Ultrasonic Enhancement for Mineral Flotation: Technology, Device, and Engineering Applications

Abstract

1. Introduction

2. Methodology

2.1. Innovation of This Review

2.2. Literature Research

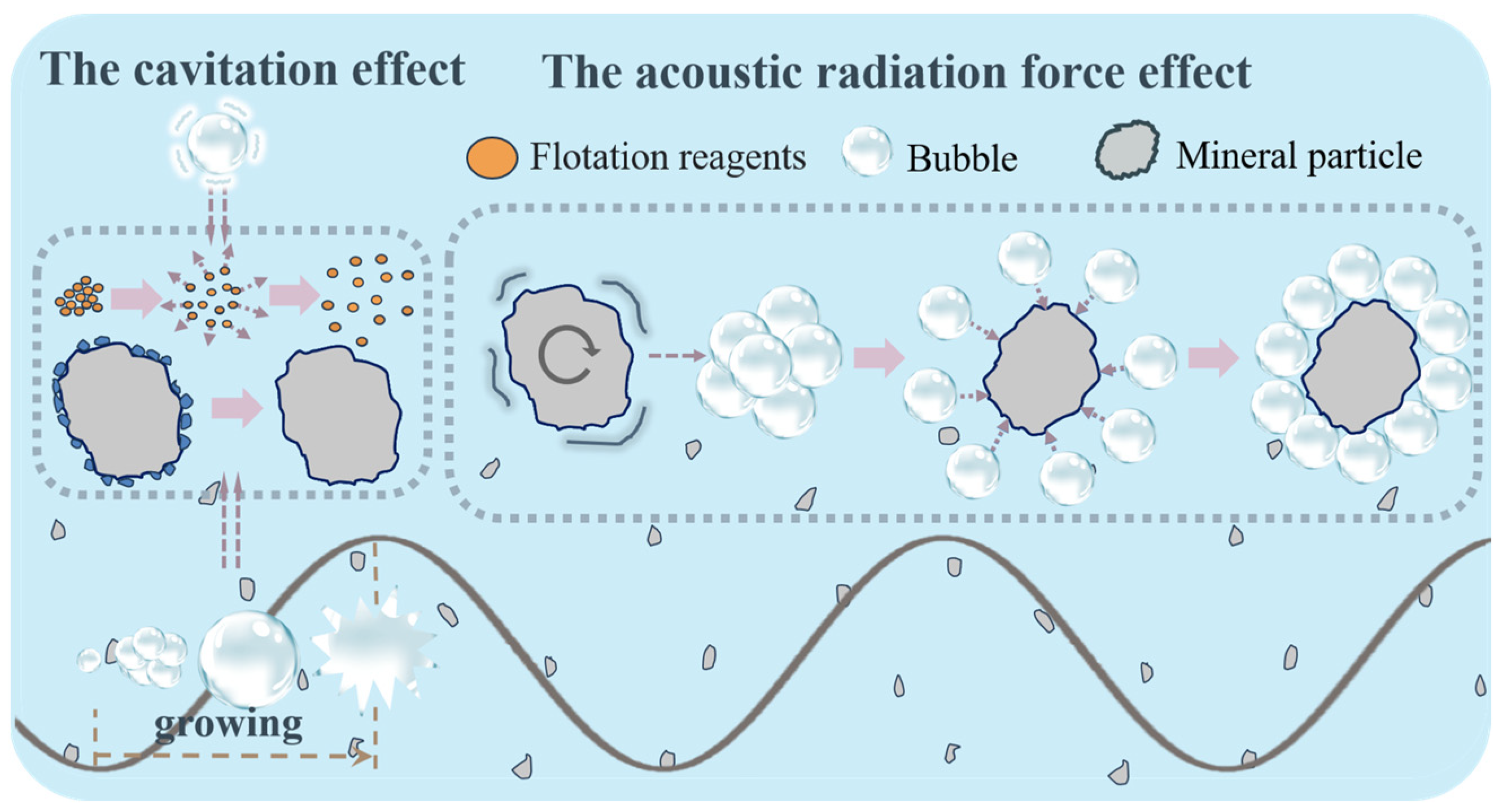

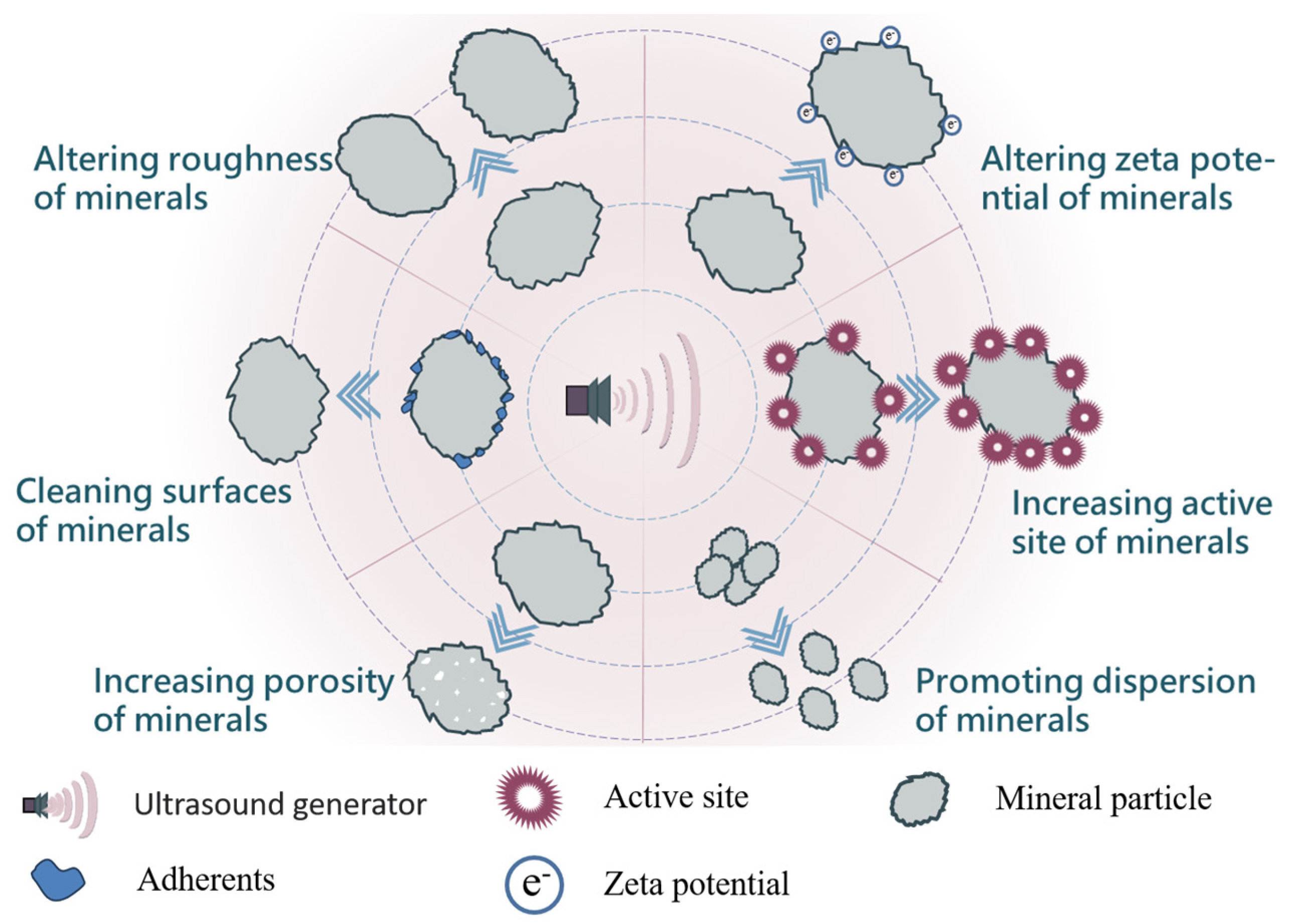

3. Effects of Ultrasound Treatment on an Aqueous Slurry

4. Improvement of Flotation Method and Technological Process

4.1. Ultrasonic Parameters

4.2. The Synergistic Effect of Ultrasound and Reagents

4.3. Particle Size Fractions

4.4. Application System

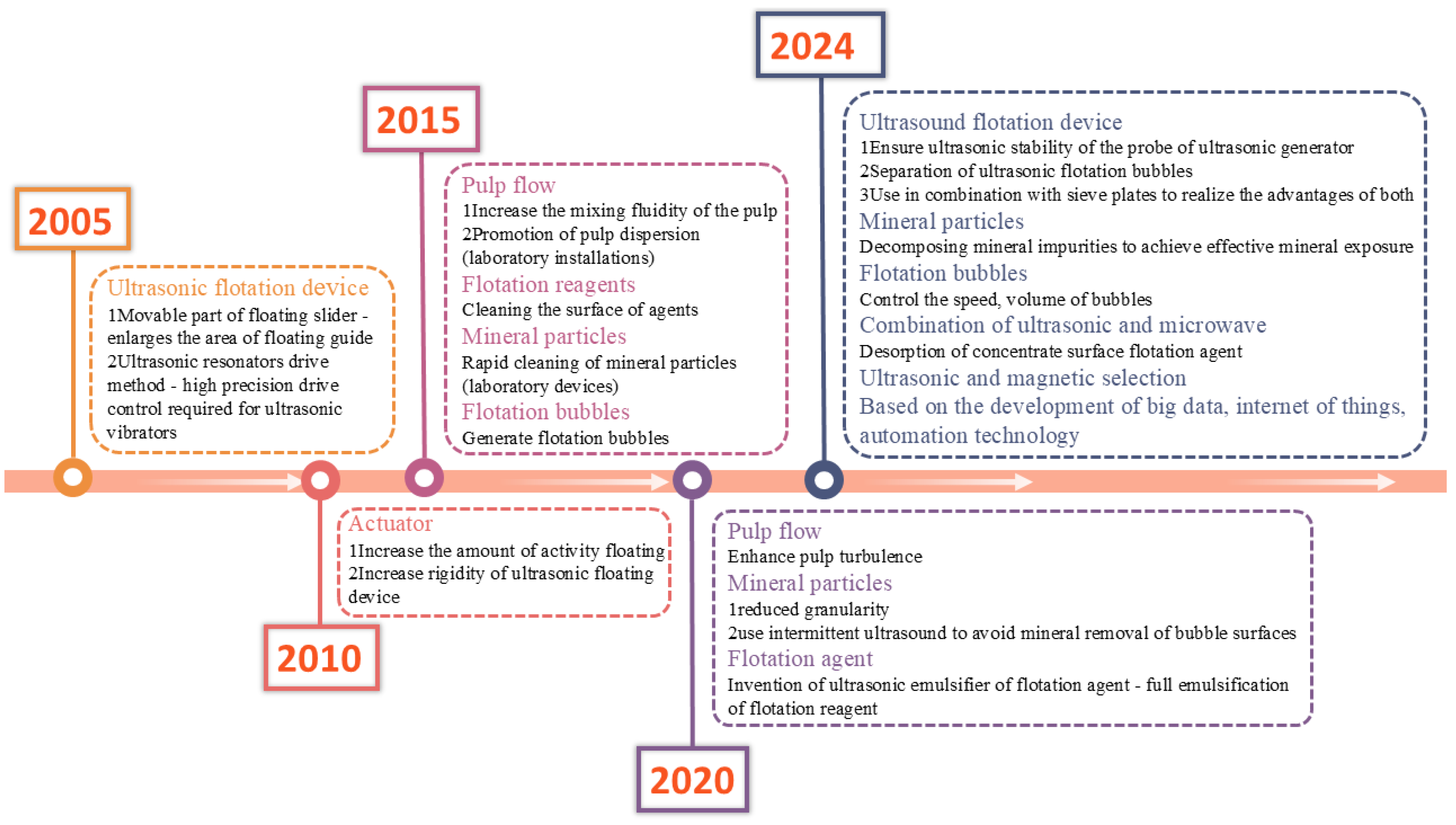

5. Ultrasonic Flotation Device

6. Application Effects in Mineral Process Engineering

6.1. Pretreatment

6.2. Simultaneous Treatment

7. Research Prospect and Direction

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Zhou, Y.; Wang, X.; Liu, H.; Cheng, Y.; Ma, P. Carbide Slag Comprehensive Utilization Device. C.N. Patent CN111717929-A, 29 September 2020. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Huang, W.; Hu, Y.; Huang, L.; Zeng, X.; Zhang, T. Application Progress of Ultrasonic Technology in Mineral Processing. Appl. Chem. Ind. 2020, 49, 3172–3177. [Google Scholar]

- Chen, Y.; Truong, V.N.T.; Bu, X.; Xie, G. A Review of Effects and Applications of Ultrasound in Mineral Flotation. Ultrason. Sonochem. 2020, 60, 104739. [Google Scholar] [CrossRef] [PubMed]

- Chen, L.; Lu, D.; Wang, Y.; Cheng, Z. Research and Application of Ultrasonic Technology in Mineral Flotation and Development Trend. Chin. J. Nonferrous Met. 2021, 31, 1042–1056. [Google Scholar]

- Zhang, H.; Du, M.; Hu, H.; Zhang, H.; Song, N. A Review of Ultrasonic Treatment in Mineral Flotation: Mechanism and Recent Development. Molecules 2024, 29, 1984. [Google Scholar] [CrossRef] [PubMed]

- Yin, W.; Cai, L.; Ma, Y.; Wang, Y. Mechanism of Ultrasonic Cavitation to Improve the Effect of Siderite on Quartz Flotation. Physicochem. Probl. Miner. Process. 2023, 59, 165930. [Google Scholar] [CrossRef]

- Jiao, Y.; Yang, Z.; Han, X.; Wang, K.; Fang, C.; Zhao, Z.; Tang, W. Ultrasonication Improves the Flotation of Coal Gasification Fine Slag Residue. Minerals 2024, 14, 363. [Google Scholar] [CrossRef]

- Ozkan, A.; Esmeli, K. Use of Ultrasonic Treatment as a Pre-Phase in the Shear Flocculation Process. Ultrasonics 2023, 134, 107052. [Google Scholar] [CrossRef]

- Yang, A.; Wang, L. A Fundamental Study of Flotation Separation of Mineral Particles Using Ultrasound-Induced Bubbles. Miner. Eng. 2024, 207, 108573. [Google Scholar] [CrossRef]

- Zhou, S.; Tong, Z.; Dong, L.; Bu, X.; Ni, C.; Xie, G.; Alheshibri, M. A Comparative Study on the Influence of Single and Combined Ultrasounds Assisted Flake Graphite Flotation. Ultrason. Sonochem. 2023, 99, 106551. [Google Scholar] [CrossRef]

- Jin, L.; Wang, W.; Tu, Y.; Zhang, K.; Lv, Z. Effect of Ultrasonic Standing Waves on Flotation Bubbles. Ultrason. Sonochem. 2021, 73, 105459. [Google Scholar] [CrossRef] [PubMed]

- Chen, Y.; Ni, C.; Xie, G.; Liu, Q. Toward Efficient Interactions of Bubbles and Coal Particles Induced by Stable Cavitation Bubbles under 600 kHz Ultrasonic Standing Waves. Ultrason. Sonochem. 2020, 64, 105003. [Google Scholar] [CrossRef]

- Kang, W.; Li, H. Effect of Ultrasonic Pretreatment on Cleaner Flotation of Graphite. J. China Univ. Min. Technol. 2020, 49, 1193–1198. [Google Scholar]

- Esmeli, K. The Influence of Ultrasound Treatment on the Hydrophobic Flocculation of Lignite. Int. J. Coal Prep. Util. 2024, 44, 1–18. [Google Scholar] [CrossRef]

- Deng, J.; Luo, D.; Bai, J.; Rong, K. Effect of Ultrasonic Pretreatment on Flotation Purification of Quartz. Physicochem. Probl. Miner. Process. 2024, 60, 190008. [Google Scholar] [CrossRef]

- Gungoren, C.; Baktarhan, Y.; Demir, I.; Ozkan, S.G. Enhancement of Galena-Potassium Ethyl Xanthate Flotation System by Low Power Ultrasound. Trans. Nonferrous Met. Soc. China 2020, 30, 1102–1110. [Google Scholar] [CrossRef]

- Filippov, L.O.; Filippova, I.V.; Barres, O.; Lyubimova, T.P.; Fattalov, O.O. Intensification of the Flotation Separation of Potash Ore Using Ultrasound Treatment. Miner. Eng. 2021, 171, 107092. [Google Scholar] [CrossRef]

- Luo, X.; Cao, J.; Gong, H.; Yan, H.; He, L. Phase Separation Technology Based on Ultrasonic Standing Waves: A Review. Ultrason. Sonochem. 2018, 48, 287–298. [Google Scholar] [CrossRef]

- Zhang, M.; Xu, Z.; Wang, L. Ultrasonic Treatment Improves the Performance of Starch as Depressant for Hematite Flotation. Ultrason. Sonochem. 2022, 82, 105877. [Google Scholar] [CrossRef]

- Cao, Q.; Li, Y.; Zou, H.; Liu, D.; Yan, Y.; Zhang, H. Synergistic Effects of Ultrasonication on the Flotation Separation of Galena from Chalcopyrite Using Sulfuric Acid as a Depressant. Min. Eng. 2024, 206, 108501. [Google Scholar] [CrossRef]

- Huang, Z.; Kuang, J.; Yuan, W.; Yu, M.; Wang, X. Regulation Mechanism of Ultrasonication on Surface Hydrophobicity of Scheelite. Colloid Surf. A 2021, 629, 127412. [Google Scholar] [CrossRef]

- Sun, X.; Zhang, L.; Xie, Z.; Li, B.; Liu, S. Improvement of Low-Rank Coal Flotation Based on the Enhancement of Wettability Difference between Organic Matter and Gangue. J. Surfactants Deterg. 2021, 24, 269–279. [Google Scholar] [CrossRef]

- Chu, H.; Chen, L.; Lu, D.; Wang, Y.; Zheng, X. Ultrasonic Pretreatment of Spodumene with Different Size Fractions and Its Influence on Flotation. Ultrason. Sonochem. 2022, 82, 105889. [Google Scholar] [CrossRef] [PubMed]

- Mao, Y.; Xia, W.; Peng, Y.; Pan, L.; Xie, G. Impact of Ultrasonic Pretreatment on the Flotation of Lignite Particles of Different Size Fractions. Int. J. Coal Prep. Util. 2022, 42, 315–330. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, S.; Liu, Q.; Chen, L.; Xian, Y.; Wang, Y. Ultrasonic Pretreatment for Enhancing Flotation Separation of Elemental Sulfur and Silver-Bearing Lead Minerals from an Oxidative Pressure Leaching Residue of Zinc Sulfide. Min. Eng. 2024, 205, 108495. [Google Scholar] [CrossRef]

- Wang, W.; Liu, D.; Tu, Y.; Jin, L.; Wang, H. Enrichment of Residual Carbon in Entrained-Flow Gasification Coal Fine Slag by Ultrasonic Flotation. Fuel 2020, 278, 118195. [Google Scholar] [CrossRef]

- Kruszelnicki, M.; Hassanzadeh, A.; Legawiec, K.J.; Polowczyk, I.; Kowalczuk, P.B. Effect of Ultrasound Pre-Treatment on Carbonaceous Copper-Bearing Shale Flotation. Ultrason. Sonochem. 2022, 84, 105962. [Google Scholar] [CrossRef]

- Liao, Y.; Zhao, G.; Feng, B.; Yan, H.; Wu, H.; Hu, W.; Zhu, D.; Qiu, T. Application of Ultrasonic Pre-Treatment for Flotation Separation Pyrrhotite from Chlorite. Colloid Surf. A 2023, 669, 131507. [Google Scholar] [CrossRef]

- Wu, H.; Fang, S.; Shu, K.; Xu, Y.; Wang, Z.; Luo, L.; Yang, J.; Xu, L. Selective Flotation and Adsorption of Ilmenite from Titanaugite by a Novel Method: Ultrasonic Treatment. Powder Technol. 2020, 363, 38–47. [Google Scholar] [CrossRef]

- Fang, S.; Xu, L.; Wu, H.; Xu, Y.; Wang, Z.; Shu, K.; Hu, Y. Influence of Surface Dissolution on Sodium Oleate Adsorption on Ilmenite and Its Gangue Minerals by Ultrasonic Treatment. Appl. Surf. Sci. 2020, 500, 144038. [Google Scholar] [CrossRef]

- Fujinaga, T.; Yamashita, Y. Ultrasonic Flotation Apparatus Includes Movable Portion Comprising Floating Sliders. J.P. Patent JP2005231746-A, 2 September 2005. Available online: https://www.j-platpat.inpit.go.jp (accessed on 24 September 2024).

- Fujinaga, T.; Yamashita, Y. Ultrasonic Vibrator Drive Method in Ultrasonic Flotation Apparatus. J.P. Patent JP2005238144-A, 8 September 2005. Available online: https://www.j-platpat.inpit.go.jp (accessed on 24 September 2024).

- Fujinaga, T.; Yamashita, Y. Ultrasonic Floatation Apparatus Used for Actuator. J.P. Patent JP2006230148-A, 31 August 2006. Available online: https://www.j-platpat.inpit.go.jp (accessed on 24 September 2024).

- Fujinaga, T.; Yamashita, Y. Ultrasonic Floatation Apparatus for Actuator. J.P. Patent JP2006247641-A, 21 September 2006. Available online: https://www.j-platpat.inpit.go.jp (accessed on 24 September 2024).

- Hu, Y.; Liu, J.; Sun, W. Flotation Column for Performing Flotation Separation on Nickel Molybdenum Rough Concentrate. C.N. Patent CN102266823-A, 7 December 2011. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Zhu, J. Ultrasonic High-Frequency Vibration Gangue Flotation Chute. C.N. Patent CN204602389-U, 2 September 2015. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Li, C.; Wang, Y.; Ding, Z.; Wang, L.; Yan, X.; Wang, A.; Cao, Y. Cyclone-Static Micro-Bubble Flotation Column Ultrasonic-Strengthened Pipe Flow Section Mineralization Device. C.N. Patent CN205868558-U, 11 January 2017. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Bastug, T. Device for Performing Flotation and Particle Size Reduction in Ores of e.g., Gold. T.R. Patent TR201618296-U, 23 January 2017. Available online: https://www.turkpatent.gov.tr/en/research (accessed on 24 September 2024).

- Wang, K.; Ceng, D.; Wang, L. Ultrasonic Experiment Single Slot Flotation Machine for Use in e.g., Mine. C.N. Patent CN202741249-U, 20 February 2013. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Qian, L. Flotation Tailing Material for Infrared Dryer Used in Mine Selecting Operation. C.N. Patent CN204594163-U, 26 August 2015. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Yu, L.; Liu, Q.; Gao, Y. Intermittent Fine Particle Oxide Ore Ultrasonic Floatation Device. C.N. Patent CN206613613-U, 7 November 2017. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Sun, X.; Chen, S.; Xuan, X.; Yang, Z.; Wang, Y.; Wang, M. Cavitation and Foaming Integrated Tailing Flotation Device. C.N. Patent CN112495592-A, 16 March 2021. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Long, D.; Wang, B.; Wang, M.; Chen, Z.; Han, G.; Miao, X.; Dong, H.; Yuan, Z.; Gao, Y.; Li, Q. Coal Slime Flotation System Device. C.N. Patent CN213792209-U, 27 July 2021. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- He, W.; Lv, Q. Ultrasonic Oscillation Type Nano-Crystal Extracting and Separating Device. C.N. Patent CN114522443-A, 24 May 2022. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Hu, Y.; Sun, W.; Peng, T.; Wang, C.; Wu, S.; Wang, J.; Tao, L.; Gao, Z. Desorption Method of the Concentrate Surface Flotation Reagent Used in Mineral Flotation Technology Field for Mineral Sorting. C.N. Patent CN115041304-A, 13 September 2022. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Liao, X.; Chen, J. Removing Arsenic by Ultrasonic Assisted Flotation of Stannite Tailings. C.N. Patent CN117065938-A, 17 November 2023. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Zhang, Y.; Ma, W.; Chen, X.; Chen, Z. Recycling Graphite from Waste Cathode by Ultrasonic Auxiliary Flotation. C.N. Patent CN117259021-A, 22 December 2023. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Yin, D. Flotation Agent Ultrasonic Emulsifier. C.N. Patent CN208494042-U, 15 February 2019. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Kang, G.; Jiang, M.; Kang, Y.; Deng, Y. Ultrasonic Flotation Pretreatment Device. C.N. Patent CN215465205-U, 11 January 2022. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Li, Y.; Wang, L.; Xia, Y.; Zhang, Y.; Ding, S.; Cao, Y.; Gui, X.; Xing, Y.; Xu, M. Ultrasonic and Mechanical Damping Block Coupling Coarse Particle Flotation Device. C.N. Patent CN114713380-A, 8 July 2022. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Cui, R.; Li, M.; Wang, X.; Xu, H.; Huang, Y. Hanging Slot Type Flotation Machine for Use in Laboratory. C.N. Patent CN204746622-U, 11 November 2015. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Feng, Y.; Lu, K.; Han, B.; Song, B.; Chen, Z.; Ma, T.; Zhao, T.; Cui, L.; Dai, S.; Wang, E. Laboratory Ultrasonic Flotation Machine for Use in Ore Dressing Device Technology Field. C.N. Patent CN114602660-A, 10 June 2022. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Liao, Q.; Xu, F.; Wang, X.; Xiao, L.; Jin, Y.; Tian, C.; She, L.; Xu, S.; Zhang, X.; Fang, C.; et al. Device for Increasing Flotation Efficiency of Phosphorite by Using Ultrasonic Wave Atomizing Administration. C.N. Patent CN209901504-U, 7 January 2020. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Ma, M.; Li, S.; Yan, T.; Fan, Z.; Deng, L. Ultrasonic Cleaning Based Flotation Device. C.N. Patent CN210815740-U, 23 June 2020. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Yan, J.; Li, X.; Huang, Q.; Yu, H.; Chen, J.; Fu, C.; Lin, X. Performing Fly Ash Flotation Coupled with Ultrasonic Emulsification and Ultrasonic Enhanced Adsorption Decarbonization. C.N. Patent CN116441059-A, 18 July 2023. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Gao, K.; Liu, H.; Sun, L.; Zeng, Q.; Chen, S.; Wang, X.; Meng, F.; Wei, H.; Zhang, Z. Focusing Action Type Ultrasonic Reinforced Flotation Bubble Mineralization Device. C.N. Patent CN113102117-A, 13 July 2021. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Sun, L.; Liu, H.; Gao, K.; Zeng, Q.; Chen, S.; Wei, H.; Zhang, Z.; Wang, X.; Meng, F. Multi-Frequency Ultrasonic Action Flotation Bubble Strengthening and Mineralizing Device. C.N. Patent CN113102120-A, 13 July 2021. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Sun, L.; Liu, H.; Gao, K.; Zeng, Q.; Chen, S.; Zhang, Z.; Wang, X.; Meng, F.; Wei, H. Inclined Ultrasonic Flotation Bubble Strengthening and Mineralizing Device. C.N. Patent CN113102119-A, 13 July 2021. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Lin, Z.; Zhang, Y.; Yin, J.; Zhu, H.; Zhu, J.; Shi, Q. Intermittent Ultrasonic Jet Coupling Reinforced Coal Slurry Flotation Device. C.N. Patent CN116786277-A, 22 September 2023. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Wei, H.; Wang, X.; Zong, W.; Sun, L.; Zhang, Z.; Gao, K. Ultrasonic Action Type Bubble Generating Device for Flotation Mineralization Device. C.N. Patent CN116618185-A, 22 August 2023. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Gao, K.; Liu, H.; Sun, L.; Zhang, Z. Effect of Gas Input Conditions and Ultrasound on the Dynamic Behavior of Flotation Bubbles. Acs Omega 2022, 7, 22326–22340. [Google Scholar] [CrossRef] [PubMed]

- Qiu, Y.; Mao, S.; Zhang, T.; Li, X. Filling Type Flotation Column of Ultrasonic Vibration Sieve Plate for Separating Micro-Particle Mineral. C.N. Patent CN219631566-U, 5 September 2023. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Smart Manufacturing Industrial Automation|Rockwell Automation|US. Available online: https://www.rockwellautomation.com/en-us.html (accessed on 24 September 2024).

- Siemens MindSphere Overview ZH Wp_tcm60-29087.Pdf. Available online: https://www.plm.automation.siemens.com/media/global/zh/Siemens%20MindSphere%20Overview%20ZH%20wp_tcm60-29087.pdf (accessed on 12 August 2024).

- MineOptimize. Available online: https://new.abb.com/mining/mineoptimize (accessed on 24 September 2024).

- Complete Digital Optimisation & Control. Available online: https://www.flsmidth.com/en-gb/company/sustainability/the-missionzero-mine/complete-digital-optimisation-control (accessed on 24 September 2024).

- Shang, Y.; Bai, J.; Duan, P.; Bai, D.; Duan, D.; Wang, C. Ultrasonic Ore Slurry Strong Magnetic Flotation Carbon Iron Device of Coal Gangue. C.N. Patent CN220759547-U, 12 April 2024. Available online: https://pss-system.cponline.cnipa.gov.cn/conventionalSearch (accessed on 24 September 2024).

- Gong, X.; Jiang, W.; Hu, S.; Yang, Z.; Liu, X.; Fan, Z. Comprehensive Utilization of Foundry Dust: Coal Powder and Clay Minerals Separation by Ultrasonic-Assisted Flotation. J. Hazard. Mater. 2021, 402, 124124. [Google Scholar] [CrossRef]

- Gong, X.; Hu, S.; Liu, X.; Yang, M.; Jiang, W.; Fan, Z. Flotation Separation of Coal Dust from Foundry Dust Enhanced by Pre-Soaking Assisted Mechanical Stirring. J. Environ. Manag. 2023, 339, 117899. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Tu, Y.; Xu, Z.; Zhang, X.; Chen, Y.; Yang, E. A Promising Method for Recovery of Graphite and Cathode Materials from Spent Lithium-Ion Batteries. Ionics 2022, 28, 2603–2611. [Google Scholar] [CrossRef]

- Chen, X.; Chen, Z.; Zhang, Y.; Chen, X.; Wang, R.; Wu, D.; Ma, W. Study on the Recovery of Graphite from Spent Carbon Cathode via Ultrasound-Assisted Foam Flotation. J. Clean. Prod. 2024, 443, 141149. [Google Scholar] [CrossRef]

- Bagheri, B.; Vazifeh Mehrabani, J.; Farrokhpay, S. Recovery of Sphalerite from a High Zinc Grade Tailing. J. Hazard. Mater. 2020, 381, 120946. [Google Scholar] [CrossRef] [PubMed]

- Dongfang, L.; Chen, L.; Ma, Y.; Zheng, X.; Wang, Y. Effects of Ultrasonic Pretreatment on the Flotation Behavior of Galena with and without the Presence of Pyrite. Physicochem. Probl. Miner. Process. 2020, 56, 611–624. [Google Scholar] [CrossRef]

- Mao, Y.; Xie, G.; Qi, X.; Peng, Y. Effects of Ultrasonic Pretreatment on Particle Size and Surface Topography of Lignite and Its Relationship to Flotation Response. Energ. Source Part A 2021, 43, 1274–1282. [Google Scholar] [CrossRef]

- Xue, Z.; Gao, F.; Dong, L.; Bao, W.; Wang, J.; Fan, P. Promotion of Hydrophobic-Hydrophilic Separation of Coal Gasification Fine Slag through Ultrasonic Pre-Treatment. J. Environ. Chem. Eng. 2023, 11, 110653. [Google Scholar] [CrossRef]

- Ann Bazar, J.; Rahimi, M.; Fathinia, S.; Jafari, M.; Chipakwe, V.; Chehreh Chelgani, S. Talc Flotation—An Overview. Minerals 2021, 11, 662. [Google Scholar] [CrossRef]

- Ren, L.; Gong, Y.; Guo, Q.; Yu, G. Enhanced Flotation of Coal Gasification Fine Slag Based on Ultrasonic Pretreatment Pulp and Composite Collector. Powder Technol. 2023, 424, 118530. [Google Scholar] [CrossRef]

- Yin, W.; Wang, Y.; Ma, Y.; Chen, K. Effects of Ultrasonic Treatment on the Flotation Behavior of Magnesite and Dolomite in a Sodium Oleate System. Green Smart Min. Eng. 2024, 1, 76–84. [Google Scholar] [CrossRef]

- Chen, L.; He, J.; Zhu, L.; Yao, Q.; Sun, Y.; Guo, C.; Chen, H.; Yang, B. Efficient Recovery of Valuable Metals from Waste Printed Circuit Boards via Ultrasound-Enhanced Flotation. Process Saf. Environ. 2023, 169, 869–878. [Google Scholar] [CrossRef]

- Mao, Y.; Bu, X.; Peng, Y.; Tian, F.; Xie, G. Effects of Simultaneous Ultrasonic Treatment on the Separation Selectivity and Flotation Kinetics of High-Ash Lignite. Fuel 2020, 259, 116270. [Google Scholar] [CrossRef]

- Chen, Y.; Chelgani, S.C.; Bu, X.; Xie, G. Effect of the Ultrasonic Standing Wave Frequency on the Attractive Mineralization for Fine Coal Particle Flotation. Ultrason. Sonochem. 2021, 77, 105682. [Google Scholar] [CrossRef]

- Bilal, M.; Park, I.; Ito, M.; Hassan, F.U.; Aikawa, K.; Jeon, S.; Hiroyoshi, N. Carrier Flotation Using Coarse Pyrite for Improving the Recovery of Finely Ground Chalcopyrite: Development of Post-Process of Carrier Flotation to Separate Finely Ground Chalcopyrite Particles from Coarse Pyrite Particles. Minerals 2023, 13, 916. [Google Scholar] [CrossRef]

- Jiang, H.; Zhang, Y.; Wang, C.; Wang, H. A Clean and Efficient Flotation towards Recovery of Hazardous Polyvinyl Chloride and Polycarbonate Microplastics through Selective Aluminum Coating: Process, Mechanism, and Optimization. J. Environ. Manag. 2021, 299, 113626. [Google Scholar] [CrossRef]

- Cao, D.; Xu, X.; Jiang, S. Ultrasound-Electrochemistry Enhanced Flotation and Desulphurization for Fine Coal. Sep. Purif. Technol. 2021, 258, 117968. [Google Scholar] [CrossRef]

| Process-Specific | System | Comparison of Results Compared to Conventional Flotation | ||

|---|---|---|---|---|

| Ultrasonic pretreatment | Coal | Residual carbon from CGFS | Keeping the ash fluctuations of tailings under 2%, the concentrate ash saw a drop from 31.81% to 18.93% as ultrasonic power escalated. | |

| The combined method increased the three concentrates’ LOIs by 1.52, 1.42, and 1.20 times, and LOIs of cut tailings by 51%, 86%, and 36%. | ||||

| Combustible components | The presence of micro–nano bubbles during 37 kHz and 80 kHz treatments raised the combustible recovery by roughly 35% and 25%, respectively. | |||

| Sphalerite | Low ash, fine lignite | As ultrasonic power and time rose, concentrate yield generally fell, with the exception at 18 W. | ||

| High-zinc-grade tailing | Silver-bearing and sulfur lead minerals | Sulfur grade rose 11.63% and concentrate recovery increased by 9.10%, while the lead and silver recoveries from tailings climbed to 8.72% and 9.50%, respectively. | ||

| Chlorite | Sphalerite | Flotation recovered over 73% of Zn from tailings, yielding a rougher concentrate at 28.61% Zn grade. | ||

| Spent carbon cathode | Pyrrhotite | Pyrrhotite recovery rose from 77.50% to 81.72%, while the MgO content dropped from 6.57% to 5.74%. | ||

| Foundry dust | Graphite | Flotation recovery rates reached 96.24%, tailings contained 9.68%, and concentrate grades peaked at 84.95%. | ||

| Gasification coal fine slag | Clay minerals and coal powder | Tailings yield was 55.3%, with 19.3% LOI and 69.22% RPC. | ||

| Simultaneous ultrasonic treatment | Lignite | Residual carbon | Concentrate yield dropped by 9.94%, ash content dropped by 16.54%, and the flotation perfect index rose by 12.60%. | |

| Magnesite and dolomite | Concentrates and combustibles | In pulp-zone ultrasonic flotation, concentrate yield and combustible recovery rose 9.72% and 18.54%, respectively, while froth zone saw gains of 14.53% and 21.42%. | ||

| Waste printed circuit boards | Magnesite and dolomite | Magnesite concentrate recovery hit 91%. | ||

| Sphalerite | Pyrite particles | Metal recovery from WPCBs collectively rose by 7.20%, with specific gains of 4.82% in Cu, 15.41% in Zn, and 5.58% in Al. | ||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, X.; Cheng, H.; Xu, K.; Ding, D.; Wang, X.; Wang, B.; Ma, Z. Ultrasonic Enhancement for Mineral Flotation: Technology, Device, and Engineering Applications. Minerals 2024, 14, 986. https://doi.org/10.3390/min14100986

Zhang X, Cheng H, Xu K, Ding D, Wang X, Wang B, Ma Z. Ultrasonic Enhancement for Mineral Flotation: Technology, Device, and Engineering Applications. Minerals. 2024; 14(10):986. https://doi.org/10.3390/min14100986

Chicago/Turabian StyleZhang, Xiaoou, Huaigang Cheng, Kai Xu, Danjing Ding, Xin Wang, Bo Wang, and Zhuohui Ma. 2024. "Ultrasonic Enhancement for Mineral Flotation: Technology, Device, and Engineering Applications" Minerals 14, no. 10: 986. https://doi.org/10.3390/min14100986

APA StyleZhang, X., Cheng, H., Xu, K., Ding, D., Wang, X., Wang, B., & Ma, Z. (2024). Ultrasonic Enhancement for Mineral Flotation: Technology, Device, and Engineering Applications. Minerals, 14(10), 986. https://doi.org/10.3390/min14100986