Optimization of Soil-Sludge Mixtures by Compaction for Potential Use in Mine Site Reclamation

Abstract

:1. Introduction

2. Materials and Methods

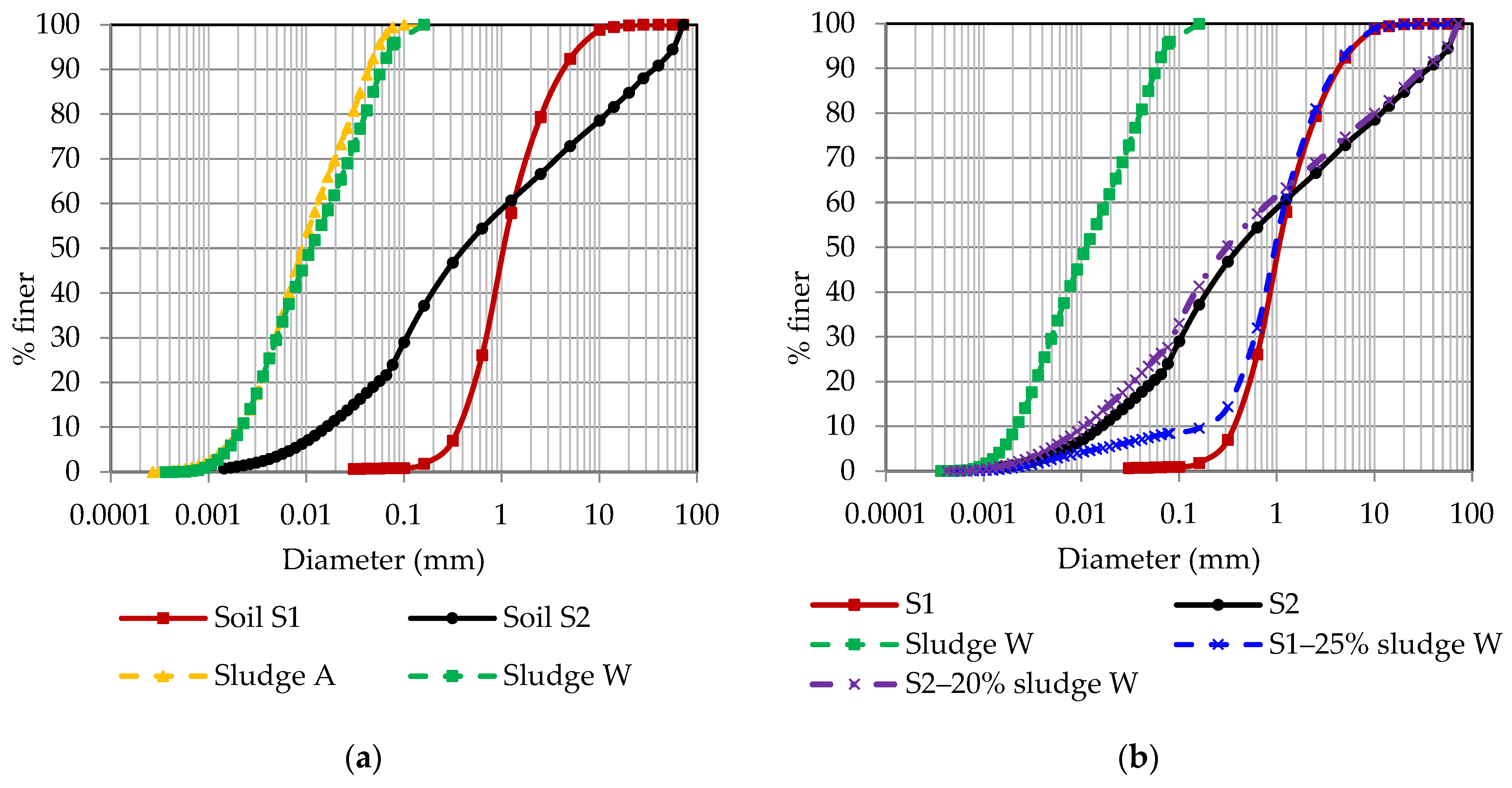

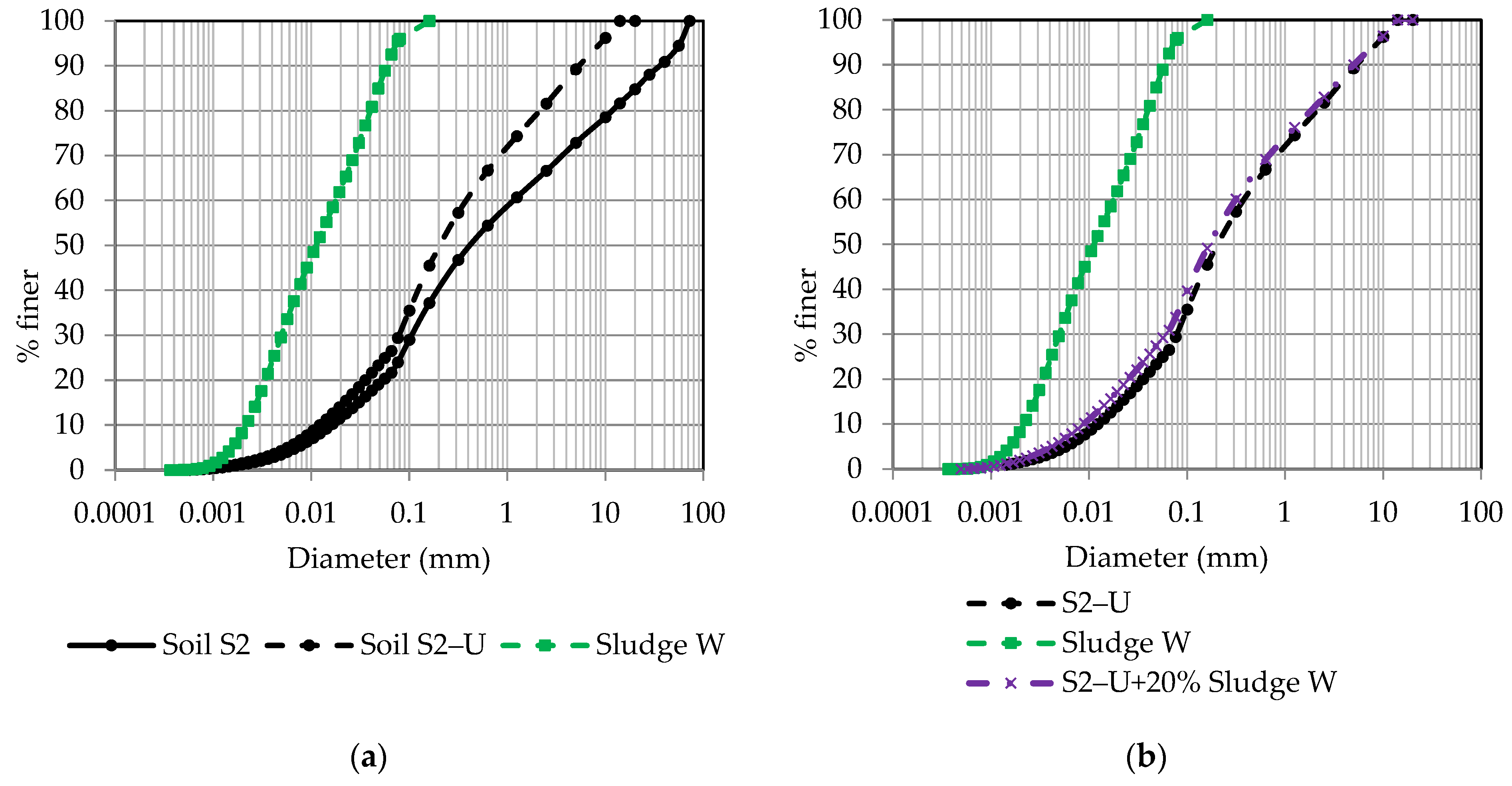

2.1. Characterization of Base Materials and Preparation of Soil-Sludge Mixtures

2.2. Optimization of Soil-Sludge Mixtures by Compaction

2.3. Hydrogeotechnical Properties of Base Materials and Optimized Soil-Sludge Mixtures

3. Results

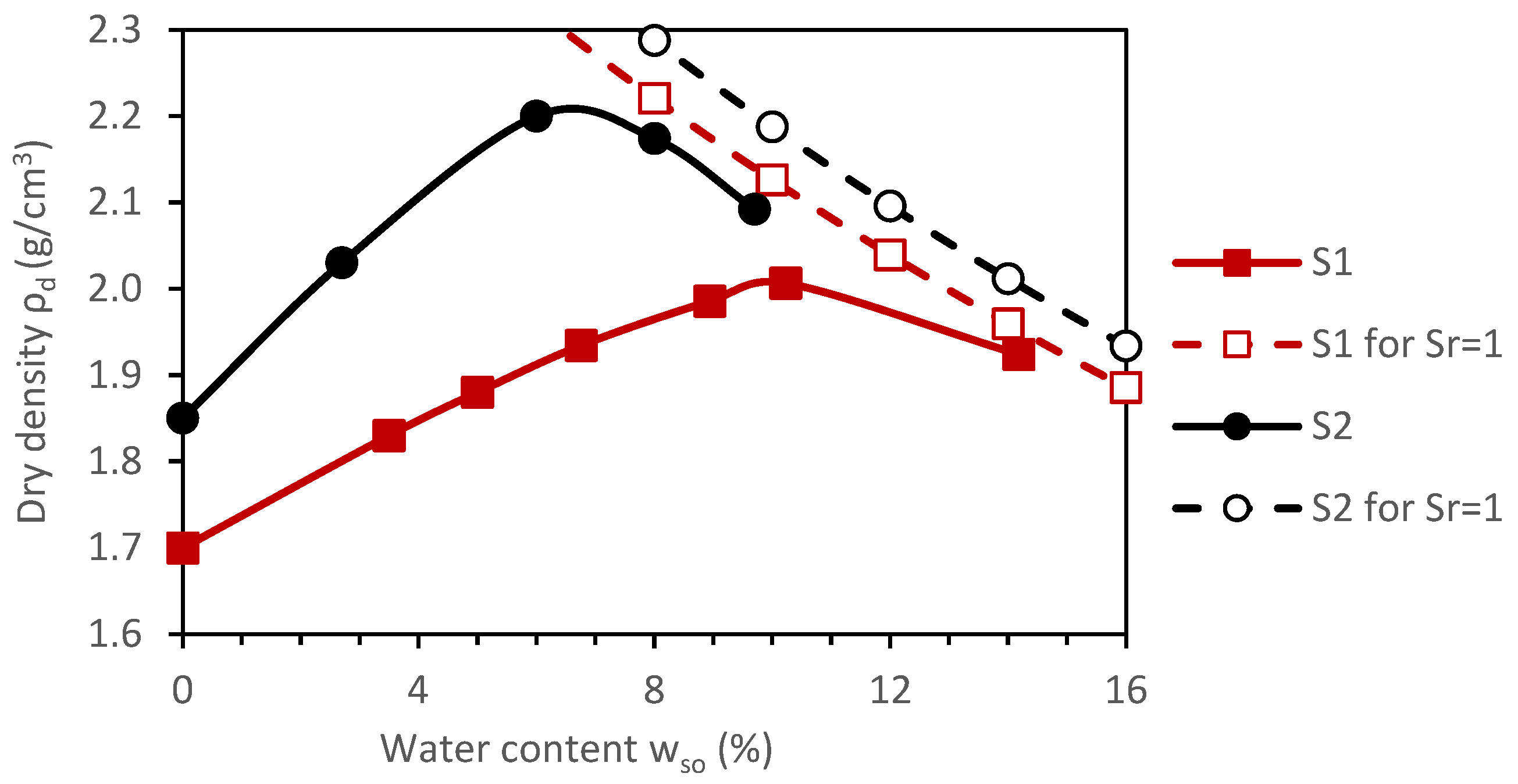

3.1. Compaction Characteristics of Soils S1 and S2

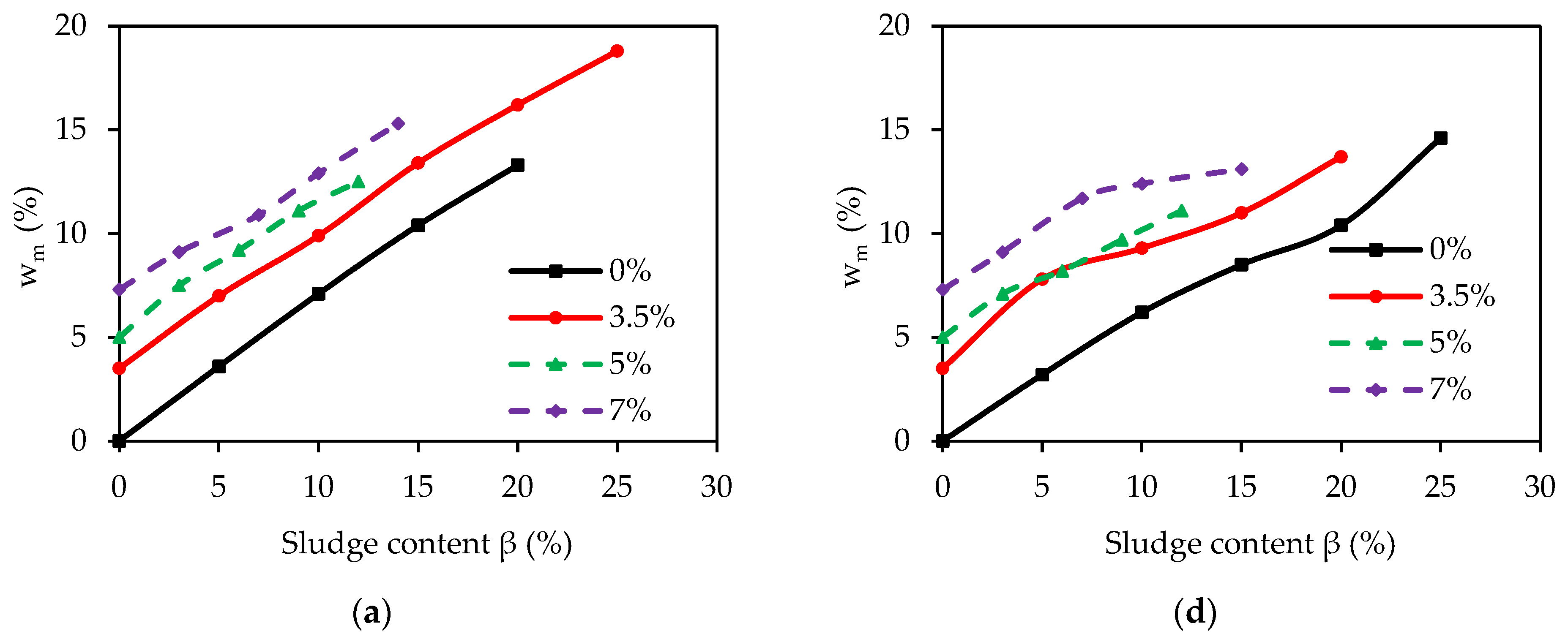

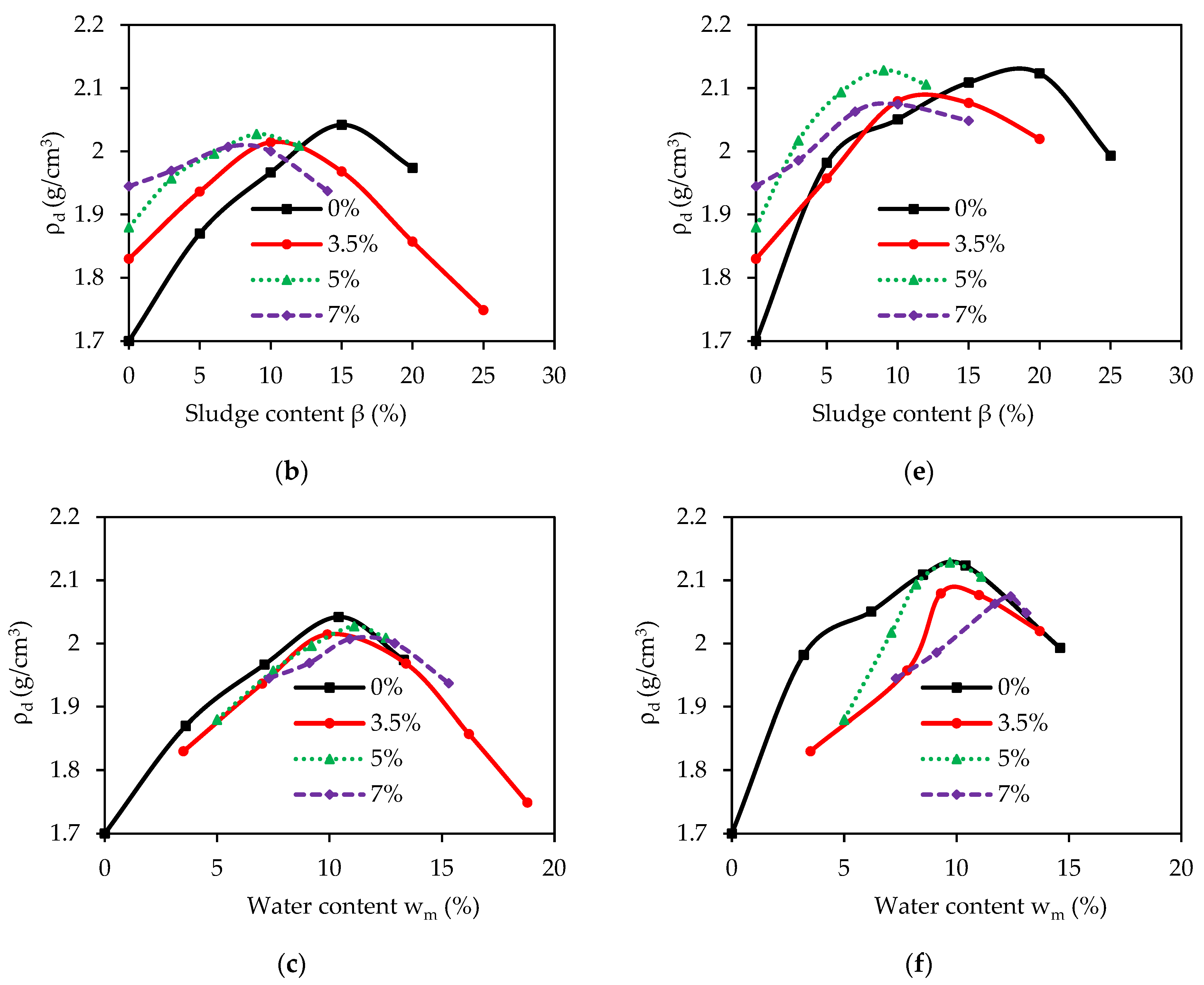

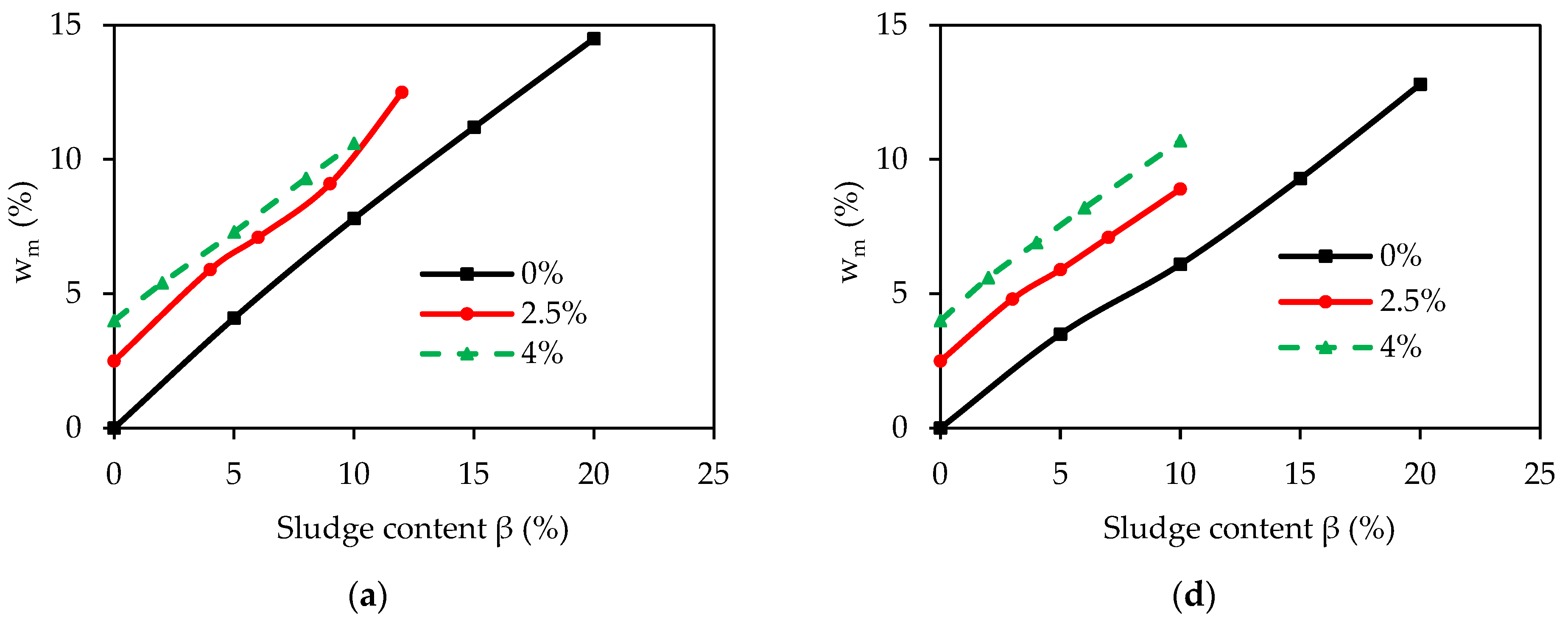

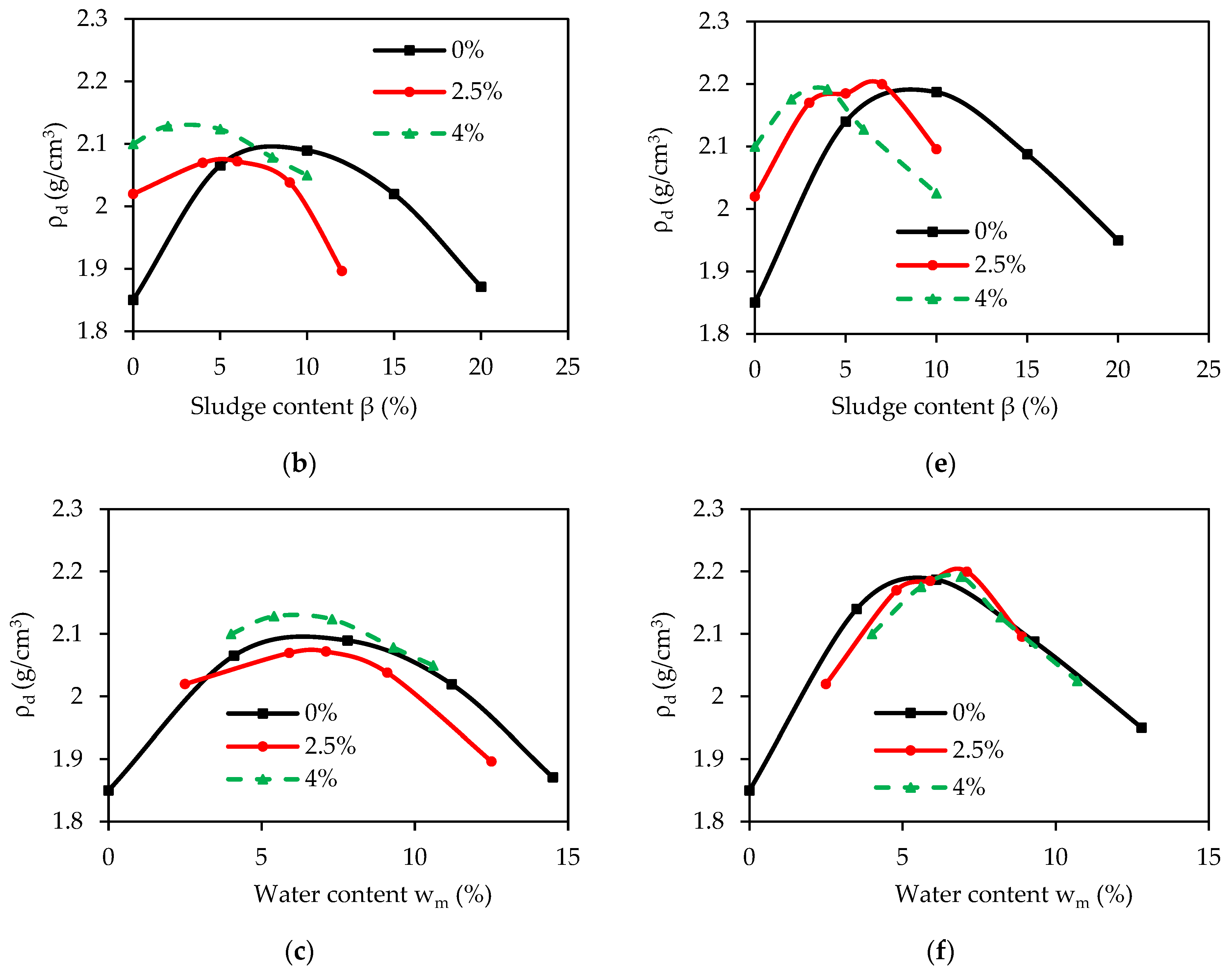

3.2. Compaction-Based Optimum Sludge Content for the S1-A and S1-W Mixtures

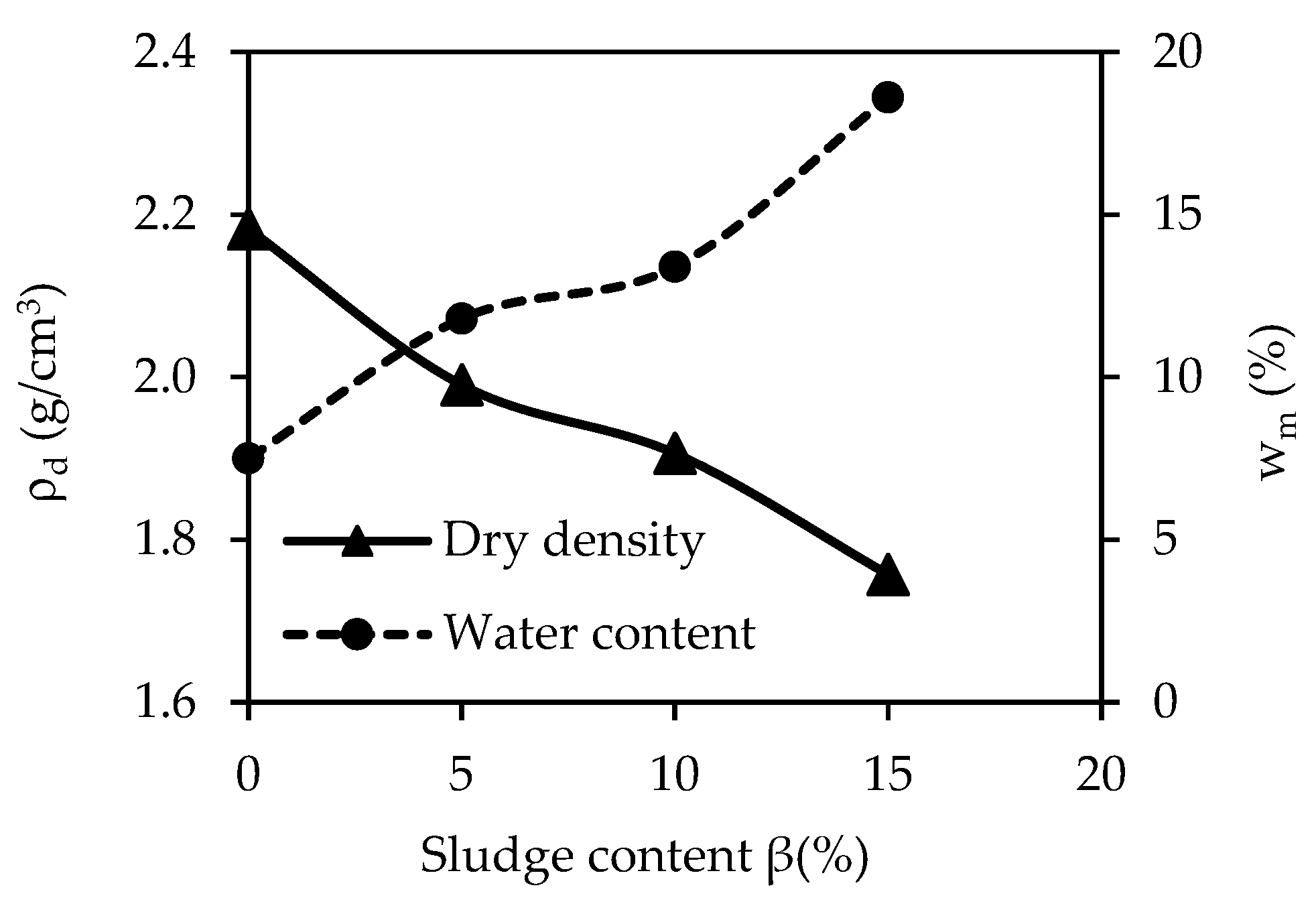

3.3. Compaction-Based Optimum Sludge Content for the S2-A and S2-W Mixtures

3.4. Saturated Hydraulic Conductivity of Base Soils and Selected Mixtures

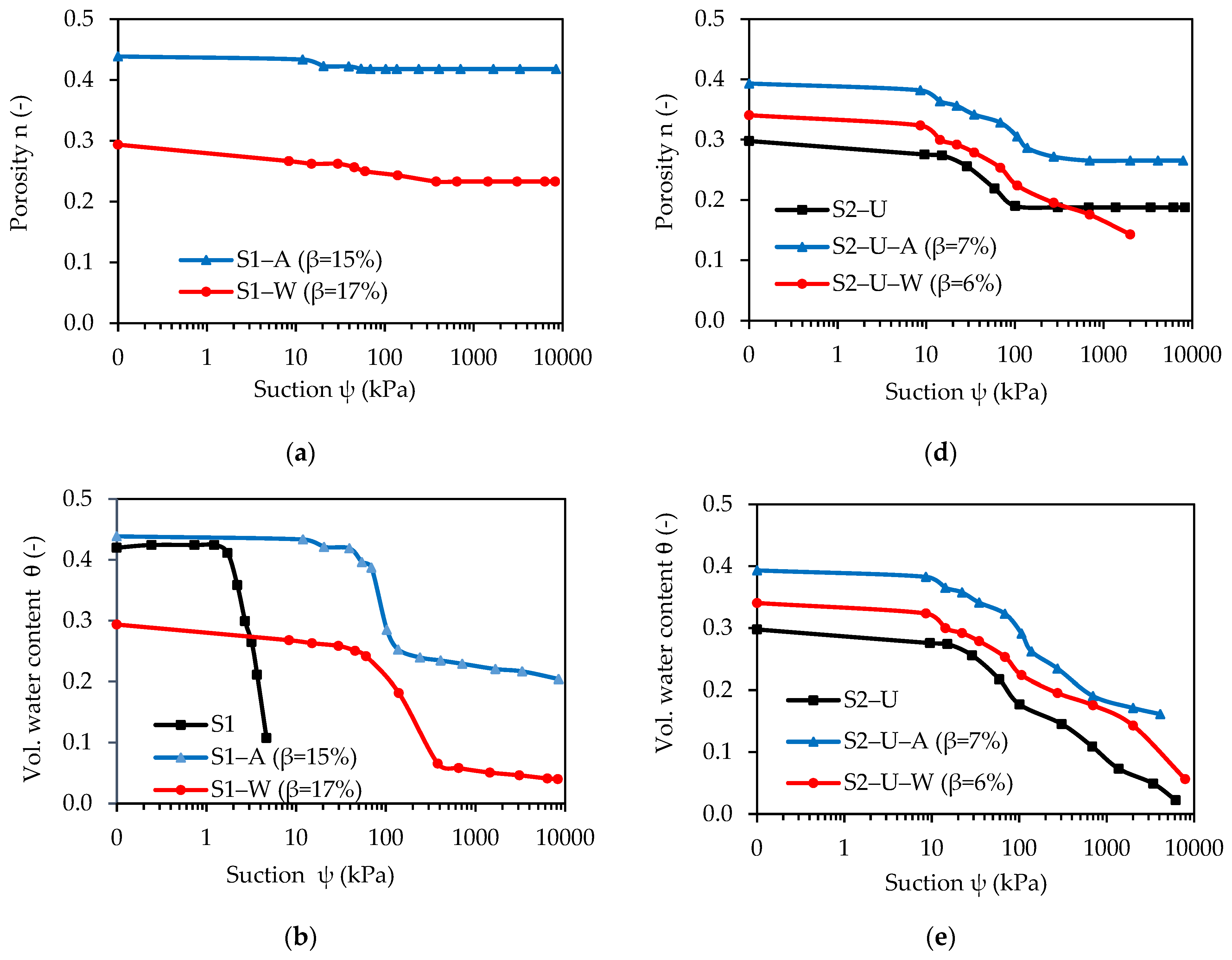

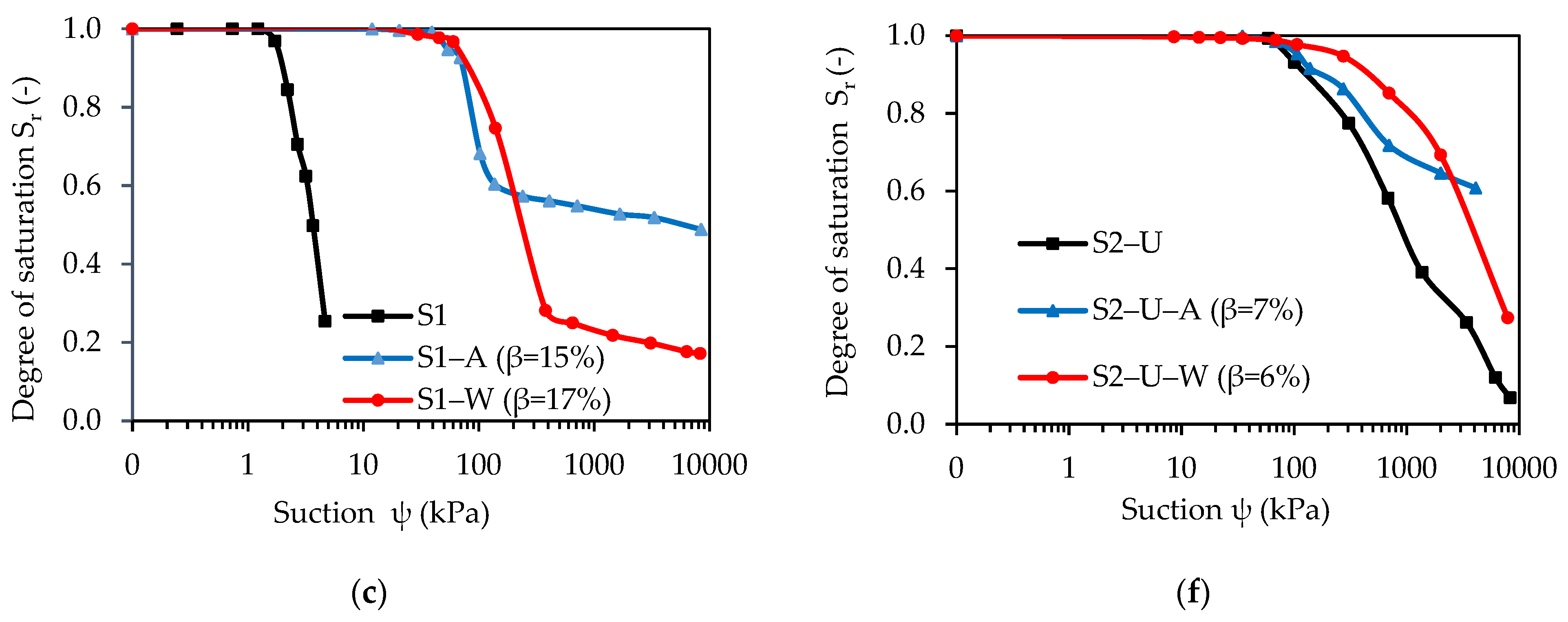

3.5. Water Retention Curves of Base Soils and Selected Mixtures

4. Discussion

4.1. Justification for the Chosen Initial Water Contents of the Base Soils

4.2. Comparison of Measured and Calculated Water Contents wm of the Mixtures

4.3. Correction of the Hydrogeotechnical Properties for Materials Containing Oversized Particles

4.4. Alternative Mixture Optimization Approaches

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Evangelou, V.P. Pyrite Oxidation and Its Control; CRC Press Inc.: Boca Raton, FL, USA, 1995. [Google Scholar]

- Park, I.; Tabelin, C.B.; Jeon, S.; Li, X.; Seno, K.; Ito, M.; Hiroyoshi, N. A review of recent strategies for acid mine drainage prevention and mine tailings recycling. Chemosphere 2019, 219, 588–606. [Google Scholar] [CrossRef] [PubMed]

- Aubertin, M.; Pabst, T.; Bussière, B.; James, M.; Mbonimpa, M.; Benzaazoua, M.; Maqsoud, A. Revue des meilleures pratiques de restauration des sites d’entreposage de rejets miniers générateurs de DMA. In Proceedings of the Symposium 2015 sur L’environnement et les Mines, Rouyn-Noranda, QC, Canada, 14–17 June 2015. [Google Scholar]

- Bussière, B.; Aubertin, M.; Chapuis, R.P. The behavior of inclined covers used as oxygen barriers. Can. Geotech. J. 2003, 40, 512–535. [Google Scholar] [CrossRef]

- Nicholson, R.V.; Gillham, R.W.; Cherry, J.A.; Reardon, E.J. Reduction of acid generation in mine tailings through the use of moisture-retaining cover layers as oxygen barriers. Can. Geotech. J. 1989, 26, 1–8. [Google Scholar] [CrossRef]

- Bussière, B.; Aubertin, M.; Julien, M. Couvertures avec effets de barrière capillaire pour limiter le drainage minier acide: Aspects théoriques et pratiques. Vecteur Environ. 2001, 34, 37–50. [Google Scholar]

- Morel-Seytoux, H. The capillary barrier effect at the interface of two soil layers with some contrast in properties. HYDROWAR Report 92.4. Hydrol. Days Public 1992, 57, 94027-3926. [Google Scholar]

- Bussière, B.; Benzaazoua, M.; Aubertin, M.; Mbonimpa, M. A laboratory study of covers made of low-sulphide tailings to prevent acid mine drainage. Environ. Geol. 2004, 45, 609–622. [Google Scholar] [CrossRef]

- Mbonimpa, M.; Aubertin, M.; Aachib, M.; Bussière, B. Diffusion and consumption of oxygen in unsaturated cover materials. Can. Geotech. J. 2003, 40, 916–932. [Google Scholar] [CrossRef]

- Aubertin, M.; Chapuis, R. Considérations hydrogéotechniques pour l’entreposage des résidus miniers dans le nord-ouest du Québec. In Proceedings of the Second International Conference on the Abatement of Acidic Drainage, Montreal, MEND/Canmet, Montreal, QC, Canada, 16–18 September 1991; pp. 1–22. [Google Scholar]

- Aubertin, M.; Chapuis, R.P.; Aachib, M.; Bussière, B.; Ricard, J.-F.; Tremblay, L. Évaluation en Laboratoire de Barrières Sèches Construites à Partir de Résidus Miniers; MEND Report 2.22.2a; CANMET: Ottawa, ON, Canada, 1995. [Google Scholar]

- Demers, I.; Pabst, T. Covers with capillary barrier effects. In Hard Rock Mine Reclamation: From Prediction to Management of Acid Mine Drainage; Bussière, B., Guittonny, M., Eds.; CRC Press: Boca Raton, FL, USA, 2021; pp. 167–186. [Google Scholar]

- Maqsoud, A.; Bussière, B.; Mbonimpa, M. Low Saturated Hydraulic Conductivity Covers. In Hard Rock Mine Reclamation: From Prediction to Management of Acid Mine Drainage; Bussière, B., Guittonny, M., Eds.; CRC Press: Boca Raton, FL, USA, 2021; pp. 93–113. [Google Scholar]

- Brown, M.; Barley, B.; Wood, H. Minewater Treatment; IWA Publishing: London, UK, 2002. [Google Scholar]

- Younger, P.L.; Banwart, S.A.; Hedin, R.S. Mine Water: Hydrology, Pollution, Remediation; Springer Science & Business Media: Berlin, Germany, 2002; Volume 5. [Google Scholar]

- McDonald, D.M.; Webb, J.A.; Taylor, J. Chemical stability of acid rock drainage treatment sludge and implications for sludge management. Environ. Sci. Technol. 2006, 40, 1984–1990. [Google Scholar] [CrossRef]

- Zinck, J.; Griffith, W. Review of Acidic Drainage Treatment and Sludge Management Operations; MEND Report 3.43.1; CANMET: Ottawa, ON, Canada, 2013; 101p. [Google Scholar]

- Zinck, J.; Wilson, L.J.; Chen, T.T.; Griffith, W.; Mikhail, S.; Turcotte, S. Characterization and Stability of Acid Mine Drainage Sludges; MEND Report 3.42.2a; CANMET: Ottawa, ON, Canada, 1997; 319p. [Google Scholar]

- Herrera, P.; Uchiyama, H.; Igarashi, T.; Asakura, K.; Ochi, Y.; Iyatomi, N.; Nagae, S. Treatment of acid mine drainage through a ferrite formation process in central Hokkaido, Japan: Evaluation of dissolved silica and aluminium interference in ferrite formation. Miner. Eng. 2007, 20, 1255–1260. [Google Scholar] [CrossRef]

- Igarashi, T.; Herrera, P.S.; Uchiyama, H.; Miyamae, H.; Iyatomi, N.; Hashimoto, K.; Tabelin, C.B. The two-step neutralization ferrite-formation process for sustainable acid mine drainage treatment: Removal of copper, zinc and arsenic, and the influence of coexisting ions on ferritization. Sci. Total Environ. 2020, 715, 136877. [Google Scholar] [CrossRef]

- Zinck, J.; Fiset, J.; Griffith, W. Stability of treatment sludge in various disposal environments: A multi-year leaching study. In Proceedings of the IMWA 2010 Symposium, Sydney, NS, Canada, 5–9 September 2010; pp. 5–9. [Google Scholar]

- Demers, I.; Benzaazoua, M.; Mbonimpa, M.; Bouda, M.; Bois, D.; Gagnon, M. Valorisation of acid mine drainage treatment sludge as remediation component to control acid generation from mine wastes, part 1: Material characterization and laboratory kinetic testing. Miner. Eng. 2015, 76, 109–116. [Google Scholar] [CrossRef]

- Mbonimpa, M.; Bouda, M.; Demers, I.; Benzaazoua, M.; Bois, D.; Gagnon, M. Preliminary geotechnical assessment of the potential use of mixtures of soil and acid mine drainage neutralization sludge as materials for the moisture retention layer of covers with capillary barrier effects. Can. Geotech. J. 2016, 53, 828–838. [Google Scholar] [CrossRef]

- Demers, I.; Bouda, M.; Mbonimpa, M.; Benzaazoua, M.; Bois, D.; Gagnon, M. Valorization of acid mine drainage treatment sludge as remediation component to control acid generation from mine wastes, part 2: Field experimentation. Miner. Eng. 2015, 76, 117–125. [Google Scholar] [CrossRef]

- Demers, I.; Mbonimpa, M.; Benzaazoua, M.; Bouda, M.; Awoh, S.; Lortie, S.; Gagnon, M. Use of acid mine drainage treatment sludge by combination with a natural soil as an oxygen barrier cover for mine waste reclamation: Laboratory column tests and intermediate scale field tests. Miner. Eng. 2017, 107, 43–52. [Google Scholar] [CrossRef]

- ASTM D1557-12e1; Standard Test Methods for Laboratory Compaction Characteristics of Soil Using Modified Effort. ASTM International: West Conshohocken, PA, USA, 2012.

- ASTM D5550-14; Standard Test Method for Specific Gravity of Soil. ASTM International: West Conshohocken, PA, USA, 2014.

- ASTM D4318-17e1; Standard Test Methods for Liquid Limit, Plastic Limit, and Plasticity Index of Soils. ASTM International: West Conshohocken, PA, USA, 2018.

- ASTM D2487-17; Standard Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System). ASTM International: West Conshohocken, PA, USA, 2020.

- Young, R.A. The Rietveld Method; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Martin, A.; Loomer, D.; Fawcett, S.; Rollo, A.; Gault, A.; Jamieson, H.; Simpson, S. MEND Report 3.44.1. Characterization and Prediction of Trace Metal Bearings Phases in ARD Neutralization Sludge; CANMET: Ottawa, ON, Canada, 2013. [Google Scholar]

- Chapuis, R.P. Predicting the saturated hydraulic conductivity of soils: A review. Bull. Eng. Geol. Environ. 2012, 71, 401–434. [Google Scholar] [CrossRef]

- ASTM D2434; Standard Test Method for Permeability of Granular Soils (Constant Head). ASTM International: West Conshohocken, PA, USA, 2000.

- ASTM D5856-95; Method for Measurement of Hydraulic Conductivity of Porous Material Using a Rigid-Wall, Compaction—Mold Permeameter. ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D6836-16; Standard Test Methods for Determination of the Soil Water Characteristic Curve for Desorption Using Hanging Column, Pressure Extractor, Chilled Mirror Hygrometer, or Centrifuge. ASTM International: West Conshohocken, PA, USA, 2016.

- Mbonimpa, M.; Aubertin, M.; Maqsoud, A.; Bussière, B. Predictive model for the water retention curve of deformable clayey soils. J. Geotech. Geoenviron. Eng. 2006, 132, 1121–1132. [Google Scholar] [CrossRef]

- Saleh-Mbemba, F.; Aubertin, M.; Mbonimpa, M.; Li, L. Experimental characterization of the shrinkage and water retention behaviour of tailings from hard rock mines. Geotech. Geol. Eng. 2016, 34, 251–266. [Google Scholar] [CrossRef]

- ASTM D4718/D4718M-15; Standard Practice for Correction of Unit Weight and Water Content for Soils Containing Oversize Particles. ASTM International: West Conshohocken, PA, USA, 2015.

- Fuller, W.B.; Thompson, S.E. The laws of proportioning concrete. Trans. Am. Soc. Civ. Eng. 1907, LIX, 67–143. [Google Scholar] [CrossRef]

- Andreasen, A.H.M.; Andersen, J. Über die Beziehung zwischen Kornabstufung und Zwischenraum in Produkten aus losen Körnern (mit einigen Experimenten). Kolloid-Z 1930, 50, 217–228. [Google Scholar] [CrossRef]

- Roquier, G. Étude de la Compacité Optimale des Mélanges Granulaires Binaires: Classe Granulaire Dominante, Effet de Paroi, Effet de Desserrement. Ph.D. Thesis, Université Paris Est, Paris, France, 15 February 2016. [Google Scholar]

- Dinger, D.R.; Funk, J.E. Predictive Process Control of Crowded Particulate Suspensions Applied to Ceramic Manufacturing; Kluwer Academic Publishers: Boston, MA, USA, 1994. [Google Scholar]

- Koltermann, C.E.; Gorelick, S.M. Fractional packing model for hydraulic conductivity derived from sediment mixtures. Water Resour. Res. 1995, 31, 3283–3297. [Google Scholar] [CrossRef]

- Côté, J.; Konrad, J.-M. Assessment of the hydraulic characteristics of unsaturated base-course materials: A practical method for pavement engineers. Can. Geotech. J. 2003, 40, 121–136. [Google Scholar] [CrossRef]

- Wickland, B.; Wilson, G.W.; Wijewickreme, D.; Klein, B. Design and evaluation of mixtures of mine waste rock and tailings. Can. Geotech. J. 2006, 43, 928–945. [Google Scholar] [CrossRef]

- Jehring, M.M.; Bareither, C.A. Tailings composition effects on shear strength behavior of co-mixed mine waste rock and tailings. Acta Geotech. 2016, 11, 1147–1166. [Google Scholar] [CrossRef]

| Parameter * | Soil S1 | Soil S2 | Soil S2-U | Sludge A | Sludge W |

|---|---|---|---|---|---|

| D10 (mm) | 0.350 | 0.014 | 0.012 | 0.002 | 0.002 |

| D30 (mm) | 0.600 | 0.100 | 0.076 | 0.005 | 0.005 |

| D50 (mm) | 1.00 | 0.400 | 0.200 | 0.009 | 0.011 |

| D60 (mm) | 1.25 | 1.20 | 0.403 | 0.015 | 0.018 |

| CU (−) | 3.6 | 85.7 | 33.6 | 5 | 9 |

| CC (−) | 0.8 | 1.7 | 0.8 | 1.3 | 0.7 |

| P#200 (%) | 0.8 | 24 | 29 | 97 | 98 |

| P#4 (%) | 92 | 72 | 89 | 0 | 0 |

| R75 (%) | 0 | 0 | 0 | 0 | 0 |

| LL (%) | - | 17 | 17 | 142 | 75 |

| PL (%) | - | 10 | 10 | - | 52 |

| PI (%) | - | 7 | 7 | - | 16 |

| USCS classification | SP | SC-SM | SC-SM | - | MH |

| Gs (−) | 2.7 | 2.8 | 2.8 | 2.6 | 2.35 |

| Mineral/Element | Soil S1 | Soil S2 | Sludge A | Sludge W |

|---|---|---|---|---|

| Albite (%) | 35.4 | 42.3 | - | - |

| Calcite (%) | - | - | 51 | - |

| IIb chlorite (%) | 0.1 | 6.4 | - | - |

| Cordierite (%) | 10.7 | 5.2 | - | - |

| Corundum (%) | - | - | 35 | 16 |

| Gypsum (%) | - | - | - | 80 |

| 2MI muscovite (%) | 0.1 | 10.0 | - | - |

| Pyrite (%) | - | 0.2 | - | - |

| Quartz (%) | 53.7 | 35.2 | 14 | 4 |

| Rutile (%) | - | 0.6 | - | - |

| Sphalerite (%) | - | 0.2 | - | - |

| Total carbon C (%) | 0.050 | 0.050 | 2.060 | 0.650 |

| Total sulfur S (%) | 0.023 | 0.048 | 0.758 | 6.537 |

| Base Material | wso (%) | Sludge Content, β (%wt) | |||

|---|---|---|---|---|---|

| S1-A | S1-W | S2-A | S2-W | ||

| S1 | 0 | 5; 10; 15; 20 | 5; 10; 15; 20; 25 | ||

| 3.5 | 5; 10; 15; 20; 25 | 5; 10; 15; 20 | |||

| 5.0 | 3; 6; 9; 12 | 3; 6; 9; 12 | |||

| 7.0 | 3; 7; 10; 14 | 3; 7; 10; 14 | |||

| S2 | 0 | 2; 5; 10; 15; 20 | 5; 10; 15; 20 | ||

| 2.5 | 4; 6; 9; 12 | 3; 5; 7; 10 | |||

| 4.0 | 2; 5; 8; 10 | 2; 4; 6; 10 | |||

| Material | ρdmax (g/cm3) | 0.98 × ρdmax (g/cm3) | β (%) | n (−) | ksat (m/s) |

|---|---|---|---|---|---|

| Soil S1 | 2.01 | 1.97 | 0 | 0.30 | 2.03 10−5 |

| S1-A | 2.00 | 1.96 | 15 | 0.34 | 8.50 10−7 |

| S1-W | 2.09 | 2.05 | 17 | 0.30 | 2.02 10−6 |

| Soil S2 | 2.21 | 2.16 | 0 | 0.20 | 4.70 10−8 |

| S2-U-A | 2.13 | 2.09 | 7 | 0.29 | 5.23 10−8 |

| S2-U-W | 2.20 | 2.16 | 6 | 0.25 | 6.9 10−8 |

| Material | β (%) | Initial Porosity n (−) | Initial Void Ratio e (−) | AEV (kPa) |

|---|---|---|---|---|

| Soil S1 | 0 | 0.42 | 0.72 | 1.3 |

| S1-A | 15 | 0.44 | 0.79 | 39 |

| S1-W | 17 | 0.29 | 0.41 | 30 |

| Soil S2-U | 0 | 0.30 | 0.43 | 60 |

| S2-U-A | 7 | 0.39 | 0.64 | 68 |

| S2-U-W | 6 | 0.34 | 0.52 | 68 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mbonimpa, M.; Ngabu, É.T.; Belem, T.; Kanteye, O.; Maqsoud, A. Optimization of Soil-Sludge Mixtures by Compaction for Potential Use in Mine Site Reclamation. Minerals 2023, 13, 806. https://doi.org/10.3390/min13060806

Mbonimpa M, Ngabu ÉT, Belem T, Kanteye O, Maqsoud A. Optimization of Soil-Sludge Mixtures by Compaction for Potential Use in Mine Site Reclamation. Minerals. 2023; 13(6):806. https://doi.org/10.3390/min13060806

Chicago/Turabian StyleMbonimpa, Mamert, Élysée Tshibangu Ngabu, Tikou Belem, Ousseynou Kanteye, and Abdelkabir Maqsoud. 2023. "Optimization of Soil-Sludge Mixtures by Compaction for Potential Use in Mine Site Reclamation" Minerals 13, no. 6: 806. https://doi.org/10.3390/min13060806

APA StyleMbonimpa, M., Ngabu, É. T., Belem, T., Kanteye, O., & Maqsoud, A. (2023). Optimization of Soil-Sludge Mixtures by Compaction for Potential Use in Mine Site Reclamation. Minerals, 13(6), 806. https://doi.org/10.3390/min13060806