Impact of Humidity and Freeze–Thaw Cycles on the Disintegration Rate of Coal Gangue in Cold and Arid Regions: A Case Study from Inner Mongolia, China

Abstract

1. Introduction

2. Materials and Methods

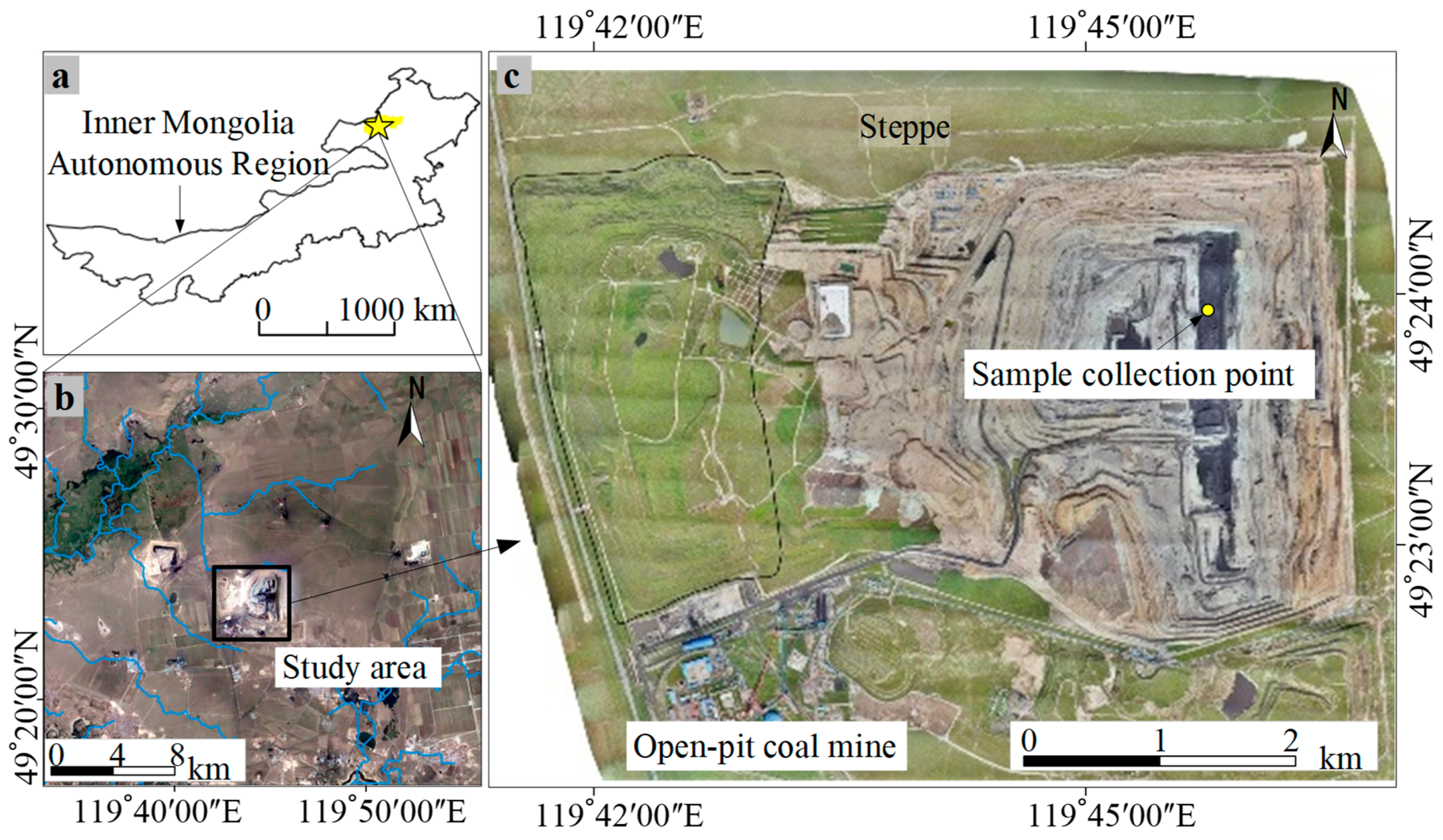

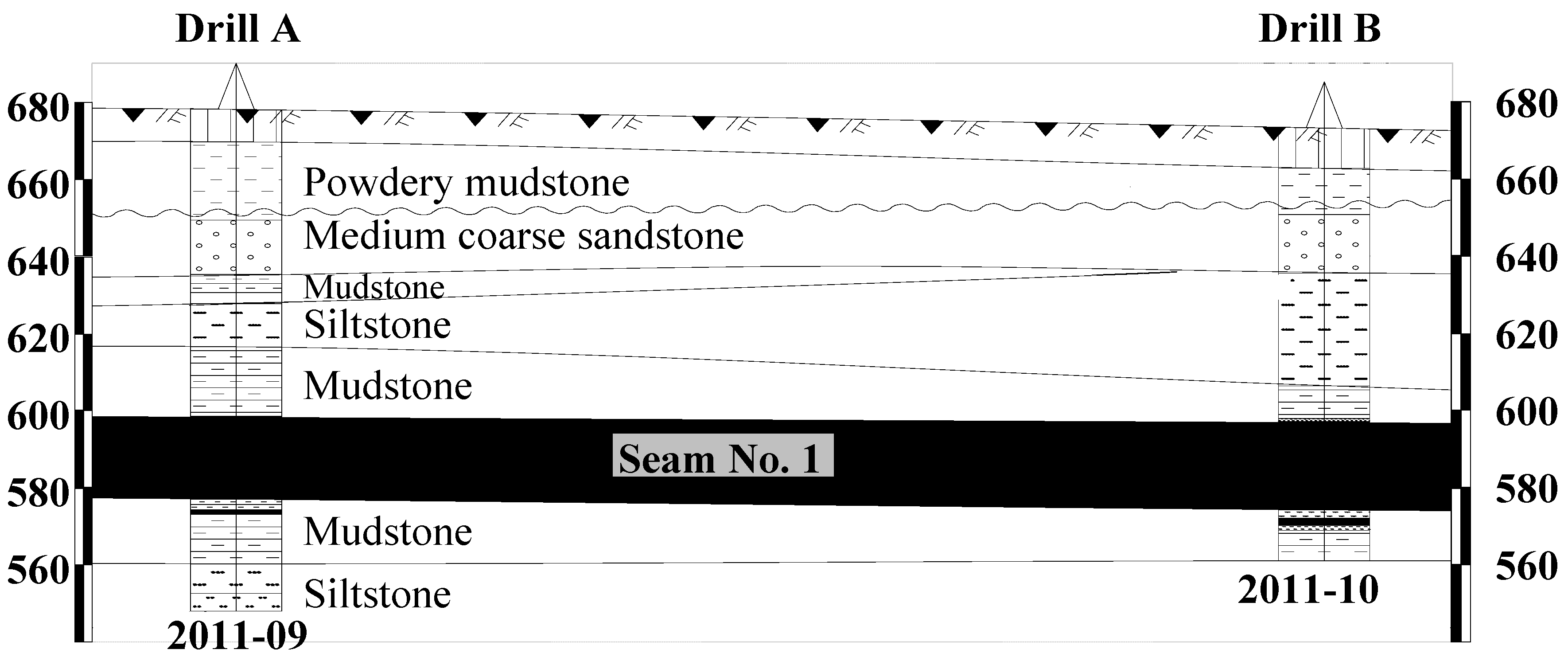

2.1. Study Area

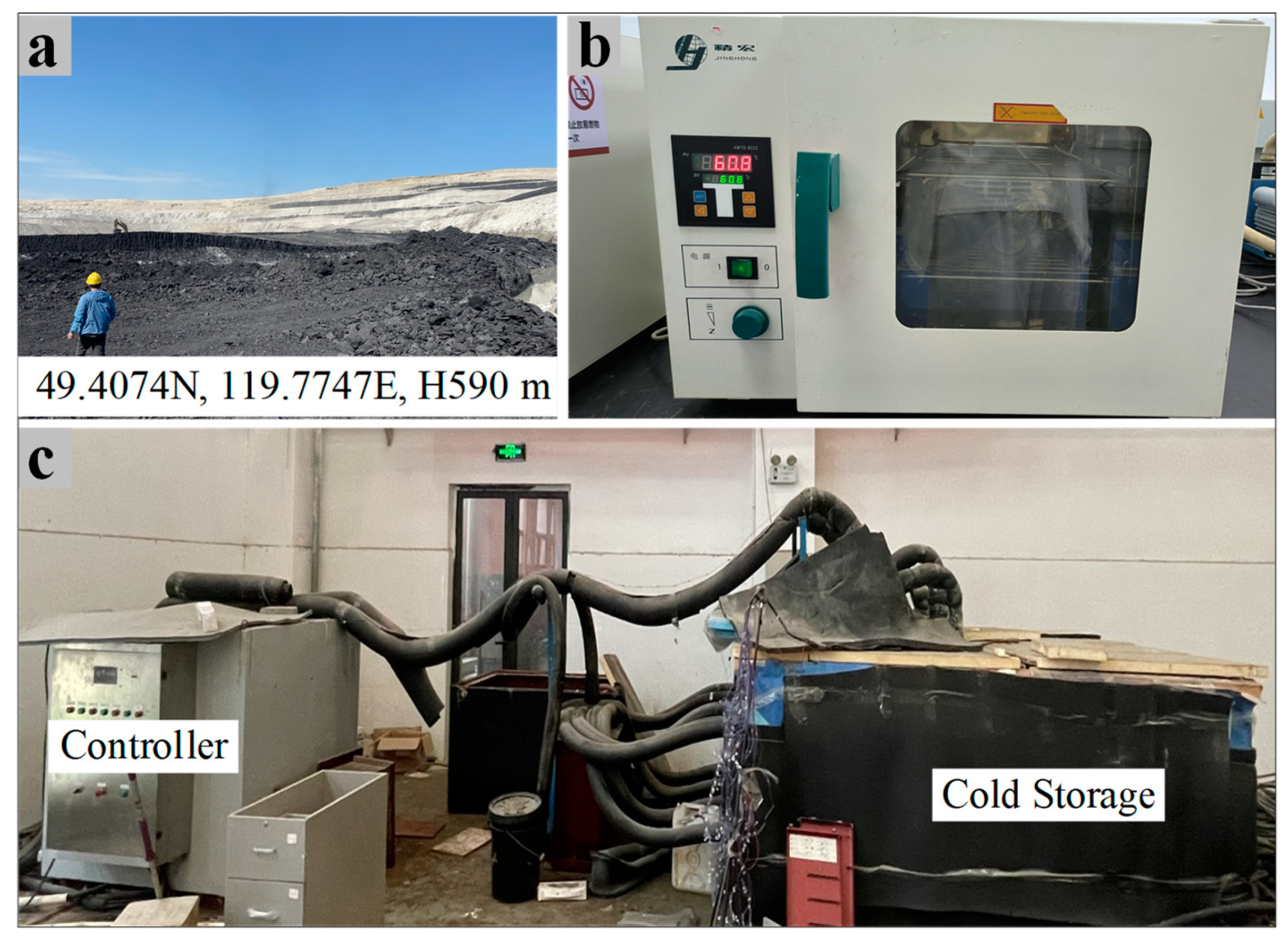

2.2. Experimental Methods

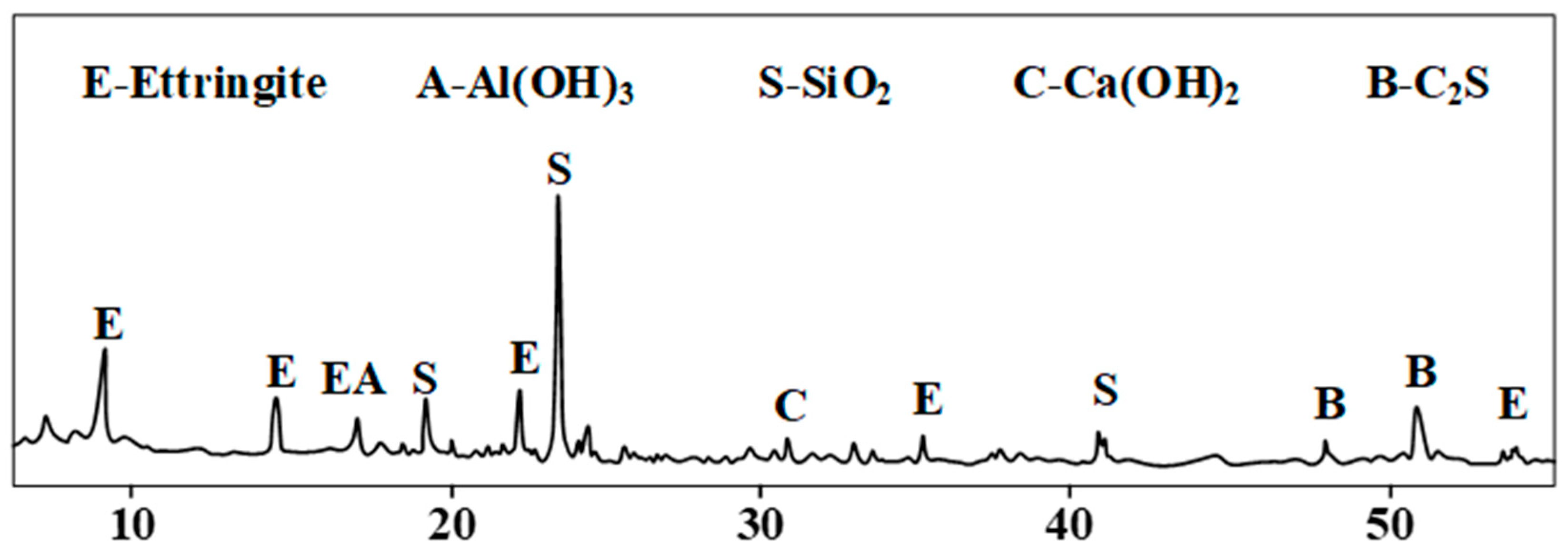

2.3. Identification of Clay Minerals and Chemical Composition in Coal Gangue

2.4. Experimental Design of Coal Gangue Weathering Disintegration Rate

3. Results

3.1. Main Physical and Chemical Parameters of Coal Gangue

3.2. Influence of Moisture Change on Coal Gangue Weathering

3.3. Effect of Freeze–Thaw Cycle on Weathering of Coal Gangue

3.4. Effect of Water and Freeze–Thaw Cycles on Weathering of Coal Gangue

4. Discussion

4.1. Weathering Rate Influences Gangue Disintegration Processes

4.2. Impact of Environmental Conditions and Statistical Analysis Insights

4.3. Analysis of Causes of Coal Gangue Weathering

5. Conclusions

- Weathering and Disintegration Rates under Different Conditions

- 2.

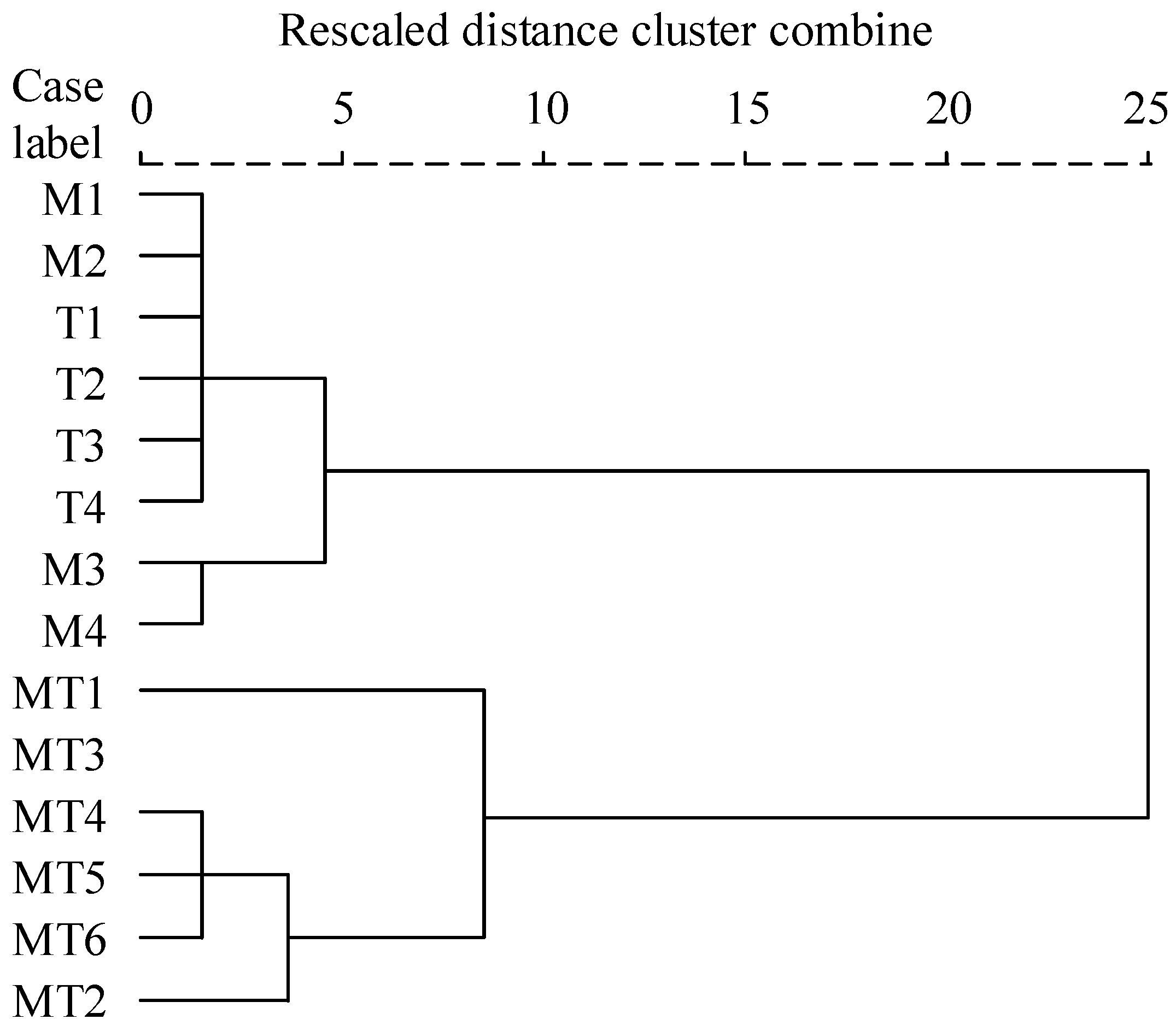

- Cluster Analysis of Treatment Effects

- 3.

- Recommendations for Onsite Conditions and Resource Utilization

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Liu, X.; Jing, M.; Bai, Z. Heavy metal concentrations of soil, rock, and coal gangue in the geological profile of a large open-pit coal mine in China. Sustainability 2022, 14, 1020. [Google Scholar] [CrossRef]

- Bian, Z.; Miao, X.; Lei, S.; Chen, S.E.; Wang, W.; Struthers, S. The challenges of reusing mining and mineral-processing wastes. Science 2012, 337, 702–703. [Google Scholar] [CrossRef]

- Song, W.; Zhang, J.; Li, M.; Yan, H.; Zhou, N.; Yao, Y.; Guo, Y. Underground disposal of coal gangue backfill in China. Appl. Sci. 2022, 12, 12060. [Google Scholar] [CrossRef]

- Zheng, Q.; Zhou, Y.; Liu, X.; Liu, M.; Liao, L.; Lv, G. Environmental hazards and comprehensive utilization of solid waste coal gangue. Prog. Nat. Sci. Mater. Int. 2024, 34, 223–239. [Google Scholar] [CrossRef]

- China National Coal Association. 13th Five Year Plan for the Development of Coal Industry; China National Coal Association: Beijing, China, 2020. [Google Scholar]

- Erdenetsogt, B.O.; Lee, I.; Bat-Erdene, D.; Jargal, L. Mongolian coal-bearing basins: Geological settings, coal characteristics, distribution, and resources. Int. J. Coal Geol. 2009, 80, 87–104. [Google Scholar] [CrossRef]

- Minyard, M.L.; Bruns, M.A.; Liermann, L.J.; Buss, H.L.; Brantley, S.L. Bacterial Associations with Weathering Minerals at the Regolith-Bedrock Interface, Luquillo Experimental Forest, Puerto Rico. Geomicrobiol. J. 2012, 29, 792–803. [Google Scholar] [CrossRef]

- Chizhikova Natalia, P.; Lessovaia Sofia, N.; Gorbushina Anna, A. Biogenic Weathering of Mineral Substrates: Biogenic—Abiogenic Interactions in Natural and Anthropogenic Systems; Springer: Berlin/Heidelberg, Germany, 2016. [Google Scholar]

- Trudgill Stephen, T.; Goudie Andrew, S.; Viles Heather, A. Weathering processes and forms. Geol. Soc. Lond. Mem. 2022, 58, 173–189. [Google Scholar] [CrossRef]

- Luo, Z.; Zhu, Z.; Jiang, Q.; Xu, X.; Liu, D.; Zhou, M. Study on the Evolution Law of Sandstone Porosity under Soaking-Drying Cycles. KSCE J. Civ. Eng. 2022, 26, 25–34. [Google Scholar] [CrossRef]

- Fantong, W.Y.; Kamtchueng, B.T.; Yamaguchi, K.; Ueda, A.; Ntchantcho, R.; Wirmvem, M.J.; Kusakabe, M.; Ohba, T.; Zhang, J.; Aka, F.T.; et al. Characteristics of chemical weathering and water–rock interaction in Lake Nyos dam (Cameroon): Implications for vulnerability to failure and re-enforcement. J. Afr. Earth Sci. 2015, 101, 42–55. [Google Scholar] [CrossRef]

- Shi, Z.; Li, J.; Zhao, Y. Study on damage evolution and constitutive model of sandstone under the coupled effects of wetting-drying cycles and cyclic loading. Eng. Fract. Mech. 2021, 253, 107883. [Google Scholar] [CrossRef]

- Shrestha, R.K.; Lal, R. Changes in physical and chemical properties of soil after surface mining and reclamation. Geoderma 2011, 161, 168–176. [Google Scholar] [CrossRef]

- Zhang, J.; Yi, W.; Yuan, W.; Liu, Y.; Sui, Z. Research on the Ecological Protection of Coal Gangue Slope Based on a Polymer Curing Agent. Adv. Mater. Sci. Eng. 2021, 2021, 8181688. [Google Scholar] [CrossRef]

- Zhang, Z.; Wang, Q.; Zhang, K.; Fang, J.; Li, S.; Ge, A.; Huang, H. Study on the physical and mechanical properties of recycled weathered rock materials in expressway subgrade in permafrost areas. Constr. Build. Mater. 2024, 430, 136494. [Google Scholar] [CrossRef]

- Anna, K.W. Sustainable reclamation practices for a large surface coal mine in shortgrass prairie, semiarid environment (Wyoming, USA): Case study. Int. J. Coal Sci. Technol. 2022, 9, 32. [Google Scholar]

- Cheng, W.; Lei, S.; Bian, Z.; Zhao, Y.; Li, Y.; Gan, Y. Geographic distribution of heavy metals and identification of their sources in soils near large, open-pit coal mines using positive matrix factorization. J. Hazard. Mater. 2020, 387, 121666. [Google Scholar] [CrossRef]

- Koele, N.; Dickie, I.A.; Blum, J.D.; Gleason, J.D.; de Graaf, L. Ecological significance of mineral weathering in ectomycorrhizal and arbuscular mycorrhizal ecosystems from a field-based comparison. Soil Biol. Biochem. 2014, 69, 63–70. [Google Scholar] [CrossRef]

- Xiao, L.; Lian, B.; Hao, J.; Liu, C.; Wang, S. Effect of carbonic anhydrase on silicate weathering and carbonate formation at present day CO2 concentrations compared to primordial values. Sci. Rep. 2015, 5, 7733. [Google Scholar] [CrossRef]

- Li, X.; Gao, J.; Zhang, J.; Wang, R.; Jin, L.; Zhou, H. Adaptive strategies to overcome challenges in vegetation restoration to coalmine wasteland in a frigid alpine setting. Catena 2019, 182, 104142. [Google Scholar] [CrossRef]

- Tamamura, S.; Ueno, A.; Aramaki, N.; Matsumoto, H.; Uchida, K.; Igarashi, T.; Kaneko, K. Effects of oxidative weathering on the composition of organic matter in coal and sedimentary rock. Org. Geochem. 2015, 81, 8–19. [Google Scholar] [CrossRef]

- Lian, H.; Yi, H.; Yang, Y.; Wu, B.; Wang, R. Impact of coal mining on the moisture movement in a vadose zone in open-pit mine areas. Sustainability 2021, 13, 4125. [Google Scholar] [CrossRef]

- ASTM C642-21; Standard Test Method for Density, Absorption, and Voids in Hardened Concrete. International ASTM: West Conshohocken, PA, USA, 2022.

- Hao, L.; Wei, Q.; Zhao, Y.; Lu, J.; Zhao, X. Optimization method for quantitative calculation of clay minerals in soil. J. Earth Syst. Sci. 2015, 124, 675–680. [Google Scholar] [CrossRef]

- Ali, A.; Chiang, Y.W.; Santos, R.M. X-ray diffraction techniques for mineral characterization: A review for engineers of the fundamentals, applications, and research directions. Minerals 2022, 12, 205. [Google Scholar] [CrossRef]

- Potts Philip, J.; Webb Peter, C. X-ray fluorescence spectrometry. J. Geochem. Explor. 1992, 44, 251–296. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, A.; Xiong, D.; Liu, G. Effect of moisture and temperature conditions on the decay rate of a purple mudstone in southwestern China. Geomorphology 2013, 182, 125–132. [Google Scholar] [CrossRef]

- Li, J.; Wang, J. Comprehensive utilization and environmental risks of coal gangue: A review. J. Clean. Prod. 2019, 239, 117946. [Google Scholar] [CrossRef]

- Wu, Q.; Meng, Z.; Tang, H.; Wang, X.; Huang, L.; Kang, J.; Liu, Y.; Wang, D.; Huo, X. Experimental investigation on weakening of discontinuities at the interface between different rock types induced by wetting and drying cycles. Rock Mech. Rock Eng. 2022, 55, 1179–1195. [Google Scholar] [CrossRef]

- Zhang, Z.; Li, M.; Wang, J.; Yin, Z.; Yang, Y.; Xun, X.; Wu, Q. A calculation model for the spatial distribution and reserves of ground ice-A case study of the Northeast China permafrost area. Eng. Geol. 2023, 315, 107022. [Google Scholar] [CrossRef]

- Xu, H.; Xu, F.; Lin, T.; Xu, Q.; Yu, P.; Wang, C.; Aili, A.; Zhao, X.; Zhao, W.; Zhang, P.; et al. A systematic review and comprehensive analysis on ecological restoration of mining areas in the arid region of China: Challenge, capability and reconsideration. Ecol. Indic. 2023, 154, 110630. [Google Scholar] [CrossRef]

- Jahandari, S.; Tao, Z.; Chen, Z.; Osborne, D.; Rahme, M. Coal wastes: Handling, pollution, impacts, and utilization. In The Coal Handbook; Elsevier: Amsterdam, The Netherlands, 2023; pp. 97–163. [Google Scholar]

- Xie, J.; Yan, M.L.; Yan, J.B. Experimental study on PVA reinforced salt-water ice under uniaxial-compression at arctic low temperatures. Cold Reg. Sci. Technol. 2023, 206, 103751. [Google Scholar] [CrossRef]

- Bian, Z.; Inyang, H.I.; Daniels, J.L.; Otto, F.; Struthers, S. Environmental issues from coal mining and their solutions. Min. Sci. Technol. 2010, 20, 215–223. [Google Scholar] [CrossRef]

- Liu, P.; Chen, R.P.; Kang, X.; Wang, P.F. Effect of drying–wetting cycles on the hydromechanical behaviour of compacted coal gangue. Environ. Geotech. 2021, 11, 40–50. [Google Scholar] [CrossRef]

- Wang, H.; Cheng, Q.; Zhou, N.; Su, H.; Yin, Q.; Du, B.; Zhang, L.; Yao, Y. An Experimental Study on the Mechanical Properties and Microstructure of the Cemented Paste Backfill Made by Coal-Based Solid Wastes and Nanocomposite Fibers under Dry–Wet Cycling. Materials 2024, 17, 2256. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Xia, J.; Li, P.; Yu, L.; Yang, H.; Chen, Y. Experimental Study and Analytical Modeling on Properties of Freeze–Thaw Durability of Coal Gangue Pervious Concrete. Materials 2023, 16, 7104. [Google Scholar] [CrossRef] [PubMed]

| Engineering Geological Classification | Rock Formation | Space Distribution | Rock Mass Structure |

|---|---|---|---|

| Quaternary loose rock formation | Clay, powdery clay | Distributed on the surface | Discrete structure |

| Gravel layer | Localized distribution | ||

| Cretaceous detrital rock formation | Weathered rock formation | The contact zone between the top of coal measures and the Quaternary system | Fragmented structure |

| Sandstone, mudstone, and conglomerate | Distributed throughout the region | ||

| Coal rock formation | Coal seam | Distributed throughout the region | Layered structure |

| Experimental Processing Conditions/°C | Different Moisture Content Treatment Conditions | |||

|---|---|---|---|---|

| 15% of Saturated Water Absorption | 30% of Saturated Water Absorption | 50% of Saturated Water Absorption | 100% of Saturated Water Absorption | |

| 20 | M1 | M2 | M3 | M4 |

| −5/40 | T1 | \ | \ | \ |

| −20/40 | T2 | MT1 | MT3 | MT5 |

| −40/40 | T3 | \ | \ | \ |

| −60/40 | T4 | MT2 | MT4 | MT6 |

| Density, g·cm−3 | Natural Moisture Content, % | Coefficient of Water Saturation, % |

|---|---|---|

| 2.21 | 2.54 | 13.31 |

| Humus | SiO2 | Al2O3 | K2O | Fe2O3 | TiO2 | MgO | CaO | Na2O | SO3 | P2O5 | Miscellaneous |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 14.82 | 52.75 | 25.34 | 1.95 | 1.74 | 1.42 | 0.55 | 0.42 | 0.34 | 0.18 | 0.03 | 0.46 |

| Sample Number | Percentage of Saturated Water Absorption | Number of Cyclic Experiments | |||||

|---|---|---|---|---|---|---|---|

| 5 | 10 | 30 | |||||

| 1 Mean/% | 2 SD | Mean/% | SD | Mean/% | SD | ||

| M1 | 15% | 0.11 | 0.05 | 0.37 | 0.02 | 1.61 | 0.13 |

| M2 | 30% | 1.08 | 0.02 | 2.23 | 0.05 | 3.94 | 0.10 |

| M3 | 50% | 1.43 | 0.03 | 2.56 | 0.07 | 5.26 | 0.09 |

| M4 | 100% | 1.71 | 0.06 | 2.82 | 0.08 | 7.44 | 0.16 |

| Sample Number | Temperature/°C | Number of Cyclic Experiments | |||||

|---|---|---|---|---|---|---|---|

| 5 | 10 | 30 | |||||

| 1 Mean/% | 2 SD | Mean/% | SD | Mean/% | SD | ||

| T1 | −5/40 | 0.27 | 0.01 | 0.35 | 0.05 | 0.48 | 0.06 |

| T2 | −20/40 | 0.24 | 0.06 | 0.36 | 0.02 | 0.59 | 0.04 |

| T3 | −40/40 | 0.23 | 0.04 | 0.39 | 0.05 | 0.61 | 0.03 |

| T4 | −60/40 | 0.25 | 0.02 | 0.48 | 0.04 | 0.67 | 0.06 |

| Sample Number | Percentage of Saturated Water Absorption | Temperature/°C | Number of Cyclic Experiments | |||||

|---|---|---|---|---|---|---|---|---|

| 5 | 10 | 30 | ||||||

| 1 Mean/% | 2 SD | Mean/% | SD | Mean/% | SD | |||

| MT1 | 30% | −20/40 | 4.33 | 0.66 | 7.52 | 0.91 | 15.55 | 2.01 |

| MT2 | −60/40 | 6.54 | 1.23 | 13.41 | 2.62 | 25.43 | 2.90 | |

| MT3 | 50% | −20/40 | 7.14 | 0.63 | 22.34 | 2.33 | 35.98 | 3.91 |

| MT4 | −60/40 | 12.45 | 1.78 | 30.55 | 2.92 | 61.31 | 2.96 | |

| MT5 | 100% | −20/40 | 15.88 | 2.90 | 41.14 | 2.75 | 67.59 | 2.39 |

| MT6 | −60/40 | 24.25 | 4.62 | 52.83 | 2.42 | 77.47 | 5.60 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gong, C.; Yang, L. Impact of Humidity and Freeze–Thaw Cycles on the Disintegration Rate of Coal Gangue in Cold and Arid Regions: A Case Study from Inner Mongolia, China. Minerals 2024, 14, 911. https://doi.org/10.3390/min14090911

Gong C, Yang L. Impact of Humidity and Freeze–Thaw Cycles on the Disintegration Rate of Coal Gangue in Cold and Arid Regions: A Case Study from Inner Mongolia, China. Minerals. 2024; 14(9):911. https://doi.org/10.3390/min14090911

Chicago/Turabian StyleGong, Chuangang, and Liya Yang. 2024. "Impact of Humidity and Freeze–Thaw Cycles on the Disintegration Rate of Coal Gangue in Cold and Arid Regions: A Case Study from Inner Mongolia, China" Minerals 14, no. 9: 911. https://doi.org/10.3390/min14090911

APA StyleGong, C., & Yang, L. (2024). Impact of Humidity and Freeze–Thaw Cycles on the Disintegration Rate of Coal Gangue in Cold and Arid Regions: A Case Study from Inner Mongolia, China. Minerals, 14(9), 911. https://doi.org/10.3390/min14090911