Estimation of Energy Consumption for Concentrate Process of Tungsten Ore towards the Integration of Renewable Energy Sources in Mongolia

Abstract

1. Introduction

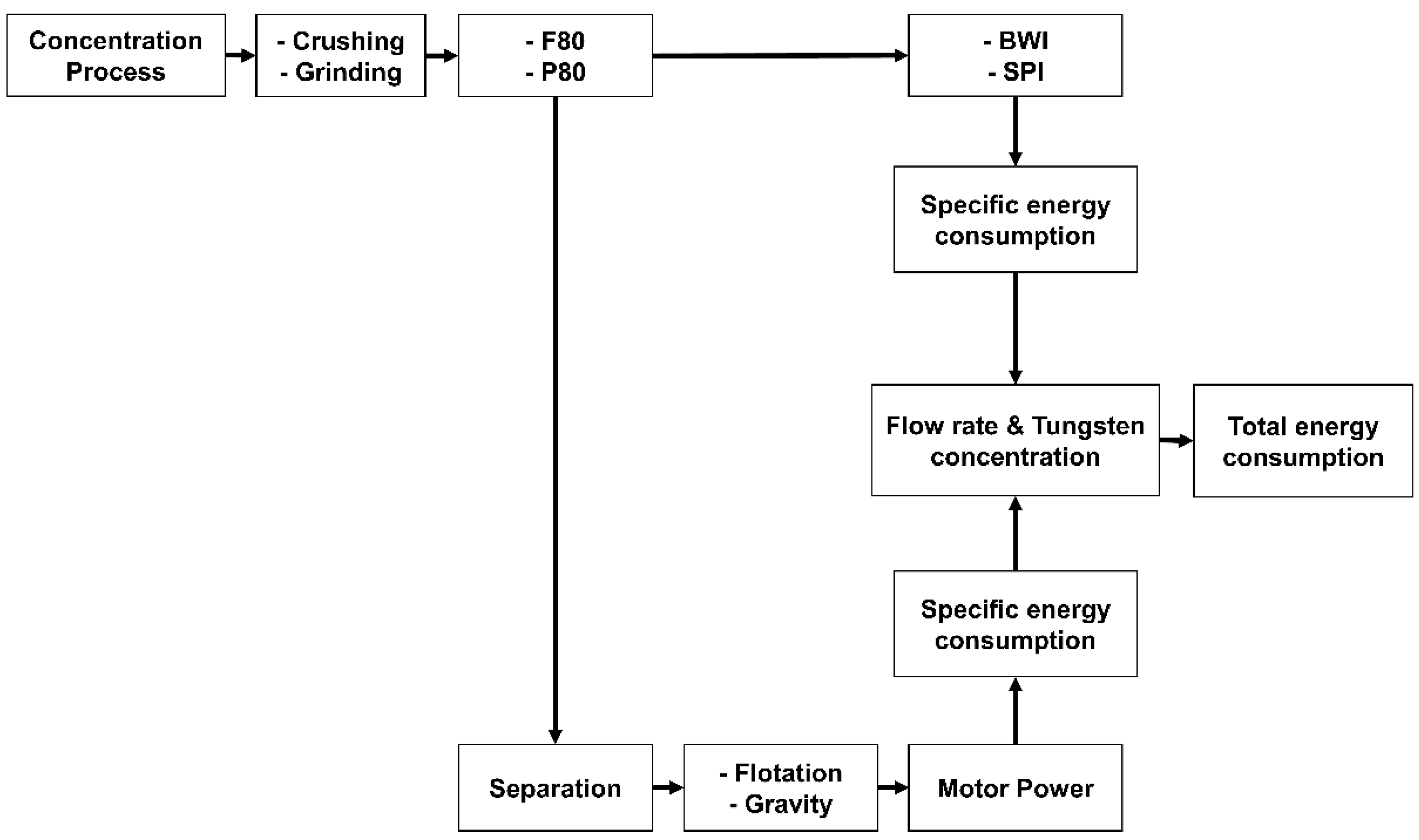

2. Methodology

2.1. Tungsten Separation Process

2.2. Calculation of Energy Consumption

3. Results and Discussion

3.1. Crushing

3.2. Grinding

3.2.1. SAG Mill

3.2.2. Ball Mill

3.3. Separation

3.3.1. Flotation

3.3.2. Gravity

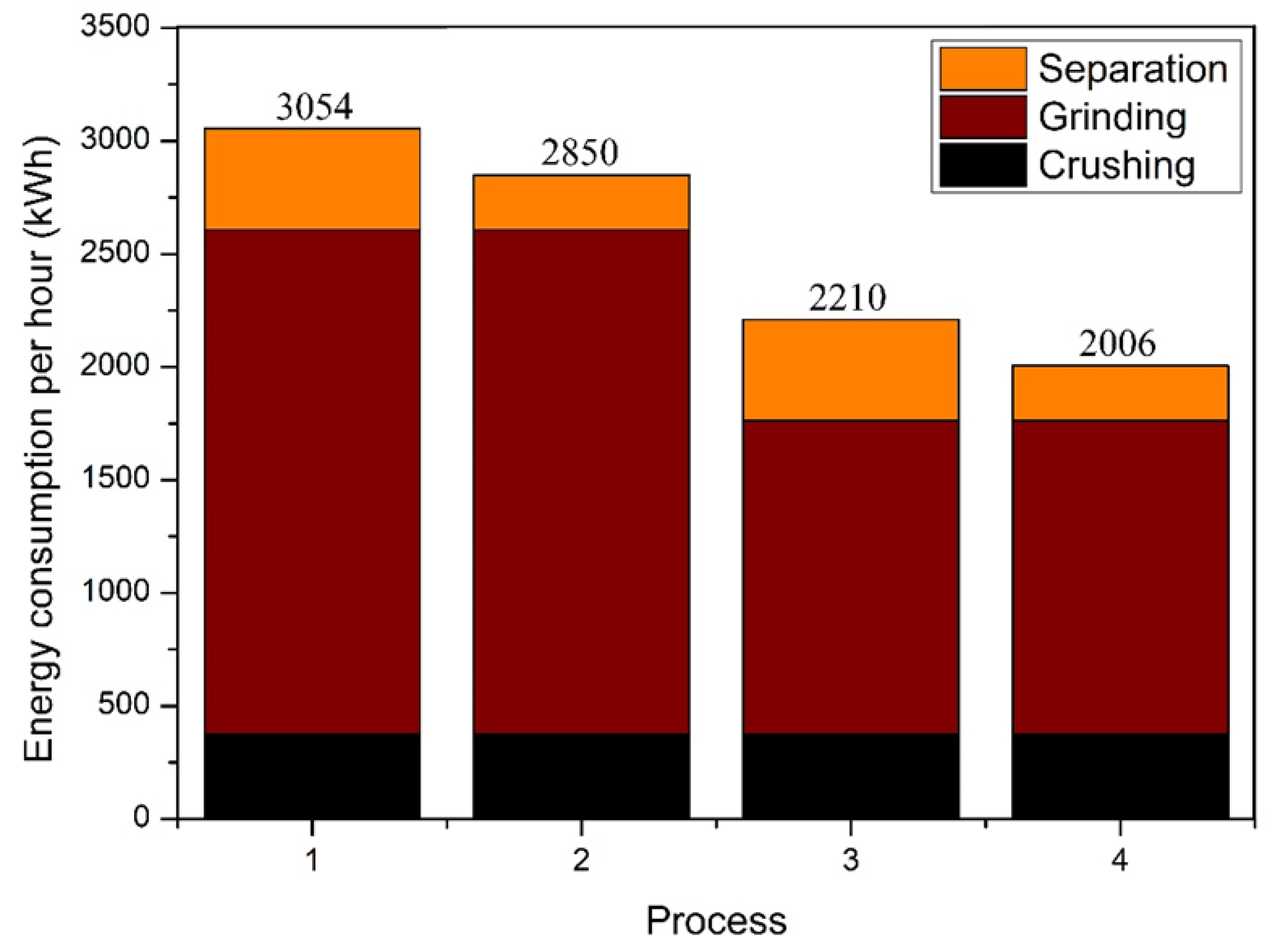

3.4. Propose the Possible Process for Concentrate of Tungsten Ore

3.5. Estimation of the Balance between Energy Demand and Supply for Concentrate of Tungsten Ore

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yang, X. Beneficiation studies of tungsten ores—A review. Miner. Eng. 2018, 125, 111–119. [Google Scholar] [CrossRef]

- Shen, L.; Li, X.; Taskinen, P. Thermodynamics of tungsten ores decomposition process options. In Proceedings of the Extraction 2018: Proceedings of the First Global Conference on Extractive Metallurgy; Springer: Cham, Switzerland, 2018; pp. 2441–2453. [Google Scholar]

- Summaries, M.C. Mineral Commodity Summaries; US Geological Survey: Reston, VA, USA, 2021; 200p. [Google Scholar]

- Igogo, T.; Awuah-Offei, K.; Newman, A.; Lowder, T.; Engel-Cox, J. Integrating renewable energy into mining operations: Opportunities, challenges, and enabling approaches. Appl. Energy 2021, 300, 117375. [Google Scholar] [CrossRef]

- Gómez, J.S.; Rodriguez, J.; Garcia, C.; Tarisciotti, L.; Flores-Bahamonde, F.; Pereda, J.; Nuñez, F.; Cipriano, A.Z.; Salas, J.C. An overview of microgrids challenges in the mining industry. IEEE Access 2020, 8, 191378–191393. [Google Scholar] [CrossRef]

- Jose-Luis, P.; Abadias, A.; Valero, A.; Valero, A.; Reuter, M. The energy needed to concentrate minerals from common rocks: The case of copper ore. Energy 2019, 181, 494–503. [Google Scholar] [CrossRef]

- Palacios, J.-L.; Fernandes, I.; Abadias, A.; Valero, A.; Valero, A.; Reuter, M.A. Avoided energy cost of producing minerals: The case of iron ore. Energy Rep. 2019, 5, 364–374. [Google Scholar] [CrossRef]

- Calvo, G.; Palacios, J.-L.; Valero, A. The influence of ore grade decline on energy consumption and GhG emissions: The case of gold. Environ. Dev. 2022, 41, 100683. [Google Scholar] [CrossRef]

- Bond, F.C. Crushing and grinding calculations, Part I. Br. Chem. Eng. 1961, 6, 378–385. [Google Scholar]

- Starkey, J.; Dobby, G. Application of the Minnovex SAG power index at five Canadian SAG plants. Proceeding Autogenous Semi-Autogenous Grind. 1996, 1, 345–360. [Google Scholar]

- Cheng, G.; Liu, J.; Ma, L.; Cao, Y.; Li, J.; Huang, G. Study on energy consumption in fine coal flotation. Int. J. Coal Prep. Util. 2014, 34, 38–48. [Google Scholar] [CrossRef]

- Weiss, N.L. SME Mineral Processing Handbook; SME: Englewood, CO, USA, 1985. [Google Scholar]

- CH440 CONE CRUSHER. Available online: https://www.rockprocessing.sandvik/en/products/stationary-crushers-and-screens/stationary-cone-crushers/ch440-cone-crusher/ (accessed on 20 April 2022).

- CJ815 JAW CRUSHER. Available online: https://www.rockprocessing.sandvik/en/products/stationary-crushers-and-screens/stationary-jaw-crushers/cj815-jaw-crusher/ (accessed on 20 April 2022).

- Metso Corporation. Basics in Minerals Processing; Metso Expect Results: Helsinki, Finland, 2011. [Google Scholar]

- Shi, F.; Morrison, R.; Cervellin, A.; Burns, F.; Musa, F. Comparison of energy efficiency between ball mills and stirred mills in coarse grinding. Miner. Eng. 2009, 22, 673–680. [Google Scholar] [CrossRef]

- Teperi, J. Effects of Mineral Sorting on Concentrator Design and Economics. Master’s Thesis, Lappeenranta University of Technology, Lappeenranta, Finland, 2 October 2013. [Google Scholar]

- Brezani, I.; Sisol, M.; Marcin, M.; Sykora, M.; Matasovsky, M.; Varga, P. Beneficiation of Talc-Magnesite Ore with Cu-Co Mineralization. Inżynieria Miner. 2019, 21, 141–144. [Google Scholar] [CrossRef]

- Atawi, I.E.; Kassem, A.M.; Zaid, S.A. Modeling, management, and control of an autonomous wind/fuel cell micro-grid system. Processes 2019, 7, 85. [Google Scholar] [CrossRef]

- THEnergy. Database: Solar & Wind Systems in the Mining Industry. Available online: https://www.th-energy.net/english/platform-renewable-energy-and-mining/database-solar-wind-power-plants (accessed on 31 October 2022).

- Choi, Y.; Song, J. Review of photovoltaic and wind power systems utilized in the mining industry. Renew. Sustain. Energy Rev. 2017, 75, 1386–1391. [Google Scholar] [CrossRef]

- Rozali, N.E.M.; Alwi, S.R.W.; Manan, Z.A.; Klemeš, J.J.; Hassan, M.Y. Optimal sizing of hybrid power systems using power pinch analysis. J. Clean. Prod. 2014, 71, 158–167. [Google Scholar] [CrossRef]

- A Guide to Biomass Power Plants. Available online: https://www.theecoexperts.co.uk/blog/biomass-power-plant (accessed on 3 August 2023).

| Stage | Equipment | Feed Particle Size F80 (μm) | Product Particle Size P80 (μm) |

|---|---|---|---|

| Crushing | Jaw crusher Cone crusher | 150,000 | 10,000 |

| Grinding | SAG mill Ball mill | 10,000 | 350 |

| Equipment | Jaw Crusher | Cone Crusher | Operating Parameters |

|---|---|---|---|

| Model | Sandvik CJ815 | Sandvik CH440 | - |

| Power (kW) | 200 | 220 | - |

| Range of CSS (mm) | 150–300 | 8–48 | 10 |

| Maximum feed size (mm) | 1170 | 250 | 100–200 |

| Capacity (t/h) | 480–1160 | 58–336 | 283 |

| Stage | Specific Energy Consumption (kWh/t) | Capacity (t/h) | Energy Consumption Per Hour (kWh) |

|---|---|---|---|

| Rougher | 0.63 | 206 | 132 |

| Scavenger | 0.72 | 180 | 131 |

| Cleaner 1 | 0.97 | 85 | 82 |

| Cleaner Scavenger | 1.15 | 43 | 49 |

| Cleaner 2 | 0.7 | 47 | 33 |

| Cleaner 3 | 0.61 | 31 | 20 |

| Total energy consumption per hour (kWh) | 447 | ||

| Country | Type of Ore | Renewable Energy | Capacity |

|---|---|---|---|

| Australia | Lithium | Wind and Solar | 116.4 kW |

| South Africa | Coal | Solar | 240 kW |

| Australia | Nickel | Solar | 300 kW |

| South Africa | Chromium | Solar | 1 MW |

| Canada | Zinc | Solar | 1 MW |

| USA | Molybdenum | Solar | 1 MW |

| Chile | Gold | Solar | 1.1 MW |

| Chile | Gold | Solar | 1.26 MW |

| Chile | Zinc gold | Wind | 1.5 MW |

| USA | Gold | Solar | 1.51 MW |

| Australia | Bauxite | Solar | 1.7 MW |

| Argentina | Gold | Wind | 2 MW |

| Canada | Nickel | Wind | 3 MW |

| Mauritania | Iron | Wind | 4.4 MW |

| Suriname | Gold | Solar | 5 MW |

| Canada | Diamond | Wind | 9.2 MW |

| Chile | Gold | Solar | 10 MW |

| Australia | Copper | Solar | 10.6 MW |

| Renewable Source | Operating Time | Time Interval (h) | Capacity (MW) | Energy Generation (MWh) | ||

|---|---|---|---|---|---|---|

| AC | DC | From | To | |||

| Wind | 0 | 12 | 12 | 1.5 | 18 | |

| Biomass | 0 | 24 | 24 | 2 | 48 | |

| Solar | 8 | 18 | 10 | 1.5 | 15 | |

| Time | Time Interval (h) | Capacity (MW) | Energy Generation (MWh) | Energy Demand (MWh) | |||

|---|---|---|---|---|---|---|---|

| AC | DC | AC | DC | AC to DC 1 | DC | ||

| 0 | |||||||

| 8 | 8 (Period 1) | 3.5 | 0 | 28 | 0 | 26.6 | 24.4 |

| 12 | 4 (Period 2) | 3.5 | 1.5 | 14 | 6 | 13.3 | 12.2 |

| 18 | 6 (Period 3) | 2 | 1.5 | 12 | 9 | 11.4 | 18.3 |

| 24 | 6 (Period 4) | 2 | 0 | 12 | 0 | 11.4 | 18.3 |

| Time | Time Interval (h) | Power Source (MW) | Energy Generation (MWh) | Energy Demand (MWh) | |||

|---|---|---|---|---|---|---|---|

| AC | DC | AC | DC | AC to DC 1 | DC | ||

| 0 | |||||||

| 8 | 8 (Period 1) | 2 | 0 | 16 | 0 | 15.2 | 16 |

| 18 | 10 (Period 2) | 2 | 1.5 | 20 | 15 | 19 | 20 |

| 24 | 6 (Period 3) | 2 | 0 | 12 | 0 | 11.4 | 12 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Son, T.; Trinh, H.B.; Kim, S.; Dugarjav, B.; Lee, J. Estimation of Energy Consumption for Concentrate Process of Tungsten Ore towards the Integration of Renewable Energy Sources in Mongolia. Minerals 2023, 13, 1059. https://doi.org/10.3390/min13081059

Son T, Trinh HB, Kim S, Dugarjav B, Lee J. Estimation of Energy Consumption for Concentrate Process of Tungsten Ore towards the Integration of Renewable Energy Sources in Mongolia. Minerals. 2023; 13(8):1059. https://doi.org/10.3390/min13081059

Chicago/Turabian StyleSon, Taehun, Ha Bich Trinh, Seunghyun Kim, Bayasgalan Dugarjav, and Jaeryeong Lee. 2023. "Estimation of Energy Consumption for Concentrate Process of Tungsten Ore towards the Integration of Renewable Energy Sources in Mongolia" Minerals 13, no. 8: 1059. https://doi.org/10.3390/min13081059

APA StyleSon, T., Trinh, H. B., Kim, S., Dugarjav, B., & Lee, J. (2023). Estimation of Energy Consumption for Concentrate Process of Tungsten Ore towards the Integration of Renewable Energy Sources in Mongolia. Minerals, 13(8), 1059. https://doi.org/10.3390/min13081059