Integrated Collaborative Control of “Shielding-Filling-Grouting” of 1 km Deep Large-Section Roadways: A Case Study

Abstract

:1. Introduction

2. In-Situ Stress Measurement of West-Wing Main Track Roadway and Difficulty in the Surrounding Rock Control in Roadways

2.1. Engineering Background of the Main Roadway in the West-Wing Track

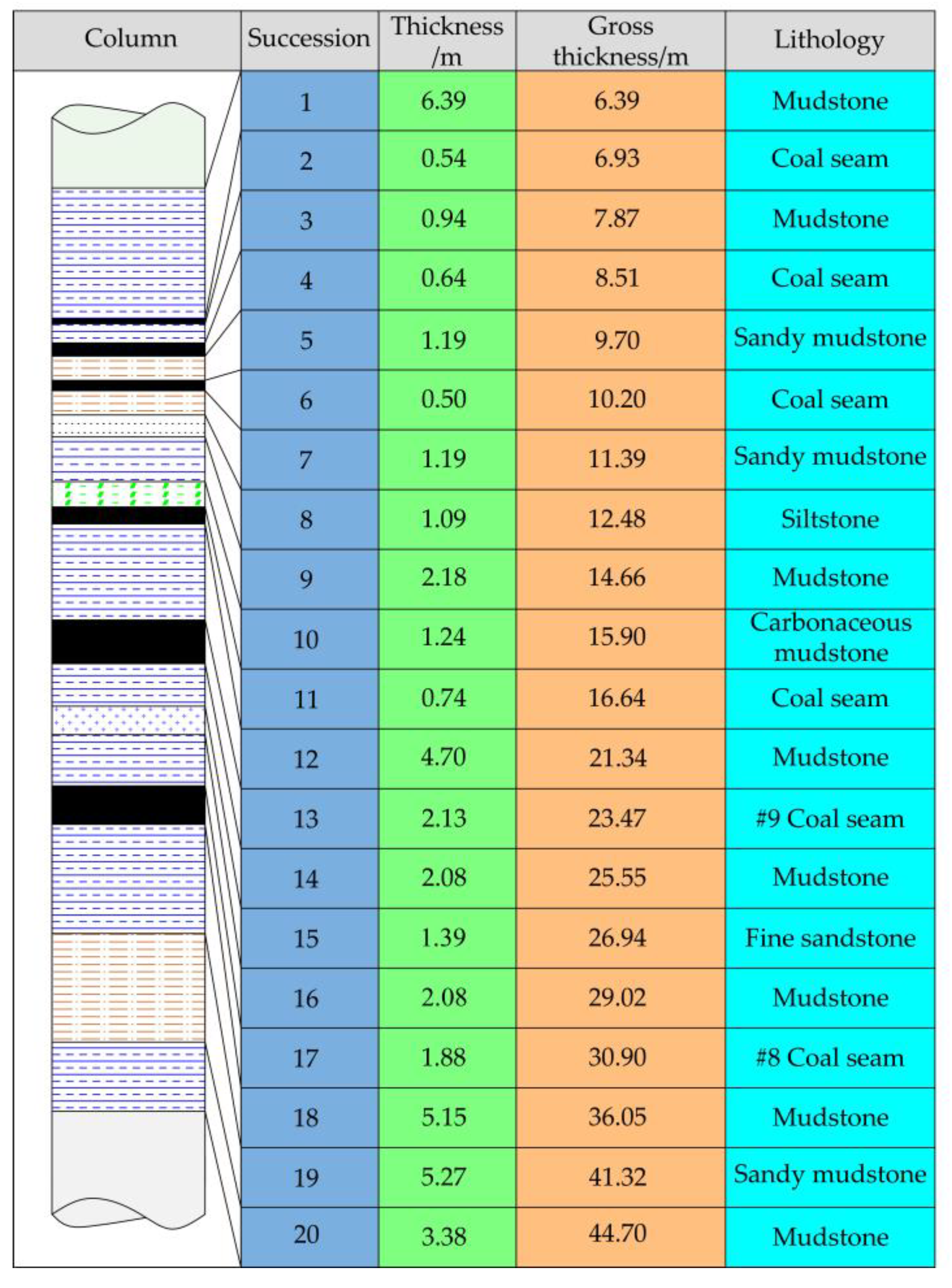

2.1.1. Stratigraphic Characteristics of the Study Area

2.1.2. Original Support Scheme of the Main Roadway

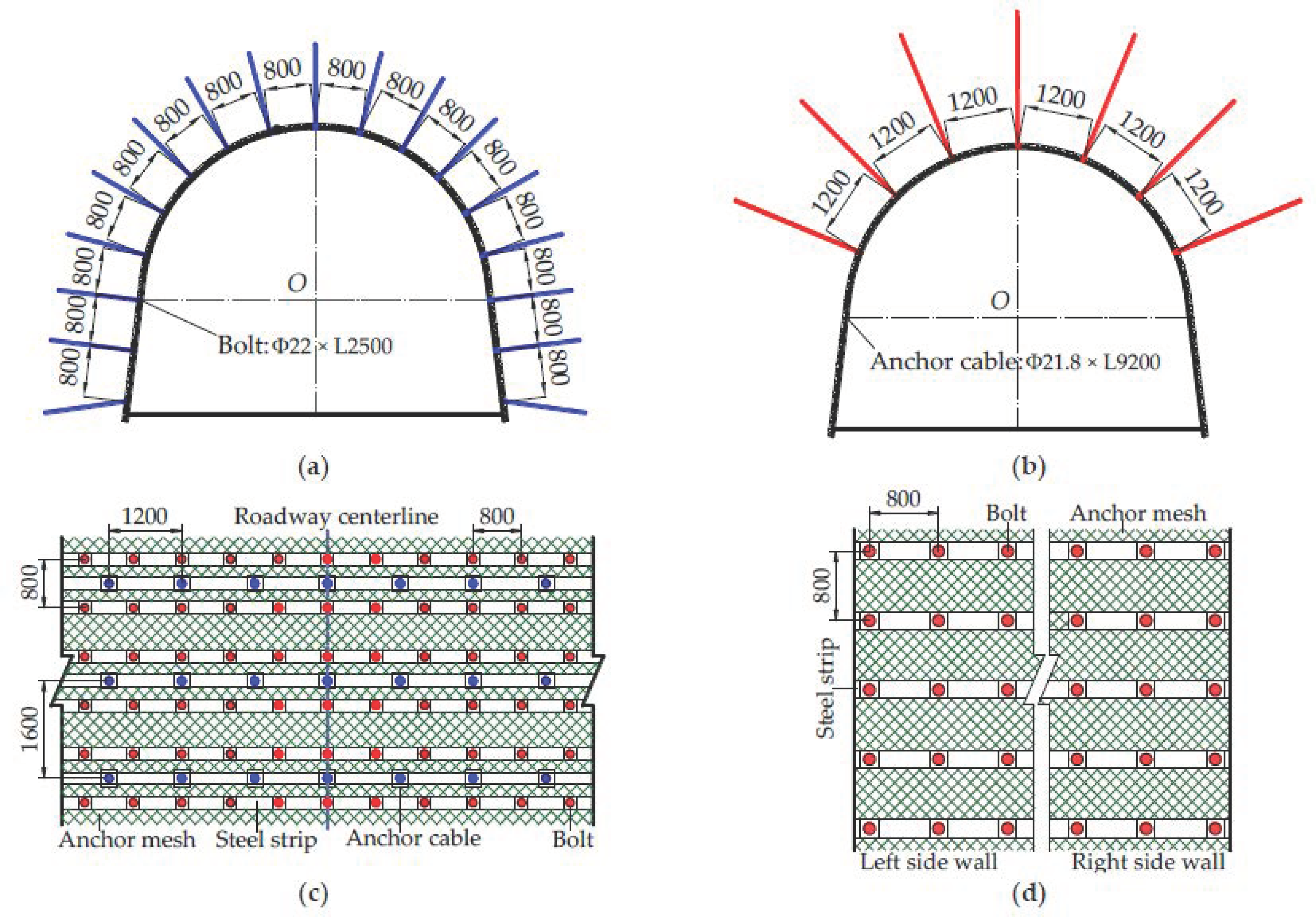

- (1)

- Roof support: Eleven bolts and seven anchor cables are symmetrically arranged in each row of the main roadway roof; the row spacing between bolts is 800 × 800 mm, the size is Φ22 × L2500 mm, the material is high-strength rebar; the row spacing between anchor cables is 1200 × 1600 mm, the size is Φ21.8 × L9200 mm, the material is steel strand; the steel strip is H-shaped steel strip welded with Φ12 mm round steel; the anchor mesh is made by reinforcement mesh, with specification Φ6 × 1000 × 2000 mm; the strength grade of shotcrete is C20, and the initial shotcrete thickness is 30~50 mm.

- (2)

- Wall support: The two walls of the main roadway are symmetrically arranged with six bolts in each row, while other support parameters are the same as the roof support.

- (3)

- Floor support: No reinforcement measures are taken for the floor of the main roadway.

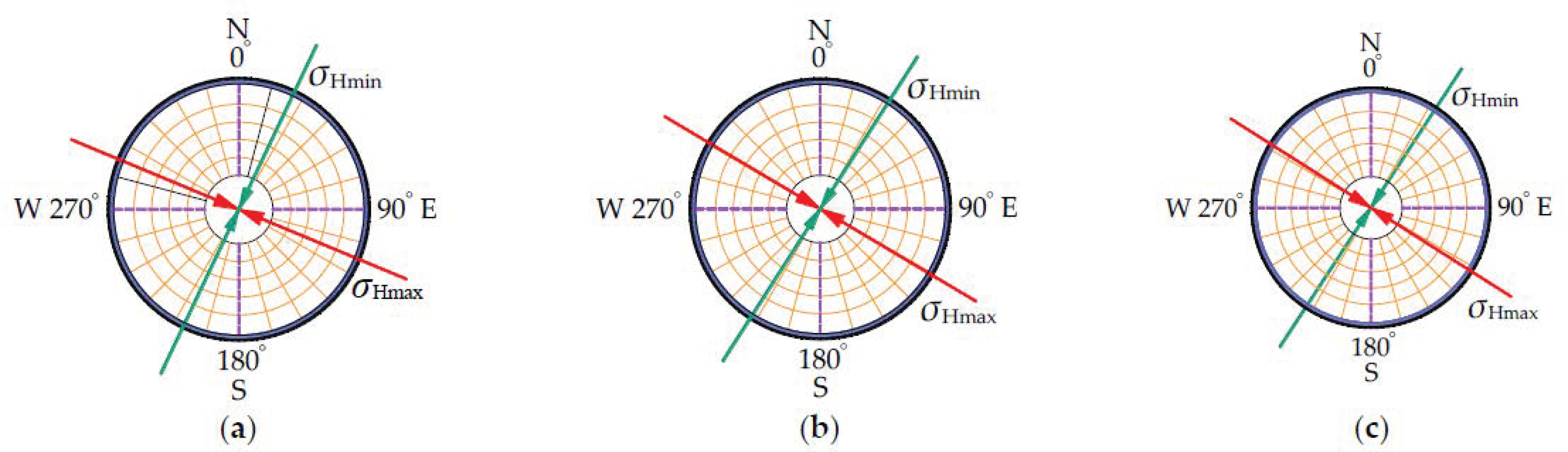

2.2. In-Situ Stress Field Measurement and Difficulties in the Roadway Surrounding Rock Control

- (1)

- Maximum and minimum depths of the three stations for monitoring of in-situ stress were 960.50 and 958.30 m, respectively, belonging to a typical 1 km deep environment. This implied that the coal rock was in high stress state. The maximum principal stresses of all three stations exceeded 30 MPa (up to 36.10 MPa) and their dip angles of maximum principal stress were below 10°. Additionally, dip angles of medium and minimum principal stresses varied widely, suggesting that the primary rock stress field of the study area was mainly structural stress in the approximately horizontal direction.

- (2)

- After the coordinate system transformation, the maximum horizontal principal stresses in all three stations exceeded 30 MPa (30.15~37.27 MPa), with the azimuth angles ranging between N 112.54° E~N 122.29° E; the minimum horizontal principal stresses ranged from 14.04 to 21.05 MPa, with the azimuth angles between N 25.43° E~N 33.28° E; the vertical principal stresses ranged from 21.40 to 27.60 MPa.

- (3)

- The maximum horizontal principal stresses of all three stations were larger than their corresponding vertical principal stresses. The respective ratio k1 ranged from 1.09 to 1.53, demonstrating that the paleotectonic interaction in the study area was relatively strong; the measured maximum-to-minimum horizontal principal stress ratio k2 ranged from 1.43 to 2.28, demonstrating that the in-situ stress in this area had obvious orientation.

3. Analysis of the West-Wing Main Track Roadway Surrounding Rock Deformation Failure Pattern and Mechanism

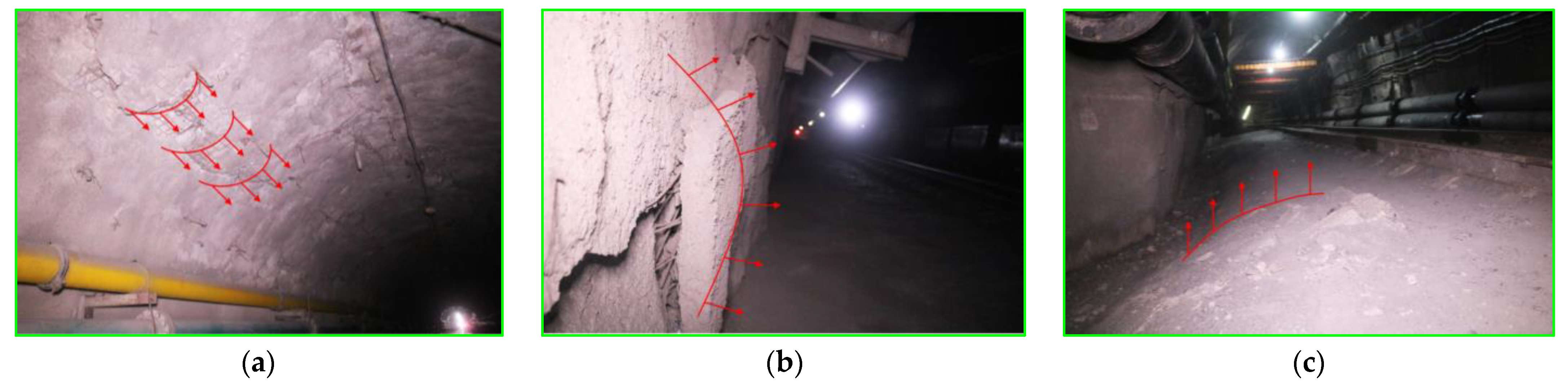

3.1. Main Roadway Surrounding Rock Full-Section Deformation Failure Pattern

- (1)

- The roadway roof surrounding rock was cracked and separated, and the damage zone extended continuously along the central axis of the main roadway, accompanied by signs of bending and sinking. The shallow bolt (anchor cable) of roof had obvious bending dislocation. Therefore, deformation of shallow surrounding rock was greater than that of deep surrounding rock.

- (2)

- The two walls of the roadway were damaged, and the surrounding rock was obviously broken unevenly and bulged into the roadway, especially in the corner. Deformation with dominating shear expansion failures also occurred in the side profile; the shotcrete layer of the inclined wall section in some areas peeled off obviously. The metal mesh was exposed, with bending and breaking tendency, while the bolt (anchor cable) at the side profile was also deformed.

- (3)

- The roadway floor deformation lasted for a long time and had poor structural integrity. The breakthrough gap for strain energy could be easily filled, increasing the loose range of the floor-surrounding rock, with a serious floor heave in some sections.

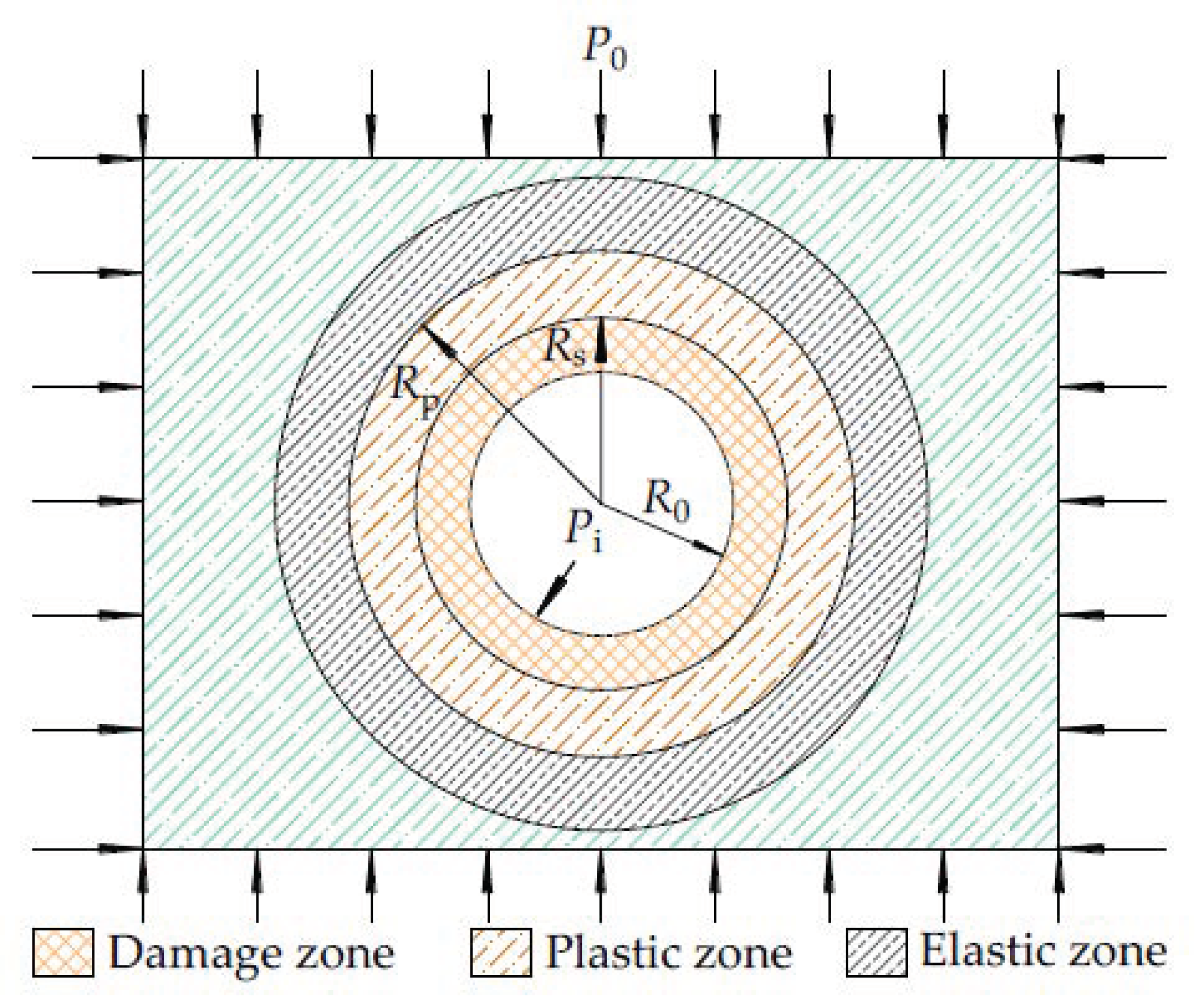

3.2. Mechanism of Nonlinear Deformation Failure of Surrounding Rock in Main Roadway

4. The “Shielding-Filling-Grouting” Integrated Collaborative Control Technology System for the West-Wing Main Track Roadway

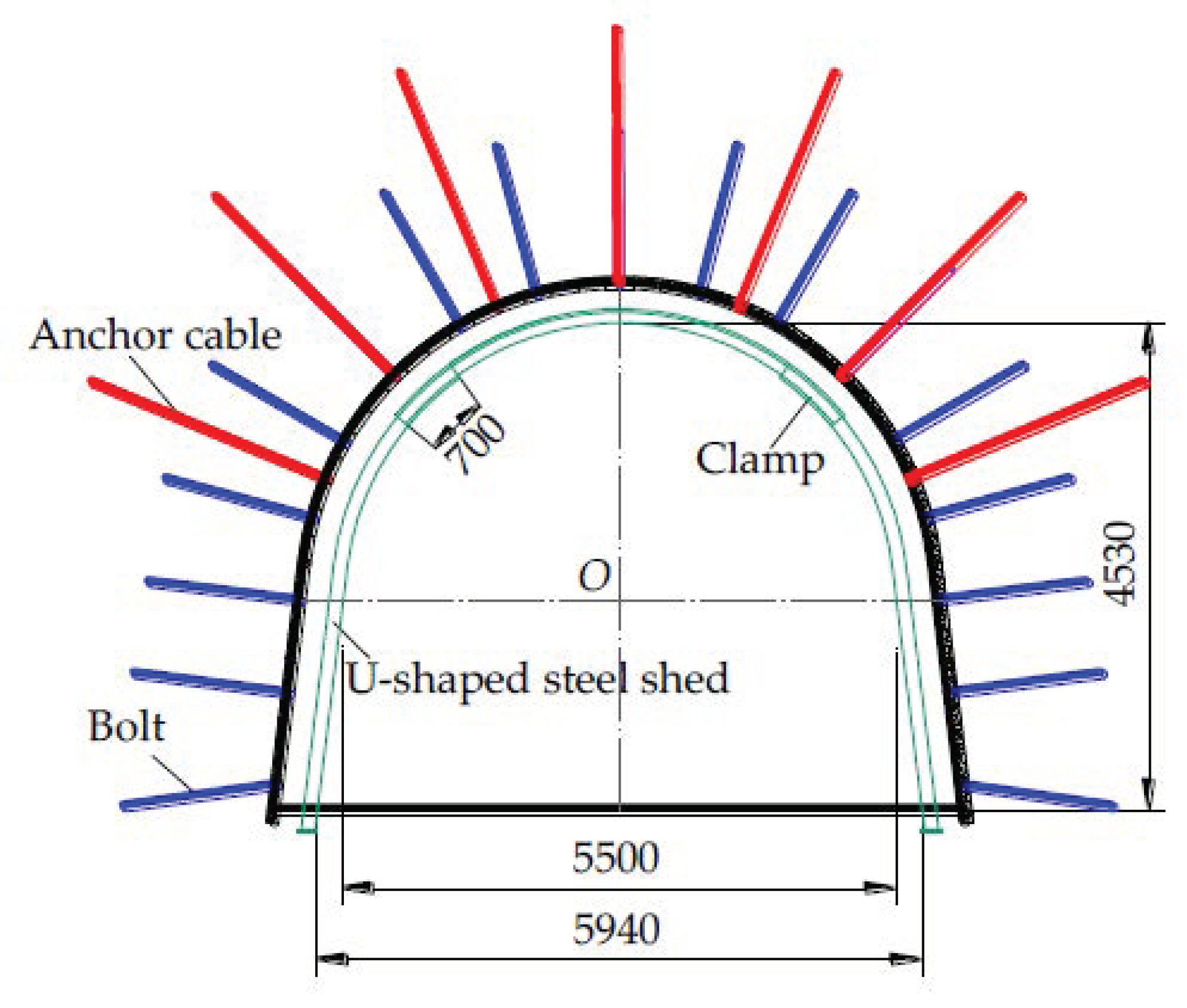

4.1. U-Shaped Steel Secondary Shed Passive Support Technology

4.2. Backwall Rapid-Setting Material Filling and Control Technology

- (1)

- First, lay the reinforcement mesh behind the U-shaped steel shed, and then lay the plastic cloth from the shed top to both sides;

- (2)

- At the starting and end positions of filling, stack woven bags filled with sand to form isolation belts, and arrange a filling window on the top of the U-shaped steel shed and two shoulder sockets, respectively;

- (3)

- The equipment is used to mix the mixture with water to form concrete; then, it is transferred to the filling place for backwall filling by concrete pump;

- (4)

- The head of the filling pipe is fixed by ladder. First, fill the side profile of the main roadway (the two walls are filled alternately), and then fill the top of the main roadway;

- (5)

- When the material reaches the filling window position, the filling is completed and stopped. Use woven bags or plastic cloth to block the shoulder socket window tightly, and then use 10# iron wire to fix it, and then fill the top window;

- (6)

- The hose is adopted for concrete delivery pump with sufficient compressive capacity (the pressure resistance shall be no less than 10 MPa), and its length can be subdivided into 10, 15, and 20 m long sections. The maximum delivery distance shall not exceed 150 m.

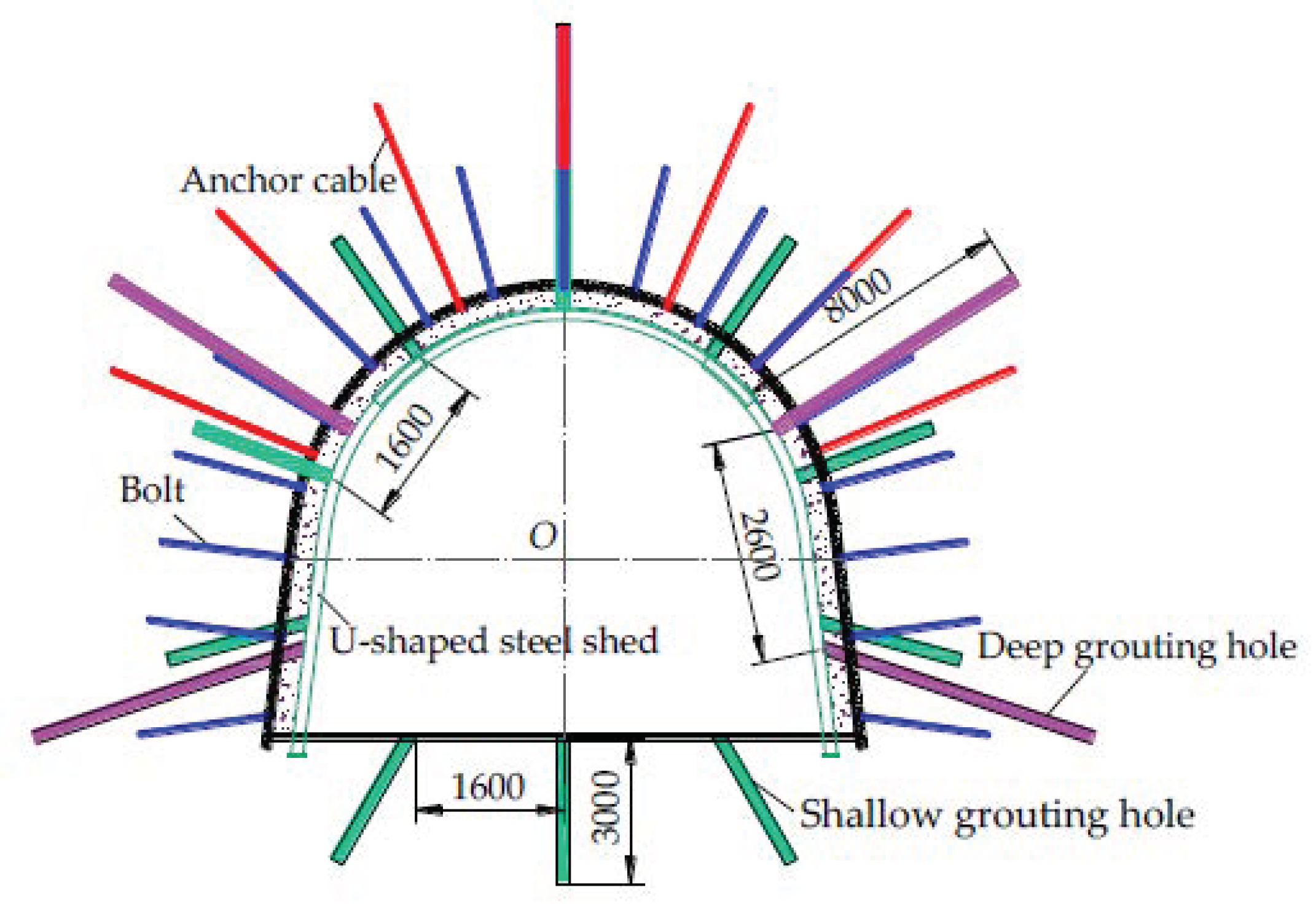

4.3. Grouting Reinforcing Technology with Combined Deep and Shallow Holes (GR-CDSH)

- (1)

- GR parameters of roof: Each row of main roadway roof was symmetrically arranged with three deep grouting holes with a depth of 8000 mm, and the row spacing was 2600 × 9600 mm, grouting pressure was 4.5 MPa; three shallow grouting holes with a depth of 3000 mm were symmetrically arranged with a row spacing of 1600 × 4800 mm, and the grouting pressure was 2.0 MPa.

- (2)

- GR parameters of the two walls: Each row of the main roadway’s two walls was symmetrically arranged with two deep grouting holes with a depth of 8000 mm, and the grouting pressure was 3.5 MPa; four shallow grouting holes with a depth of 3000 mm were arranged symmetrically. Other reinforcement parameters were the same as roof support.

- (3)

- GR parameters of floor: As an important transportation, ventilation, and pedestrian passage of the KCM, the main roadway floor of the west-wing main track roadway was required to lay tracks to ensure the safety of material transportation. Therefore, the stability of the main roadway floor should be strictly controlled to avoid large floor heave deformation. Three shallow grouting holes with a depth of 3000 mm were symmetrically arranged in the main roadway floor, and the spacing and grouting pressure of these were the same as that of the GR parameters of roof.

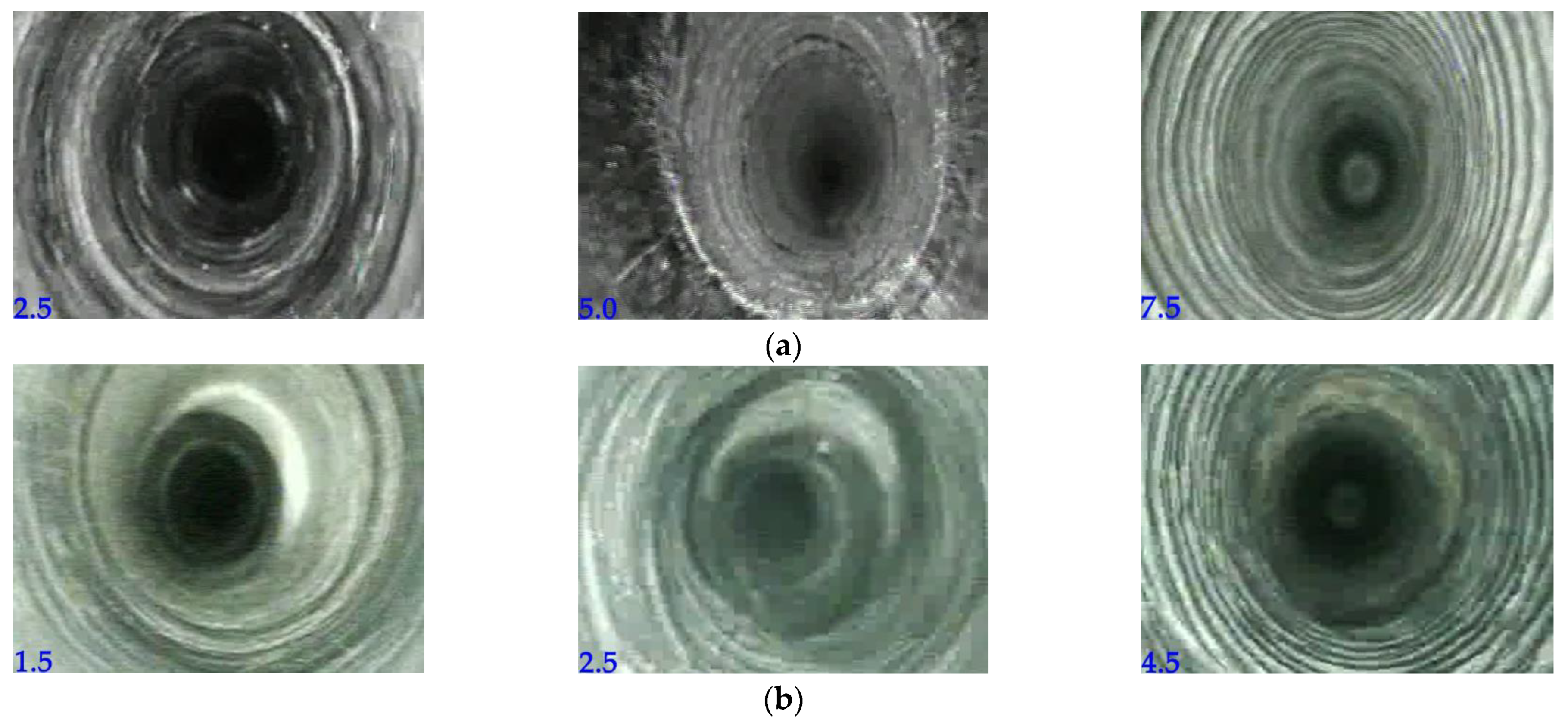

5. Effect Analysis of the Industrial Field Test

5.1. Field Observation Scheme Design

5.1.1. Borehole Peeping of Deep Failure Characteristic of the Surrounding Rock in the Main Roadway

5.1.2. Field Observation of Surface Displacement of the Surrounding Rock in the Main Roadway

5.2. Field Test

6. Conclusions

- (1)

- Field measurement of the in-situ stress in the study area revealed that the in-situ stress state was dominated by the horizontal in-situ stress, showing typical structural stress field features. When the original “bolt mesh cable shotcrete” combined support scheme was adopted for the main roadway, the roadway surrounding rock presented full-section nonlinear deformation failure features, breaching the requirements of mine safety production.

- (2)

- The analysis of elastoplastic mechanism of deformation failure of the surrounding rock in the main roadway revealed that the main roadway surrounding rock structure distribution was related to the original physical and mechanical properties of the rock mass, stress environment, and support mode. The main reasons for the above failure mode were the low strength of the main roadway surrounding rock, the complex stress environment of the horizontal structure, the insufficient support scheme strength of the original “bolt mesh cable shotcrete”, and the lack of effective control measures for the main roadway floor.

- (3)

- Aiming at the specific engineering geological conditions of the west-wing main track roadway and considering the advantages and disadvantages of the main roadway’s original support scheme, a set of targeted “shielding-filling-grouting” integrated collaborative control technology system was proposed. It mainly included the U-shaped steel secondary shed passive support technology, the quick-setting material filling and compaction control technology behind the wall, and GR-CDSH support technology.

- (4)

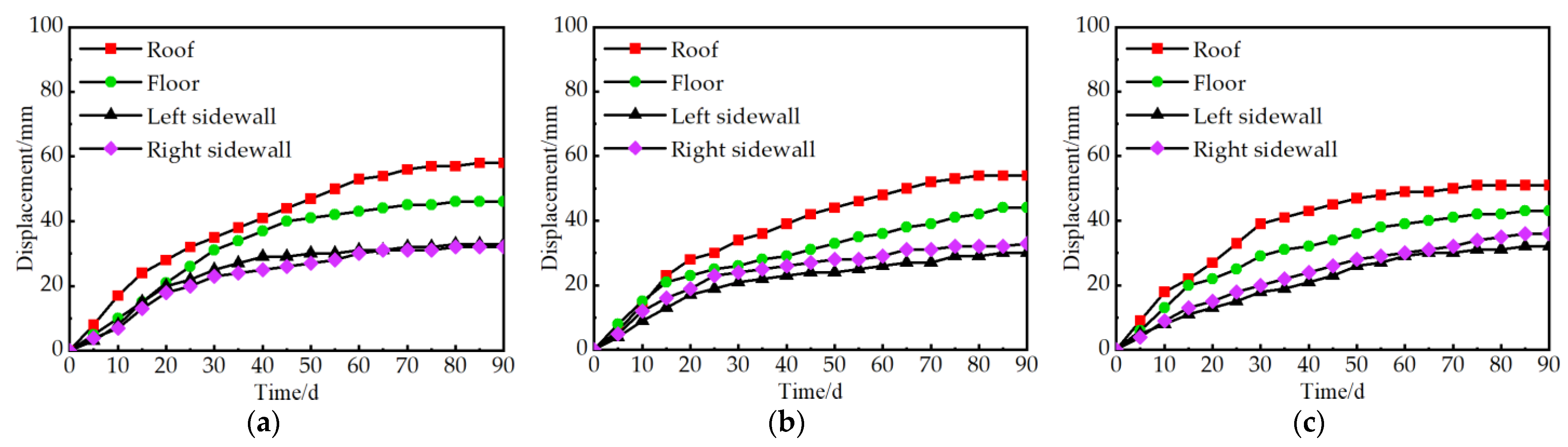

- The industrial field test revealed that when the integrated collaborative control scheme of “shielding-filling-grouting” was adopted in the main roadway, the grouting slurry could effectively fill the surrounding rock’s crack and bond with it to form a relatively complete structure, achieving a sound grouting effect. The average changes in the displacements of rock surfaces surrounding the main roadway roof, floor, and two walls were 54, 44, 32, and 34 mm, respectively. There were no severe deformation failures in the surrounding rock. The proposed scheme achieved strength improvement and structural compensation of the weak position of the main surrounding rock, provided the active and passive support collaborative control, guaranteed the long-term stability of the roadway, and ensured the safety of staff and equipment, satisfying the requirements of mine safety and efficient production.

Author Contributions

Funding

Conflicts of Interest

References

- Xie, H.; Wang, J.; Wang, G.; Ren, H.; Liu, J.; Ge, S.; Zhou, H.; Wu, G.; Ren, S. New ideas of coal revolution and layout of coal science and technology development. J. China Coal Soc. 2018, 43, 1187–1197. [Google Scholar]

- Zhang, N.; Li, X.; Zheng, X.; Xue, F. Current status and challenges of deep coal mining. In Proceedings of the National Symposium on Mining Technology of Kilometer Deep Coal Mine, Tai’an, China, 25 July 2013. [Google Scholar]

- He, M.; Xie, H.; Peng, S.; Jiang, Y. Study on rock mechanics in deep mining engineering. Chin. J. Rock Mech. Eng. 2005, 24, 2803–2813. [Google Scholar]

- He, M.; Wang, X.; Liu, W.; Yang, S. Numerical simulation on asymmetric deformation of deep soft rock roadway in Kongzhuang Coal Mine. Chin. J. Rock Mech. Eng. 2008, 27, 673–678. [Google Scholar]

- Shen, B. Coal mine roadway stability in soft rock: A case study. Rock Mech. Rock Eng. 2014, 47, 2225–2238. [Google Scholar] [CrossRef]

- Liu, W.; Guo, Z.; Wang, C.; Niu, S. Physico-mechanical and microstructure properties of cemented coal Gangue-Fly ash backfill: Effects of curing temperature. Constr. Build. Mater. 2021, 299, 124011. [Google Scholar] [CrossRef]

- Skrzypkowski, K.; Zagórski, K.; Zagórska, A.; Apel, D.B.; Wang, J.; Xu, H.; Guo, L. Choice of the arch yielding support for the preparatory roadway located near the fault. Energies 2022, 15, 3774. [Google Scholar] [CrossRef]

- Hou, C.; Wang, X.; Bai, J.; Meng, N.; Wu, W. Basic theory and technology study of stability control for surrounding rock in deep roadway. J. China Univ. Min. Technol. 2021, 50, 1–12. [Google Scholar]

- Xie, H.; Gao, M.; Zhang, R.; Peng, G.; Wang, W.; Li, A. Study on the mechanical properties and mechanical response of coal mining at 1000 m or deeper. Rock Mech. Rock Eng. 2019, 52, 1475–1490. [Google Scholar] [CrossRef]

- Kang, H. “Strata control and intelligent mining technology in deep coal mines with depth more than 1000 m” Guest editor of the album to readers. J. China Coal Soc. 2020, 45, 1211–1212. [Google Scholar]

- Ma, Q.; Tan, Y.; Liu, X.; Zhao, Z.; Fan, D. Mechanical and energy characteristics of coal-rock composite sample with different height ratios: A numerical study based on particle flow code. Environ. Earth Sci. 2021, 80, 1–14. [Google Scholar] [CrossRef]

- Jing, H.; Wu, J.; Yin, Q.; Wang, K. Deformation and failure characteristics of anchorage structure of surrounding rock in deep roadway. Int. J. Min. Sci. Technol. 2020, 30, 593–604. [Google Scholar] [CrossRef]

- Fu, Y.; Ju, W.; Wu, Y.; He, J.; Jiao, J. Study on principle application of energy absorption and bump reduction of high impact toughness rock bolt. Coal Sci. Technol. 2019, 47, 68–75. [Google Scholar]

- Yang, J.; Yang, S. Experimental study on reinforcement of deep soft roadway by using ACZ-1 modified grouting material. Saf. Coal Mines 2017, 48, 60–64. [Google Scholar]

- Yu, Y.; Qin, Z.; Wang, X.; Zhang, L.; Chen, D.; Zhu, S. Development of modified grouting material and its application in roadway repair engineering. Geofluids 2021, 2021, 1–15. [Google Scholar] [CrossRef]

- Zhang, H.; Zhou, R.; Liu, S.; Zhu, Y.; Wang, S.; Wang, J.; Guan, X. Enhanced toughness of ultra-fine sulphoaluminate cement-based hybrid grouting materials by incorporating in-situ polymerization of acrylamide. Constr. Build. Mater. 2021, 292, 123421. [Google Scholar] [CrossRef]

- Oggeri, C.; Oreste, P.; Spagnoli, G. Creep behaviour of two-component grout and interaction with segmental lining in tunnelling. Tunn. Undergr. Space Technol. 2022, 119, 104216. [Google Scholar] [CrossRef]

- Kang, H.; Jiang, P.; Huang, B.; Guan, X.; Wang, Z.; Wu, Y.; Gao, F.; Yang, J.; Cheng, L.; Zheng, Y.; et al. Roadway strata control technology by means of bolting-modification-destressing in synergy in 1000 m deep coal mines. J. China Coal Soc. 2020, 45, 845–864. [Google Scholar]

- Zhang, Z.; Kang, H.; Jiang, Z.; Li, W.; Jiang, P.; Cai, R.; Zhu, Y.; Wang, J. Study and application of high-pressure splitting grouting modification technology in coalmine with depth more than 1000 m. J. China Coal Soc. 2020, 45, 972–981. [Google Scholar]

- Huang, B.; Zhang, N.; Jing, H.; Kan, J.; Meng, B.; Li, N.; Xie, W.; Jiao, J. Large deformation theory of rheology and structural instability of the surrounding rock in deep mining roadway. J. China Coal Soc. 2020, 45, 911–926. [Google Scholar]

- Zhang, G.; Zhu, W.; Zhao, P. In-situ stress measurements and analysis of action of geological structures of deep coal mines in Xuzhou. Chin. J. Geotech. Eng. 2012, 34, 2318–2324. [Google Scholar]

- Qin, W.; Gui, S. Field study on ground stress distribution laws in Huainan Mining Area. Saf. Coal Mines 2013, 44, 185–188. [Google Scholar]

- Yang, R.; Chen, J.; Xue, H.; Cheng, C.; Wang, W. Research of influencing factors of coalmine ground stress test precision by stress relieving method. China Min. Mag. 2014, 23, 136–139. [Google Scholar]

- Wu, H.; Zhao, G.; Ma, S. Failure behavior of horseshoe-shaped tunnel in hard rock under high stress: Phenomenon and mechanisms. Trans. Nonferr. Met. Soc. China 2022, 32, 639–656. [Google Scholar] [CrossRef]

- Wang, Q. Study on the Relationship between Kou Zidong Mine Deep Crustal Stress Distribution and Roadway Layout. Master’s Thesis, Anhui University of Science and Technology, Huainan, China, 2014. [Google Scholar]

- Shen, M.; Chen, J. Rockmass Mechanics, 1st ed.; Tongji University Press: Shanghai, China, 2006; pp. 142–184. [Google Scholar]

- Podkopaiev, S.; Gogo, V.; Yefremov, I.; Kipko, O.; Iordanov, I.; Simonova, Y. Phenomena of stability of the coal seam roof with a yielding support. Min. Miner. Depos. 2019, 13, 28–41. [Google Scholar] [CrossRef]

- Zhao, G.; Zhang, X.; Wang, C.; Meng, X. Mechanical analysis and numerical simulation for deep and shallow bearing structures of soft and broken roadway surrounding rock. J. China Coal Soc. 2016, 41, 1632–1642. [Google Scholar]

- Wang, H.; Zhang, D.; Deng, D.; Jiang, Y.; Liu, Y. Stress distribution characteristics of roadway surrounding rock damaged zone under non-hydrostatic pressure. J. China Coal Soc. 2020, 45, 3717–3725. [Google Scholar]

- Yuan, W.; Chen, J. Analysis of plastic zone and damaged zone of roadway in softened rock stratum. J. China Coal Soc. 1986, 11, 77–86. [Google Scholar]

- Zuo, J.; Hong, Z.; Yu, M.; Liu, H.; Wang, Z. Study on gradient support model and classification control of borken surrounding rock. J. China Univ. Min. Technol. 2022, 51, 1–11. [Google Scholar]

- Wang, Q.; Xie, W.; Jing, S.; Zang, L.; Zhang, N. Research on U-shape steel frame and anchor cable collaborative support mechanism and loading law of roadway under dynamical pressure impact. J. China Coal Soc. 2015, 40, 301–307. [Google Scholar]

- Rotkegel, M.; Szot, Ł.; Fabich, S. The analysis of selected methods of the yielding of a circular arch support made of V profiles. Arch. Min. Sci. 2020, 65, 521–550. [Google Scholar]

- Xie, W.; Jing, S.; Wang, T.; Ren, Y.; Zhang, N. Structural stability of U-steel support and it’s control technology. Chin. J. Rock Mech. Eng. 2010, 29, 3743–3748. [Google Scholar]

- Skrzypkowski, K. Case studies of rock bolt support loads and rock mass monitoring for the room and pillar method in the legnica-głogów copper district in poland. Energies 2020, 13, 2998. [Google Scholar] [CrossRef]

| Station | Depth (m) | σ/MPa | α | σHmax/MPa | σHmin/MPa | σV/MPa | β | γ | k1 | k2 |

|---|---|---|---|---|---|---|---|---|---|---|

| G1 | 960.50 | σ1 = 30.15 | 9.01° | 30.15 | 21.05 | 27.60 | N 112.54° E | N 25.43° E | 1.09 | 1.43 |

| σ2 = 27.64 | −69.54° | |||||||||

| σ3 = 21.01 | −22.32° | |||||||||

| G2 | 958.50 | σ1 = 32.81 | 3.08° | 31.97 | 14.04 | 21.40 | N 120.71° E | N 32.57° E | 1.49 | 2.28 |

| σ2 = 20.58 | −57.31° | |||||||||

| σ3 = 14.01 | 39.01° | |||||||||

| G3 | 958.30 | σ1 = 36.10 | 1.48° | 37.27 | 20.63 | 24.30 | N 122.29° E | N 33.28° E | 1.53 | 1.81 |

| σ2 = 24.32 | −69.47° | |||||||||

| σ3 = 16.78 | 18.54° |

| Steel Grade | Specification | Yield Stress (MPa) | Tensile Trength (MPa) | Elongation (%) |

|---|---|---|---|---|

| 20 MnK | 36 U | 400 | 550 | 18 |

| Time (h) | 5 | 12 | 24 | 48 |

|---|---|---|---|---|

| Compressive strength (MPa) | 5 | 10 | 15 | 20 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, W.; Zhang, Y.; Zhu, Y.; Tang, J.; Cheng, L.; Suo, Z. Integrated Collaborative Control of “Shielding-Filling-Grouting” of 1 km Deep Large-Section Roadways: A Case Study. Minerals 2022, 12, 854. https://doi.org/10.3390/min12070854

Zhang W, Zhang Y, Zhu Y, Tang J, Cheng L, Suo Z. Integrated Collaborative Control of “Shielding-Filling-Grouting” of 1 km Deep Large-Section Roadways: A Case Study. Minerals. 2022; 12(7):854. https://doi.org/10.3390/min12070854

Chicago/Turabian StyleZhang, Wei, Yandong Zhang, Yanchao Zhu, Jiajia Tang, Longtao Cheng, and Zhiliang Suo. 2022. "Integrated Collaborative Control of “Shielding-Filling-Grouting” of 1 km Deep Large-Section Roadways: A Case Study" Minerals 12, no. 7: 854. https://doi.org/10.3390/min12070854