Probing the Pore Structure of the Berea Sandstone by Using X-ray Micro-CT in Combination with ImageJ Software

Abstract

:1. Introduction

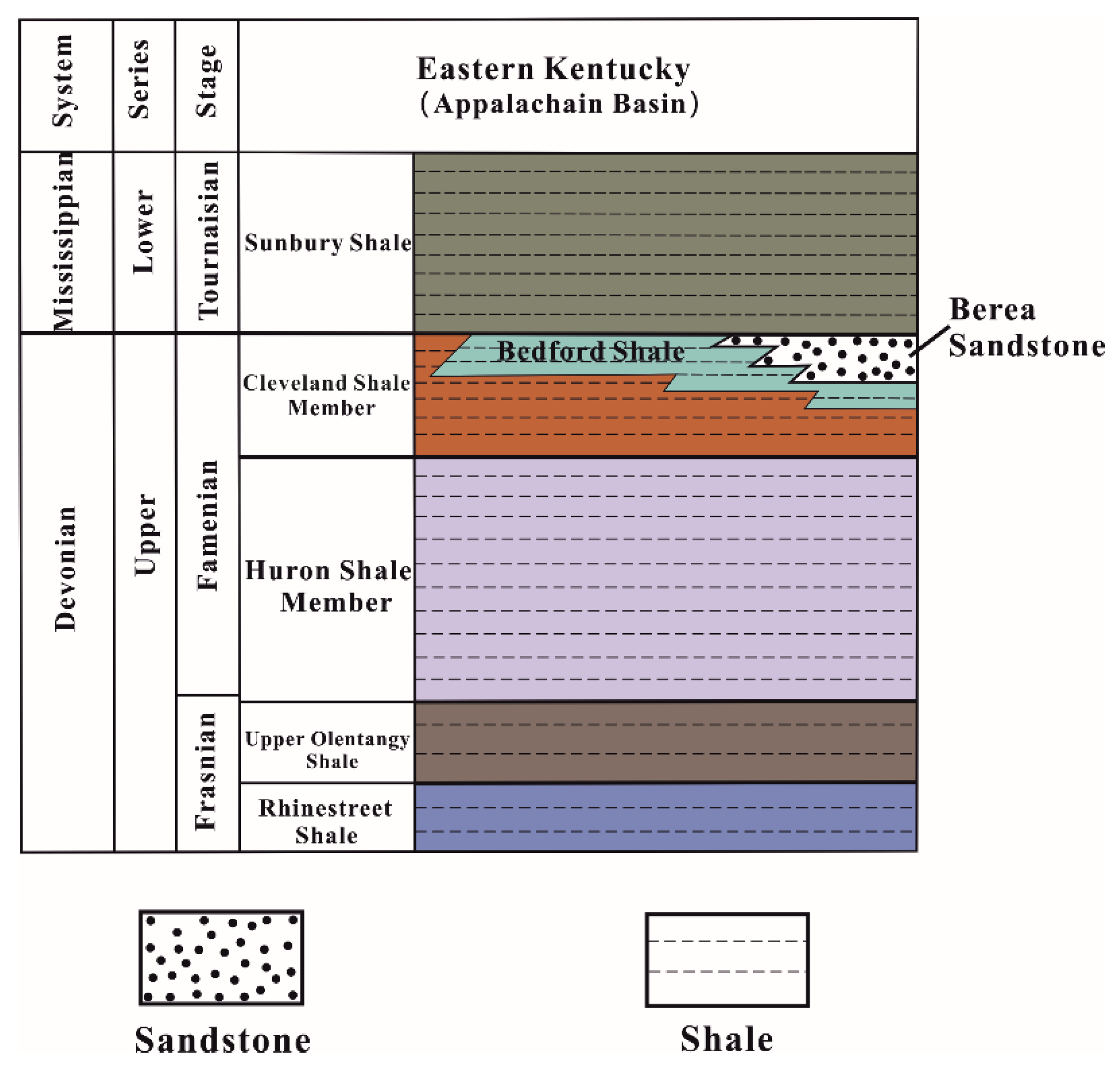

2. Geological Setting

3. Samples

4. Methods

4.1. X-ray Micro-CT

4.2. Workflow of Image Processing and Analysis

5. Results

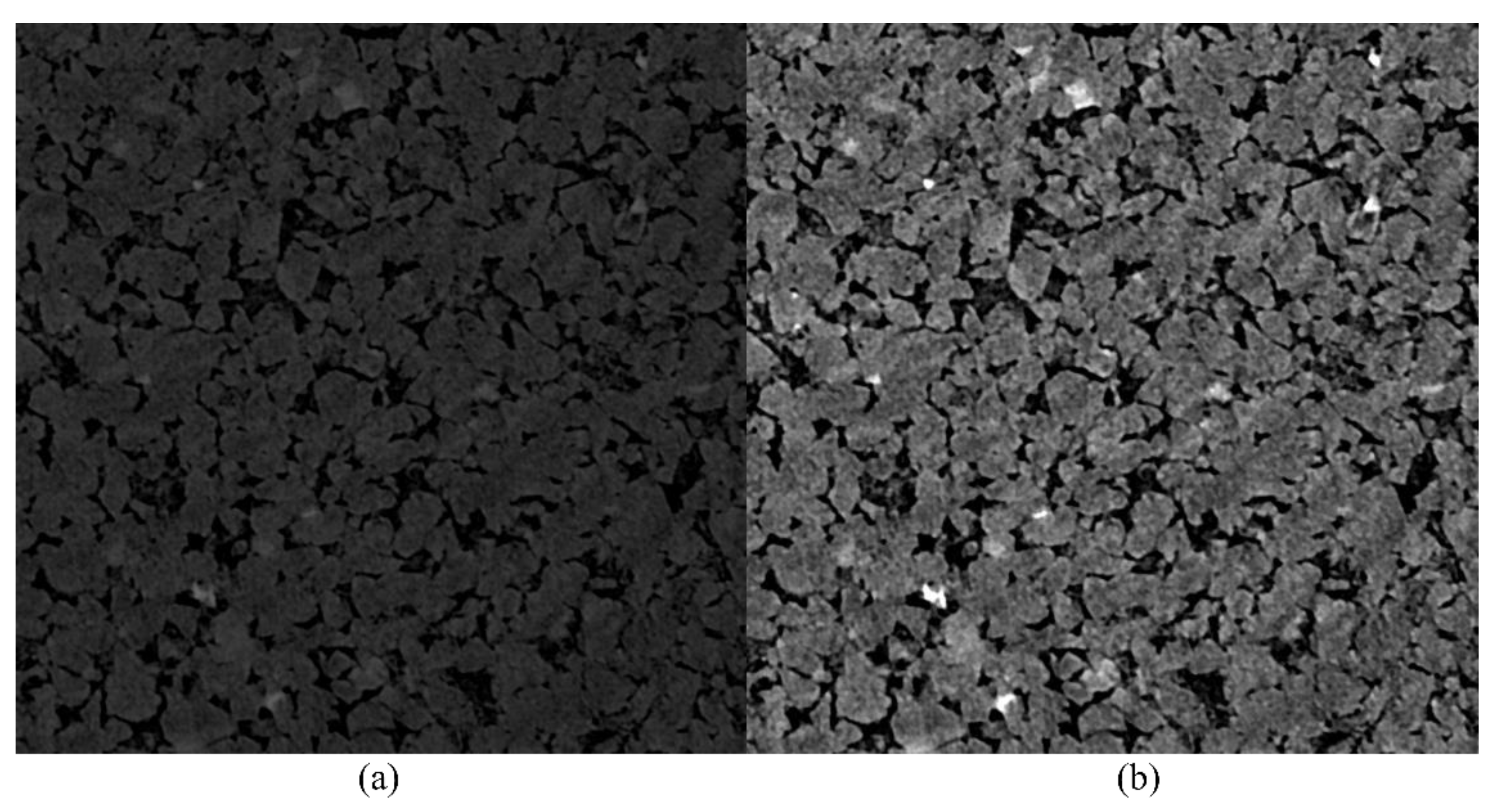

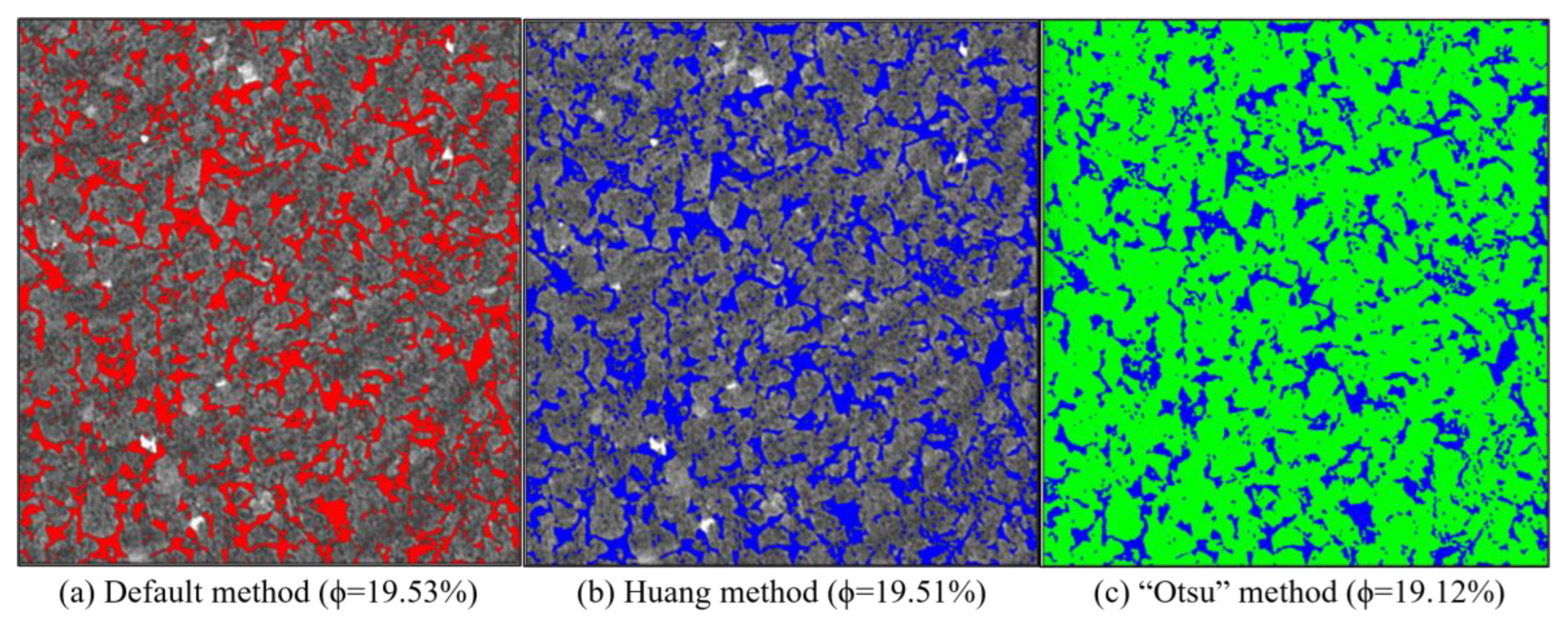

5.1. Image Processing

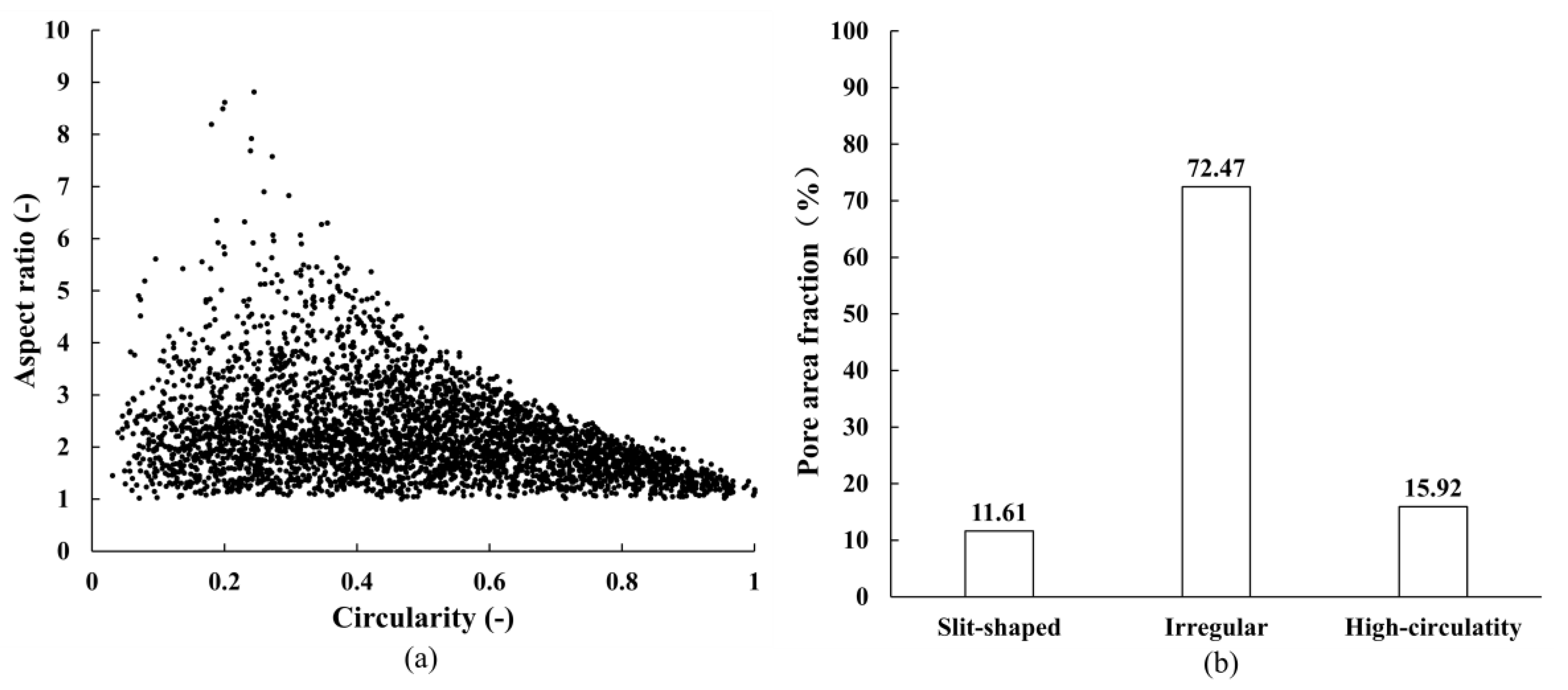

5.2. Pore Geometry

5.3. Porosity and Pore Size Distribution

6. Discussion

6.1. Methodological Comparison of Porosity

6.2. Pore Structure Analysis

7. Conclusions

- (1)

- The pores in Berea Sandstone can be segmented from the mineral grains in the micro-CT images by using three different thresholding methods (Default, Huang and Otsu) in a highly accurate way, which paves the way for statistical geometrical measurements.

- (2)

- The average porosity (19.10%) derived from the image analysis is quite comparable to the porosity (18.96%) determined by a helium pycnometer on the same sample, which indicates that connected and effective pores are dominant in the pore space of the studied Berea Sandstone.

- (3)

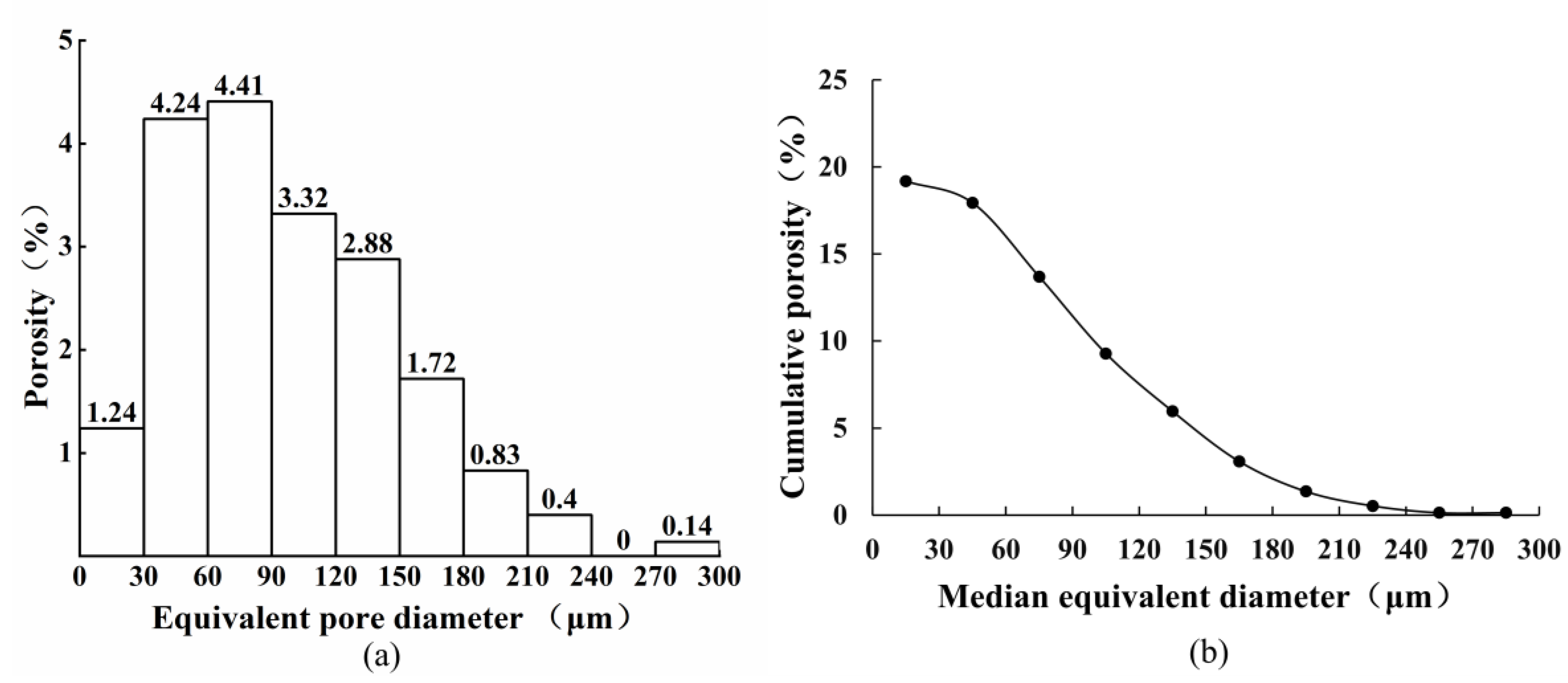

- Based on the circularity values calculated, the pores in Berea Sandstone can be classified into irregular, high-circularity and slit-shaped pores. Irregular pores are the most abundant type, with an area fraction of 72.74%. Pores identified in this study are mostly in the range of 30 and 180 μm, which contributes 86.4% of the total pore area.

- (4)

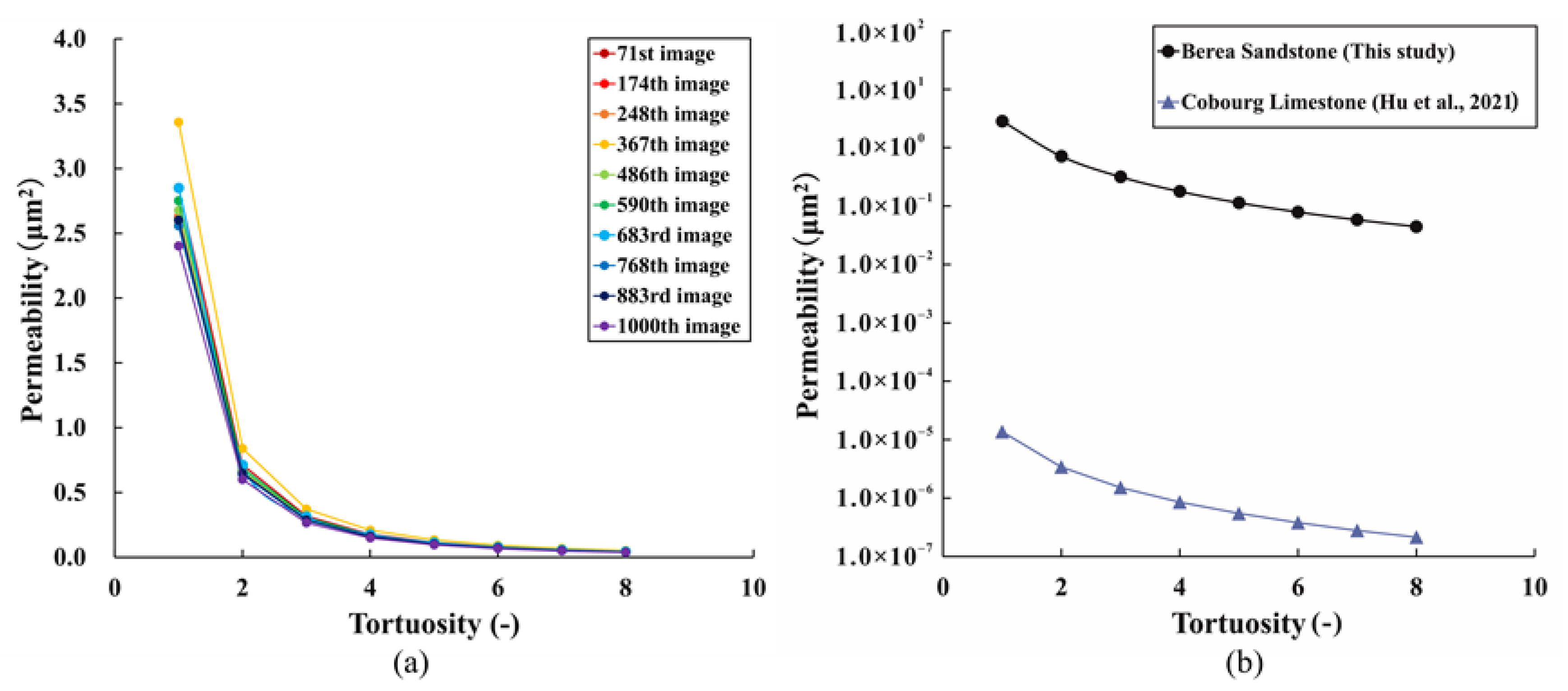

- The permeability coefficients of Berea Sandstone estimated based on the “bundle of capillary tubes” model exponentially decrease with increasing tortuosity values. Based on this relationship, tortuosity values were calculated in the range of 4–6 to match the experimental permeability data.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Pettijohn, F.J.; Potter, P.E.; Siever, R. Sand and Sandstone; Springer: New York, NY, USA, 2012. [Google Scholar]

- Leeder, M.R. Sedimentology and Sedimentary Basins: From Turbulence to Tectonics; Wiley: New York, NY, USA, 2009. [Google Scholar]

- Nichols, G. Sedimentology and Stratigraphy; Wiley: New York, NY, USA, 2009. [Google Scholar]

- Blatt, H.; Tracy, R.; Owens, B. Petrology: Igneous, Sedimentary, and Metamorphic; Macmillan: New York, NY, USA, 2006. [Google Scholar]

- Peters, E.J. Petrophysics; University of Texas at Austin: Austin, TX, USA, 2005. [Google Scholar]

- Anovitz, L.M.; Cole, D.R. Characterization and Analysis of Porosity and Pore Structures. Rev. Mineral. Geochem. 2015, 80, 61–164. [Google Scholar] [CrossRef] [Green Version]

- Tiab, D.; Donaldson, E.C. Theory and Practice of Measuring Reservoir Rock and Fluid Transport Properties; Gulf Professional Publishing: Burlington, MA, USA, 2015. [Google Scholar]

- Hu, Z.; Gaus, G.; Seemann, T.; Zhang, Q.; Littke, R.; Fink, R. Pore structure and sorption capacity investigations of Ediacaran and Lower Silurian gas shales from the Upper Yangtze platform, China. Geomech. Geophys. Geo-Energy Geo-Resour. 2021, 7, 1–26. [Google Scholar] [CrossRef]

- Busch, A.; Schweinar, K.; Kampman, N.; Coorn, A.; Pipich, V.; Feoktystov, A.; Leu, L.; Amann-Hildenbrand, A.; Bertier, P. Shale Porosity - What Can We Learn from Different Methods? In Proceedings of the Fifth EAGE Shale Workshop, Catania, Italy, 2–4 May 2016. [Google Scholar]

- Hu, Z.; Klaver, J.; Schmatz, J.; Dewanckele, J.; Littke, R.; Krooss, B.M.; Amann-Hildenbrand, A. Stress sensitivity of porosity and permeability of Cobourg limestone. Eng. Geol. 2020, 273, 105632. [Google Scholar] [CrossRef]

- Wardlaw, N.C.; McKellar, M. Mercury porosimetry and the interpretation of pore geometry in sedimentary rocks and artificial models. Powder Technol. 1981, 29, 127–143. [Google Scholar] [CrossRef]

- Abell, A.B.; Willis, K.L.; Lange, D.A. Mercury Intrusion Porosimetry and Image Analysis of Cement-Based Materials. J. Colloid Interface Sci. 1999, 211, 39–44. [Google Scholar] [CrossRef]

- Hildenbrand, A.; Urai, J.L. Investigation of the morphology of pore space in mudstones—First results. Mar. Petrol. Geol. 2003, 20, 1185–1200. [Google Scholar] [CrossRef]

- Kelly, S.; El-Sobky, H.; Torres-Verdin, C.; Balhoff, M.T. Assessing the utility of FIB-SEM images for shale digital rock physics. Adv. Water Resour. 2016, 95, 302–316. [Google Scholar] [CrossRef]

- Cnudde, V.; Boone, M.N. High-resolution X-ray computed tomography in geosciences: A review of the current technology and applications. Earth-Sci. Rev. 2013, 123, 1–17. [Google Scholar] [CrossRef] [Green Version]

- Andrä, H.; Combaret, N.; Dvorkin, J.; Glatt, E.; Han, J.; Kabel, M.; Keehm, Y.; Krzikalla, F.; Lee, M.; Madonna, C.; et al. Digital rock physics benchmarks-part II: Computing effective properties. Comput. Geosci. 2013, 50, 33–43. [Google Scholar] [CrossRef]

- Saxena, N.; Hofmann, R.; Alpak, F.O.; Berg, S.; Dietderich, J.; Agarwal, U.; Tandon, K.; Hunter, S.; Freeman, J.; Wilson, O.B. References and benchmarks for pore-scale flow simulated using micro-CT images of porous media and digital rocks. Adv. Water Resour. 2017, 109, 211–235. [Google Scholar] [CrossRef]

- Signoroni, A.; Savardi, M.; Baronio, A.; Benini, S. Deep Learning Meets Hyperspectral Image Analysis: A Multidisciplinary Review. J. Imaging 2019, 5, 52. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Chen, S.; Li, Y.; Zhang, T.; Zhu, X.; Sun, S.; Gao, X. Lunar features detection for energy discovery via deep learning. Appl. Energy 2021, 296, 117085. [Google Scholar] [CrossRef]

- Lucas, A.M.; Ryder, P.V.; Li, B.; Cimini, B.A.; Eliceiri, K.W.; Carpenter, A.E. Open-source deep-learning software for bioimage segmentation. Mol. Biol. Cell 2021, 32, 823–829. [Google Scholar] [CrossRef] [PubMed]

- Girish, V.; Vijayalakshmi, A.J.I.j.o.c. Affordable image analysis using NIH Image/ImageJ. Indian J. Cancer 2004, 41, 47. [Google Scholar]

- Schneider, C.A.; Rasband, W.S.; Eliceiri, K.W. NIH Image to ImageJ: 25 years of image analysis. Nat. Methods 2012, 9, 671–675. [Google Scholar] [CrossRef] [PubMed]

- Arena, E.T.; Rueden, C.T.; Hiner, M.C.; Wang, S.; Yuan, M.; Eliceiri, K.W. Quantitating the cell: Turning images into numbers with ImageJ. Wiley Interdiscip Rev. Dev. Biol. 2017, 6, e260. [Google Scholar] [CrossRef]

- Irving, B.A.; Weltman, J.Y.; Brock, D.W.; Davis, C.K.; Gaesser, G.A.; Weltman, A. NIH ImageJ and Slice-O-Matic Computed Tomography Imaging Software to Quantify Soft Tissue. Obesity 2007, 15, 370–376. [Google Scholar] [CrossRef]

- Grishagin, I.V. Automatic cell counting with ImageJ. Anal. Biochem. 2015, 473, 63–65. [Google Scholar] [CrossRef]

- Lumagui, K.N.M.; Manuel, L.J.R.; Quilloy, E.P.; Yaptenco, K.F. Varietal Classification of Selected Green Coffee Beans (Coffea arabica L. and Coffea canephora Pierre ex A. Froehner) Using Image Processing Software. Philipp. J. Agric. Biosyst. Eng. 2020, 16, 16. [Google Scholar]

- Grove, C.; Jerram, D.A. jPOR: An ImageJ macro to quantify total optical porosity from blue-stained thin sections. Comput. Geosci. 2011, 37, 1850–1859. [Google Scholar] [CrossRef]

- Wopara, F.O.; Lyuke, S.E. Prediction of flow and transport properties in porous media. Int. J. Oil Gas Coal Technol. 2018, 17, 284–303. [Google Scholar] [CrossRef]

- Ettensohn, F.R. Modeling the nature and development of major paleozoic clastic wedges in the Appalachian Basin, USA. J. Geodyn. 2004, 37, 657–681. [Google Scholar] [CrossRef]

- Qiu, K. Tectonic Evolution and Sedimentary Characteristics of Foreland Basin in North America; China University of Geosciences (Beijing): Beijing, China, 2013. [Google Scholar]

- Thomas, W.A. The Appalachian-Ouachita rifted margin of southeastern North America. GSA Bull. 1991, 103, 415–431. [Google Scholar] [CrossRef]

- Greb, S.F.; Harris, D.C.; Bowersox, J.R. Reservoir geology of the Berea Sandstone (uppermost Devonian), eastern Kentucky. AAPG Bull. 2021, 105, 597–628. [Google Scholar] [CrossRef]

- Pepper, J.F.; de Witt, W.; Demarest, D.F. Geology of the Bedford Shale and Berea Sandstone in the Appalachian Basin. Science 1954, 119, 512–513. [Google Scholar] [CrossRef] [PubMed]

- Parris, T.M.; Nuttall, B.C. Berea Sandstone: New developments in a mature oil and gas play, eastern Kentucky and Ohio. AAPG Bull. 2021, 105, 485–492. [Google Scholar] [CrossRef]

- Hackley, P.C.; Parris, T.M.; Eble, C.F.; Greb, S.F.; Harris, D.C. Oil–source correlation studies in the shallow Berea Sandstone petroleum system, eastern Kentucky. AAPG Bull. 2021, 105, 517–542. [Google Scholar] [CrossRef]

- Churcher, P.L.; French, P.R.; Shaw, J.C.; Schramm, L.L. Rock Properties of Berea Sandstone, Baker Dolomite, and Indiana Limestone. In Proceedings of the SPE International Symposium on Oilfield Chemistry, Anaheim, CA, USA, 20–22 February 1991. [Google Scholar]

- Neumann, R.F.; Barsi-Andreeta, M.; Lucas-Oliveira, E.; Barbalho, H.; Trevizan, W.A.; Bonagamba, T.J.; Steiner, M.B. High accuracy capillary network representation in digital rock reveals permeability scaling functions. Sci. Rep. 2021, 11, 11370. [Google Scholar] [CrossRef]

- Leu, L.; Berg, S.; Enzmann, F.; Armstrong, R.T.; Kersten, M. Fast X-ray Micro-Tomography of Multiphase Flow in Berea Sandstone: A Sensitivity Study on Image Processing. Transp. Porous Media 2014, 105, 451–469. [Google Scholar] [CrossRef]

- Prodanovic, M.; Maria, E.; Matthew, H.; Gaurav, N.; Prateek, A. Digital Rocks Portal: A repository for porous media images. 2015. [Google Scholar] [CrossRef]

- Lucas-Oliveira, E.; Barsi-Andreeta, M.; Neumann, R.F.; Trevizan, W.A.; Steiner, M.B.; Bonagamba, T.J. Micro-computed tomography of sandstone rocks: Raw, filtered and segmented datasets. Data Brief 2022, 41, 107893. [Google Scholar] [CrossRef]

- Buades, A.; Coll, B.; Morel, J.-M. Non-Local Means Denoising. Image Process. Line 2011, 1, 208–212. [Google Scholar] [CrossRef] [Green Version]

- Ridler, T.W.; Calvard, S. Picture Thresholding Using an Iterative Selection Method. IEEE Trans. Syst. Man Cybern. 1978, 8, 630–632. [Google Scholar] [CrossRef]

- Huang, L.-K.; Wang, M.-J.J. Image thresholding by minimizing the measures of fuzziness. Pattern Recognit. 1995, 28, 41–51. [Google Scholar] [CrossRef]

- Otsu, N. A Threshold Selection Method from Gray-Level Histograms. IEEE Trans. Syst. Man Cybern. 1979, 9, 62–66. [Google Scholar] [CrossRef] [Green Version]

- Philipp, T.; Amann-Hildenbrand, A.; Laurich, B.; Desbois, G.; Littke, R.; Urai, J.L. The effect of microstructural heterogeneity on pore size distribution and permeability in Opalinus Clay (Mont Terri, Switzerland): Insights from an integrated study of laboratory fluid flow and pore morphology from BIB-SEM images. Geol. Soc. London Spéc. Publ. 2017, 454, 85–106. [Google Scholar] [CrossRef]

- Hu, Z.; Lu, S.; Klaver, J.; Dewanckele, J.; Amann-Hildenbrand, A.; Gaus, G.; Littke, R. An Integrated Imaging Study of the Pore Structure of the Cobourg Limestone—A Potential Nuclear Waste Host Rock in Canada. Minerals 2021, 11, 1042. [Google Scholar] [CrossRef]

| Sampling Site | Northern Ohio | Eastern Kentucky | Northeastern Kentucky | Southern Ohio |

|---|---|---|---|---|

| Porosity (%) | 19.04–26.01 | 2.01–16.10 | 18.86–19.05 | 16.7–18.7 |

| Methods for porosity measurements | SEM | MIP | HP | Micro-CT |

| Permeability (mD) | 114~1168 | 5 × 10−5–2.5 | 109~133 | 320~780 |

| Methods for permeability measurements | Steady-state gas flow | Pulsed neutron decay | Steady-state gas flow | Lattice Boltzmann |

| Data source | [36] | [32] | [37] | [38] |

| Image Number | Number of Pores | Total Pore Area (μm2) | Average Pore Area (μm2) | Average Perimeter (μm) | Average Circularity | Average Aspect Ratio |

|---|---|---|---|---|---|---|

| 71 | 356 | 985,866.18 | 2769.29 | 297.91 | 0.48 | 1.90 |

| 174 | 367 | 994,492.68 | 2709.78 | 302.82 | 0.46 | 1.94 |

| 248 | 397 | 960,503.06 | 2419.40 | 272.54 | 0.50 | 1.93 |

| 367 | 351 | 991,764.00 | 2825.54 | 294.28 | 0.49 | 1.90 |

| 486 | 357 | 1,015,765.31 | 2845.28 | 314.36 | 0.48 | 1.95 |

| 590 | 378 | 975,386.81 | 2580.38 | 283.92 | 0.48 | 1.94 |

| 683 | 341 | 988,572.75 | 2899.04 | 315.67 | 0.47 | 1.97 |

| 768 | 416 | 912,627.00 | 2193.81 | 251.97 | 0.50 | 1.97 |

| 883 | 376 | 936,506.81 | 2490.72 | 275.16 | 0.50 | 1.95 |

| 1000 | 366 | 947,649.37 | 2589.21 | 293.40 | 0.49 | 1.92 |

| Image Number | 71 | 174 | 248 | 367 | 486 | 590 | 683 | 768 | 883 | 1000 |

|---|---|---|---|---|---|---|---|---|---|---|

| Default (%) | 19.47 | 19.64 | 18.97 | 19.59 | 20.06 | 19.27 | 19.53 | 18.03 | 18.50 | 18.72 |

| Huang (%) | 19.47 | 19.68 | 19.14 | 20.08 | 18.96 | 18.33 | 19.51 | 18.04 | 18.76 | 18.87 |

| Otsu (%) | 19.48 | 19.67 | 18.94 | 20.07 | 19.02 | 18.29 | 19.12 | 18.31 | 18.76 | 18.84 |

| Average porosity (%) | 19.47 | 19.66 | 19.02 | 19.91 | 19.35 | 18.63 | 19.39 | 18.13 | 18.67 | 18.81 |

| SD (%) | 0.01 | 0.02 | 0.11 | 0.28 | 0.62 | 0.55 | 0.23 | 0.16 | 0.15 | 0.08 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hu, Z.; Zhang, R.; Zhu, K.; Li, D.; Jin, Y.; Guo, W.; Liu, X.; Zhang, X.; Zhang, Q. Probing the Pore Structure of the Berea Sandstone by Using X-ray Micro-CT in Combination with ImageJ Software. Minerals 2023, 13, 360. https://doi.org/10.3390/min13030360

Hu Z, Zhang R, Zhu K, Li D, Jin Y, Guo W, Liu X, Zhang X, Zhang Q. Probing the Pore Structure of the Berea Sandstone by Using X-ray Micro-CT in Combination with ImageJ Software. Minerals. 2023; 13(3):360. https://doi.org/10.3390/min13030360

Chicago/Turabian StyleHu, Zhazha, Rui Zhang, Kai Zhu, Dongyin Li, Yi Jin, Wenbing Guo, Xiao Liu, Xiaodong Zhang, and Qian Zhang. 2023. "Probing the Pore Structure of the Berea Sandstone by Using X-ray Micro-CT in Combination with ImageJ Software" Minerals 13, no. 3: 360. https://doi.org/10.3390/min13030360