Effect of Solid Concentration on Particle Size Distribution and Grinding Kinetics in Stirred Mills

Abstract

1. Introduction

2. Theoretical Backgrounds

2.1. Population Balance Model

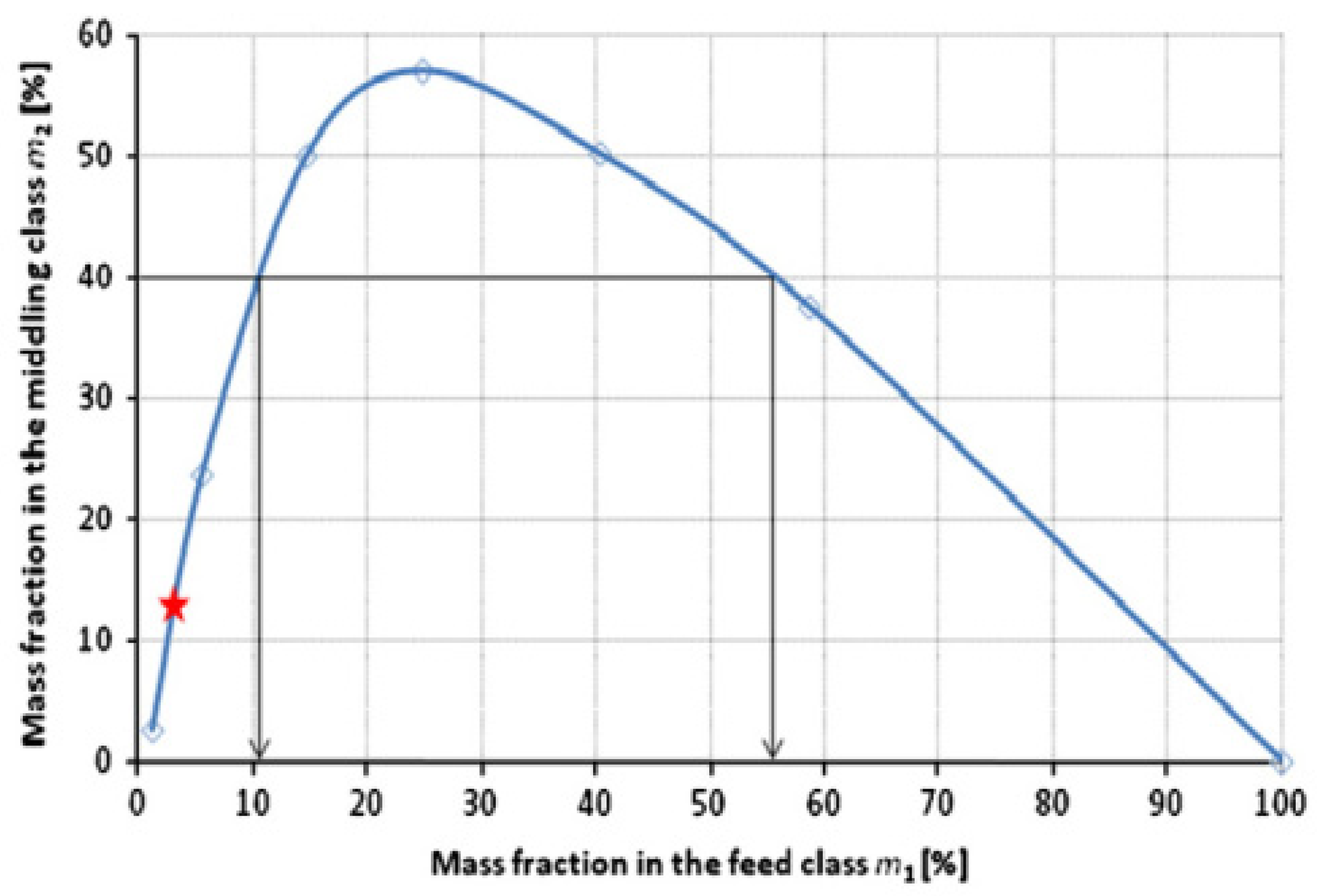

2.2. The Attainable Region Method

2.3. The Fractal Theory and Rosin–Rammler–Benne Model

3. Materials and Experimental Methods

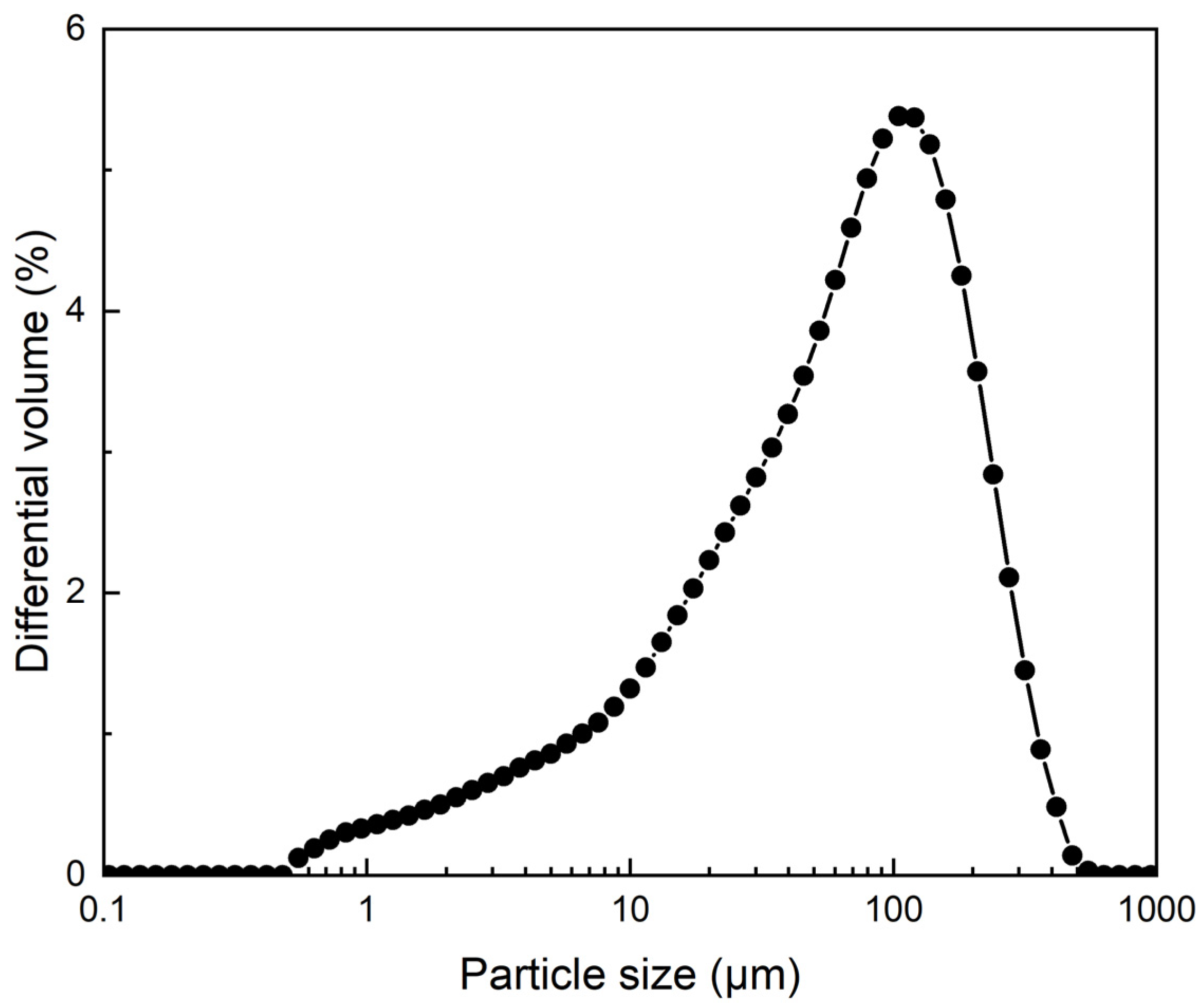

3.1. Materials

3.2. Batch Wet Grinding Tests

4. Particle Size Distribution Features

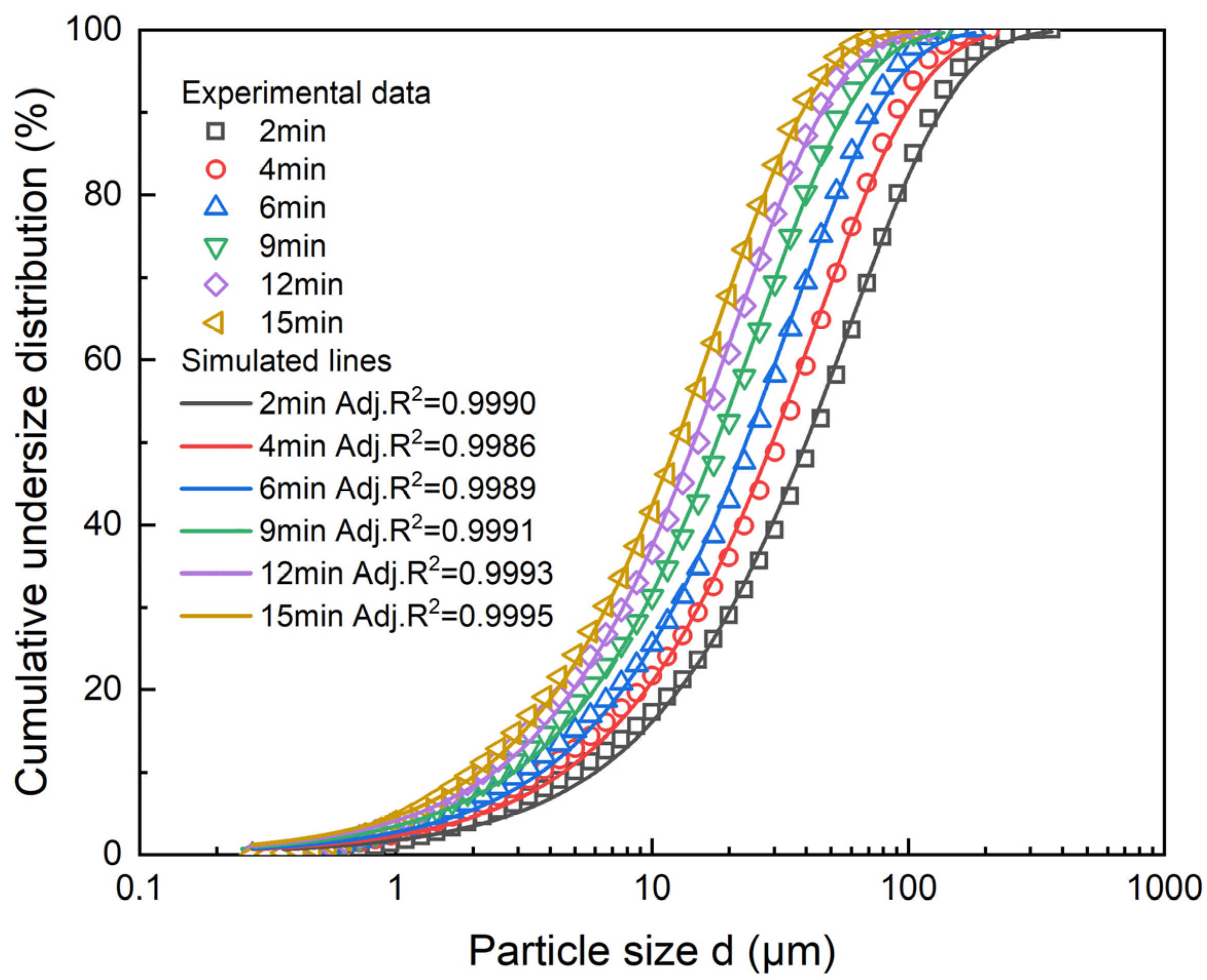

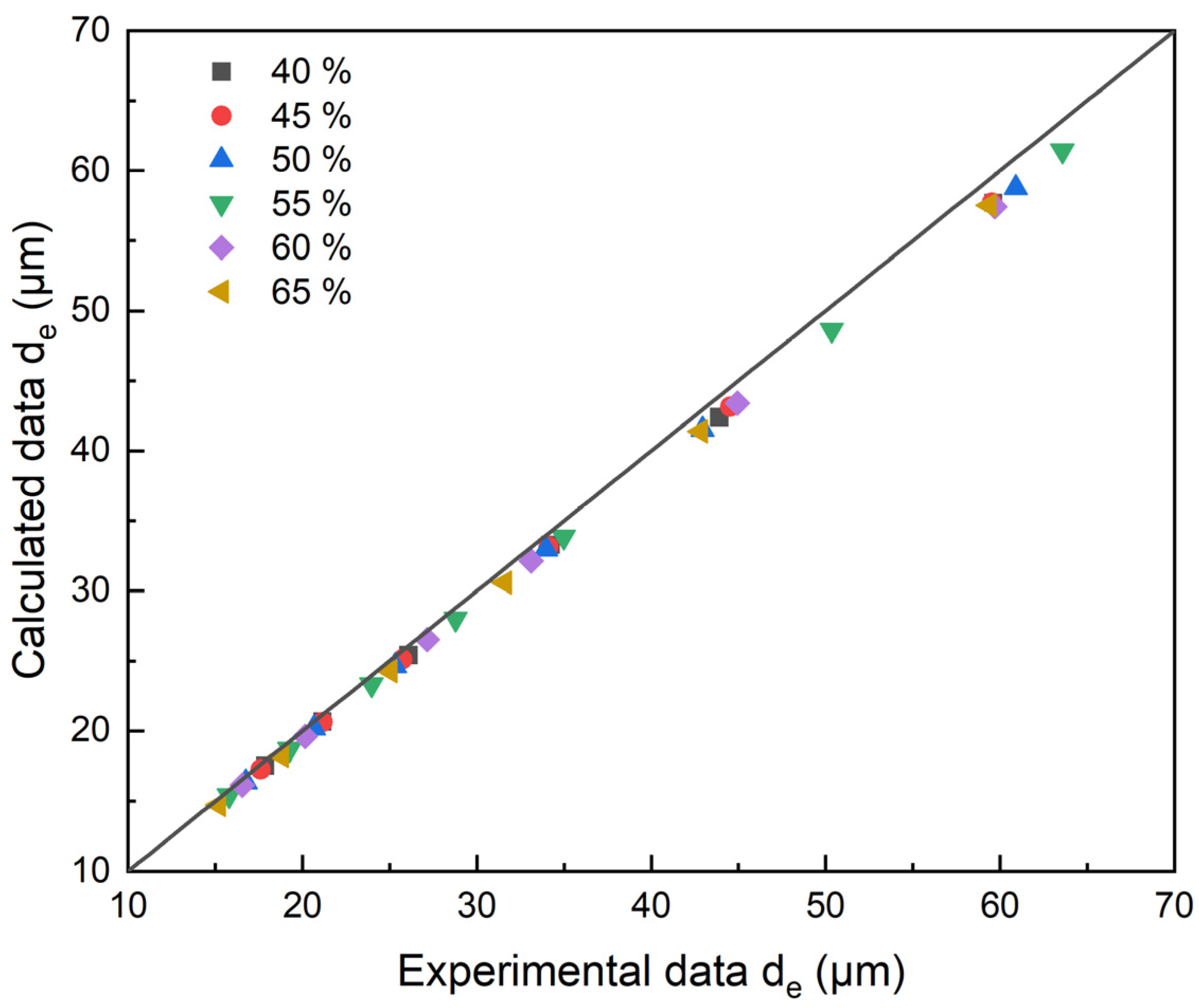

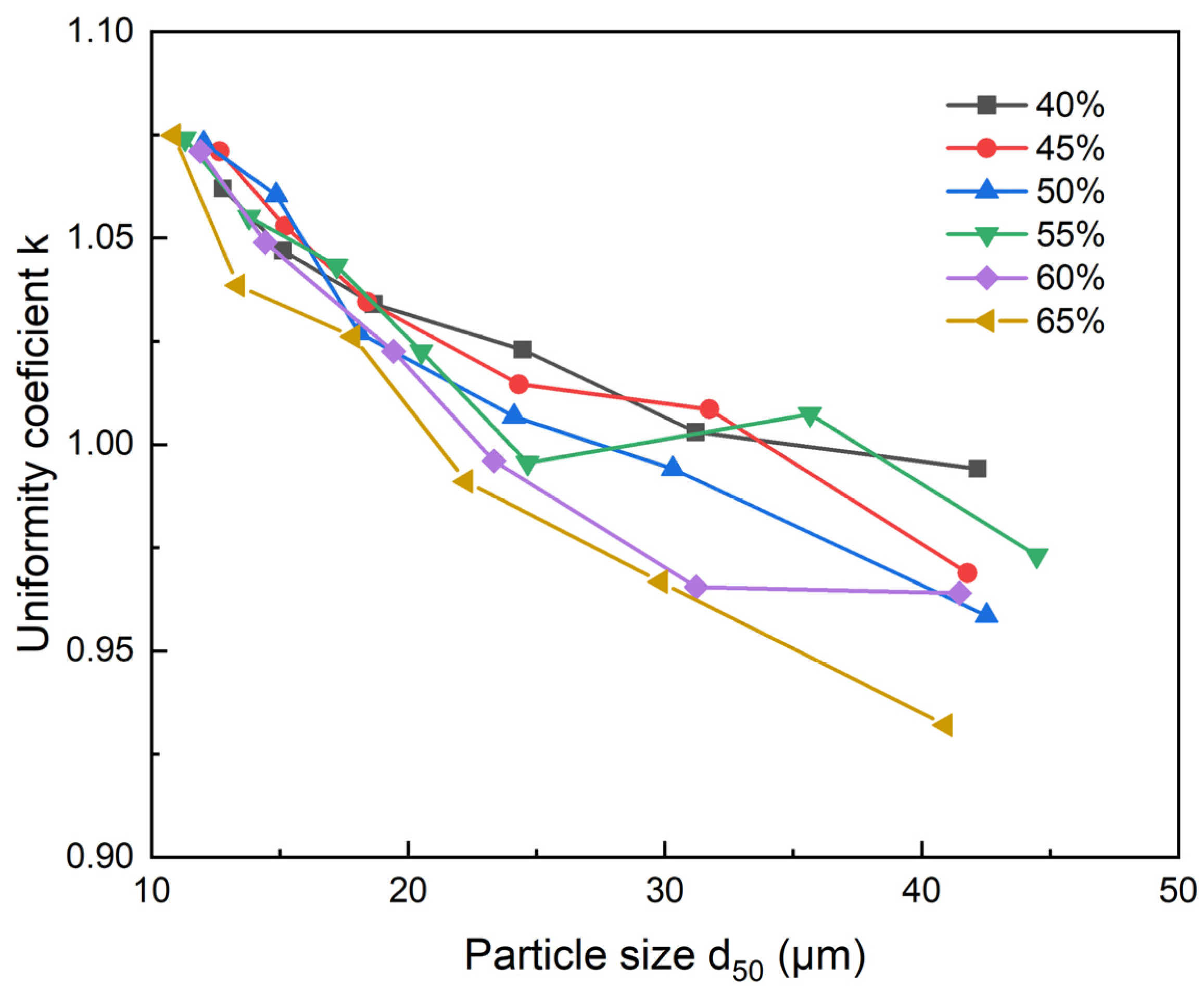

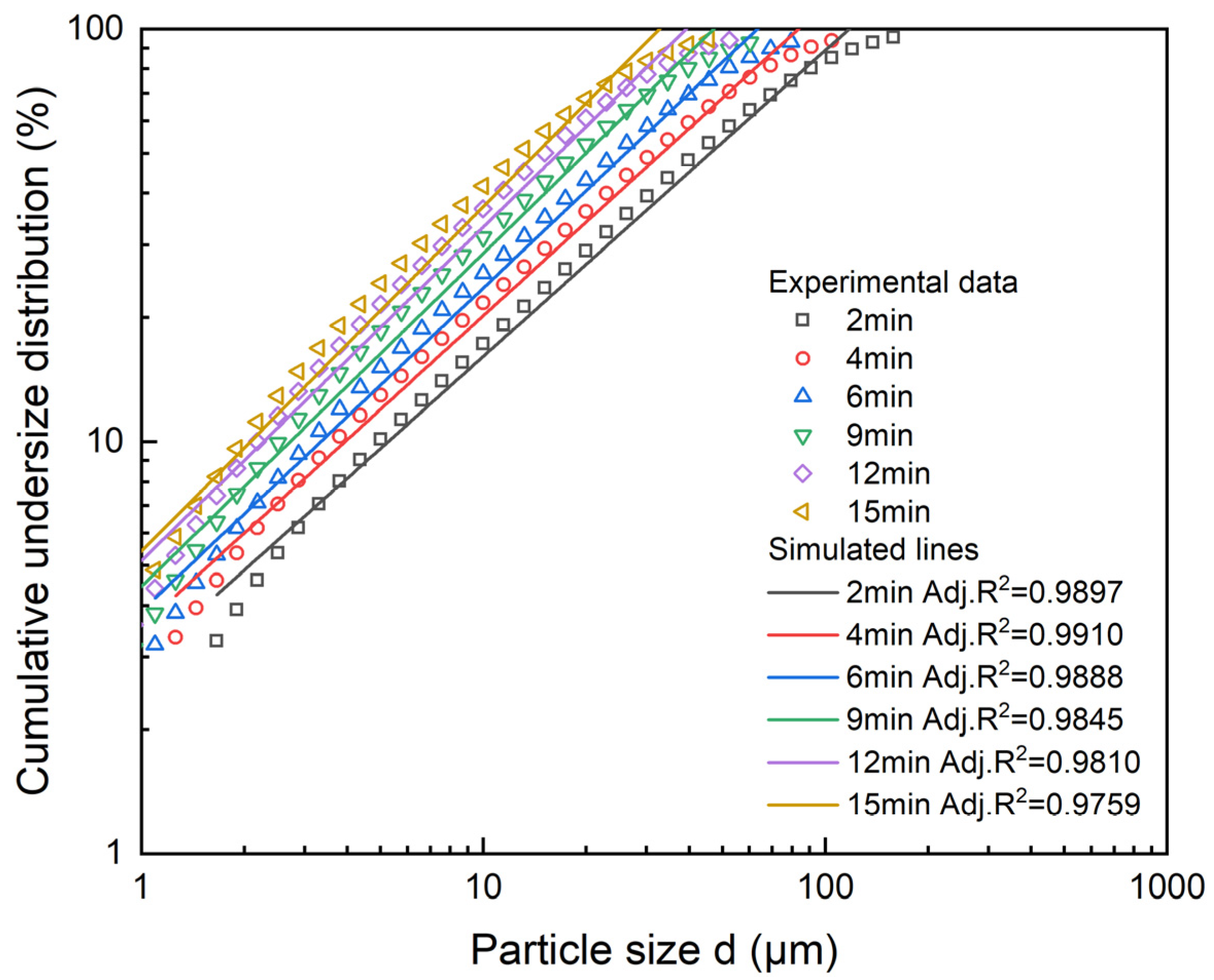

4.1. Rosin–Rammler–Benne Model

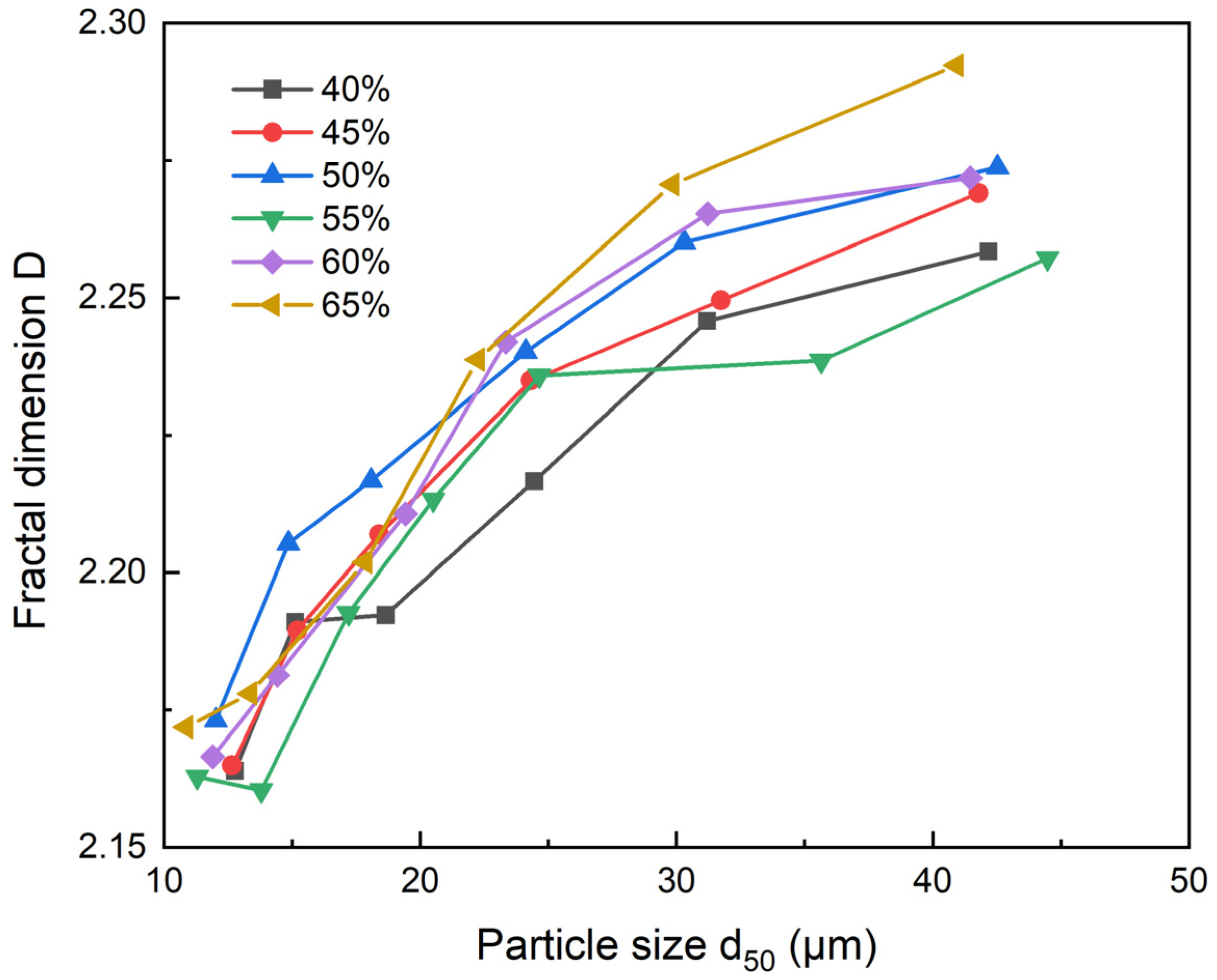

4.2. The Fractal Characteristic of Particle Size Distribution

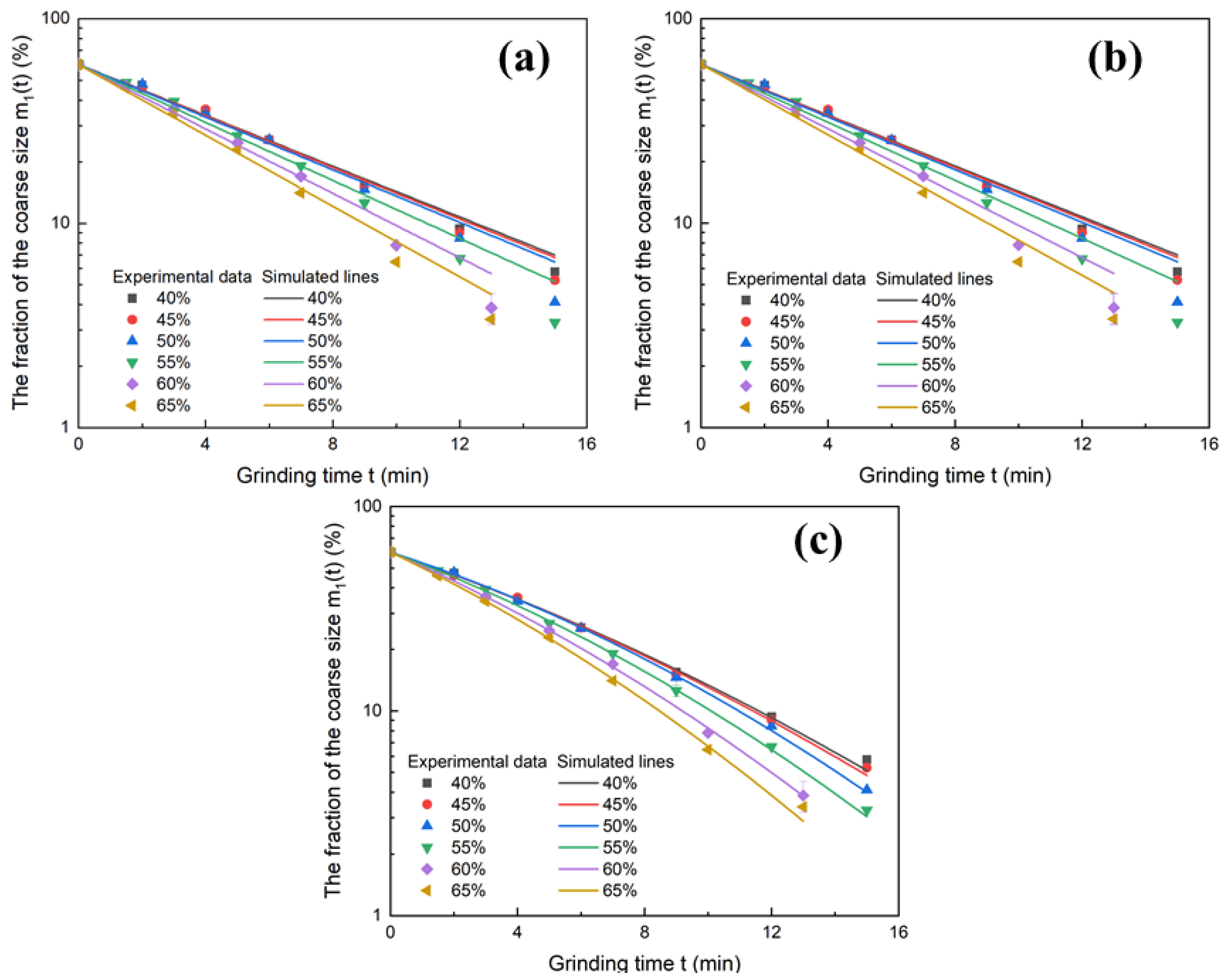

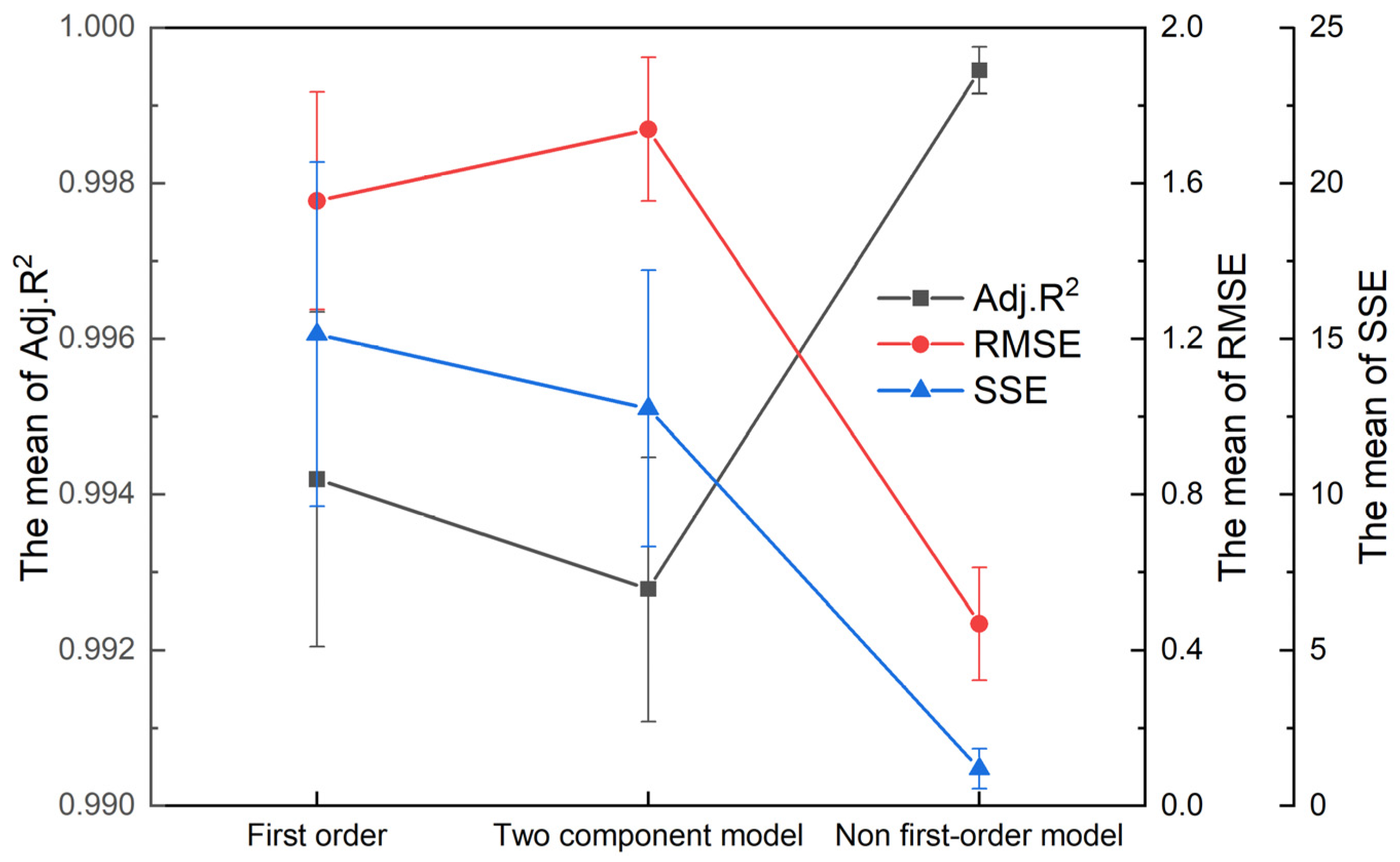

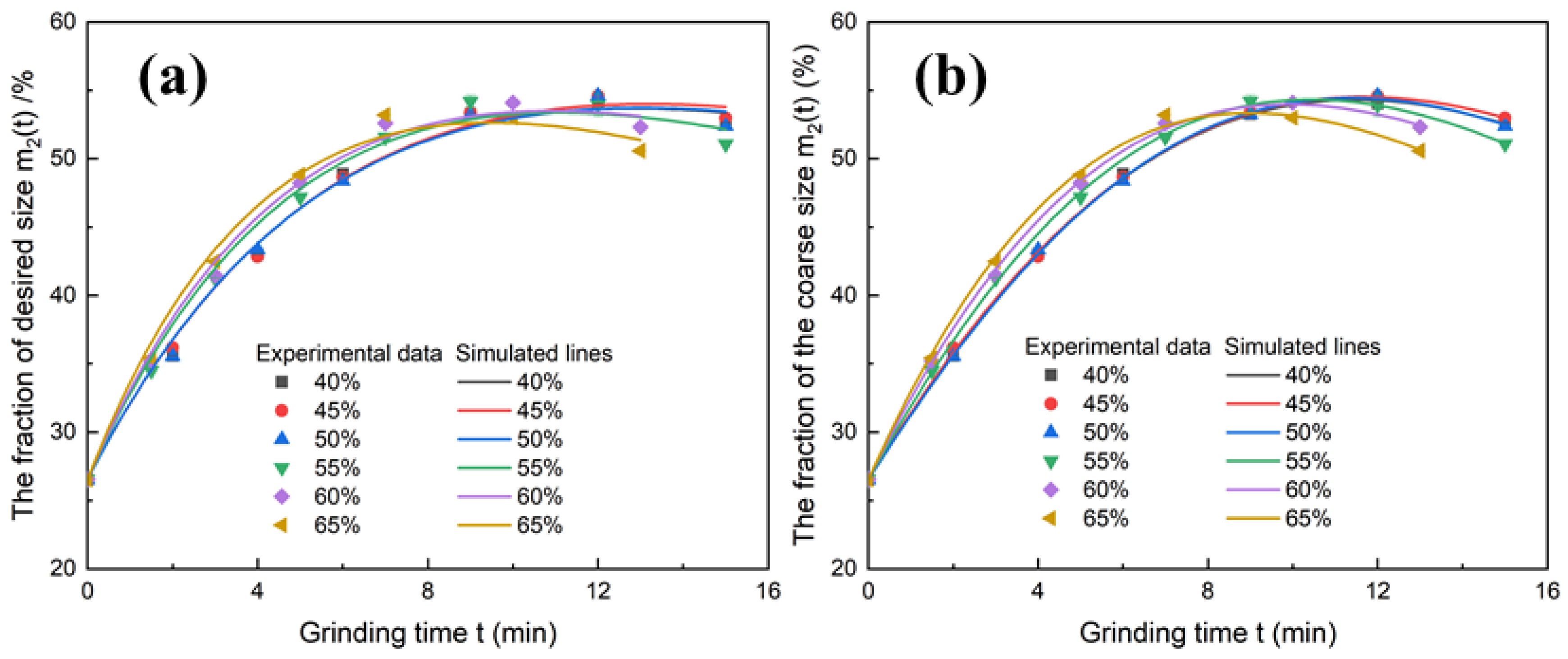

4.3. Kinetic Behavior of Each Size Interval

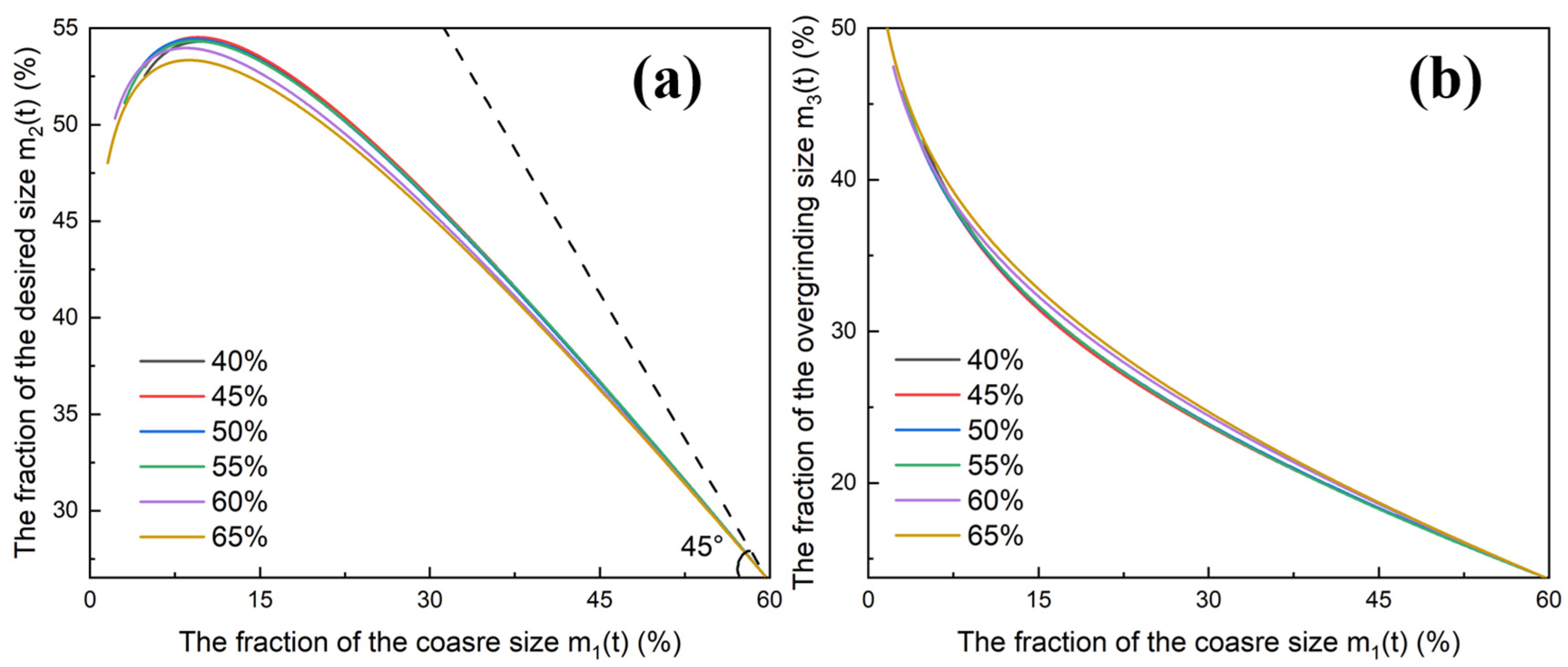

4.4. Analyses with Attainable Region Method

4.5. Differences in the Change Rates

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Kohmuench, J.N.; Mankosa, M.J.; Thanasekaran, H.; Hobert, A. Improving coarse particle flotation using the HydroFloat™(raising the trunk of the elephant curve). Miner. Eng. 2018, 121, 137–145. [Google Scholar] [CrossRef]

- Yu, J.; Jin, S.H.; Raju, K.; Lee, Y.; Lee, H.K. Analysis of individual and interaction effects of processing parameters on wet grinding performance in ball milling of alumina ceramics using statistical methods. Ceram. Int. 2021, 47, 31202–31213. [Google Scholar] [CrossRef]

- Bu, X.; Chen, Y.; Ma, G.; Sun, Y.; Ni, C.; Xie, G. Differences in dry and wet grinding with a high solid concentration of coking coal using a laboratory conical ball mill: Breakage rate, morphological characterization, and induction time. Adv. Powder Technol. 2019, 30, 2703–2711. [Google Scholar] [CrossRef]

- Zhu, G.; Wang, Y.; Liu, X.; Yu, F.; Lu, D. The cleavage and surface properties of wet and dry ground spodumene and their flotation behavior. Appl. Surf. Sci. 2015, 357, 333–339. [Google Scholar] [CrossRef]

- Prziwara, P.; Hamilton, L.D.; Breitung-Faes, S.; Kwade, A. Impact of grinding aids and process parameters on dry stirred media milling. Powder Technol. 2018, 335, 114–123. [Google Scholar] [CrossRef]

- Fan, C.; Ren, L.; Zhang, Y.; Bao, S. Grinding effect of sodium silicate on muscovite and its mechanism analysis. Miner. Eng. 2023, 199, 108106. [Google Scholar] [CrossRef]

- Zhang, X.; Han, Y.; Gao, P.; Li, Y. Effects of grinding media on grinding products and flotation performance of chalcopyrite. Miner. Eng. 2020, 145, 106070. [Google Scholar] [CrossRef]

- Iwasaki, I.; Riemer, S.C.; Orlich, J.N.; Natarajan, K.A. Corrosive and abrasive wear in ore grinding. Wear 1985, 103, 253–267. [Google Scholar] [CrossRef]

- Austin, L.G. Introduction to the mathematical description of grinding as a rate process. Powder Technol. 1971, 5, 1–17. [Google Scholar] [CrossRef]

- Austin, L.G.; Klimpel, R.R.; Luckie, P.T. Process Engineering of Size Reduction: Ball Milling; Society of Mining Engineers of the AIME: San Ramon, CA, USA, 1984. [Google Scholar]

- Wang, X.; Gui, W.; Yang, C.; Wang, Y. Wet grindability of an industrial ore and its breakage parameters estimation using population balances. Int. J. Miner. Process. 2011, 98, 113–117. [Google Scholar] [CrossRef]

- Danha, G.; Hildebrandt, D.; Glasser, D.; Bhondayi, C. Application of basic process modeling in investigating the breakage behavior of UG2 ore in wet milling. Powder Technol. 2015, 279, 42–48. [Google Scholar] [CrossRef]

- Tangsathitkulchai, C. Acceleration of particle breakage rates in wet batch ball milling. Powder Technol. 2002, 124, 67–75. [Google Scholar] [CrossRef]

- Bilgili, E.; Scarlett, B. Population balance modeling of non-linear effects in milling processes. Powder Technol. 2005, 153, 59–71. [Google Scholar] [CrossRef]

- Khumalo, N.; Glasser, D.; Hildebrandt, D.; Hausberger, B.; Kauchali, S. The application of the attainable region analysis to comminution. Chem. Eng. Sci. 2006, 61, 5969–5980. [Google Scholar] [CrossRef]

- Katubilwa, F.O.M.; Moys, M.H.; Glasser, D.; Hildebrandt, D. An attainable region analysis of the effect of ball size on milling. Powder Technol. 2011, 210, 36–46. [Google Scholar] [CrossRef]

- Tavares, L.M.M.; King, R.P. Continuum damage modeling of particle fracture. ZKG Int. 2005, 58, 49–58. [Google Scholar]

- Xu, Y. The fractal evolution of particle fragmentation under different fracture energy. Powder Technol. 2018, 323, 337–345. [Google Scholar] [CrossRef]

- Turcotte, D.L. Fractals and fragmentation. J. Geophys. Res. 1986, 91, 1921–1926. [Google Scholar] [CrossRef]

- Liu, S.; Li, Q.; Song, J. Study on the grinding kinetics of copper tailing powder. Powder Technol. 2018, 330, 105–113. [Google Scholar] [CrossRef]

- Gómez, R.; Castro, R.L.; Casali, A.; Palma, S.; Hekmat, A.A. comminution model for secondary fragmentation assessment for block caving. Rock Mech. Rock Eng. 2017, 50, 3073–3084. [Google Scholar] [CrossRef]

- Wang, G.; Peng, G.; Zhidong, T.; Yuexin, H.; Xiangzhi, M. Effect of grinding media properties and stirrer tip speed on the grinding efficiency of a stirred mill. Powder Technol. 2021, 382, 556–565. [Google Scholar]

- Chimwani, N.; Mohale, T.M.; Bwalya, M.M. Tailoring ball mill feed size distribution for the production of a size-graded product. Miner. Eng. 2019, 141, 105891. [Google Scholar] [CrossRef]

- Austin, L.G.; Luckie, P.T. Methods for determination of breakage distribution parameters. Powder Technol. 1972, 5, 215–222. [Google Scholar] [CrossRef]

- Ozkan, A.; Yekeler, M.; Calkaya, M. Kinetics of fine wet grinding of zeolite in a steel ball mill in comparison to dry grinding. Int. J. Miner. Process. 2009, 90, 67–73. [Google Scholar] [CrossRef]

- Gao, P.; Zhou, W.; Han, Y.; Li, Y.; Ren, W. Enhancing the capacity of large-scale ball mill through process and equipment optimization: An industrial test verification. Adv. Powder Technol. 2020, 31, 2079–2091. [Google Scholar] [CrossRef]

| Scheme | First Order Model | Two-Component First-Order Model | Non-First-Order Model | |||

|---|---|---|---|---|---|---|

| S1 (min−1) | S1,A (min−1) | φ | S1,B (min−1) | S1,ini (min−1) | a1 | |

| 40 | 0.1430 | 0.1429 | 0.9283 | 0.1430 | 0.1208 | 0.0238 |

| 45 | 0.1449 | 0.1450 | 0.9133 | 0.1449 | 0.1211 | 0.0256 |

| 50 | 0.1481 | 0.1482 | 0.8905 | 0.1481 | 0.1160 | 0.0369 |

| 55 | 0.1631 | 0.1632 | 0.8999 | 0.1631 | 0.1325 | 0.0333 |

| 60 | 0.1811 | 0.1812 | 0.8488 | 0.1811 | 0.1536 | 0.0288 |

| 65 | 0.1991 | 0.1980 | 0.7429 | 0.1980 | 0.1696 | 0.0288 |

| Solid Concentration (%) | First-Order Model | Non-First-Order Model | |||

|---|---|---|---|---|---|

| S2 (min−1) | b21 | S2,ini (min−1) | a2 | b21 | |

| 40 | 0.0196 | 0.7727 | 0.0013 | 0.8905 | 0.7114 |

| 45 | 0.0180 | 0.7565 | 0.0044 | 0.2113 | 0.7210 |

| 50 | 0.0179 | 0.7441 | 0.0063 | 0.1455 | 0.7277 |

| 55 | 0.0232 | 0.7749 | 0.0123 | 0.0675 | 0.7525 |

| 60 | 0.0204 | 0.7239 | 0.0169 | 0.0335 | 0.7371 |

| 65 | 0.0250 | 0.7278 | 0.0210 | 0.0268 | 0.7377 |

| Solid Concentration (%) | Grinding Time (min) | Fraction of Each Size Interval (%) | ||

|---|---|---|---|---|

| Coarse Size (+45 μm) | Desired Size (-45 + 10 μm) | Overgrinding Size (-10 μm) | ||

| 40 | 11.49 | 9.86 | 54.31 | 35.82 |

| 45 | 11.66 | 9.54 | 54.53 | 35.93 |

| 50 | 11.38 | 9.16 | 54.44 | 36.40 |

| 55 | 10.43 | 9.29 | 54.33 | 36.38 |

| 60 | 9.89 | 8.48 | 53.97 | 37.55 |

| 65 | 9.00 | 8.75 | 53.34 | 37.91 |

| Solid Concentration (%) | Grinding Time (min) | Fraction of Each Size Interval (%) | ||

|---|---|---|---|---|

| Coarse Size | Desired Size | Overgrinding Size | ||

| 40 | 6.87 | 22.46 | 50.33 | 27.21 |

| 45 | 6.88 | 22.42 | 50.40 | 27.17 |

| 50 | 6.69 | 22.69 | 50.08 | 27.23 |

| 55 | 5.96 | 23.17 | 49.87 | 26.96 |

| 60 | 5.27 | 23.50 | 49.04 | 27.46 |

| 65 | 4.60 | 24.69 | 48.11 | 27.20 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Guo, W.; Guo, K. Effect of Solid Concentration on Particle Size Distribution and Grinding Kinetics in Stirred Mills. Minerals 2024, 14, 720. https://doi.org/10.3390/min14070720

Guo W, Guo K. Effect of Solid Concentration on Particle Size Distribution and Grinding Kinetics in Stirred Mills. Minerals. 2024; 14(7):720. https://doi.org/10.3390/min14070720

Chicago/Turabian StyleGuo, Wang, and Keqi Guo. 2024. "Effect of Solid Concentration on Particle Size Distribution and Grinding Kinetics in Stirred Mills" Minerals 14, no. 7: 720. https://doi.org/10.3390/min14070720

APA StyleGuo, W., & Guo, K. (2024). Effect of Solid Concentration on Particle Size Distribution and Grinding Kinetics in Stirred Mills. Minerals, 14(7), 720. https://doi.org/10.3390/min14070720