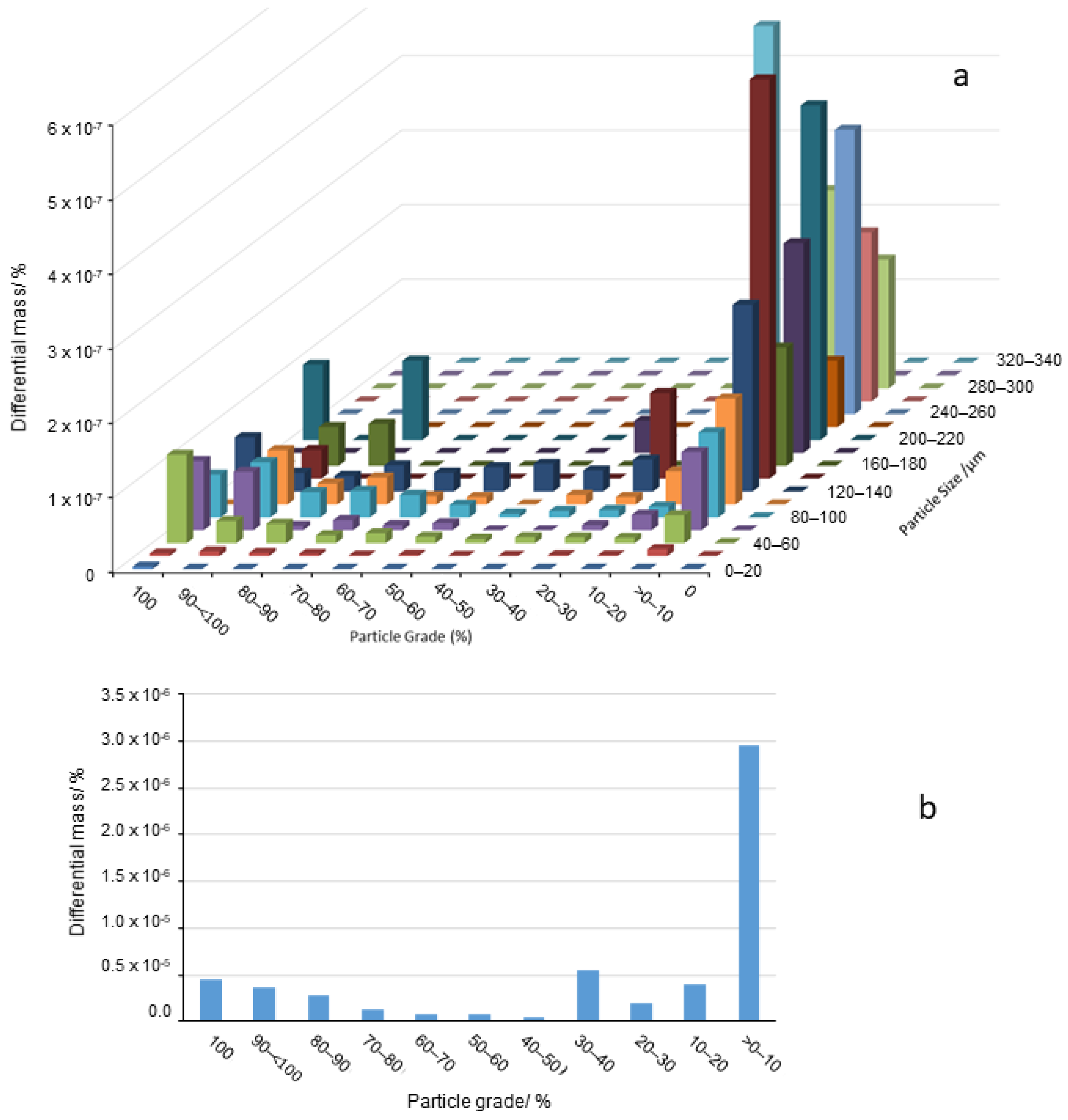

3.4.2. Monazite

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2004, 84, 411–420. [Google Scholar] [CrossRef]

- Khan, M.M.; Mahajani, S.M.; Jadhav, G.N.; Vishwakarma, R.; Malgaonkar, V.; Mandre, S. Mechanical and thermal methods for reclamation of waste foundry sand. J. Environ. Manag. 2021, 279, 111628. [Google Scholar] [CrossRef] [PubMed]

- Asr, E.T.; Kakaie, R.; Ataei, M.; Mohammadi, M.R.T. A review of studies on sustainable development in mining life cycle. J. Clean. Prod. 2019, 229, 213–231. [Google Scholar] [CrossRef]

- Laurence, D. Establishing a sustainable mining operation: An overview. J. Clean. Prod. 2011, 19, 278–284. [Google Scholar] [CrossRef]

- United Nations. The future We Want. In Proceedings of the United Nations Conference on Sustainable Development, Rio de Janeiro, Brazil, 20–22 June 2012. [Google Scholar]

- Dold, B. Sustainability in metal mining: From exploration, over processing to mine waste management. Rev. Environ. Sci. Biotechnol. 2008, 7, 275–285. [Google Scholar] [CrossRef]

- Ahlfeld, F. The tin deposits of Llallagua, Bolivia. Econ. Geol. 1936, 31, 219–221. [Google Scholar] [CrossRef]

- Ahlfeld, F.; Schneider-Scherbina, A. Los yacimientos minerales y de hidrocarburos de Bolivia. Bol. Dept. Nac. Geol. 1964, 5, 1–388. [Google Scholar]

- Hyrsl, J.; Petrov, A. Famous mineral localities: Llallagua, Bolivia. Mineral. Rec. 2006, 37, 17–163. [Google Scholar]

- Zambrana, R.N. Retratamiento de Colas Finales Planta C-4 de Catavi y Propuesta Técnica Económica y Ambiental. Master’s Thesis, Universitat Politècnica de Catalunya, Manresa, Spain, 2011. [Google Scholar]

- Villalpando, B.A. The tin ore deposits of Bolivia. In Geology of Tin Deposits in Asia and the Pacific; Hutchinson, C.S., Ed.; Springer: Berlin/Heidelberg, Germany, 1988; pp. 201–215. [Google Scholar]

- Romero, F.M.; Canet, C.; Alfonso, P.; Zambrana, R.N.; Soto, N. The role of cassiterite controlling arsenic mobility in an abandoned stanniferous tailings impoundment at Llallagua, Bolivia. Sci. Total Environ. 2014, 481, 100–107. [Google Scholar] [CrossRef]

- Kempe, U.; Lehmann, B.; Wolf, D.; Rodionov, N.; Bombach, K.; Schwengfelder, U.; Dietrich, A. U–Pb SHRIMP geochronology of Th-poor, hydrothermal monazite: An example from the Llallagua tin-porphyry deposit, Bolivia. Geochim. Cosmochim. Acta 2008, 72, 4352–4366. [Google Scholar] [CrossRef]

- Catlos, E.J.; Miller, N.R. Speculations Linking Monazite Compositions to Origin: Llallagua Tin Ore Deposit (Bolivia). Resources 2017, 6, 36. [Google Scholar] [CrossRef]

- Betkowski, W.B.; Rakovan, J.; Harlov, D.E. Geochemical and textural characterization of phosphate accessory phases in the vein assemblage and metasomatically altered Llallagua tin porphyry. Mineral. Petrol. 2017, 111, 547–568. [Google Scholar] [CrossRef]

- Zglinicki, K.; Szamałek, K.; Konopka, G. Monazite-bearing post processing wastes and their potential economic significance. Miner. Resour. Manag. 2020, 36, 37–58. [Google Scholar]

- Zhou, B.; Li, Z.; Chen, C. Global potential of rare earth resources and rare earth demand from clean technologies. Minerals 2017, 7, 203. [Google Scholar] [CrossRef]

- Massari, S.; Ruberti, M. Rare earth elements as critical raw materials: Focus on international markets and future strategies. Resour. Policy 2013, 38, 36–43. [Google Scholar] [CrossRef]

- European Commission. Study on the Review of the List of Critical Raw Materials: 546 Executive Summary. European Commission, Directorate-General for Internal Market, 547 Industry, Entrepreneurship and SMEs. Available online: https://publications.europa.eu/en/publication548detail/-/publication/08fdab5f-9766-11e7-b92d-01aa75ed71a1/language-en (accessed on 15 November 2021).

- Binnemans, K.; Jones, P.T.; Blanpain, B.; Van Gerven, T.; Pontikes, Y. Towards zero-waste valorisation of rare-earth-containing industrial process residues: A critical review. J. Clean. Prod. 2015, 99, 17–38. [Google Scholar] [CrossRef]

- Pereira, L.; Birtel, S.; Möckel, R.; Michaux, B.; Silva, A.C.; Gutzmer, J. Constraining the economic potential of by-product recovery by using a geometallurgical approach: The example of rare earth element recovery at Catalão I, Brazil. Econ. Geol. 2019, 114, 1555–1568. [Google Scholar] [CrossRef]

- Sillitoe, R.H.; Halls, C.; Grant, J.N. Porphyry tin deposits in Bolivia. Econ. Geol. 1975, 70, 913–927. [Google Scholar] [CrossRef]

- Dietrich, A.; Lehmann, B.; Wallianos, A. Bulk Rock and melt inclusion geochemistry of Bolivian tin porphyry systems. Econ. Geol. 2000, 95, 313–326. [Google Scholar] [CrossRef]

- Grant, J.N.; Halls, C.; Ávila Salinas, W.; Snelling, N.J. K-Ar ages of igneous rocks and mineralization in part of the Bolivian tin belt. Econ. Geol. 1979, 74, 838–851. [Google Scholar] [CrossRef]

- Lehmann, B. Petrochemical factors governing the metallogeny of the Bolivian tin belt. In Tectonics of the Southern Central Andes, Structure and Evolution of an Active Continental Margin; Reutter, K.J., Scheuber, E., Wigger, P., Eds.; Springer: Berlin, Germany, 1994; pp. 317–326. [Google Scholar]

- Grant, J.N.; Halls, C.; Avila, W.; Avila, G. Igneous geology and the evolution of hydrothermal systems in some subvolcanic tin deposits of Bolivia. Geol. Soc. Lond. Spec. Publ. 1977, 7, 117–126. [Google Scholar] [CrossRef]

- Mlynarczyk, M.; Williams-Jones, A.E. The role of collisional tectonics in the metallogeny of the central Andean tin belt. Earth Planet Sci. Lett. 2005, 240, 656–667. [Google Scholar] [CrossRef]

- Schulz, B.; Sandmann, D.; Gilbricht, S. SEM-Based Automated Mineralogy and Its Application in Geo- and Material Sciences. Minerals 2020, 10, 1004. [Google Scholar] [CrossRef]

- Arancibia, J.R.H.; Alfonso, P.; García-Valles, M.; Martínez, S.; Canet, C.; Romero, F.M. Obtención de vidrio a partir de residuos de la minería del estaño en Bolivia. Bol. Soc. Esp. Ceram. Vidr. 2013, 52, 143–150. [Google Scholar] [CrossRef][Green Version]

- Menzie, W.D.; Reed, B.L.; Singer, D.A. Models of grades and tonnages of some lode tin deposits. In Geology of Tin Deposits in Asia and the Pacific; Springer: Berlin/Heidelberg, Germany, 1988; pp. 73–88. [Google Scholar]

- Ishihara, S.; Murakami, H.; Marquez-Zavalia, M.F. Inferred indium resources of the Bolivian tin-polymetallic deposits. Resour. Geol. 2011, 61, 174–191. [Google Scholar] [CrossRef]

- Jiménez-Franco, A.; Alfonso, P.; Canet, C.; Trujillo, J.E. Mineral chemistry of In-bearing minerals in the Santa Fe mining district, Bolivia. Andean Geol. 2018, 45, 410–432. [Google Scholar] [CrossRef]

- Torró, L.; Melgarejo, J.C.; Gemmrich, L.; Mollinedo, D.; Cazorla, M.; Martínez, Á.; Artiaga, D.; Torres, B.; Alfonso, P.; Arce, O. Spatial and Temporal Controls on the Distribution of Indium in Xenothermal Vein-Deposits: The Huari Huari District, Potosí, Bolivia. Minerals 2019, 9, 304. [Google Scholar] [CrossRef]

- Alfonso, P.; Garcia-Valles, M.; Llorens, T.; Tomasa, O.; Calvo, D.; Guasch, E.; Anticoi, H.; Oliva, J.; López Moro, J.; García Polonio, F. Nb-Ta mineralization from the rare element granite from Penouta, Galicia, Spain. Mineral. Mag. 2018, 82, S199–S222. [Google Scholar] [CrossRef]

- Gray, F.; Kramer, D.A.; Bliss, J.D. Gallium and Gallium Compounds; Wiley-VCH Verlag GmbH & Co. KGaA: Weinheim, Germany, 2000; ISBN 978-3-527-30673–2. [Google Scholar]

- Mordberg, L.E.; Stanley, C.J.; Germann, K. Rare earth element anomalies in crandallite group minerals from the Schugorsk bauxite deposit, Timan, Russia. Eur. J. Mineral. 2000, 12, 1229–1243. [Google Scholar] [CrossRef]

- Evans, C.L.; Napier-Munn, T.J. Estimating error in measurements of mineral grain size distribution. Miner. Eng. 2013, 52, 198–203. [Google Scholar] [CrossRef]

- Spencer, S.; Sutherland, D. Stereological correction of mineral liberation grade distributions estimated by single sectioning of particles. Image Anal. Stereol. 2000, 19, 175–182. [Google Scholar] [CrossRef]

- Ueda, T.; Oki, T.; Koyanaka, S. Comparison of seven texture analysis indices for their applicability to stereological correction of mineral liberation assessment in binary particle systems. Minerals 2017, 7, 222. [Google Scholar] [CrossRef]

- Gupta, A.; Yan, D. Mineral Processing Design and Operations: An Introduction; Elsevier: Amsterdam, The Netherlands, 2016; pp. 563–628. [Google Scholar]

- Bru, K.; Sousa, R.; Leite, M.M.; Broadbent, C.; Stuart, G.; Pashkevich, D.; Martin, M.; Kern, M.; Parvaz, D.B. Pilot-scale investigation of two Electric Pulse Fragmentation (EPF) approaches for the mineral processing of a low-grade cassiterite schist ore. Miner. Eng. 2020, 150, 106270. [Google Scholar] [CrossRef]

- Abouzeid, A.Z.M.; Fuerstenau, D.W. Grinding of mineral mixtures in high-pressure grinding rolls. Int. J. Miner. Process. 2009, 93, 59–65. [Google Scholar] [CrossRef]

- Hamid, S.A.; Alfonso, P.; Anticoi, H.; Guasch, E.; Oliva, J.; Dosbaba, M.; Garcia-valles, M.; Chugunova, M. Quantitative mineralogical comparison between HPGR and ball mill products of a Sn-Ta ore. Minerals 2018, 8, 151. [Google Scholar] [CrossRef]

- Genç, Ö. Analysis of grinding media effect on specific breakage rate function of particles in a full-scale open circuit three-compartment cement ball mill. Miner. Eng. 2015, 81, 10–17. [Google Scholar] [CrossRef]

- Nduwa-Mushidi, J.; Anderson, C.G. Surface Chemistry and Flotation Behaviors of Monazite–Apatite–Ilmenite–Quartz–Rutile–Zircon with Octanohydroxamic Acid. J. Sustain. Metall. 2017, 3, 62–72. [Google Scholar] [CrossRef]

- Wanhainen, C.; Pålsson, B.I.; Martinsson, O.; Lahaye, Y. Rare earth mineralogy in tailings from Kiirunavaara iron ore, northern Sweden: Implications for mineral processing. Miner. Metall. Processing 2017, 34, 189–200. [Google Scholar] [CrossRef]

- Abaka-Wood, G.B.; Addai-Mensah, J.; Skinner, W. The Use of Mining Tailings as Analog of Rare Earth Elements Resources: Part 1–Characterization and Preliminary Separation. Miner. Process. Extr. Metall. Rev. 2021, 1–15. [Google Scholar] [CrossRef]

- Alves, F.E.; Neumann, R.; Ávila, C.A.; Ferreira, P.E.; Assumpção, C.D.S.; Carneiro, M.C.; Garcia, P.H. Mineralogical auditing of the Volta Grande Mine (SE Brazil) Sn-Ta-Nb-Li processing plant, aiming at REE recovery as by-products. Appl. Earth Sci. 2021, 130, 198–208. [Google Scholar] [CrossRef]

- Adiputra, R.N.; Agustin, F.; Sulastri, A.; Abdullah, C.I.; Nugraha, I.; Andriansyah, R.; Hadiprayitno, M. The tin ore separation process and optimizing the rare earth mineral (monazite) as a by-product of tin mining in East Belitung Regency. IOP Conf. Ser. Earth Environ. Sci. 2020, 413, 012004, IOP Publishing. [Google Scholar] [CrossRef]

- Udayakumar, S.; Noor, A.F.M.; Hamid, S.A.R.S.A.; Putra, T.A.R.; Anderson, C.G. Chemical and mineralogical characterization of Malaysian monazite concentrate. Min. Metall. Explor. 2020, 37, 415–431. [Google Scholar] [CrossRef]

| Material | SiO2 | Al2O3 | Fe2O3 | TiO2 | MnO | CaO | K2O | MgO | Na2O | P2O5 | SnO2 | LOI * |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Feed | 77.75 | 11.19 | 2.58 | 0.44 | 0.01 | 0.07 | 1.43 | 1.09 | 0.37 | 0.19 | 0.40 | 1.79 |

| Concentrate | 11.42 | 4.64 | 5.55 | 3.52 | 0.03 | 0.00 | 0.22 | 0.61 | 0.24 | 0.72 | 52.43 | 3.03 |

| Final tailings | 79.20 | 10.52 | 2.42 | 0.43 | 0.01 | 0.07 | 1.20 | 1.09 | 0.38 | 0.15 | 0.29 | 1.78 |

| Element | Final Tailings | Intermediate Concentrate | Final Concentrate 1 | Final Concentrate 2 |

|---|---|---|---|---|

| ppm | LG-2 | LG-4 | LG-35 | LG-41 |

| Ce | 74.5 | 3370 | 5670 | 4140 |

| Dy | 3.51 | 56.3 | 123 | 83.9 |

| Er | 1.72 | 19.1 | 47.6 | 30.1 |

| Eu | 1.09 | 31.5 | 56 | 40.3 |

| Gd | 3.86 | 109.5 | 210 | 144.5 |

| Ho | 0.63 | 8.5 | 18.9 | 13.05 |

| La | 37.2 | 1640 | 2860 | 2160 |

| Lu | 0.34 | 1.4 | 4.16 | 2.93 |

| Pr | 8.86 | 358 | 667 | 431 |

| Nd | 40.3 | 1250 | 2210 | 1520 |

| Sm | 5.48 | 185.5 | 366 | 251 |

| Tb | 0.6 | 13.3 | 23.3 | 16.85 |

| Tm | 0.25 | 2.1 | 5.81 | 3.75 |

| Yb | 1.74 | 11.3 | 32.7 | 21.8 |

| Σ RRE | 170.5 | 7056.5 | 12,294.5 | 8859.18 |

| Mineral | Formula | wt % |

|---|---|---|

| Cassiterite | SnO2 | 57.41 |

| Quartz | SiO2 | 7.13 |

| Plagioclase | (Na,Ca)(Si,Al)4O8 | 0.02 |

| Tourmaline | Na(Mg,Fe)3Al6(BO3)3Si6O18(OH)4 | 11.22 |

| Muscovite | KAl3Si3O10(OH)2 | 1.41 |

| Biotite | KMg2.5Fe2+0.5AlSi3O10(OH)1.75F0.25 | 0.32 |

| Chlorite | (Mg,Fe)3(Si,Al)4O10(OH)2(Mg,Fe)3(OH)6 | 0.09 |

| Kaolinite | Al2Si2O5(OH)4 | 0.23 |

| Rutile | TiO2 | 4.60 |

| Ilmenite | Fe2+TiO3 | 0.04 |

| Fe oxides | Fe2O3 | 10.44 |

| Pyrrhotite | FeS | 1.28 |

| Pyrite | FeS2 | 0.37 |

| Arsenopyrite | FeAsS | 0.05 |

| Stannite | SnS | 0.01 |

| Galena | PbS | 0.01 |

| Crandallite | CaAl3(PO4)2(OH)5H2O | 0.10 |

| Florencite | CeAl3(PO4)2(OH)6 | 0.16 |

| Plumbogummite | PbAl3(PO4)2(OH)5(H2O) | 0.26 |

| Fe-Pb Phosphate | (Pb,Fe)3(PO4)2 | 0.33 |

| Scorodite | FeAsO4·2(H2O) | 0.15 |

| Jarosite | KFe3(SO4)2(OH)6 | 1.30 |

| Barite | Ba(SO4) | 0.14 |

| Xenotime | Y(PO4) | 0.04 |

| Monazite | (La,Ce,Nd,Th)(PO4) | 1.62 |

| Zircon | ZrSiO4 | 0.69 |

| Wolframite | (Fe,Mn)(WO4) | 0.47 |

| Total | 100.00 |

| Cassiterite | Monazite | |

|---|---|---|

| Total ore (wt %) | 57.41 | 1.62 |

| Number of particles | 24,794 | 1190 |

| Particles contain% | 50.20 | 2.41 |

| Number of liberated particles | 19,708 | 586 |

| Mass liberated respect the total ore % | 65.74 | 63.83 |

| Mass liberated respect the total concentrate % | 37.74 | 1.03 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alfonso, P.; Ruiz, M.; Zambrana, R.N.; Sendrós, M.; Garcia-Valles, M.; Anticoi, H.; Sidki-Rius, N.; Salas, A. Process Mineralogy of the Tailings from Llallagua: Towards a Sustainable Activity. Minerals 2022, 12, 214. https://doi.org/10.3390/min12020214

Alfonso P, Ruiz M, Zambrana RN, Sendrós M, Garcia-Valles M, Anticoi H, Sidki-Rius N, Salas A. Process Mineralogy of the Tailings from Llallagua: Towards a Sustainable Activity. Minerals. 2022; 12(2):214. https://doi.org/10.3390/min12020214

Chicago/Turabian StyleAlfonso, Pura, Miguel Ruiz, Rubén Néstor Zambrana, Miquel Sendrós, Maite Garcia-Valles, Hernan Anticoi, Nor Sidki-Rius, and Antonio Salas. 2022. "Process Mineralogy of the Tailings from Llallagua: Towards a Sustainable Activity" Minerals 12, no. 2: 214. https://doi.org/10.3390/min12020214

APA StyleAlfonso, P., Ruiz, M., Zambrana, R. N., Sendrós, M., Garcia-Valles, M., Anticoi, H., Sidki-Rius, N., & Salas, A. (2022). Process Mineralogy of the Tailings from Llallagua: Towards a Sustainable Activity. Minerals, 12(2), 214. https://doi.org/10.3390/min12020214