Experimental Study of CO2-ECBM by Injection Liquid CO2

Abstract

:1. Introduction

2. Theory and Experiment

2.1. Theoretical Analyses

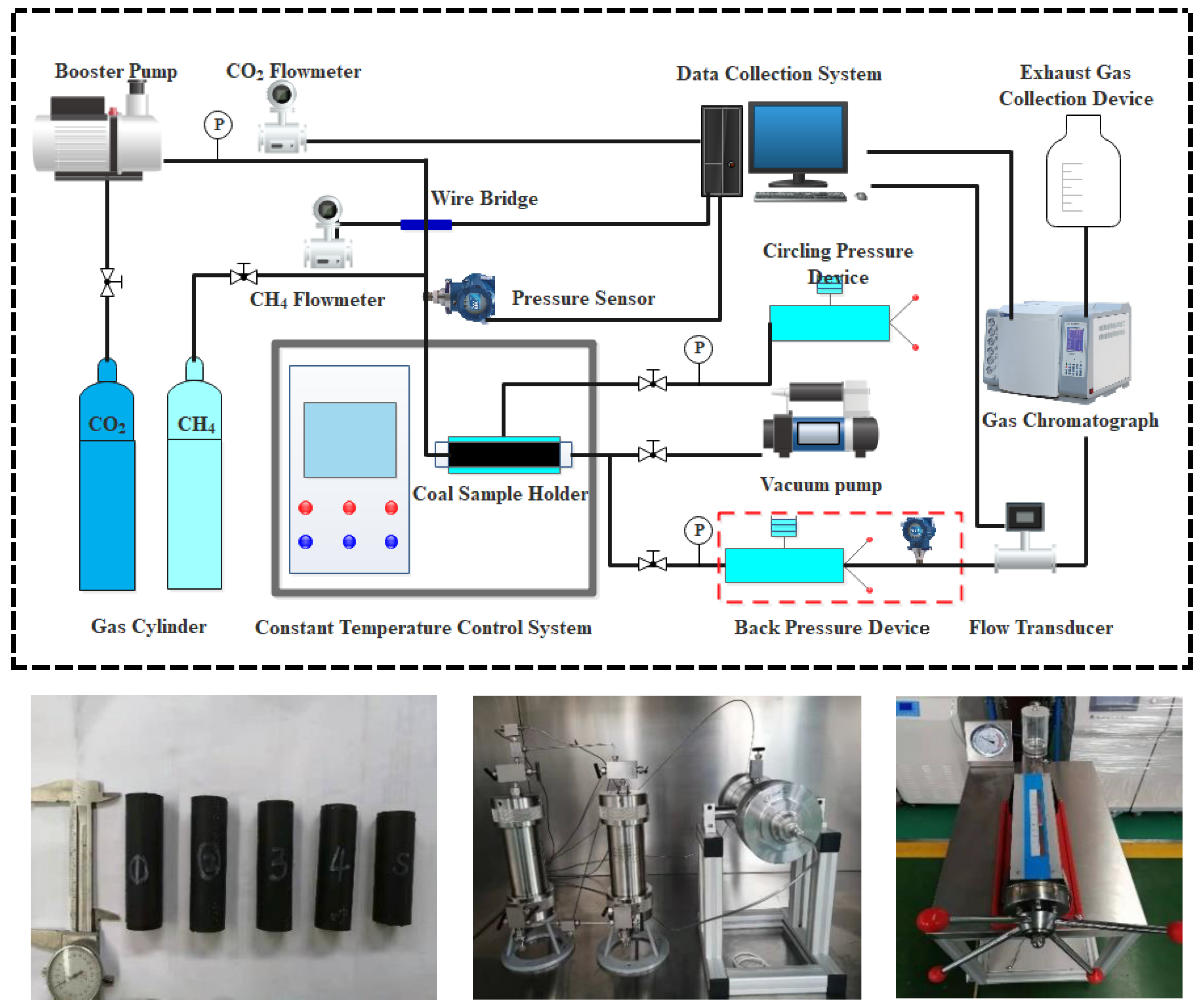

2.2. Experiment of Displacing Coal Seam CH4 by CO2

- (1)

- Experimental preparation

- (2)

- Experimental structure

- (3)

- Experimental procedure

- Vacuuming: The inlet stop valve was closed, and the vacuum pump was connected to the sample holder at the outlet. The outlet stop valve and vacuum pump were opened for 5–6 h.

- Setting confining pressure: The valve was closed at the outlet. The holder was applied with a confining pressure of 8.0 MPa.

- CH4 adsorption equilibrium: The CH4 cylinder was opened to set to a pressure of 1.5 MPa while opening the inlet valve. To ensure that the coal sample fully adsorbed the CH4, the adsorption time was more than 24 h, and the changes in flow and pressure were monitored during the adsorption process.

- CO2 injection: The CH4 intake valve was closed, the CO2 intake valve was opened, and the pressure was adjusted to the target value. After the pressure was balanced at both ends, the back pressure valve was adjusted, and the flow of the discharged gas was monitored and collected.

- Gas analysis: The outlet mixed gas was analyzed by gas chromatography.

- Pressure relief: The intake valve was closed. The internal pressure of the gripper was released by adjusting the back-pressure valve. The next set of tests were performed after the pressure was released.

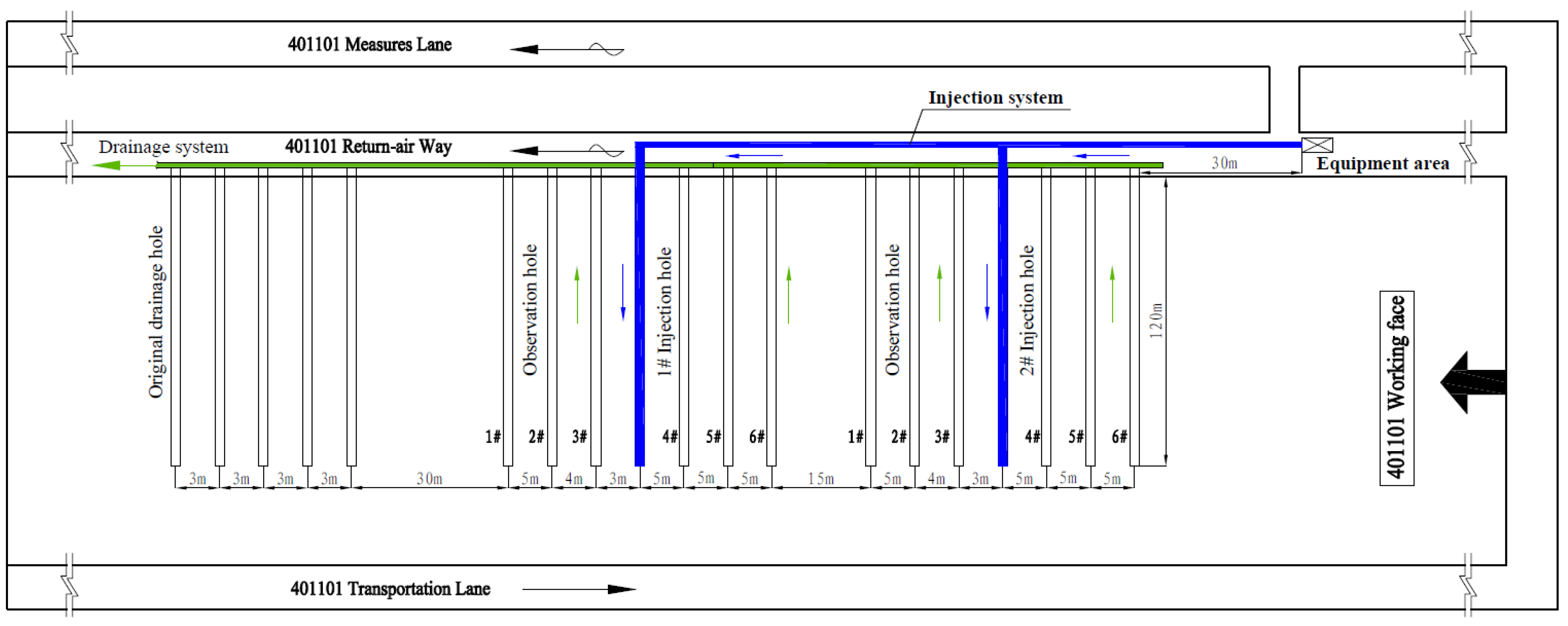

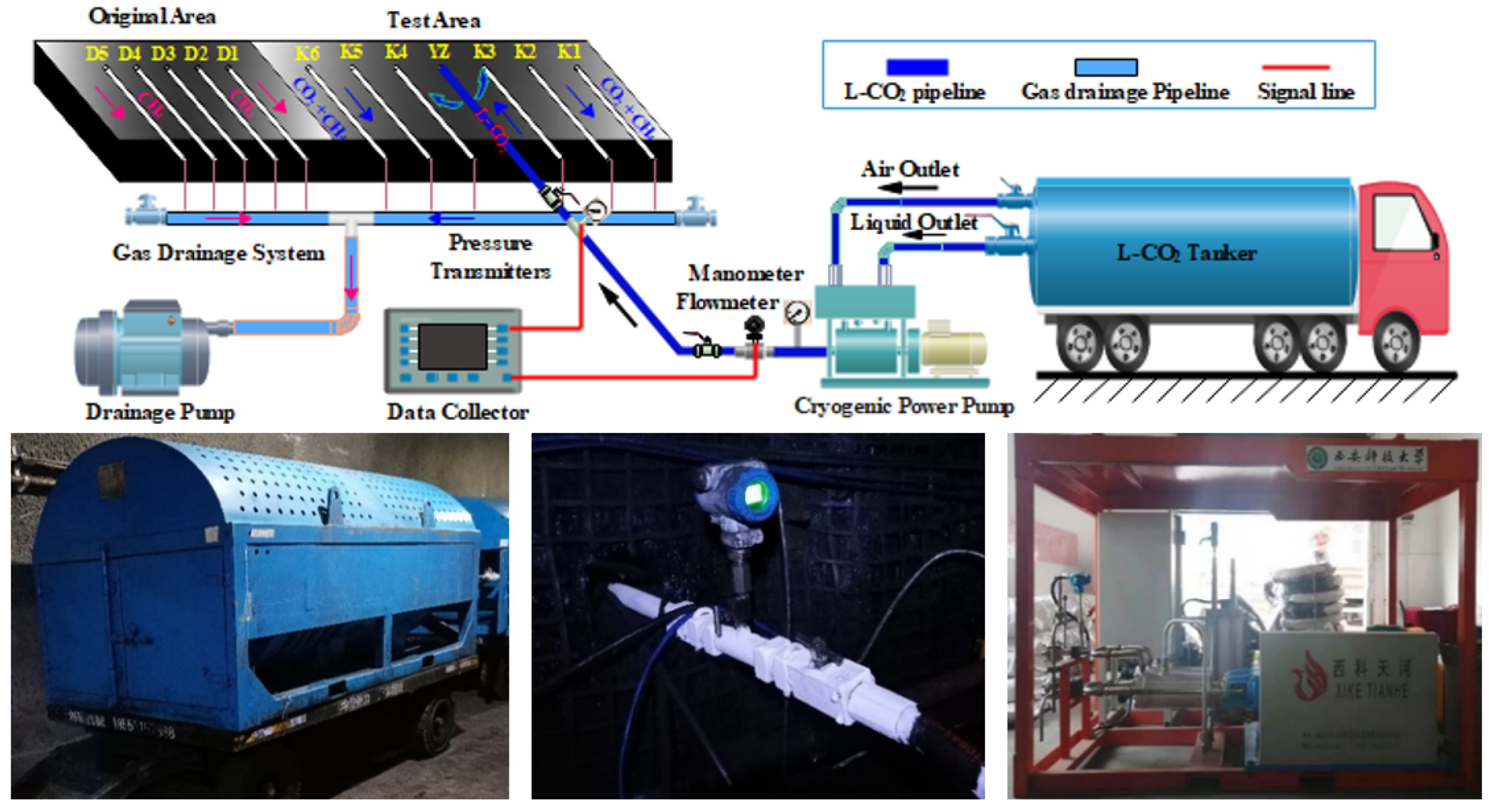

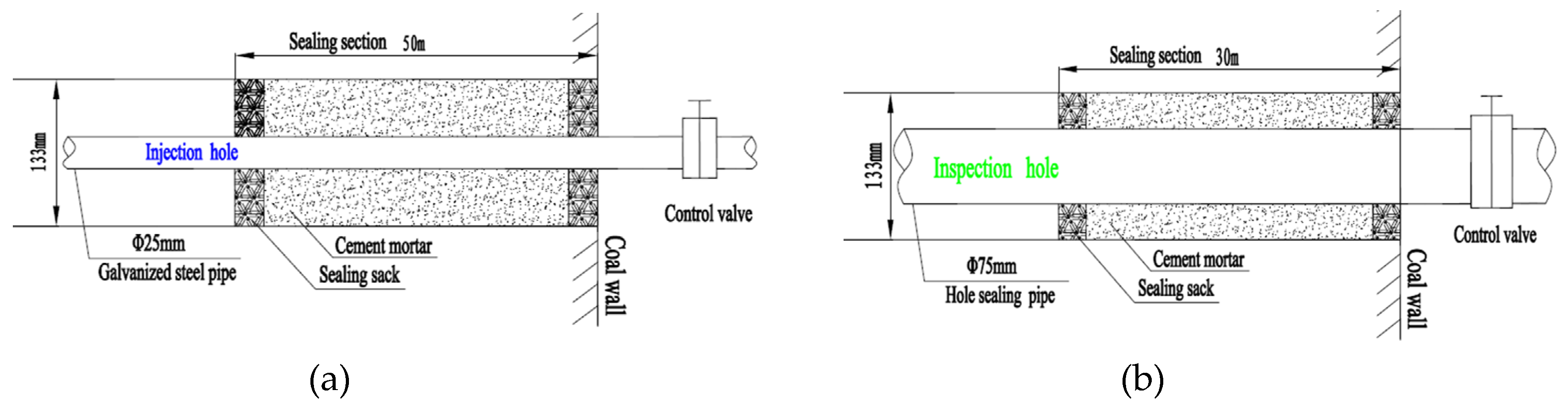

2.3. In Situ Experiment

2.3.1. Experimental Design and System Process

2.3.2. Experimental Analysis

- (1)

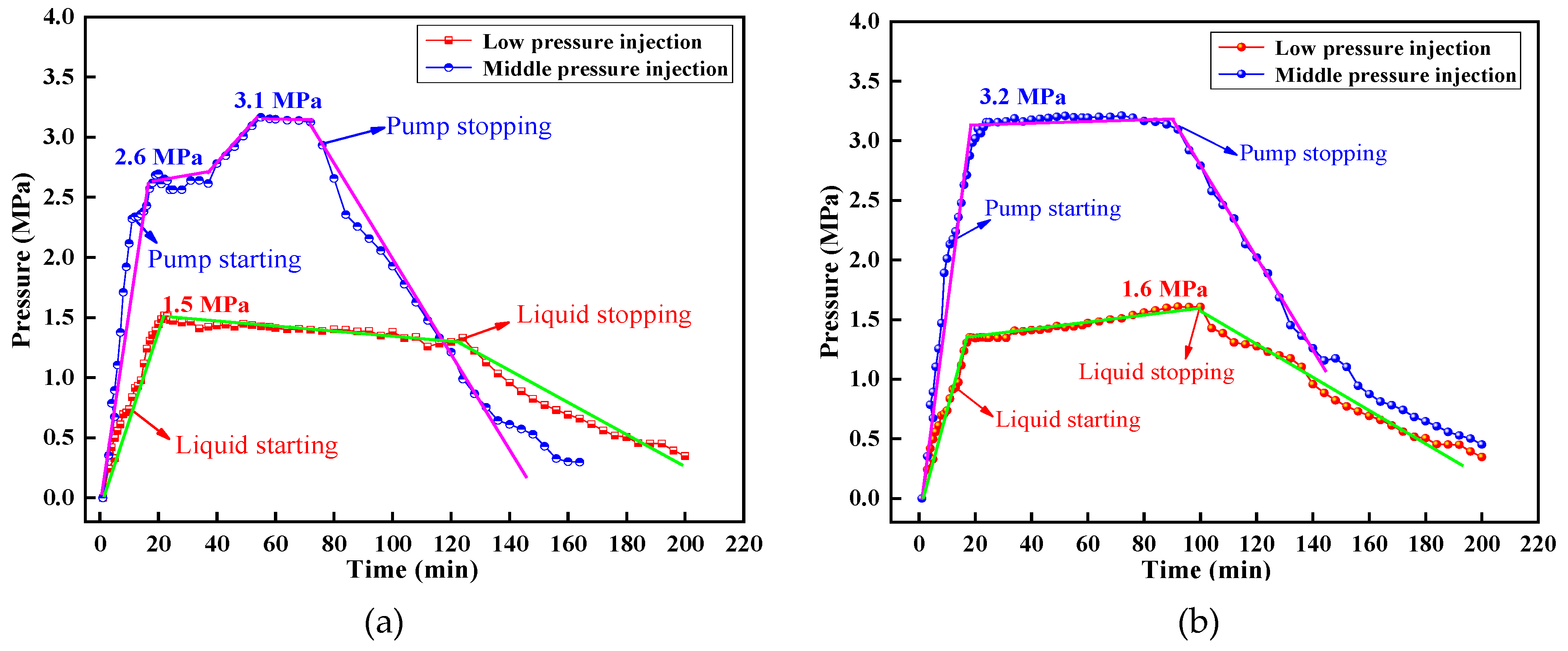

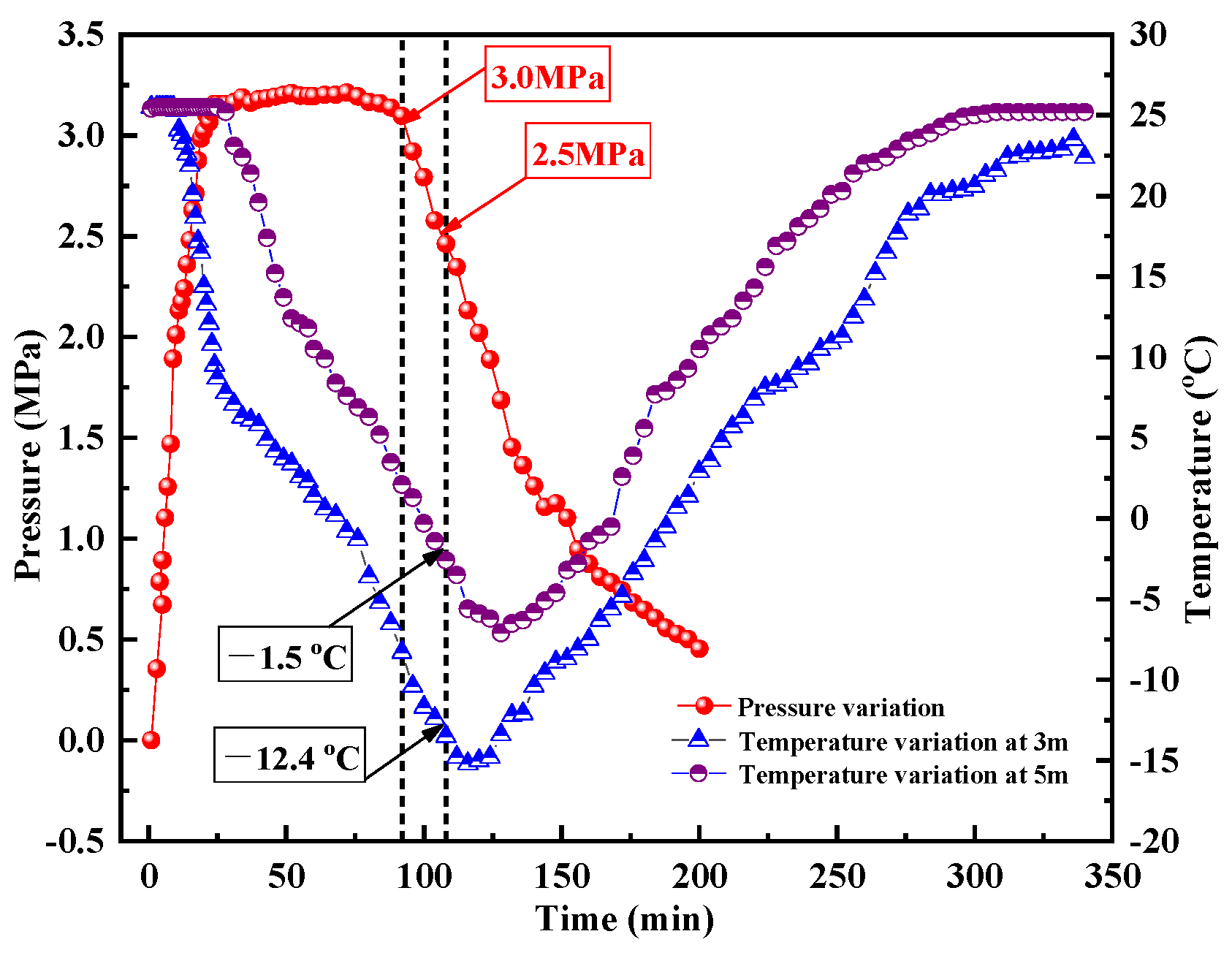

- Pressure changes

- (2)

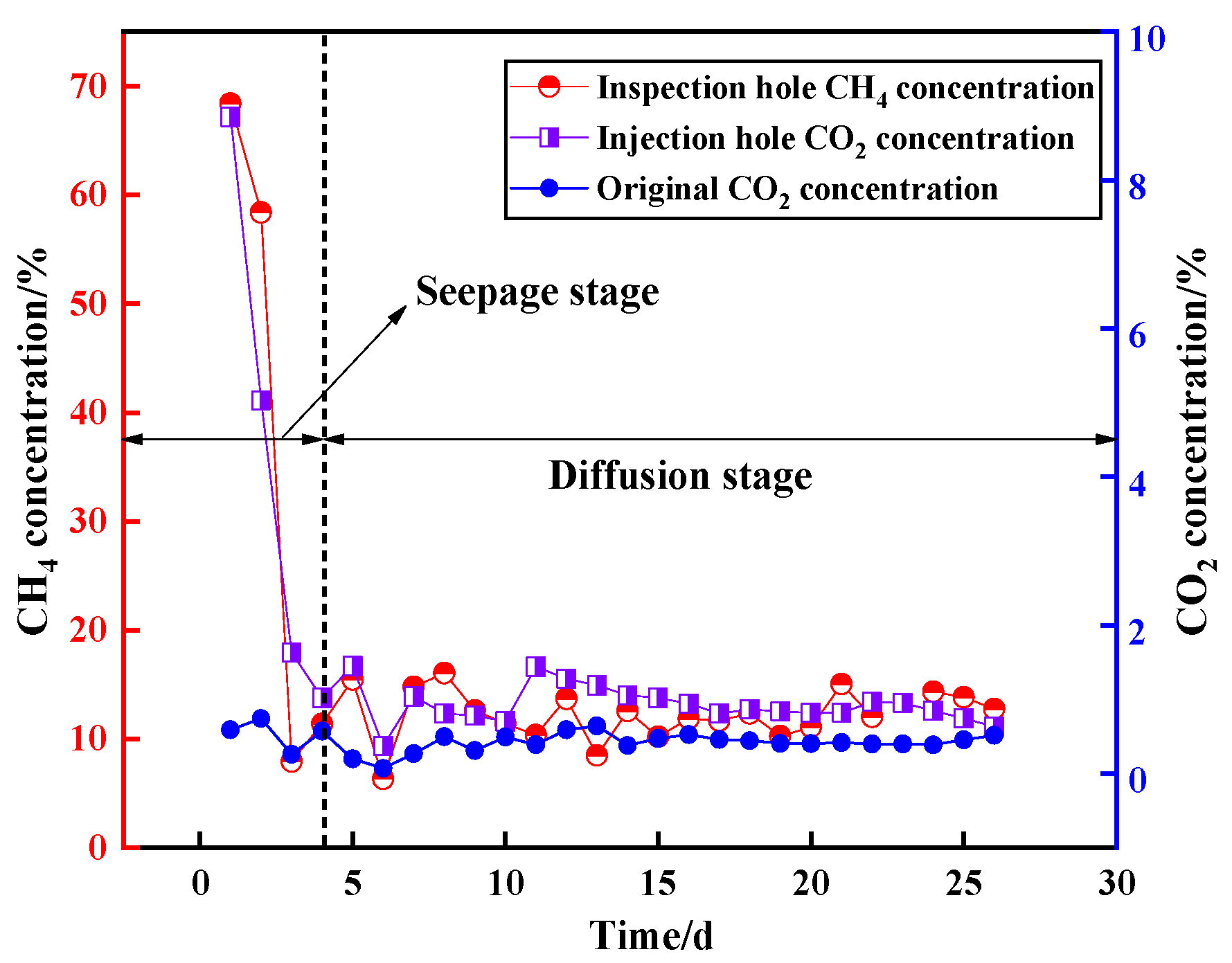

- Analysis of displacement process

- (3)

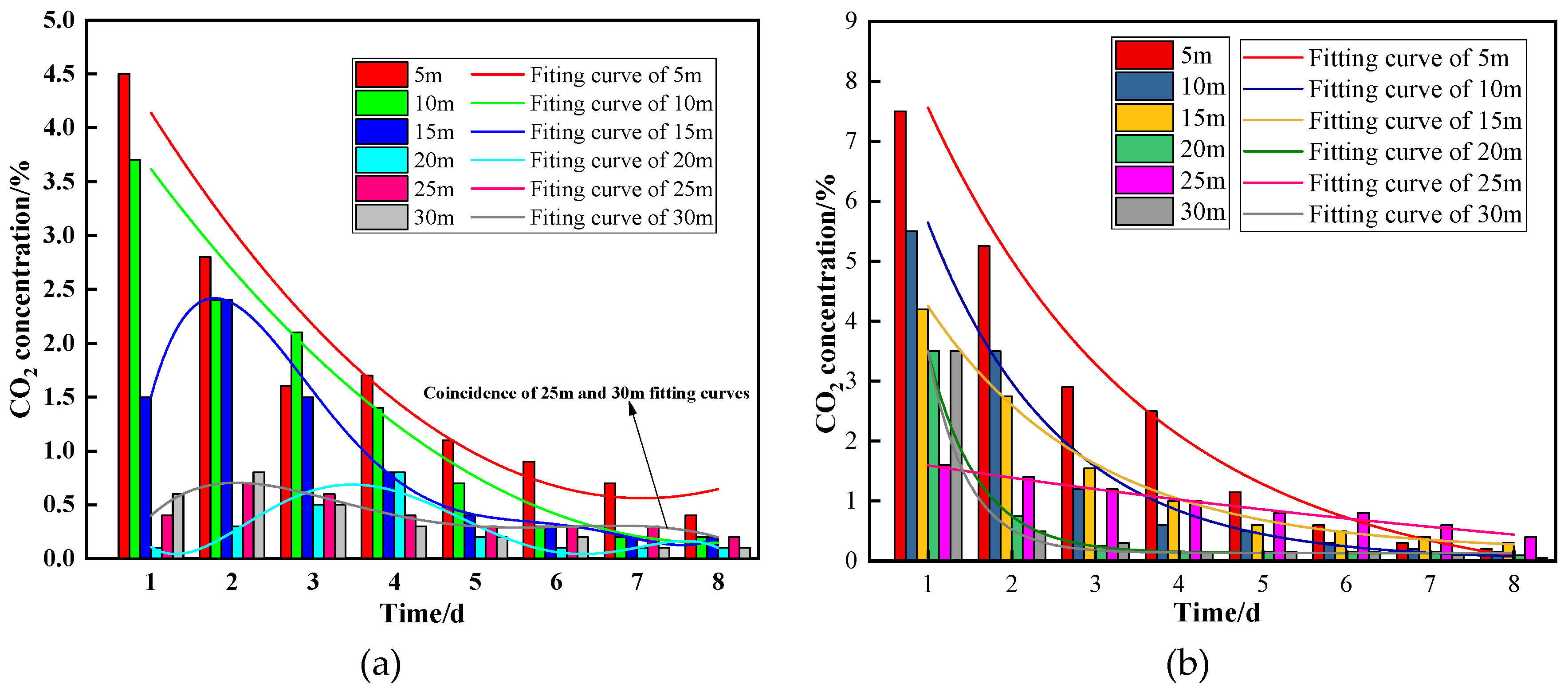

- Seepage diffusion range for CO2

- (4)

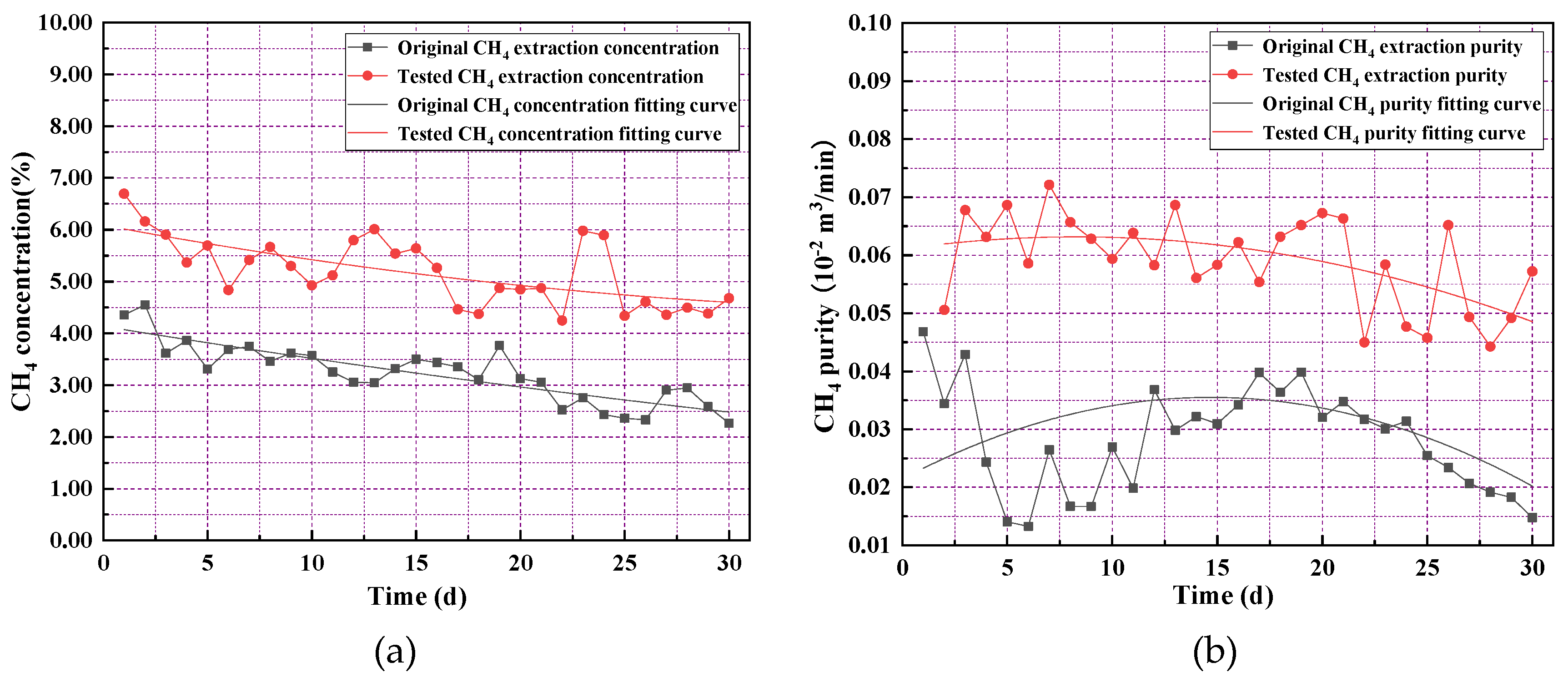

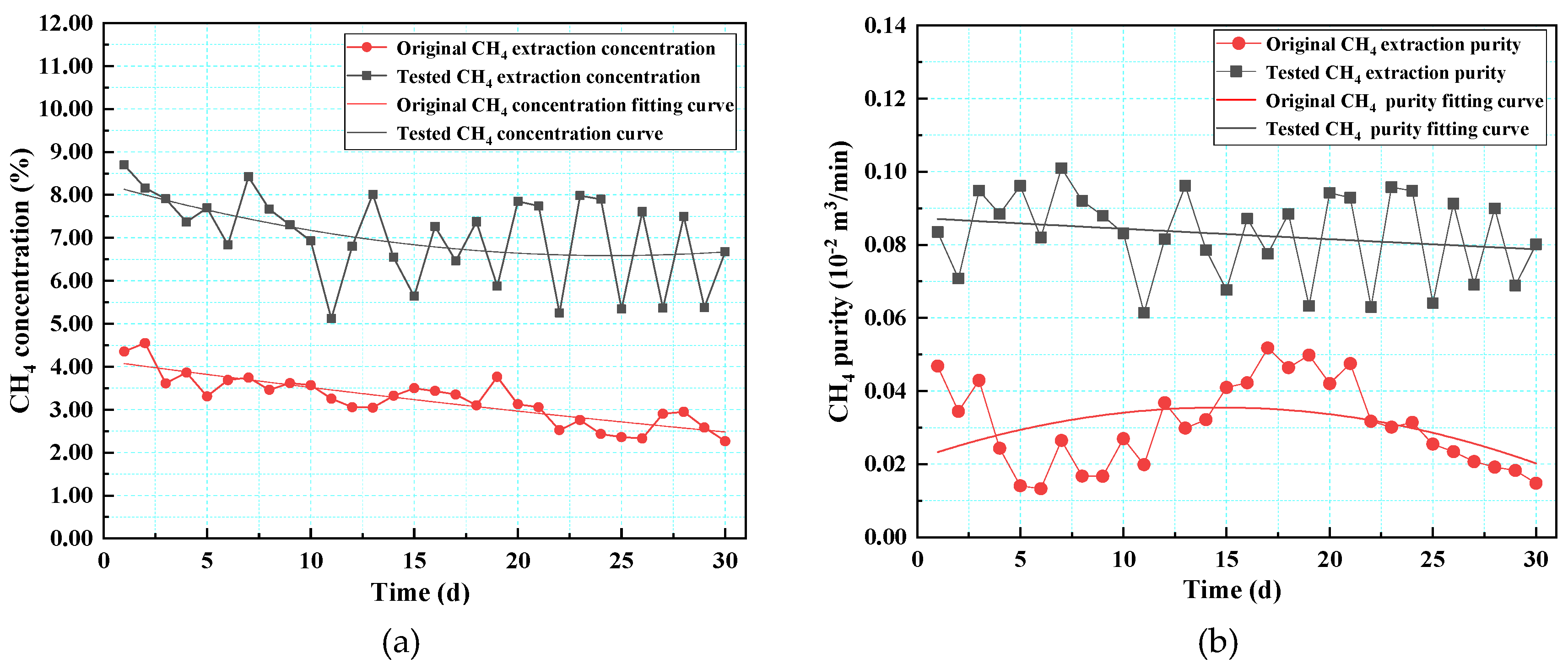

- Analysis of the displacement effect

- (5)

- Comparison of sweep efficiency

3. Conclusions

- (1)

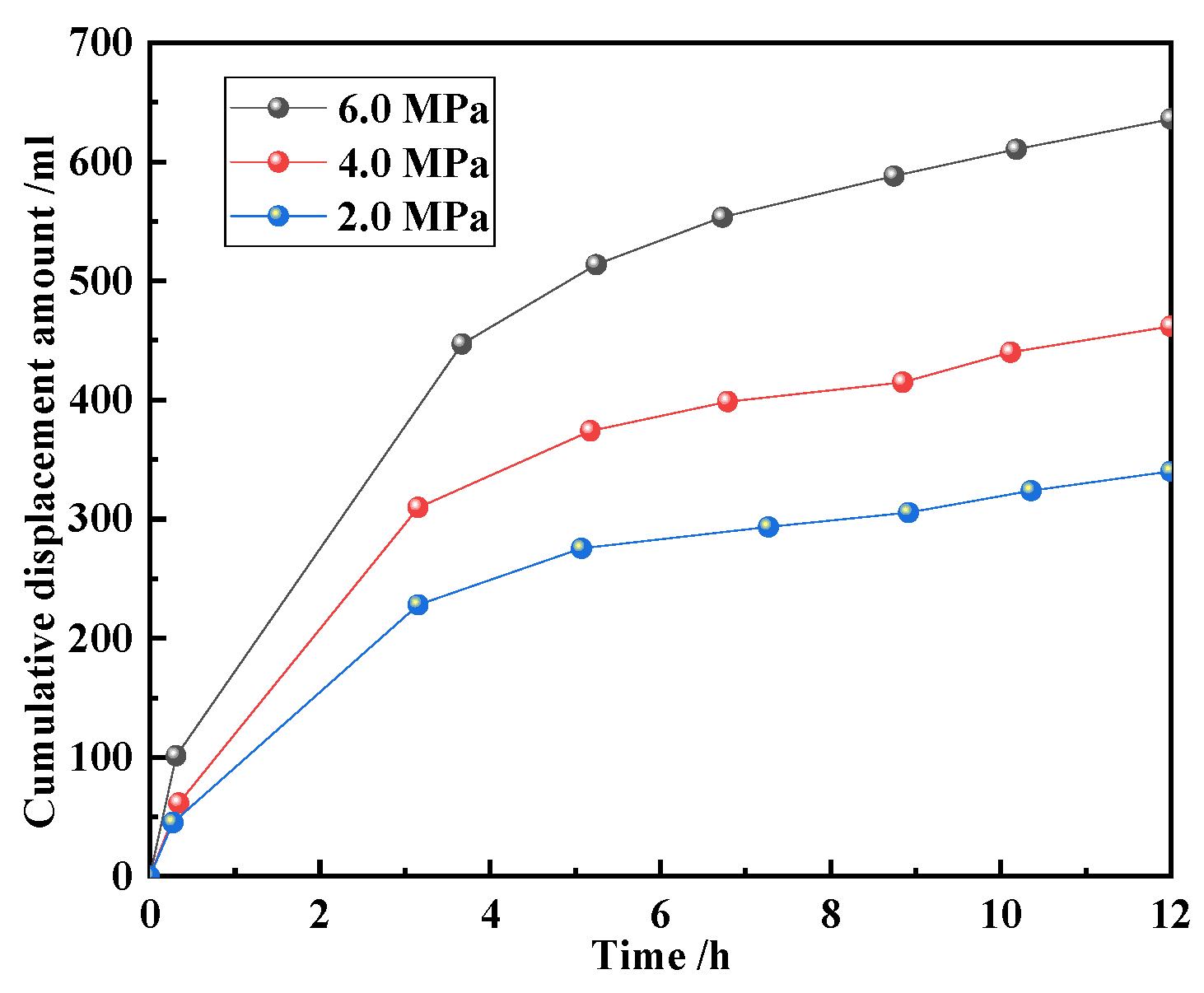

- The CH4 production rates under different pressures (2.0 MPa, 4.0 MPa, and 6.0 MPa) were 43.6%, 54.3%, and 70.7%, respectively. With the increase in pressure, the CH4 production rate increased by 24.4% and 61.9%, respectively. The displacement ratios of CH4 in the coal samples injected with different pressures were 3.85, 3.15, and 2.45. As the pressure increased, the displacement ratios decreased by 18.2% and 36.4%, respectively, and the sweep efficiency increased by 12.5% and 62.2%, respectively. Increasing the pressure improved the CH4 sweep efficiency and decreased the displacement ratio.

- (2)

- The maximum pressure of the low-pressure injection was 1.52 MPa, while the maximum pressure of the medium-pressure injection was 3.16 MPa. The pressure was 2.1 times that of the low-pressure injection. The pressure rise rate was 2.82 times that of low-pressure injection, and the pressure drop rate was 1.32 times that of the low-pressure injection. (3) Through a comparative analysis of the change trend of the CH4 concentration and CO2 concentration in the observation hole, it was determined that the change trend remained the same. The process of L-CO2 displacing gas can be roughly divided into two stages: the seepage stage and the diffusion stage. In the seepage stage, CO2 had a more obvious driving effect on free gas, and the gas concentration was relatively high in the initial stage. In the diffusion stage, CO2 played a major role in the displacement and desorption of adsorbed gas, and the gas concentration gradually decreased. A higher displacement pressure effectively promoted the displacement of CH4 by L-CO2. The diffusion range of CO2 under the low-pressure injection was 20–25 m, while under medium-pressure injection it was 25–30 m.

- (3)

- Inspection of the gas extraction field revealed that the concentration of CH4 extracted increased from 3.23% to 5.19% after the low-pressure injection of L-CO2 into the coal seam, increasing the concentration of gas extracted by 0.61 times. The pure flow of gas extracted increased from 0.028 m3/min to 0.059 m3/min, increasing the pure flow of gas extracted by 1.08 times. The concentration of CH4 extracted increased from 3.23% to 7.02% after the medium-pressure injection of L-CO2 into the coal seam, increasing the concentration of gas extracted by 1.17 times. The pure flow of gas extracted increased from 0.028 m3/min to 0.083 m3/min, increasing the pure flow of gas extracted by 1.94 times. The average gas drainage concentration of the medium-pressure injection was 1.35 times that of the low-pressure injection, and the average gas drainage scalar medium-pressure injection was 1.41 times that of low-pressure injection. The sweep efficiency of the medium-pressure injection (average pressure—2.8 MPa) was 26% higher than that of the low-pressure injection (average pressure—1.4 MPa). The overall efficiency of the medium-pressure injection was much higher.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Zhou, F.; Xia, T.; Wang, X.; Zhang, Y.; Sun, Y.; Liu, J. Recent developments in coal mine methane extraction and utilization in China: A review. J. Nat. Gas Sci. Eng. 2016, 31, 437–458. [Google Scholar] [CrossRef]

- Zhang, D.; Cen, X.; Wang, W.; Deng, J.; Wen, H.; Xiao, Y.; Shu, C.-M. The graded warning method of coal spontaneous combustion in Tangjiahui Mine. Fuel 2021, 288, 119635. [Google Scholar] [CrossRef]

- Chen, X.; Li, L.; Wang, L.; Qi, L. The current situation and prevention and control countermeasures for typical dynamic disasters in kilometer-deep mines in China. Saf. Sci. 2019, 115, 229–236. [Google Scholar] [CrossRef]

- Wei, G.; Wen, H.; Deng, J.; Ma, L.; Li, Z.; Lei, C.; Fan, S.; Liu, Y. Liquid CO2 injection to enhance coalbed methane recovery: An experiment and in-situ application test. Fuel 2021, 284, 119043. [Google Scholar] [CrossRef]

- Li, Z.; Wei, G.; Liang, R.; Shi, P.; Wen, H.; Zhou, W. LCO2-ECBM technology for preventing coal and gas outburst: Integrated effect of permeability improvement and gas displacement. Fuel 2021, 285, 119219. [Google Scholar] [CrossRef]

- Lin, J.; Ren, T.; Cheng, Y.; Nemcik, J.; Wang, G. Cyclic N2 injection for enhanced coal seam gas recovery: A laboratory study. Energy 2019, 188, 116115. [Google Scholar] [CrossRef]

- Durucan, S.; Shi, J.-Q. Improving the CO2 well injectivity and enhanced coalbed methane production performance in coal seams. Int. J. Coal Geol. 2009, 77, 214–221. [Google Scholar] [CrossRef]

- Wen, H.; Li, Z.; Deng, J.; Shu, C.-M.; Laiwang, B.; Wang, Q.; Ma, L. Influence on coal pore structure during liquid CO2-ECBM process for CO2 utilization. J. CO2 Util. 2017, 21, 543–552. [Google Scholar] [CrossRef]

- Qin, L.; Li, S.; Zhai, C.; Lin, H.; Zhao, P.; Shi, Y.; Bai, Y. Changes in the pore structure of lignite after repeated cycles of liquid nitrogen freezing as determined by nitrogen adsorption and mercury intrusion. Fuel 2020, 267, 117214. [Google Scholar] [CrossRef]

- Wen, H.; Cheng, X.; Chen, J.; Zhang, C.; Yu, Z.; Li, Z.; Fan, S.; Wei, G.; Cheng, B. Micro-pilot test for optimized pre-extraction boreholes and enhanced coalbed methane recovery by injection of liquid carbon dioxide in the Sangshuping coal mine. Process Saf. Environ. Prot. 2020, 136, 39–48. [Google Scholar] [CrossRef]

- Yan, F.; Lin, B.; Zhu, C.; Shen, C.; Zou, Q.; Guo, C.; Liu, T. A novel ECBM extraction technology based on the integration of hydraulic slotting and hydraulic fracturing. J. Nat. Gas Sci. Eng. 2015, 22, 571–579. [Google Scholar] [CrossRef]

- Ranathunga, A.S.; Perera, M.S.A.; Ranjith, P.G.; Zhang, X.G.; Wu, B. Super-critical carbon dioxide flow behaviour in low rank coal: A meso-scale experimental study. J. CO2 Util. 2017, 20, 1–13. [Google Scholar] [CrossRef]

- Sander, R.; Pan, Z.; Connell, L.D. Laboratory measurement of low permeability unconventional gas reservoir rocks: A review of experimental methods. J. Nat. Gas Sci. Eng. 2017, 37, 248–279. [Google Scholar] [CrossRef]

- Zou, Q.; Lin, B. Fluid–Solid Coupling Characteristics of Gas-Bearing Coal Subjected to Hydraulic Slotting: An Experimental Investigation. Energy Fuels 2018, 32, 1047–1060. [Google Scholar] [CrossRef]

- Busch, A.; Gensterblum, Y. CBM and CO2-ECBM related sorption processes in coal: A review. Int. J. Coal Geol. 2011, 87, 49–71. [Google Scholar] [CrossRef]

- Zhou, F.; Hussain, F.; Cinar, Y. Injecting pure N2 and CO2 to coal for enhanced coalbed methane: Experimental observations and numerical simulation. Int. J. Coal Geol. 2013, 116–117, 53–62. [Google Scholar] [CrossRef]

- Vishal, V. In-situ disposal of CO2: Liquid and supercritical CO2 permeability in coal at multiple down-hole stress conditions. J. CO2 Util. 2017, 17, 235–242. [Google Scholar] [CrossRef]

- Lin, J.; Ren, T.; Wang, G.; Booth, P.; Nemcik, J. Experimental investigation of N2 injection to enhance gas drainage in CO2-rich low permeable seam. Fuel 2018, 215, 665–674. [Google Scholar] [CrossRef]

- Syah, R.; Alizadeh, S.M.; Darvishzadeh, L.; Elveny, M.; Abedi, M.; Ramdan, D. Simultaneous injection of chemical agents and carbon dioxide to enhance the sweep efficiency from fractured tight core samples. Energy Rep. 2021, 7, 5639–5646. [Google Scholar] [CrossRef]

- Kumar, H.; Elsworth, D.; Mathews, J.P.; Liu, J.; Pone, D. Effect of CO2 injection on heterogeneously permeable coalbed reservoirs. Fuel 2014, 135, 509–521. [Google Scholar] [CrossRef]

- Merkel, A.; Gensterblum, Y.; Krooss, B.M.; Amann, A. Competitive sorption of CH4, CO2 and H2O on natural coals of different rank. Int. J. Coal Geol. 2015, 150–151, 181–192. [Google Scholar] [CrossRef]

- Dutka, B.; Kudasik, M.; Pokryszka, Z.; Skoczylas, N.; Topolnicki, J.; Wierzbicki, M. Balance of CO2/CH4 exchange sorption in a coal briquette. Fuel Process. Technol. 2013, 106, 95–101. [Google Scholar] [CrossRef]

- Liu, Z.; Cheng, Y.; Wang, Y.; Wang, L.; Li, W. Experimental investigation of CO2 injection into coal seam reservoir at in-situ stress conditions for enhanced coalbed methane recovery. Fuel 2019, 236, 709–716. [Google Scholar] [CrossRef]

- Kumar, H.; Elsworth, D.; Liu, J.; Pone, D.; Mathews, J.P. Optimizing enhanced coalbed methane recovery for unhindered production and CO2 injectivity. Int. J. Greenh. Gas Control 2012, 11, 86–97. [Google Scholar] [CrossRef]

- Kim, S.; Ko, D.; Mun, J.; Kim, T.-H.; Kim, J. Techno-economic evaluation of gas separation processes for long-term operation of CO2 injected enhanced coalbed methane (ECBM). Korean J. Chem. Eng. 2018, 35, 941–955. [Google Scholar] [CrossRef]

- Topolnicki, J.; Kudasik, M.; Dutka, B. Simplified model of the CO2/CH4 exchange sorption process. Fuel Process. Technol. 2013, 113, 67–74. [Google Scholar] [CrossRef]

- Mazzotti, M.; Pini, R.; Storti, G. Enhanced coalbed methane recovery. J. Supercrit. Fluids 2009, 47, 619–627. [Google Scholar] [CrossRef]

- Bai, X.; Zhang, D.; Zeng, S.; Zhang, S.; Wang, D.; Wang, F. An enhanced coalbed methane recovery technique based on CO2 phase transition jet coal-breaking behavior. Fuel 2020, 265, 116912. [Google Scholar] [CrossRef]

- Wang, J.; Liu, J.; Li, Z.; Li, H.; Zhang, J.; Li, W.; Zhang, Y.; Ping, Y.; Yang, H.; Wang, P. Synchronous injection-production energy replenishment for a horizontal well in an ultra-low permeability sandstone reservoir: A case study of Changqing oilfield in Ordos Basin, NW China. Pet. Explor. Dev. 2020, 47, 827–835. [Google Scholar] [CrossRef]

- Chen, H.; Wang, Z.; Chen, X.; Chen, X.; Wang, L. Increasing permeability of coal seams using the phase energy of liquid carbon dioxide. J. CO2 Util. 2017, 19, 112–119. [Google Scholar] [CrossRef]

- Wei, G.; Wen, H.; Deng, J.; Li, Z.; Fan, S.; Lei, C.; Liu, M.; Ren, L. Enhanced coalbed permeability and methane recovery via hydraulic slotting combined with liquid CO2 injection. Process Saf. Environ. Prot. 2021, 147, 234–244. [Google Scholar] [CrossRef]

- Vishal, V. Saturation time dependency of liquid and supercritical CO2 permeability of bituminous coals: Implications for carbon storage. Fuel 2017, 192, 201–207. [Google Scholar] [CrossRef]

- Wen, H.; Wei, G.; Ma, L.; Li, Z.; Lei, C.; Hao, J. Damage characteristics of coal microstructure with liquid CO2 freezing-thawing. Fuel 2019, 249, 169–177. [Google Scholar] [CrossRef]

- Fujioka, M.; Yamaguchi, S.; Nako, M. CO2-ECBM field tests in the Ishikari Coal Basin of Japan. Int. J. Coal Geol. 2010, 82, 287–298. [Google Scholar] [CrossRef]

- Liang, W.; Zhao, Y.; Wu, D.; Dusseault, M.B. Experiments on Methane Displacement by Carbon Dioxide in Large Coal Specimens. Rock Mech. Rock Eng. 2011, 44, 579–589. [Google Scholar] [CrossRef]

- Perera, M.S.A.; Ranjith, P.G.; Airey, D.W.; Choi, S.K. Sub- and super-critical carbon dioxide flow behavior in naturally fractured black coal: An experimental study. Fuel 2011, 90, 3390–3397. [Google Scholar] [CrossRef]

- Godec, M.; Koperna, G.; Gale, J. CO2-ECBM: A Review of its Status and Global Potential. Energy Procedia 2014, 63, 5858–5869. [Google Scholar] [CrossRef] [Green Version]

- Zhang, X.; Ranjith, P.G. Experimental investigation of effects of CO2 injection on enhanced methane recovery in coal seam reservoirs. J. CO2 Util. 2019, 33, 394–404. [Google Scholar] [CrossRef]

- Al-Abri, A.; Sidiq, H.; Amin, R. Mobility ratio, relative permeability and sweep efficiency of supercritical CO2 and methane injection to enhance natural gas and condensate recovery: Coreflooding experimentation. J. Nat. Gas Sci. Eng. 2012, 9, 166–171. [Google Scholar] [CrossRef]

- Wen, H.; Liu, M.; Wei, G.; Zhai, X.; Fan, S.; Cheng, X.; Wang, H.; Hao, J.; Xia, B.-W. Gas Displacement Engineering Test by Combination of Low and Medium Pressure Injection with Liquid CO2 in High Gas and Low Permeability Coal Seam. Geofluids 2020, 2020, 8840602. [Google Scholar] [CrossRef]

- Wen, H.; Wang, H.; Fan, S.; Li, Z.; Chen, J.; Cheng, X.; Cheng, B.; Yu, Z. Improving coal seam permeability and displacing methane by injecting liquid CO2: An experimental study. Fuel 2020, 281, 118747. [Google Scholar] [CrossRef]

- Fan, S.; Zhang, D.; Wen, H.; Cheng, X.; Liu, X.; Yu, Z.; Hu, B. Enhancing coalbed methane recovery with liquid CO2 fracturing in underground coal mine: From experiment to field application. Fuel 2021, 290, 119793. [Google Scholar] [CrossRef]

- Zhao, W.; Cheng, Y.; Pan, Z.; Wang, K.; Liu, S. Gas diffusion in coal particles: A review of mathematical models and their applications. Fuel 2019, 252, 77–100. [Google Scholar] [CrossRef]

| Numbering | Size of Coal Sample (mm) | CH4 Adsorption Pressure (MPa) | CH4 Adsorption Time (h) | Confining Pressure (MPa) | CO2 Injection Pressure (MPa) | Back Pressure (MPa) | Temperature (°C) |

|---|---|---|---|---|---|---|---|

| 1# | 25.1 × 60.0 | 1.0–2.0 | 16–24 | 8 | 2.0–3.0 | 1.0–1.5 | 30 |

| 2# | 24.9 × 61.0 | 1.0–2.0 | 16–24 | 8 | 4.0–5.0 | 2.0–3.0 | 30 |

| 3# | 25.0 × 59.0 | 1.0–2.0 | 16–24 | 8 | 6.0–7.0 | 4.0–5.0 | 30 |

| Order Number | Injection Volume/mL | Injection Pressure/MPa | Output Volume/mL | CO2 Storage/mL | Replacement Ratio | Sweep Efficiency/% | ||

|---|---|---|---|---|---|---|---|---|

| CH4 | CO2 | CH4 | CO2 | |||||

| 1 | 779 | 4370 | 2.0 | 340 | 3060 | 1310 | 3.85 | 43.6 |

| 2 | 851 | 5192 | 4.0 | 462 | 3738 | 1454 | 3.15 | 54.3 |

| 3 | 900 | 6220 | 6.0 | 636 | 4664 | 1556 | 2.45 | 70.7 |

| Boreholes | Depth (m) | Orientation (°) | Dip Angle (°) | Aperture (mm) | Sealing Length (m) |

|---|---|---|---|---|---|

| YZ | 120 | 90 | 0.5–1 | 133 | 50 |

| K1–K6 | 120 | 90 | 0.5–1 | 133 | 30 |

| D1–D5 | 120 | 90 | 0–0.5 | 133 | 12 |

| Serial Number | Boost Time of Pressure/min | Pressure Fluctuation Range/MPa | Pressure Fluctuation time/min | Maximum Pressure/MPa | Cumulative Injection Volume/m3 |

|---|---|---|---|---|---|

| 1 | 23 | 1.3–1.6 | 110 | 1.52 | 5.9 |

| 2 | 17 | 2.5–3.2 | 60 | 3.16 | 5.8 |

| y0 | A | B | R2 | Distance/m | |

|---|---|---|---|---|---|

| y1 | 0.51 | 6.56 | −0.51 | 0.9679 | 5 |

| y2 | −0.53 | 5.55 | −0.28 | 0.9742 | 10 |

| y0 | A | B | R2 | Distance/m | |

|---|---|---|---|---|---|

| y1 | −0.49 | 11.75 | −0.38 | 0.9879 | 5 |

| y2 | 0.02 | 10.69 | −0.64 | 0.9737 | 10 |

| y3 | 0.17 | 6.85 | −0.52 | 0.9958 | 15 |

| y4 | 0.14 | 18.40 | −1.70 | 0.9997 | 20 |

| y5 | −1.15 | 2.97 | −0.08 | 0.9818 | 25 |

| y6 | 0.14 | 28.92 | −2.15 | 0.9965 | 30 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Wen, H.; Fan, S.; Wang, Z.; Fei, J.; Wei, G.; Cheng, X.; Wang, H. Experimental Study of CO2-ECBM by Injection Liquid CO2. Minerals 2022, 12, 297. https://doi.org/10.3390/min12030297

Liu M, Wen H, Fan S, Wang Z, Fei J, Wei G, Cheng X, Wang H. Experimental Study of CO2-ECBM by Injection Liquid CO2. Minerals. 2022; 12(3):297. https://doi.org/10.3390/min12030297

Chicago/Turabian StyleLiu, Mingyang, Hu Wen, Shixing Fan, Zhenping Wang, Jinbiao Fei, Gaoming Wei, Xiaojiao Cheng, and Hu Wang. 2022. "Experimental Study of CO2-ECBM by Injection Liquid CO2" Minerals 12, no. 3: 297. https://doi.org/10.3390/min12030297

APA StyleLiu, M., Wen, H., Fan, S., Wang, Z., Fei, J., Wei, G., Cheng, X., & Wang, H. (2022). Experimental Study of CO2-ECBM by Injection Liquid CO2. Minerals, 12(3), 297. https://doi.org/10.3390/min12030297