Temperature Variation Characteristics and Model Optimization of Flocculation Sedimentation of Overflow Ultra-Fine Iron Tailings

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.1.1. Test Sample

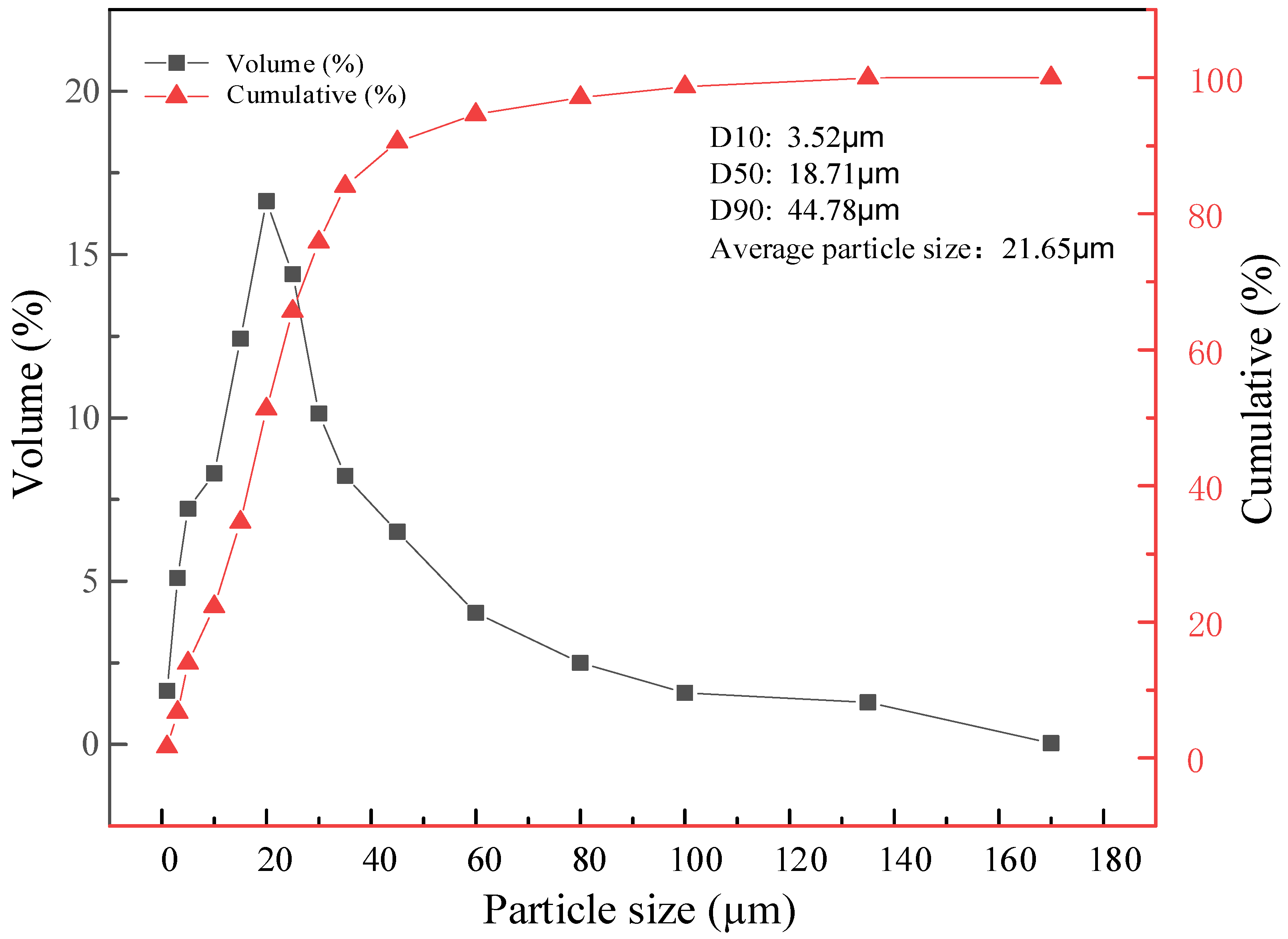

2.1.2. Particle Size Composition

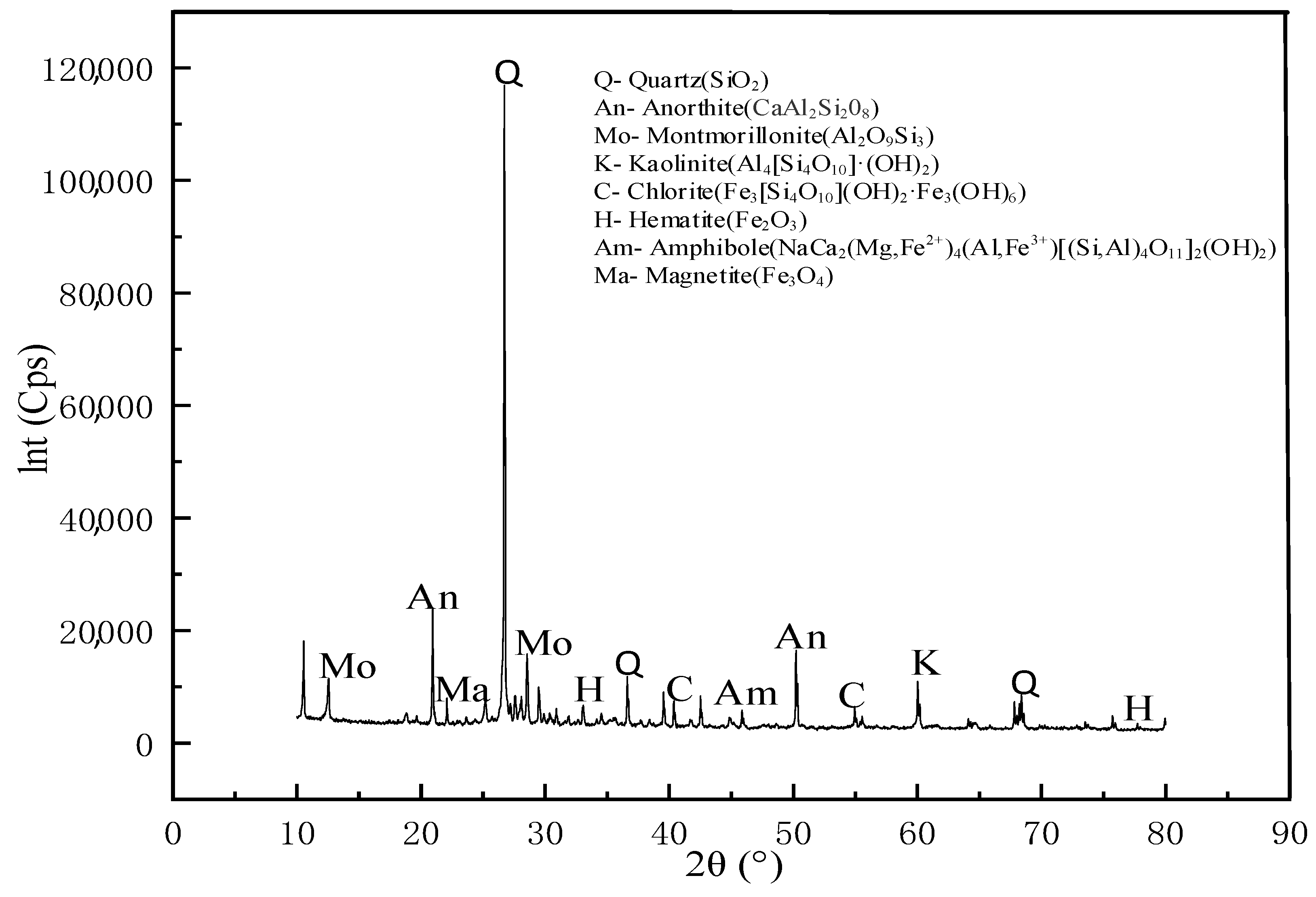

2.1.3. Mineral Composition

2.2. Flocculant

2.3. Test Method

2.4. Floc Structure Test

2.4.1. Floc Particle Size and Fractal Dimension Test

2.4.2. Density Test

2.4.3. SEM Test

2.5. Settlement Model

3. Results and Discussion

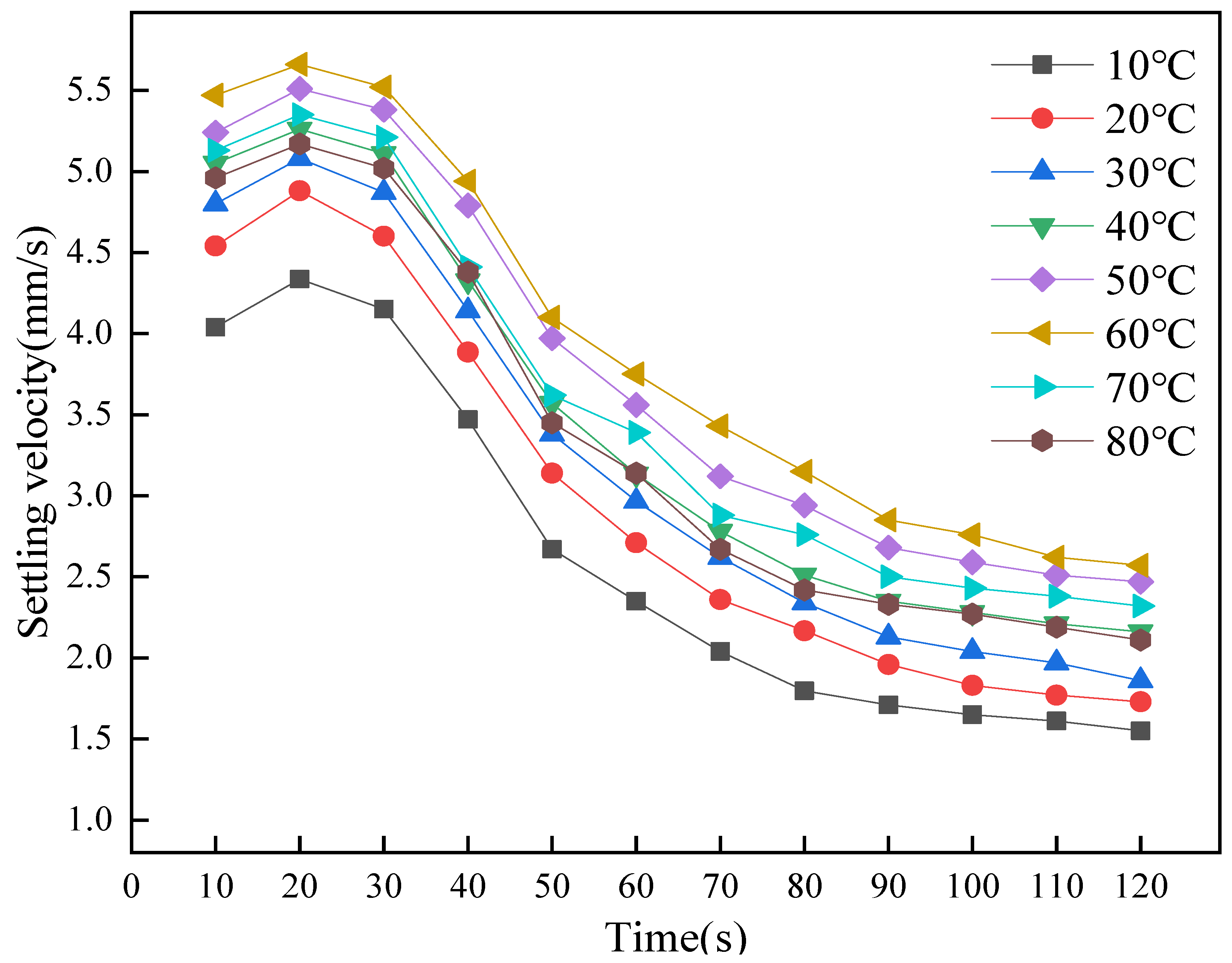

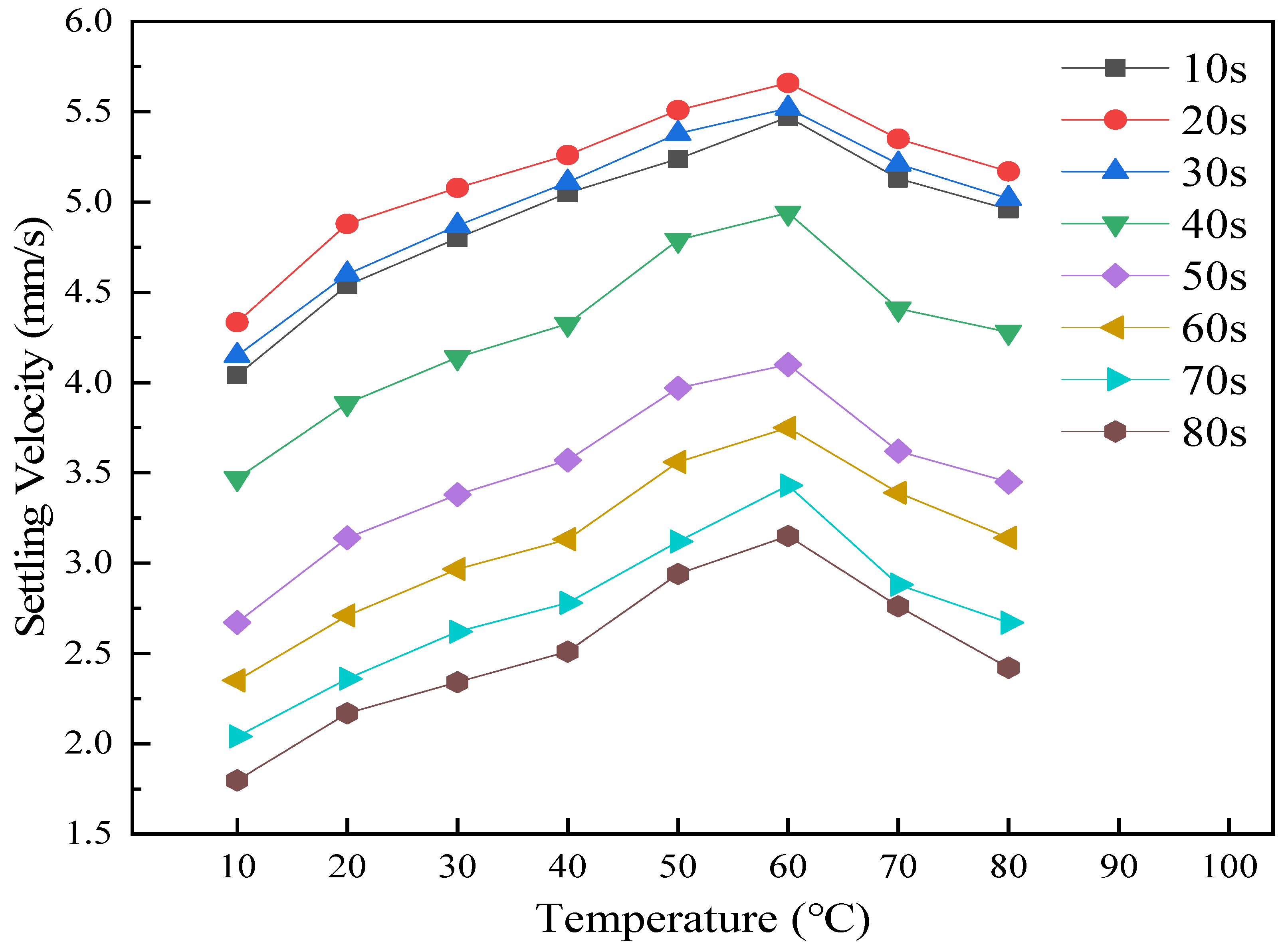

3.1. Flocculation Settlement Results

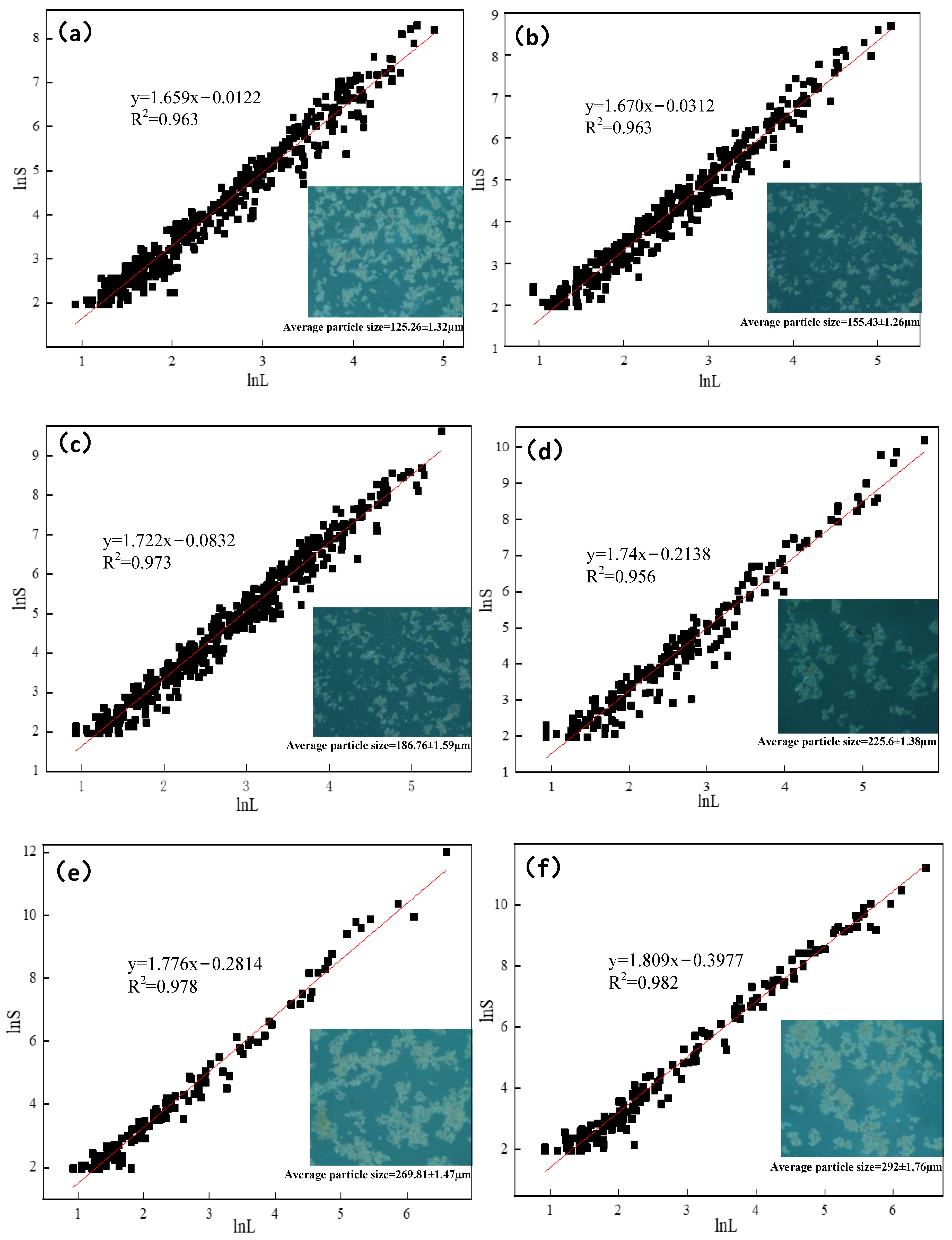

3.2. Floc Particle Size and Fractal Dimension Results

3.3. Density Results

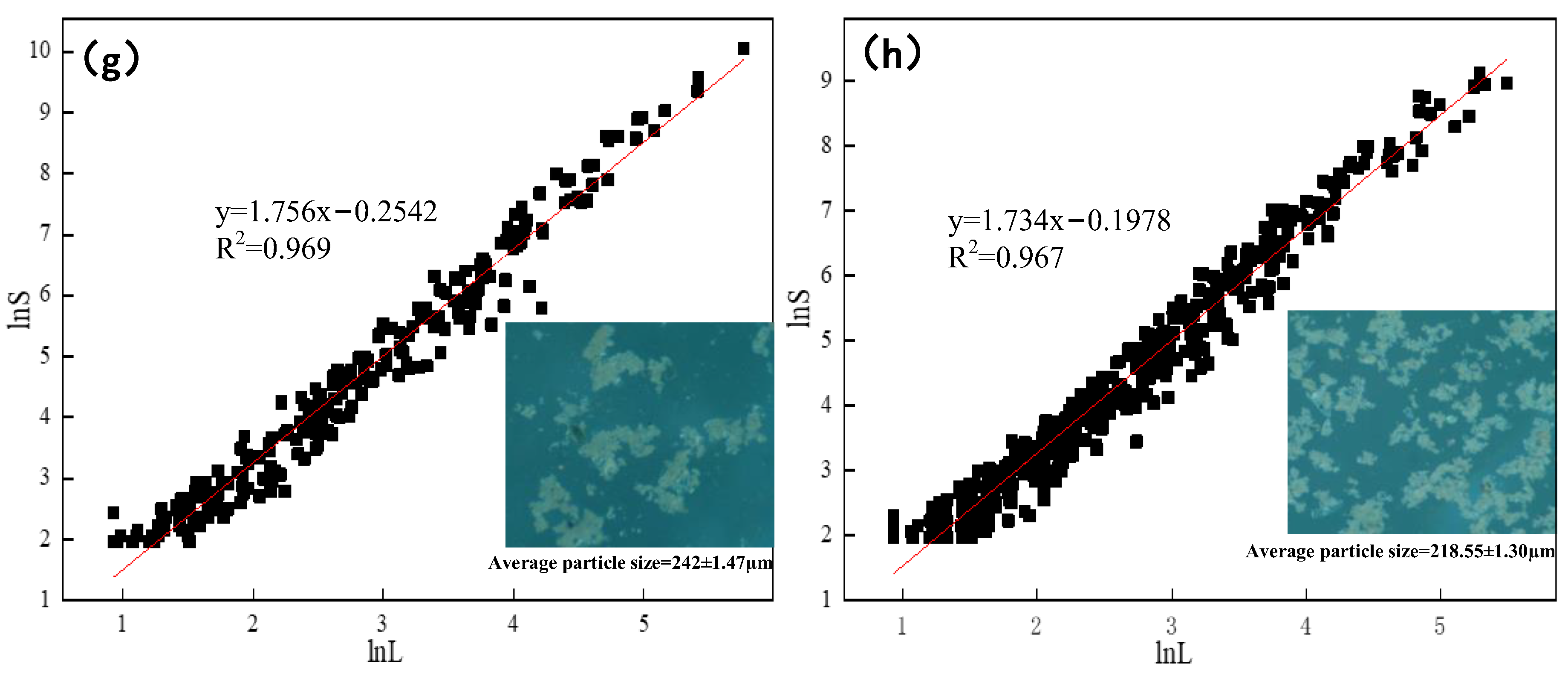

3.4. SEM Results

4. Temperature Model of Flocculation and Sedimentation of Tailings Particles

4.1. Optimization of Mineral Particle Temperature Model

4.2. Experimental Verification of Flocculation Settlement Model of Ultra-Fine Minerals

4.3. Mechanism Analysis

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Wang, D.; Zhang, Q.; Chen, Q.; Qi, C.; Feng, Y.; Xiao, C. Temperature variation characteristics in flocculation settlement of tailings and its mechanism. Int. J. Miner. Metall. Mater. 2020, 27, 1438–1448. [Google Scholar] [CrossRef]

- Yin, S.; Shao, Y.; Wu, A.; Wang, H.; Liu, X.; Wang, Y. A systematic review of paste technology in metal mines for cleaner production in China. J. Clean. Prod. 2020, 247, 119590. [Google Scholar] [CrossRef]

- Ma, N.Y.; Houser, J.B. Recycling of steelmaking slag fines by weak magnetic separation coupled with selective particle size screening. J. Clean. Prod. 2014, 82, 221–231. [Google Scholar] [CrossRef]

- Yin, S.; Liu, J.; Shao, Y.; Zhang, H.; Armelle, B.; Kou, Y. Influence rule of early compressive strength and solidification mechanism of full tailings paste with coarse aggregate. J. Cent. South Univ. (Sci. Technol.) 2020, 51, 478–488. [Google Scholar]

- Sriramoju, S.K.; Kumar, D.; Majumdar, S.; Dash, P.S.; Shee, D.; Banerjee, R. Sustainability of coal mines: Separation of clean coal from the fine-coal rejects by ultra-fine grinding and density-gradient-centrifugation. Powder Technol. 2021, 383, 356–370. [Google Scholar] [CrossRef]

- Dayarathne, H.N.P.; Angove, M.J.; Jeong, S.; Aryal, R.; Paudel, S.R.; Mainali, B. Effect of temperature on turbidity removal by coagulation: Sludge recirculation for rapid settling. J. Water Process Eng. 2022, 46, 102559. [Google Scholar] [CrossRef]

- Dos Santos, S.L.; Chaves, S.R.M.; van Haandel, A. Influence of temperature on the performance of anaerobic treatment systems of municipal wastewater. Water SA 2018, 44, 211–222. [Google Scholar] [CrossRef] [Green Version]

- Fekry, M.; Mazrouaa, A.M.; Mohamed, M.G. Highly water-repellent magnetite/polyacrylate esters nano-composites powder for highly removing waste oil. Pet. Sci. Technol. 2019, 37, 727–738. [Google Scholar] [CrossRef]

- Liu, Q.S.; Banerjee, S.K.; Jackson, M.J.; Chen, F.H.; Pan, Y.X.; Zhu, R.X. An integrated study of the grain-size-dependent magnetic mineralogy of the Chinese loess/paleosol and its environmental significance. J. Geophys. Res.-Solid Earth 2003, 108, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Bian, J.; Wang, X.; Xiao, C. Experimental study on dynamic flocculating sedimentation of unclassified tailings. J. Cent. South Univ. (Sci. Technol.) 2017, 48, 3278–3283. [Google Scholar]

- Peng, X.; Yang, X.; Guo, L. Experimental study on the hindered settling process of backfill tailings. J. China Coal Sci. 2019, 44, 1521–1526. [Google Scholar]

- Jiao, H.; Wang, H.; Wu, A.; Ji, X.; Yan, Q.; Li, X. Rule and mechanism of flocculation sedimentation of unclassified tailings. J. Univ. Sci. Technol. Beijing 2010, 32, 702–707. [Google Scholar]

- Cao, J.S.; Deng, Z.Y.; Li, W.; Hu, Y.D. Remote sensing inversion and spatial variation of land surface temperature over mining areas of Jixi, Heilongjiang, China. PeerJ 2020, 8, e10257. [Google Scholar] [CrossRef] [PubMed]

- Song, Z.X.; Song, G.F.; Tang, W.Z.; Zhao, Y.; Yan, D.D.; Zhang, W.L. Spatial and temporal distribution of Mo in the overlying water of a reservoir downstream from mining area. J. Environ. Sci. 2021, 102, 256–262. [Google Scholar] [CrossRef] [PubMed]

- Kompanizare, M.; Petrone, R.M.; Shafii, M.; Robinson, D.T.; Rooney, R.C. Effect of climate change and mining on hydrological connectivity of surficial layers in the Athabasca Oil Sands Region. Hydrol. Process 2018, 32, 3698–3716. [Google Scholar] [CrossRef] [Green Version]

- Zheng, Y.N.; Li, Q.Z.; Zhang, G.Y.; Zhao, Y.; Zhu, P.F.; Ma, X.; Li, X.W. Study on the coupling evolution of air and temperature field in coal mine goafs based on the similarity simulation experiments. Fuel 2020, 283, 118905. [Google Scholar] [CrossRef]

- Wang, Y.; Wu, A.; Ruan, Z.; Wang, H.; Wang, Y.; Jin, F.; Deive, F. Temperature Effects on Rheological Properties of Fresh Thickened Copper Tailings that Contain Cement. J. Chem. 2018, 2018, 5082636. [Google Scholar] [CrossRef] [Green Version]

- Cao, Y. Experimental study on flocculation settlement of high muddied coal slurry in Pansan coal preparation plant. Coal Prep. Technol. 2014, 5, 19–21+16. [Google Scholar]

- Wang, M. Study on the composite system with flocculants for treating refinery wastewater. Ind. Water Treat. 2011, 31, 53–56. [Google Scholar]

- Tadokoro, M.; Ohhata, Y.; Shimazaki, Y.; Ishimaru, S.; Yamada, T.; Nagao, Y.; Sugaya, T.; Isoda, K.; Suzuki, Y.; Kitagawa, H.; et al. Anomalous Enhancement of Proton Conductivity for Water Molecular Clusters Stabilized in Interstitial Spaces of Porous Molecular Crystals. Chem.-Eur. J. 2014, 20, 13698–13709. [Google Scholar] [CrossRef]

- Zhen, F.; Zhang, J.; Fu, J. Experimental study on the effects of temperature on the flocculation and setting of kaolin in the settling column. Chin. J. Hydrodyn. 2018, 33, 801–806. [Google Scholar]

- Lau, Y. Temperature effect on settling velocity and deposition of cohesive sediments. J. Hydraul. Res. 1994, 32, 41–51. [Google Scholar] [CrossRef]

- Chen, X. Experimental Study on Deposition in Static Water of Fine Sediment of Yangtze River Estuary. Master’s Thesis, Ocean University of China, Qingdao, China, 2013. [Google Scholar]

- Wan, Y.; Wu, H.; Shen, Q.; Gu, F. Experimental study on the settling velocity of suspended sediment in the Yangtze River Estuary. Mar. Sci. 2015, 39, 78–85. [Google Scholar]

- Guo, X.; Dong, W.; Lv, C. Research and practice on flocculating sedimentation of acidic copper-containing ore pulp. Gold 2021, 42, 83–86. [Google Scholar]

- Winkler, M.K.H.; Bassin, J.P.; Kleerebezem, R.; Lans, R.G.J.M.; Loosdrecht, M.C.M. Temperature and salt effects on settling velocity in granular sludge technology. Water Res. 2012, 46, 5445–5451. [Google Scholar] [CrossRef]

- Hayet, C.; Hédi, S.; Sami, A.; Ghada, J.; Mariem, M. Temperature effect on settling velocity of activated sludge. In Proceedings of the 2010 2nd International Conference on Chemical, Biological and Environmental Engineering, Cairo, Egypt, 2–4 November 2010; pp. 290–292. [Google Scholar]

- Yu, Z.; Wang, L.; Mao, J.; Dai, H. Effects of Water Temperature on Chlorophyll-a Concentration Stratification in the Tributary Bay of Three Gorges Reservoir. J. Aerosp. Eng. 2012, 26, 667–675. [Google Scholar] [CrossRef]

- Qiao, G.; Zhang, J.; Zhang, Q. Study on the influence of temperature to cohesive sediment flocculation. J. Sediment Res. 2017, 42, 35–40. [Google Scholar]

- Naghipour, N.; Ayyoubzadeh, S.; Sedighkia, M. Investigation on the effect of different factors on clay particle sedimentation in freshwaters. J. Biodivers. Environ. Sci. 2014, 5, 75–81. [Google Scholar]

- Zhao, D.; Zhu, L.; Sun, Z.; Song, L. Experiment on Deep Concentration Flocculation and Settlement of Fine Iron Tailings. Mod. Min. 2018, 34, 144–146. [Google Scholar]

- Huang, C.; Ju, Y.; Zhu, H.; Qi, Y.; Yu, K.; Sun, Y.; Ju, L. Nano-Scale Pore Structure and Fractal Dimension of Longmaxi Shale in the Upper Yangtze Region, South China: A Case Study of the Laifeng–Xianfeng Block Using HIM and N2 Adsorption. Minerals 2019, 9, 356. [Google Scholar] [CrossRef] [Green Version]

- Sreedhara, S.S.; Tata, N.R. A Novel Method for Measurement of Porosity in Nanofiber Mat using Pycnometer in Filtration. J. Eng. Fibers Fabr. 2014, 8, 132–137. [Google Scholar] [CrossRef]

- Giang, N.; Khai, D. Some new regularity criteria for the Navier-Stokes equations in terms of one directional derivative of the velocity field. Nonlinear Anal. Real World Appl. 2021, 62, 103379. [Google Scholar] [CrossRef]

- Wu, A.; Ruan, Z.; Wang, J.; Yin, S.; Ai, C. Optimizing the flocculation behavior of ultrafine tailings by ultra-flocculation. Chin. J. Eng. 2019, 41, 981–986. [Google Scholar]

- Li, S.F. Study on Particle-Bubble Collision and Attachment Characteristics under Different Flow Patterns in Froth Flotation. Master’s Thesis, Shandong University of Science and Technology, Qingdao, China, 2021. [Google Scholar]

- Yuan, Z.; Zhu, P.; Geng, F.; Peng, Z. Gas-Solid Two-Phase Flow and Numerical Simulation. Master’s Thesis, Nanjing Southeast University, Nanjing, China, 2013. [Google Scholar]

- Xu, C.; Luo, W.; Chen, Y.; Wang, P. Review on calculation methods of hindered setting velocity for fine sediment. J. Sediment Res. 2022, 47, 73–80. [Google Scholar]

- Guo, G.; Deng, S.; Zhang, F.; Wang, D. Force Balance Analysis of the Particles in three-phase-liquid-liquid hydrocyclone. Guangdong Chem. Ind. 2010, 37, 35–36. [Google Scholar]

- Moshfegh, A.; Farhadi, M.; Shams, M. Numerical Simulation of Particle Dispersion and Deposition in Channe Flow Over Two Square Cylinders in Tandem. J. Dispers. Sci. Technol. 2010, 31, 852–859. [Google Scholar] [CrossRef]

- Pourciau, B. Newton’s interpretation of Newton’s second law. Arch. Hist. Exact Arch. 2006, 60, 157–207. [Google Scholar] [CrossRef]

- Ekiel-Jezewska, M.L.; Wajnryb, E. Accuracy of the multipole expansion applied to a sphere in a creeping flow parallel to a wall. Q. J. Mech. Appl. Math. 2006, 59, 563–585. [Google Scholar] [CrossRef] [Green Version]

- Jiang, X. Fractal Characteristics of Granular Sludge during Start-Up of Baffled Anaerobic Reactor (ABR). Master’s Thesis, Beijing Forestry University, Beijing, China, 2008. [Google Scholar]

- Nikushchenko, D.; Pavlovsky, V.; Nikushchenko, E. Fluid Flow Development in a Pipe as a Demonstration of a Sequential Change in Its Rheological Properties. Appl. Sci. 2022, 12, 3058. [Google Scholar] [CrossRef]

- Wang, M.; Geng, H.R.; Li, Z.Y.; Deng, Y.B. Viscosity, resistivity, and structural of melt of Bi60Ga40 alloy melt with liquid-liquid phase separation. Rev. Adv. Mater. Sci. 2013, 33, 311–315. [Google Scholar]

- Oyegbile, B.; Ay, P.; Narra, S. Flocculation kinetics and hydrodynamic interactions in natural and engineered flow systems: A review. Environ. Eng. Res. 2016, 21, 1–14. [Google Scholar] [CrossRef] [Green Version]

- Morris, J.K.; Knocke, W.R. Temperature Effects on the Use of Metal-Ion Coagulants for Water Treatment. J. Am. Water Works Assoc. 1984, 76, 74–79. [Google Scholar] [CrossRef]

- Nadella, M.; Sharma, R.; Chellam, S. TI Fit-for-purpose treatment of produced water with iron and polymeric coagulant for reuse in hydraulic fracturing: Temperature effects on aggregation and high-rate sedimentation. Water Res. 2020, 170, 115330. [Google Scholar] [CrossRef] [PubMed]

- Ruan, Z.; Wu, A.; Bürger, R.; Betancourt, F.; Ordoñez, R.; Wang, J.; Wang, S.; Wang, Y. A Population Balance Model for Shear-Induced Polymer-Bridging Flocculation of Total Tailings. Minerals 2022, 12, 40. [Google Scholar] [CrossRef]

- Cho, J.H.; Kleinman, L. TI Adsorption structure of acetylene on Ge (001): A first-principles study. J. Chem. Phys. 2003, 119, 2820–2824. [Google Scholar] [CrossRef]

- Ghernaout, D.; Al-Ghonamy, A.; Boucherit, A.; Ghernaout, B.; Naceur, M.; Messaoudene, N.; Aichouni, M.; Mahjoubi, A.; Elboughdiri, N. Brownian motion and coagulation process. Am. J. Environ. Prot. 2015, 4, 1–15. [Google Scholar] [CrossRef]

- Zheng, L. A quantitative discussion of Brownian motion. J. Yuxi Norm. Univ. 1999, 3, 26–29. [Google Scholar]

- Liu, T. Investigation on Directed Transport Characteristics of Temperature Feedback Ratchets. Master’s Thesis, Shenyang Normal University, Shenyang, China, 2021. [Google Scholar]

- Wu, Y. Synthesis and Flocculation Behavior of Temperature-Sensitive Polymer Flocculant. Master Thesis, Jiangxi University of Science and Technology, Ganzhou, China, 2016. [Google Scholar]

- Li, D. Study on Fractal Characteristics of the Yellow River Sediment Bridging Flocs. Master Thesis, Xi’an University of Architecture and Technology, Xi’an, China, 2005. [Google Scholar]

| SiO2 | Fe2O3 | CaO | Al2O3 | MgO | K2O | Na2O |

|---|---|---|---|---|---|---|

| 63.320 | 12.150 | 8.326 | 7.353 | 3.881 | 1.925 | 0.975 |

| TiO2 | P2O5 | SO3 | MnO | Cl | Cr2O3 | ZnO |

| 0.744 | 0.727 | 0.389 | 0.140 | 0.027 | 0.025 | 0.017 |

| Temperature (°C) | 10 | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

|---|---|---|---|---|---|---|---|---|

| Density (g/cm3) | 2.422 | 2.468 | 2.491 | 2.543 | 3.057 | 3.186 | 2.854 | 2.507 |

| Statistical Indicators | Theoretical Model Velocity | Modified Model Velocity |

|---|---|---|

| Mean absolute error | 0.872 | 0.007 |

| Root mean square error | 0.794 | 0.002 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Niu, F.; Zhang, H.; Zhang, J.; Yu, X. Temperature Variation Characteristics and Model Optimization of Flocculation Sedimentation of Overflow Ultra-Fine Iron Tailings. Minerals 2022, 12, 643. https://doi.org/10.3390/min12050643

Niu F, Zhang H, Zhang J, Yu X. Temperature Variation Characteristics and Model Optimization of Flocculation Sedimentation of Overflow Ultra-Fine Iron Tailings. Minerals. 2022; 12(5):643. https://doi.org/10.3390/min12050643

Chicago/Turabian StyleNiu, Fusheng, Hongmei Zhang, Jinxia Zhang, and Xiaodong Yu. 2022. "Temperature Variation Characteristics and Model Optimization of Flocculation Sedimentation of Overflow Ultra-Fine Iron Tailings" Minerals 12, no. 5: 643. https://doi.org/10.3390/min12050643

APA StyleNiu, F., Zhang, H., Zhang, J., & Yu, X. (2022). Temperature Variation Characteristics and Model Optimization of Flocculation Sedimentation of Overflow Ultra-Fine Iron Tailings. Minerals, 12(5), 643. https://doi.org/10.3390/min12050643