Superplasticizer Dosage Effect on Strength, Microstructure and Permeability Enhancement of Cementitious Paste Fills

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

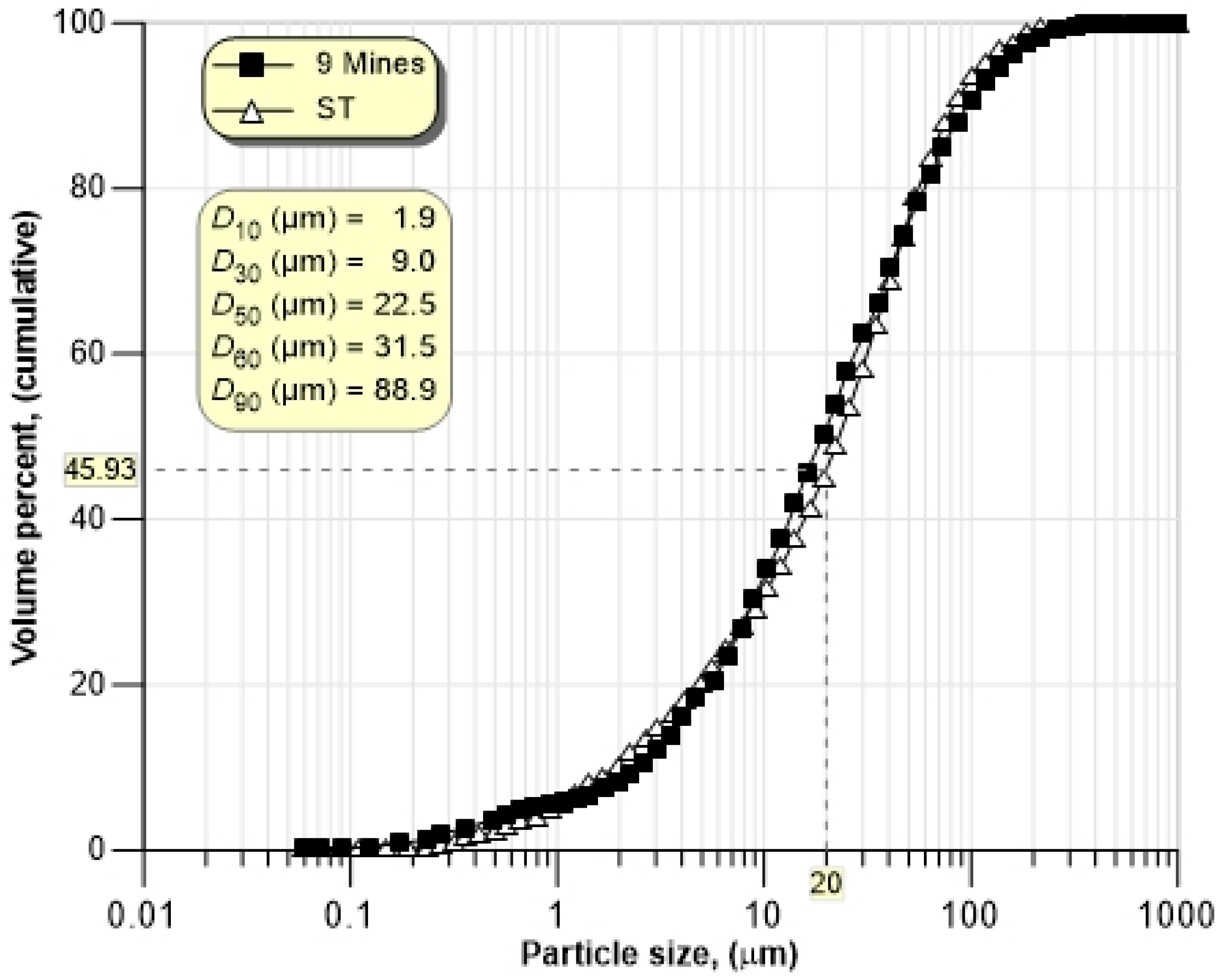

2.1.1. Cement and Silica Tailings

2.1.2. Admixture

2.1.3. CPF Sample Preparation and Mixing Recipes

2.2. Testing of Samples

2.2.1. Fresh Fill Rheology

2.2.2. Hardened Fill Strengths

2.2.3. Microstructural Test

2.2.4. Hydraulic Conductivity Test

3. Results and Discussion

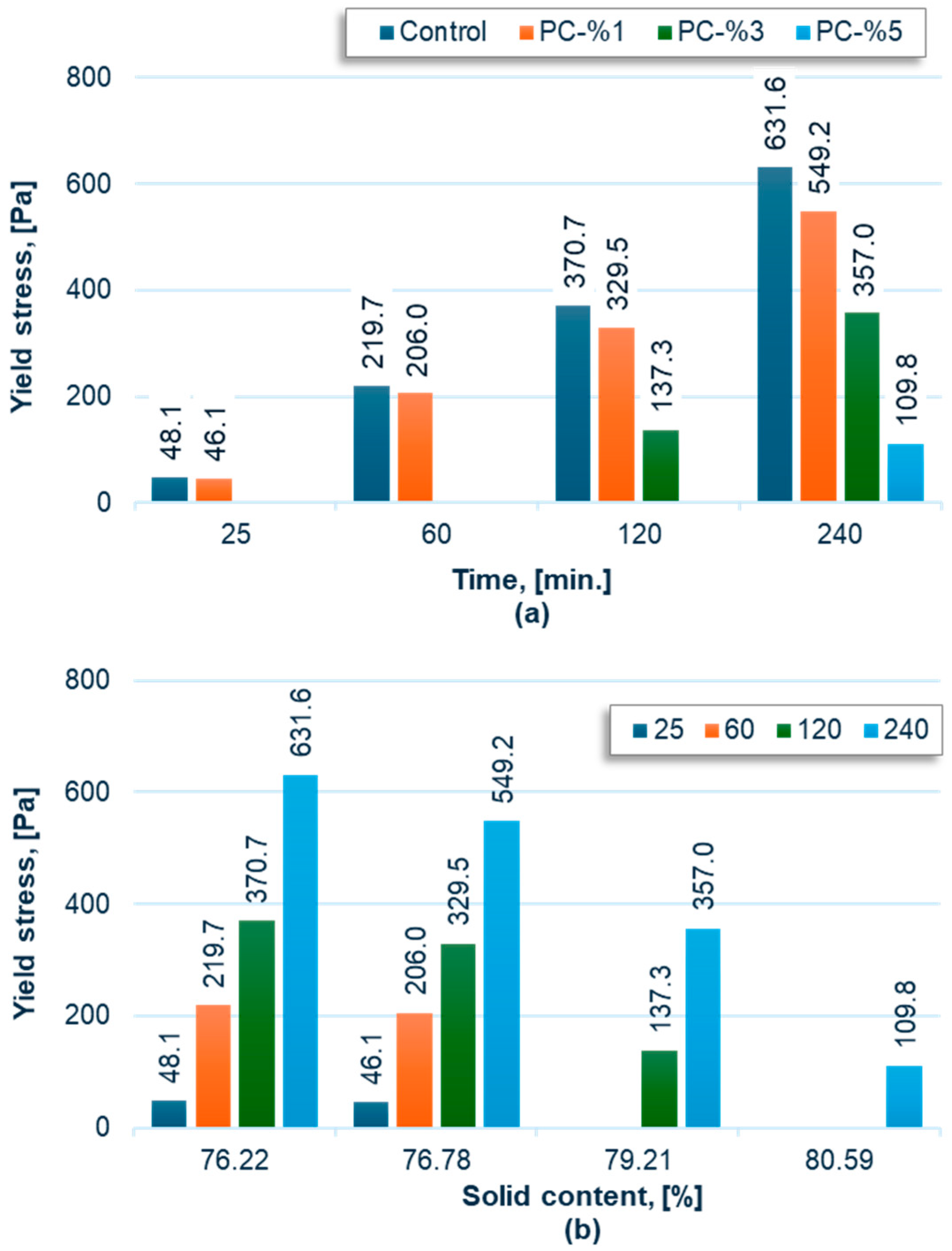

3.1. Rheology of Fresh CPF

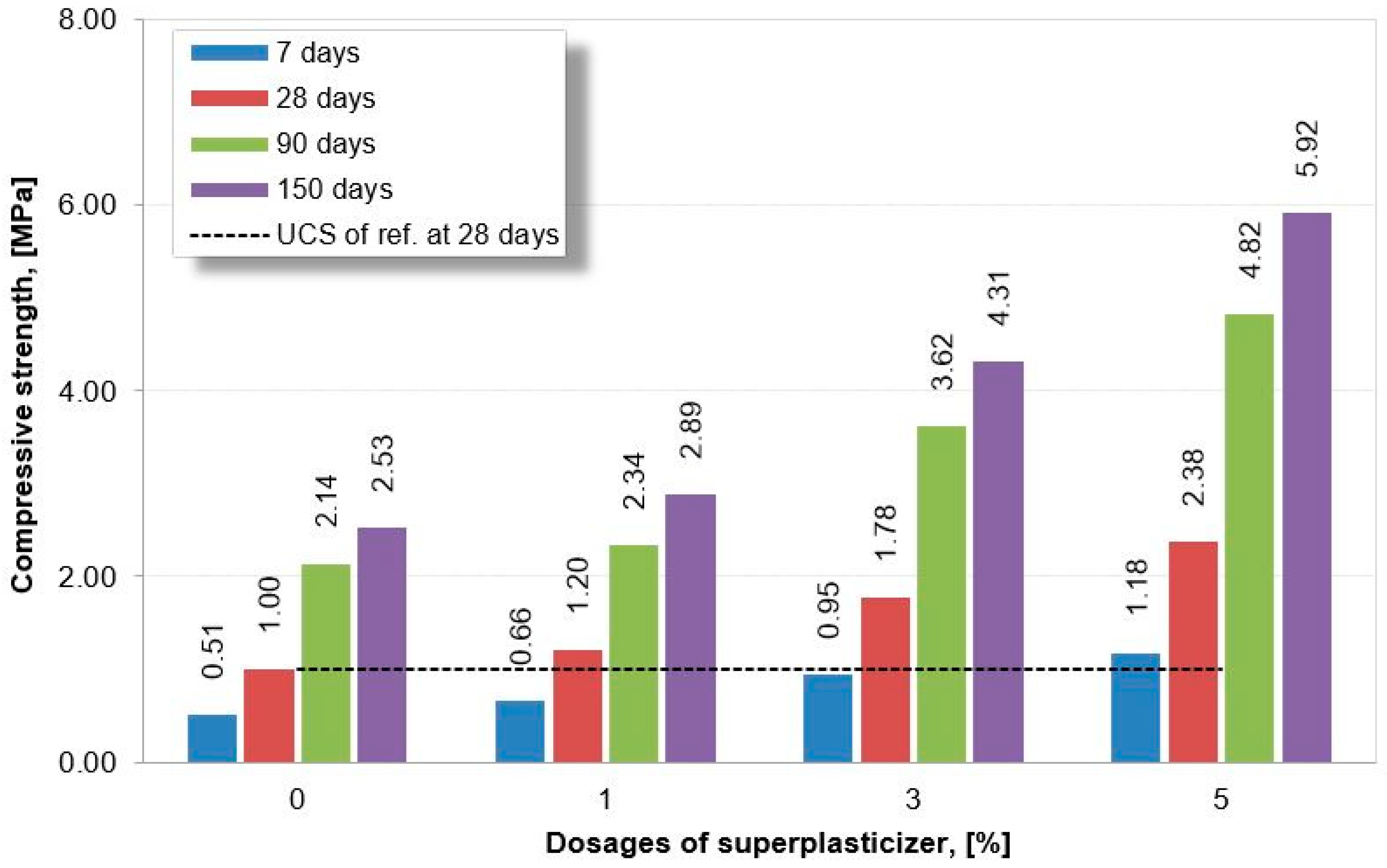

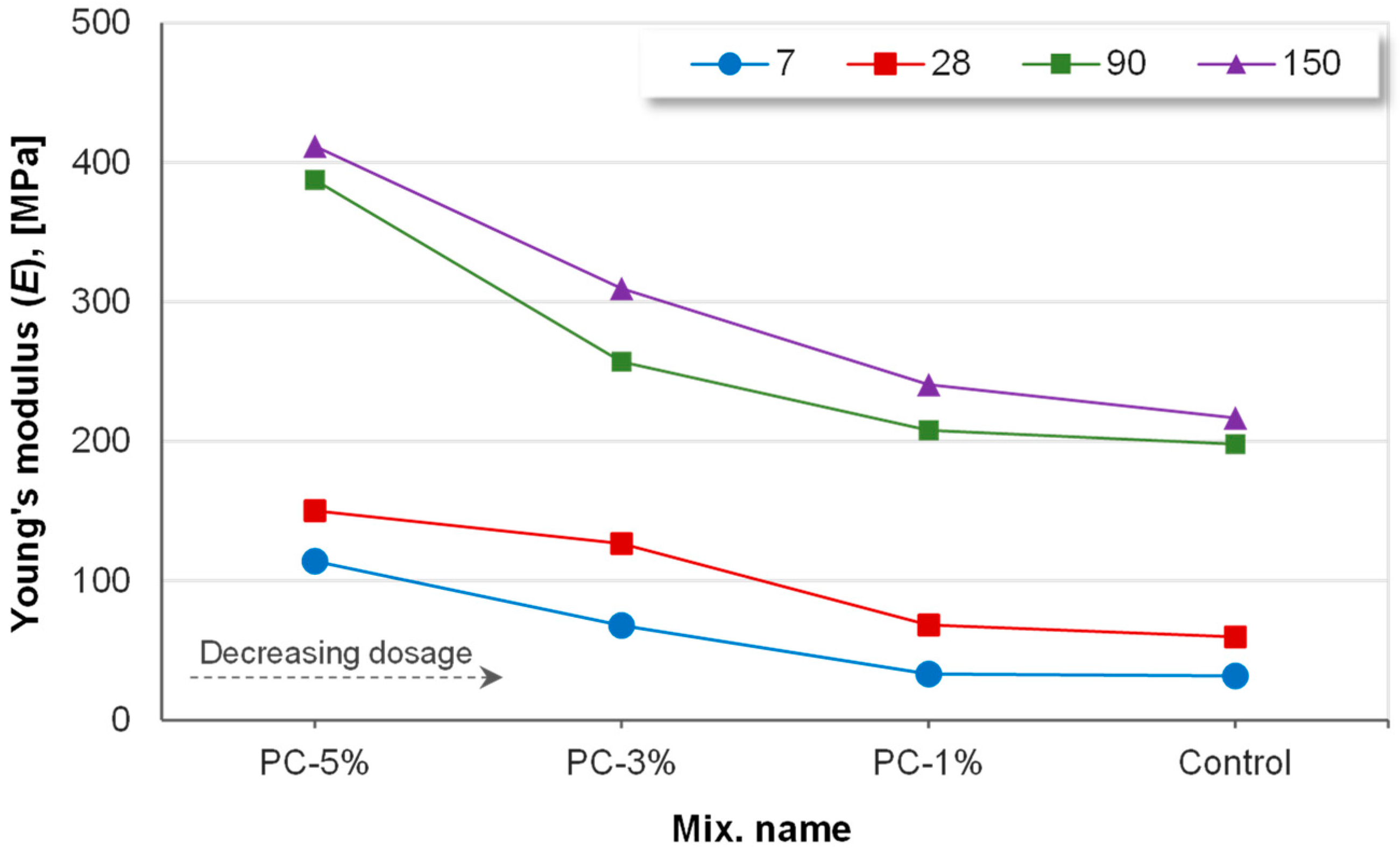

3.2. Superplasticizer Effect on a Fill’s Strength Growth and Stress–Strain Behavior

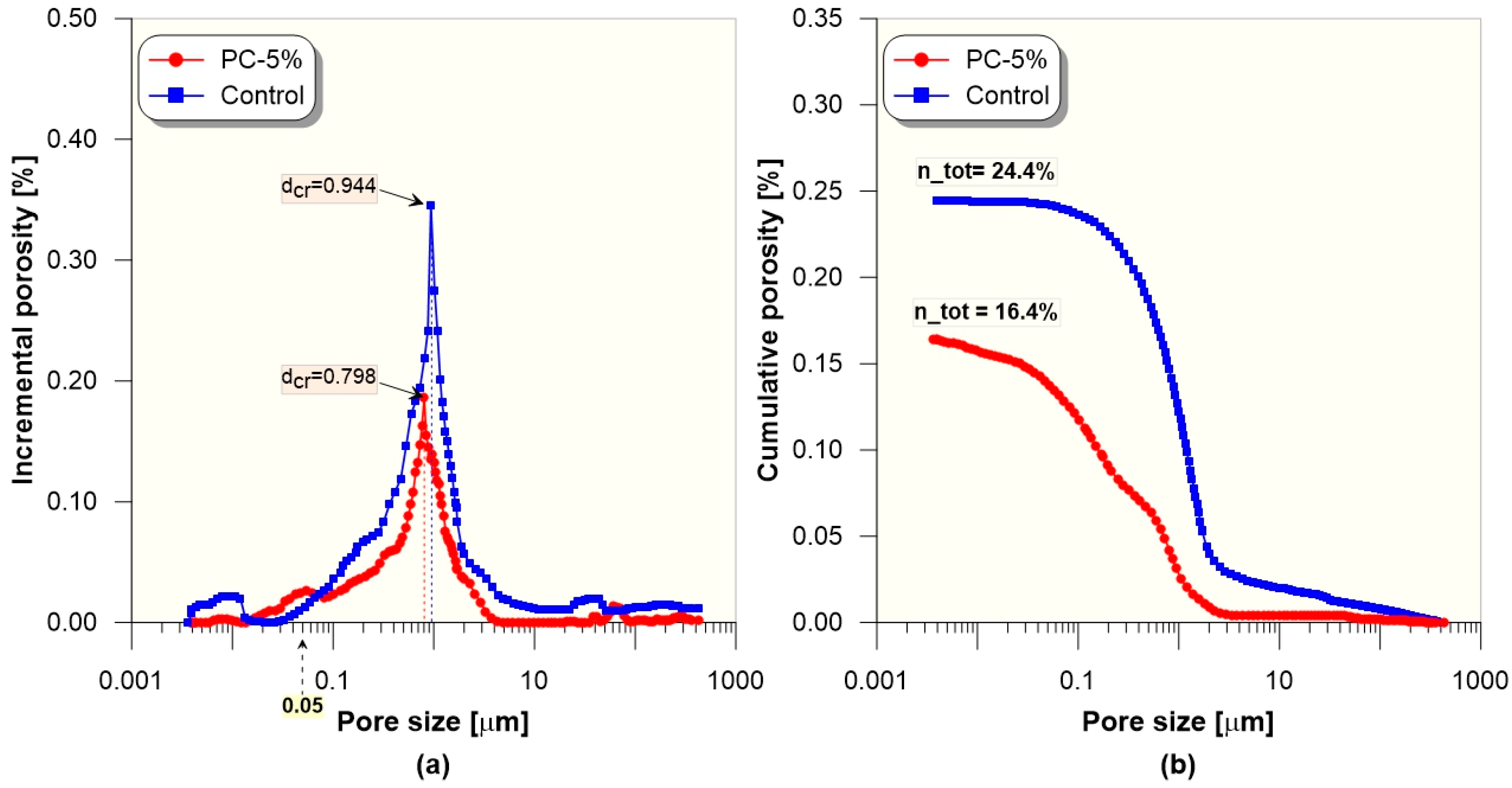

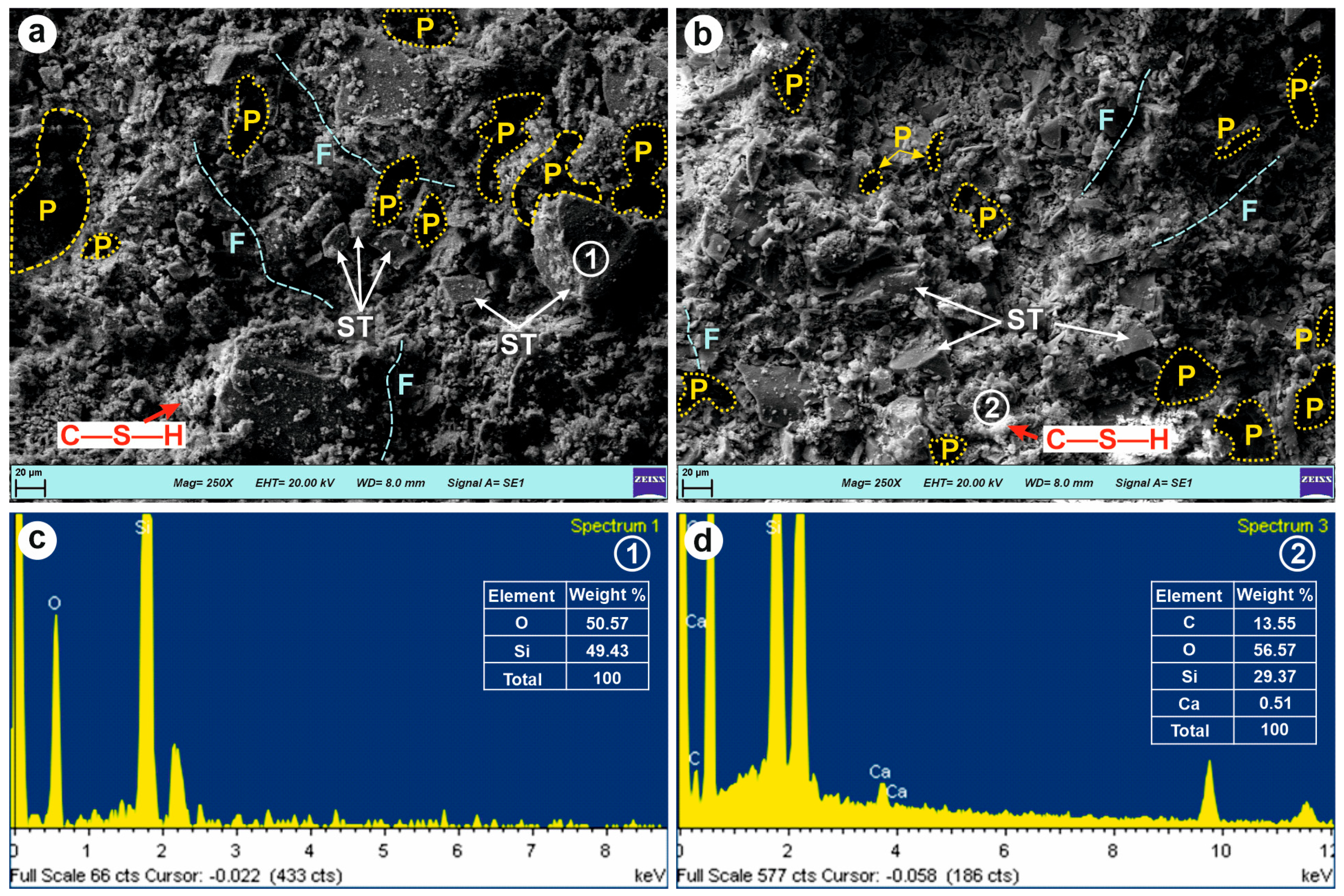

3.3. Superplasticizer Impact on Fill Pore Structure

3.4. Superplasticizer Effect on Fills’ Hydraulic Conductivity

4. Conclusions

- The addition of a superplasticizer to fill mixtures at a dosage of 0% to 5% caused a major 23% drop in water demand and a remarkable 6-fold decrease in yield stress from 631.6 Pa to 109.8 Pa at 240 min. hydration time, leading to a more flowable and workable paste that can be easily transferred underground and reduce the risk of pipe blockages.

- The superplasticizer addition pointedly enhanced one fill sample’s long-aged strength, with a 2.4-fold increase at 5% dosage compared to the control. This strength improvement was accompanied by a notable shift in the stress–strain behavior, resulting in a sizeable rise in the fill’s elastic modulus and load–bearing capacity. Additionally, the incorporation of superplasticizer resulted in a drop of strain values at the fill’s peak stress, attributed to the prolonged curing time and increased dosage.

- Incorporating a superplasticizer in fills caused pore refinement, which manifested as a significant reduction in MIP n_tot porosity from 24.4% to 16.4%, representing a notable decrease of approximately 32%. SEM analysis further revealed that the samples with superplasticizers were more compact and denser, resulting in a more uniform hydration process, corroborating the observed reduction in porosity.

- Utilizing a superplasticizer in one fill mixture caused a significant drop in hydraulic conductivity, decreasing its permeability by almost 30 times. At 150-day curing, the fill’s hydraulic conductivity with a 5% superplasticizer addition decreased from 2.96 × 10−8 cm/s to 8.73 × 10−7 cm/s compared to the control sample.

- TG/DTG-XRD studies revealed that incorporating a superplasticizer enhanced the generation of hydration crops within a fill’s cement paste. Hydration crops increased by the admixture effectively filling the voids within the cement matrix, resulting in a significant decrease in porosity.

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Sun, Q.; Zhang, J.; Zhang, Q.; Yan, H. A case study of mining-induced impacts on the stability of multi-tunnels with the backfill mining method and controlling strategies. Environ. Earth. Sci. 2018, 77, 234. [Google Scholar] [CrossRef]

- Benzaazoua, M.; Fall, M.; Belem, T. A contribution to understanding the hardening process of cemented paste fill. Miner. Eng. 2004, 17, 141–152. [Google Scholar] [CrossRef]

- Fall, M.; Benzaazoua, M.; Saa, E.G. Mix proportioning of underground cemented tailings backfill. Tunn. Undergr. Space Technol. 2008, 23, 80–90. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Thompson, B.D.; Bawden, W.F.; Grabinsky, M.W. In situ measurements of cemented paste backfill at the Cayeli Mine. Can. Geotech. J. 2012, 49, 755–772. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Benzaazoua, M. Effects of curing and stress conditions on hydromechanical, geotechnical and geochemical properties of cemented paste backfill. Eng. Geol. 2014, 168, 23–37. [Google Scholar] [CrossRef]

- Belem, T.; Benzaazoua, M. Design and application of underground mine paste backfill technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Fall, M.; Belem, T.; Samb, S.; Benzaazoua, M. Experimental characterization of the stress-strain behaviour of cemented paste backfill in compression. J. Mater. Sci. 2007, 42, 3914–3922. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Coupled thermo-hydro-mechanical—Chemical behaviour of cemented paste backfill in column experiments. Part I: Physical, hydraulic and thermal processes and characteristics. Eng. Geol. 2013, 164, 195–207. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Coupled thermo-hydro-mechanical–chemical behaviour of cemented paste backfill in column experiments: Part II: Mechanical, chemical and microstructural processes and characteristics. Eng. Geol. 2014, 170, 11–23. [Google Scholar] [CrossRef]

- Ercikdi, B.; Cihangir, F.; Kesimal, A.; Deveci, H. Practical importance of tailings for cemented paste backfill. In Paste Tailings Management; Yilmaz, E., Fall, M., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 7–32. [Google Scholar] [CrossRef]

- Ghirian, A.; Fall, M. Properties of cemented paste backfill. In Paste Tailings Management; Yilmaz, E., Fall, M., Eds.; Springer International Publishing: Cham, Switzerland, 2017; pp. 59–109. [Google Scholar] [CrossRef]

- Liu, J.; Sui, W.; Zhang, D.; Zhao, Q. Durability of water-affected paste backfill material and its clean use in coal mining. J. Clean. Prod. 2020, 250, 119576. [Google Scholar] [CrossRef]

- Wang, Y.; Cao, Y.; Cui, L.; Si, Z.; Wang, H. Effect of external sulfate attack on the mechanical behavior of cemented paste backfill. Constr. Build. Mater. 2020, 263, 120968. [Google Scholar] [CrossRef]

- Fall, M.; Adrien, D.; Célestin, J.C.; Pokharel, M.; Touré, M. Saturated hydraulic conductivity of cemented paste backfill. Miner. Eng. 2009, 22, 1307–1317. [Google Scholar] [CrossRef]

- Pokharel, M.; Fall, M. Combined influence of sulphate and temperature on the saturated hydraulic conductivity of hardened cemented paste backfill. Cem. Concr. Compos. 2013, 38, 21–28. [Google Scholar] [CrossRef]

- Haruna, S.; Fall, M. Insight into saturated hydraulic conductivity of cemented paste backfill containing polycarboxylate ether-based superplasticizer. Minerals 2022, 12, 93. [Google Scholar] [CrossRef]

- Akkaya, U.G.; Cinku, K.; Yilmaz, E. Characterization of strength and quality of cemented mine backfill made up of lead-zinc processing tailings. Front. Mater. 2021, 8, 740116. [Google Scholar] [CrossRef]

- Sari, M.; Yilmaz, E.; Kasap, T.; Guner, N.U. Strength and microstructure evolution in cemented mine backfill with low and high pH pyritic tailings: Effect of mineral admixtures. Constr. Build. Mater. 2022, 328, 127109. [Google Scholar] [CrossRef]

- Fang, K.; Zhang, J.; Cui, L.; Haruna, S.; Li, M. Cost optimization of cemented paste backfill: State-of-the-art review and future perspectives. Miner. Eng. 2023, 204, 108414. [Google Scholar] [CrossRef]

- Bull, A.J.; Fall, M. Curing temperature dependency of the release of arsenic from cemented paste backfill made with portland cement. J. Environ. Manag. 2020, 269, 110772. [Google Scholar] [CrossRef]

- Veenstra, R.; Grabinsky, M.; Bawden, W.; Thompson, B. A numerical analysis of how permeability affects the development of pore water pressure in early age cemented paste backfill in a backfilled stope. In Proceedings of the Eleventh International Symposium on Mining with Backfill, Australian Centre for Geomechanics, Perth, WA, Australia, 20–22 May 2014; pp. 83–95. [Google Scholar] [CrossRef]

- Cihangir, F.; Akyol, Y. Mechanical, hydrological and microstructural assessment of the durability of cemented paste backfill containing alkali-activated slag. Int. J. Min. Reclam. Environ. 2018, 32, 123–143. [Google Scholar] [CrossRef]

- Behera, S.K.; Mishra, D.P.; Singh, P.; Mishra, K.; Mandal, S.K.; Ghosh, C.N.; Kumar, R.; Mandal, P.K. Utilization of mill tailings, fly ash and slag as mine paste backfill material: Review and future perspective. Constr. Build. Mater. 2021, 309, 125120. [Google Scholar] [CrossRef]

- Ercikdi, B.; Cihangir, F.; Kesimal, A.; Deveci, H.; Alp, İ. Utilization of water-reducing admixtures in cemented paste backfill of sulphide-rich mill tailings. J. Hazard. Mater. 2010, 179, 940–946. [Google Scholar] [CrossRef] [PubMed]

- Ouattara, D.; Yahia, A.; Mbonimpa, M.; Belem, T. Effects of superplasticizer on rheological properties of cemented paste backfills. Int. J. Miner. Process. 2017, 161, 28–40. [Google Scholar] [CrossRef]

- Koohestani, B.; Darban, A.K.; Mokhtari, P. A comparison between the influence of superplasticizer and organosilanes on different properties of cemented paste backfill. Constr. Build. Mater. 2018, 173, 180–188. [Google Scholar] [CrossRef]

- Mangane, M.B.C.; Argane, R.; Trauchessec, R.; Lecomte, A.; Benzaazoua, M. Influence of superplasticizers on mechanical properties and workability of cemented paste backfill. Miner. Eng. 2018, 116, 3–14. [Google Scholar] [CrossRef]

- Ouattara, D.; Belem, T.; Mbonimpa, M.; Yahia, A. Effect of superplasticizers on the consistency and unconfined compressive strength of cemented paste backfills. Constr. Build. Mater. 2018, 181, 59–72. [Google Scholar] [CrossRef]

- Panchal, S.; Deb, D.; Sreenivas, T. Variability in rheology of cemented paste backfill with hydration age, binder and superplasticizer dosages. Adv. Powder Technol. 2018, 29, 2211–2220. [Google Scholar] [CrossRef]

- Yang, L.; Yilmaz, E.; Li, J.; Liu, H.; Jiang, H. Effect of superplasticizer type and dosage on fluidity and strength behavior of cemented tailings backfill with different solid contents. Constr. Build. Mater. 2018, 187, 290–298. [Google Scholar] [CrossRef]

- Cavusoglu, I.; Yilmaz, E.; Yilmaz, A.O. Additivity effect on properties of cemented coal fly ash backfill containing water-reducing admixtures. Constr. Build. Mater. 2021, 267, 121021. [Google Scholar] [CrossRef]

- Haruna, S.; Fall, M. Time- and temperature-dependent rheological properties of cemented paste backfill that contains superplasticizer. Powder. Technol. 2020, 360, 731–740. [Google Scholar] [CrossRef]

- Nasir, O.; Fall, M. Shear behaviour of cemented pastefill-rock interfaces. Eng. Geol. 2008, 101, 146–153. [Google Scholar] [CrossRef]

- Fall, M.; Pokharel, M. Coupled effects of sulphate and temperature on the strength development of cemented tailings backfills: Portland cement-paste backfill. Cem. Concr. Compos. 2010, 32, 819–828. [Google Scholar] [CrossRef]

- Fall, M.; Célestin, J.C.; Pokharel, M.; Touré, M. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill. Eng. Geol. 2010, 114, 397–413. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, Z.; Yang, L.; Jiang, H.; Zhao, Y. Effect of tailings fineness on flow, strength, ultrasonic and microstructure characteristics of cemented paste backfill. Constr. Build. Mater. 2020, 263, 120645. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Jiang, H.; Zhang, S.; Ding, H. Improving the performance of superfine-tailings cemented paste backfill with a new blended binder. Powder. Technol. 2021, 394, 149–160. [Google Scholar] [CrossRef]

- Landriault, D. Backfill in Underground Mining; SME, Society for Mining, Metallurgy, and Exploration (SME): Littleton, CO, USA, 2001; pp. 601–614. [Google Scholar]

- ASTM C494; Standard Specification for Chemical Admixtures for Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- ASTM C143/C143M; Standard Test Method for Slump of Hydraulic-Cement Concrete. ASTM International: West Conshohocken, PA, USA, 2015.

- Boger, D.; Scales, P.; Sofra, F. Rheological concepts. In Paste and Thickened Tailings—A Guide, 2nd ed.; Jewell, R.J., Fourie, A.B., Eds.; Australian Centre for Geomechanics: Perth, Australia, 2006; pp. 1–25. [Google Scholar]

- ASTM C39; Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. ASTM International: West Conshohocken, PA, USA, 2016.

- Ghirian, A.; Fall, M. Long-term coupled behaviour of cemented paste backfill in load cell experiments. Geomech. Geoeng. Int. J. 2016, 4, 237–251. [Google Scholar] [CrossRef]

- ASTM D5084-16a; Standard Test Methods for Measurement of Hydraulic Conductivity of Saturated Porous Materials Using a Flexible Wall Permeameter 1. ASTM International: West Conshohocken, PA, USA, 2016.

- Thomashausen, S.; Maennling, N.; Mebratu-Tsegaye, T. A comparative overview of legal frameworks governing water use and waste water discharge in the mining sector. Resour. Policy 2018, 55, 143–151. [Google Scholar] [CrossRef]

- Niroshan, N.; Sivakugan, N.; Veenstra, R.L. Flow characteristics of cemented paste backfill. Geotech. Geol. Eng. 2018, 36, 2261–2272. [Google Scholar] [CrossRef]

- Cao, S.; Yilmaz, E.; Song, W. Evaluation of viscosity, strength and microstructural properties of cemented tailings backfill. Minerals 2018, 8, 352. [Google Scholar] [CrossRef]

- Zhang, J.; Deng, H.; Taheri, A.; Deng, J.; Ke, B. Effects of Superplasticizer on the Hydration, Consistency, and Strength Development of Cemented Paste Backfill. Minerals 2018, 8, 381. [Google Scholar] [CrossRef]

- Cavusoglu, I.; Fall, M. Engineering properties of cemented paste backfill with full-range water-reducing admixture. Int. J. Civ. Eng. 2023, 21, 1567–1582. [Google Scholar] [CrossRef]

- Mehta, P.K.; Monteiro, P.J.M. Concrete: Microstructure, Properties, and Materials, 2nd ed.; Prentice Hall: Upper Saddle River, NJ, USA, 1993. [Google Scholar]

- Hong, S.; de Bruyn, K.; Bescher, E.; Ramseyer, C.; Kang, T.H.K. Porosimetric features of calcium sulfoaluminate and portland cement pastes: Testing protocols and data analysis. J. Struct. Integr. Maint. 2018, 3, 52–66. [Google Scholar] [CrossRef]

- Qian, X.; Yu, C.; Zhang, L.; Qian, K.; Fang, M.; Lai, J. Influence of superplasticizer type and dosage on early-age drying shrinkage of cement paste with consideration of pore size distribution and water loss. J. Wuhan. Univ. Technol.-Mat. Sci. Edit. 2020, 35, 758–767. [Google Scholar] [CrossRef]

- Ouellet, S.; Bussière, B.; Mbonimpa, M.; Benzaazoua, M.; Aubertin, M. Reactivity and mineralogical evolution of an underground mine sulphidic cemented paste backfill. Miner. Eng. 2006, 19, 407–419. [Google Scholar] [CrossRef]

- Aldhafeeri, Z.; Fall, M. Time and damage induced changes in the chemical reactivity of cemented paste backfill. J. Environ. Chem. Eng. 2016, 4, 4038–4049. [Google Scholar] [CrossRef]

- Aldhafeeri, Z.; Fall, M. Coupled effect of sulphate and temperature on the reactivity of cemented tailings backfill. Int. J. Min. Reclam. Environ. 2021, 35, 80–94. [Google Scholar] [CrossRef]

- Perrot, A.; Rangeard, D.; Picandet, V.; Mélinge, Y. Hydro-mechanical properties of fresh cement pastes containing polycarboxylate superplasticizer. Cem. Concr. Res. 2013, 53, 221–228. [Google Scholar] [CrossRef]

- Bhatty, J.I.; Reid, K.J. Use of thermal analysis in the hydration studies of a type 1 portland cement produced from mineral tailings. Thermochim. Acta 1985, 91, 95–105. [Google Scholar] [CrossRef]

- Lothenbach, B.; Durdziński, P.; Weerdt, K.D. Thermogravimetric analysis. In A Practical Guide to Microstructural Analysis of Cementitious Materials, 1st ed.; Scrivener, K., Snellings, R., Lothenbach, B., Eds.; CRC Press Taylor & Francis Group: London, UK, 2016; pp. 177–212. [Google Scholar] [CrossRef]

- Li, W.; Fall, M. Sulphate effect on the early age strength and self-desiccation of cemented paste backfill. Constr. Build. Mater. 2016, 106, 296–304. [Google Scholar] [CrossRef]

- Haruna, S.; Fall, M. Strength development of cemented tailings materials containing polycarboxylate ether-based superplasticizer: Experimental results on the effect of time and temperature. Can. J. Civ. Eng. 2021, 48, 429–442. [Google Scholar] [CrossRef]

- Al-Moselly, Z.; Fall, M.; Haruna, S. Further insight into the strength development of cemented paste backfill materials containing polycarboxylate ether-based superplasticizer. J. Build. Eng. 2022, 47, 103859. [Google Scholar] [CrossRef]

| Component Unit | SiO2 (%) | Al2O3 (%) | Fe2O3 (%) | MgO (%) | CaO (%) | SO3 (%) | Specific Gravity |

|---|---|---|---|---|---|---|---|

| GU | 18.03 | 4.53 | 2.70 | 2.65 | 62.82 | 3.82 | 3.10 |

| Silica Tailing | 99.80 | 0.05 | 0.035 | <0.01 | 0.01 | - | 2.70 |

| Name | Dose: wt.% of 100 kg Binder | Specific Gravity | pH |

|---|---|---|---|

| Polycarboxylate | 150–950 mL | 1.12 (21 °C) | 4.55 (23 °C) |

| Mix Name | Admixture Dose [1] | Binder Dose [2] | Solid Dose [3] | Water/Cement Value [4] | Slump |

|---|---|---|---|---|---|

| (wt.%) | (wt.%) | (wt.%) | (w/c) | (cm) | |

| Control | - | 4.5 | 76.22 | 7.25 | ≈20 |

| PC-1% | 1 | 4.5 | 76.78 | 7.03 | ≈20 |

| PC-3% | 3 | 4.5 | 79.21 | 6.12 | ≈20 |

| PC-5% | 5 | 4.5 | 80.59 | 5.64 | ≈20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cavusoglu, I. Superplasticizer Dosage Effect on Strength, Microstructure and Permeability Enhancement of Cementitious Paste Fills. Minerals 2024, 14, 1242. https://doi.org/10.3390/min14121242

Cavusoglu I. Superplasticizer Dosage Effect on Strength, Microstructure and Permeability Enhancement of Cementitious Paste Fills. Minerals. 2024; 14(12):1242. https://doi.org/10.3390/min14121242

Chicago/Turabian StyleCavusoglu, Ibrahim. 2024. "Superplasticizer Dosage Effect on Strength, Microstructure and Permeability Enhancement of Cementitious Paste Fills" Minerals 14, no. 12: 1242. https://doi.org/10.3390/min14121242

APA StyleCavusoglu, I. (2024). Superplasticizer Dosage Effect on Strength, Microstructure and Permeability Enhancement of Cementitious Paste Fills. Minerals, 14(12), 1242. https://doi.org/10.3390/min14121242