Exploring the Effect of Particle Loading Density on Respirable Dust Classification by SEM-EDX

Abstract

1. Introduction

2. Materials and Methods

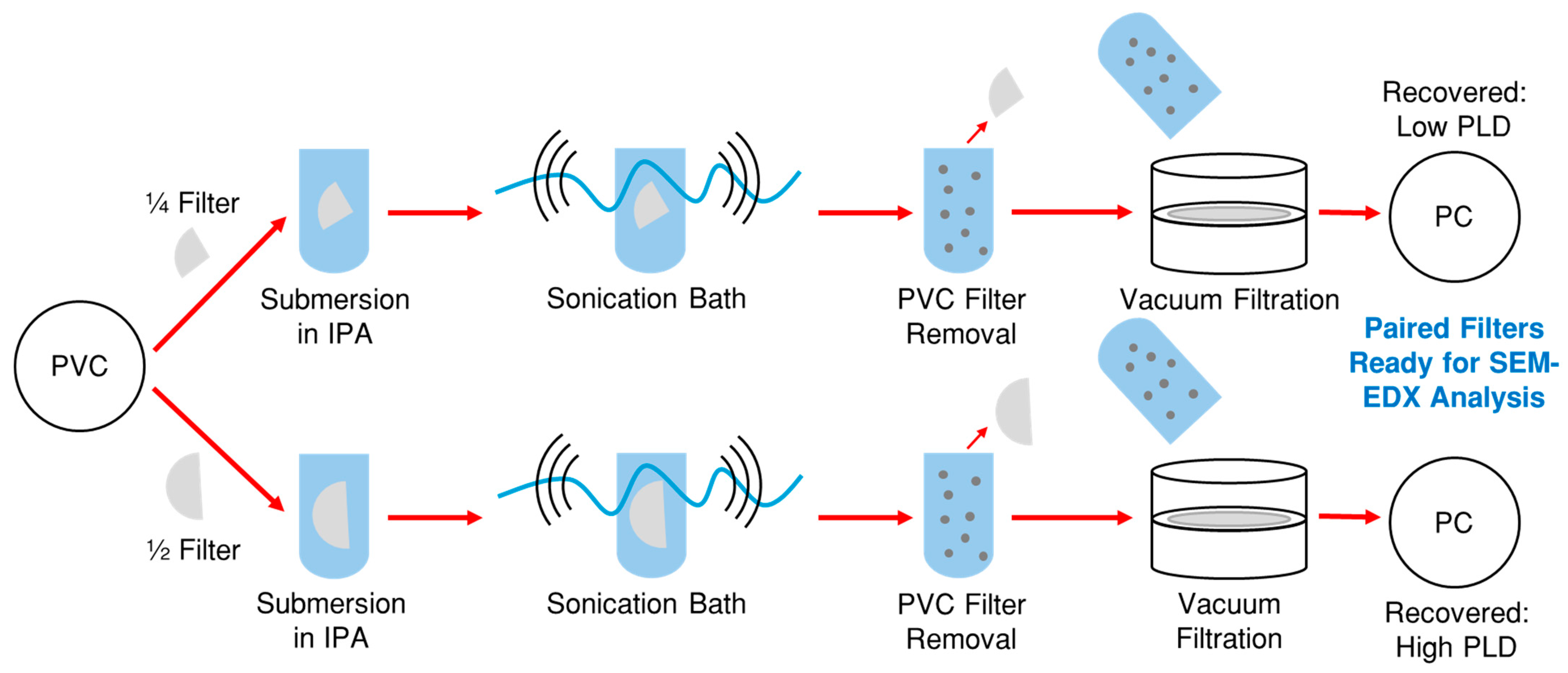

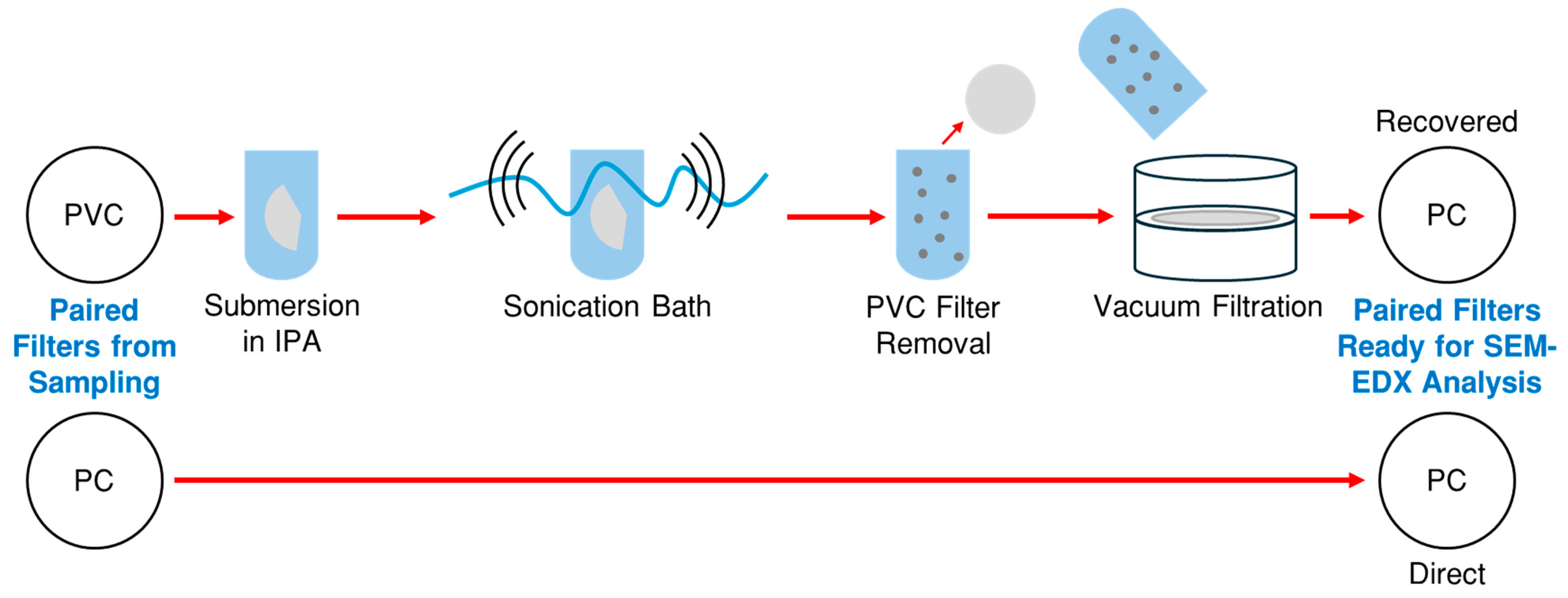

2.1. Respirable Coal Mine Dust Filter Samples

2.2. SEM-EDX Analysis

2.3. Particle Classification

3. Results and Discussion

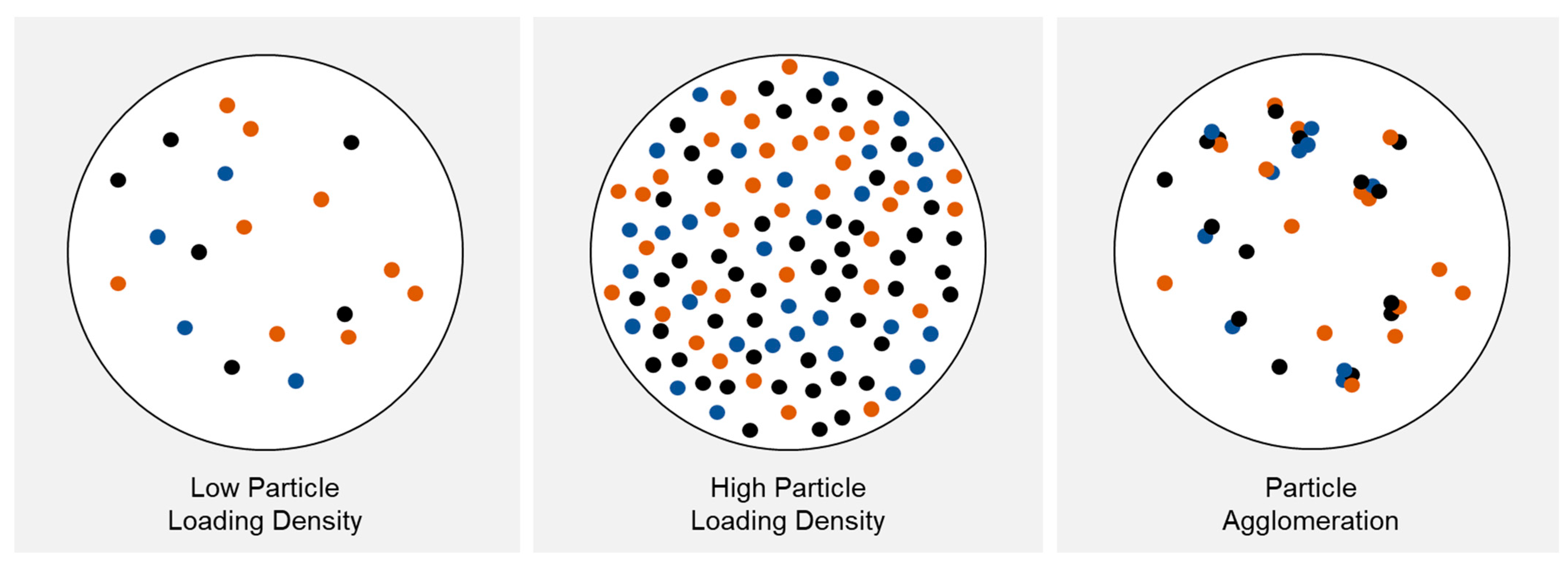

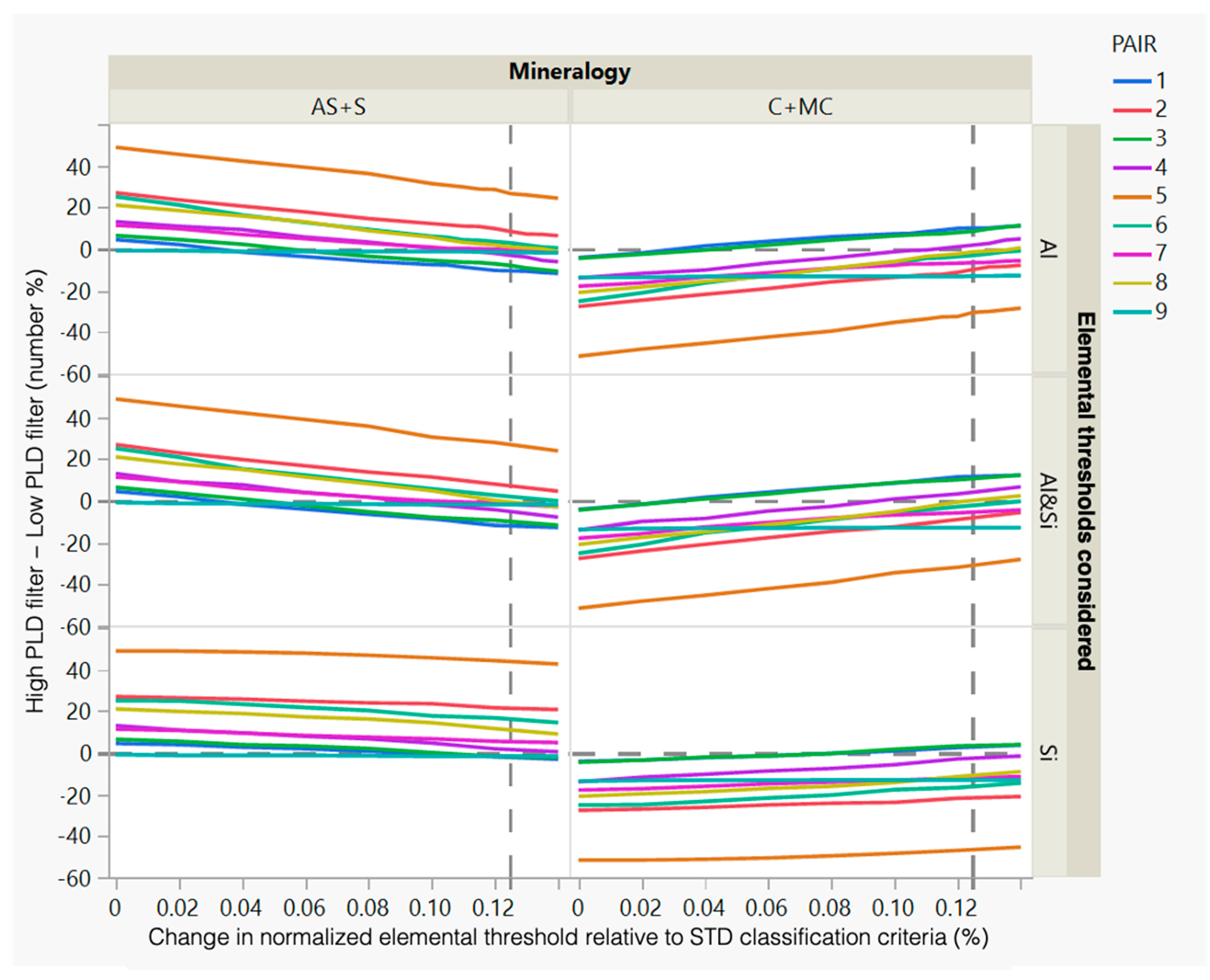

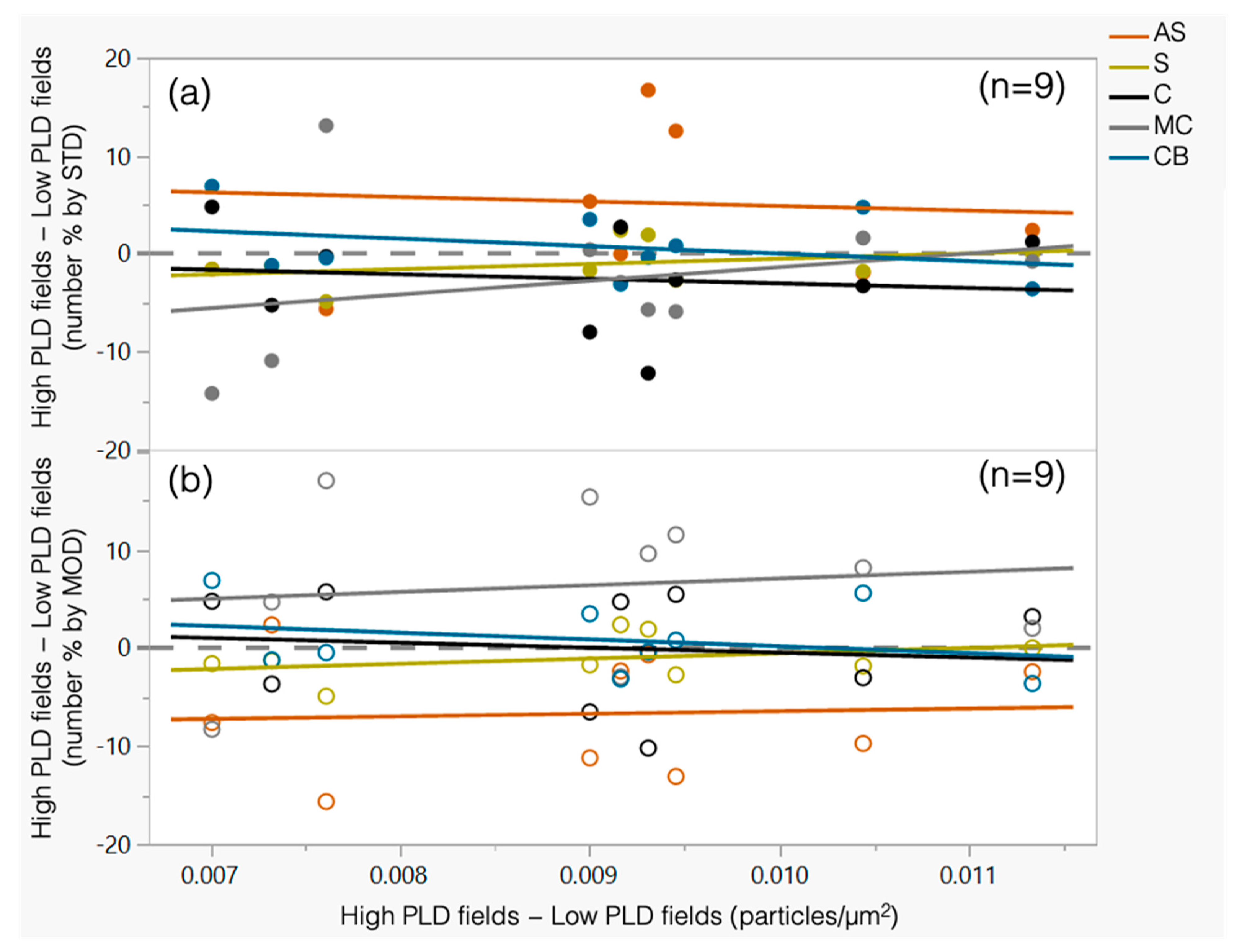

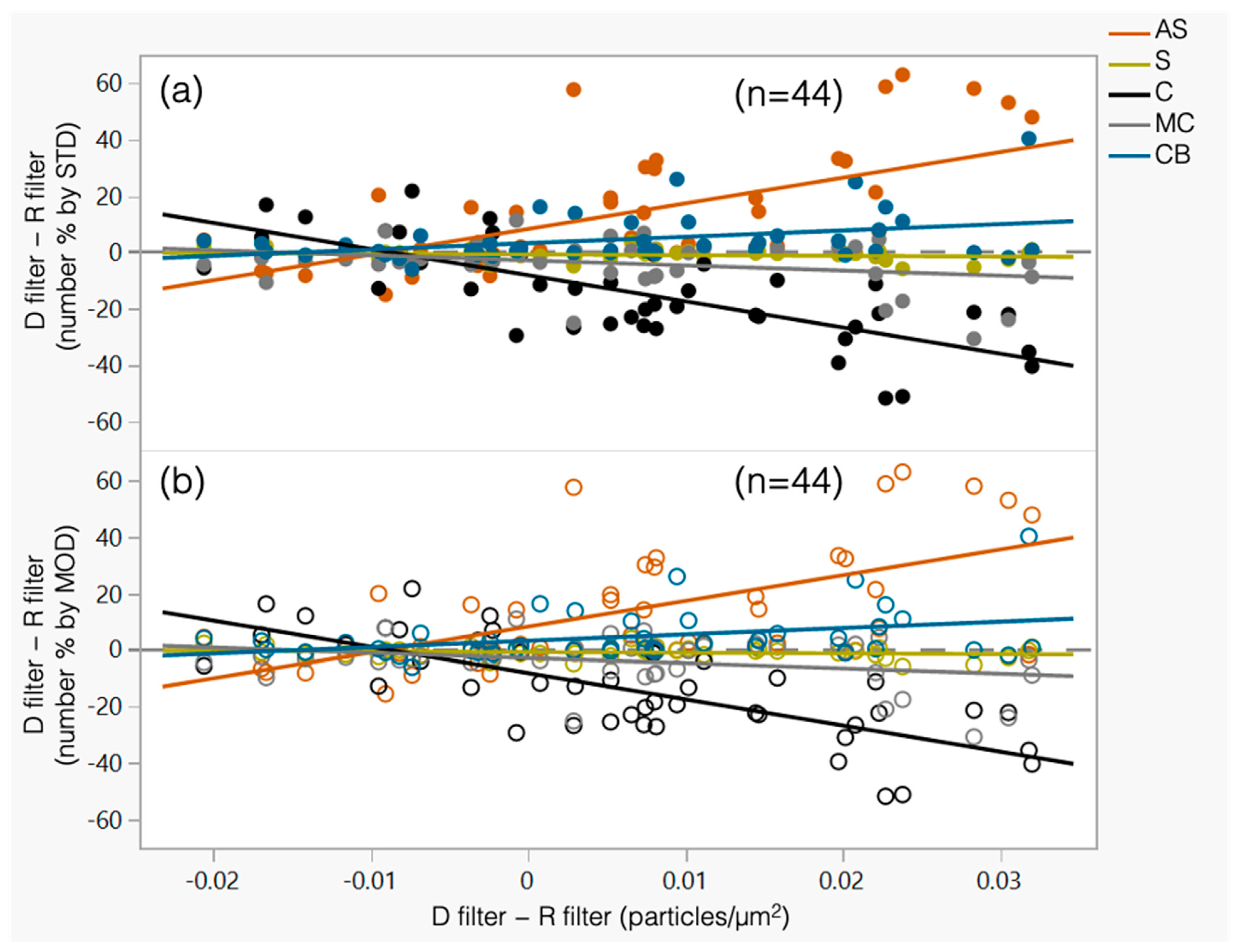

3.1. Modified Classification Criteria for High PLD Conditions

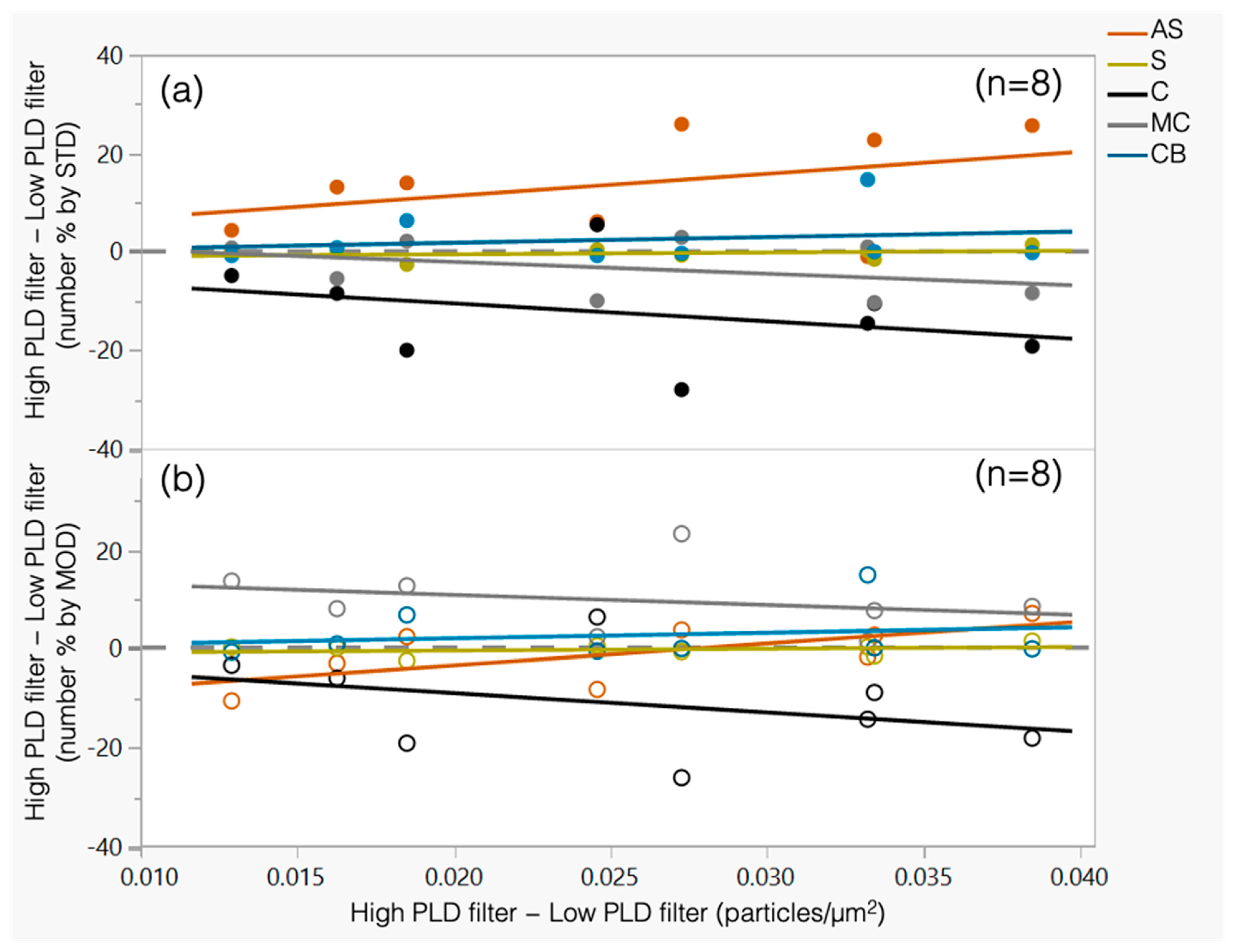

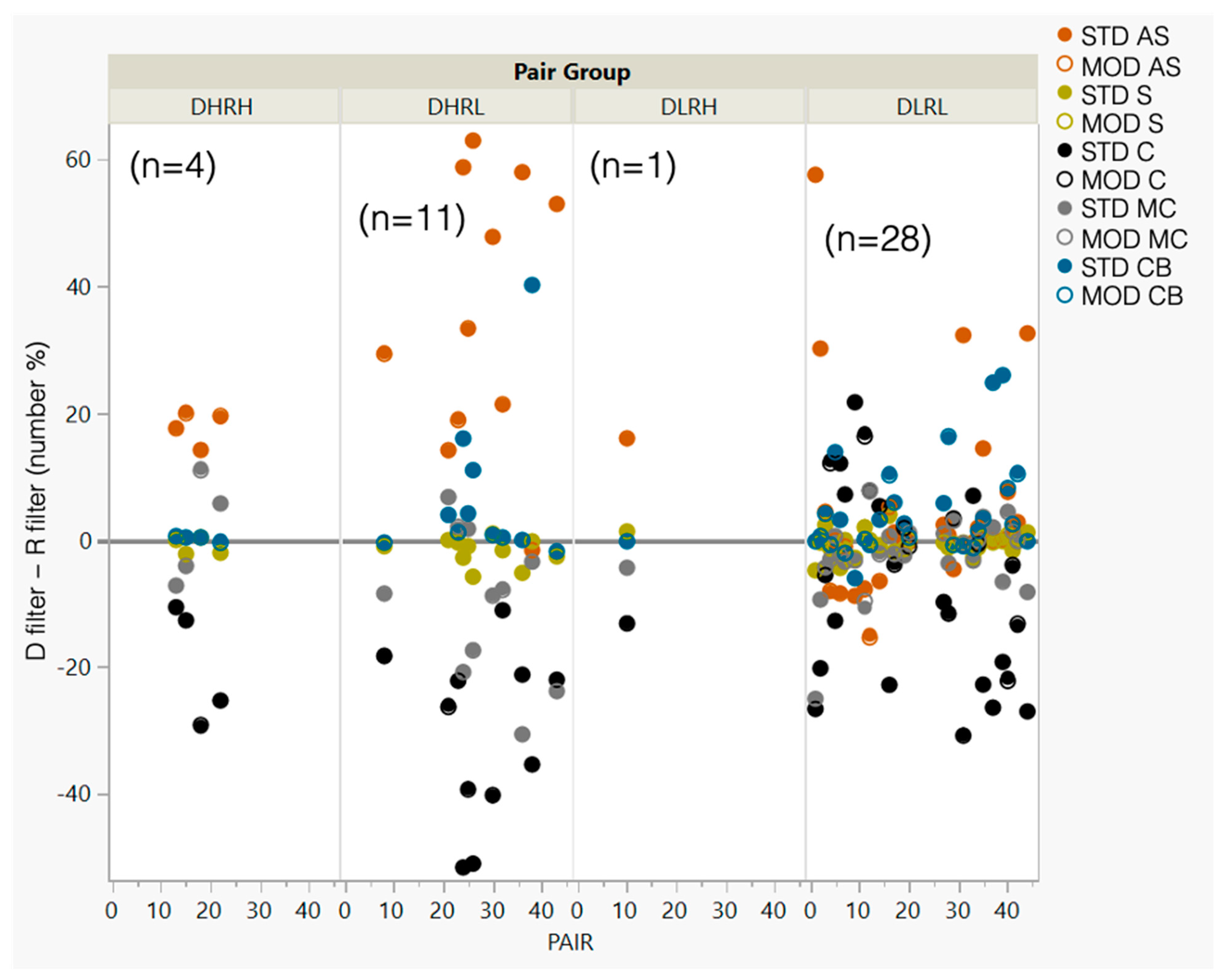

3.2. Relative Effect of High PLD on Mineralogy Distributions

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Han, S.; Chen, H.; Harvey, M.; Stemn, E.; Cliff, D. Focusing on Coal Workers’ Lung Diseases: A Comparative Analysis of China, Australia, and the United States. Int. J. Environ. Res. Public Health 2018, 15, 2565. [Google Scholar] [CrossRef]

- Kamanzi, C.; Becker, M.; Jacobs, M.; Konečný, P.; Von Holdt, J.; Broadhurst, J. The Impact of Coal Mine Dust Characteristics on Pathways to Respiratory Harm: Investigating the Pneumoconiotic Potency of Coals. Environ. Geochem. Health 2023, 45, 7363–7388. [Google Scholar] [CrossRef] [PubMed]

- Li, J.; Yin, P.; Wang, H.; Wang, L.; You, J.; Liu, J.; Liu, Y.; Wang, W.; Zhang, X.; Niu, P.; et al. The Burden of Pneumoconiosis in China: An Analysis from the Global Burden of Disease Study 2019. BMC Public Health 2022, 22, 1114. [Google Scholar] [CrossRef] [PubMed]

- Lu, C.; Dasgupta, P.; Cameron, J.; Fritschi, L.; Baade, P. A Systematic Review and Meta-Analysis on International Studies of Prevalence, Mortality and Survival Due to Coal Mine Dust Lung Disease. PLoS ONE 2021, 16, e0255617. [Google Scholar] [CrossRef]

- McCall, C. Australia’s New Coal Mine Plan: A “Public Health Disaster”. Lancet 2017, 389, 588. [Google Scholar] [CrossRef] [PubMed]

- Naidoo, R.N.; Robins, T.G.; Murray, J. Respiratory Outcomes among South African Coal Miners at Autopsy. Am. J. Ind. Med. 2005, 48, 217–224. [Google Scholar] [CrossRef]

- Naidoo, R.N.; Robins, T.G.; Seixas, N.; Lalloo, U.G.; Becklake, M. Respirable Coal Dust Exposure and Respiratory Symptoms in South-African Coal Miners: A Comparison of Current and Ex-Miners. J. Occup. Environ. Med. 2006, 48, 581–590. [Google Scholar] [CrossRef]

- Ndlovu, N.; Nelson, G.; Vorajee, N.; Murray, J. 38 Years of Autopsy Findings in South African Mine Workers. Am. J. Ind. Med. 2016, 59, 307–314. [Google Scholar] [CrossRef]

- Shi, P.; Xing, X.; Xi, S.; Jing, H.; Yuan, J.; Fu, Z.; Zhao, H. Trends in Global, Regional and National Incidence of Pneumoconiosis Caused by Different Aetiologies: An Analysis from the Global Burden of Disease Study 2017. Occup. Environ. Med. 2020, 77, 407–414. [Google Scholar] [CrossRef]

- Zosky, G.R.; Hoy, R.F.; Silverstone, E.J.; Brims, F.J.; Miles, S.; Johnson, A.R.; Gibson, P.G.; Yates, D.H. Coal Workers’ Pneumoconiosis: An Australian Perspective. Med. J. Aust. 2016, 204, 414–418. [Google Scholar] [CrossRef]

- Almberg, K.S.; Halldin, C.N.; Blackley, D.J.; Laney, A.S.; Storey, E.; Rose, C.S.; Go, L.H.T.; Cohen, R.A. Progressive Massive Fibrosis Resurgence Identified in U.S. Coal Miners Filing for Black Lung Benefits, 1970–2016. Ann. Am. Thorac. Soc. 2018, 15, 1420–1426. [Google Scholar] [CrossRef] [PubMed]

- Blackley, D.J.; Halldin, C.N.; Laney, A.S. Resurgence of a Debilitating and Entirely Preventable Respiratory Disease among Working Coal Miners. Am. J. Respir. Crit. Care Med. 2014, 190, 708–709. [Google Scholar] [CrossRef] [PubMed]

- Hall, N.B.; Blackley, D.J.; Halldin, C.N.; Laney, A.S. Current Review of Pneumoconiosis among Us Coal Miners. Curr. Environ. Health Rep. 2019, 6, 137–147. [Google Scholar] [CrossRef] [PubMed]

- National Academies of Sciences, Engineering. Monitoring and Sampling Approaches to Assess Underground Coal Mine Dust Exposures; The National Academies Press: Washington, DC, USA, 2018. [Google Scholar]

- Goldstein, J.I.; Newbury, D.E.; Michael, J.R.; Ritchie, N.W.M.; Scott, J.H.J.; Joy, D.C. Scanning Electron Microscopy and X-ray Microanalysis; Springer New York: New York, NY, USA, 2017. [Google Scholar]

- Kuo, J. Electron Microscopy: Methods and Protocols; Humana Press: Totowa, NJ, USA, 2008. [Google Scholar]

- Reed, S.J.B. Electron Microprobe Analysis and Scanning Electron Microscopy in Geology; Cambridge University Press: Cambridge, UK, 2005. [Google Scholar]

- Willis, R.D.; Blanchard, F.T.; Conner, T.L. Guidelines for the Application of Sem/Edx Analytical Techniques to Particulate Matter Samples; National Exposure Research Laboratory Office of Research and Development U.S. Environmental Protection Agency: Washington, DC, USA, 2002.

- Abbasi, B.; Wang, X.; Chow, J.C.; Watson, J.G.; Peik, B.; Nasiri, V.; Riemenschnitter, K.B.; Elahifard, M. Review of Respirable Coal Mine Dust Characterization for Mass Concentration, Size Distribution and Chemical Composition. Minerals 2021, 11, 426. [Google Scholar] [CrossRef]

- Laskin, A.; Cowin, J.P. Automated Single-Particle Sem/Edx Analysis of Submicrometer Particles Down to 0.1 Μm. Anal. Chem. 2001, 73, 1023–1029. [Google Scholar] [CrossRef] [PubMed]

- Lu, S.; Hao, X.; Liu, D.; Wang, Q.; Zhang, W.; Liu, P.; Zhang, R.; Yu, S.; Pan, R.; Wu, M.; et al. Mineralogical Characterization of Ambient Fine/Ultrafine Particles Emitted from Xuanwei C1 Coal Combustion. Atmos. Res. 2016, 169, 17–23. [Google Scholar] [CrossRef]

- Pan, L.; Golden, S.; Assemi, S.; Sime, M.F.; Wang, X.; Gao, Y.; Miller, J. Characterization of Particle Size and Composition of Respirable Coal Mine Dust. Minerals 2021, 11, 276. [Google Scholar] [CrossRef]

- Johann-Essex, V.; Keles, C.; Sarver, E. A Computer-Controlled Sem-Edx Routine for Characterizing Respirable Coal Mine Dust. Minerals 2017, 7, 15. [Google Scholar] [CrossRef]

- Keles, C.; Jaramillo Taborda, M.; Sarver, E. Updating “Characteristics of Respirable Dust in Eight Appalachian Coal Mines: A Dataset Including Particle Size and Mineralogy Distributions, and Metal and Trace Element Mass Concentrations” with Expanded Data to Cover a Total of 25 Us Mines. Data Brief 2022, 42, 108125. [Google Scholar] [CrossRef]

- Sarver, E.; Keles, C.; Afrouz, S. Particle Size and Mineralogy Distributions in Respirable Dust Samples from 25 Us Underground Coal Mines. Int. J. Coal Geol. 2021, 247, 103851. [Google Scholar] [CrossRef]

- Sarver, E.; Keles, C.; Rezaee, M. Beyond Conventional Metrics: Comprehensive Characterization of Respirable Coal Mine Dust. Int. J. Coal Geol. 2019, 207, 84–95. [Google Scholar] [CrossRef]

- Pokhrel, N.; Agioutanti, E.; Keles, C.; Afrouz, S.; Sarver, E. Comparison of Respirable Coal Mine Dust Constituents Estimated Using FTIR, TGA, and SEM–EDX. Min. Metall. Explor. 2022, 39, 291–300. [Google Scholar] [CrossRef]

- Sellaro, R.; Sarver, E.; Baxter, D. A Standard Characterization Methodology for Respirable Coal Mine Dust Using Sem-Edx. Resources 2015, 4, 939–957. [Google Scholar] [CrossRef]

- Gonzalez, J.; Keles, C.; Pokhrel, N.; Jaramillo, L.; Sarver, E. Respirable Dust Constituents and Particle Size: A Case Study in a Thin-Seam Coal Mine. Min. Metall. Explor. 2022, 39, 1007–1015. [Google Scholar] [CrossRef]

- Gonzalez, J.; Keles, C.; Sarver, E. On the Occurrence and Persistence of Coal-Mineral Microagglomerates in Respirable Coal Mine Dust. Min. Metall. Explor. 2022, 39, 271–282. [Google Scholar] [CrossRef]

- Keles, C.; Sarver, E. A Study of Respirable Silica in Underground Coal Mines: Particle Characteristics. Minerals 2022, 12, 1555. [Google Scholar] [CrossRef]

- Keles, C.; Pokhrel, N.; Sarver, E. A Study of Respirable Silica in Underground Coal Mines: Sources. Minerals 2022, 12, 1115. [Google Scholar] [CrossRef]

- Pandey, J.K.; Agarwal, D.; Gorain, S.; Dubey, R.K.; Vishwakarma, M.K.; Mishra, K.K.; Pal, A.K. Characterisation of Respirable Dust Exposure of Different Category of Workers in Jharia Coalfields. Arab. J. Geosci. 2017, 10, 183. [Google Scholar] [CrossRef]

- Su, X.; Ding, R.; Zhuang, X. Characteristics of Dust in Coal Mines in Central North China and Its Research Significance. ACS Omega 2020, 5, 9233–9250. [Google Scholar] [CrossRef]

- Armbruster, L. Agglomeration of Coal Mine Dust and Its Effect on Respirable Dust Sampling. Ann. Occup. Hyg. 1988, 12, 393–401. [Google Scholar]

- Greth, A.; Afrouz, S.; Keles, C.; Sarver, E. Characterization of Respirable Coal Mine Dust Recovered from Fibrous Polyvinyl Chloride Filters by Scanning Electron Microscopy. Min. Metall. Explor. 2024, 41, 1145–1154. [Google Scholar] [CrossRef]

- LaBranche, N.; Teale, K.; Wightman, E.; Johnstone, K.; Cliff, D. Characterization Analysis of Airborne Particulates from Australian Underground Coal Mines Using the Mineral Liberation Analyser. Minerals 2022, 12, 796. [Google Scholar] [CrossRef]

| Class | Normalized Atomic % | Assumption for Estimating Particle Mass | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| C | O | Al | Si | Ca | Mg | Ti | Fe | S:I | SG | |

| C | ≥75 | <29 | ≤0.30 | ≤0.30 | ≤0.41 | ≤0.50 | ≤0.06 | ≤0.15 | 0.6 | 1.4 |

| MC | <0.35 | <0.35 | ≤0.50 | ≤0.50 | ≤0.60 | ≤0.60 | 0.6 | 1.4 | ||

| AS | ≥0.35 | ≥0.35 | 0.4 | 2.6 | ||||||

| OS 1 | ≥0.33 | 0.4 | 2.6 | |||||||

| S 2 | ≥0.33 | 0.7 | 2.7 | |||||||

| CB | <88 | >9 | >0.50 | >0.50 | 0.7 | 2.7 | ||||

| HM | >1.00 | >1.00 | >1.00 | 0.7 | 5.0 | |||||

| Class | Normalized Atomic % | Assumptions for Estimating Particle Mass | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C | O | Al (STD) | Al (MOD) | Si | Ca | Mg | Ti | Fe | S:I | SG | |

| C | ≥75 | <29 | ≤0.30 | ≤0.425 | ≤0.30 | ≤0.41 | ≤0.50 | ≤0.06 | ≤0.15 | 0.6 | 1.4 |

| MC | <0.35 | <0.475 | <0.35 | ≤0.50 | ≤0.50 | ≤0.60 | ≤0.60 | 0.6 | 1.4 | ||

| AS | ≥0.35 | ≥0.475 | ≥0.35 | 0.4 | 2.6 | ||||||

| OS 1 | ≥0.33 | 0.4 | 2.6 | ||||||||

| S 2 | ≥0.33 | 0.7 | 2.7 | ||||||||

| CB | <88 | >9 | >0.50 | >0.50 | 0.7 | 2.7 | |||||

| HM | >1.00 | >1.00 | >1.00 | >1.00 | 0.7 | 5.0 | |||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sweeney, D.; Keles, C.; Sarver, E. Exploring the Effect of Particle Loading Density on Respirable Dust Classification by SEM-EDX. Minerals 2024, 14, 728. https://doi.org/10.3390/min14070728

Sweeney D, Keles C, Sarver E. Exploring the Effect of Particle Loading Density on Respirable Dust Classification by SEM-EDX. Minerals. 2024; 14(7):728. https://doi.org/10.3390/min14070728

Chicago/Turabian StyleSweeney, Daniel, Cigdem Keles, and Emily Sarver. 2024. "Exploring the Effect of Particle Loading Density on Respirable Dust Classification by SEM-EDX" Minerals 14, no. 7: 728. https://doi.org/10.3390/min14070728

APA StyleSweeney, D., Keles, C., & Sarver, E. (2024). Exploring the Effect of Particle Loading Density on Respirable Dust Classification by SEM-EDX. Minerals, 14(7), 728. https://doi.org/10.3390/min14070728