Discrimination of Mineralization Types of Skarn Deposits by Magnetite Chemistry

Abstract

:1. Introduction

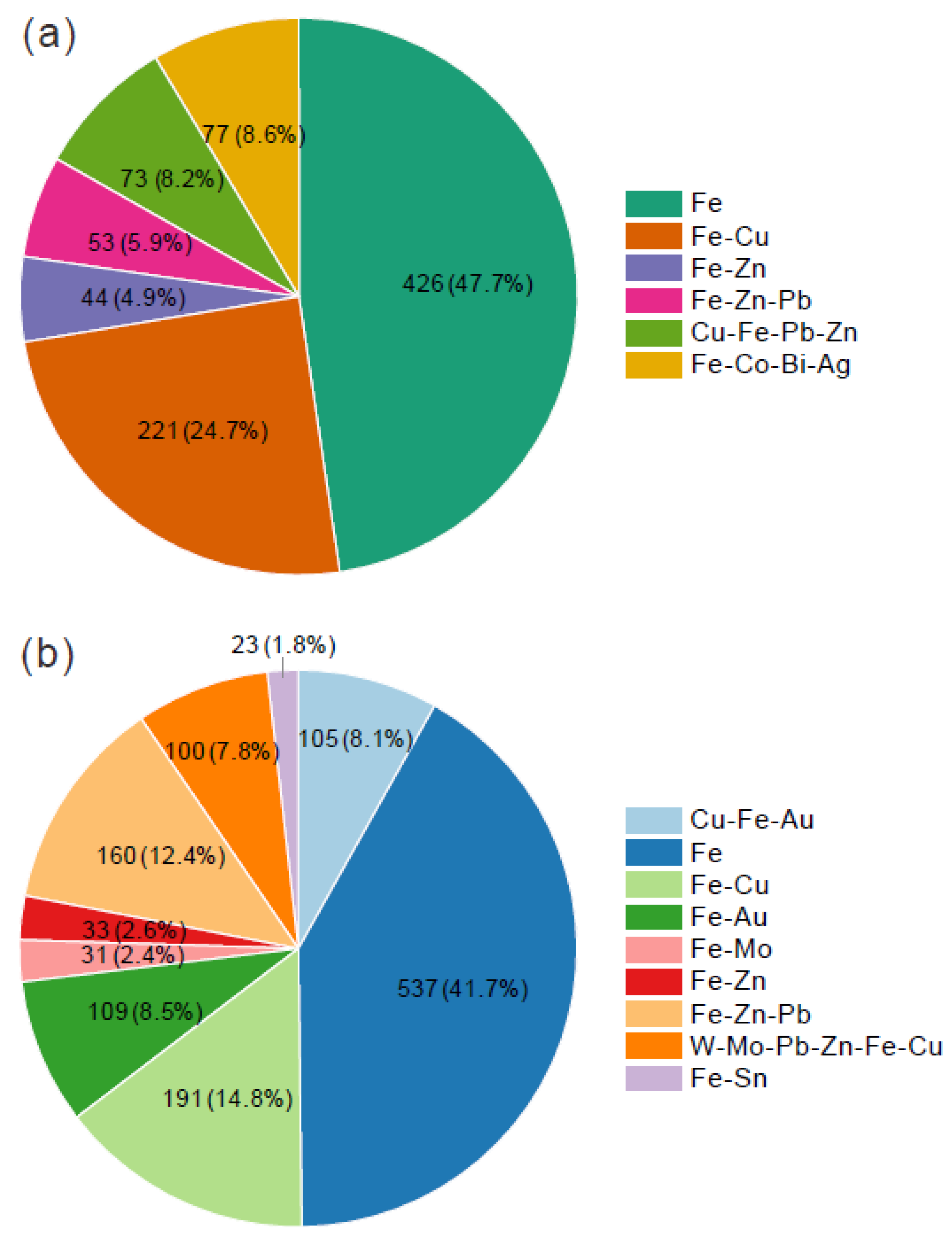

2. Data and Analytical Methods

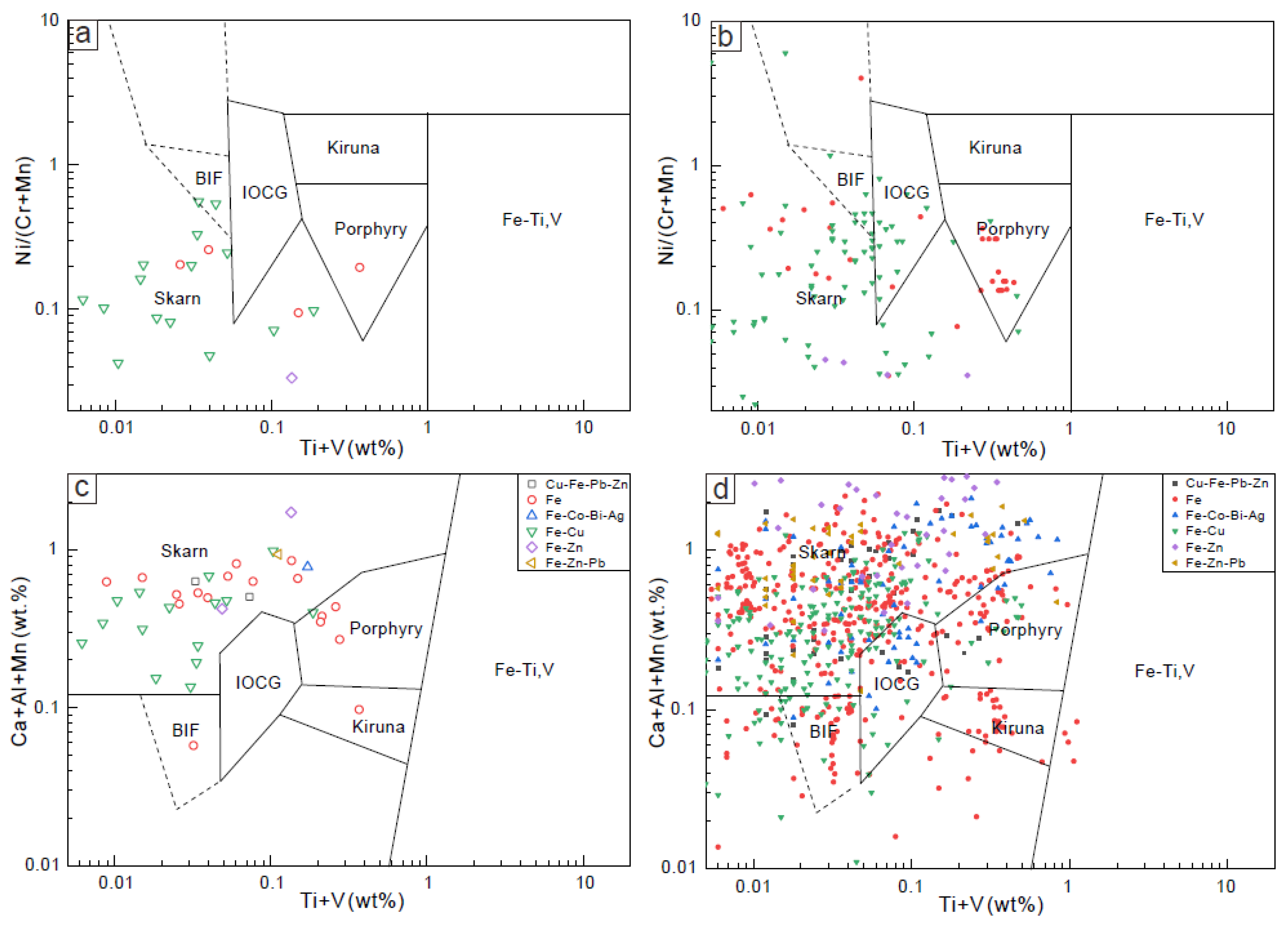

2.1. Data Preparation

2.2. Statistical Methods

3. Results

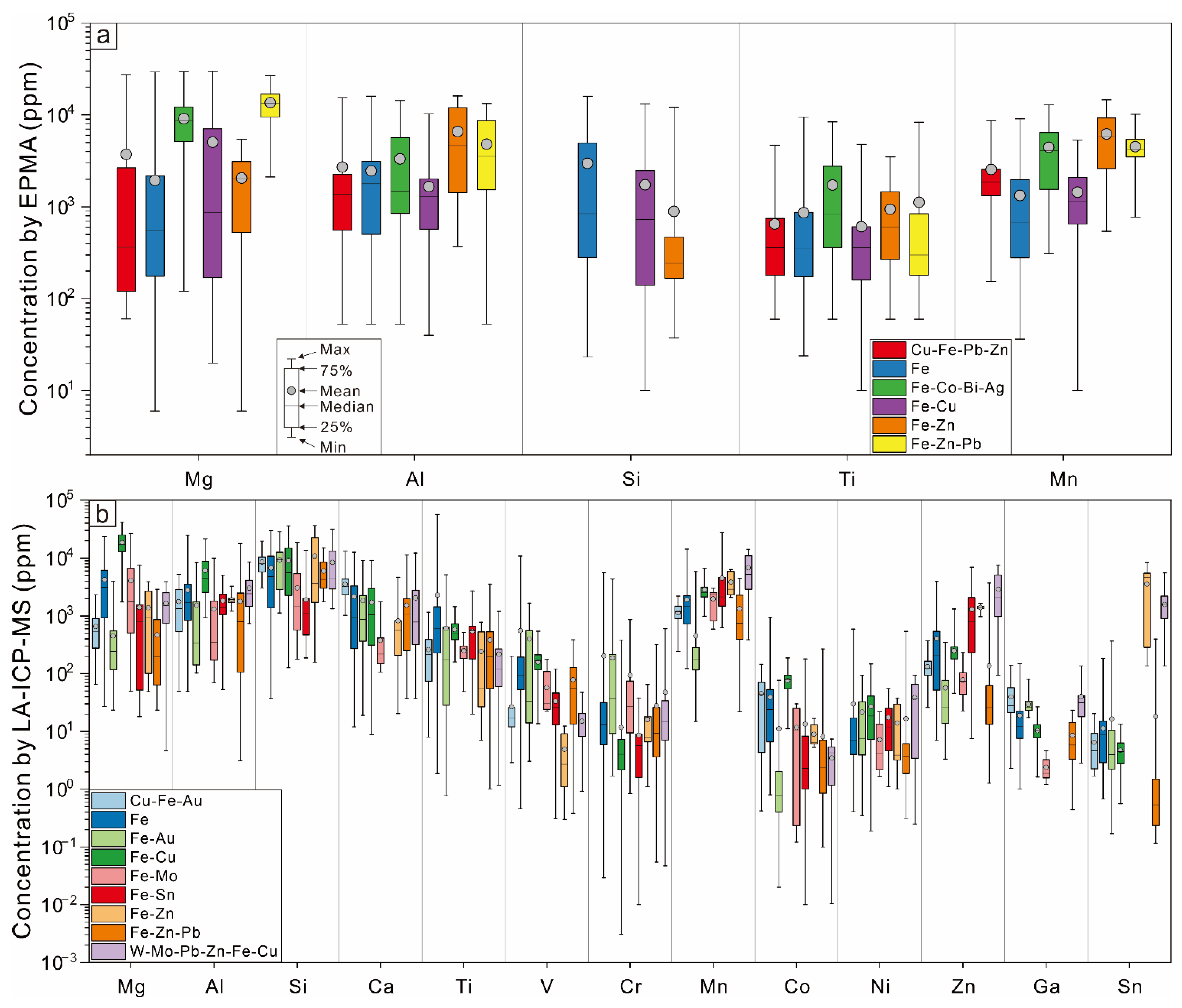

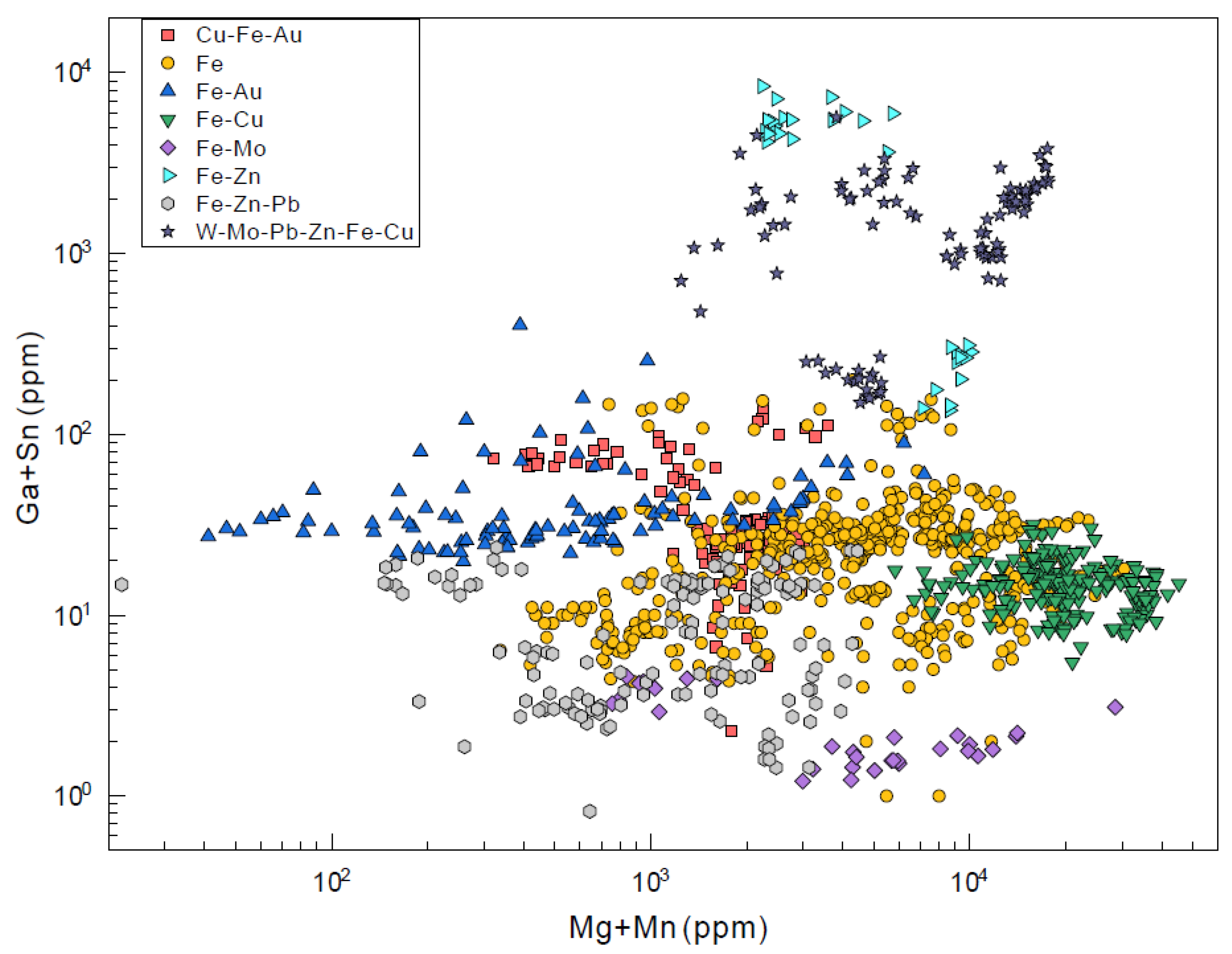

3.1. Chemical Composition of Magnetite

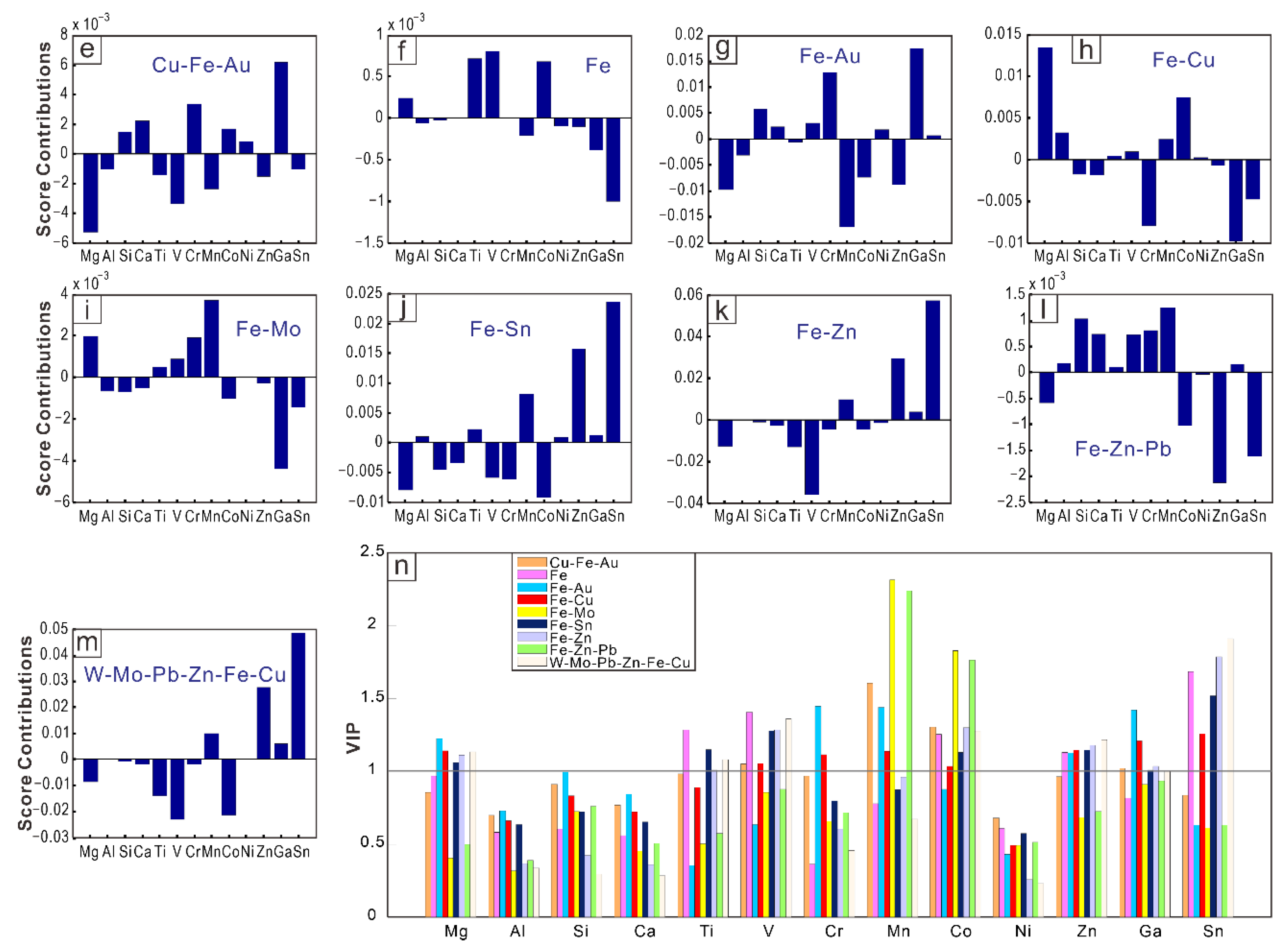

3.2. PLS-DA Results of Different Mineralization Types of Skarn Deposits

4. Discussion

4.1. Factors for Variation in Chemistry of Skarn Magnetite

4.1.1. Intrusive Compositions

4.1.2. Fluid–Rock Interaction

4.1.3. Temperature

4.1.4. Oxygen Fugacity

4.1.5. Co-Crystallized Minerals

4.2. Discrimination between Magnetite from Different Mineralization Types of Skarn Deposits

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Einaudi, M.T.; Meinert, L.D.; Newberry, R.J. Skarn deposits. Econ. Geol. 1981, 75, 317–391. [Google Scholar]

- Meinert, L.D.; Dipple, G.M.; Nicolescu, S. World skarn deposits. In Economic Geology 100th Anniversary Volume; Hedenquist, J.W., Thompson, J.F.H., Goldfarb, R.J., Richards, J.P., Eds.; Society of Economic Geologists: Littleton, Colorado, 2005; pp. 299–336. [Google Scholar]

- Meinert, L.D. Skarns and skarn deposits. Geosci. Can. 1992, 19, 145–162. [Google Scholar]

- Chang, Z.; Shu, Q.; Meinert, L.D. Skarn Deposits of China. SEG Spec. Publ. 2019, 22, 189–234. [Google Scholar]

- Dupuis, C.; Beaudoin, G. Discriminant diagrams for iron oxide trace element fingerprinting of mineral deposit types. Miner. Depos. 2011, 46, 1–17. [Google Scholar] [CrossRef]

- Nadoll, P.; Angerer, T.; Mauk, J.L.; French, D.; Walshe, J. The chemistry of hydrothermal magnetite: A review. Ore Geol. Rev. 2014, 61, 1–32. [Google Scholar] [CrossRef]

- Makvandi, S.; Ghasemzadeh-Barvarz, M.; Beaudoin, G.; Grunsky, E.C.; McClenaghan, M.B.; Duchesne, C.; Boutroy, E. Partial least squares-discriminant analysis of trace element compositions of magnetite from various VMS deposit subtypes: Application to mineral exploration. Ore Geol. Rev. 2016, 78, 388–408. [Google Scholar] [CrossRef]

- Huang, X.-W.; Sappin, A.-A.; Boutroy, É.; Beaudoin, G.; Makvandi, S. Trace Element Composition of Igneous and Hydrothermal Magnetite from Porphyry Deposits: Relationship to Deposit Subtypes and Magmatic Affinity. Econ. Geol. 2019, 114, 917–952. [Google Scholar] [CrossRef]

- Huang, X.-W.; Gao, J.-F.; Qi, L.; Meng, Y.-M.; Wang, Y.-C.; Dai, Z.-H. In-situ LA-ICP-MS trace elements analysis of magnetite: The Fenghuangshan Cu-Fe-Au deposit, Tongling, Eastern China. Ore Geol. Rev. 2016, 72, 746–759. [Google Scholar] [CrossRef]

- Zhao, L.; Zhang, Y.; Shao, Y.; Li, H.; Ahmad Shah, S.; Zhou, W. Using garnet geochemistry discriminating different skarn mineralization systems: Perspective from Huangshaping W-Mo-Sn-Cu polymetallic deposit, South China. Ore Geol. Rev. 2021, 138, 104412. [Google Scholar] [CrossRef]

- Tian, Z.-D.; Leng, C.-B.; Zhang, X.-C.; Zafar, T.; Zhang, L.-J.; Hong, W.; Lai, C.-K. Chemical composition, genesis and exploration implication of garnet from the Hongshan Cu-Mo skarn deposit, SW China. Ore Geol. Rev. 2019, 112, 103016. [Google Scholar] [CrossRef]

- Huang, X.W.; Boutroy, E.; Makvandi, S.; Beaudoin, G.; Corriveau, L.; De Toni, A.F. Trace element composition of iron oxides from IOCG and IOA deposits: Relationship to hydrothermal alteration and deposit subtypes. Miner. Depos. 2019, 54, 525–552. [Google Scholar] [CrossRef] [Green Version]

- De Iorio, M.; Ebbels, T.; Stephens, D. Statistical Techniques in Metabolic Profiling. Handb. Stat. Genet. 2007, 1, 347–373. [Google Scholar]

- Wold, S.; Sjostrom, M.; Eriksson, L. PLS-regression: A basic tool of chemometrics. Chemom. Intell. Lab. Syst. 2001, 58, 109–130. [Google Scholar] [CrossRef]

- Dare, S.A.S.; Barnes, S.-J.; Beaudoin, G.; Méric, J.; Boutroy, E.; Potvin-Doucet, C. Trace elements in magnetite as petrogenetic indicators. Miner. Depos. 2014, 49, 785–796. [Google Scholar] [CrossRef]

- Hu, H.; Lentz, D.; Li, J.-W.; McCarron, T.; Zhao, X.-F.; Hall, D. Reequilibration processes in magnetite from iron skarn deposits. Econ. Geol. 2015, 110, 1–8. [Google Scholar] [CrossRef]

- Huang, X.-W.; Beaudoin, G. Textures and Chemical Compositions of Magnetite from Iron Oxide Copper-Gold (IOCG) and Kiruna-Type Iron Oxide-Apatite (IOA) Deposits and Their Implications for Ore Genesis and Magnetite Classification Schemes. Econ. Geol. 2019, 114, 953–979. [Google Scholar] [CrossRef]

- Hu, H.; Li, J.-W.; Lentz, D.; Ren, Z.; Zhao, X.-F.; Deng, X.-D.; Hall, D. Dissolution-reprecipitation process of magnetite from the Chengchao iron deposit: Insights into ore genesis and implication for in-situ chemical analysis of magnetite. Ore Geol. Rev. 2014, 57, 393–405. [Google Scholar] [CrossRef]

- Li, C.; Zhou, X.; Zhao, F.; Liu, Z. Summarizing on the associated mineral characteristics and comprehensive recovery status of skarn iron deposits. Land Resour. Her. 2020, 17, 31–35. (In Chinese) [Google Scholar]

- Tosdal, R.M.; Dilles, J.H.; Cooke, D.R. From Source to Sinks in Auriferous Magmatic-Hydrothermal Porphyry and Epithermal Deposits. Elements 2009, 5, 289–295. [Google Scholar] [CrossRef]

- Toplis, M.J.; Carroll, M.R. An experimental study of the influence of oxygen fugacity on Fe-Ti oxide stability, phase relations, and mineral-melt equilibria in ferro-basaltic systems. J. Petrol. 1995, 36, 1137–1170. [Google Scholar] [CrossRef]

- Canil, D.; Lacourse, T. Geothermometry using minor and trace elements in igneous and hydrothermal magnetite. Chem. Geol. 2020, 541, 119576. [Google Scholar] [CrossRef]

- Frost, B.R. Introduction to oxygen fugacity and its petrologic importance. In Oxide Minerals: Petrologic and Magnetic Significance; Lindsley, D.H., Ed.; Reviews in Mineralogy; Mineralogical Society of America: Chantilly, VA, USA, 1991; Volume 25, pp. 1–9. [Google Scholar]

- Toplis, M.J.; Corgne, A. An experimental study of element partitioning between magnetite, clinopyroxene and iron-bearing silicate liquids with particular emphasis on vanadium. Contrib. Mineral. Petrol. 2002, 144, 22–37. [Google Scholar] [CrossRef]

- Dare, S.A.S.; Barnes, S.-J.; Beaudoin, G. Variation in trace element content of magnetite crystallized from a fractionating sulfide liquid, Sudbury, Canada: Implications for provenance discrimination. Geochim. Cosmochim. Acta 2012, 88, 27–50. [Google Scholar] [CrossRef]

- Sun, X.; Lin, H.; Fu, Y.; Li, D.; Hollings, P.; Yang, T.; Liu, Z. Trace element geochemistry of magnetite from the giant Beiya gold-polymetallic deposit in Yunnan Province, Southwest China and its implications for the ore forming processes. Ore Geol. Rev. 2017, 91, 477–490. [Google Scholar] [CrossRef]

- Wang, C.-M.; Zhang, L.; Tang, H.-S.; Chen, H.-Y.; Li, X.-L.; Zheng, Y.; Li, D.-F.; Fang, J.; Dong, L.-H.; Qu, X. Genesis of the Kaladawan Fe-Mo ore field in Altyn, Xinjiang, China: Constraints from mineralogy and geochemistry. Ore Geol. Rev. 2017, 81, 587–601. [Google Scholar] [CrossRef]

- Ilton, E.S.; Eugster, H.P. Base metal exchange between magnetite and a chloride-rich hydrothermal fluid. Geochim. Cosmochim. Acta 1989, 53, 291–301. [Google Scholar] [CrossRef]

- Hu, X.; Chen, H.; Zhao, L.; Han, J.; Xia, X. Magnetite geochemistry of the Longqiao and Tieshan Fe-(Cu) deposits in the Middle-Lower Yangtze River Belt: Implications for deposit type and ore genesis. Ore Geol. Rev. 2017, 89, 822–835. [Google Scholar] [CrossRef]

- Liu, Y.N.; Fan, Y.; Zhou, T.F.; Xiao, X.; White, N.C.; Thompson, J.; Hong, H.L.; Zhang, L.J. Geochemical characteristics of magnetite in Longqiao skarn iron deposit in the Middle-Lower Yangtze Metallogenic Belt, Eastern China. Miner. Deposita 2019, 54, 1229–1242. [Google Scholar] [CrossRef]

- Xie, Q.; Zhang, Z.; Hou, T.; Jin, Z.; Santosh, M. Geochemistry and oxygen isotope composition of magnetite from the Zhangmatun deposit, North China Craton: Implications for the magmatic-hydrothermal evolution of Cornwall-type iron mineralization. Ore Geol. Rev. 2017, 88, 57–70. [Google Scholar] [CrossRef]

- Li, G. Iron Ore Deposits in the Eastern Tianshan Orogenic Belt (China): The Magnetite-Skarn-Magmatism Association. Ph.D. Thesis, University of Orleans, Orléans, France, 2012. [Google Scholar]

- Yang, Y.-L.; Ni, P.; Pan, J.-Y.; Wang, G.-G.; Xu, Y.-F. Constraints on the mineralization processes of the Makeng iron deposit, eastern China: Fluid inclusion, H-O isotope and magnetite trace element analysis. Ore Geol. Rev. 2017, 88, 791–808. [Google Scholar] [CrossRef]

- Huang, X.-W.; Zhou, M.-F.; Beaudoin, G.; Gao, J.-F.; Qi, L.; Lyu, C. Origin of the volcanic-hosted Yamansu Fe deposit, Eastern Tianshan, NW China: Constraints from pyrite Re-Os isotopes, stable isotopes, and in situ magnetite trace elements. Miner. Deposita 2018, 53, 1039–1060. [Google Scholar] [CrossRef]

- Neumann, E.-R.; Svensen, H.H.; Polozov, A.G.; Hammer, Ø. Formation of Si-Al-Mg-Ca-rich zoned magnetite in an end-Permian phreatomagmatic pipe in the Tunguska Basin, East Siberia. Miner. Deposita 2017, 52, 1205–1222. [Google Scholar] [CrossRef]

- Zhao, W.W.; Zhou, M.-F. In-situ LA-ICP-MS trace elemental analyses of magnetite: The Mesozoic Tengtie skarn Fe deposit in the Nanling Range, South China. Ore Geol. Rev. 2015, 65, 872–883. [Google Scholar] [CrossRef]

- Hu, H.; Li, J.-W.; Harlov, D.E.; Lentz, D.R.; McFarlane, C.R.; Yang, Y.-H. A genetic link between iron oxide-apatite and iron skarn mineralization in the Jinniu volcanic basin, Daye district, eastern China: Evidence from magnetite geochemistry and multi-mineral U-Pb geochronology. Geol. Soc. Am. Bull. 2019, 132, 899–917. [Google Scholar] [CrossRef]

- Canil, D.; Grondahl, C.; Lacourse, T.; Pisiak, L.K. Trace elements in magnetite from porphyry Cu-Mo-Au deposits in British Columbia, Canada. Ore Geol. Rev. 2016, 72, 1116–1128. [Google Scholar] [CrossRef] [Green Version]

- Sun, W.A.; Yuan, F.; Jowitt, S.M.; Zhou, T.F.; Liu, G.X.; Li, X.H.; Wang, F.Y.; Troll, V.R. In situ LA-ICP-MS trace element analyses of magnetite: Genetic implications for the Zhonggu orefield, Ningwu volcanic basin, Anhui Province, China. Miner. Deposita 2019, 54, 1243–1264. [Google Scholar] [CrossRef]

- Wang, M.; Wang, W.; Liu, K.; Michalak, P.P.; Wei, K.; Hu, M. In-situ LA-ICP-MS trace elemental analyzes of magnetite: The Tieshan skarn Fe-Cu deposit, Eastern China. Geochemistry 2017, 77, 169–181. [Google Scholar] [CrossRef]

- Duan, S.; Zhang, Z.; Jiang, Z.; Zhao, J.; Zhang, Y.; Li, F.; Tian, J. Geology, geochemistry, and geochronology of the Dunde iron-zinc ore deposit in western Tianshan, China. Ore Geol. Rev. 2014, 57, 441–461. [Google Scholar] [CrossRef]

- Wang, X.; Wei, W.; Lv, X.; Fan, X.; Wang, S. Stanniferous magnetite composition from the Haobugao skarn Fe-Zn deposit, southern Great Xing’an Range: Implication for mineral depositional mechanism. Geol. J. 2018, 53, 1823–1839. [Google Scholar] [CrossRef]

- Ding, T.; Ma, D.; Lu, J.; Zhang, R. Magnetite as an indicator of mixed sources for W-Mo-Pb-Zn mineralization in the Huangshaping polymetallic deposit, southern Hunan Province, China. Ore Geol. Rev. 2018, 95, 65–78. [Google Scholar] [CrossRef]

- Chen, F.; Deng, J.; Wang, Q.; Huizenga, J.M.; Li, G.; Gu, Y. LA-ICP-MS trace element analysis of magnetite and pyrite from the Hetaoping Fe-Zn-Pb skarn deposit in Baoshan block, SW China: Implications for ore-forming processes. Ore Geol. Rev. 2020, 103309. [Google Scholar] [CrossRef]

- Li, D.-F.; Chen, H.-Y.; Hollings, P.; Zhang, L.; Sun, X.-M.; Zheng, Y.; Xia, X.-P.; Xiao, B.; Wang, C.-M.; Fang, J. Trace element geochemistry of magnetite: Implications for ore genesis of the Talate skarn Pb-Zn (-Fe) deposit, Altay, NW China. Ore Geol. Rev. 2018, 100, 471–482. [Google Scholar] [CrossRef]

- Yi, L.; Gu, X.; Lu, A.; Liu, J.; Lei, H.; Wang, Z.; Cui, Y.; Zuo, H.; Shen, C. Major and trace elements of magnetite from the Qimantag metallogenic belt: Insights into evolution of ore–forming fluids. Acta Geol. Sin. (Engl. Ed.) 2015, 89, 1226–1243. [Google Scholar]

- Wang, C.; Shao, Y.; Zhang, X.; Dick, J.; Liu, Z. Trace Element Geochemistry of Magnetite: Implications for Ore Genesis of the Huanggangliang Sn-Fe Deposit, Inner Mongolia, Northeastern China. Minerals 2018, 8, 195. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, H.; Huang, X.; Meng, Y.; Tan, H.; Qi, L. Discrimination of Mineralization Types of Skarn Deposits by Magnetite Chemistry. Minerals 2022, 12, 608. https://doi.org/10.3390/min12050608

Xie H, Huang X, Meng Y, Tan H, Qi L. Discrimination of Mineralization Types of Skarn Deposits by Magnetite Chemistry. Minerals. 2022; 12(5):608. https://doi.org/10.3390/min12050608

Chicago/Turabian StyleXie, Huan, Xiaowen Huang, Yumiao Meng, Houmingrui Tan, and Liang Qi. 2022. "Discrimination of Mineralization Types of Skarn Deposits by Magnetite Chemistry" Minerals 12, no. 5: 608. https://doi.org/10.3390/min12050608

APA StyleXie, H., Huang, X., Meng, Y., Tan, H., & Qi, L. (2022). Discrimination of Mineralization Types of Skarn Deposits by Magnetite Chemistry. Minerals, 12(5), 608. https://doi.org/10.3390/min12050608