Prediction of Ore Production in a Limestone Underground Mine by Combining Machine Learning and Discrete Event Simulation Techniques

Abstract

1. Introduction

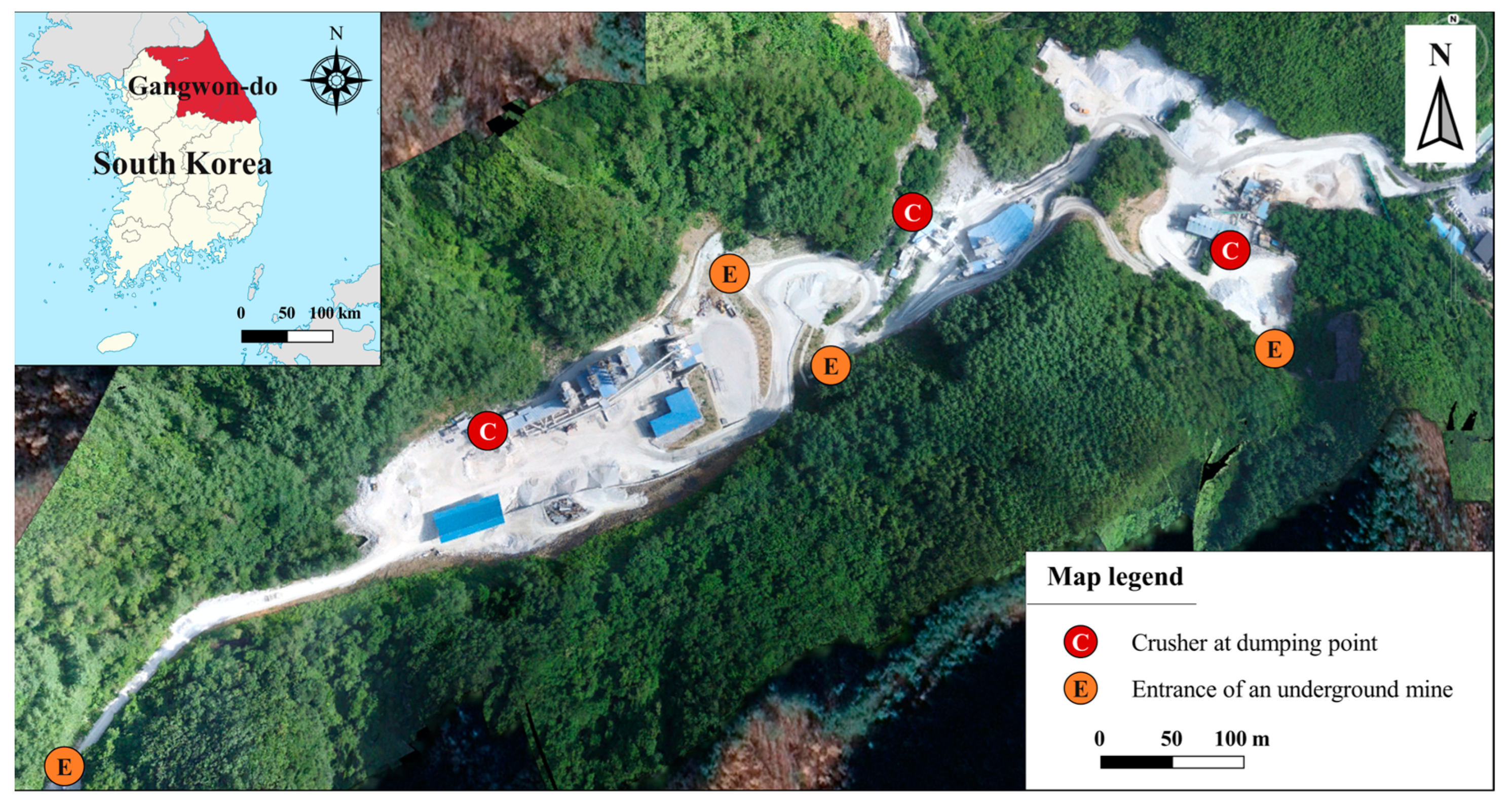

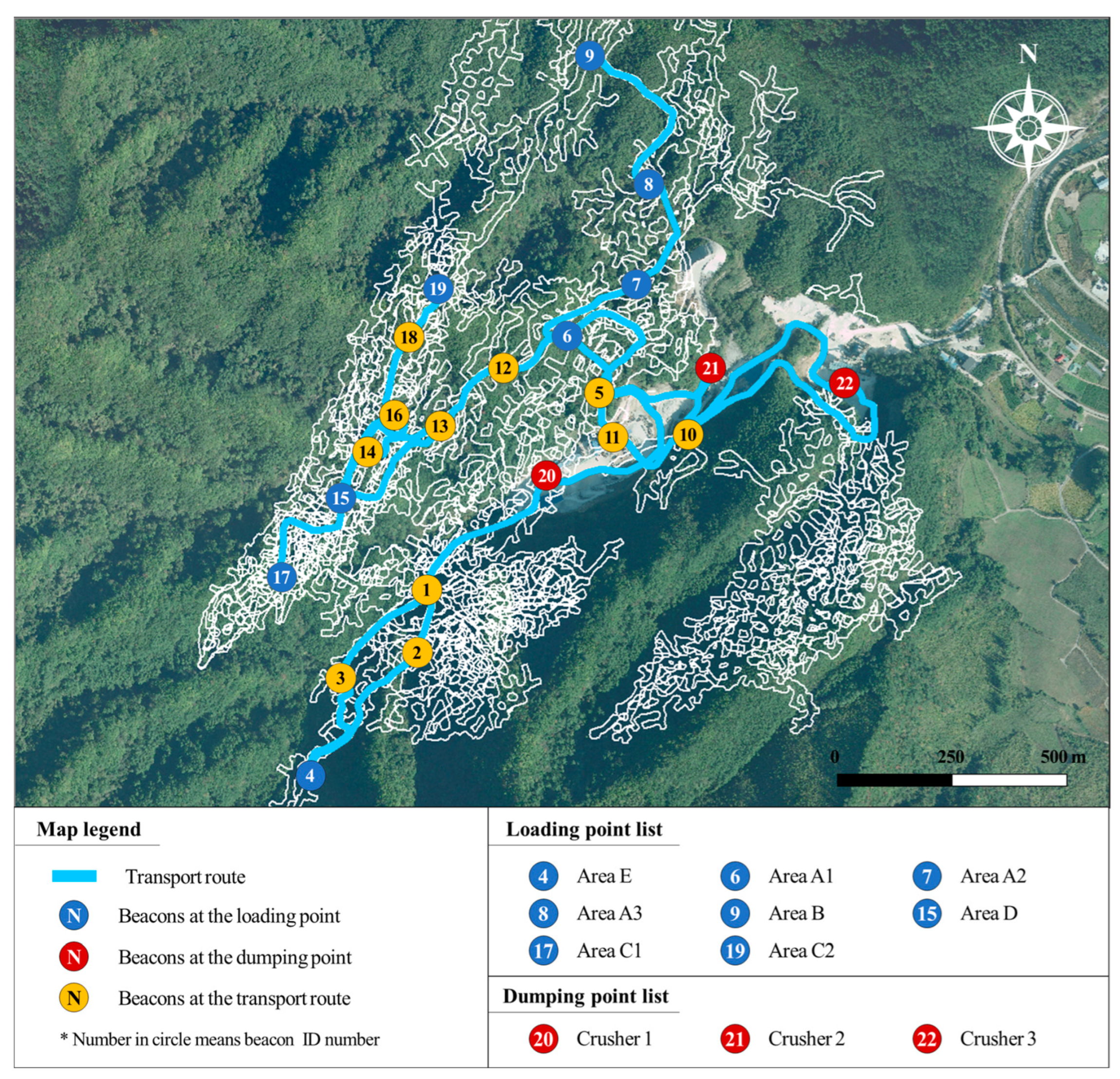

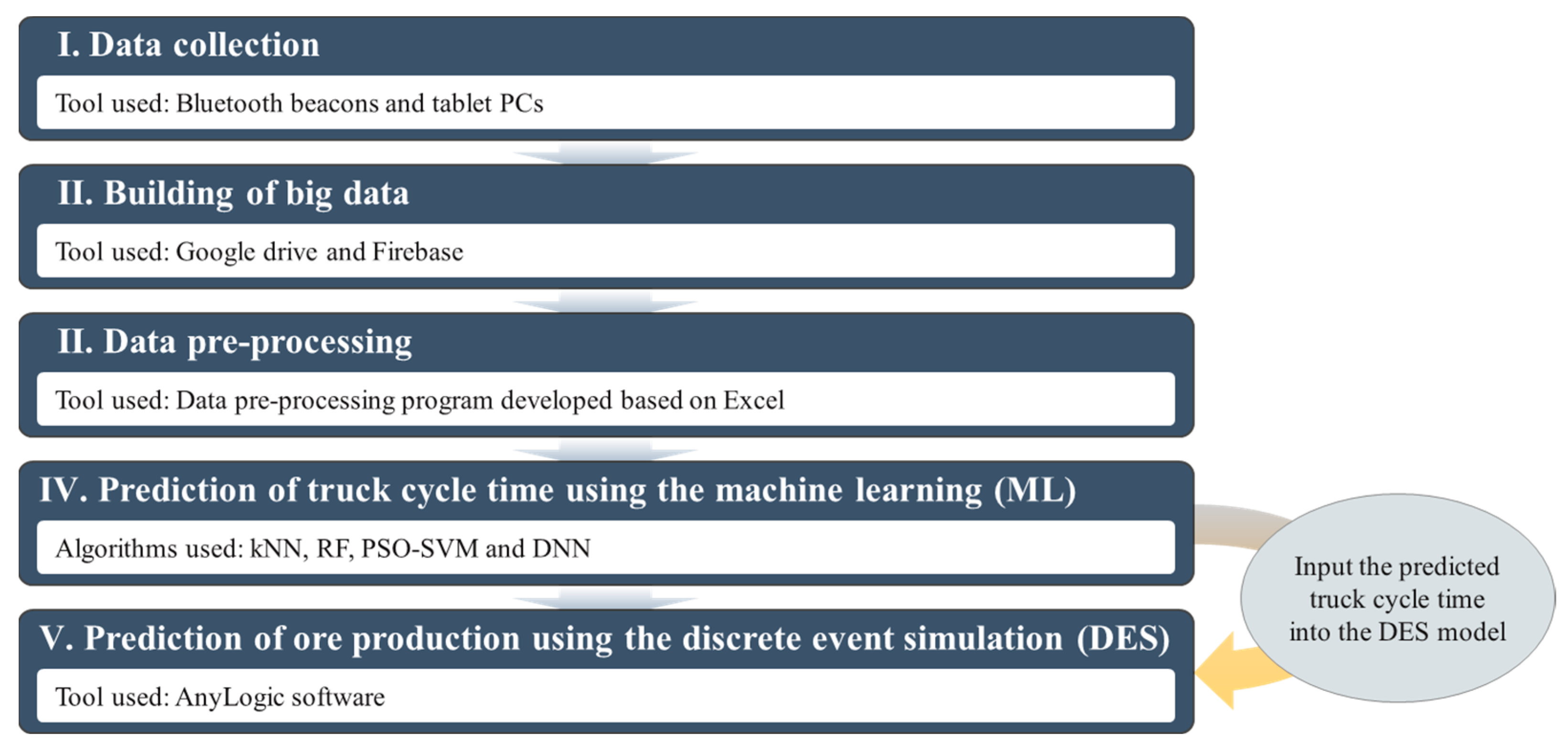

2. Research Area and Data Collection

2.1. Research Area

2.2. Data

2.2.1. Method for Data Collection

2.2.2. Data Pre-Processing and Validation

3. Methods

3.1. Development of Machine Learning (ML) Models for Predicting Truck Cycle Times

3.1.1. Training Data Production and Pre-Processing

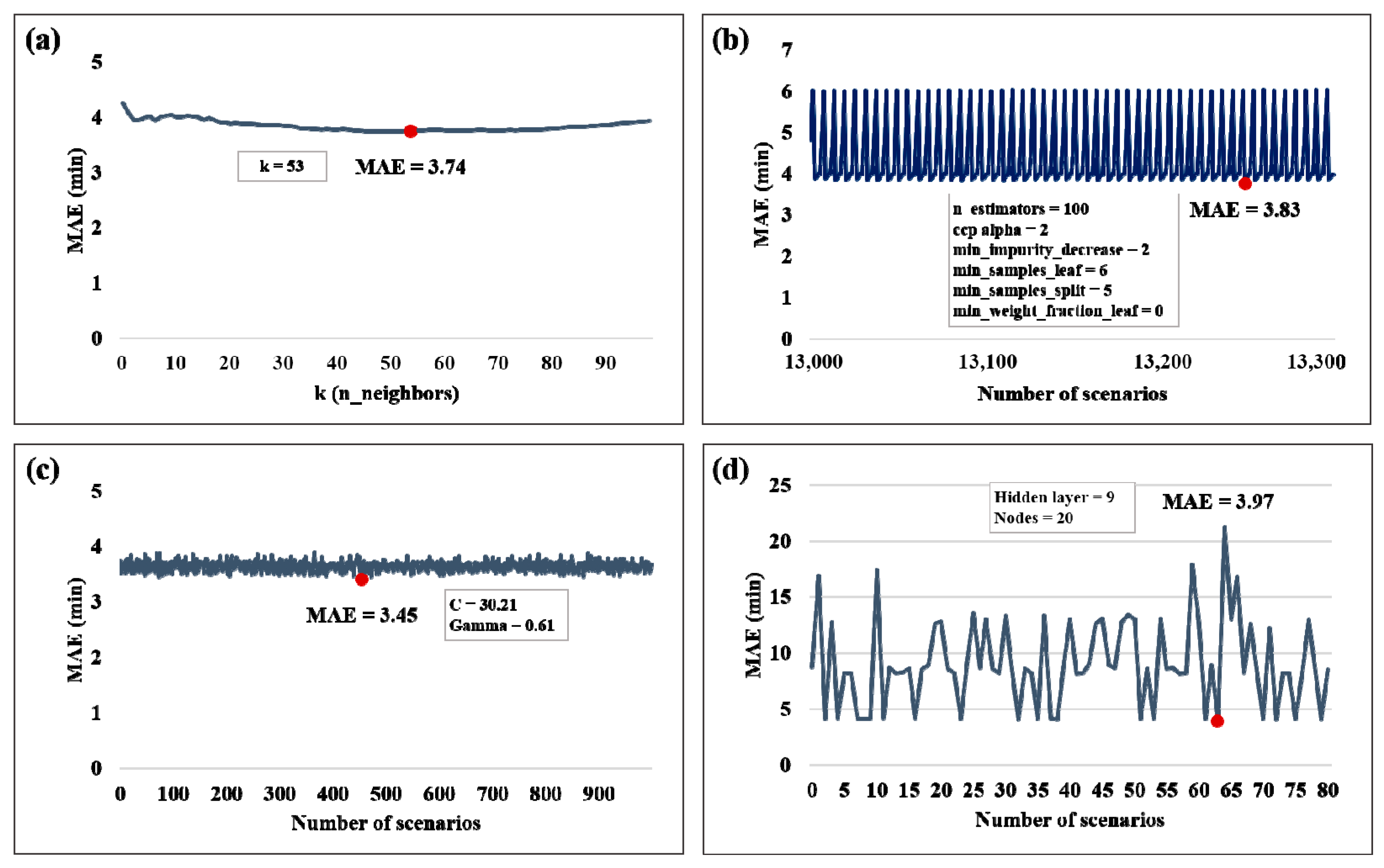

3.1.2. Application of ML Algorithms

3.1.3. ML Model Verification and Optimal Model Selection

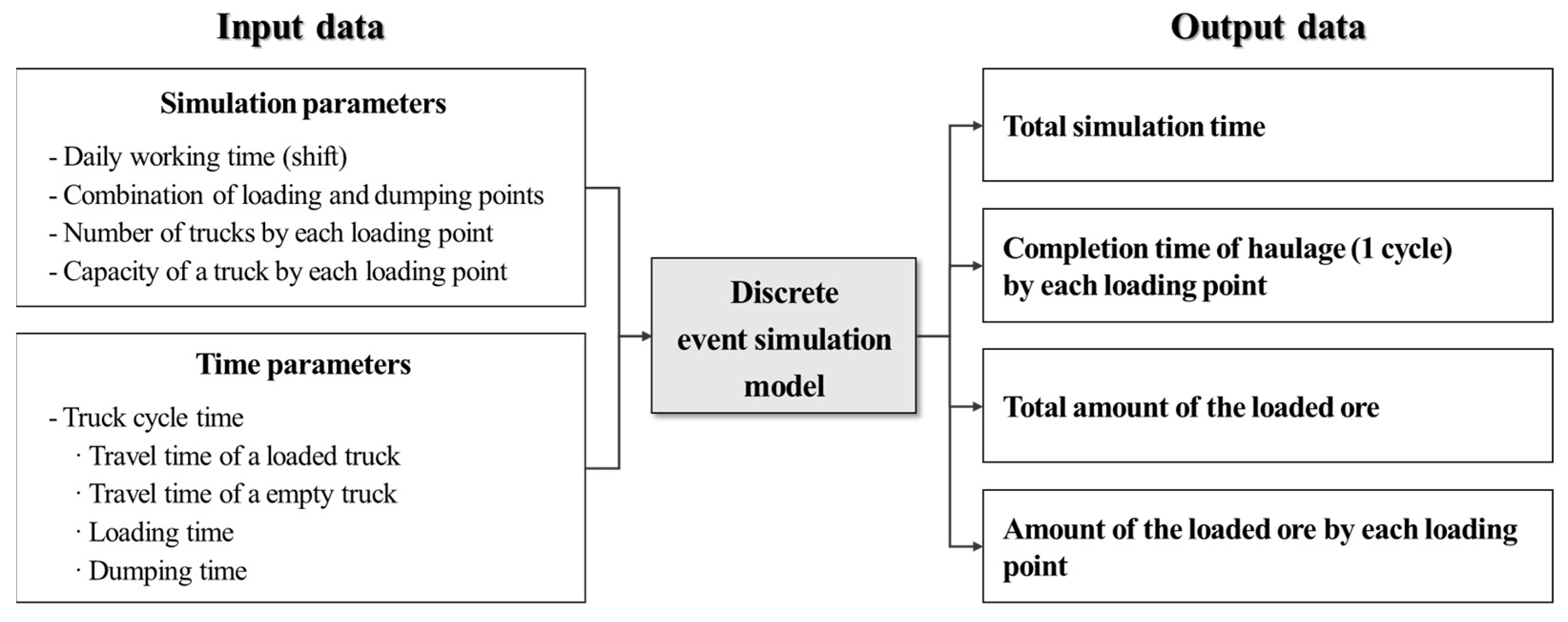

3.2. Development of a Production Prediction ML–Discrete Event Simulation (DES) Model

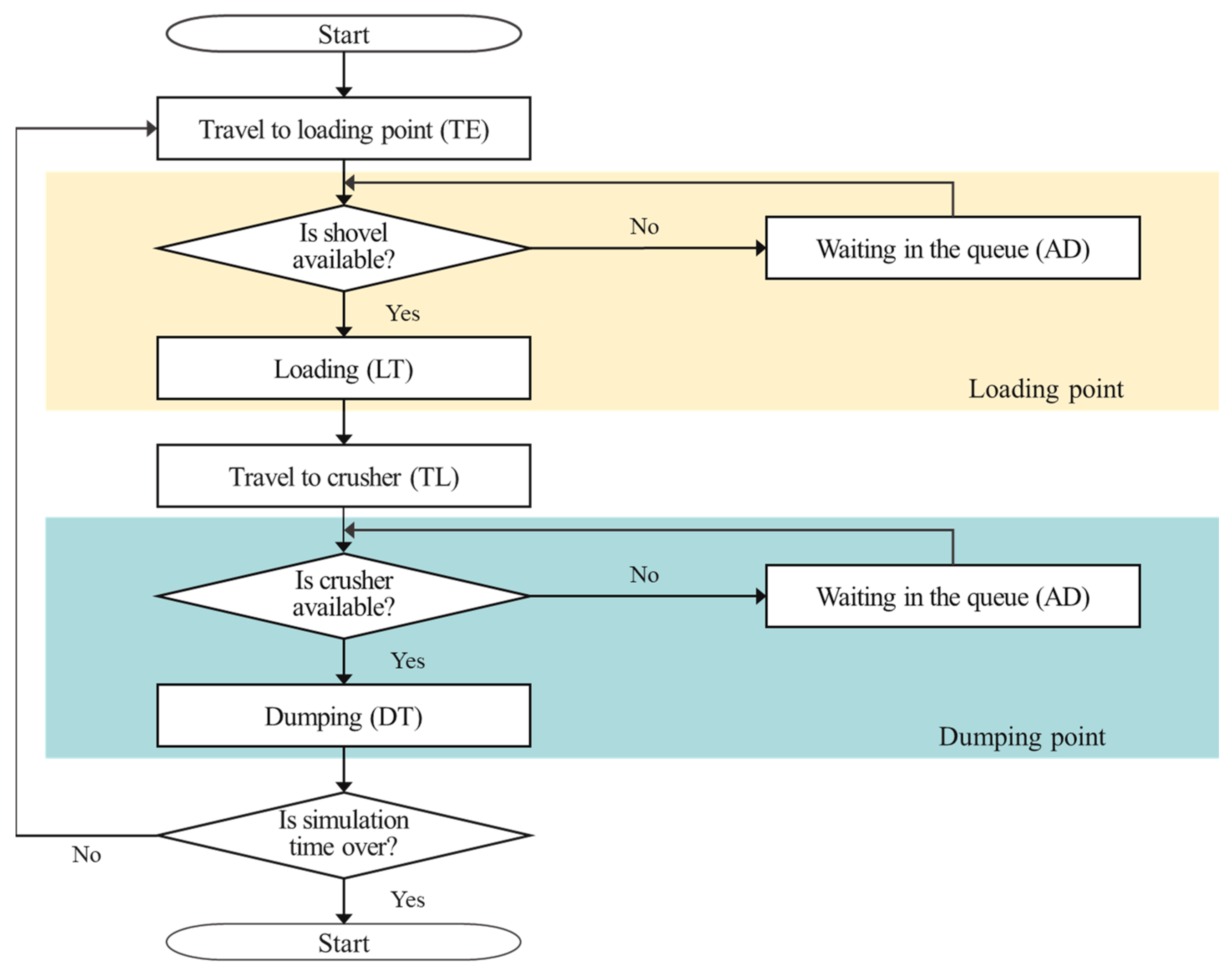

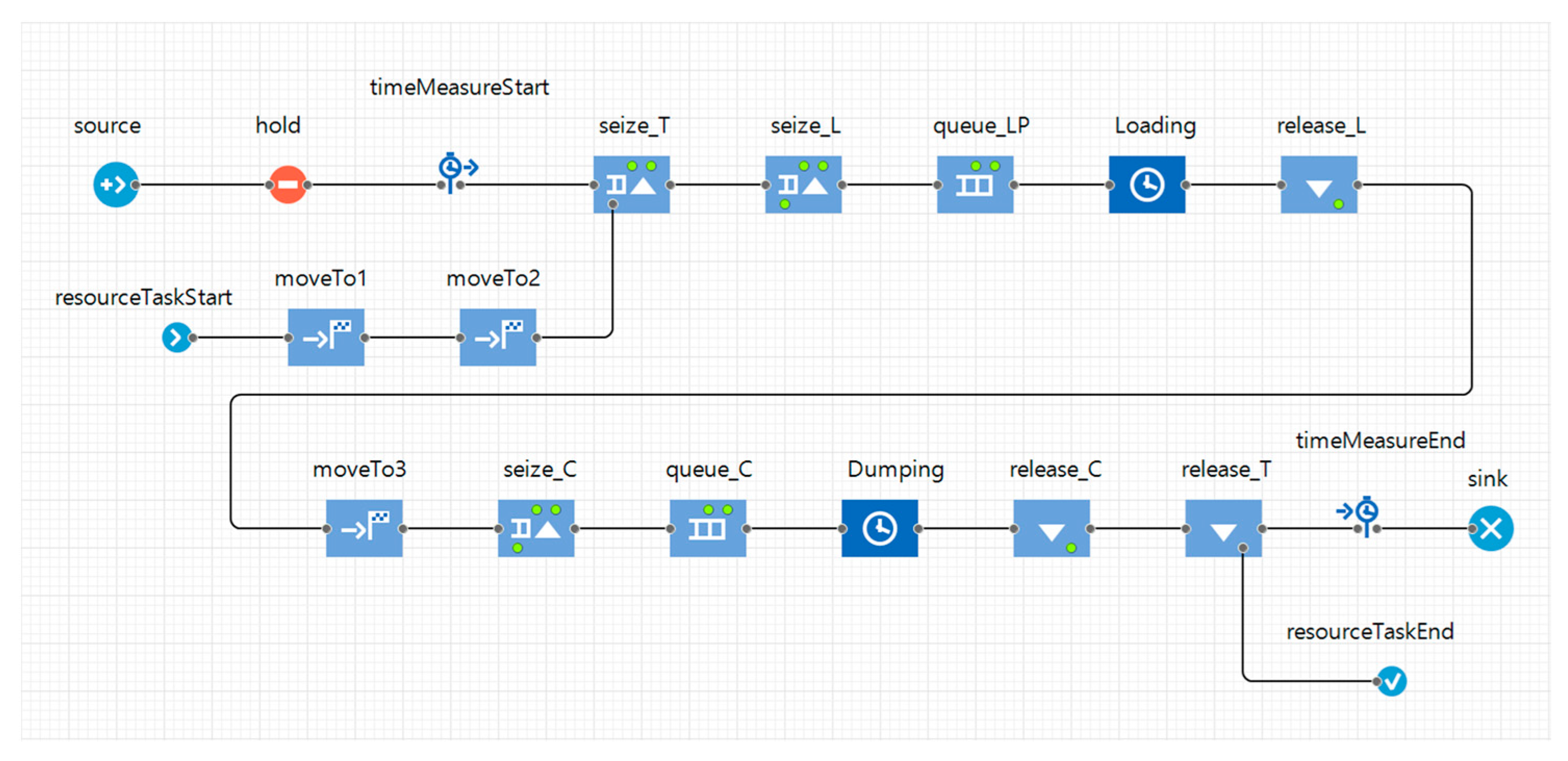

3.2.1. Design of ML–DES Model

3.2.2. Development of Simulation Algorithm

3.2.3. Verification of Simulation Algorithm

4. Results

4.1. Results of Development of Cycle Time Prediction ML Model

4.1.1. Results of ML Model Training

4.1.2. Results of Performance Evaluation of Cycle Time Prediction Model

4.2. Results of the Production Prediction ML–DES Model

4.2.1. Settings of Simulation Scenario and Parameters

4.2.2. Results and Verification of Simulations

5. Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Data Availability Statement

Conflicts of Interest

Abbreviation List

| Full Name | Abbreviation |

| Artificial neural networks | ANNs |

| Coefficient of determination | R2 |

| Comma-separated values | CSV |

| Deep neural network | DNN |

| Discrete event simulation | DES |

| Genetic algorithms | Gas |

| Grid search | GS |

| Internet of Things | IoT |

| k-nearest neighbor | kNN |

| Load-haul-dump | LHD |

| Machine learning | ML |

| Mean absolute error | MAE |

| Mean squared error | MSE |

| Partial least squares | PLS |

| Particle swarm optimization | PSO |

| Random forest | RF |

| Root mean square error | RMSE |

| Support vector machine | SVM |

| Truck cycle time | TCT |

References

- Alarie, S.; Gamache, M. Overview of Solution Strategies Used in Truck Dispatching Systems for Open Pit Mines. Int. J. Surf. Min. Reclam. Environ. 2002, 16, 59–76. [Google Scholar] [CrossRef]

- Osanloo, M.; Paricheh, M. In-pit crushing and conveying technology in open-pit mining operations: A literature review and research agenda. Int. J. Min. Reclam. Environ. 2020, 34, 430–457. [Google Scholar] [CrossRef]

- Bao, H.; Knights, P.; Kizil, M.; Nehring, M. Electrification Alternatives for Open Pit Mine Haulage. Mining 2023, 3, 1–25. [Google Scholar] [CrossRef]

- Hartman, H.L.; Mutmansky, J.M. Unit operations of mining. In Introductory Mining Engineering, 2nd ed.; Wiley: New York, NY, USA, 2002; pp. 119–152. [Google Scholar]

- Ercelebi, S.G.; Bascetin, A. Optimization of shovel-truck system for surface mining. J. S. Afr. Inst. Min. Metall. 2009, 109, 433–439. [Google Scholar]

- Choi, Y.; Nieto, A. Optimal haulage routing of off-road dump trucks in construction and mining sites using Google Earth and a modified least-cost path algorithm. Autom. Constr. 2011, 20, 982–997. [Google Scholar] [CrossRef]

- Choi, Y.; Nieto, A. Software for simulating open-pit truck/shovel haulage systems using Google Earth and GPSS/H. J. Korean Soc. Miner. Energy Resour. Eng. 2011, 48, 734–743. [Google Scholar]

- Matamoros, M.E.V.; Dimitrakopoulos, R. Stochastic short-term mine production schedule accounting for fleet allocation, operational considerations and blending restrictions. Eur. J. Oper. Res. 2016, 255, 911–921. [Google Scholar] [CrossRef]

- Jung, D.; Baek, J.; Choi, Y. Stochastic Predictions of Ore Production in an Underground Limestone Mine Using Different Probability Density Functions: A Comparative Study Using Big Data from ICT System. Appl. Sci. 2021, 11, 4301. [Google Scholar] [CrossRef]

- Rist, K. The solution of a transportation problem by use of a Monte Carlo technique, mining world. In Proceedings of the 1st APCOM, Tucson, AZ, USA, November 1961. [Google Scholar]

- Douglas, J. Prediction Shovel-Truck Production, A Reconciliation of Computer and Conventional Estimates; Stanford University: Stanford, CA, USA, 1964. [Google Scholar]

- Doe, D.C.; Griffin, W.F. Experimental design and mining system simulation. Continuous surface mining. In Proceedings of the 1st International Symposium on Continuous Surface Mining, Edmonton, AB, Canada, 29 September–1 October 1986; Golosinski, T.S., Boehm, F.G., Eds.; Trans Tech Publications Inc.: Zürich, Switzerland, 1986; pp. 317–324. [Google Scholar]

- Sturgul, J.R.; Harrison, J. Simulation models for surface mines. Int. J. Min. Reclam. Environ. 1987, 1, 187–189. [Google Scholar] [CrossRef]

- Harrison, J.; Sturgul, J.R. GPSS computer simulation of equipment requirements for the iron duke mine. In Proceedings of the Australasian Institute of Mining and Metallurgy, Second Large Open Pit Mining Conference, Latrobe Valley Vic, Gippsland, VIC, Australia, April 1988; pp. 133–136. [Google Scholar]

- Basu, A.J.; Baafi, E.Y. Discrete event simulation of mining systems: Current practice in Australia. Int. J. Surf. Min. Reclam. Environ. 1999, 13, 79–84. [Google Scholar] [CrossRef]

- Vagenas, N. Applications of discrete-event simulation in Canadian mining operations in the nineties. Int. J. Surf. Min. Reclam. Environ. 1999, 13, 77–78. [Google Scholar] [CrossRef]

- Awuah-Offei, K.; Temeng, V.A.; Al-Hassan, S. Predicting equipment requirements using SIMAN simulation—A case study. Min. Technol. 2003, 112, 180–184. [Google Scholar] [CrossRef]

- Burt, C.N.; Caccetta, L. Match factor for heterogeneous truck and loader fleets. Int. J. Surf. Min. Reclam. Environ. 2007, 21, 262–270. [Google Scholar] [CrossRef]

- Smith, S.D.; Wood, G.S.; Gould, M. A new earthworks estimating methodology. Constr. Manag. Econ. 2000, 18, 219–228. [Google Scholar] [CrossRef]

- Choi, Y. New software for simulating truck-shovel operation in open pit mines. J. Korean Soc. Miner. Energy Resour. Eng. 2011, 48, 448–459. [Google Scholar]

- Dindarloo, S.R.; Osanloo, M.; Frimpong, S. A stochastic simulation framework for truck and shovel selection and sizing in open pit mines. J. S. Afr. Inst. Min. Metall. 2015, 115, 209–219. [Google Scholar] [CrossRef]

- Krause, A.; Musingwini, C. Modelling open pit shovel-truck systems using the machine repair model. J. S. Afr. Inst. Min. Metall. 2007, 107, 469–476. [Google Scholar]

- Lee, C.; Choi, Y. Integration of simulation and animation for truck-loader haulage systems in an underground mine using GPSS/H and PROOF5. J. Korean Soc. Miner. Energy Resour. Eng. 2018, 55, 185–193. [Google Scholar] [CrossRef]

- Jung, D.; Baek, J.; Choi, Y. Simulation and Real-time Visualization of Truck-Loader Haulage Systems in an Open Pit Mine using AnyLogic. J. Korean Soc. Miner. Energy Resour. Eng. 2020, 57, 45–57. [Google Scholar] [CrossRef]

- Torkamani, E.; Askari-nasab, H. Verifying Short-Term Production Schedules using Truck-Shovel Simulation. In Mining Optimization Laboratory (MOL); University of Alberta: Edmonton, AB, Canada, 2012; pp. 190–205. [Google Scholar]

- Salama, A.; Greberg, J. Optimization of truck-loader haulage system in an underground mine: A simulation approach using SimMine. In Proceedings of the MassMin 2012: 6th International Conference & Exhibition on Mass Mining, Sudbury, ON, Canada, 10–14 June 2012. [Google Scholar]

- Ozdemir, B.; Kumral, M. Simulation-based optimization of truck-shovel material handling systems in multi-pit surface mines. Simul. Model. Pract. Theory 2019, 95, 36–48. [Google Scholar] [CrossRef]

- Park, S.; Choi, Y. Simulation of shovel-truck haulage systems by considering truck dispatch methods. J. Korean Soc. Miner. Energy Resour. Eng. 2013, 50, 543–556. [Google Scholar] [CrossRef]

- Park, S.; Choi, Y.; Park, H.-S. Simulation of shovel-truck haulage systems in open-pit mines by considering breakdown of trucks and crusher capacity. Tunn. Undergr. Space 2014, 24, 1–10. [Google Scholar] [CrossRef]

- Park, S.; Choi, Y.; Park, H.-S. Simulation of truck-loader haulage systems in an underground mine using GPSS/H. Tunn. Undergr. Space 2014, 24, 430–439. [Google Scholar] [CrossRef]

- Park, S.; Lee, S.; Choi, Y.; Park, H.-S. Development of a windows-based simulation program for selecting equipment in open-pit shovel-truck haulage systems. Tunn. Undergr. Space 2014, 24, 111–119. [Google Scholar] [CrossRef]

- Park, S.; Choi, Y.; Park, H. Optimization of Truck-loader Haulage Systems in an Underground Mine Using Simulation Methods. Geosyst. Eng. 2016, 19, 222–231. [Google Scholar] [CrossRef]

- Choi, Y.; Park, S.; Lee, S.-J.; Baek, J.; Jung, J.; Park, H.-S. Development of a windows-based program for discrete event simulation of truck-loader haulage systems in an underground mine. Tunn. Undergr. Space 2016, 26, 87–99. [Google Scholar] [CrossRef]

- Soofastaei, A.; Aminossadati, S.M.; Kizil, M.S.; Knights, P. A discrete-event model to simulate the effect of truck bunching due to payload variance on cycle time, hauled mine materials and fuel consumption. Int. J. Min. Sci. Technol. 2016, 26, 745–752. [Google Scholar] [CrossRef]

- Baek, J.; Choi, Y. Deep Neural Network for Ore Production and Crusher Utilization Prediction of Truck Haulage System in Underground Mine. Appl. Sci. 2019, 9, 4180. [Google Scholar] [CrossRef]

- Baek, J.; Choi, Y. Deep Neural Network for Predicting Ore Production by Truck-Haulage Systems in Open-Pit Mines. Appl. Sci. 2020, 10, 1657. [Google Scholar] [CrossRef]

- Choi, Y.; Nguyen, H.; Bui, X.-N.; Nguyen-Thoi, T.; Park, S. Estimating Ore Production in Open-pit Mines Using Various Machine Learning Algorithms Based on a Truck-Haulage System and Support of Internet of Things. Nat. Resour. Res. 2021, 30, 1141–1173. [Google Scholar] [CrossRef]

- Peña-Graf, F.; Órdenes, J.; Wilson, R.; Navarra, A. Discrete Event Simulation for Machine-Learning Enabled Mine Production Control with Application to Gold Processing. Metals 2022, 12, 225. [Google Scholar] [CrossRef]

- Wilson, R.; Mercier, P.H.J.; Patarachao, B.; Navarra, A. Partial Least Squares Regression of Oil Sands Processing Variables within Discrete Event Simulation Digital Twin. Minerals 2021, 11, 689. [Google Scholar] [CrossRef]

- Wilson, R.; Mercier, P.H.J.; Navarra, A. Integrated Artificial Neural Network and Discrete Event Simulation Framework for Regional Development of Refractory Gold Systems. Mining 2022, 2, 123–154. [Google Scholar] [CrossRef]

- Yao, Y.; Wang, J.; Long, P.; Xie, M.; Wang, J. Small-batch-size convolutional neural network based fault diagnosis system for nuclear energy production safety with big-data environment. Int. J. Energy Res. 2020, 44, 5841–5855. [Google Scholar] [CrossRef]

- Pandya, D.H.; Upadhyay, S.H.; Harsha, S.P. Fault diagnosis of rolling element bearing with intrinsic mode function of acoustic emission data using APF-KNN. Expert Syst. Appl. 2013, 40, 4137–4145. [Google Scholar] [CrossRef]

- Boser, B.E.; Guyon, I.M.; Vapnik, V.N. A training algorithm for optimal margin classifiers. In Proceedings of the COLT92: 5th Annual Workshop on Computational Learning Theory, Pittsburgh, PA, USA, 27–29 July 1992. [Google Scholar] [CrossRef]

- Yélamos, I.; Escudero, G.; Graells, M.; Puigjaner, L. Performance assessment of a novel fault diagnosis system based on support vector machines. Comput. Chem. Eng. 2009, 33, 244–255. [Google Scholar] [CrossRef]

- Yoon, D.; Kim, S.; Kim, J.; Park, G.; Byun, J.; Suh, J.; Lee, C.; Jang, I.; Cho, S.; Choi, Y. Machine learning and deep learning basic. In Introduction to Machine Learning in Resource Development; CIR: Seoul, Republic of Korea, 2018; pp. 265–288. [Google Scholar]

- Kennedy, J.; Eberhart, R. Particle swarm optimization. In Proceedings of the ICNN′95-International Conference on Neural Networks, Perth, WA, Australia, 27 November–1 December 1995; Volume 4, pp. 1942–1948. [Google Scholar] [CrossRef]

- Nugraha, Y.R.; Wibawa, A.P.; Zaeni, I.A.E. Particle Swarm Optimization-Support Vector Machine (PSO-SVM) Algorithm for Journal Rank Classification. In Proceedings of the 2019 2nd International Conference of Computer and Informatics Engineering (IC2IE), Banyuwangi, Indonesia, 10–11 September 2019. [Google Scholar] [CrossRef]

- Suboleski, S.C. Mine Systems Engineering Lecture Notes; The Pennsylvania State University, University Park: State College, PA, USA, 1975. [Google Scholar]

| Equipment | Capacity | Amount |

|---|---|---|

| Loaders | 4.76 m3 | 1 |

| 5.00 m3 | 1 | |

| 5.70 m3 | 1 | |

| Trucks | 23.0 ton | 7 |

| 37.5 ton | 3 |

| Dataset | Description | Data Type |

|---|---|---|

| Features | Path ID | Character |

| Truck ID | Character | |

| Daily mean temperature | Float (°C) | |

| Precipitation | Float (mm/day) | |

| Label | Truck cycle time | Float (min) |

| Statistics | Truck Cycle Time (min) | Daily Mean Temperature (°C) | Daily Precipitation (mm/Day) |

|---|---|---|---|

| Mean | 25.98 | −4.44 | 0.31 |

| Standard deviation | 7.43 | 5.42 | 0.84 |

| Minimum value | 14.30 | −14.30 | 0.10 |

| Maximum value | 54.50 | 8.80 | 6.90 |

| Model | kNN | RF | PSO–SVR | DNN |

|---|---|---|---|---|

| Parameter | n_neighbors | n_estimators ccp_alpha/ min_impurity_decrease/ min_samples_leaf/ min_samples_split/ min_weight_fraction_leaf | C/ | Hidden layer node |

| Min | 1 | 100/0/0/1/1/0.1 | 10/0.1 | 2/20 |

| Max | 100 | 100/10/10/10/10/1 | 100/1 | 10/100 |

| Step | (+) 1 | (+) 0/1/1/1/1/0.1 | - | (+) 1/10 |

| Blocks | Function |

|---|---|

| source | Start of the truck haulage system Creation of ore to be loaded and transported (at the loading point) |

| sink | Termination of truck haulage system Removal of loaded and transported ore (at the dumping point) |

| hold | Control the start and termination of the simulation |

| TimeMeasureStart | Measure the time it takes to load and haul ore once |

| timeMeasureEnd | |

| resourceTaskStart | Creation of trucks to carry out the loading and hauling of ore |

| resourceTaskEnd | Removal of trucks to carry out the loading and hauling of ore |

| moveTo1 | Moving to the loading point of the empty truck |

| moveTo2 | Moving to the loading point of the empty truck |

| moveTo3 | Moving to the dumping point of the loaded truck |

| seize_T | Designation of truck to carry out ore loading and hauling operations |

| seize_L | Designation of loader to perform loading operation |

| seize_C | Designation of crusher to perform dumping operation |

| release_T | Deselection of truck that has completed loading and hauling operations |

| release_L | Deselection of loader that has completed loading operation |

| release_C | Deselection of crusher that has completed dumping operation |

| Loading | Loading operation |

| Dumping | Dumping operation |

| queue_C | Queues created at dumping points |

| queue_LP | Queues created at loading points |

| Indicator | kNN | RF | PSO–SVR | DNN |

|---|---|---|---|---|

| MAE (min) | 2.89 | 2.88 | 2.79 | 2.95 |

| MSE (min2) | 13.65 | 15.40 | 14.29 | 16.14 |

| RMSE (min) | 3.69 | 3.92 | 3.78 | 4.02 |

| R2 | 0.69 | 0.65 | 0.68 | 0.64 |

| Route ID | Loading Point | Dumping Point | Beacon IDs |

|---|---|---|---|

| A | Area A | Crusher 3 | 4 ↔ 2 ↔ 1 ↔ 20 |

| B | Area B | Crusher 3 | 9 ↔ 8 ↔ 7 ↔ 6 ↔ 5 ↔ 20 |

| C | Area C1 | Crusher 1 | 17 ↔ 16 ↔ 14 ↔ 13 ↔ 12 ↔ 6 ↔ 11 ↔ 10 ↔ 22 |

| D | Area C2 | Crusher 1 | 19 ↔ 18 ↔ 16 ↔ 14 ↔ 13 ↔ 12 ↔ 6 ↔ 11 ↔ 10 ↔ 22 |

| Date | Truck ID | Truck Type (tons) | Route ID | Operating Time (Simulation Time, hh:mm) |

|---|---|---|---|---|

| 23 November 2020 | 1 | 37.5 | A | 08:00~12:00 |

| 6 | 23.0 | C | 10:00~12:00, 13:00~14:30 | |

| 4 | 23.0 | C | 09:00~12:00, 13:00~14:30 | |

| 7 | 23.0 | C | 10:00~12:00, 13:00~14:30 | |

| 24 November 2020 | 3 | 23.0 | B | 08:00~12:00, 13:00~17:00 |

| 25 November 2020 | 1 | 37.5 | A | 08:00~12:00, 13:00~14:30 |

| 2 | 37.5 | A | 08:00~12:00, 13:00~14:30 | |

| 3 | 23.0 | B | 08:00~12:00, 13:00~17:00 | |

| 26 November 2020 | 1 | 37.5 | A | 14:00~16:30 |

| 2 | 37.5 | A | 14:00~16:00 | |

| 3 | 23.0 | B | 08:00~12:00, 13:00~16:30 | |

| 6 | 23.0 | D | 08:00~12:00, 13:00~16:30 | |

| 5 | 23.0 | D | 08:00~12:00, 13:00~16:30 | |

| 4 | 23.0 | D | 08:00~11:00 | |

| 7 | 23.0 | D | 08:00~10:30 | |

| 27 November 2020 | 1 | 37.5 | A | 08:00~12:00, 13:00~15:00 |

| 2 | 37.5 | A | 08:00~12:00, 13:00~15:00 | |

| 6 | 23.0 | D | 13:00~17:00 | |

| 4 | 23.0 | D | 13:00~17:00 | |

| 7 | 23.0 | D | 13:00~17:00 | |

| 28 November 2020 | 3 | 23.0 | B | 08:00~12:00, 13:00~17:00 |

| 5 | 23.0 | C | 10:30~12:00, 13:00~15:30 | |

| 4 | 23.0 | C | 10:30~12:00, 13:00~15:30 | |

| 7 | 23.0 | C | 10:30~12:00, 13:00~15:30 | |

| 6 | 23.0 | D | 08:00~10:30 | |

| 5 | 23.0 | D | 08:00~10:30 | |

| 4 | 23.0 | D | 08:00~10:30 | |

| 7 | 23.0 | D | 08:00~10:30 |

| Truck ID | Route ID | Travel Time with Empty Truck (Mean ± SD) | Loading Time (Mean ± SD) | Travel Time with Loaded Truck (Mean ± SD) | Dumping Time (Mean ± SD) |

|---|---|---|---|---|---|

| 1 | A | 8.83 ± 1.77 | 3.73 ± 0.75 | 8.23 ± 1.65 | 0.62 ± 0.12 |

| C | 13.13 ± 2.63 | 3.73 ± 0.75 | 12.24 ± 2.45 | 0.62 ± 0.12 | |

| 2 | A | 9.14 ± 1.83 | 3.73 ± 0.75 | 8.52 ± 1.7 | 0.62 ± 0.12 |

| B | 12.22 ± 2.44 | 3.73 ± 0.75 | 11.39 ± 2.28 | 0.62 ± 0.12 | |

| C | 16.36 ± 3.27 | 3.73 ± 0.75 | 15.26 ± 3.05 | 0.62 ± 0.12 | |

| 3 | B | 12.38 ± 2.48 | 4.05 ± 0.81 | 9.67 ± 1.93 | 0.88 ± 0.18 |

| 4 | C | 16.57 ± 3.31 | 4.05 ± 0.81 | 12.94 ± 2.59 | 0.88 ± 0.18 |

| D | 16.07 ± 3.21 | 4.05 ± 0.81 | 12.55 ± 2.51 | 0.88 ± 0.18 | |

| 5 | C | 18.28 ± 3.66 | 4.05 ± 0.81 | 14.28 ± 2.86 | 0.88 ± 0.18 |

| D | 13.24 ± 2.65 | 4.05 ± 0.81 | 10.34 ± 2.07 | 0.88 ± 0.18 | |

| 6 | C | 16.79 ± 3.36 | 4.05 ± 0.81 | 13.12 ± 2.62 | 0.88 ± 0.18 |

| D | 14.47 ± 2.89 | 4.05 ± 0.81 | 11.3 ± 2.26 | 0.88 ± 0.18 | |

| 7 | C | 17.04 ± 3.41 | 4.05 ± 0.81 | 13.31 ± 2.66 | 0.88 ± 0.18 |

| D | 14.93 ± 2.99 | 4.05 ± 0.81 | 11.66 ± 2.33 | 0.88 ± 0.18 |

| Date | Truck ID | Route ID | Vehicle Operation Log | Discrete Event Simulation | ||

|---|---|---|---|---|---|---|

| Amount of Loaded Ores (tons) | Amount of Loaded Ores (tons) | |||||

| AM (08:00~12:00) | PM (13:00~17:00) | AM (08:00~12:00) | PM (13:00~17:00) | |||

| 23 November 2020 | 1 | A | 412.5 | - | 412.5 | - |

| 6 | C | 112.5 | 112.5 | 150.0 | 112.5 | |

| 4 | C | 187.5 | 112.5 | 187.5 | 112.5 | |

| 7 | C | 112.5 | 112.5 | 150.0 | 75.0 | |

| 24 November 2020 | 3 | B | 300.0 | 300.0 | 375.0 | 375.0 |

| 25 November 2020 | 1 | A | 337.5 | 75.0 | 450.0 | 150.0 |

| 2 | A | 412.5 | 37.5 | 412.5 | 150.0 | |

| 3 | B | 300.0 | 337.5 | 337.5 | 337.5 | |

| 26 November 2020 | 1 | A | - | 262.5 | - | 300.0 |

| 2 | A | - | 187.5 | - | 187.5 | |

| 3 | B | 300.0 | 225.0 | 412.5 | 300.0 | |

| 6 | D | 262.5 | 225.0 | 262.5 | 262.5 | |

| 5 | D | 262.5 | 187.5 | 300.0 | 300.0 | |

| 4 | D | 225.0 | - | 187.5 | - | |

| 7 | D | 150.0 | - | 187.5 | - | |

| 27 November 2020 | 1 | A | 375.0 | 150.0 | 412.5 | 187.5 |

| 2 | A | 375.0 | 187.5 | 412.5 | 187.5 | |

| 6 | D | - | 337.5 | - | 262.5 | |

| 4 | D | - | 337.5 | - | 262.5 | |

| 7 | D | - | 337.5 | - | 300.0 | |

| 28 November 2020 | 3 | B | 300.0 | 300.0 | 412.5 | 337.5 |

| 5 | C | 75.0 | 187.5 | 112.5 | 187.5 | |

| 4 | C | 75.0 | 187.5 | 112.5 | 187.5 | |

| 7 | C | 75.0 | 187.5 | 112.5 | 150.0 | |

| 6 | D | 187.5 | - | 187.5 | - | |

| 5 | D | 187.5 | - | 187.5 | - | |

| 4 | D | 150.0 | - | 150.0 | - | |

| 7 | D | 187.5 | - | 187.5 | - | |

| Time | Route A | Route B | Route D | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Truck 1 | Truck 2 | Truck 3 | Truck 4 | Truck 5 | Truck 6 | Truck 7 | ||||||||

| Actual Log | DES | Actual Log | DES | Actual Log | DES | Actual Log | DES | Actual Log | DES | Actual Log | DES | Actual Log | DES | |

| 8:00 | 08:10 08:40 | 08:11 08:35 08:58 | 08:19 08:51 | 08:27 | 08:34 | 08:16 08:21 | 08:25 08:58 | 08:19 08:45 | 08:29 | 08:24 08:54 | ||||

| 9:00 | 09:10 09:38 | 09:17 09:41 | 09:21 09:51 | 09:05 09:48 | 09:06 09:36 | 09:09 09:34 | 09:27 09:56 | 09:21 09:54 | 09:02 09:31 | 09:25 09:51 | ||||

| 10:00 | 10:06 10:33 | 10:09 10:33 10;58 | 10:20 10:48 | 10:19 10:53 | 10:05 10:35 | 10:03 10:31 | 10:25 10:52 | 10:27 | 10:01 | 10:24 | ||||

| 11:00 | 11:00 11:27 | 11:22 11:47 | 11:02 11:35 | 11:06 11:43 | 11:26 | 11:03 11:39 | ||||||||

| 12:00 | Lunch time | |||||||||||||

| 13:00 | 13:17 13:43 | 13:15 13:35 | 13:23 | 13:18 13:24 | 13:13 13:44 | 13:22 13:29 | ||||||||

| 14:00 | 14:00 14:25 14:51 | 14:07 14:27 14:46 | 14:10 14:37 14:57 | 14:22 14:41 | 14:12 14:42 | 14:00 14:27 14:49 | 14:05 14:53 | 14:14 14:37 | 14:38 | 14:18 14:45 | ||||

| 15:00 | 15:08 15:28 15:46 | 15:04 15:26 15:46 | 15:17 15:38 | 15:07 15:30 15:52 | 15:14 15:56 | 15:15 15:41 | 15:21 15:50 | 15:04 15:30 15:55 | 15:03 15:29 | 15:19 15:50 | ||||

| 16:00 | 16:05 | 16:04 16:26 | 16:15 | 16:21 | 16:02 | 16:23 | ||||||||

| Number of haulage | 7 | 8 | 5 | 5 | 14 | 18 | 6 | 5 | 12 | 16 | 13 | 14 | 4 | 5 |

| Scenario ID | Truck 1 | Truck 2 | Truck 4 | Truck 5 | Truck 6 | Truck 7 |

|---|---|---|---|---|---|---|

| 37.5 tons | 37.5 tons | 23 tons | 23 tons | 23 tons | 23 tons | |

| 19 | A | C | C | D | D | C |

| 20 | A | C | D | D | C | C |

| 23 | A | C | C | D | D | D |

| 24 | A | C | D | C | D | D |

| 25 | A | C | D | D | C | D |

| 26 | A | C | D | D | D | C |

| 31 | C | A | C | C | D | D |

| 32 | C | A | C | D | D | C |

| 33 | C | A | D | D | C | C |

| 36 | C | A | C | D | D | D |

| 37 | C | A | D | C | D | D |

| 38 | C | A | D | D | C | D |

| 39 | C | A | D | D | D | C |

| Scenario ID | Ore Production (tons) | Time Required to Achieve Target Production (min) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| By Truck | By Route (Loading Points) | Total | |||||||||

| 1 | 2 | 4 | 5 | 6 | 7 | A | C | D | |||

| 19 | 862.5 | 637.5 | 345.0 | 391.0 | 345.0 | 299.0 | 862.5 | 1281.5 | 736.0 | 2880.0 | 466 |

| 20 | 900.0 | 600.0 | 299.0 | 414.0 | 368.0 | 299.0 | 900.0 | 1267.0 | 713.0 | 2880.0 | 480 |

| 23 | 862.5 | 637.5 | 368.0 | 414.0 | 345.0 | 368.0 | 862.5 | 1005.5 | 1127.0 | 2995.0 | 386 |

| 24 | 825.0 | 637.5 | 299.0 | 345.0 | 345.0 | 368.0 | 825.0 | 982.5 | 1012.0 | 2819.5 | 399 |

| 25 | 862.5 | 600.0 | 299.0 | 414.0 | 345.0 | 345.0 | 862.5 | 945.0 | 1058.0 | 2865.5 | 411 |

| 26 | 862.5 | 600.0 | 299.0 | 414.0 | 345.0 | 299.0 | 862.5 | 899.0 | 1058.0 | 2819.5 | 405 |

| 31 | 600.0 | 825.0 | 345.0 | 345.0 | 368.0 | 345.0 | 825.0 | 1290.0 | 713.0 | 2828.0 | 471 |

| 32 | 600.0 | 862.5 | 345.0 | 391.0 | 322.0 | 299.0 | 862.5 | 1244.0 | 713.0 | 2819.5 | 464 |

| 33 | 600.0 | 825.0 | 299.0 | 414.0 | 368.0 | 299.0 | 825 | 1267.0 | 713.0 | 2805.0 | 474 |

| 36 | 637.5 | 862.5 | 345.0 | 414.0 | 322.0 | 368.0 | 862.5 | 982.5 | 1104 | 2949.0 | 390 |

| 37 | 600.0 | 825.0 | 276.0 | 368.0 | 345.0 | 368.0 | 825.0 | 968.0 | 989.0 | 2782.0 | 403 |

| 38 | 637.5 | 825.0 | 299.0 | 391.0 | 368.0 | 391.0 | 825.0 | 1005.5 | 1081.0 | 2911.5 | 393 |

| 39 | 637.5 | 825.0 | 299.0 | 414.0 | 345.0 | 299.0 | 825.0 | 936.5 | 1058.0 | 2819.5 | 422 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Park, S.; Jung, D.; Choi, Y. Prediction of Ore Production in a Limestone Underground Mine by Combining Machine Learning and Discrete Event Simulation Techniques. Minerals 2023, 13, 830. https://doi.org/10.3390/min13060830

Park S, Jung D, Choi Y. Prediction of Ore Production in a Limestone Underground Mine by Combining Machine Learning and Discrete Event Simulation Techniques. Minerals. 2023; 13(6):830. https://doi.org/10.3390/min13060830

Chicago/Turabian StylePark, Sebeom, Dahee Jung, and Yosoon Choi. 2023. "Prediction of Ore Production in a Limestone Underground Mine by Combining Machine Learning and Discrete Event Simulation Techniques" Minerals 13, no. 6: 830. https://doi.org/10.3390/min13060830

APA StylePark, S., Jung, D., & Choi, Y. (2023). Prediction of Ore Production in a Limestone Underground Mine by Combining Machine Learning and Discrete Event Simulation Techniques. Minerals, 13(6), 830. https://doi.org/10.3390/min13060830