Study on Acoustic Emission and Coda Wave Characteristics of Layered Cemented Tailings Backfill under Uniaxial Compression

Abstract

:1. Introduction

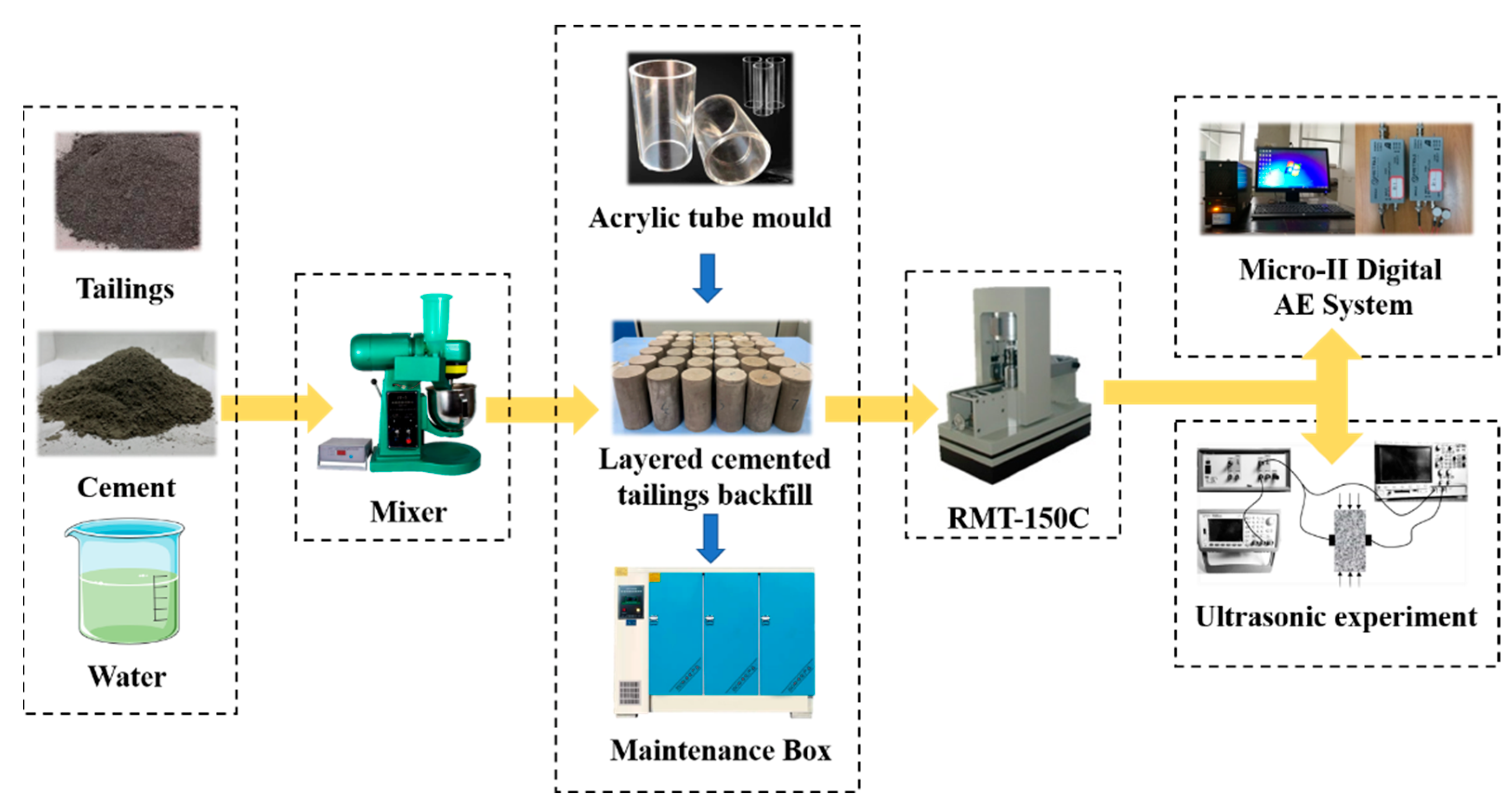

2. Materials and Methods

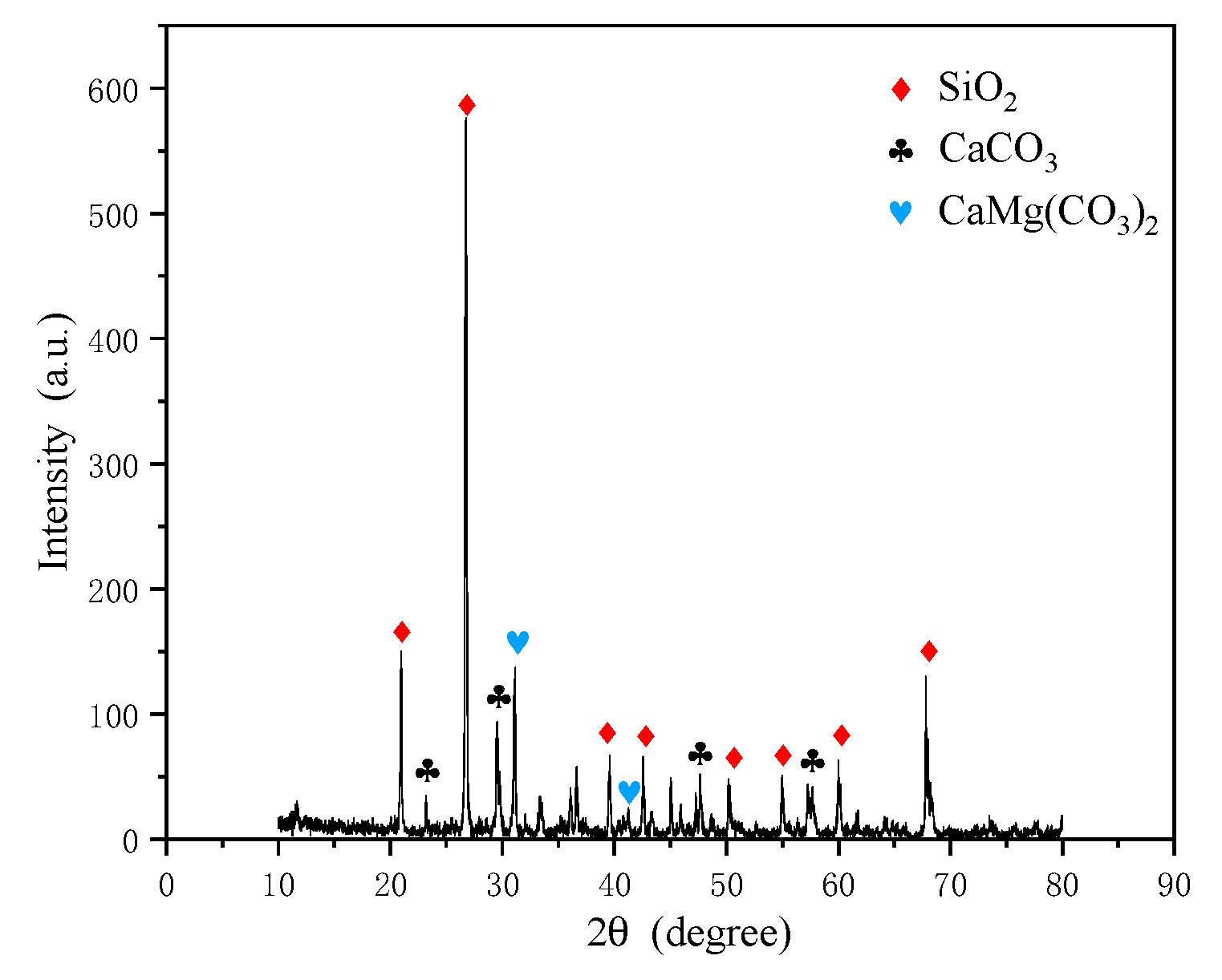

2.1. Materials

2.2. Methods

3. Results

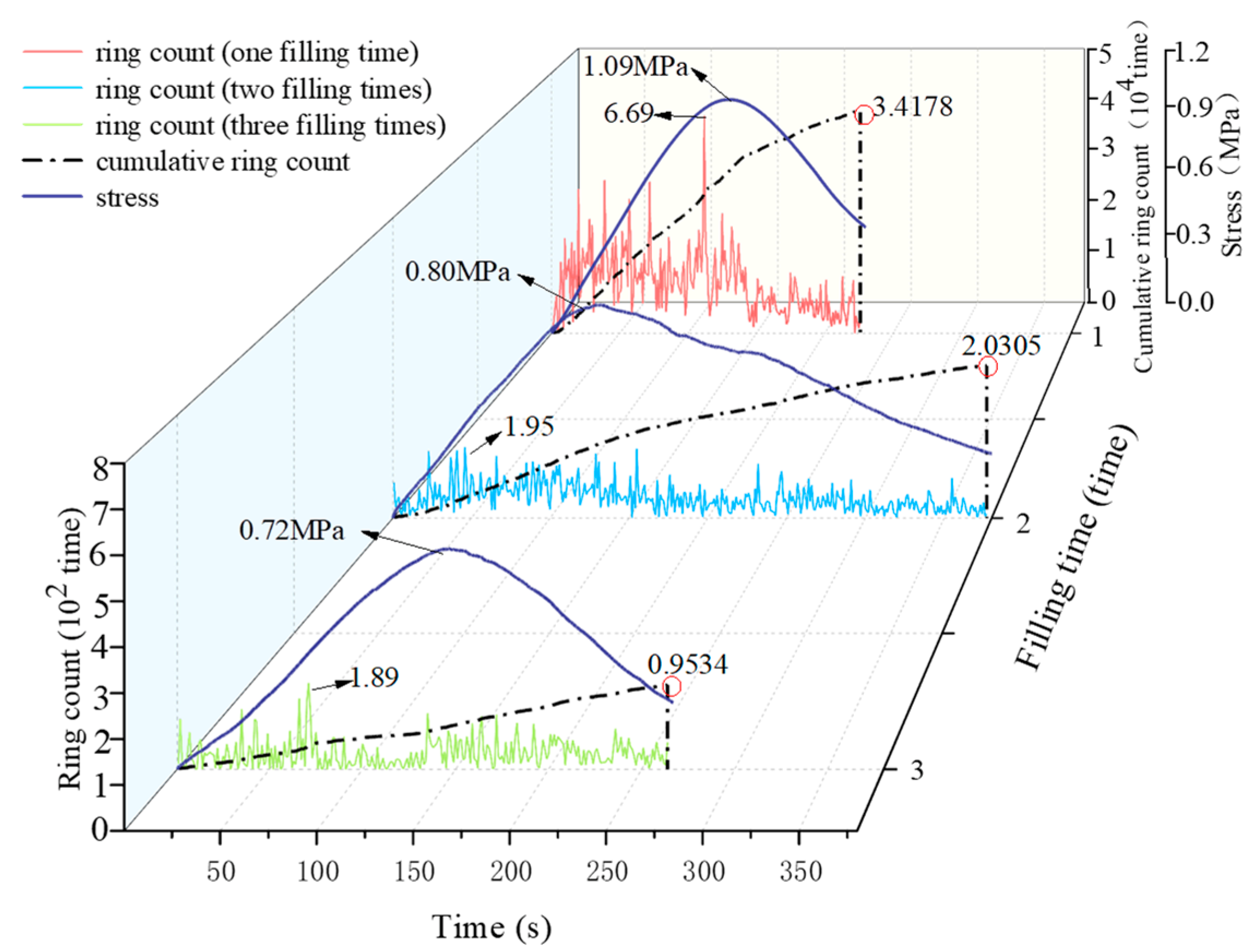

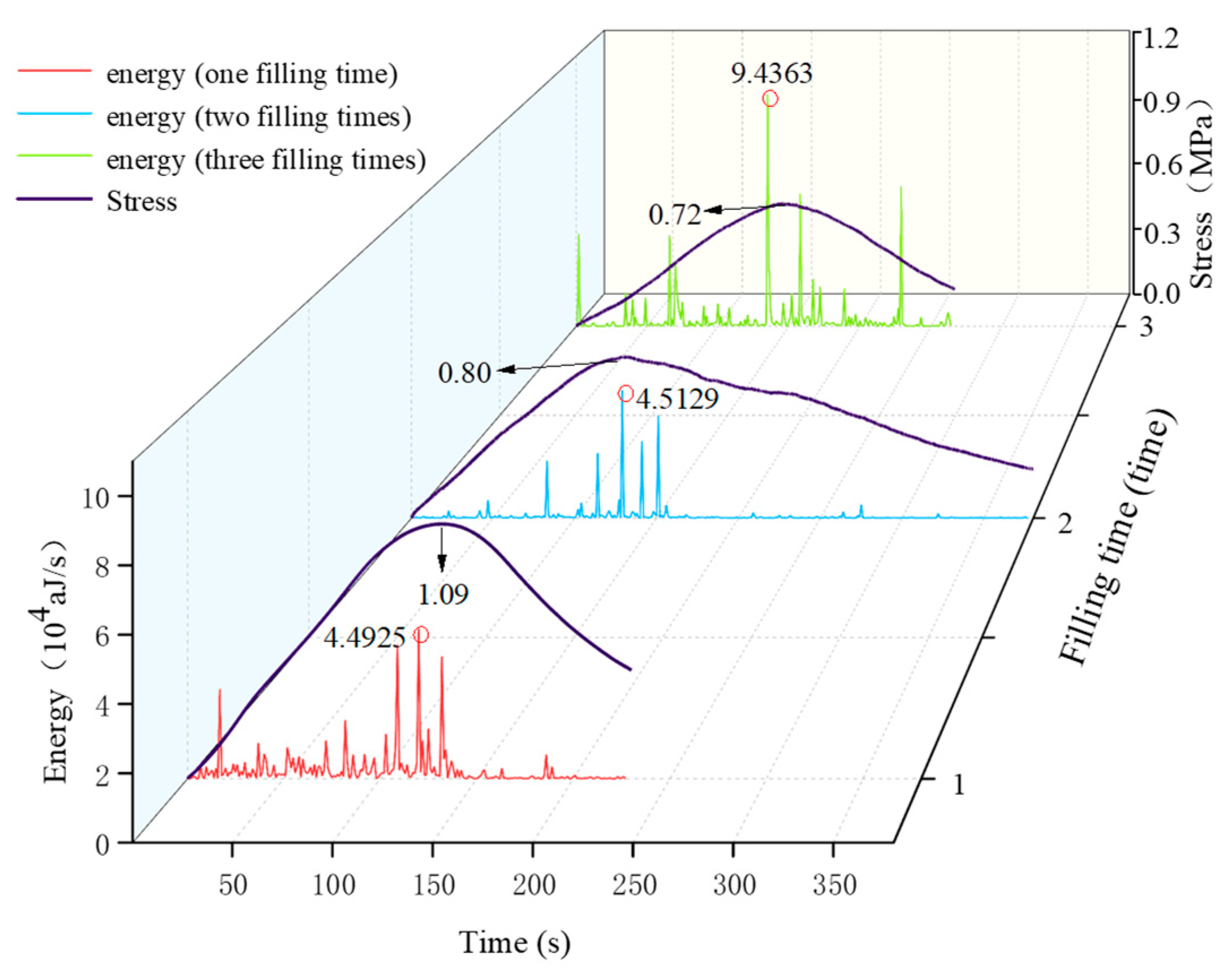

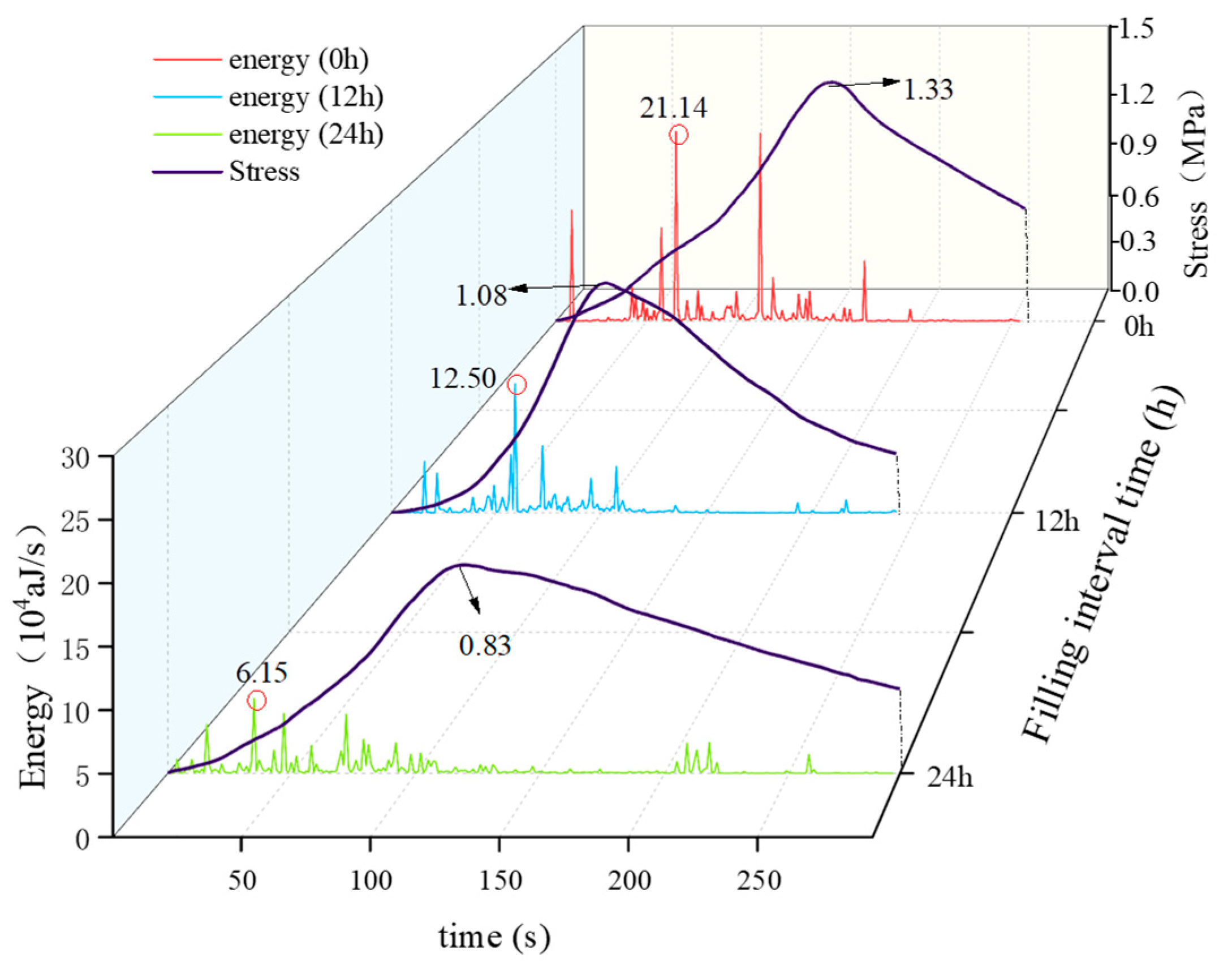

3.1. AE Characteristics

3.1.1. Analysis of Acoustic Emission Parameters

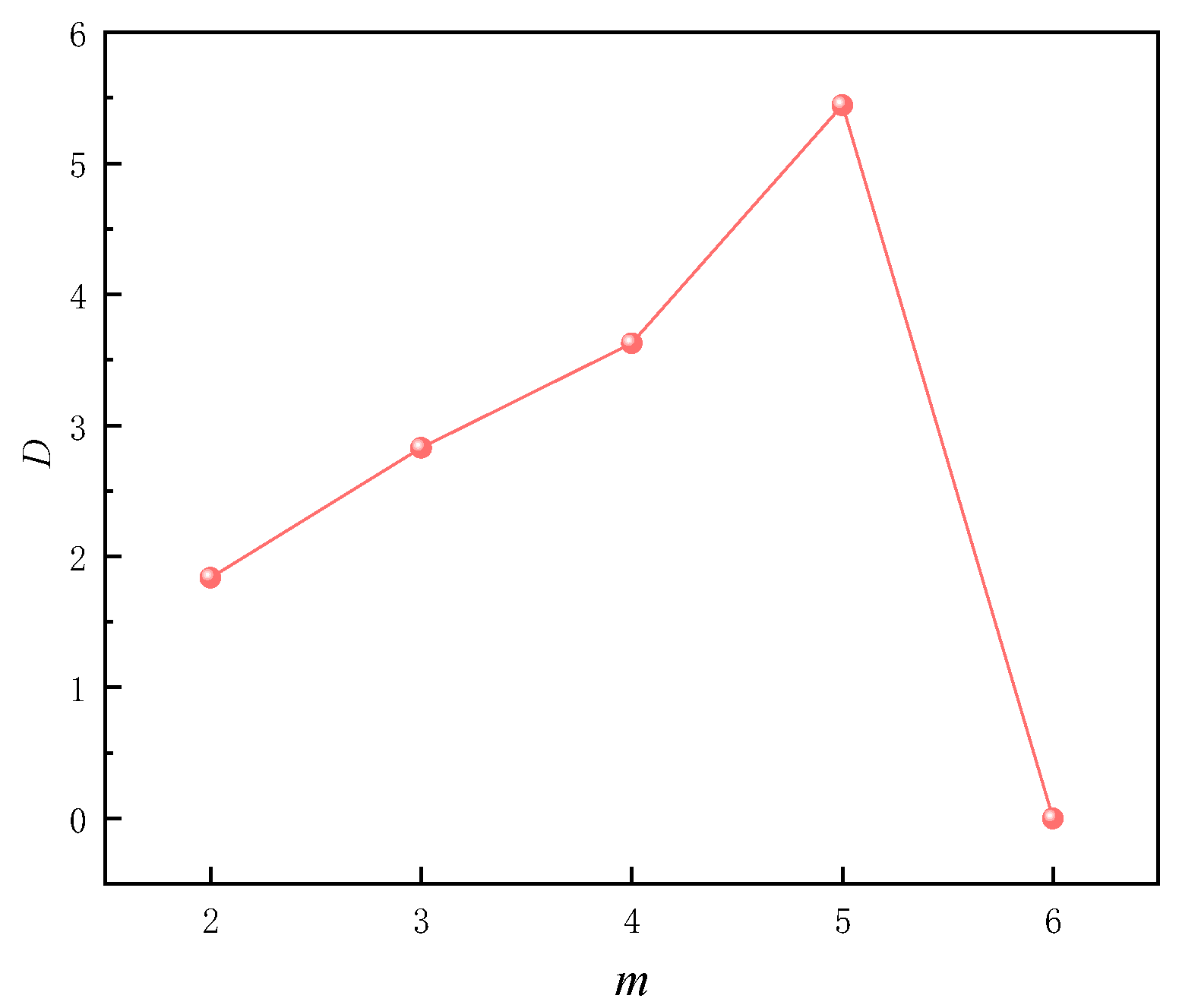

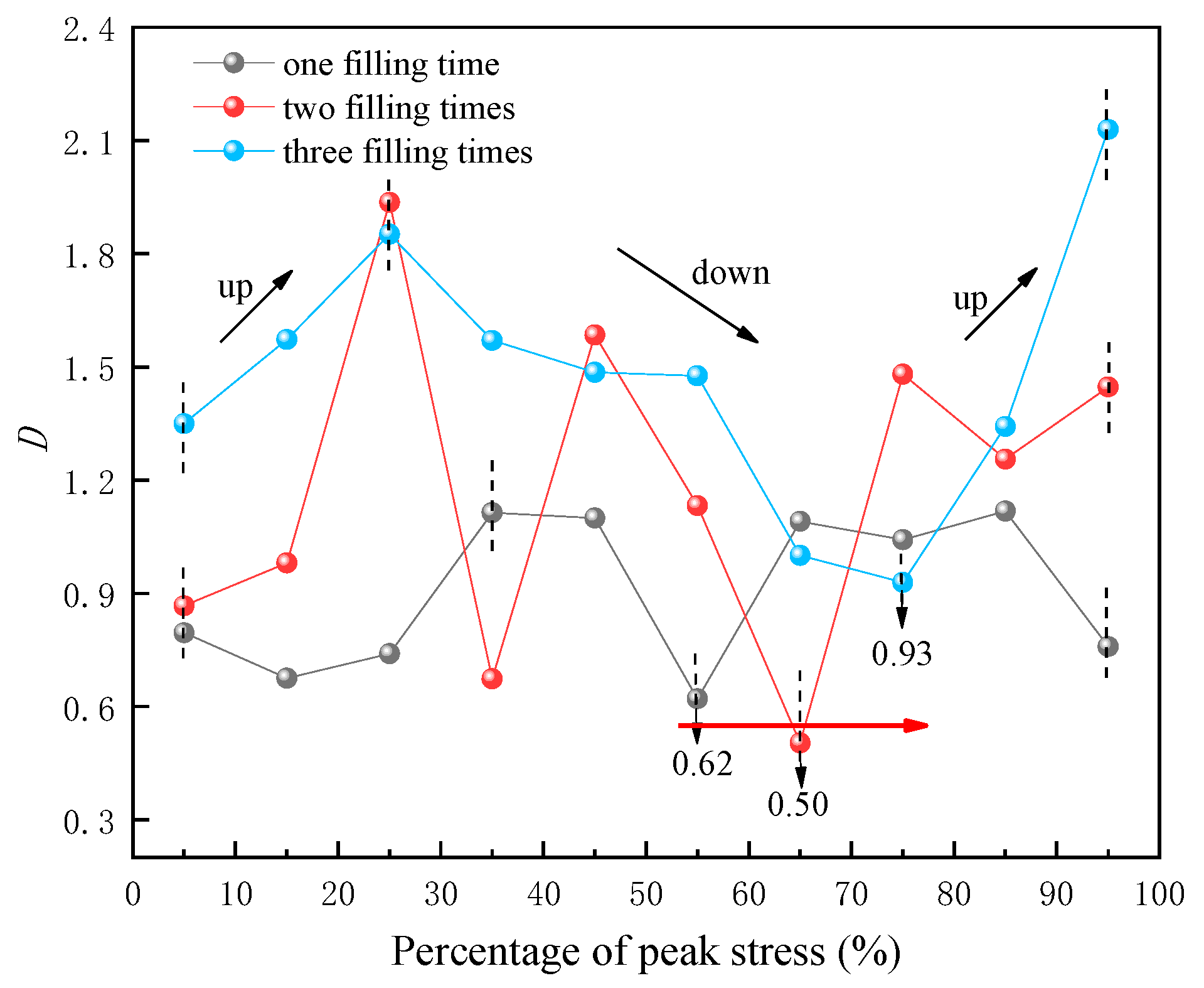

3.1.2. Fractal Characteristics of Ringing Counts

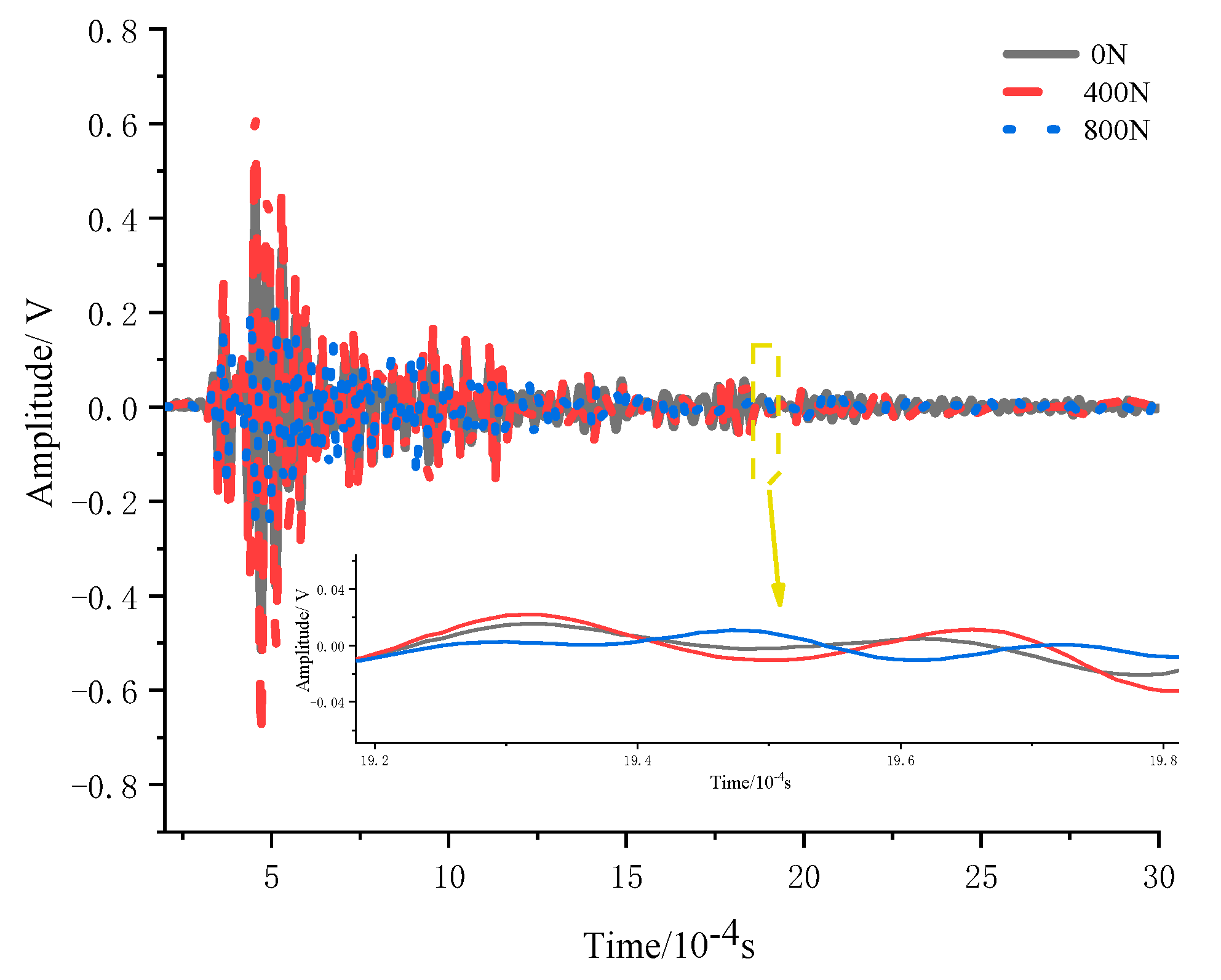

3.2. Analysis of Coda Wave

3.2.1. Coda Wave Interferometry and Ultrasonic Parameter Determination

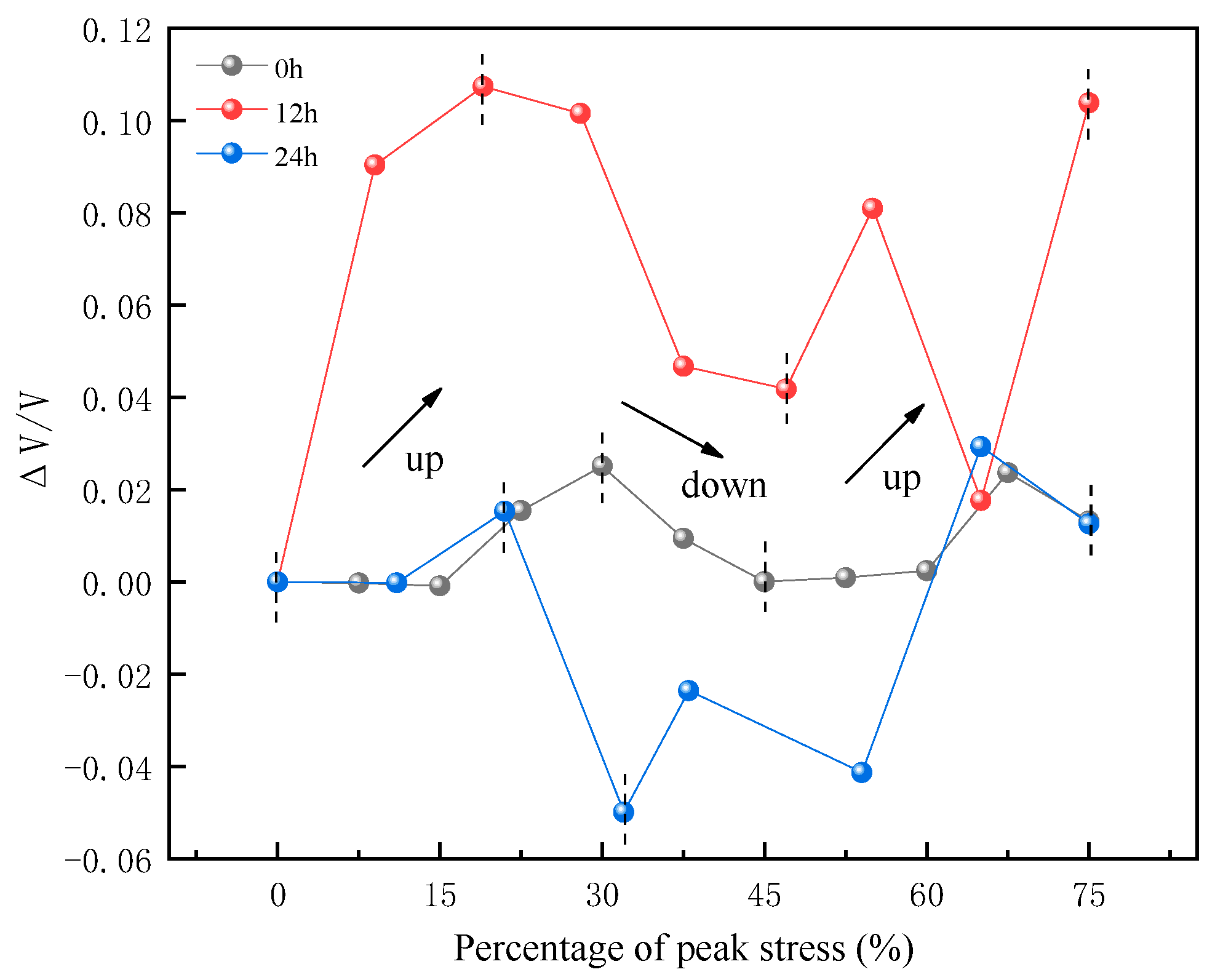

3.2.2. Analysis of Coda Wave Velocity Variation Rate

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Fall, M.; Benzaazoua, M.; Saa, E.G. Mix proportioning of underground cemented tailings backfill. Tunn. Undergr. Space Technol. 2008, 23, 80–90. [Google Scholar] [CrossRef]

- Đurđevac Ignjatović, L.; Krstić, V.; Radonjanin, V.; Jovanović, V.; Malešev, M.; Ignjatović, D.; Đurđevac, V. Application of Cement Paste in Mining Works, Environmental Protection, and the Sustainable Development Goals in the Mining Industry. Sustainability 2022, 14, 7902. [Google Scholar] [CrossRef]

- Kongar-Syuryun, C.; Ivannikov, A.; Khayrutdinov, A.; Tyulyaeva, Y. Geotechnology using composite materials from man-made waste is a paradigm of sustainable development. Mater. Today Proc. 2021, 38, 2078–2082. [Google Scholar] [CrossRef]

- Fu, J.X.; Wang, J.; Song, W.D. Damage constitutive model and strength criterion of cemented paste backfill based on layered effect considerations. J. Mater. Res. Technol. 2020, 9, 6073–6084. [Google Scholar] [CrossRef]

- Zhao, K.; Huang, M.; Yan, Y. Mechanical properties and synergistic deformation characteristics of tailings cemented filling assembled material body with different cement-tailings ratios. Chin. J. Rock Mech. Eng. 2021, 40, 2781–2789. [Google Scholar] [CrossRef]

- Cao, S.; Song, W.; Yilmaz, E. Influence of structural factors on uniaxial compressive strength of cemented tailings backfill. Constr. Build. Mater. 2018, 174, 190–201. [Google Scholar] [CrossRef]

- Wang, J.; Fu, J.; Song, W.; Zhang, Y.; Wang, Y. Mechanical behavior, acoustic emission properties and damage evolution of cemented paste backfill considering structural feature. Constr. Build. Mater. 2020, 261, 119958. [Google Scholar] [CrossRef]

- Wang, J.; Fu, J.; Song, W.; Zhang, Y.; Wu, S. Acoustic emission characteristics and damage evolution process of layered cemented tailings backfill under uniaxial compression. Constr. Build. Mater. 2021, 295, 123663. [Google Scholar] [CrossRef]

- Qiu, H.; Zhang, F.; Liu, L.; Huan, C.; Hou, D.; Kang, W. Experimental study on acoustic emission characteristics of cemented rock-tailings backfill. Constr. Build. Mater. 2022, 315, 125278. [Google Scholar] [CrossRef]

- Ran, H.; Guo, Y.; Feng, G.; Qi, T.; Du, X. Creep properties and resistivity-ultrasonic-AE responses of cemented gangue backfill column under high-stress area. Int. J. Min. Sci. Technol. 2021, 31, 401–412. [Google Scholar] [CrossRef]

- Xu, S.; Suorineni, F.T.; Li, K.; Li, Y. Evaluation of the strength and ultrasonic properties of foam-cemented paste backfill. Int. J. Min. Reclam. Environ. 2017, 31, 544–557. [Google Scholar] [CrossRef]

- Cheng, A.; Zhang, Y.; Dai, S.; Dong, F.; Zeng, W.; Li, D. Space-time evolution of acoustic emission parameters of cemented backfill and its fracture prediction under uniaxial compression. Rock Soil Mech. 2019, 40, 2965–2974. [Google Scholar] [CrossRef]

- Gong, C.; Li, C.; Zhao, K. Experimental study on b-value characteristics of acoustic emission of cemented filling body under loading and unloading test. J. Min. Saf. Eng. 2014, 31, 788–794. [Google Scholar] [CrossRef]

- Zhao, K.; Yu, X.; Zhu, S.; Zhou, Y.; Wang, Q.; Wang, J. Acoustic emission investigation of cemented paste backfill prepared with tantalum-niobium tailings. Constr. Build. Mater. 2020, 237, 117523. [Google Scholar] [CrossRef]

- Cheng, A.; Dai, S.; Zhang, Y.; Huang, S.; Ye, Z. Study on size effect of damage evolution of cemented backfill. Chin. J. Rock Mech. Eng. 2019, 38, 3053–3060. [Google Scholar] [CrossRef]

- He, W.; Zheng, C.S.; Li, S.H.; Shi, W.F.; Zhao, K. Strength Development Monitoring of Cemented Paste Backfill Using Guided Waves. Sensors 2021, 21, 8499. [Google Scholar] [CrossRef] [PubMed]

- Yan, B.; Zhu, W.; Hou, C.; Yilmaz, E.; Saadat, M. Characterization of early age behavior of cemented paste backfill through the magnitude and frequency spectrum of ultrasonic P-wave. Constr. Build. Mater. 2020, 249, 118733. [Google Scholar] [CrossRef]

- Akdag, S.; Karakus, M.; Nguyen, G.D.; Taheri, A.; Bruning, T. Evaluation of the propensity of strain burst in brittle granite based on post-peak energy analysis. Undergr. Space 2021, 6, 1–11. [Google Scholar] [CrossRef]

- Xu, W.B.; Cao, Y.; Liu, B.H. Strength efficiency evaluation of cemented tailings backfill with different stratified structures. Eng. Struct. 2019, 180, 18–28. [Google Scholar] [CrossRef]

- Xu, W.; Tian, M.; Li, Q. Time-dependent rheological properties and mechanical performance of fresh cemented tailings backfill containing flocculants. Miner. Eng. 2020, 145, 106064. [Google Scholar] [CrossRef]

- Deng, H.; Duan, T.; Tian, G.; Liu, Y.; Zhang, W. Research on Strength Prediction Model and Microscopic Analysis of Mechanical Characteristics of Cemented Tailings Backfill under Fractal Theory. Minerals 2021, 11, 886. [Google Scholar] [CrossRef]

- Feng, G.; Qi, T.; Du, X.; Wang, Z.; Zhang, Y. Acoustic Emission and Ultrasonic Characteristics in the Failure Process of Cemented Waste Concrete-Coal Gangue Backfilling (CWCGB) under Uniaxial Loading. Adv. Civ. Eng. 2018, 2018, 8960806. [Google Scholar] [CrossRef] [Green Version]

- He, Z.W.; Zhao, K.; Yan, Y.J.; Ning, F.J.; Zhou, Y.; Song, Y.F. Mechanical response and acoustic emission characteristics of cement paste backfill and rock combination. Constr. Build. Mater. 2021, 288, 123119. [Google Scholar] [CrossRef]

- Sang, G.; Liu, S.; Elsworth, D. Quantifying fatigue-damage and failure-precursors using ultrasonic coda wave interferometry. Int. J. Rock Mech. Min. Sci. 2020, 131, 104366. [Google Scholar] [CrossRef]

- Xu, X.; Sun, X.; Yao, W.; Wu, P.; Qiu, J.; Guo, Z.; Liu, N. Strength and Ultrasonic Characteristics of Cemented Paste Backfill Incorporating Foaming Agent. Minerals 2021, 11, 681. [Google Scholar] [CrossRef]

- Xiu, Z.; Wang, S.; Ji, Y.; Wang, F.; Ren, F.; Van-Tuan, N. Loading rate effect on the uniaxial compressive strength (UCS) behavior of cemented paste backfill (CPB). Constr. Build. Mater. 2021, 271, 121526. [Google Scholar] [CrossRef]

- Liu, S.M.; Li, X.L.; Li, Z.H.; Chen, P.; Yang, X.L.; Liu, Y.J. Energy distribution and fractal characterization of acoustic emission (AE) during coal deformation and fracturing. Measurement 2019, 136, 122–131. [Google Scholar] [CrossRef]

- Zhang, S.W.; Shou, K.J.; Xian, X.F.; Zhou, J.P.; Liu, G.J. Fractal characteristics and acoustic emission of anisotropic shale in Brazilian tests. Tunn. Undergr. Space Technol. 2018, 71, 298–308. [Google Scholar] [CrossRef]

- Snieder, R. The theory of coda wave interferometry. Pure Appl. Geophys. 2006, 163, 455–473. [Google Scholar] [CrossRef]

- Snieder, R.; Gret, A.; Douma, H.; Scales, J. Coda wave interferometry for estimating nonlinear behavior in seismic velocity. Science 2002, 295, 2253–2255. [Google Scholar] [CrossRef] [Green Version]

- Sens-Schonfelder, C.; Wegler, U. Passive image interferometry and seasonal variations of seismic velocities at Merapi Volcano, Indonesia. Geophys. Res. Lett. 2006, 33, L21302. [Google Scholar] [CrossRef]

- Singh, J.; Curtis, A.; Zhao, Y.; Cartwright-Taylor, A.; Main, I. Coda Wave Interferometry for Accurate Simultaneous Monitoring of Velocity and Acoustic Source Locations in Experimental Rock Physics. J. Geophys. Res. Solid Earth 2019, 124, 5629–5655. [Google Scholar] [CrossRef]

| Factors | Variables | Target Stress Value/N |

|---|---|---|

| filling times | 1 | 1570 |

| 2 | 1197 | |

| 3 | 1000 | |

| filling interval time | 0 h | 1943 |

| 12 h | 1629 | |

| 24 h | 1256 |

| Equipment Name | Waveform Generator | Power Amplifier | Oscilloscope | Sensor |

|---|---|---|---|---|

| Model | 33522B | 2350 | DSOX2022A | R6α |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, C.; He, W.; Lu, B.; Wang, M.; Li, S.; Xiao, C. Study on Acoustic Emission and Coda Wave Characteristics of Layered Cemented Tailings Backfill under Uniaxial Compression. Minerals 2022, 12, 896. https://doi.org/10.3390/min12070896

Huang C, He W, Lu B, Wang M, Li S, Xiao C. Study on Acoustic Emission and Coda Wave Characteristics of Layered Cemented Tailings Backfill under Uniaxial Compression. Minerals. 2022; 12(7):896. https://doi.org/10.3390/min12070896

Chicago/Turabian StyleHuang, Chongjie, Wen He, Bokai Lu, Manman Wang, Shenhai Li, and Changbo Xiao. 2022. "Study on Acoustic Emission and Coda Wave Characteristics of Layered Cemented Tailings Backfill under Uniaxial Compression" Minerals 12, no. 7: 896. https://doi.org/10.3390/min12070896

APA StyleHuang, C., He, W., Lu, B., Wang, M., Li, S., & Xiao, C. (2022). Study on Acoustic Emission and Coda Wave Characteristics of Layered Cemented Tailings Backfill under Uniaxial Compression. Minerals, 12(7), 896. https://doi.org/10.3390/min12070896