Cracking of Gem Opals

Abstract

:1. Introduction

1.1. What Is Opal?

1.2. Water in Opals

1.3. Instability of Opals by Cracking

2. Materials and Methods

3. Results

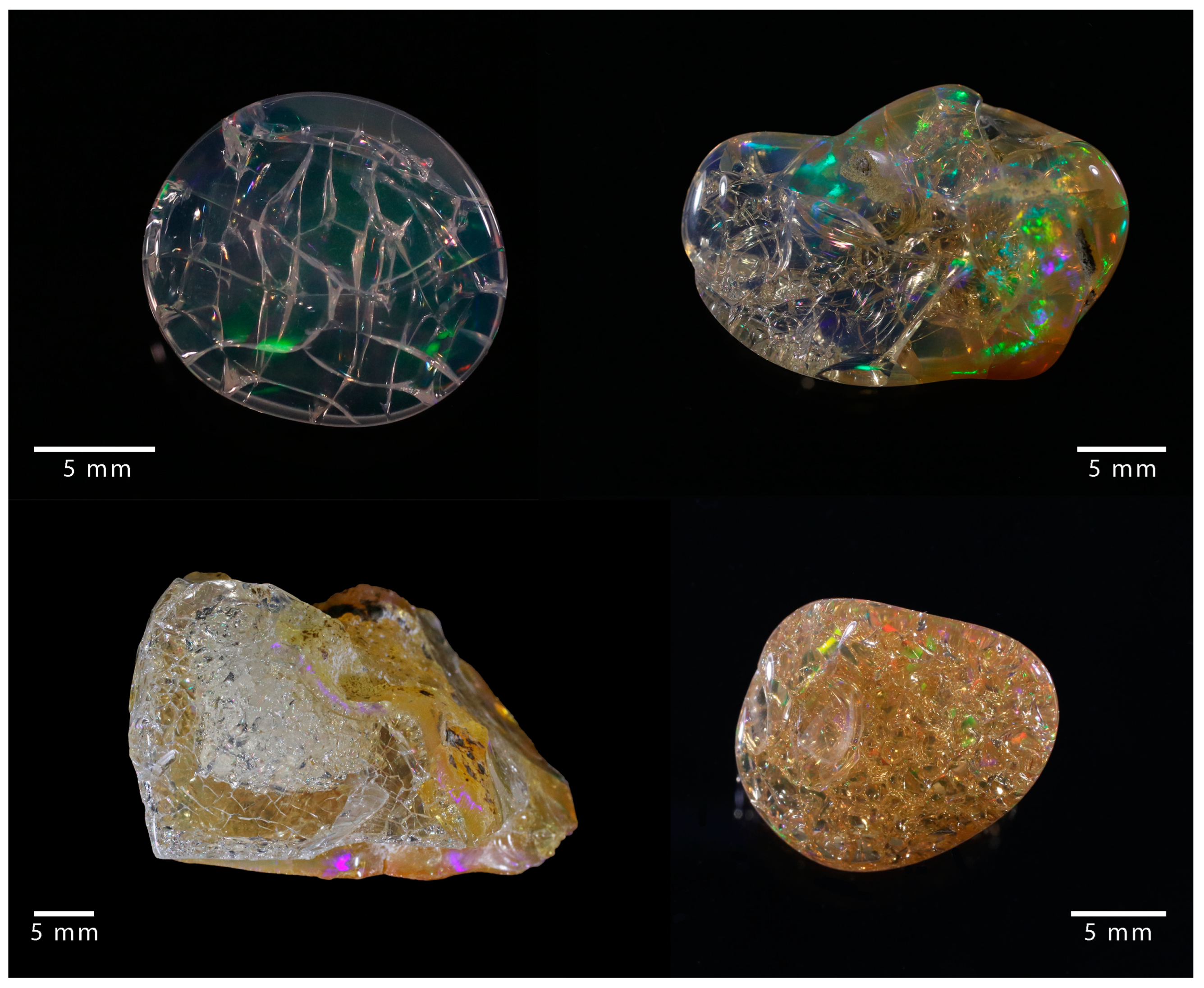

3.1. Visual Examinations

3.2. Thermogravimetric Analysis (Air-Stored Samples)

- No loss of water until 200–400 °C, and most dehydration (up to 90%) occurred between 300 °C and 700 °C (black trace). Observed for samples 86.2, 785, 928, 1040, 1543a, 1543b, 1545, 1548, 1552a, 1552b, and 1552d;

- Loss of water starts as soon as heating starts, and most water is lost under 300 °C (red dashed trace). Observed for samples 208, FT1111, VTB, WT86, 521, YM12, and 43l.

- Progressive irregular loss of water from room temperatures up to 900 °C for sample 1551 (blue trace).

3.3. Raman Spectroscopy

4. Discussion

4.1. Stress Resistance of Opal

4.2. Cracking Processes

- (i)

- Cracking for air-stored samples, occurring at high temperatures (>250 °C) without any other effects;

- (ii)

- Cracking in water-stored samples, occurring at “low” temperature (<150 °C) and developing anisotropic features and peak shifts in the Raman spectra.

4.2.1. Decrepitation

4.2.2. Drying Shrinkage

- The tension induced by the fluid interface tends to increase the stress at the drying front; thus, as evaporation is initiated at the surface, the surface tends to contract faster than the interior, producing a cracked surface, as is commonly observed [1,63]. We could assume that if the drying front is already inside the sample but the evaporation rate rapidly increases, such as when opal is initially extracted, the stress strongly increases. This may result in a cracked volume inside a transparent opal, with a shape related to the outside shape of the opal piece and, hence, to the shape of the drying front [1].

4.3. Practical Considerations

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Rondeau, B.; Fritsch, E.; Mazzero, F.; Gauthier, J. Opal – The Craze for Stability. Color 2011, 4, 2–5. [Google Scholar]

- Paris, M.; Fritsch, E.; Aguilar-Reyes, B. 1H, 29Si and 27Al NMR study of the destabilization process of a paracrystalline opal from Mexico. J. Non. Cryst. Solids 2007, 353, 1650–1656. [Google Scholar] [CrossRef]

- Aguilar-Reyes, B. Etude microstructurale des opales: Application à la déstabilisation par blanchissement. Ph.D. Thesis, Université de Nantes, Nantes, France, 2004. [Google Scholar]

- Johnson, M.L.; Kammerling, R.C.; Deghionno, D.G.; Koivula, J.I. Opal from Shewa province, Ethiopia. Gems Gemol. 1996, 32, 112–120. [Google Scholar] [CrossRef]

- Smith, K.L. Opals from Opal Butte, Oregon. Gems Gemol. 1988, 24, 229–236. [Google Scholar] [CrossRef]

- Pearson, G. Role of Water in Cracking of Opal. Aust. Gemol. 1985, 15, 435–445. [Google Scholar]

- Jones, J.B.; Segnit, E.R. Nature of Opal Part I: Nomenclature and constituent phases. J. Geol. Soc. Aust. 1971, 18, 57–68. [Google Scholar] [CrossRef]

- Fröhlich, F. The opal-CT nanostructure. J. Non. Cryst. Solids 2020, 533, 119938. [Google Scholar] [CrossRef]

- Elzea, J.M.; Rice, S.B. Tem and X-Ray Diffraction Evidence for Cristobalite and Tridymite Stacking Sequences in Opal. Clays Clay Miner. 1996, 44, 492–500. [Google Scholar] [CrossRef]

- Rice, S.B.; Freund, H.; Huang, W.-L.; Clouse, J.A.; Isaacs, C.M. Application of Fourier Transform Infrared Spectroscopy to Silica Diagenesis: The Opal-A to Opal-CT Transformation. SEPM J. Sediment. Res. 1995, 65A, 639–647. [Google Scholar] [CrossRef]

- Wilson, M.J.; Russell, J.D.; Tait, J.M. A new interpretation of the structure of disordered α-cristobalite. Contrib. to Mineral. Petrol. 1974, 47, 1–6. [Google Scholar] [CrossRef]

- Langer, K.; Flörke, O.W.W. Near infrared absorption spectra (4000-9000 cm−1) of opals and the role of “water” in these SiO2-nH2O minerals. Fortschritte der Mineral. 1974, 52, 17–51. [Google Scholar]

- Göttlicher, J.; Pentinghaus, H.J.; Himmel, B. On the Microstructure of Geyserites and Hyalites, Natural Hydrous Forms of Silica. J. Sol-Gel Sci. Technol. 1998, 13, 85–88. [Google Scholar] [CrossRef]

- Flörke, O.W. Transport and Deposition of SiO2 with H2O under Supercritical Conditions. Krist. Und Tech. 1972, 7, 159–166. [Google Scholar] [CrossRef]

- Plumeré, N.; Ruff, A.; Speiser, B.; Feldmann, V.; Mayer, H.A. Stöber silica particles as basis for redox modifications: Particle shape, size, polydispersity, and porosity. J. Colloid Interface Sci. 2012, 368, 208–219. [Google Scholar] [CrossRef]

- Meier, M.; Ungerer, J.; Klinge, M.; Nirschl, H. Synthesis of nanometric silica particles via a modified Stöber synthesis route. Colloids Surfaces A Physicochem. Eng. Asp. 2018, 538, 559–564. [Google Scholar] [CrossRef]

- Stöber, W.; Fink, A.; Bohn, E. Controlled growth of monodisperse silica spheres in the micron size range. J. Colloid Interface Sci. 1968, 26, 62–69. [Google Scholar] [CrossRef]

- Gaillou, E.; Fritsch, E.; Aguilar-Reyes, B.; Rondeau, B.; Post, J.; Barreau, A.; Ostroumov, M. Common gem opal: An investigation of micro- to nano-structure. Am. Mineral. 2008, 93, 1865–1873. [Google Scholar] [CrossRef]

- Darragh, P.J.; Gaskin, A.J.; Terrell, B.C.; Sanders, J.V. Origin of Precious Opal. Nature 1966, 209, 13–16. [Google Scholar] [CrossRef]

- Darragh, J.; Perdrix, J.L. Precious opal-developments towards synthesis. Aust. Gemol. 1973, 11, 17–21. [Google Scholar]

- Jones, J.B.; Sanders, J.V.; Segnit, E.R. Structure of Opal. Nature 1964, 204, 990–991. [Google Scholar] [CrossRef]

- Smallwood, A.G. A preliminary investigation of precious opal by laser Raman spectroscopy. Aust. Gemol. 2000, 20, 363–366. [Google Scholar]

- Ostrooumov, M.; Fritsch, E.; Lasnier, B.; Lefrant, S. Spectres Raman des opales: Aspect diagnostique et aide à la classification. Eur. J. Mineral. 1999, 11, 899–908. [Google Scholar] [CrossRef]

- Curtis, N.J.; Gascooke, J.R.; Johnston, M.R.; Pring, A. A Review of the Classification of Opal with Reference to Recent New Localities. Minerals 2019, 9, 299. [Google Scholar] [CrossRef] [Green Version]

- Adamo, I.; Ghisoli, C.; Caucia, F. A contribution to the study of FTIR spectra of opals. Neues Jahrb. Mineral. Abhandlungen 2010, 187, 63–68. [Google Scholar] [CrossRef]

- Wilson, M.J. The structure of opal-CT revisited. J. Non. Cryst. Solids 2014, 405, 68–75. [Google Scholar] [CrossRef]

- Chauviré, B.; Rondeau, B.; Mangold, N. Near infrared signature of opal and chalcedony as a proxy for their structure and formation conditions. Eur. J. Mineral. 2017, 29, 409–421. [Google Scholar] [CrossRef]

- Sun, V.Z.; Milliken, R.E. Distinct Geologic Settings of Opal-A and More Crystalline Hydrated Silica on Mars. Geophys. Res. Lett. 2018, 45, 10–221. [Google Scholar] [CrossRef] [Green Version]

- Brown, L.D.; Ray, A.S.; Thomas, P.S. 29Si and 27Al NMR study of amorphous and paracrystalline opals from Australia. J. Non. Cryst. Solids 2003, 332, 242–248. [Google Scholar] [CrossRef]

- Curtis, N.J.; Gascooke, J.R.; Johnston, M.R.; Pring, A. 29 Si Solid-State NMR Analysis of Opal-AG, Opal-AN and Opal-CT: Single Pulse Spectroscopy and Spin-Lattice T1 Relaxometry. Minerals 2022, 12, 323. [Google Scholar] [CrossRef]

- Herdianita, N.R.; Browne, P.R.L.; Rodgers, K.A.; Campbell, K.A. Mineralogical and textural changes accompanying ageing of silica sinter. Miner. Depos. 2000, 35, 48–62. [Google Scholar] [CrossRef]

- Jones, B.; Renaut, R.W. Formation of silica oncoids around geysers and hot springs at El Tatio, northern Chile. Sedimentology 1997, 44, 287–304. [Google Scholar] [CrossRef]

- Vysotsky, S.V.; Barkar, A.V.; Kuryavy, V.G.; Chusovitin, E.A.; Karabtsov, A.A.; Safronov, P.P. Hydrothermal noble opal: Structure and genesis. Geol. Ore Depos. 2010, 52, 815–820. [Google Scholar] [CrossRef]

- Vysotskiy, S.V.; Ignatiev, a.V.; Khlestunova, A.G.; Velivetskaya, T.A.; Okrugin, A.S. Peculiarities of the oxygen isotope ratio in precious opals. Russ. J. Pacific Geol. 2013, 7, 427–430. [Google Scholar] [CrossRef]

- Rey, P.F. Opalisation of the Great Artesian Basin (central Australia): An Australian story with a Martian twist. Aust. J. Earth Sci. 2013, 60, 291–314. [Google Scholar] [CrossRef]

- Townsend, I.J. The geology of Australian opal deposits. Aust. Gemol. 2001, 21, 34–37. [Google Scholar]

- Spencer, R.J.; Levinson, A.A.; Koivula, J.I. Opal from Quérétaro, Mexico: Fluid inclusion study. Gems Gemol. 1992, 28, 28. [Google Scholar] [CrossRef] [Green Version]

- Rondeau, B.; Cenki-Tok, B.B.B.; Fritsch, E.; Mazzero, F.; Gauthier, J.-P.; Bodeur, Y.; Bekele, E.; Gaillou, E.; Ayalew, D. Geochemical and petrological characterization of gem opals from Wegel Tena, Wollo, Ethiopia: Opal formation in an Oligocene soil. Geochemistry Explor. Environ. Anal. 2012, 12, 93–104. [Google Scholar] [CrossRef]

- Chauviré, B.; Rondeau, B.; Mazzero, F.; Ayalew, D. The Precious Opal Deposit At Wegel Tena, Ethiopia: Formation Via Successive Pedogenesis Events. Can. Mineral. 2017, 55, 701–723. [Google Scholar] [CrossRef]

- Chauviré, B.; Rondeau, B.; Alexandre, A.; Chamard-Bois, S.; La, C.; Mazzero, F. Pedogenic origin of precious opals from Wegel Tena (Ethiopia): Evidence from trace elements and oxygen isotopes. Appl. Geochemistry 2019, 101, 127–139. [Google Scholar] [CrossRef]

- Darragh, B.P.J.; Gaskin, A.J. The nature and origin of opal. Aust. Gemol. 1966, 8, 5–9. [Google Scholar]

- Fritsch, E.; Ostrooumov, M.; Rondeau, B.; Barreau, A.; Albertini, D.; Marie, A.-M.; Lasnier, B.; Wery, J. Mexican Gem Opals: Nano- and micro-structure, origin of colour, comparison with other common opals of gemological significance. Aust. Gemol. 2002, 21, 230–233. [Google Scholar]

- Fritsch, E.; Gaillou, E.; Rondeau, B.; Barreau, A.; Albertini, D.; Ostroumov, M. The nanostructure of fire opal. J. Non. Cryst. Solids 2006, 352, 3957–3960. [Google Scholar] [CrossRef]

- Darragh, P.J.; Sanders, J. V The origin of colour in opal. Aust. Gemol. 1965, 7, 9–12. [Google Scholar]

- Graetsch, H.; Flörke, O.W.; Miehe, G. The nature of water in chalcedony and opal-C from brazilian agate geodes. Phys. Chem. Miner. 1985, 12, 300–306. [Google Scholar] [CrossRef]

- Boboň, M.; Christy, A.A.; Kluvanec, D.; Illášová, L. State of water molecules and silanol groups in opal minerals: A near infrared spectroscopic study of opals from Slovakia. Phys. Chem. Miner. 2011, 38, 809–818. [Google Scholar] [CrossRef]

- Smallwood, A.G.; Thomas, P.S.; Ray, A.S. Characterisation of the dehydration of australian sedimentary and volcanic precious opal by thermal methods. J. Therm. Anal. Calorim. 2008, 92, 91–95. [Google Scholar] [CrossRef]

- Brown, L.D.; Ray, A.S.; Thomas, P.S.; Guerbois, J.P. Thermal characteristics of Australian sedimentary opals. J. Therm. Anal. Calorim. 2002, 68, 31–36. [Google Scholar] [CrossRef]

- Smallwood, A.G.; Thomas, P.S.; Ray, A.S. The thermophysical properties of australian opal. In Proceedings of the 9th International Congress for Applied Mineralogy, Bisbane, Queensland, Australia, 8–10 September 2008; pp. 557–565. [Google Scholar]

- Thomas, P.S.; Guerbois, J.-P.; Smallwood, A.G. Low temperature DSC characterisation of water in opal. J. Therm. Anal. Calorim. 2013, 113, 1255–1260. [Google Scholar] [CrossRef]

- Thomas, P.S.; Šesták, J.; Heide, K.; Fueglein, E.; Šimon, P. Thermal properties of Australian sedimentary opals and Czech moldavites. J. Therm. Anal. Calorim. 2010, 99, 861–867. [Google Scholar] [CrossRef]

- Thomas, P.; Chauviré, B.; Flower-Donaldson, K.; Aldridge, L.; Smallwood, A.; Liu, B. FT-NIR and DSC characterisation of water in opal. Ceram. Int. 2020, 46, 29443–29450. [Google Scholar] [CrossRef]

- Graetsch, H. Structural characteristics of opaline and microcrystalline silica minerals. Rev. Mineral. 1994, 29, 209–232. [Google Scholar]

- Gaillou, E. Relations entre nanostructure, propriétés physiques et mode de formation des opales A et CT. Ph.D. Thesis, Université de Nantes, Nantes, France, 2016. [Google Scholar]

- Thomas, P.S.; Aldridge, L.; Smallwood, A. Water in opal - what can it tell us ? Color 2019, 41, 63–69. [Google Scholar]

- Adams, S.J.; Hawkes, G.E.; Curzon, E.H. A solid state 29Si nuclear magnetic resonance study of opal and other hydrous silicas. Am. Mineral. 1991, 76, 1863–1871. [Google Scholar]

- Bayliss, P.; Males, P.A. The Mineralogical Similarity of Precious and Common Opal from Australia. Mineral. Mag. 1965, 35, 429–431. [Google Scholar] [CrossRef]

- Chauviré, B.; Thomas, P.S. DSC of natural opal: Insights into the incorporation of crystallisable water in the opal microstructure. J. Therm. Anal. Calorim. 2020, 140, 2077–2085. [Google Scholar] [CrossRef]

- De Jong, B.H.W.S.; Van Hoek, J.; Veeman, W.S.; Manson, D. V X-ray diffraction and 29Si magic-angle-spinning NMR of opals; incoherent long-and short-range order in opal-CT. Am. Mineral. 1987, 72, 1195–1203. [Google Scholar]

- Gallacher, A.D. Geochemistry of Sedimentary Opal, Hebel, Southern Queensland; University of Melbourne: Melbourne, Australia, 2001. [Google Scholar]

- Segnit, E.R.; Stevens, T.J.; Jones, J.B. The role of water in opal. J. Geol. Soc. Aust. 1965, 12, 211–226. [Google Scholar] [CrossRef]

- Chauviré, B.; Pineau, M.; Quirico, E.; Beck, P. Near infrared signature of opaline silica at Mars-relevant pressure and temperature. Earth Planet. Sci. Lett. 2021, 576, 117239. [Google Scholar] [CrossRef]

- Filin, S.V.; Puzynin, A.I. Prevention of cracking in Ethiopian opal. Aust. Gemmol. 2009, 23, 579–582. [Google Scholar]

- Griffith, A.A. VI. The phenomena of rupture and flow in solids. Philos. Trans. R. Soc. London. Ser. A, Contain. Pap. a Math. or Phys. Character 1921, 221, 163–198. [Google Scholar] [CrossRef] [Green Version]

- Irwin, G.R. Analysis of Stresses and Strains Near the End of a Crack Traversing a Plate. J. Appl. Mech. 1957, 24, 361–364. [Google Scholar] [CrossRef]

- Orowan, E. Fracture and strength of solids. Reports Prog. Phys. 1949, 12, 185–232. [Google Scholar] [CrossRef]

- Simonton, T.C.; Roy, R.; Komarneni, S.; Breval, E. Microstructure and mechanical properties of synthetic opal: A chemically bonded ceramic. J. Mater. Res. 1986, 1, 667–674. [Google Scholar] [CrossRef]

- Rimsza, J.M.; Jones, R.E.; Criscenti, L.J. Crack propagation in silica from reactive classical molecular dynamics simulations. J. Am. Ceram. Soc. 2018, 101, 1488–1499. [Google Scholar] [CrossRef]

- Lucas, J.P.; Moody, N.R.; Robinson, S.L.; Hanrock, J.; Hwang, R.Q. Determining fracture toughness of vitreous silica glass. Scr. Metall. Mater. 1995, 32, 743–748. [Google Scholar] [CrossRef]

- Lee, M.; Brun, M.K. Fracture toughness measurement by microindentation and three-point bend methods. Mater. Sci. Eng. 1988, 105–106, 369–375. [Google Scholar] [CrossRef]

- Wiederhorn, S.M. Fracture Surface Energy of Glass. J. Am. Ceram. Soc. 1969, 52, 99–105. [Google Scholar] [CrossRef]

- Thomas, P.S.; Smallwood, A.S.; Ray, A.S.; Briscoe, B.J.; Parsonage, D. Nanoindentation hardness of banded Australian sedimentary opal. J. Phys. D Appl. Phys. 2008, 41, 074028. [Google Scholar] [CrossRef]

- Beake, B.D.; Smith, J.F. High-temperature nanoindentation testing of fused silica and other materials. Philos. Mag. A 2002, 82, 2179–2186. [Google Scholar] [CrossRef]

- Zeng, K.; Chiu, C.H. An analysis of load-penetration curves from instrumented indentation. Acta Mater. 2001, 49, 3539–3551. [Google Scholar] [CrossRef]

- Akram, A.; Briscoe, B.J.; Adams, M.J.; Johnson, S.A. Nanoindentation of polymer-bound silica agglomerate layers. Philos. Mag. A Phys. Condens. Matter, Struct. Defects Mech. Prop. 2002, 82, 2103–2112. [Google Scholar] [CrossRef]

- Marszewski, M.; Dashti, A.; McNeil, P.E.; Fox, M.; Wall, V.; Butts, D.M.; King, S.C.; Kashanchi, G.N.; Tolbert, S.H.; Dunn, B.; et al. Elastic and plastic mechanical properties of nanoparticle-based silica aerogels and xerogels. Microporous Mesoporous Mater. 2022, 330, 111569. [Google Scholar] [CrossRef]

- Scherer, G.W. Bending of gel beams: Method for characterizing elastic properties and permeability. J. Non. Cryst. Solids 1992, 142, 18–35. [Google Scholar] [CrossRef]

- Rimsza, J.M.; Jones, R.E.; Criscenti, L.J. Fracture Toughness of Amorphous Silica from Atomistic Scale Simulations; Sandia National Lab.(SNL-NM): Albuquerque, NM, USA, 2017. [Google Scholar]

- Rimsza, J.M.; Jones, R.E.; Criscenti, L.J. Surface Structure and Stability of Partially Hydroxylated Silica Surfaces. Langmuir 2017, 33, 3882–3891. [Google Scholar] [CrossRef]

- Raman, C.V. The optical anisotropy and heterogeneity of vitreous silica. Proc. Indian Acad. Sci. Sect. A 1950, 31, 141–148. [Google Scholar] [CrossRef]

- Galbraith, J.; Chapman, L.; Zwanziger, J.W.; Aldridge, M.; Kieffer, J. Elasto-Optic Coefficients of Borate, Phosphate, and Silicate Glasses: Determination by Brillouin Spectroscopy. J. Phys. Chem. C 2016, 120, 21802–21810. [Google Scholar] [CrossRef]

- Mueller, H. Theory of photoelasticity in amorphous solids. J. Appl. Phys. 1935, 6, 179–184. [Google Scholar] [CrossRef]

- Scherer, G.W. Stress-induced index profile distortion in optical waveguides: Correction. Appl. Opt. 1980, 19, 2656. [Google Scholar] [CrossRef]

- Howell, D. Strain-induced birefringence in natural diamond: A review. Eur. J. Mineral. 2012, 24, 575–585. [Google Scholar] [CrossRef]

- Tallant, D.R.; Michalske, T.A.; Smith, W.L. The effects of tensile stress on the Raman spectrum of silica glass. J. Non. Cryst. Solids 1988, 106, 380–383. [Google Scholar] [CrossRef]

- Trouilh, M.; Hourdet, D.; Marcellan, A.; Colomban, P. Analyse Raman in situ de la déformation d’un hydrogel nanocomposite. Rev. des Compos. des matériaux avancés 2014, 24, 67–79. [Google Scholar] [CrossRef]

- Roedder, E.; Bodnar, R.J. Geologic Pressure Determinations from Fluid Inclusion Studies. Annu. Rev. Earth Planet. Sci. 1980, 8, 263–301. [Google Scholar] [CrossRef]

- Thomas, P.S.; Šimon, P.; Smallwood, A.G.; Ray, A.S. Estimation of the diffusion coefficient of water evolved during the non-isothermal dehydration of Australian sedimentary opal. J. Therm. Anal. Calorim. 2007, 88, 231–235. [Google Scholar] [CrossRef]

- Smallwood, A.; Thomas, P.S.; Ray, A.S.; Šimon, P. Application of a Fickian model of diffusion to the dehydration of graded specimens of a precious Australian sedimentary opal derived from Coober Pedy. J. Therm. Anal. Calorim. 2009, 97, 685–688. [Google Scholar] [CrossRef]

- Jones, J.B.; Segnit, E.R. Water in Sphere-Type Opal. Mineral. Mag. 1969, 37, 357–361. [Google Scholar] [CrossRef] [Green Version]

- Smallwood, A.; Thomas, P.S.; Ray, A.S.; Šimon, P. TMA and SEM characterization of the thermal dehydration of australian sedimentary opal. J. Therm. Anal. Calorim. 2007, 88, 185–188. [Google Scholar] [CrossRef]

- Hansteen, T.H.; Klugel, A. Fluid Inclusion Thermobarometry as a Tracer for Magmatic Processes. Rev. Mineral. Geochemistry 2008, 69, 143–177. [Google Scholar] [CrossRef]

- Chi, G.; Diamond, L.W.; Lu, H.; Lai, J.; Chu, H. Common problems and pitfalls in fluid inclusion study: A review and discussion. Minerals 2021, 11, 7. [Google Scholar] [CrossRef]

- Shi, L.; Mao, S. Applications of the IAPWS-95 formulation in fluid inclusion and mineral-fluid phase equilibria. Geosci. Front. 2012, 3, 51–58. [Google Scholar] [CrossRef] [Green Version]

- Williams, L.A.; Crerar, D.A. Silica Diagenesis, II. General Mechanisms. SEPM J. Sediment. Res. 1985, Vol. 55, 312–321. [Google Scholar] [CrossRef]

- Williams, L.A.; Parks, G.A.; Crerar, D.A. Silica Diagenesis, I. Solubility Controls. SEPM J. Sediment. Res. 1985, 55, 301–311. [Google Scholar] [CrossRef]

- Jones, B. Siliceous sinters in thermal spring systems: Review of their mineralogy, diagenesis, and fabrics. Sediment. Geol. 2021, 413, 105820. [Google Scholar] [CrossRef]

- Brinker, C.J.; Scherer, G.W. Sol-Gel Science—The Physics and Chemistry of Sol-Gel-Processing; Academic Press, Boston, MA, USA, 1990; ISBN 0-12-134970-5. [Google Scholar]

- Scherer, G.W. Recent progress in drying of gels. J. Non. Cryst. Solids 1992, 147–148, 363–374. [Google Scholar] [CrossRef]

- Scherer, G.W. Drying Mechanics of Gels. MRS Proc. 1986, 73, 225. [Google Scholar] [CrossRef]

- Scherer, G.W. Theory of Drying. J. Am. Ceram. Soc. 1990, 73, 3–14. [Google Scholar] [CrossRef]

- Scherer, G.W. Drying gels. VIII. Revision and review. J. Non. Cryst. Solids 1989, 109, 171–182. [Google Scholar] [CrossRef]

- Bisson, A.; Rigacci, A.; Lecomte, D.; Rodier, E.; Achard, P. Drying of Silica Gels to Obtain Aerogels:Phenomenology and Basic Techniques. Dry. Technol. 2003, 21, 593–628. [Google Scholar] [CrossRef]

- Smith, D.M.; Scherer, G.W.; Anderson, J.M. Shrinkage during drying of silica gel. J. Non. Cryst. Solids 1995, 188, 191–206. [Google Scholar] [CrossRef]

- Siouffi, A.M. Silica gel-based monoliths prepared by the sol-gel method: Facts and figures. J. Chromatogr. A 2003, 1000, 801–818. [Google Scholar] [CrossRef] [PubMed]

- Satha, H.; Atamnia, K.; Despetis, F. Effect of Drying Processes on the Texture of Silica Gels. J. Biomater. Nanobiotechnol. 2013, 4, 17–21. [Google Scholar] [CrossRef] [Green Version]

- Scherer, G.W. Stress and strain during supercritical drying. J. Sol-Gel Sci. Technol. 2019, 90, 8–19. [Google Scholar] [CrossRef]

- Shahzamani, M.; Bagheri, R.; Masoomi, M.; Haghgoo, M.; Dourani, A. Effect of drying method on the structure and porous texture of silica-polybutadiene hybrid gels: Supercritical vs. ambient pressure drying. J. Non. Cryst. Solids 2017, 460, 119–124. [Google Scholar] [CrossRef]

- Strøm, R.A.; Masmoudi, Y.; Rigacci, A.; Petermann, G.; Gullberg, L.; Chevalier, B.; Einarsrud, M.A. Strengthening and aging of wet silica gels for up-scaling of aerogel preparation. J. Sol-Gel Sci. Technol. 2007, 41, 291–298. [Google Scholar] [CrossRef]

- Pajonk, G.M. Drying methods preserving the textural properties of gels. Le J. Phys. Colloq. 1989, 24, C4-13–C4-22. [Google Scholar] [CrossRef]

- Pillai, R.; Jariwala, C.; Kumar, S. Influence of pH on the Spherical Shape and Particle Size of the Freeze Drying Assisted Sol-gel Derived Silica Nano-Particles (SNPs). Imp. J. Interdiscip. Res. IJIR 2017, 3, 2347–2353. [Google Scholar]

- Scherer, G.W. Stress from re-immersion of partially dried gel. J. Non. Cryst. Solids 1997, 212, 268–280. [Google Scholar] [CrossRef]

- Adachi, T.; Sakka, S. Microstructural Changes in Sol-Gel Derived Silica Gel Monolith with Heating as Revealed by the Crack Formation on Immersion in Water. J. Ceram. Soc. Japan 1989, 97, 203–207. [Google Scholar] [CrossRef] [Green Version]

- Gunnarsson, I.; Arnórsson, S. Amorphous silica solubility and the thermodynamic properties of H4SiO°4 in the range of 0° to 350°C at Psat. Geochim. Cosmochim. Acta 2000, 64, 2295–2307. [Google Scholar] [CrossRef]

- Alexander, G.B.; Heston, W.M.; Iler, R.K. The Solubility of Amorphous Silica in Water. J. Phys. Chem. 1954, 58, 453–455. [Google Scholar] [CrossRef]

- Woignier, T.; Primera, J.; Alaoui, A.; Etienne, P.; Despestis, F.; Calas-Etienne, S. Mechanical properties and brittle behavior of silica aerogels. Gels 2015, 1, 256–275. [Google Scholar] [CrossRef] [PubMed] [Green Version]

| Variety | Sample | Geological Origin |

|---|---|---|

| Opal-AG | 785 | Honduras |

| 86.2 | Kashau, Slovakia | |

| 1040 | Coober Pedy, South Australia, Australia | |

| Opal-CT | 928 | Mali |

| 1545 | Unknown | |

| 1548 | Fougère, Brittany, France | |

| 1543a | San Martin, Jalisco, Mexico | |

| 1543b | ||

| 1552a | ||

| 1552b | ||

| 1552d | ||

| 43l | Humbolt County, USA | |

| 521 | Mezezo, Ethiopia | |

| 1551 | ||

| YM12 | ||

| 208 | Wegel Tena, Ethiopia | |

| FT1111 | ||

| VTB | ||

| WT86 | ||

| KOK01 * | ||

| KOK03 * | ||

| KOK04 * | ||

| KOK05 * | ||

| CH01 * | ||

| CH0p * | ||

| AN02 * |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chauviré, B.; Mollé, V.; Guichard, F.; Rondeau, B.; Thomas, P.S.; Fritsch, E. Cracking of Gem Opals. Minerals 2023, 13, 356. https://doi.org/10.3390/min13030356

Chauviré B, Mollé V, Guichard F, Rondeau B, Thomas PS, Fritsch E. Cracking of Gem Opals. Minerals. 2023; 13(3):356. https://doi.org/10.3390/min13030356

Chicago/Turabian StyleChauviré, Boris, Valentin Mollé, Florine Guichard, Benjamin Rondeau, Paul Stephen Thomas, and Emmanuel Fritsch. 2023. "Cracking of Gem Opals" Minerals 13, no. 3: 356. https://doi.org/10.3390/min13030356