Investigating Dynamic Behavior in SAG Mill Pebble Recycling Circuits: A Simulation Approach

Abstract

1. Introduction

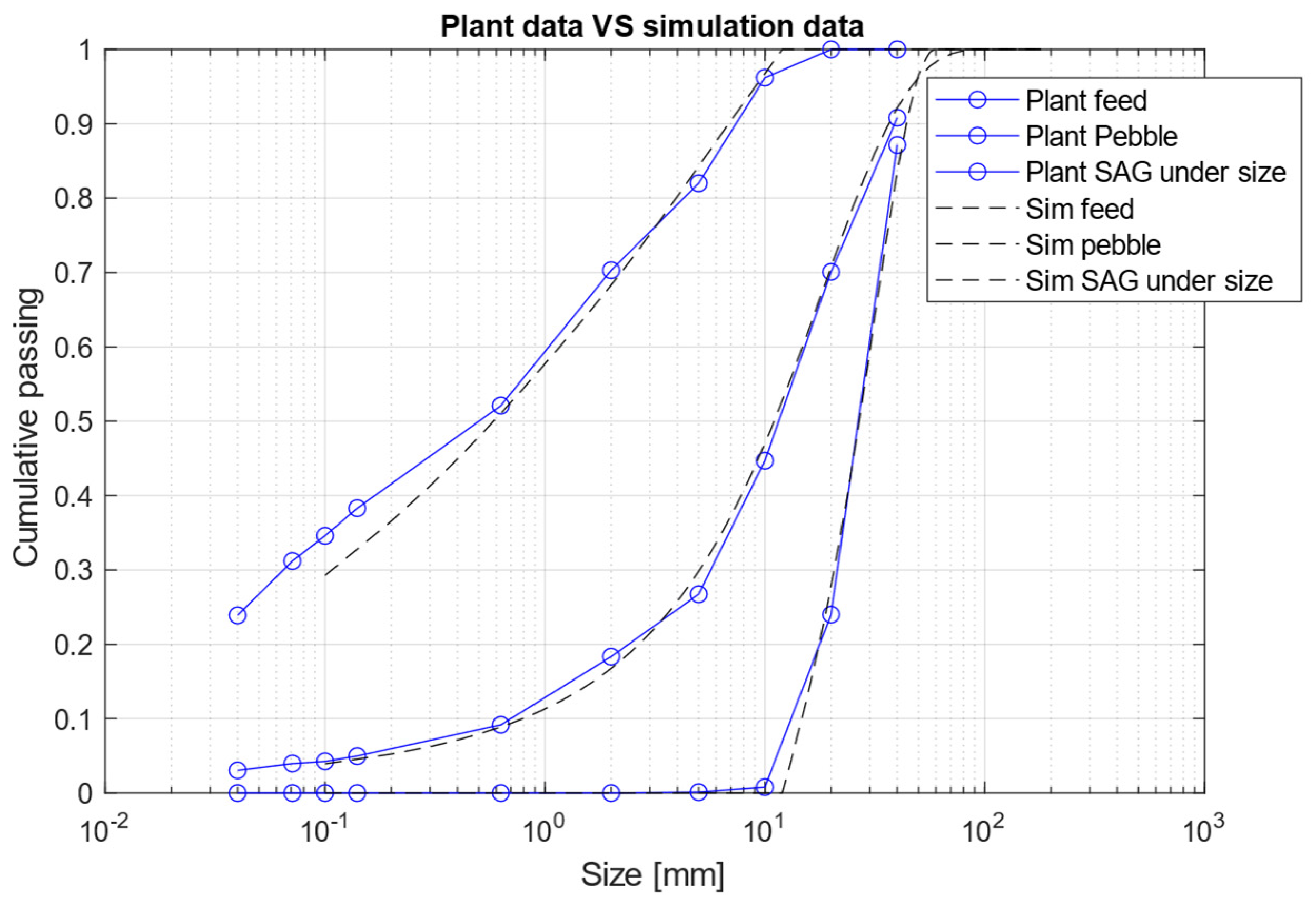

2. Materials and Methods

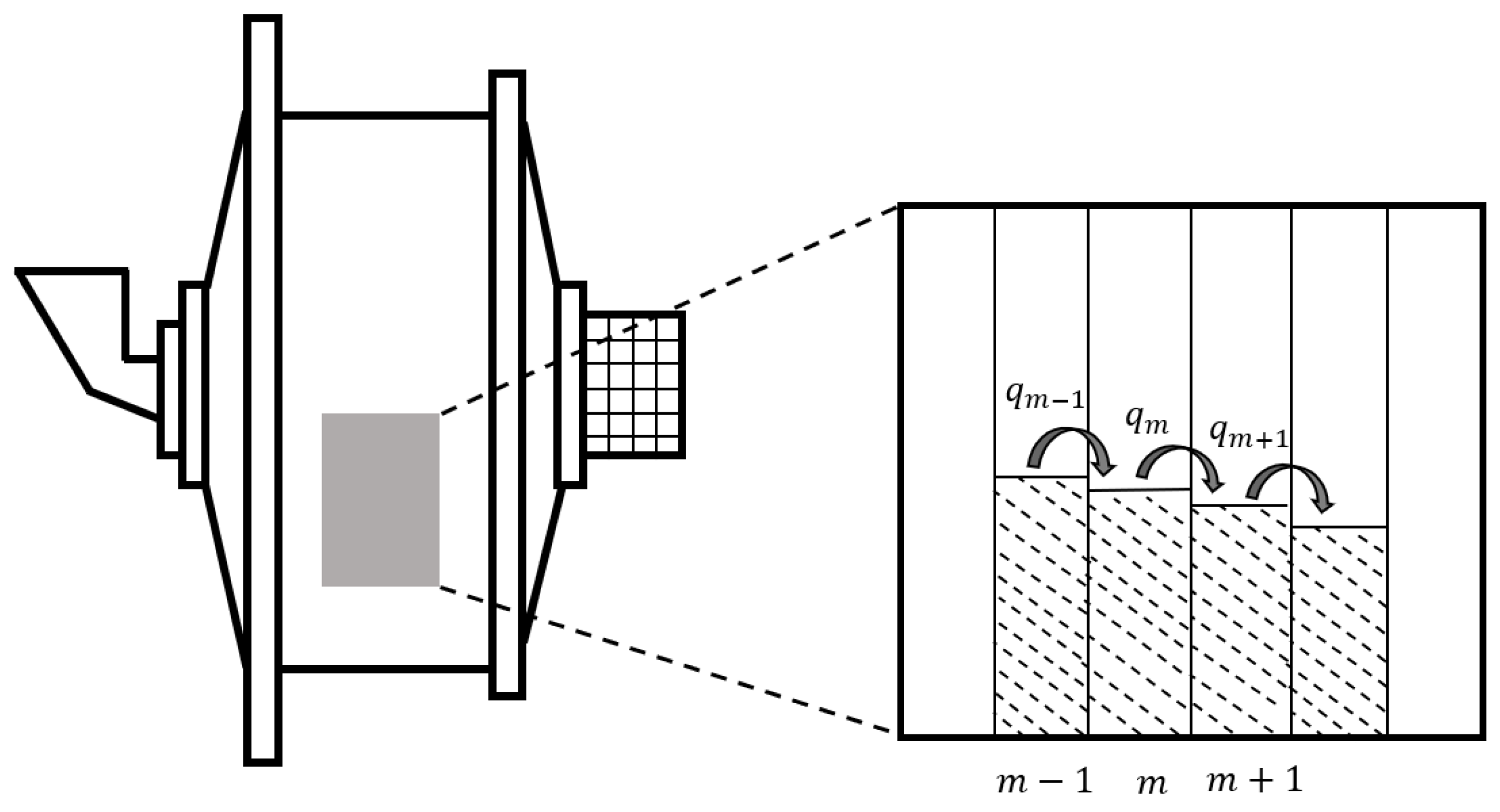

2.1. Mill, Cone Crusher and Other Equipment Modelling

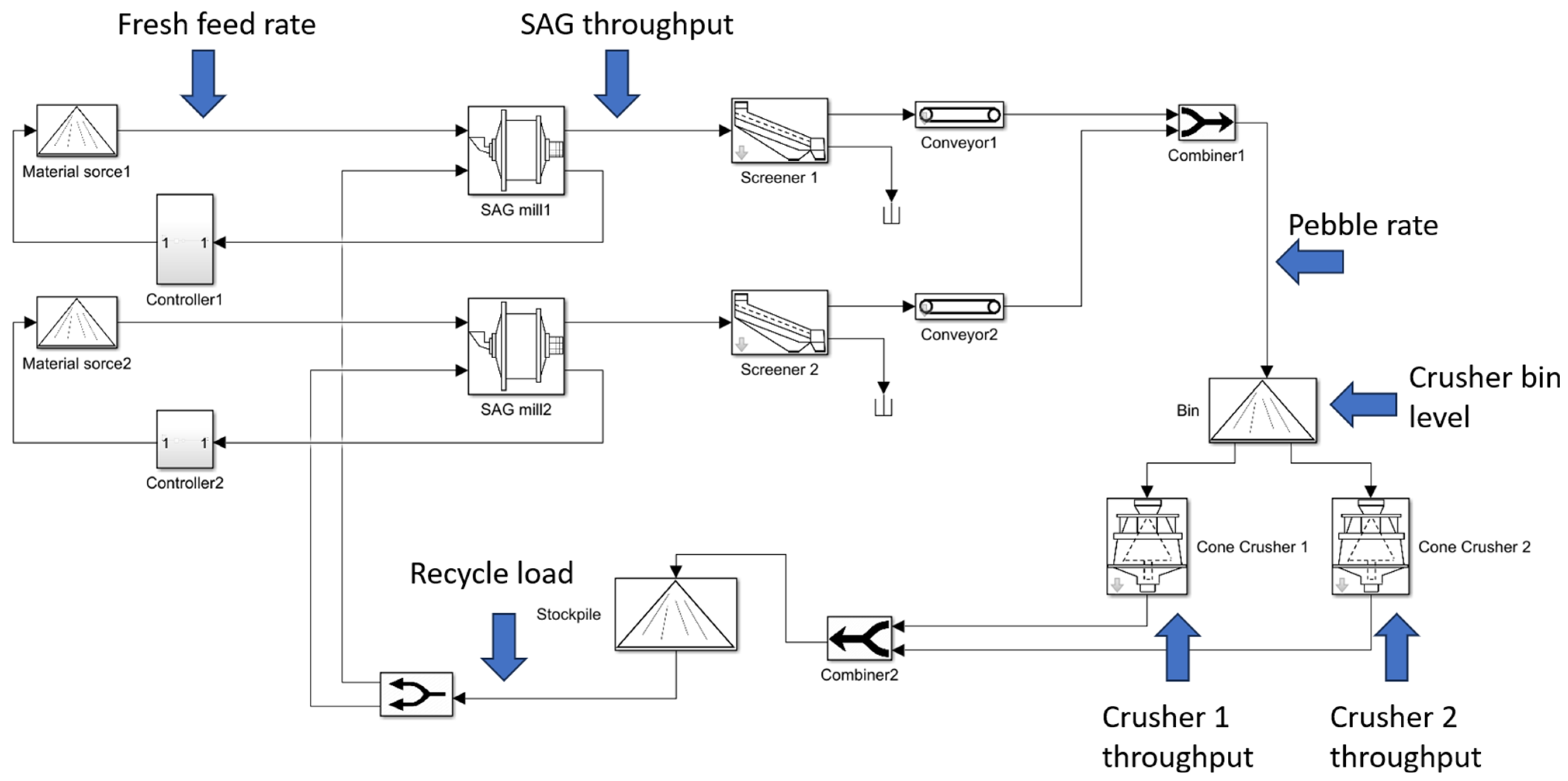

2.2. DOE for SAG Mill Pebble Crushing Circuit Study

- Parameters and conditions:

- •

- Hardness of Feed Material:

- Levels: Two levels of hardness (e.g., hard and soft, see Table A3).

- Condition: The hardness of the feed material can vary significantly. This affects the efficiency of the grinding process in the SAG mill.

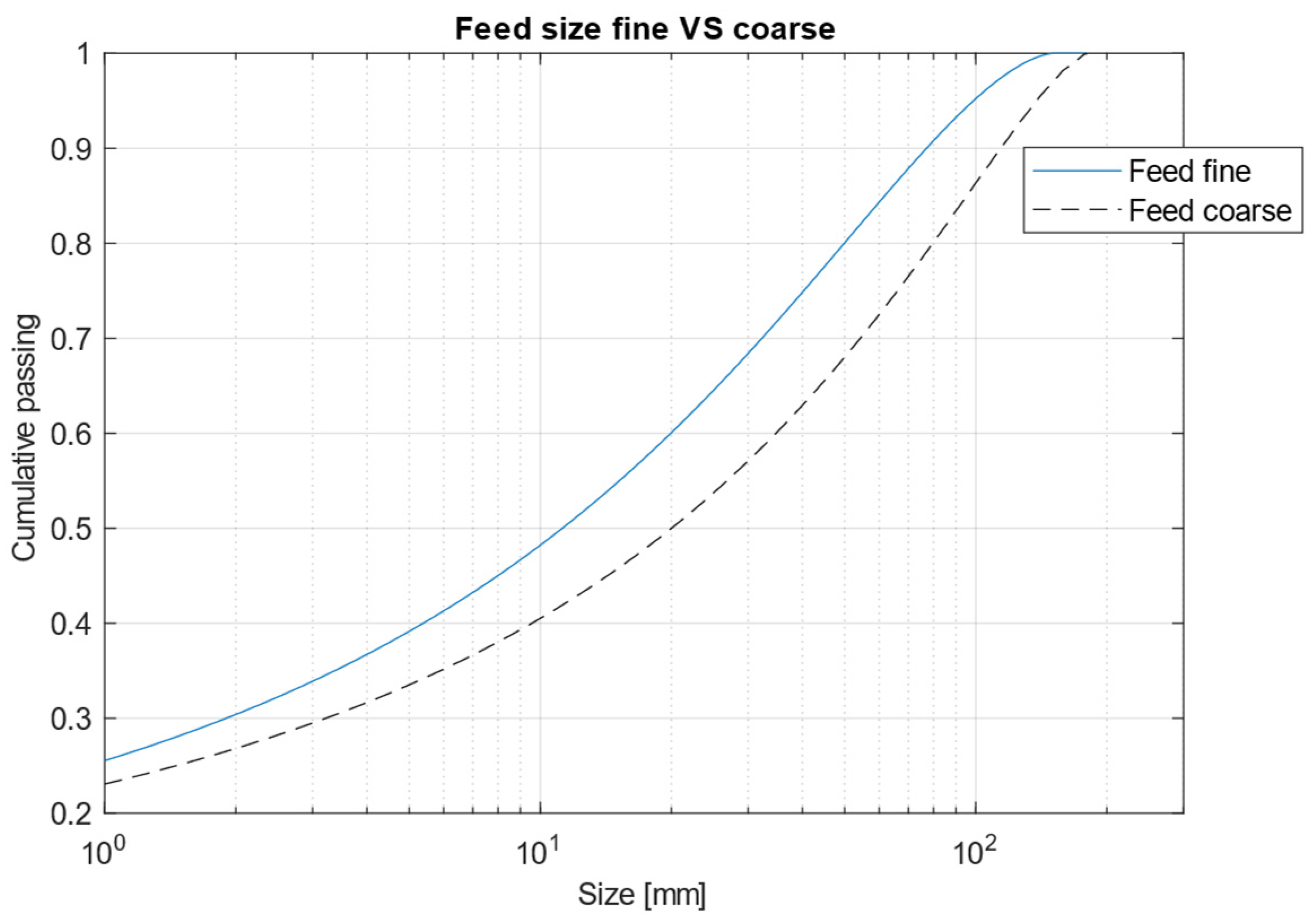

- Feed Size to SAG Mill:

- Levels: Two levels of feed size (e.g., coarse and fine, see Figure A2).

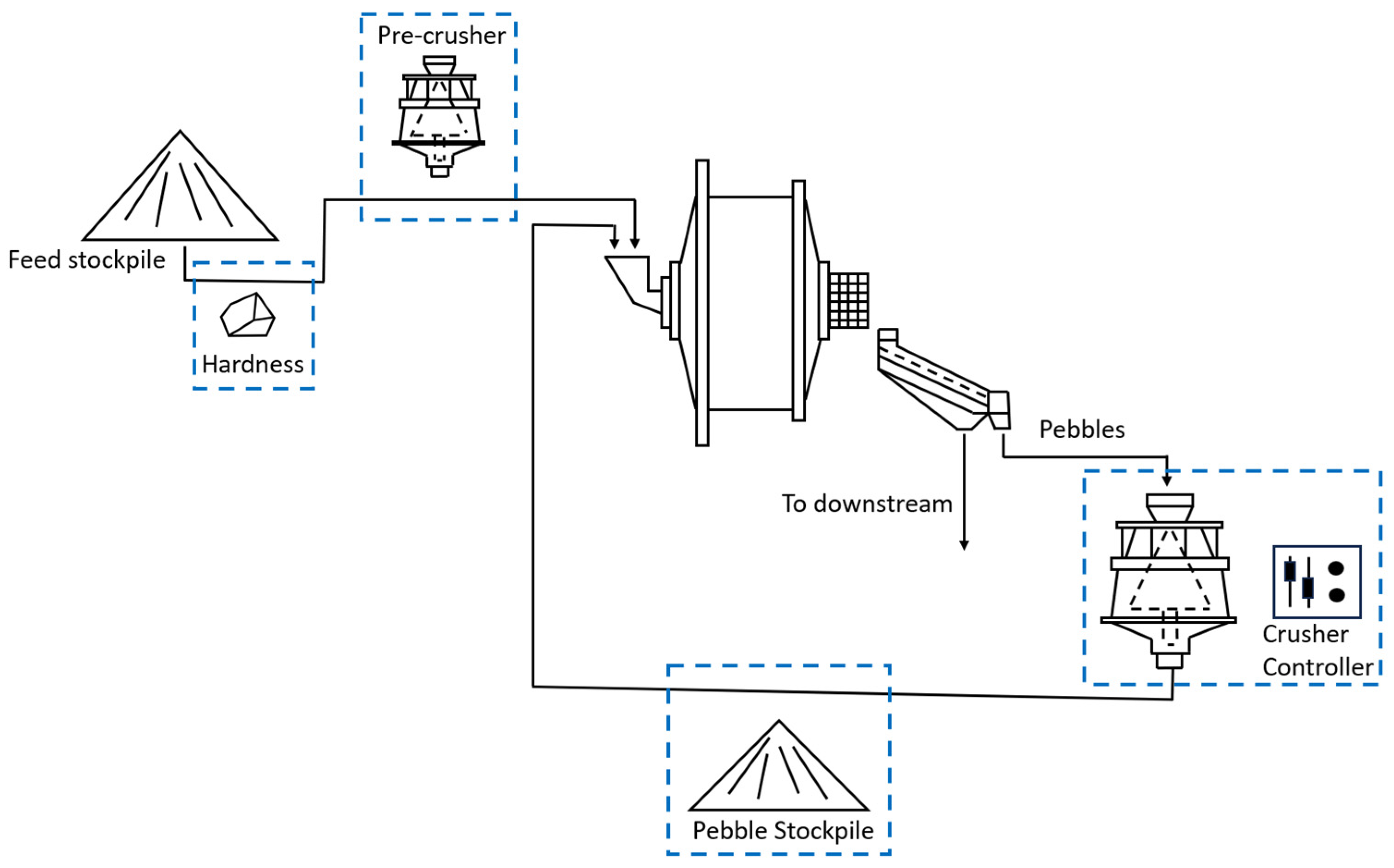

- Condition: Adding a pre-crusher before the feed enters the SAG mill. This helps to reduce the size of the feed material, improving the grinding efficiency of the SAG mill.

- Presence of Pebble Stockpile:

- Levels: With stockpile and Without stockpile.

- Condition: Including a stockpile for pebbles. This allows for better management of the pebbles extracted from the SAG mill, ensuring a consistent feed to the pebble crusher and improving the overall circuit efficiency. In this study, a simple on/off controller based on the stockpile level is applied.

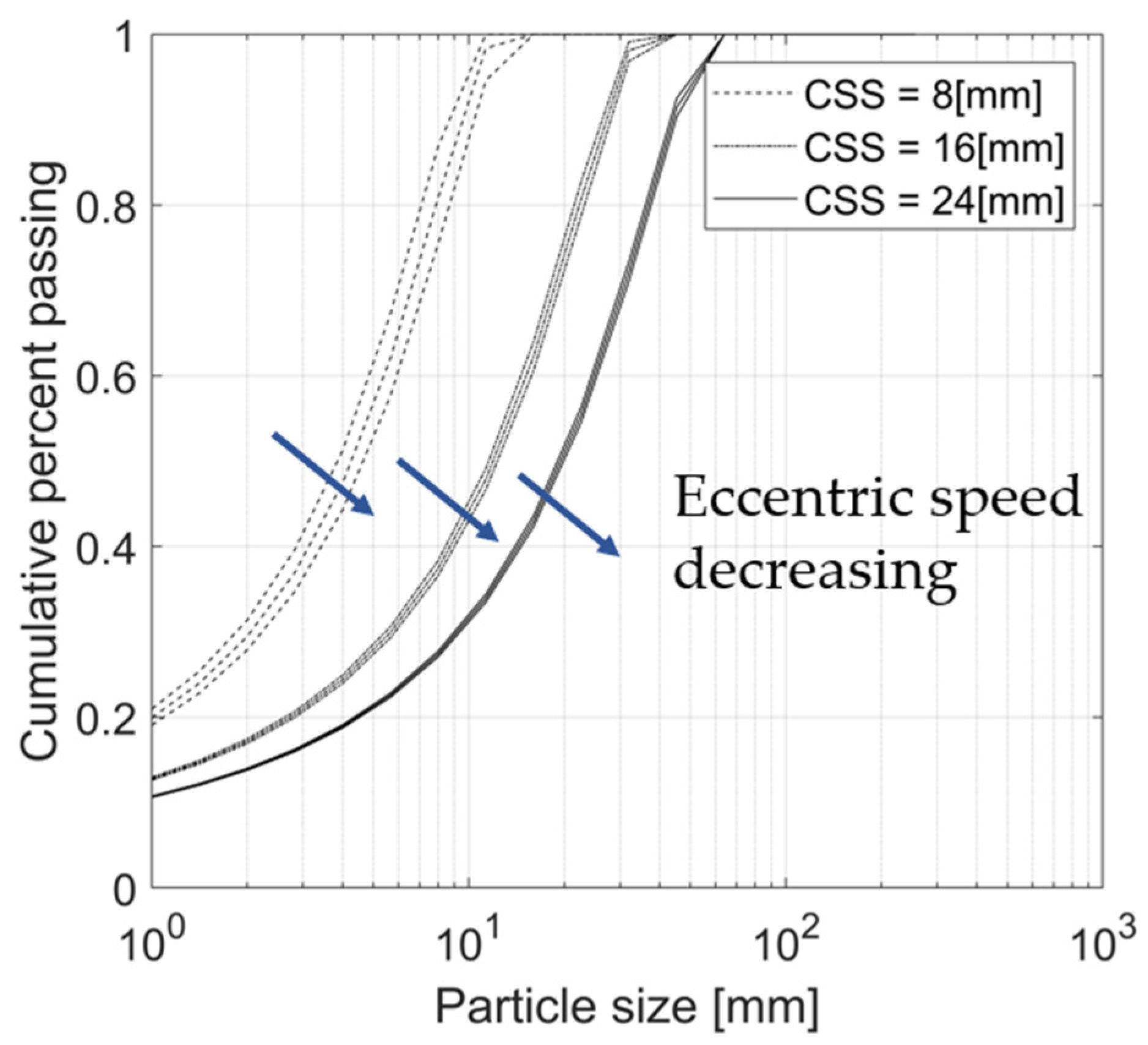

- Crusher Controller Implementation:

- Levels: With controller and Without controller.

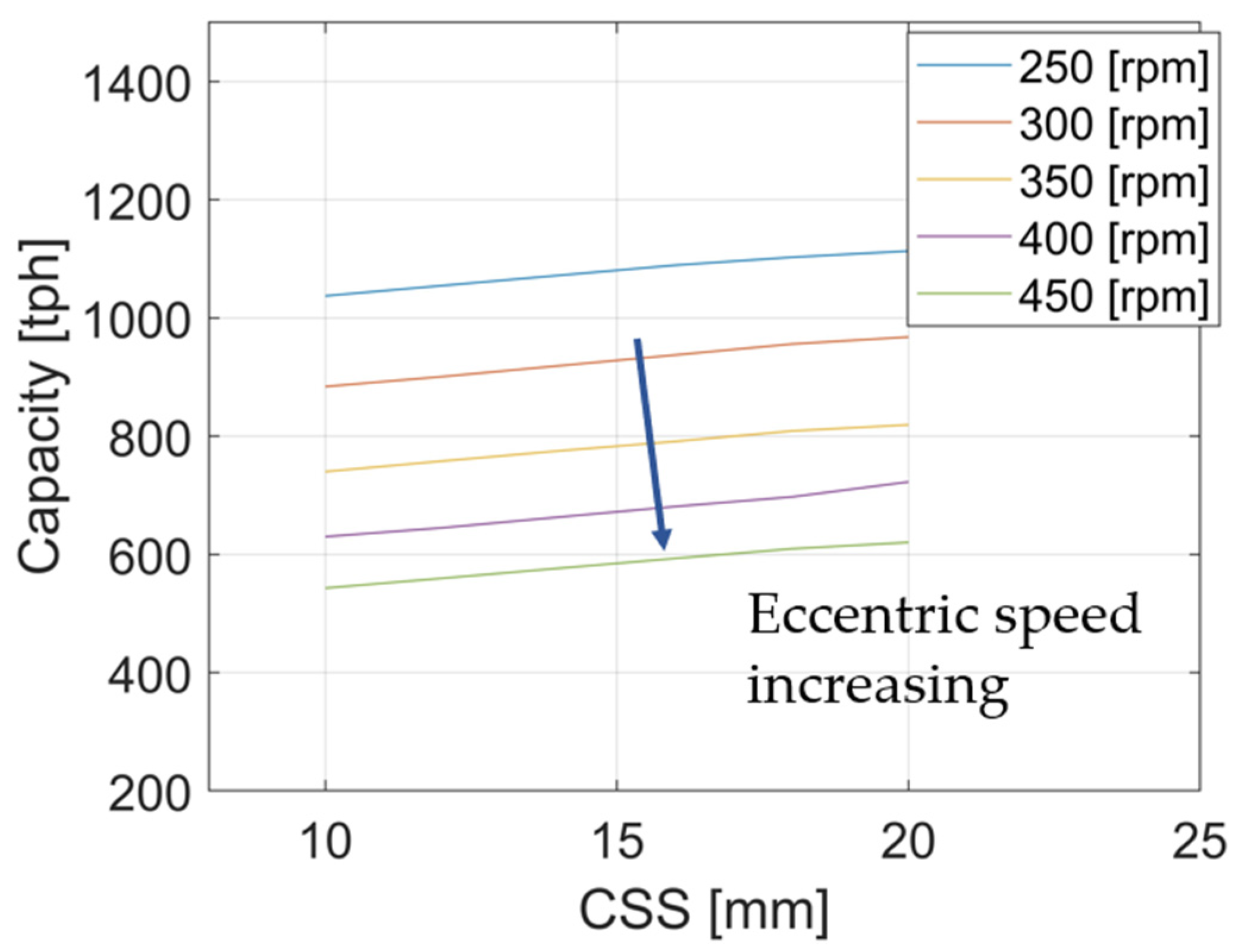

- Condition: Implementing a controller for the pebble crusher optimizes the operation by adjusting the settings based on the real-time conditions, thereby improving the efficiency of the crushing process. The main control parameters in this study are the closed side setting and speed. The settings of the pebble crusher are CSS = 10 mm and speed = 400 rpm, versus CSS = 28 mm and speed = 280 rpm, at two different levels. It should be noted that the capacity of the crusher decreases with a tighter CSS and a higher eccentric speed. In the simulations, we apply a 25% capacity loss to account for these changes, as presented in Figure 3.

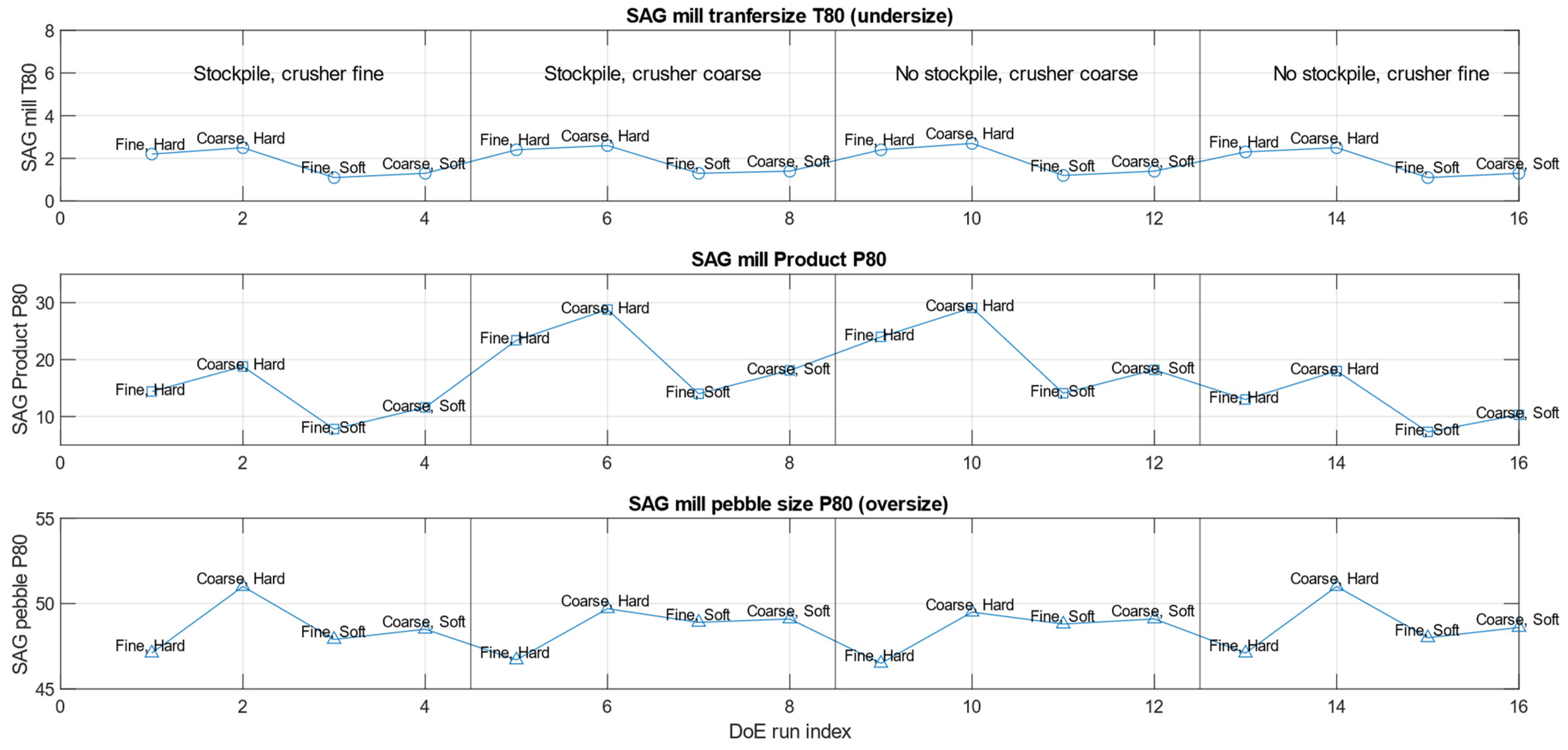

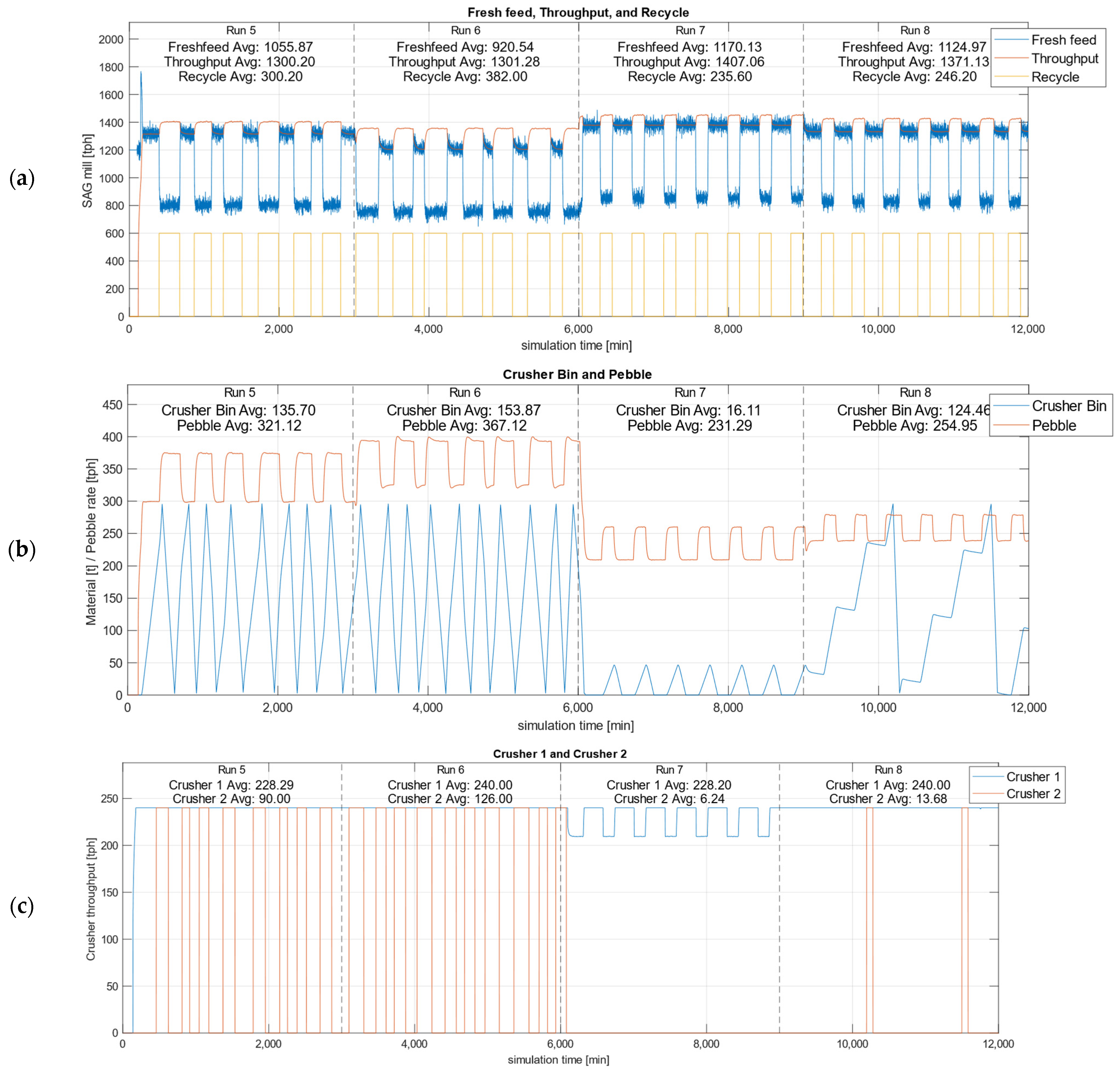

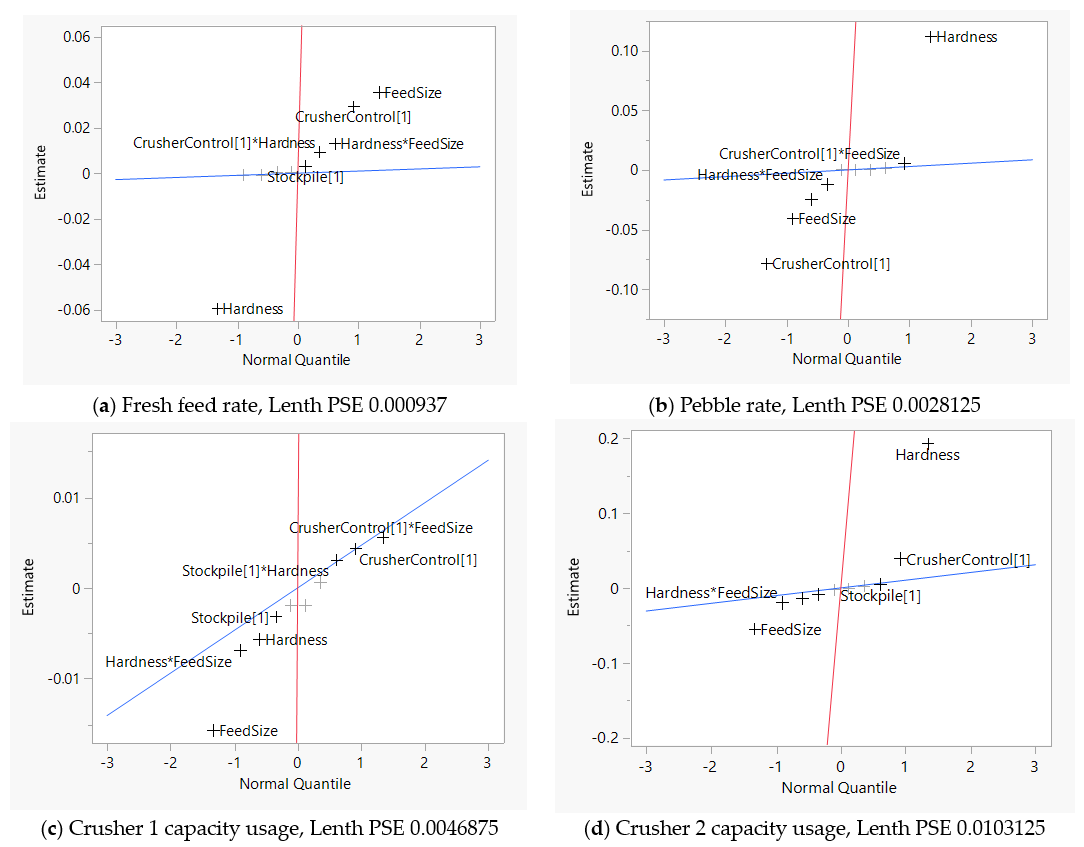

3. Results

- Key Dynamics and Observations:

- Crusher Controller’s Role:

- Feed Size Impact (with Pre-crusher):

- Pebble Stockpile Effect:

- Material Hardness Influence:

- Interactions and Optimizations:

- Optimal Conditions for Maximum Throughput:

- Strategic Use of Crusher Controller:

- Recycling Rate and Stockpile Management:

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameters | Value | Parameter | Value |

|---|---|---|---|

| 0.1 | 0.7 | ||

| 5 × 10−4 | 2 mm | ||

| 0.9 | (SAG discharge) | 60 mm | |

| 1.8 | 0.35 | ||

| 2.6 | Screen aperture | 10 mm | |

| 1.8 |

| Parameter | Diameter | Length | Ball Charge | Installed Power | Speed |

|---|---|---|---|---|---|

| Value | 34′ | 15′ | ~10% | 9000 kW | 9.94 rpm |

| Soft Ore | Hard Ore | |

|---|---|---|

| A × b | 70–80 | 40–50 |

| SAG Spec energy | 3.7 kWh/t | 6.1 kWh/t |

Appendix B

References

- Yu, P. A Generic Dynamic Model Structure for Tumbling Mills. Ph.D. Thesis, University of Queensland, Brisbane, Australia, 2017. [Google Scholar]

- Morrell, S. Power draw of wet tumbling mills and its relationship to charge dynamics. Pt. 2: An empirical approach to modelling of mill power draw. Transactions of the Institution of Mining and Metallurgy. Section C. Miner. Process. Extr. Metall. 1996, 105, C43–C51. [Google Scholar]

- Kojovic, T.; Hilden, M.; Powell, M.; Bailey, C. Updated Julius Kruttschnitt semi-autogenous grinding mill model. In Proceedings of the 11th AusIMM Mill Operators’ Conference 2012, Hobart, Australia, 29–31 October 2012. [Google Scholar]

- Yu, P.; Xie, W.; Liu, L.; Powell, M. Development of a dynamic mill model structure for tumbling mills. In Proceedings of the XXVII International Mineral Processing Congress-IMPC 2014 Conference Proceedings, Santiago, Chile, 1 January 2014. [Google Scholar]

- Morrell, S.; Valery, W.; Banini, G.; Latchireddi, S. Developments in AG/SAG mill modelling. In Proceedings of the Autogenous and Semiautogenous Grinding Technology, Vancouver, BC, Canada, 30 September–3 October 2001; pp. 71–84. [Google Scholar]

- de Carvalho, M. Mechanistic Modelling of Semi-Autogenous Grinding. Ph.D. Thesis, University of Rio de Janeiro, Rio de Janeiro, Brazil, 2013. [Google Scholar]

- Hoseinian, F.S.; Faradonbeh, R.S.; Abdollahzadeh, A.; Rezai, B.; Soltani-Mohammadi, S. Semi-autogenous mill power model development using gene expression programming. Powder Technol. 2017, 308, 61–69. [Google Scholar] [CrossRef]

- Saldaña, M.; Gálvez, E.; Navarra, A.; Toro, N.; Cisternas, L.A. Optimization of the SAG grinding process using statistical analysis and machine learning: A case study of the Chilean copper mining industry. Materials 2023, 16, 3220. [Google Scholar] [CrossRef] [PubMed]

- Avalos, S.; Kracht, W.; Ortiz, J.M. Machine learning and deep learning methods in mining operations: A data-driven SAG mill energy consumption prediction application. Min. Metall. Explor. 2020, 37, 1197–1212. [Google Scholar] [CrossRef]

- Evertsson, C.M. Cone Crusher Performance. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2000. [Google Scholar]

- Quist, J. Simulation of Wear in Cone Crushers. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2016. [Google Scholar]

- Hulthén, E. Real-Time Optimization of Cone Crushers. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2010. [Google Scholar]

- Powell, M.; Evertsson, C.M.; Mainza, A. Redesigning SAG Mill Recycle Crusher Operation. In Proceedings of the SAG Conference 2019 Vancouver, Vancouver, BC, Canada, 22–26 September 2019. [Google Scholar]

- Erwin, K.; Meinke, C.; Chandramohan, R.; Lane, G.; Foggiatto, B. Pebble Crushing Circuits: A SAG Mill’s Unappreciated Saviour. In Proceedings of the SAG Conference 2023 Vancouver, Vancouver, BC, Canada, 24–28 September 2023. [Google Scholar]

- Tavares, L.M.; de Carvalho, R.M. Modeling breakage rates of coarse particles in ball mills. Miner. Eng. 2009, 22, 650–659. [Google Scholar] [CrossRef]

- Powell, M.S.; Mainza, A.N.; Hilden, M.; Yahyaei, M. Full pre-crush to SAG mills–the case for changing this practice. In Proceedings of the 6th International Conference on Semi-Autogenous and High-Pressure Grinding Technology, Canadian Institute of Mining and Metallurgy (CIM), Vancouver, BC, Canada, 20–24 September 2015. [Google Scholar]

- de Carvalho, R.M.; Gama, T.S.; da Silva, B.P.; Tavares, L.M. Long-term simulation of an industrial coke breeze grinding circuit. Miner. Eng. 2024, 205, 108498. [Google Scholar] [CrossRef]

- Bhadani, K.; Asbjörnsson, G.; Hofling, K.; Hulthén, E.; Evertsson, M. Application of design of experiments (DoE) in evaluating crushing-screening performance for aggregates production. Miner. Eng. 2024, 209, 108616. [Google Scholar] [CrossRef]

- Li, H.; Evertsson, M.; Lindqvist, M.; Hulthén, E.; Asbjörnsson, G. Dynamic modeling and simulation of a SAG mill-pebble crusher circuit by controlling crusher operational parameters. Miner. Eng. 2018, 127, 98–104. [Google Scholar] [CrossRef]

- Austin, L.G.; Cho, H. An alternative method for programming mill models. Powder Technol. 2002, 122, 96–100. [Google Scholar] [CrossRef]

- Powell, M.; Hilden, M.; Ballantyne, G.; Liu, L.; Tavares, M. The appropriate, and inappropriate, application of the JKMRC t10 relationship. In Proceedings of the XXVII International Mineral Processing Congress–IMPC, Santiago, Chile, 20–24 October 2014. [Google Scholar]

- Jnr, W.V.; Morrell, S. The development of a dynamic model for autogenous and semi-autogenous grinding. Miner. Eng. 1995, 8, 1285–1297. [Google Scholar]

- Asbjörnsson, G. Crushing Plant Dynamics. Ph.D. Thesis, Chalmers University of Technology, Gothenburg, Sweden, 2015. [Google Scholar]

- Cornish, B.; Butar, B.; Muzinda, I.; Peacock, R. Evaluating the Operating Performance of 40-Foot SAG Mill Circuit Designs. In Proceedings of the SAG Conference 2023 Vancouver, Vancouver, BC, Canada, 24–28 September 2023. [Google Scholar]

| Run | Pebble Stockpile | Crusher Controller | Feed Size | Hardness |

|---|---|---|---|---|

| 1 | Yes | Fine | Fine | Hard |

| 2 | Yes | Fine | Coarse | Hard |

| 3 | Yes | Fine | Fine | Soft |

| 4 | Yes | Fine | Coarse | Soft |

| 5 | Yes | Coarse | Fine | Hard |

| 6 | Yes | Coarse | Coarse | Hard |

| 7 | Yes | Coarse | Fine | Soft |

| 8 | Yes | Coarse | Coarse | Soft |

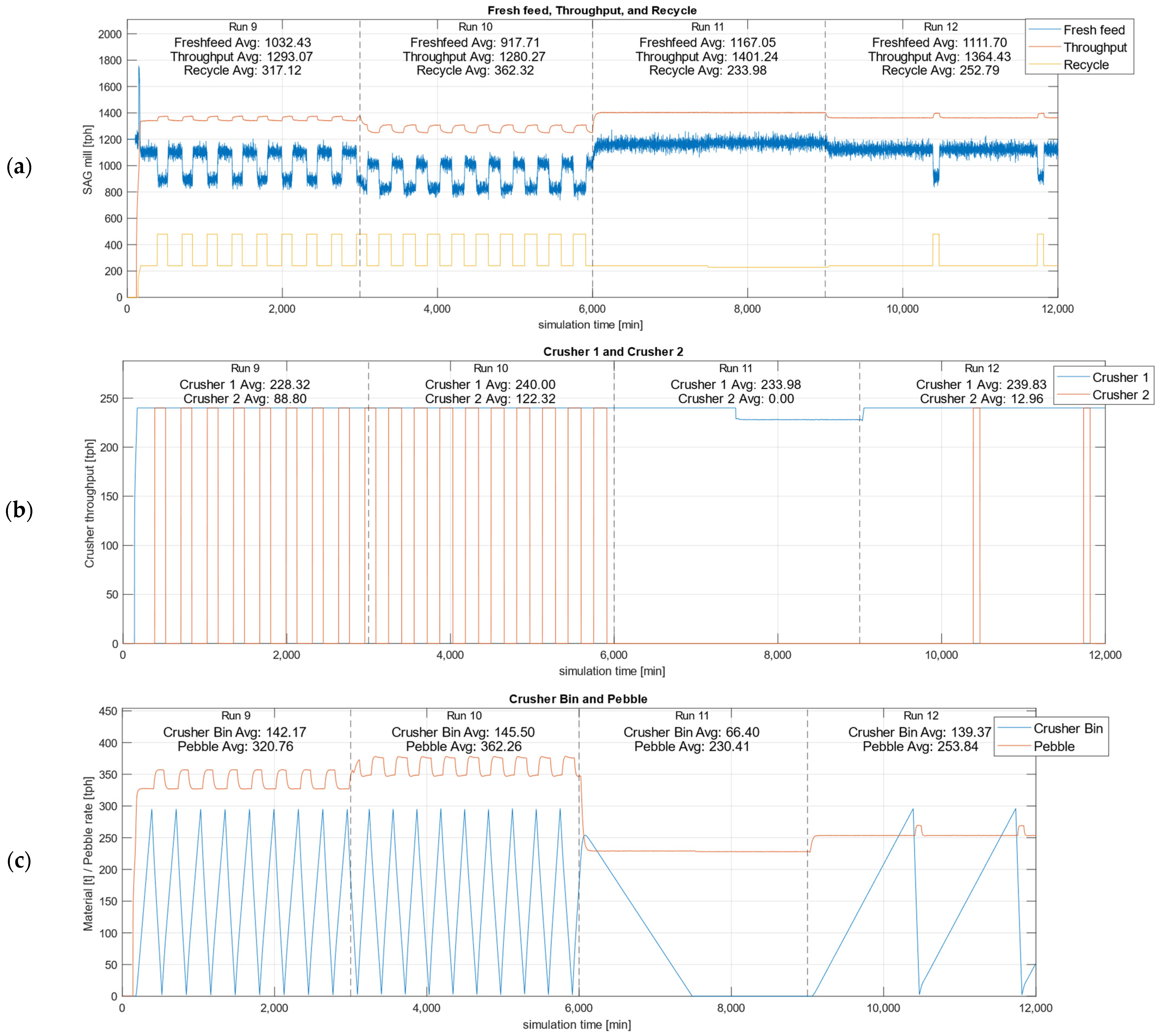

| 9 | No | Coarse | Fine | Hard |

| 10 | No | Coarse | Coarse | Hard |

| 11 | No | Coarse | Fine | Soft |

| 12 | No | Coarse | Coarse | Soft |

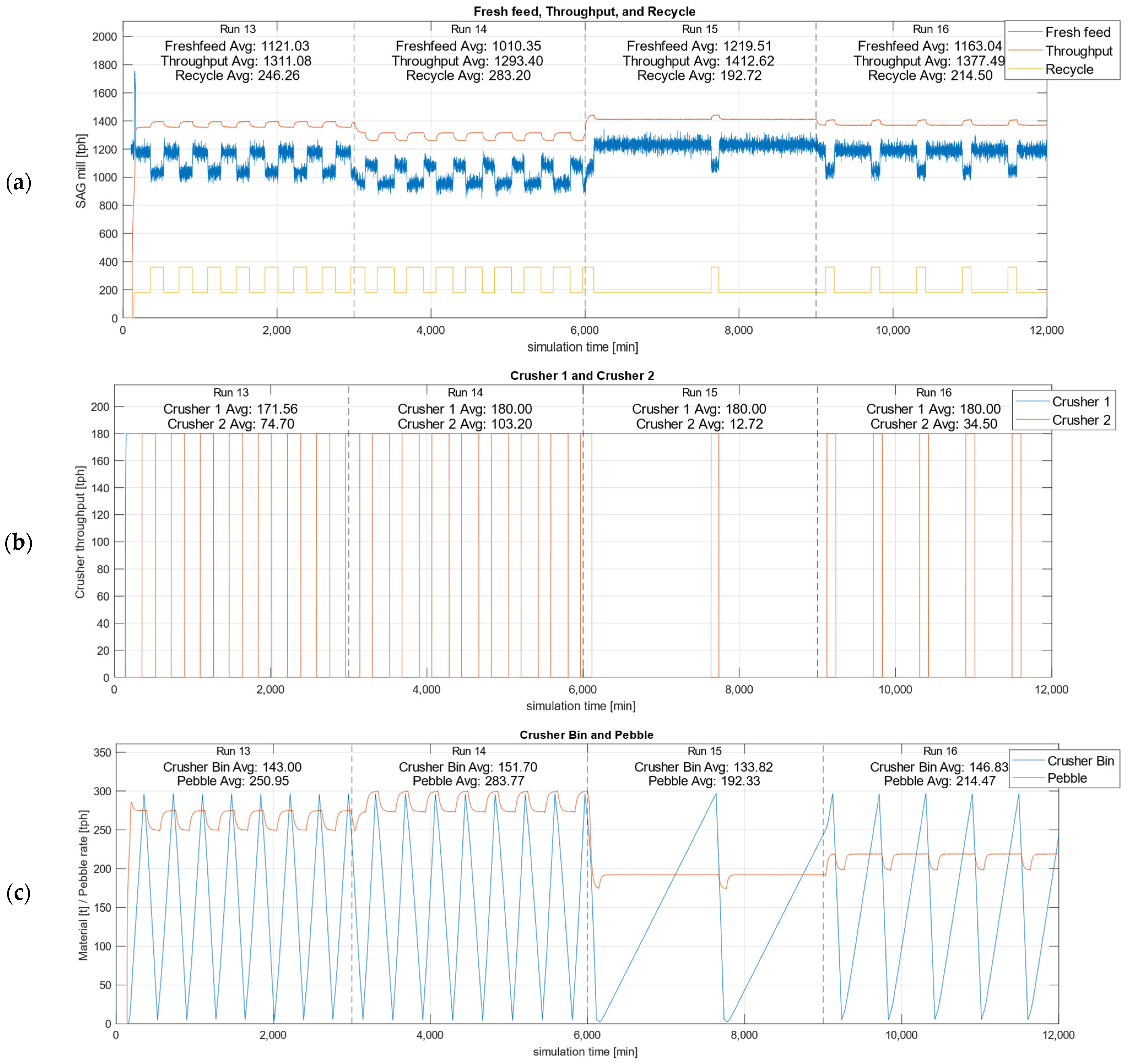

| 13 | No | Fine | Fine | Hard |

| 14 | No | Fine | Coarse | Hard |

| 15 | No | Fine | Fine | Soft |

| 16 | No | Fine | Coarse | Soft |

| Run | Pebble Stockpile | Crusher Settings | Feed Size | Hardness | Fresh Feed Avg | Pebble Rate Avg | Pebble/ Freshfeed | Crusher1 Usage | Crusher2 Usage | SAG T80 (mm) |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Yes | Fine | Fine | Hard | 0.93 | 0.69 | 0.22 | 0.96 | 0.42 | 2.2 |

| 2 | Yes | Fine | Coarse | Hard | 0.83 | 0.77 | 0.28 | 1 | 0.58 | 2.5 |

| 3 | Yes | Fine | Fine | Soft | 1 | 0.53 | 0.16 | 0.99 | 0.11 | 1.1 |

| 4 | Yes | Fine | Coarse | Soft | 0.96 | 0.58 | 0.18 | 0.99 | 0.18 | 1.3 |

| 5 | Yes | Coarse | Fine | Hard | 0.86 | 0.87 | 0.3 | 0.95 | 0.38 | 2.4 |

| 6 | Yes | Coarse | Coarse | Hard | 0.75 | 1 | 0.4 | 1 | 0.52 | 2.6 |

| 7 | Yes | Coarse | Fine | Soft | 0.96 | 0.63 | 0.2 | 0.95 | 0.02 | 1.3 |

| 8 | Yes | Coarse | Coarse | Soft | 0.92 | 0.69 | 0.22 | 1 | 0.06 | 1.4 |

| 9 | No | Coarse | Fine | Hard | 0.84 | 0.87 | 0.31 | 0.95 | 0.37 | 2.4 |

| 10 | No | Coarse | Coarse | Hard | 0.75 | 0.99 | 0.4 | 1 | 0.51 | 2.7 |

| 11 | No | Coarse | Fine | Soft | 0.96 | 0.63 | 0.2 | 0.98 | 0 | 1.2 |

| 12 | No | Coarse | Coarse | Soft | 0.91 | 0.69 | 0.23 | 1 | 0.05 | 1.4 |

| 13 | No | Fine | Fine | Hard | 0.92 | 0.68 | 0.22 | 0.96 | 0.42 | 2.3 |

| 14 | No | Fine | Coarse | Hard | 0.83 | 0.77 | 0.28 | 1 | 0.57 | 2.5 |

| 15 | No | Fine | Fine | Soft | 1 | 0.52 | 0.16 | 1 | 0.07 | 1.1 |

| 16 | No | Fine | Coarse | Soft | 0.95 | 0.58 | 0.18 | 1 | 0.19 | 1.3 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, H.; Asbjörnsson, G.; Bhadani, K.; Evertsson, M. Investigating Dynamic Behavior in SAG Mill Pebble Recycling Circuits: A Simulation Approach. Minerals 2024, 14, 716. https://doi.org/10.3390/min14070716

Li H, Asbjörnsson G, Bhadani K, Evertsson M. Investigating Dynamic Behavior in SAG Mill Pebble Recycling Circuits: A Simulation Approach. Minerals. 2024; 14(7):716. https://doi.org/10.3390/min14070716

Chicago/Turabian StyleLi, Haijie, Gauti Asbjörnsson, Kanishk Bhadani, and Magnus Evertsson. 2024. "Investigating Dynamic Behavior in SAG Mill Pebble Recycling Circuits: A Simulation Approach" Minerals 14, no. 7: 716. https://doi.org/10.3390/min14070716

APA StyleLi, H., Asbjörnsson, G., Bhadani, K., & Evertsson, M. (2024). Investigating Dynamic Behavior in SAG Mill Pebble Recycling Circuits: A Simulation Approach. Minerals, 14(7), 716. https://doi.org/10.3390/min14070716