Wastes in Underground Coal Mines and Their Behavior during Mine Water Level Rebound—A Review

Abstract

:1. Introduction

- (1)

- The composition and quantity of waste materials within the underground mine(s).

- (2)

- The extent and geometry of the underground workings and, in the case of neighboring mines, their connections.

- (3)

- The transport mechanisms of various types of contaminants.

- (4)

- The utilization of specialized mine water modeling software as predictive tools.

2. Waste Materials in Underground Coal Mines

2.1. Backfill Material

2.2. Abondoned Waste Materials, Lubricants, Oil, PCB and PCDM

2.3. Mine Water and Acid Mine Drainage

3. Case Study: Wastes in the Ruhr Area—Germany

3.1. Underground Mining in the Ruhr Area

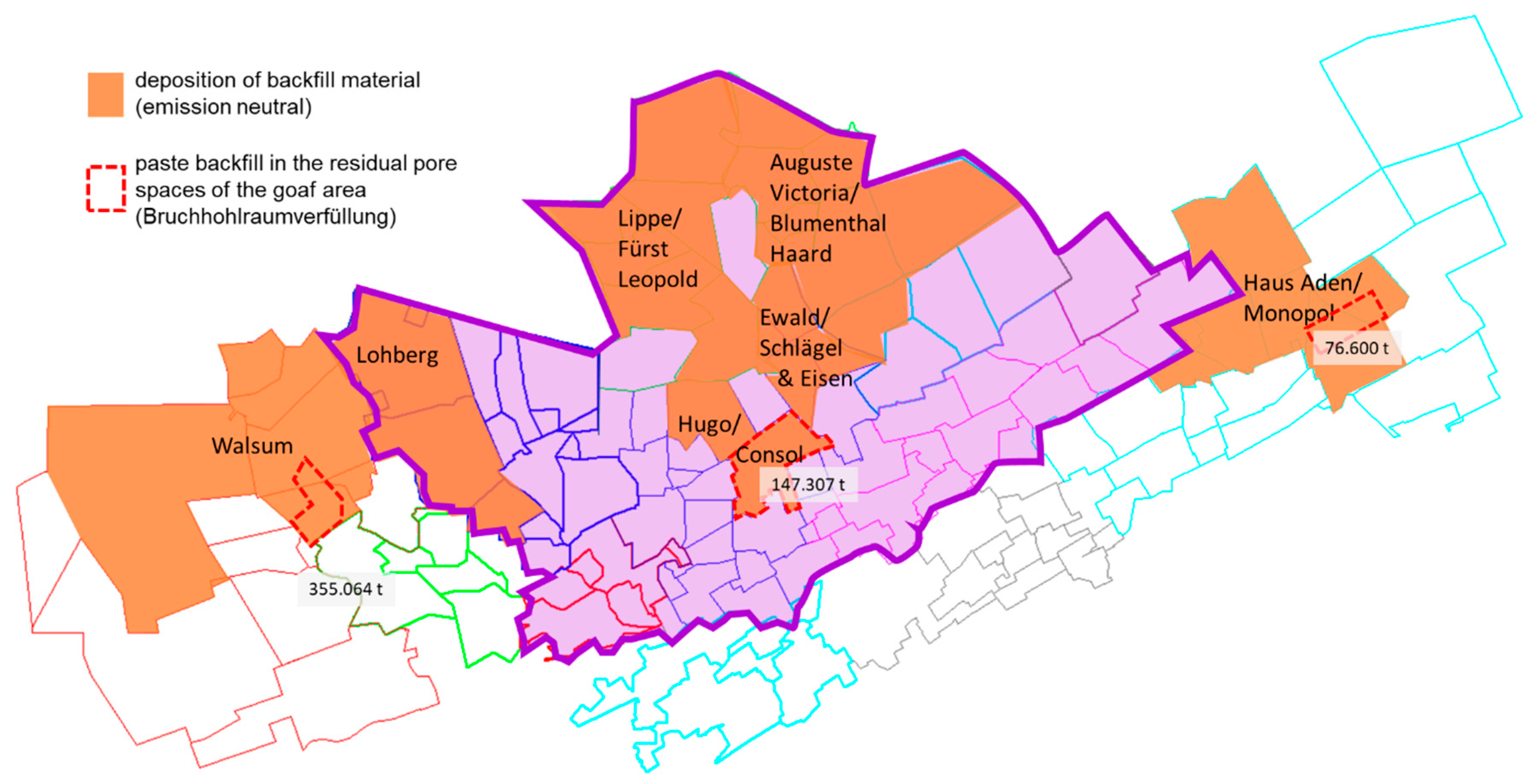

3.2. Backfill Material

- -

- The paste material reacts with the rising mine water, causing elevated pH values. The heavy metals, however, require low pH values for dissolution. At least 1000 years are required for the pH value to decrease to a point where Zn and Pb could possibly be leached. More realistic scenarios, where more backfill matrix material reacts with the mine water, indicate that the geochemical barrier will remain active for several tens of thousands of years.

- -

- If heavy metals such as Zn, Cd or Pb are leached from the backfill material, sorption processes to the clay-rich formations take place, thus further decreasing the contaminant load. It is stated that within 100 m from the deposited backfill material, the potential concentrations of heavy metals Zn and Pb would decrease to a minimal percentage of the original value.

- -

- In case mine water pumping is still maintained after the initial release of Pb or Zn, i.e., once the geochemical barrier is no longer active, the increase in Pb and Zn in the pumped mine water would increase in the per mill range and is therefore negligible.

- -

- Without pumping, the flow paths would be ~2000 m long, which would take ~0.8 million years to reach the next receiving waters. Along this flow path, sorption processes will take place, which will reduce the concentrations to negligible values.

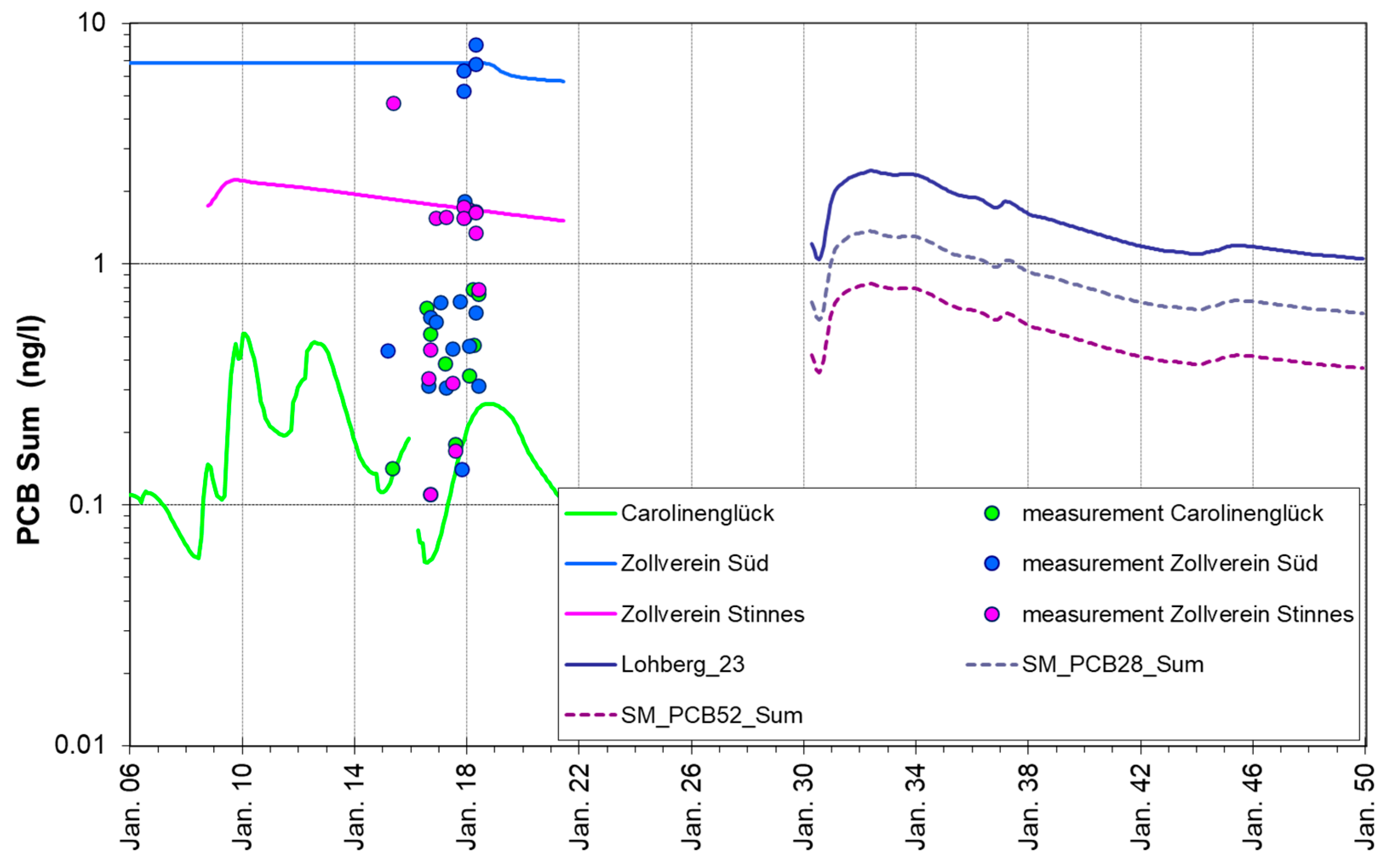

3.3. PCB

- -

- Particles containing PCB, whose mobilization and transport behavior are considered in the model.

- -

- PCB-free particles, which are also taken into account with fractions in the model.

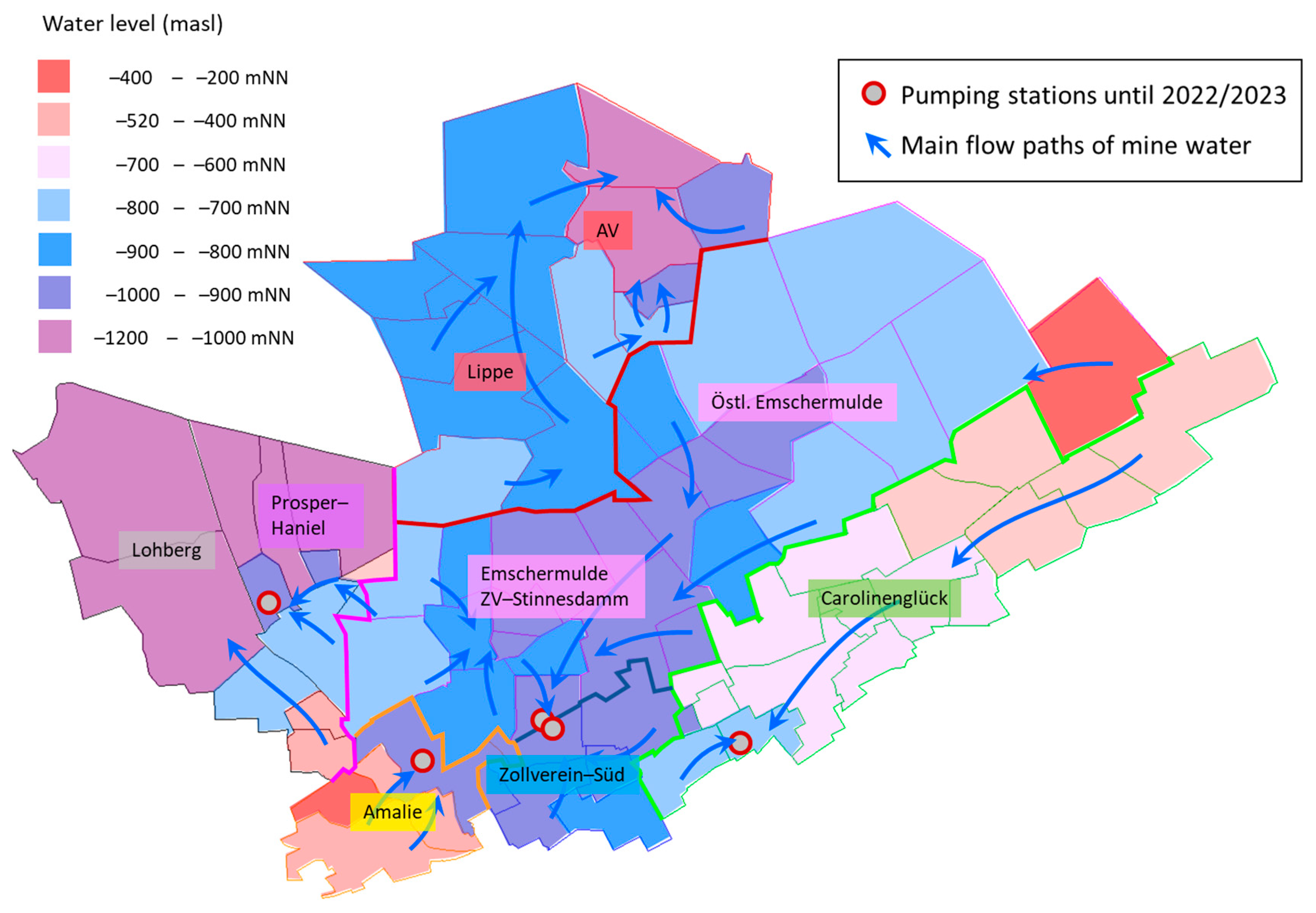

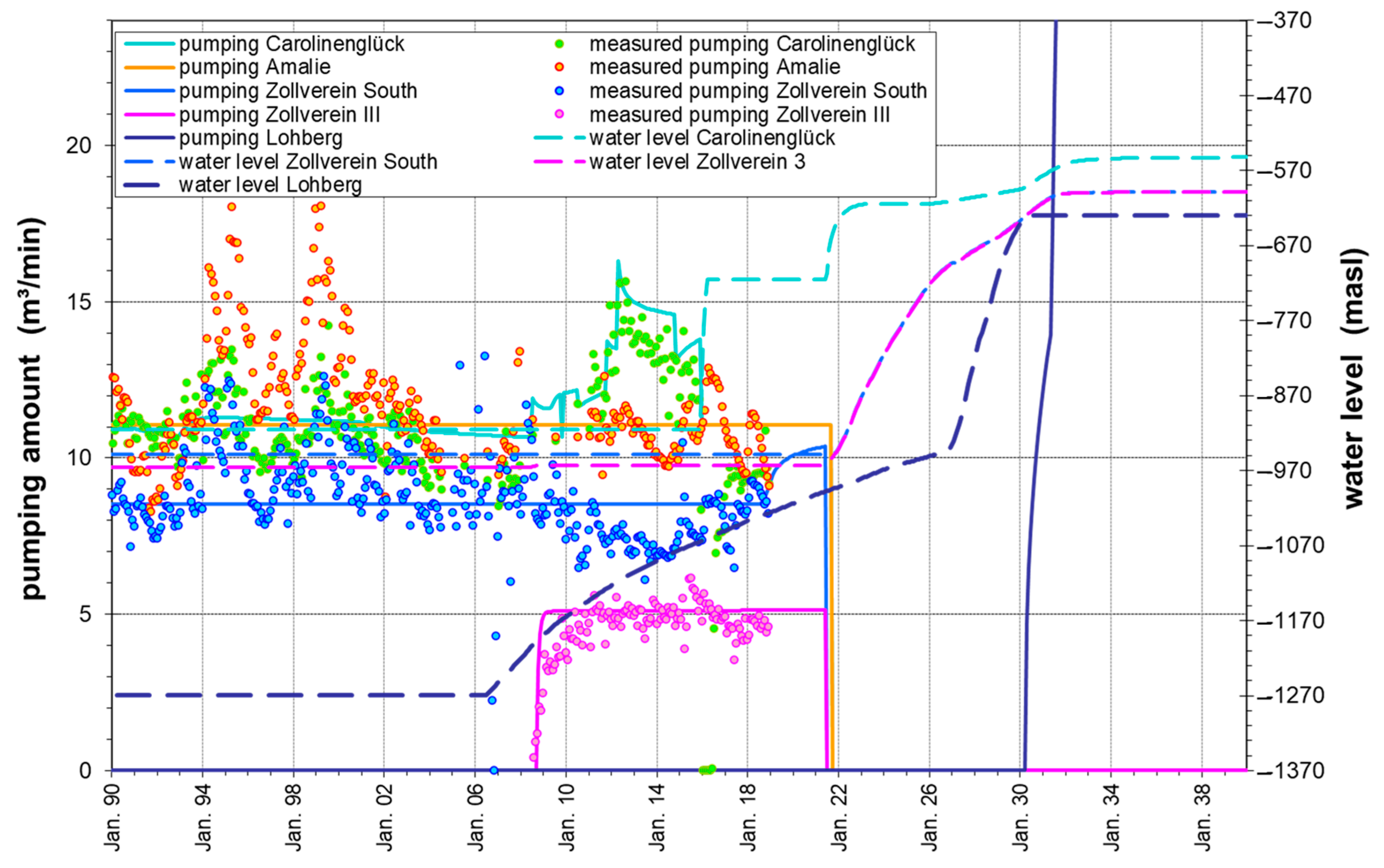

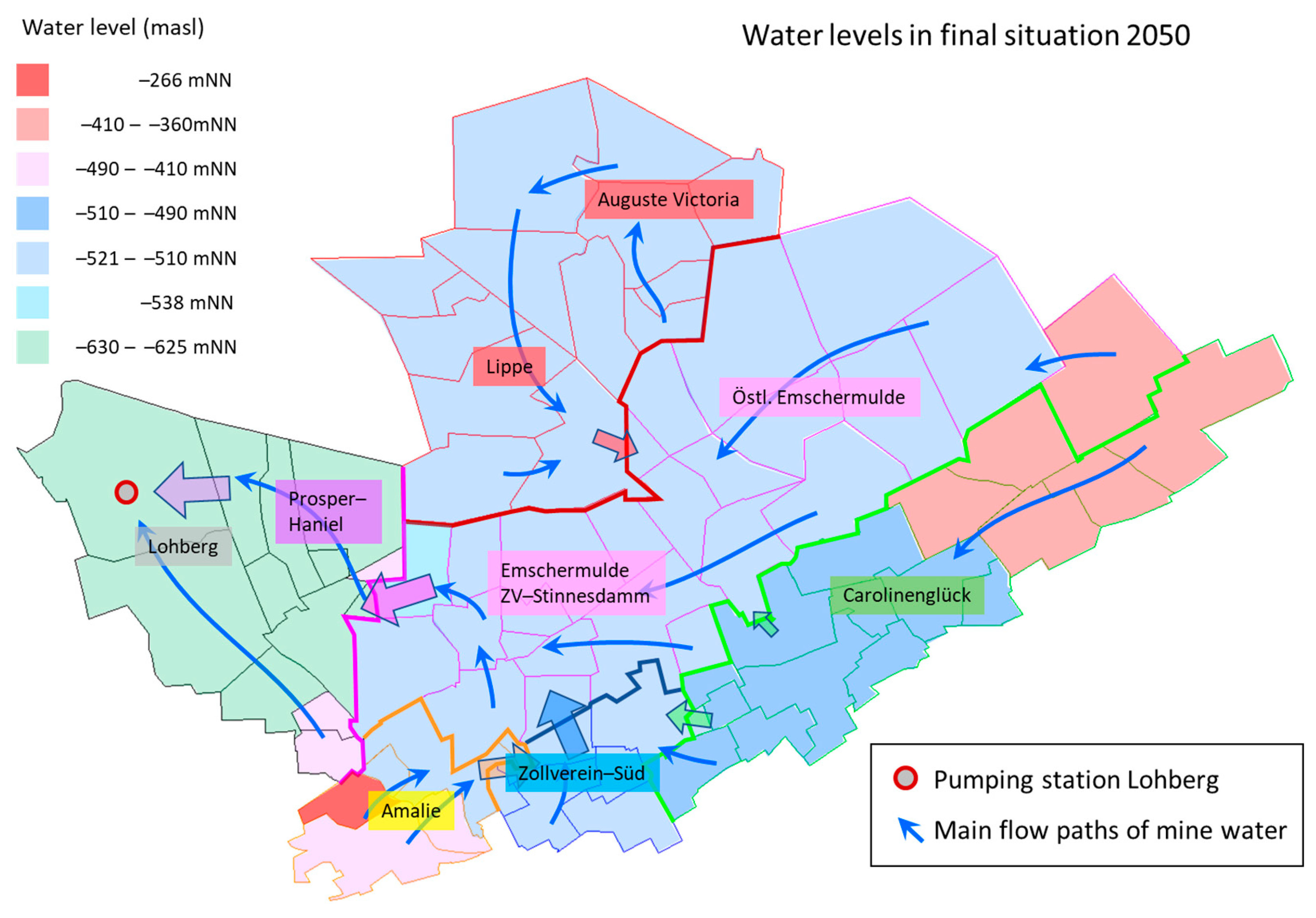

3.4. Spatial and Temporal Evolution of Mine Water in the Central Water Province

3.5. Chemical Evolution of Mine Water

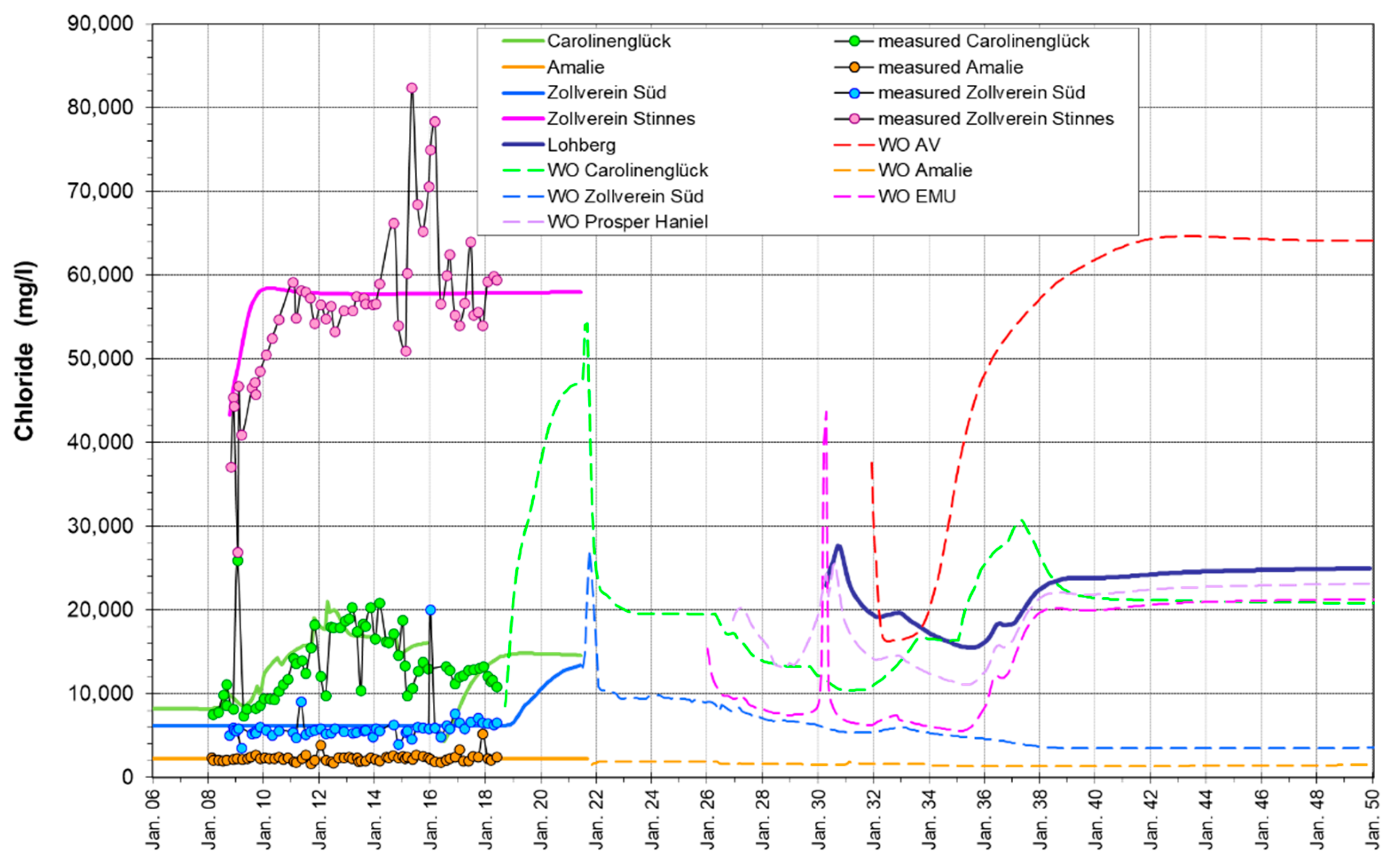

3.5.1. Chloride

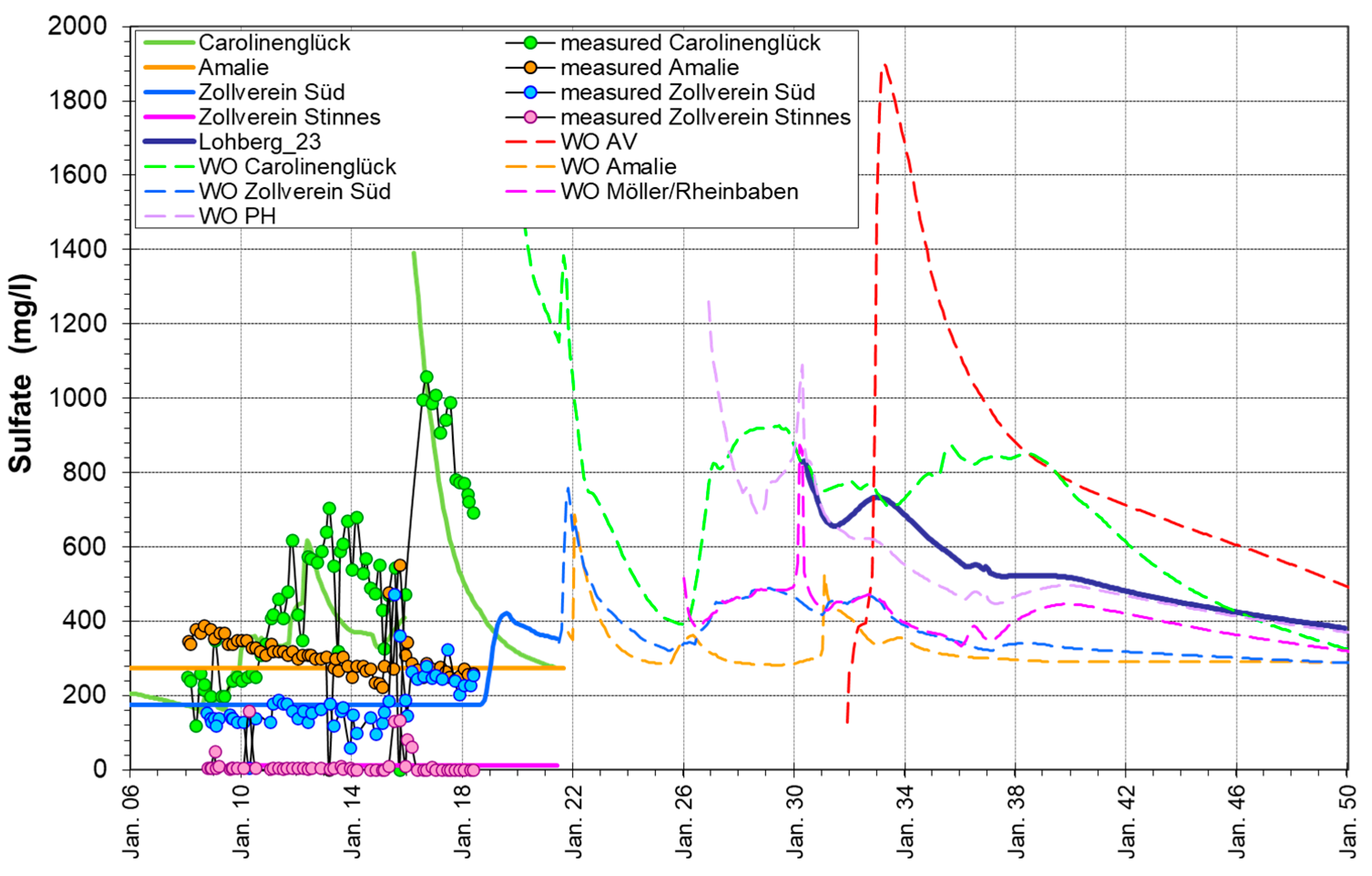

3.5.2. Sulfate

3.5.3. Iron

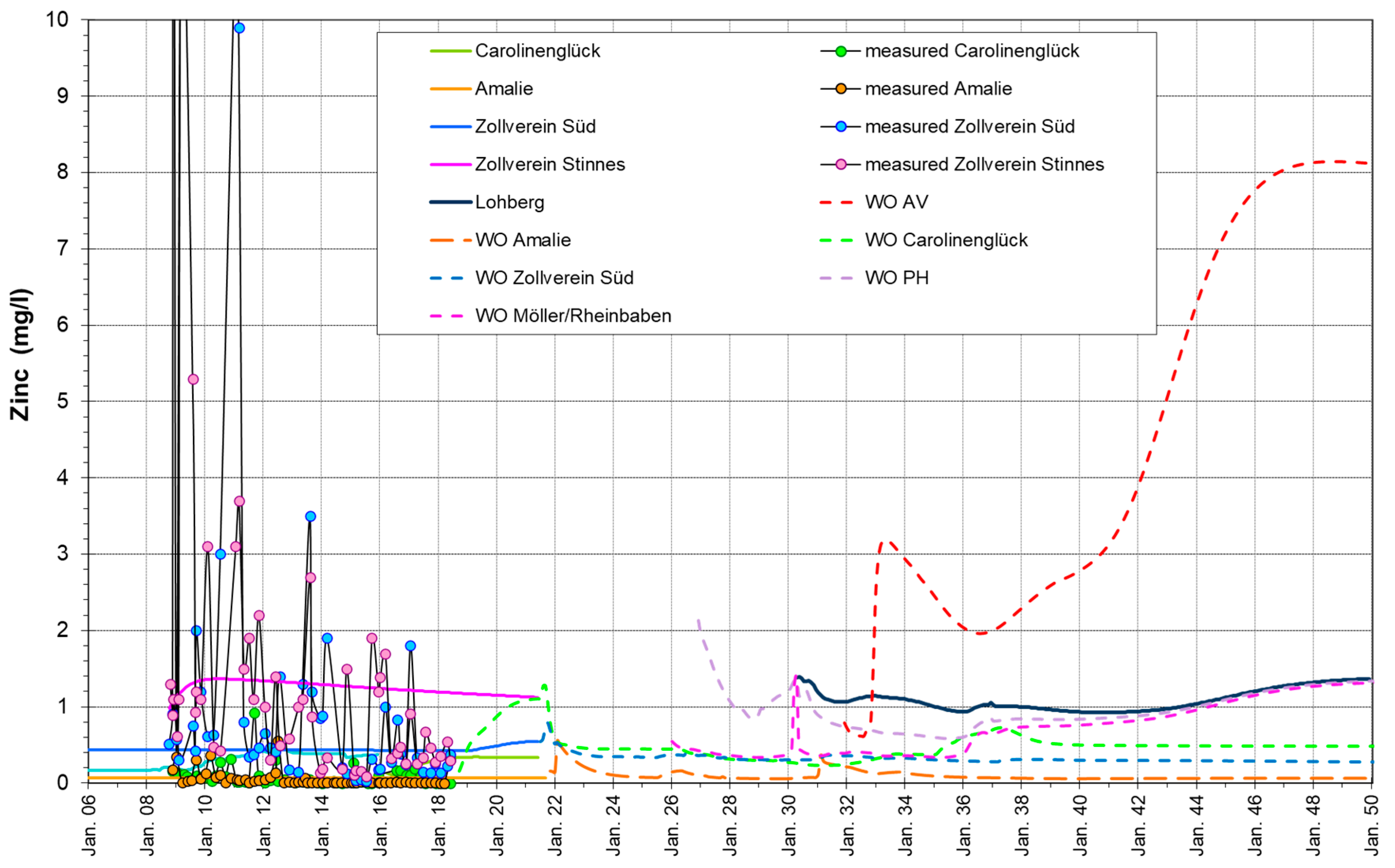

3.5.4. Zinc

4. Conclusions and Suggestions

Author Contributions

Funding

Conflicts of Interest

References

- Stanley, M.C.; Strongman, J.E.; Perks, R.B.; Nguyen, H.B.T.; Cunningham, W.; Schmillen, A.D.; McCormick, M.S. Managing Coal Mine Closure: Achieving a Just Transition for All; The World Bank: Washington, DC, USA, 2018. [Google Scholar]

- Alves Dias, P.; Kanellopoulos, K.; Medarac, H.; Kapetaki, Z.; Miranda Barbosa, E.; Shortall, R.; Czako, V.; Telsnig, T.; Vazquez Hernandez, T.; Lacal Arantegui, R.; et al. EU Coal Regions: Opportunities and Challenges Ahead; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Claxton, A.; Ganguly, A.; Her, S. Global Coal Mine Tracker. Available online: https://globalenergymonitor.org/ (accessed on 23 June 2023).

- Gombert, P.; Sracek, O.; Koukouzas, N.; Gzyl, G.; Valladares, S.T.; Frączek, R.; Klinger, C.; Bauerek, A.; Areces, J.E.Á.; Chamberlain, S.; et al. An Overview of Priority Pollutants in Selected Coal Mine Discharges in Europe. Mine Water Environ. 2019, 38, 16–23. [Google Scholar] [CrossRef]

- Jasnowski-Peters, H.J.; Melchers, C. Mine Water Rebound in the Former Hard Coal Mining Area of the Ruhr District—Hydrogeochemical Monitoring for a Sustainable, Ecological and Economical Feasible Post-Mining Approach. Min. Rep. Glückauf 2022, 158, 333–343. [Google Scholar]

- Seidel, M.; Li, F.; Winking, C.; Sommerhäuser, M.; Lüderitz, V. Should We Sample More than Required by the European Water Framework Directive? Case Study: Emscher Catchment. Clean Soil Air Water 2022, 50, 2000391. [Google Scholar] [CrossRef]

- European Parliament; Council of the European Union. Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on waste and repealing certain Directives. Off. J. Eur. Union 2008, 51, 0003–0030. [Google Scholar]

- European Parliament; Council of the European Union. Directive 2006/21/EC of the European Parliament and of the Council of 15 March 2006 on the Management of Waste from Extractive Industries and Amending Directive 2004/35/EC—Statement by the European Parliament, the Council, and the Commission. Off. J. Eur. Union 2006, 15, 15–34. [Google Scholar]

- Garbarino, E.; Orveillon, O.; Saveyn, H.; Barthe, P.; Eder, P. Best Available Techniques (BAT) Reference Document for the Management of Waste from Extractive Industries in Accordance with Directive 2006/21/EC; Publications Office of the European Union: Luxembourg, 2018. [Google Scholar]

- Vogt, M. Machbarkeitsstudie Zentrale Wasserhaltung Lohberg; RAG Aktiengesellschaft: Essen, Germany, 2020. [Google Scholar]

- Stemke, M.; Wieber, G. Closure of German Hard Coal Mines: Effects and Legal Aspects of Mine Flooding. Mine Water Environ. 2022, 41, 280–291. [Google Scholar] [CrossRef]

- Agboola, O.; Babatunde, D.E.; Isaac Fayomi, O.S.; Sadiku, E.R.; Popoola, P.; Moropeng, L.; Yahaya, A.; Mamudu, O.A. A Review on the Impact of Mining Operation: Monitoring, Assessment and Management. Results Eng. 2020, 8, 100181. [Google Scholar] [CrossRef]

- Lee, A. Cleaning up after Canada’s Largest Tailings Pond Leak. 2014. Available online: https://macleans.ca/news/canada/cleaning-up-after-canadas-largest-tailings-pond-leak/ (accessed on 5 October 2023).

- Van Zweel, K.N. Development of a Geochemical Model to Predict Leachate Water Quality Associated with Coal Mining Practices; Magister Scientiae, North-West University: Potchefstroom, South Africa, 2016. [Google Scholar]

- Donovan, J.; Karfakis, M. Underground Disposal of Coal Waste for Enhanced Ground Control and Recovery. Transactions 2007, 322, 45–50. [Google Scholar]

- Yin, Y.; Zhao, T.; Zhang, Y.; Tan, Y.; Qiu, Y.; Taheri, A.; Jing, Y. An Innovative Method For Placement Of Gangue Backfilling Material In Steep Underground Coal Mines. Minerals 2019, 9, 107. [Google Scholar] [CrossRef]

- Kessler, T.; Mugova, E.; Jasnowski-Peters, H.; Rinder, T.; Stemke, M.; Wolkersdorfer, C.; Hilberg, S.; Melchers, C.; Struckmeier, W.; Wieber, G.; et al. Groundwater In Former German Coal Mining Areas—A Scientific Perspective On Mine Floodings. Grundwasser 2020, 25, 259–272. [Google Scholar] [CrossRef]

- RAG Konzept Zur Langfristigen Optimierung Der Grubenwasserhaltung Der RAG Aktiengesellschaft Für Nordrhein-Westfalen; RAG: Herne, Germany, 2014.

- Denneborg, M.; Müller, F.; van Berk, W.; König, C.M.; Schwarzbauer, J.-C.; Rüde, T.R.; Preuße, A. Gutachten Zur Prüfung Möglicher Umweltauswirkungen Des Einsatzes Von Abfall-Und Reststoffen Zur Bruch-Hohlraumverfüllung In Steinkohlenbergwerken In Nordrhein-Westfalen, Teil 2 Endbericht; ahu GmbH: Aachen, Germany, 2018; Available online: https://www.umweltauswirkungen-utv.de/index.html (accessed on 5 October 2023).

- Szczepañska-Plewa, J.; Stefaniak, S.; Twardowska, I. Coal Mining Waste Management and Its Impact on the Groundwater Chemical Status Exemplified in the Upper Silesia Coal Basin (Poland). Biul. Panstw. Inst. Geol. 2010, 441, 157–166. [Google Scholar]

- Bedford, M.; Markowska, M.; Kruczek, M.; Janson, E.; Wrana, A.; Skalny, A.; Łabaj, P.; Wrona, P.; Różański, Z.; Suponik, T.; et al. Texmin Handbook. A Guide to Managing the Risks Posed to Working and Abandoned Mining Facilities, and to the Surrounding Environment, Caused by Climate Change; Central Mining Institute (GIG), University of Exeter: Exeter, UK, 2022. [Google Scholar]

- Wang, Z.; Xu, Y.; Zhang, Z.; Zhang, Y. Review: Acid Mine Drainage (AMD) in Abandoned Coal Mines of Shanxi, China. Water 2021, 13, 8. [Google Scholar] [CrossRef]

- Schabronath, C.; Klinger, C.; Löchte, J. Planning and Implementation of Environment-Friendly Phasing Out of German Hard Coal Mining Under Consideration of Water-Hazardous Organic Substances. In Mine Water Management for Future Generations; Stanley, P., Wolkersdorfer, C., Wolkersdorfer, K., Eds.; Natural Resources Wales, The Coal Authority, Welsh Government, Cardiff University: Cardiff, UK, 2021; pp. 508–513. [Google Scholar]

- Bench, D. Identification, Management, and Proper Disposal of PCB-Containing Electrical Equipment Used in Mines. In Proceedings of the 14th International Conference on Tailings and Mine Waste, Vail, CO, USA, 17–20 October 2010; pp. 275–286. [Google Scholar]

- Melymuk, L.; Blumenthal, J.; Sáňka, O.; Shu-Yin, A.; Singla, V.; Šebková, K.; Pullen Fedinick, K.; Diamond, M.L. Persistent Problem: Global Challenges to Managing PCBs. Environ. Sci. Technol. 2022, 56, 9029–9040. [Google Scholar] [CrossRef] [PubMed]

- Pohl, W.L. Economic Geology; Schweizerbart Science Publishers: Stuttgart, Germany, 2020; ISBN 9783510654413. [Google Scholar]

- Wood, S.C.; Younger, P.L.; Robins, N.S. Long-Term Changes in the Quality of Polluted Minewater Discharges from Abandoned Underground Coal Workings in Scotland. Q. J. Eng. Geol. 1999, 32, 69–79. [Google Scholar] [CrossRef]

- Lambert, D.C.; McDonough, K.M.; Dzombak, D.A. Long-Term Changes in Quality Of Discharge Water from Abandoned Underground Coal Mines in Uniontown Syncline, Fayette County, Pa, Usa. Water Res. 2004, 38, 277–288. [Google Scholar] [CrossRef] [PubMed]

- Rinder, T.; Dietzel, M.; Stammeier, J.A.; Leis, A.; Bedoya-González, D.; Hilberg, S. Geochemistry of Coal Mine Drainage, Groundwater, and Brines from the Ibbenbüren Mine, Germany: A Coupled Elemental-Isotopic Approach. Appl. Geochem. 2020, 121, 104693. [Google Scholar] [CrossRef]

- Wolkersdorfer, C.; Mugova, E. Effects of Mining on Surface Water. In Encyclopedia of Inland Waters, 2nd ed.; Elsevier: Amsterdam, The Netherlands, 2022; Volume 4, pp. 170–188. ISBN 9780128220412. [Google Scholar]

- Klinger, C.; Eckart, M.; Löchte, J. Integration of Solid Matter Coupled Contaminant Transport into the 3D Reactive Transport Boxmodel by the Example of PCB in German Hard Coal Mining. In Proceedings of the Mine Water and Circular Economy, IMWA 2017, Lappeenranta, Finland, 25–30 June 2017; pp. 1–9. [Google Scholar]

- Tran, T.Q.; Banning, A.; Wisotzky, F.; Wohnlich, S. Mine Water Hydrogeochemistry of Abandoned Coal Mines in the Outcropped Carboniferous Formations, Ruhr Area, Germany. Environ. Earth Sci. 2020, 79, 84. [Google Scholar] [CrossRef]

- Drobniewski, M.; Balzer, I.; Frankenhoff, H.; Witthaus, H. Mine Water Management in the Ruhr Coalfield. In Mine Water and Circular Economy; IMWA: Lappeenranta, Finland, 2017. [Google Scholar]

- Eckart, M.; Kories, H.; Rengers, R.; Unland, W. Application of a Numerical Model to Facilitate Mine Water Management in Large Coal Fields in Germany. In Proceedings of the IMWA Symposium “Mine Water 2004—Process, Policy and Progress”, Newcastle upon Tyne, UK, 20–25 September 2004; Jarvis, A.P., Dudgeon, B.A., Younger, P.L., Eds.; University of Newcastle: Newcastle Upon Tyne, UK, 2004; pp. 209–218. [Google Scholar]

- Balzer, I.M.R. Mine Water in the Ruhr Area-Opportunities for the Future. Min. Rep. 2019, 155, 254–261. [Google Scholar]

- Kretschmann, J. Sustainable Change of Coal-Mining Regions. Min Met. Explor. 2019, 37, 167–178. [Google Scholar] [CrossRef]

- Klinger, C. Mobilisationsverhalten von Anorganischen Schadstoffen in Der Umgebung von Untertägigen Versatzbereichen Am Beispiel von Reststoffen Aus Müllverbrennungsanlagen Im Steinkohlengebirge Des Ruhrkarbons; Rheinische Friedrich-Wilhelms-Universität Bonn: Bonn, Germany, 1993. [Google Scholar]

- Klinger, C.; Eckart, M.; Rüterkamp, P.; Steinmetz, T. Einfluss Eines Wasseranstiegs Durch Einstellung Der Wasserhaltungen Zollverein, Carolinenglück, Amalie Und AV Auf Die PCB-Und Sonstige Stoffgehalte Im Grubenwasser; Ingenieur- und Planungsbüro Lange GbR: Moers, Germany, 2019. [Google Scholar]

- Reisinger, T.; Rüde, T.R. Mass Transport of Hydraulically Stowed Residues in Adjacent Aquifers in the Ruhr Area, Germany. In Proceedings of the Mine Water and Circular Economy, IMWA 2017; Wolkersdorfer, C., Sartz, L., Sillanpää, M., Häkkinen, A., Eds.; IMWA: Lappeenranta, Finland, 2017. [Google Scholar]

- Jäger, B.; Obermann, P.; Wilke, F.L. Studie Zur Eignung von Steinkohlebergwerken Im Rechtsrheinischen Ruhrkohlenbezirk Zur Untertageverbringung von Abfall- Und Reststoffen Kurzfassung; Landesamt für Wasser und Abfall Nordrhein-Westfalen: Düsseldrof, Germany, 1991. [Google Scholar]

- Paas, N. Untersuchungen Zur Ermittlung Der Geochemischen Barriere von Gesteinen Aus Dem Umfeld Untertägiger Versatzräume Im Steinkohlenbergbau Des Ruhrkarbons; Rheinische Friedrich-Wilhelms-Universität Bonn: Bonn, Germany, 1997. [Google Scholar]

- RAG Quartals- Und Abschlussberichte Zu Den Reststoffverbringungen in Die Bergwerke Haus Aden Monopol, Hugo/Consolidation, Walsum, (1993–2004); RAG: Herne, Germany, 2005.

- Coldewey, W.G.; Semrau, L. Mine Water in the Ruhr Area (Federal Republic of Germany); University of Nottingham, Department of Mineral Resources Engineering: Nottingham, UK, 1994; pp. 613–629. [Google Scholar]

- RVR Regionalverband Ruhr. Available online: https://www.rvr.ruhr/en/about-us/ruhr-metropolis/ (accessed on 23 November 2023).

- Huske, J. Die Steinkohlenzechen Im Ruhrrevier; Deutsches Bergbau-Museum: Bochum, Germany, 2006; ISBN 3-937203-24-9. [Google Scholar]

- Eckart, M.; Gzyl, G.; Kories, H.; Metz, M.; Rengers, R.; Paul, M. Das Boxmodell-Konzept—Von Der Modellbasierten Flutungskonzeption Des Wismut-Standorts Ronneburg Zur Anwendung in Der Deutschen Steinkohle. In Proceedings of the Internationales Bergbausymposium WISMUT, Gera, Germany, 10–12 September 2007; pp. 439–446. [Google Scholar]

- Hamm, R.; Storchmann, K.H. Black Coal Mining in the Ruhr Area—Development, Political Framework, Regional Involvement and Diversification; Rheinisch-Westfaelisches Inst. fuer Wirtschaftsforschung: Essen, Germany, 1992. [Google Scholar]

- Bench, D. PCBs, Mining, and Water Pollution. In Proceedings of the Mine Design, Operations & Closure Conference, Polson, Montana, 27 April–1 May 2003; pp. 1–12. [Google Scholar]

- Rahm, H.; Obschernicat, K.; Dittmar, M.; Rosenbaum-Mertens, J.; Selent, K. Belastungen von Oberflächengewässern Und von Aktiven Grubenwassereinleitungen Mit Bergbaubürtigen PCB (Und PCB-Ersatzstoffen); Umwelt und Verbraucherschutz NRW: Recklinghausen, Germany, 2018. [Google Scholar]

- Characterization of Waste—Determination of Selected Polychlorinated Biphenyls (PCB) in Solid Waste by Gas Chromatography with Electron Capture or Mass Spectrometric Detection; DIN EN 15308; European Committee for Standardization: Brussels, Belgium, 2016.

- Wei, W.; Ma, R.; Sun, Z.; Zhou, A.; Bu, J.; Long, X.; Liu, Y. Effects of Mining Activities on the Release of Heavy Metals (HMs) in a Typical Mountain Headwater Region, the Qinghai-Tibet Plateau in China. Int. J. Environ. Res. Public Health 2018, 15, 1987. [Google Scholar] [CrossRef] [PubMed]

- Kauppila, T.; Bellenfant, G.; Solismaa, L.; Mittelstädt, P. Digitalisation of Continuous Mine Closure Planning and Management: An EIT RawMaterials Initiative. In Mine Closure 2019: Proceedings of the 13th International Conference on Mine Closure; Australian Centre for Geomechanics: Perth, Australia, 2019; pp. 1023–1030. [Google Scholar]

| Waste Type/Contamination Source | Types of Contamination |

|---|---|

| Exposed rock in shafts and galleries | AMD (acid mine drainage), metals |

| Fractured rock and residual coal in goaf areas, coal mine spoil | AMD, metals, coal fines and dust |

| Abandoned equipment and machinery | Oil, solvents and lubricants, PCB, PCDM (polychlorinated diphenylmethanes), plasticizers from the conveyor belts (mostly remained underground) and many more |

Backfill materials of various origin, e.g.,:

| Metals, salts, etc. |

| Gallery supporting material/cables | Metals (Fe, Cu) |

| Mine water and EWIW | Salts (Cl, NO3, SO4, etc.), metals, radionuclides |

| Main Water Province | Mine Water Pumping Stations in 2006 | Mine Water Pumping Stations after Implementation of Mine Water Management Plan |

|---|---|---|

| West | West, Walsum, Concordia | Walsum |

| Central | Amalie, Emschermulde, Zollverein, Prosper-Haniel, Lohberg, Carolinenglück, Lippe, Auguste Victoria | Lohberg |

| East | Hansa, Haus Aden, East | Haus Aden |

| Ruhr | Robert Müser, Friedlicher Nachbar, Heinrich | Robert Müser, Friedlicher Nachbar, Heinrich |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mittelstädt, P.; Pollmann, N.; Karimzadeh, L.; Kories, H.; Klinger, C. Wastes in Underground Coal Mines and Their Behavior during Mine Water Level Rebound—A Review. Minerals 2023, 13, 1496. https://doi.org/10.3390/min13121496

Mittelstädt P, Pollmann N, Karimzadeh L, Kories H, Klinger C. Wastes in Underground Coal Mines and Their Behavior during Mine Water Level Rebound—A Review. Minerals. 2023; 13(12):1496. https://doi.org/10.3390/min13121496

Chicago/Turabian StyleMittelstädt, Philip, Nele Pollmann, Lotfollah Karimzadeh, Holger Kories, and Christoph Klinger. 2023. "Wastes in Underground Coal Mines and Their Behavior during Mine Water Level Rebound—A Review" Minerals 13, no. 12: 1496. https://doi.org/10.3390/min13121496

APA StyleMittelstädt, P., Pollmann, N., Karimzadeh, L., Kories, H., & Klinger, C. (2023). Wastes in Underground Coal Mines and Their Behavior during Mine Water Level Rebound—A Review. Minerals, 13(12), 1496. https://doi.org/10.3390/min13121496