A Negative Value of the Non-Darcy Flow Coefficient in Pore-Fracture Media under Hydro-Mechanical Coupling

Abstract

1. Introduction

2. Theoretical Background

- (1)

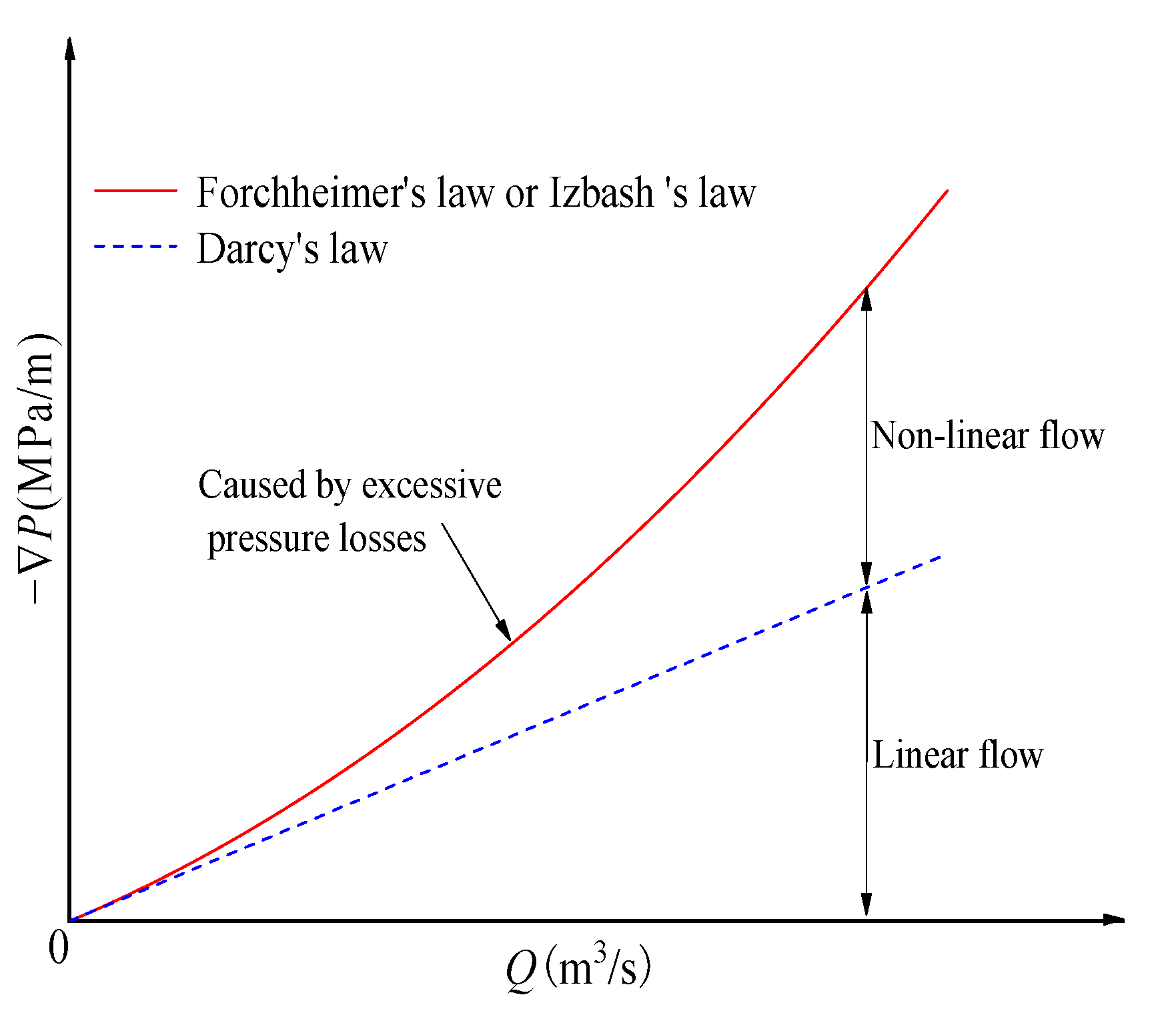

- When β > 0 and β > −μ2/4ρ|−∇P|k2, the β value is positive, and Equation (7) has a solution. The seepage system has an equilibrium state, and the non-linear seepage characteristic in Figure 1 is generally present in most hydraulic tests. The nonlinear seepage characteristic is due to the obvious inertia effect causing additional pressure loss. Therefore, the increase of −∇P is greater than that of Q in linear proportion, and the nonlinear curve is convex to the Q axis.

- (2)

- When −μ2/4ρ|−∇P|k2 < β < 0, the β value is negative, Equation (7) has a solution, and the seepage system has an equilibrium state. There are currently two explanations for the causes of such non-linear characteristics. (1) Under the confining pressure, the non-linear flow is caused by the expansion of rock fractures with the increased seepage water pressure [34]. The pores or cracks in the rock are compressed under the confining pressure. The confining pressure is reduced with the increased seepage water pressure, which leads to expanded fractures and increased flow rates. It gradually shows non-linearity. Develi and Babadagli also observed a similar phenomenon in their experiments [41]. In addition, this phenomenon has also widely appeared in rock engineering such as dams, shale gas/oil wells, and tunnels [22,34]. Mastering such nonlinear seepage characteristics is vital for the seepage characteristic evaluation and optimization design of rock engineering. (2) The non-linear flow is due to strong solid–liquid interaction (solid–liquid interface effect) in the rocks of low-permeability, micro/nano-scale, pore-fracture media [33,34,35]. This is similar to the flow behaviors of non-Newtonian fluids. We should strengthen the research on the flow mechanism of micro/nano-scale fractures in the future.

- (3)

- When β < −μ2/4ρ|−∇P|k2 < 0, Equation (7) has no solution, and there is no equilibrium state in the seepage system. The pore and fracture structures inside the rock change when the hydraulic–mechanical coupling develops to a certain stage and degree. Fluid flow expands the seepage channel, which may lead to the complete loss of the barrier effect of the rock on the fluid. It greatly changes its permeability and ultimately causes seepage instability. Li Wenliang et al. expounded this phenomenon through experiments [35]. In mining engineering, as the rock mass is affected by mining, its pore and fracture structures significantly change. Correspondingly, the seepage characteristic changes greatly, resulting in the instability of the seepage system and inducing water inrush disasters.

3. Experimental and Simulation Methodology

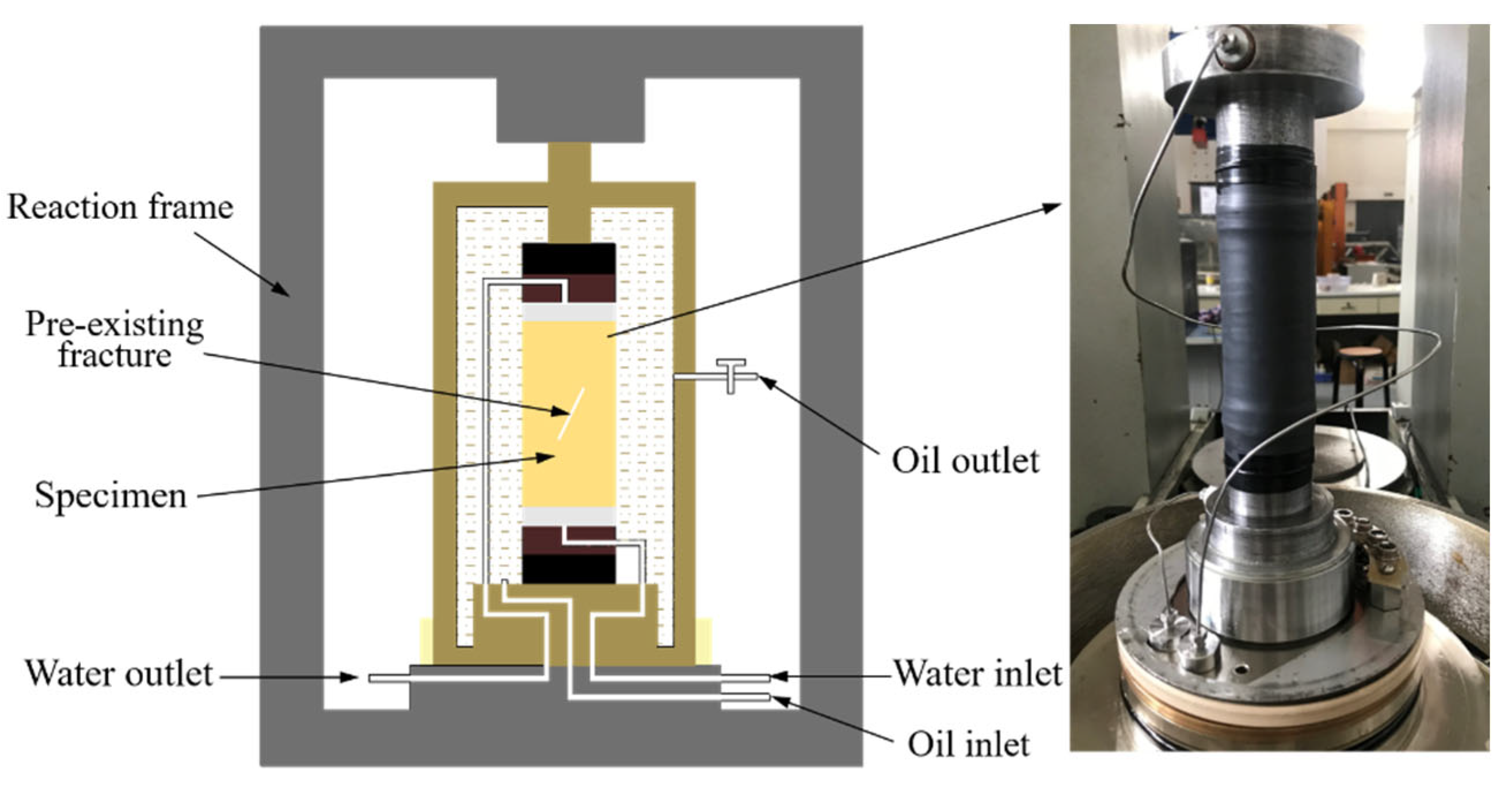

3.1. Laboratory Experiment

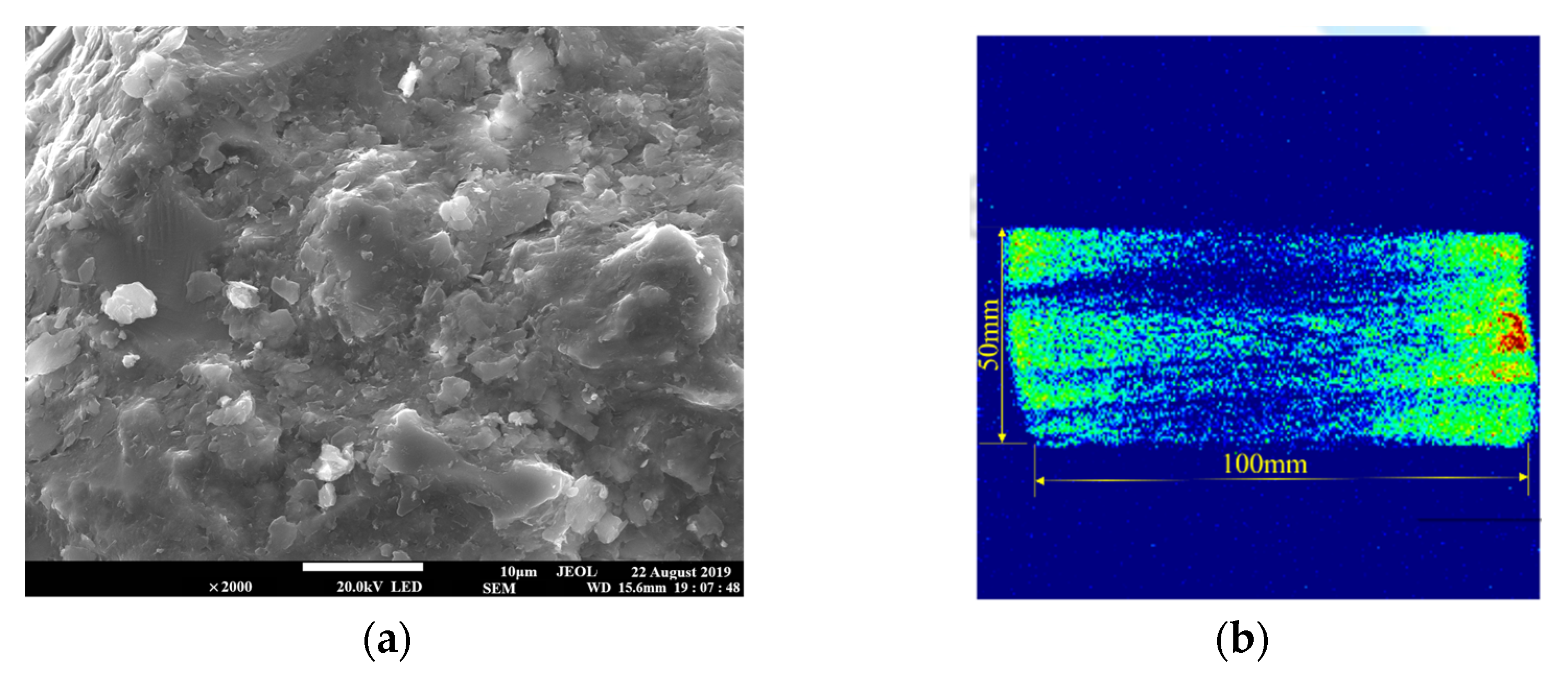

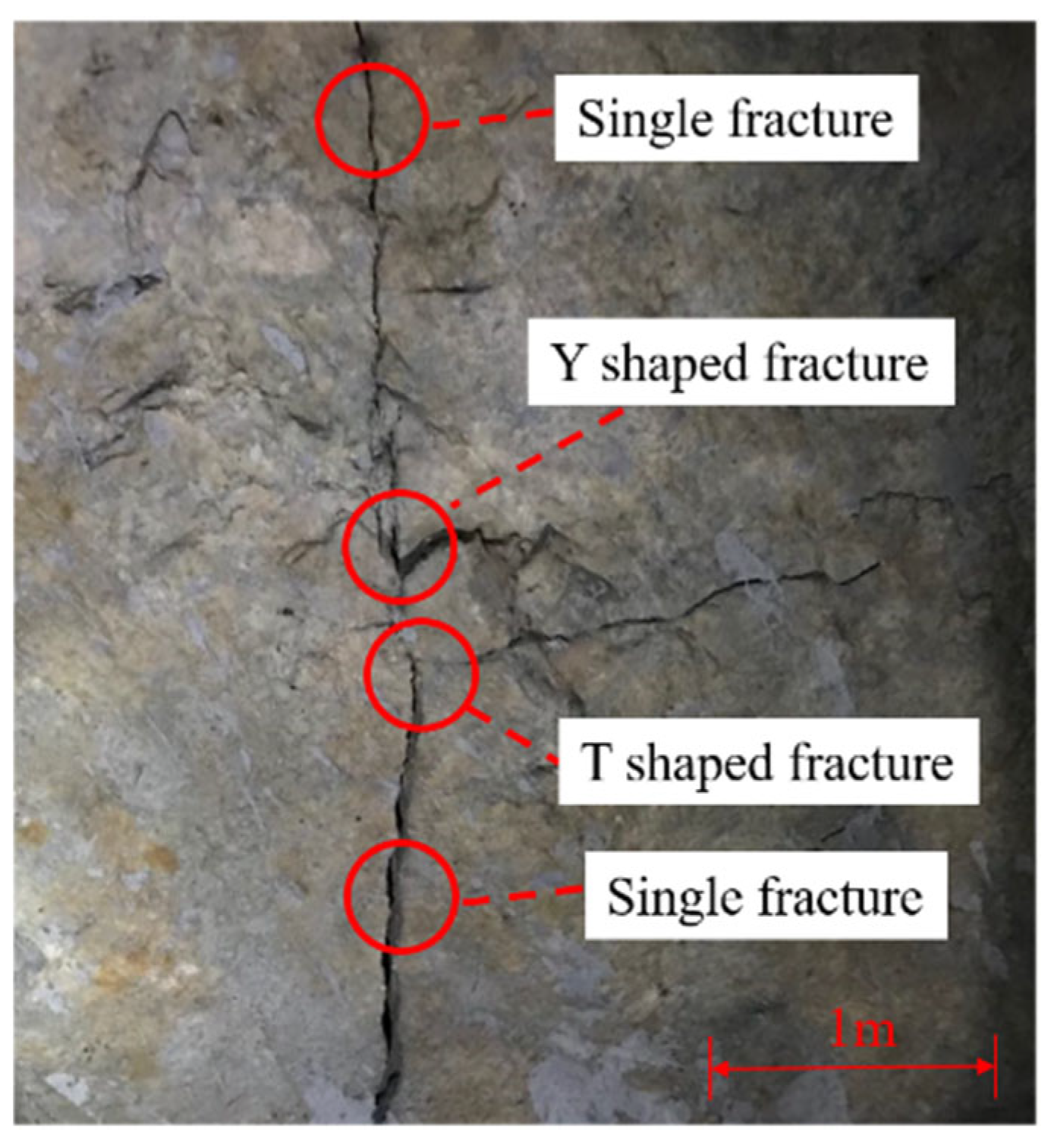

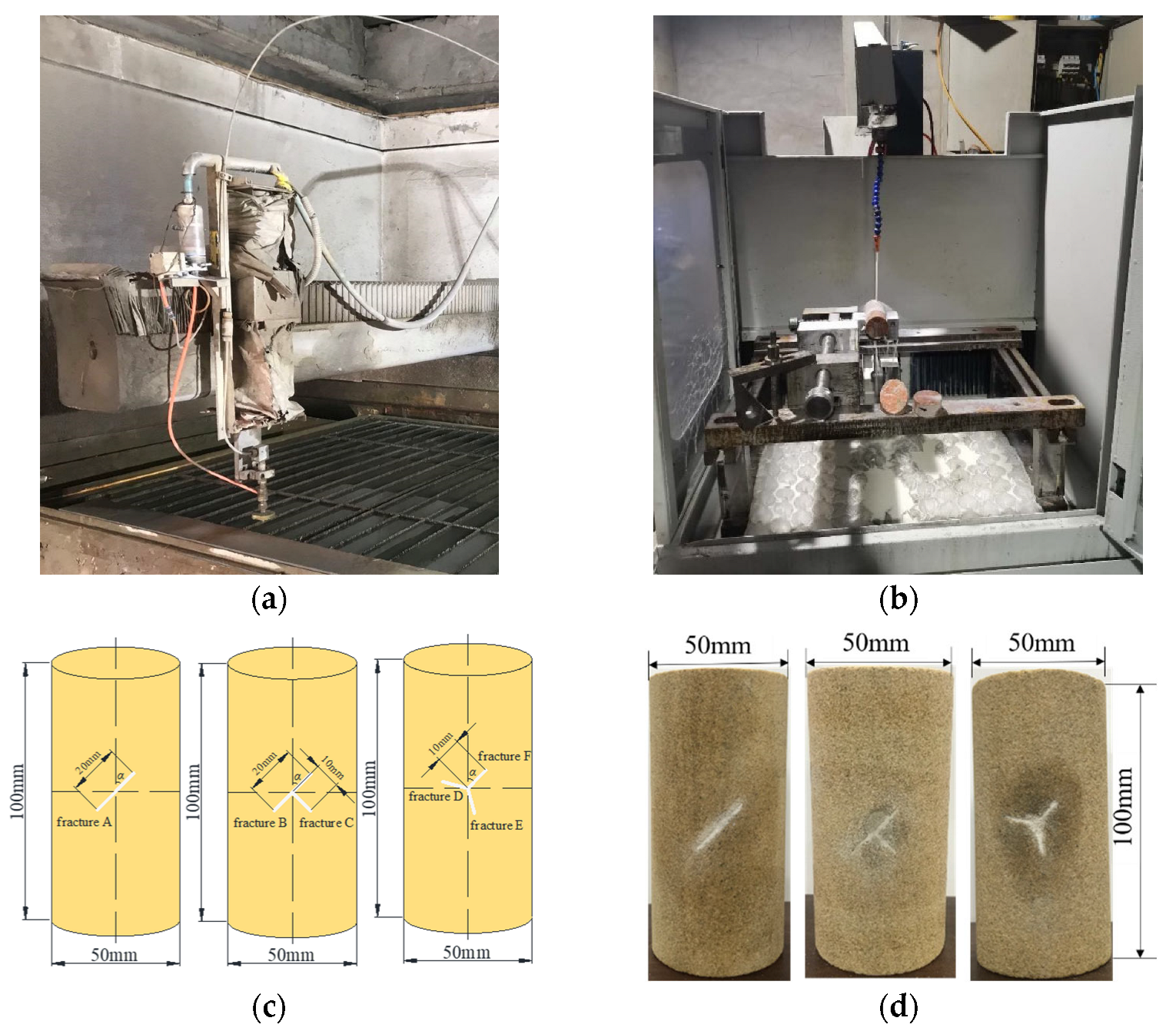

3.1.1. Sample Preparation

3.1.2. Test Plan and Process

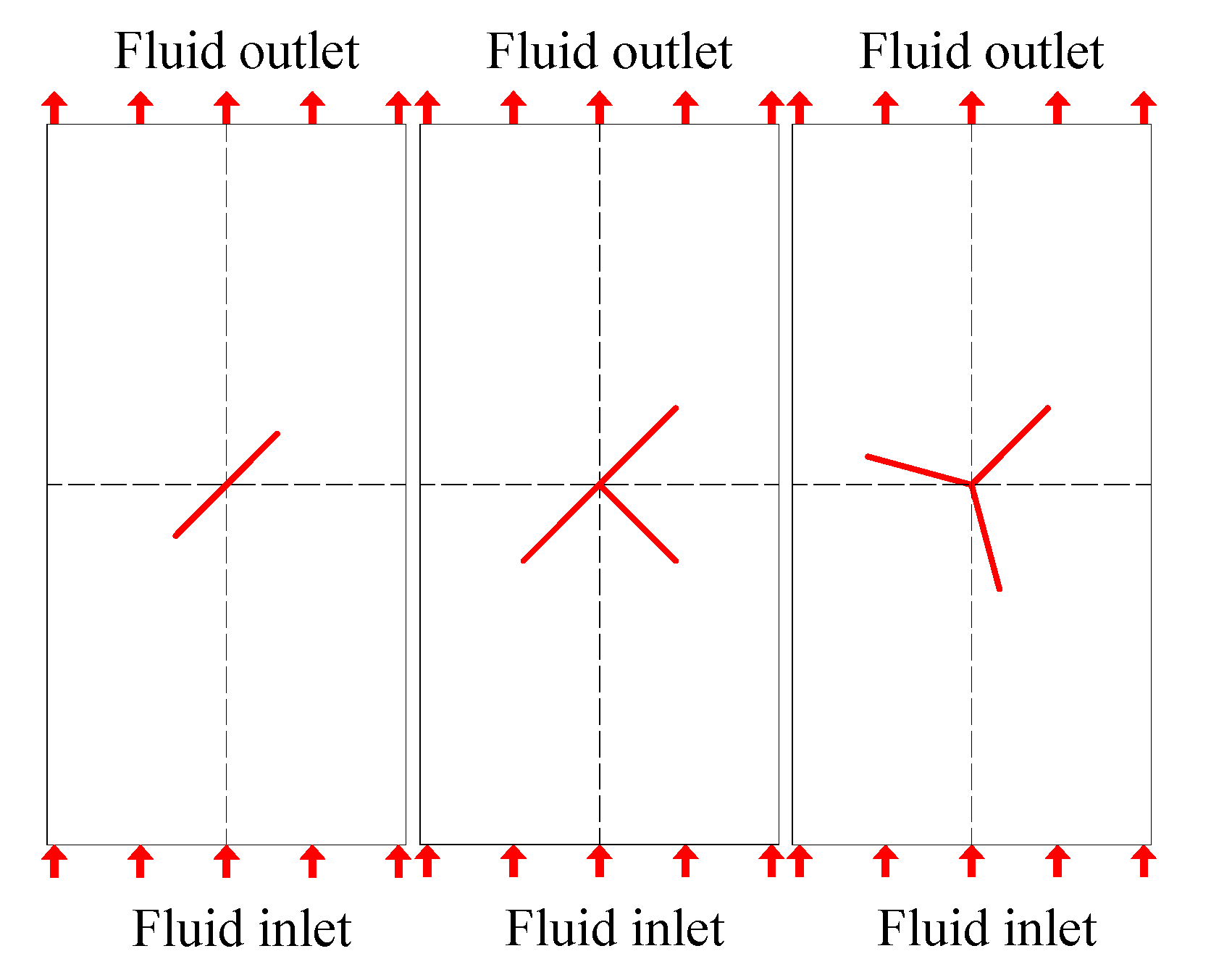

3.2. Numerical Simulation

3.2.1. Model Construction and Grid Division

3.2.2. Boundary Conditions and Governing Equations

4. Analysis of Test Results

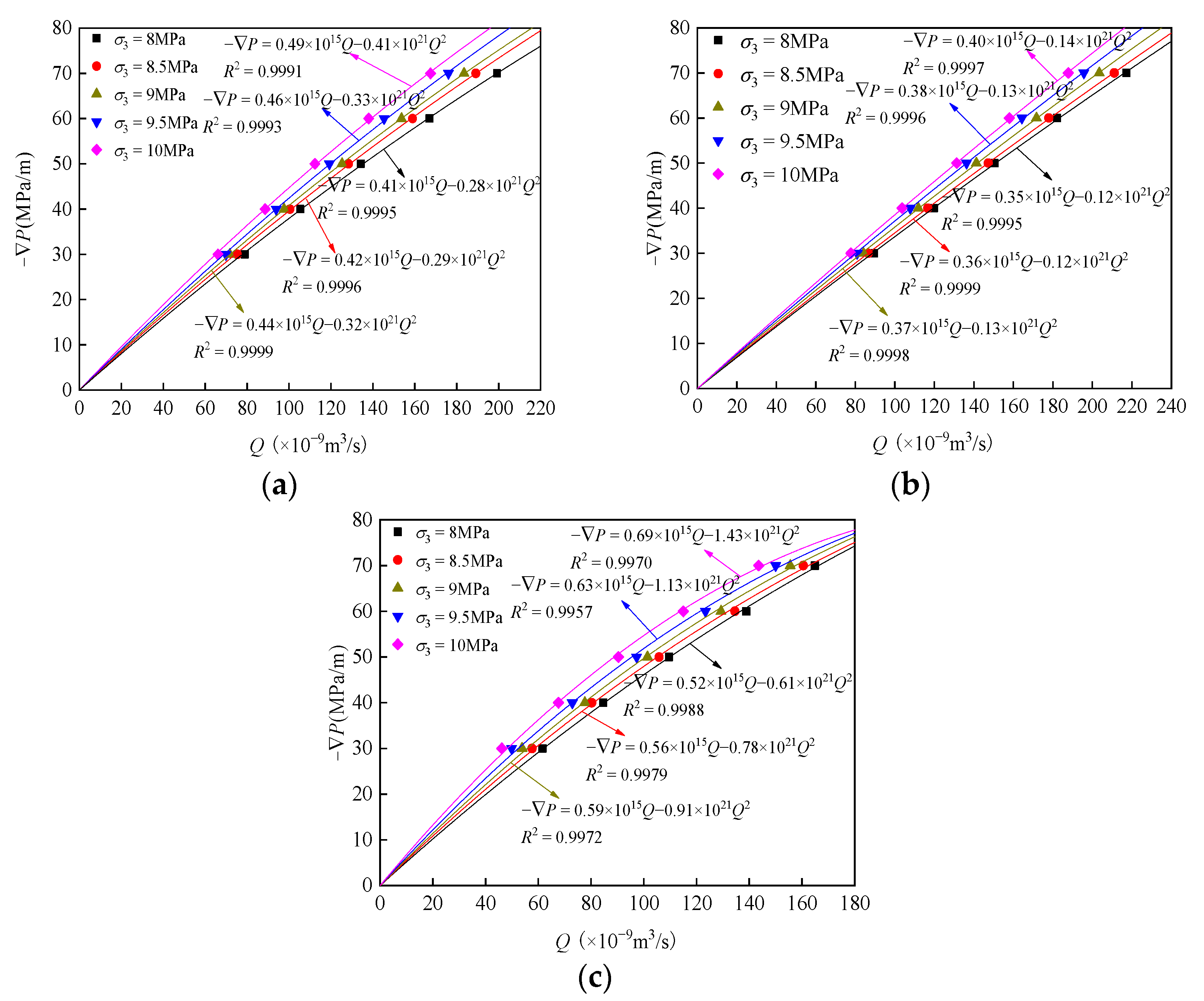

4.1. Analysis of the Nonlinear Seepage Behaviors with Negative β

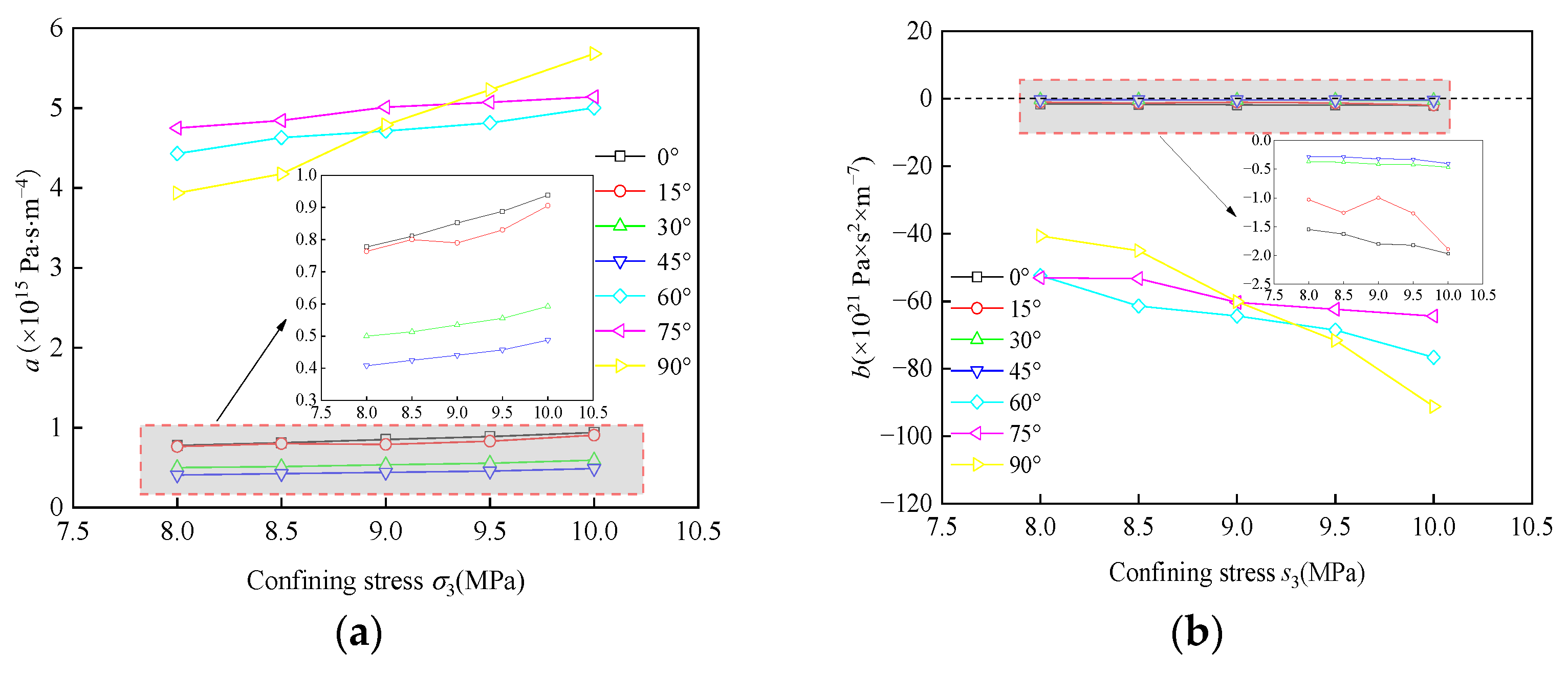

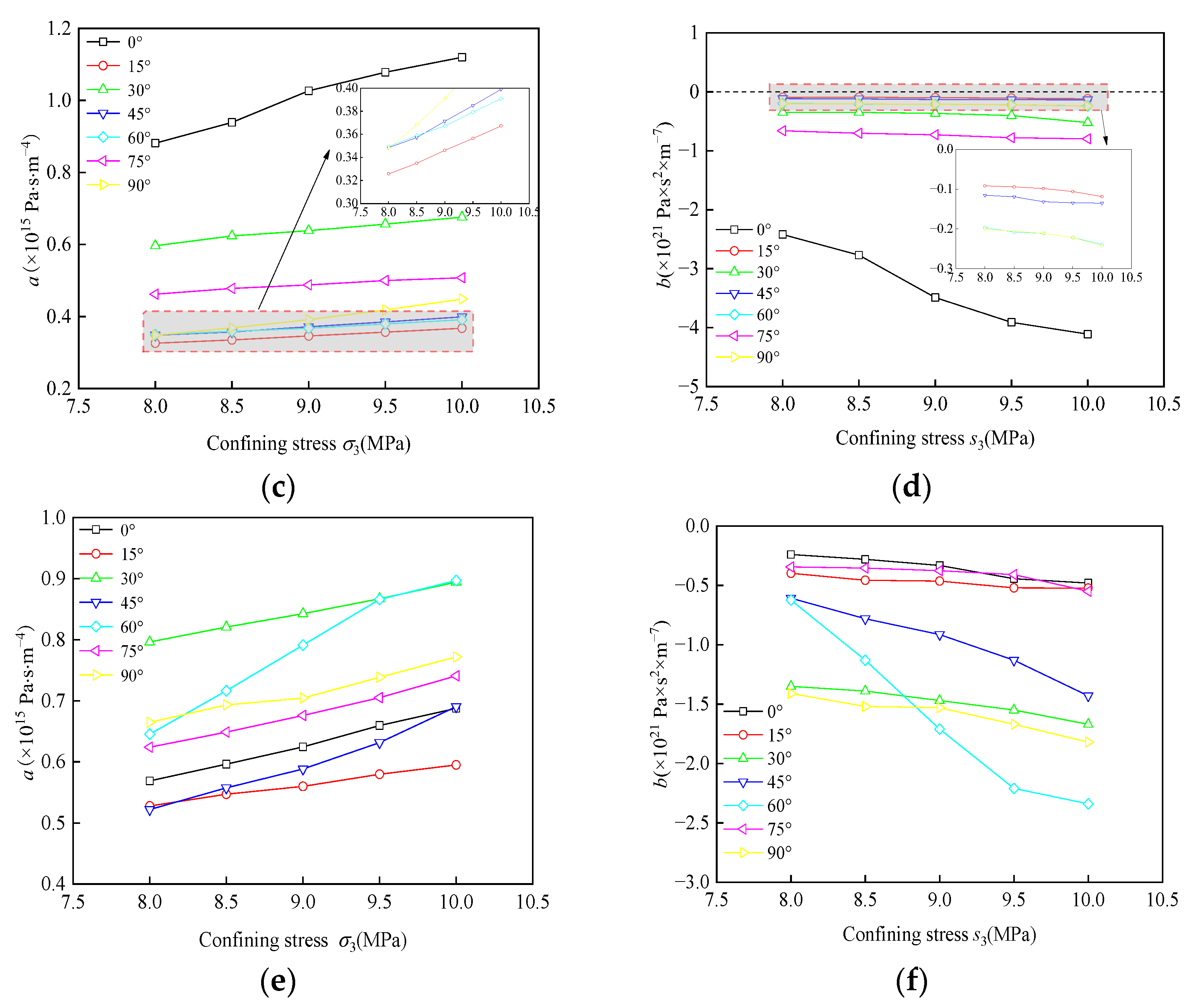

4.2. Parameter Expression Construction with Negative β

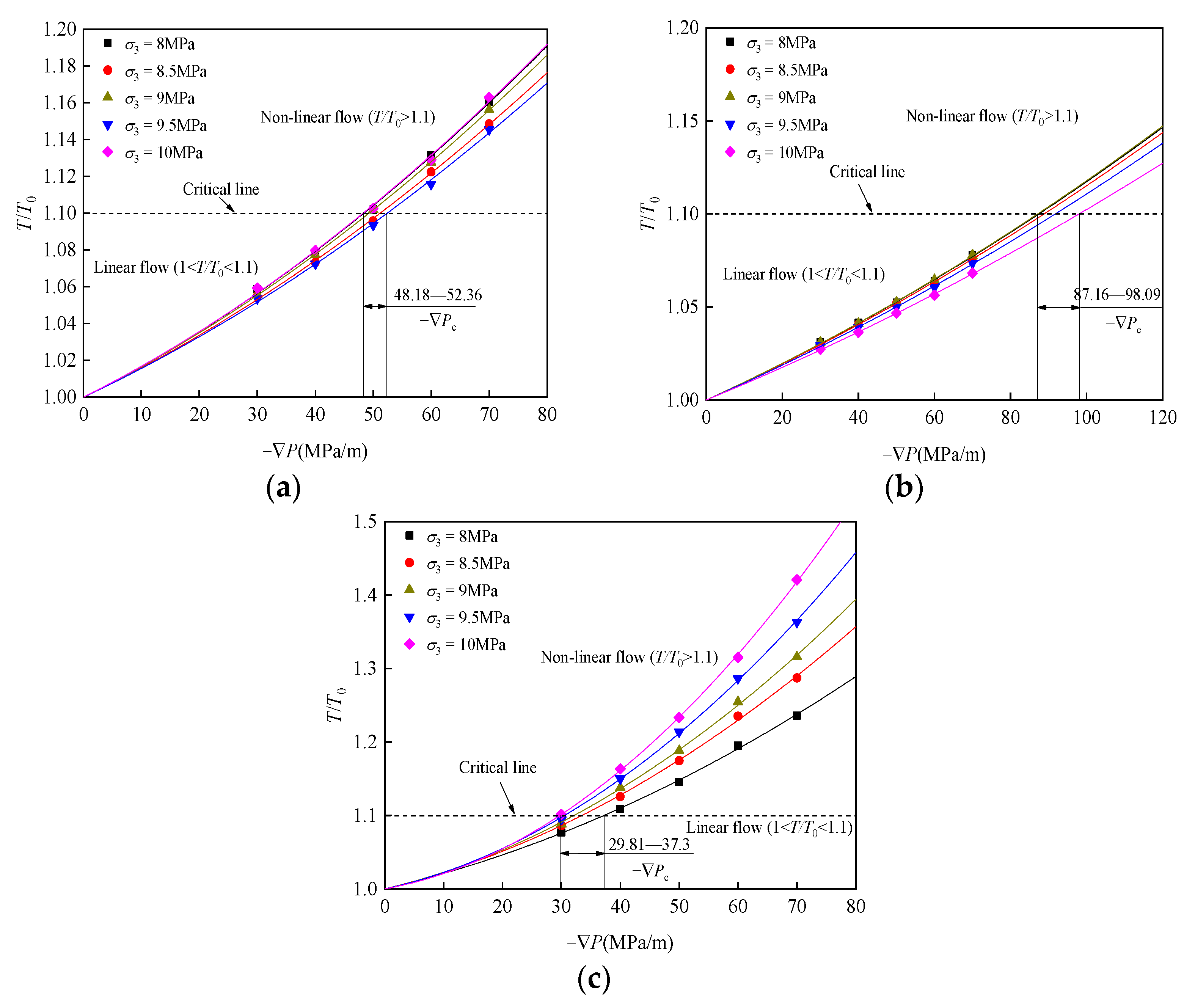

4.3. Determination of Critical Pressure Gradient with Negative β

5. Discussion

5.1. Theoretical Analysis

- (1)

- When −μ2/4ρ|−∇P|k2 < β < 0, Equation (7) has a solution, and the seepage system has an equilibrium state. The fractures and pores are compressed, and a certain seepage pressure is required to stabilize the seepage system when a certain confining pressure is applied to the fractured sandstone sample, due to the prefabricated fractures of different shapes and inclinations. When the seepage water pressure increases too close to the confining pressure restraint, the effective confining force produced by the confining pressure is suppressed. However, the test results show the nonlinear seepage characteristic is produced, resulting in a negative β value. The reason may be that under the action of hydraulic–mechanical coupling, the water flow state changes near the combined area of pores and prefabricated fractures. Anti-skid boundary conditions are assumed to become invalid, and the fracture surface is equivalent to a smooth surface, leading to excessive flow in the area of prefabricated fractures, and finally causes the change of the entire seepage system.

- (2)

- When β < −μ2/4ρ|−∇P|k2 < 0, Equation (7) has no solution, and there is no equilibrium state in the seepage system, because the flow state of the fluid inside the sample cannot be observed during the test, and some sample outlets have large flow. Therefore, it is possible that the rock has no barrier effect of the rock on the fluid and causes seepage instability, which may be another reason for the nonlinear seepage characteristics in this paper.

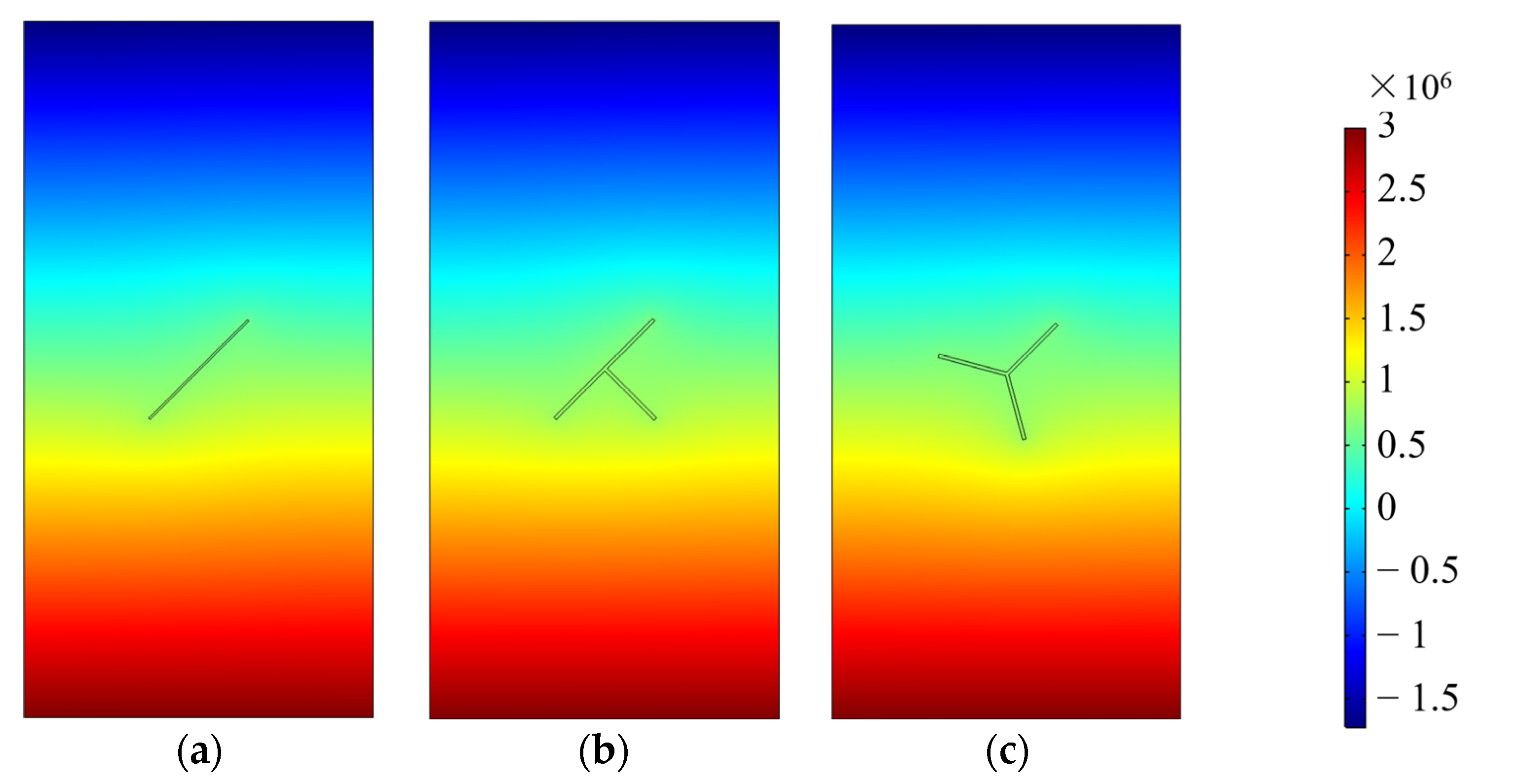

5.2. Numerical Simulation Analysis

6. Conclusions

- The Forchheimer equation was used for the fitting analysis on the correlation between seepage pressure gradient −∇P and volume flow Q of samples with single, T-shaped, and Y-shaped fractures. The correlation coefficient (R2) value exceeded 0.9900, with a good fitting effect. In the relationship between −∇P and Q, the different fractured samples increased with the increased −∇P, and the fitting curve was convex to −∇P axis. Moreover, the increase of Q was higher than the linear increase, presenting significant non-linearity. In this case, non-Darcy flow coefficient β (or nonlinear term coefficient b) of the Forchheimer equation was negative. When the pressure gradient was constant, the pores and fractures were closed due to the increased confining pressure, and the volume flow of samples with different fractures gradually decreased with the increased confining pressure.

- Coefficient a in the sandstone samples with single, T-shaped, and Y-shaped fractures gradually increased with increased σ3, which was caused by the closure of internal fractures in the sample under the confining pressure. Coefficient b gradually decreased with increased σ3. Moreover, the angle of the single-fracture sample had a greater impact on the seepage characteristic of pore-fracture media, and the angles of the sandstone samples with T- and Y-shaped fractures had a relatively small impact.

- The nonlinear inertial-parameter equation of fluid flow in pore-fracture media was fitted based on the experiment. This equation showed that the relationship between non-Darcy flow coefficient β (negative value) and inherent permeability k was still following the power function.

- When β was a negative value, critical nonlinear effect E was −0.1, and corresponding Forchheimer’s coefficient F0 was −0.091. The normalized hydraulic conductivity method is used to evaluate the applicability of Darcy’s law, which provided a clear quantitative standard for predicting nonlinear flow behaviors.

- Through the combination of experiment and numerical simulation, it can be seen that the nonlinear seepage characteristic phenomenon in this paper satisfies −μ2/4ρ|−∇P|k2 < β < 0. Under the seepage water pressure, the water flow first passes through the porous area of the sandstone sample and then passes through the combined area of pores and prefabricated fractures. The existence of prefabricated fracture has a significant influence on the seepage law, and the different spatial combinations of pores and prefabricated fractures are the main reason for the nonlinear seepage characteristic.

- The expanded value range of non-Darcy flow coefficient β could open up new research directions and improve the research field of nonlinear seepage, providing strong support for developing the rock-mass seepage theory.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Bear, J. Dynamics of Fluids in Porous Media; Elsevier: New York, NY, USA, 1972. [Google Scholar]

- Tsang, Y.W.; Witherspoon, P.A. Hydromechanical behavior of a deformable rock fracture subject to normal stress. J. Geophys. Res. Solid Earth 1981, 86, 9287–9298. [Google Scholar] [CrossRef]

- Chen, Z.; Narayan, S.P.; Yang, Z.; Rahman, S.S. An experimental investigation of hydraulic behaviour of fractures and joints in granitic rock. Int. J. Rock Mech. Min. Sci. 2000, 37, 1061–1071. [Google Scholar] [CrossRef]

- Nazridoust, K.; Ahmadi, G.; Smith, D.H. A new friction factor correlation for laminar, single-phase flows through rock fractures. J. Hydrol. 2006, 329, 315–328. [Google Scholar] [CrossRef]

- Crandall, D.; Ahmadi, G.; Smith, D.H. Computational Modeling of Fluid Flow through a Fracture in Permeable Rock. Transp. Porous Media 2010, 84, 493–510. [Google Scholar] [CrossRef]

- Yang, Y.; Zhang, D.; Zhang, B.; Ye, C.; Yang, B. Analysis of Strength and permeability of crystalline sandstone under loading-unloading conditions. Energy Sources Part A: Recover. Util. Environ. Eff. 2019, 41, 2650–2661. [Google Scholar]

- Zeng, Z.; Grigg, R. A criterion for non-Darcy flow in porous media. Transp. Porous Media 2006, 63, 57–69. [Google Scholar] [CrossRef]

- Sidiropoulou, M.G.; Moutsopoulos, K.N.; Tsihrintzis, V.A. Determination of Forchheimer equation coefficients a and b. Hydrol. Process. 2007, 21, 534–554. [Google Scholar] [CrossRef]

- Moutsopoulos, K.N.; Papaspyros, I.N.E.; Tsihrintzis, V.A. Experimental investigation of inertial flow processes in porous media. J. Hydrol. 2009, 374, 242–254. [Google Scholar] [CrossRef]

- Eck, B.J.; Barrett, M.E.; Charbeneau, R.J. Forchheimer flow in gently sloping layers: Application to drainage of porous asphalt. Water Resour. Res. 2012, 48, W01530. [Google Scholar] [CrossRef]

- Ghane, E.; Fausey, N.R.; Brown, L.C. Non-Darcy flow of water through woodchip media. J. Hydrol. 2014, 519, 3400–3409. [Google Scholar] [CrossRef]

- Schrauf, T.W.; Evans, D.D. Laboratory studies of gas flow through a single natural fracture. Water Resour. Res. 1986, 22, 1038–1050. [Google Scholar] [CrossRef]

- Zimmerman, R.W.; Al-Yaarubi, A.; Pain, C.C.; Grattoni, C.A. Non-linear regimes of fluid flow in rock fractures. Int. J. Rock Mech. Min. Sci. 2004, 41, 163–169. [Google Scholar] [CrossRef]

- Ranjith, P.G.; Darlington, W. Nonlinear single-phase flow in real rock joints. Water Resour. Res. 2007, 43, W09502. [Google Scholar] [CrossRef]

- Zhang, Z.; Nemcik, J. Fluid flow regimes and nonlinear flow characteristics in deformable rock fractures. J. Hydrol. 2013, 477, 139–151. [Google Scholar] [CrossRef]

- Javadi, M.; Sharifzadeh, M.; Shahriar, K.; Mitani, Y. Critical Reynolds number for nonlinear flow through rough-walled fractures: The role of shear processes. Water Resour. Res. 2014, 50, 1789–1804. [Google Scholar] [CrossRef]

- Tzelepis, V.; Moutsopoulos, K.N.; Papaspyros, J.N.E.; Tsihrintzis, V.A. Experimental investigation of flow behavior in smooth and rough artificial fractures. J. Hydrol. 2015, 521, 108–118. [Google Scholar] [CrossRef]

- Mathias, S.A.; Butler, A.P.; Zhan, H. Approximate solutions for Forchheimer flow to a well. J. Hydraul. Eng. 2008, 134, 1318–1325. [Google Scholar] [CrossRef]

- Johnson, J.; Brown, S.; Stockman, H. Fluid flow and mixing in rough-walled fracture intersections. J. Geophys. Res. Solid Earth 2006, 111, B12206. [Google Scholar] [CrossRef]

- Qian, J.; Zhan, H.; Luo, S.; Zhao, W. Experimental evidence of scale-dependent hydraulic conductivity for fully developed turbulent flow in a single fracture. J. Hydrol. 2007, 339, 206–215. [Google Scholar] [CrossRef]

- Zou, L.; Jing, L.; Cvetkovic, V. Roughness decomposition and nonlinear fluid flow in a single rock fracture. Int. J. Rock Mech. Min. Sci. 2015, 75, 102–118. [Google Scholar] [CrossRef]

- Quinn, P.M.; Parker, B.L.; Cherry, J.A. Using constant head step tests to determine hydraulic apertures in fractured rock. J. Contam. Hydrol. 2011, 126, 85–99. [Google Scholar] [CrossRef] [PubMed]

- Qian, J.; Wang, M.; Zhang, Y.; Yan, X.; Zhao, W. Experimental study of the transition from non-Darcian to Darcy behavior for flow through a single fracture. J. Hydrodyn. 2015, 27, 679–688. [Google Scholar] [CrossRef]

- Rong, G.; Tan, J.; Zhan, H.B.; He, R.H.; Zhang, Z.Y. Quantitative evaluation of fracture geometry influence on nonlinear flow in a single rock fracture. J. Hydrol. 2020, 589, 125162. [Google Scholar] [CrossRef]

- Xing, K.; Qian, J.Z.; Zhao, W.D.; Ma, H.C.; Ma, L. Experimental and numerical study for the inertial dependence of non-Darcy coefficient in rough single fractures. J. Hydrol. 2021, 603, 127148. [Google Scholar] [CrossRef]

- Cornell, D.; Katz, D.L. Flow of gases through consolidated porous media. Indus. Eng Chem. 1953, 45, 2145–2152. [Google Scholar] [CrossRef]

- Ruth, D.; Ma, H. On the derivation of the Forchheimer equation by means of the averaging theorem. Trans. Porous Med. 1992, 7, 255–264. [Google Scholar] [CrossRef]

- Li, D.; Engler, T.W. Literature review on correlations of the non-Darcy coefficient. In Proceedings of the SPE Permian Basin Oil and Gas Recovery Conference, Midland, TX, USA, 23–26 March 2001. [Google Scholar]

- Rong, G.; Yang, J.; Cheng, L.; Zhou, C. Laboratory investigation of nonlinear flow characteristics in rough fractures during shear process. J. Hydrol. 2016, 541, 1385–1394. [Google Scholar] [CrossRef]

- Macini, P.; Mesini, E.; Viola, R. Laboratory measurements of non-Darcy flow coefficients in natural and artificial unconsolidated porous media. J. Pet. Sci. Eng. 2011, 77, 365–374. [Google Scholar] [CrossRef]

- Yin, Q.; Ma, G.; Jing, H.; Wang, H.; Su, H.; Wang, Y.; Liu, R. Hydraulic properties of 3D rough-walled fractures during shearing: An experimental study. J. Hydrol. 2017, 555, 169–184. [Google Scholar] [CrossRef]

- Yu, B.Y.; Chen, Z.Q.; Ding, Q.L.; Wang, L.Z. Non-Darcy flow seepage characteristics of saturated broken rocks under compression with lateral constraint. Int. J. Min. Sci. Technol. 2016, 26, 1145–1151. [Google Scholar] [CrossRef]

- Zhou, J.Q.; Hu, S.H.; Fang, S.; Chen, Y.F.; Zhou, C.B. Nonlinear flow behavior at low Reynolds numbers through rough-walled fractures subjected to normal compressive loading. Int. J. Rock Mech. Min. Sci. 2015, 80, 202–218. [Google Scholar] [CrossRef]

- Chen, Y.F.; Zhou, J.Q.; Hu, S.H.; Hu, R.; Zhou, C.B. Evaluation of Forchheimer equation coefficients for non-Darcy flow in deformable rough-walled fractures. J. Hydrol. 2015, 529, 993–1006. [Google Scholar] [CrossRef]

- Li, W.L.; Zhou, J.Q.; He, X.L.; Chen, Y.F.; Zhou, C.B. Nonlinear flow characteristics of broken granite subjected to confining pressures. Rock Soil Mech. 2017, 38, 140–150. [Google Scholar]

- Ma, D.; Miao, X.X.; Chen, Z.Q.; Mao, X.B. Experimental Investigation of Seepage Properties of Fractured Rocks Under Different Confining Pressures. Rock Mech. Rock Eng. 2013, 46, 1135–1144. [Google Scholar] [CrossRef]

- Dary, H. Les Fontaines Publiques de la Ville de Dijon, Exposition et Application des Principes a Suivre et des Formules a Employer Dans les Questions de Distribution D’eau; Victor Dalmont: Paris, France, 1856; p. 647. [Google Scholar]

- Zimmerman, R.W.; Bodvarsson, G.S. Hydraulic conductivity of rock fractures. Transp. Porous Media 1996, 23, 1–30. [Google Scholar] [CrossRef]

- Medici, G.; West, L.J. Review of groundwater flow and contaminant transport modelling approaches for the Sherwood Sandstone aquifer, UK; Insights from analogous successions worldwide. Q. J. Eng. Geol. Hydrogeol. 2022, 55, qjegh2021-176. [Google Scholar] [CrossRef]

- Forchheimer, P. Wasserbewegung durch boden. Z. Ver. Dtsch. Ing. 1901, 45, 1782–1788. [Google Scholar]

- Develi, K.; Babadagli, T. Experimental and visual analysis of single-phase flow through rough fracture replicas. Int. J. Rock Mech. Min. Sci. 2015, 73, 139–155. [Google Scholar] [CrossRef]

- Pan, J.; Xi, X.; Wu, X.; Guo, Q.; Ren, F.; Cai, M. Physical properties evolution and microscopic mechanisms of granite modified by thermal and chemical stimulation. Case Stud. Therm. Eng. 2023, 41, 102633. [Google Scholar] [CrossRef]

- Belhaj, H.A.; Aghj, K.R.; Nouri, A.M.; Butt, S.D.; Vaziri, H.H.; Islam, M.R. Numerical and experimental modeling of non-Darcy flow in porous media. In Proceedings of the Society of Petroleum Engineers, SPE Latin America and Caribbean Petroleum Engineering Conference, Port of Spain, Trinidad and Tobago, 27–30 April 2003; pp. 1–9. [Google Scholar]

- Skjetne, E.; Auriault, J.L. New insights on steady, non-linear flow in porous media. Eur. J. Mech. B Fluids 1999, 18, 131–145. [Google Scholar] [CrossRef]

- Cherubini, C.; Giasi, C.I.; Pastore, N. Bench scale laboratory tests to analyze non-linear flow in fractured media. Hydrol. Earth Syst. Sci. 2012, 16, 2511–2522. [Google Scholar] [CrossRef]

| Confining Pressure/MPa | Water Pressure/MPa | Time/s | Confining Pressure/MPa | Water Pressure/MPa | Time/s |

|---|---|---|---|---|---|

| 8.0 | 3 | 100 | 9.5 | 3 | 100 |

| 8.0 | 4 | 100 | 9.5 | 4 | 100 |

| 8.0 | 5 | 100 | 9.5 | 5 | 100 |

| 8.0 | 6 | 100 | 9.5 | 6 | 100 |

| 8.0 | 7 | 100 | 9.5 | 7 | 100 |

| 8.5 | 3 | 100 | 10.0 | 3 | 100 |

| 8.5 | 4 | 100 | 10.0 | 4 | 100 |

| 8.5 | 5 | 100 | 10.0 | 5 | 100 |

| 8.5 | 6 | 100 | 10.0 | 6 | 100 |

| 8.5 | 7 | 100 | 10.0 | 7 | 100 |

| 9.0 | 3 | 100 | |||

| 9.0 | 4 | 100 | |||

| 9.0 | 5 | 100 | |||

| 9.0 | 6 | 100 | |||

| 9.0 | 7 | 100 |

| Sample No. | Fitting Equation | R2 |

|---|---|---|

| SF0 | β = −1.74 × 10−6k−1.25 | 0.9589 |

| SF15 | β = −1.40 × 10−47k−3.84 | 0.9238 |

| SF30 | β = −2.30 × 10−8k−1.35 | 0.9632 |

| SF45 | β = −4.80 × 10−20k−2.10 | 0.9196 |

| SF60 | β = −7.98 × 10−36k−3.06 | 0.9955 |

| SF75 | β = −2.56 × 10−30k−2.72 | 0.9549 |

| SF90 | β = −2.37 × 10−22k−2.24 | 0.9898 |

| ST0 | β = −2.04 × 10−22k−2.26 | 0.9906 |

| ST15 | β = −1.23 × 10−21k−2.18 | 0.9072 |

| ST30 | β = −3.39 × 10−43k−3.56 | 0.6875 |

| ST45 | β = −1.15 × 10−6k−1.22 | 0.8347 |

| ST60 | β = −2.48 × 10−13k−1.66 | 0.9630 |

| ST75 | β = −4.43 × 10−19k−2.05 | 0.9928 |

| ST90 | β = −51.44k−0.74 | 0.8346 |

| SY0 | β = −1.55 × 10−47k−3.83 | 0.9747 |

| SY15 | β = −2.81 × 10−22k−2.24 | 0.9131 |

| SY30 | β = −9.44 × 10−17k−1.90 | 0.9761 |

| SY45 | β = −6.00 × 10−33k−2.93 | 0.9950 |

| SY60 | β = −3.46 × 10−42k−3.51 | 0.9659 |

| SY75 | β = −4.94 × 10−33k−2.91 | 0.8154 |

| SY90 | β = −1.36 × 10−13k−1.71 | 0.9899 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Shang, Q.; Zhang, D.; Pan, J.; Xi, X.; Wang, P.; Cai, M. A Negative Value of the Non-Darcy Flow Coefficient in Pore-Fracture Media under Hydro-Mechanical Coupling. Minerals 2023, 13, 373. https://doi.org/10.3390/min13030373

Zhang Y, Shang Q, Zhang D, Pan J, Xi X, Wang P, Cai M. A Negative Value of the Non-Darcy Flow Coefficient in Pore-Fracture Media under Hydro-Mechanical Coupling. Minerals. 2023; 13(3):373. https://doi.org/10.3390/min13030373

Chicago/Turabian StyleZhang, Ying, Qingqing Shang, Dongsheng Zhang, Jiliang Pan, Xun Xi, Peitao Wang, and Meifeng Cai. 2023. "A Negative Value of the Non-Darcy Flow Coefficient in Pore-Fracture Media under Hydro-Mechanical Coupling" Minerals 13, no. 3: 373. https://doi.org/10.3390/min13030373

APA StyleZhang, Y., Shang, Q., Zhang, D., Pan, J., Xi, X., Wang, P., & Cai, M. (2023). A Negative Value of the Non-Darcy Flow Coefficient in Pore-Fracture Media under Hydro-Mechanical Coupling. Minerals, 13(3), 373. https://doi.org/10.3390/min13030373