Innovative Seismic Imaging of the Platinum Deposits, Maseve Mine: Surface and In-Mine

Abstract

:1. Introduction

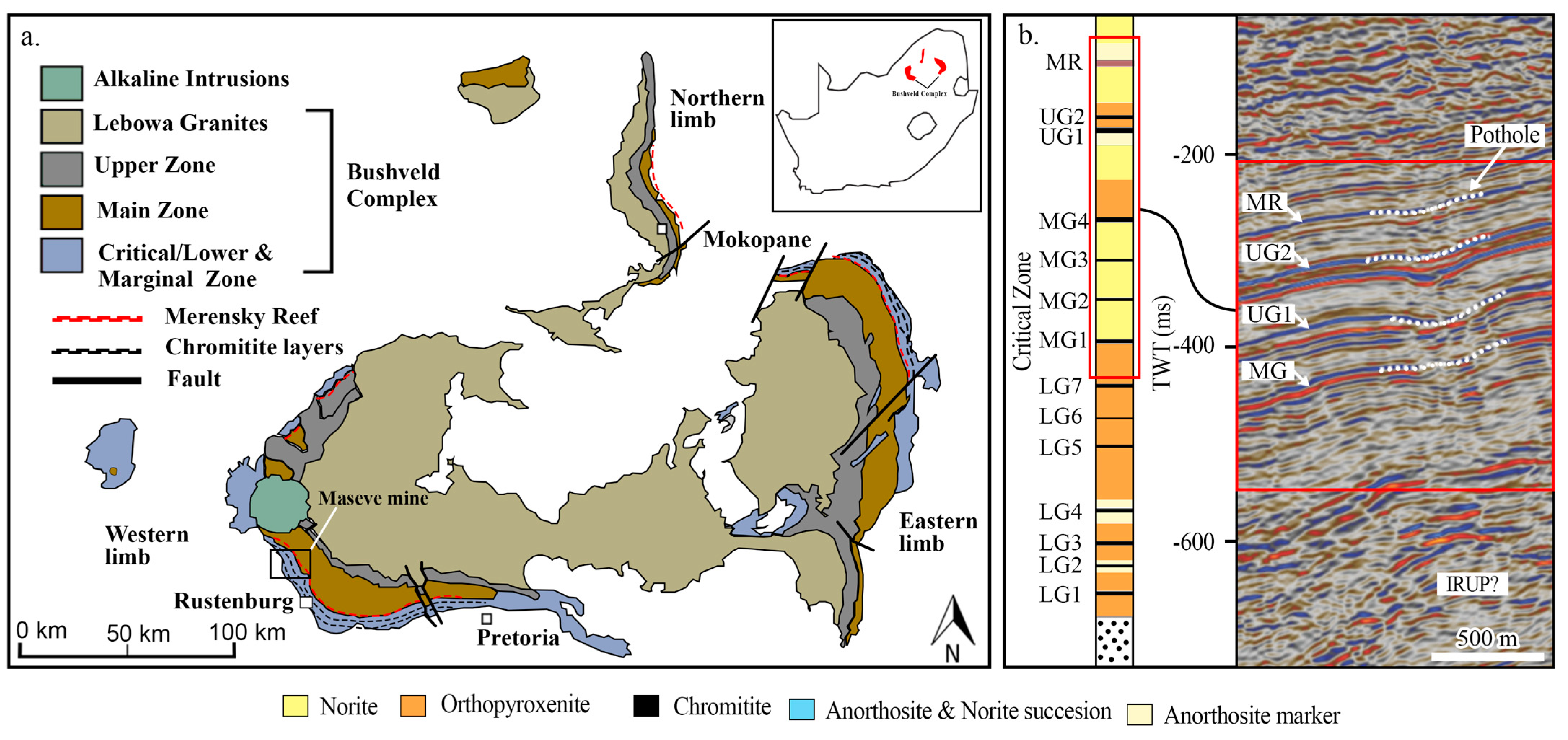

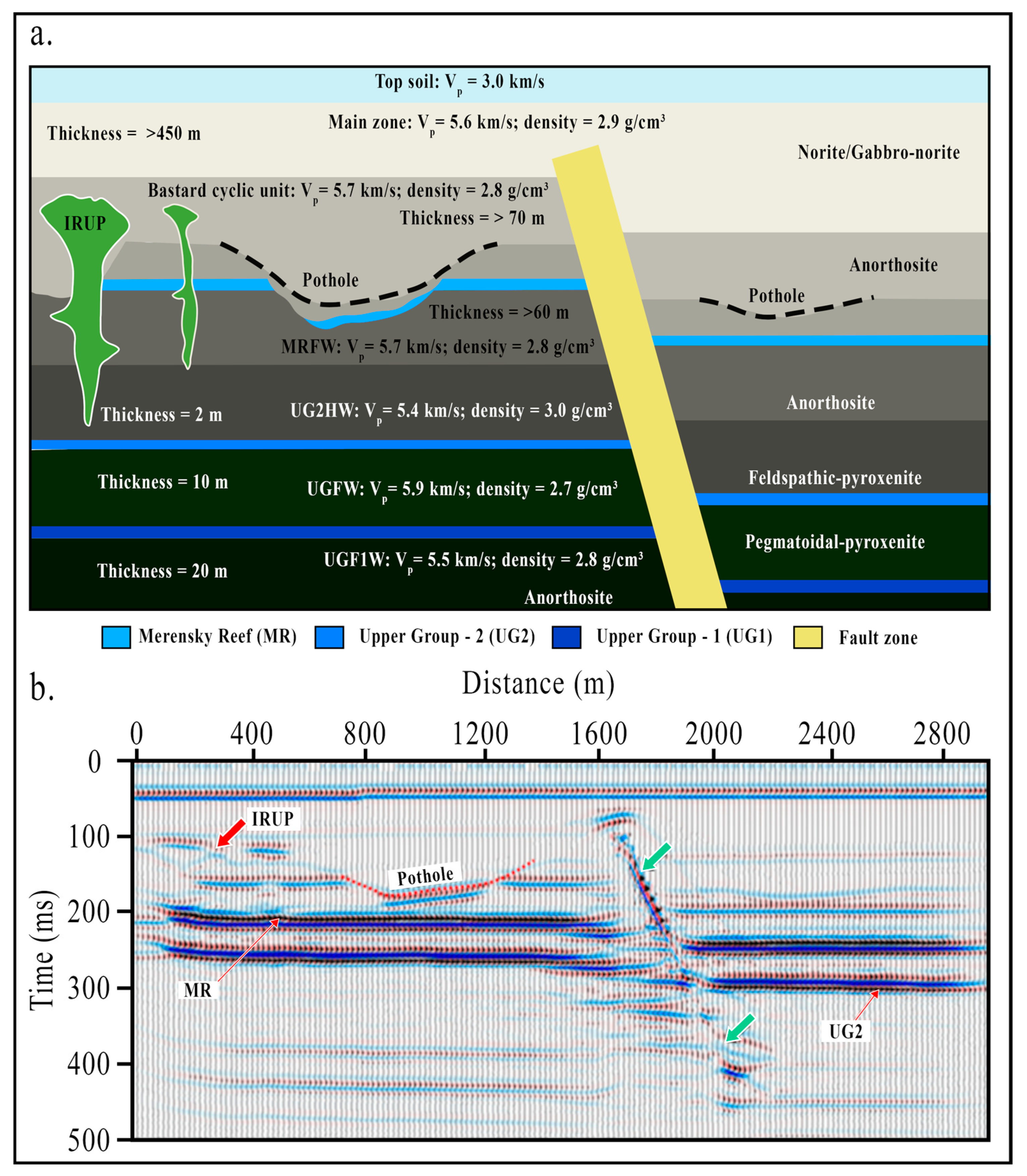

2. Geological Background

3. Data Acquisition

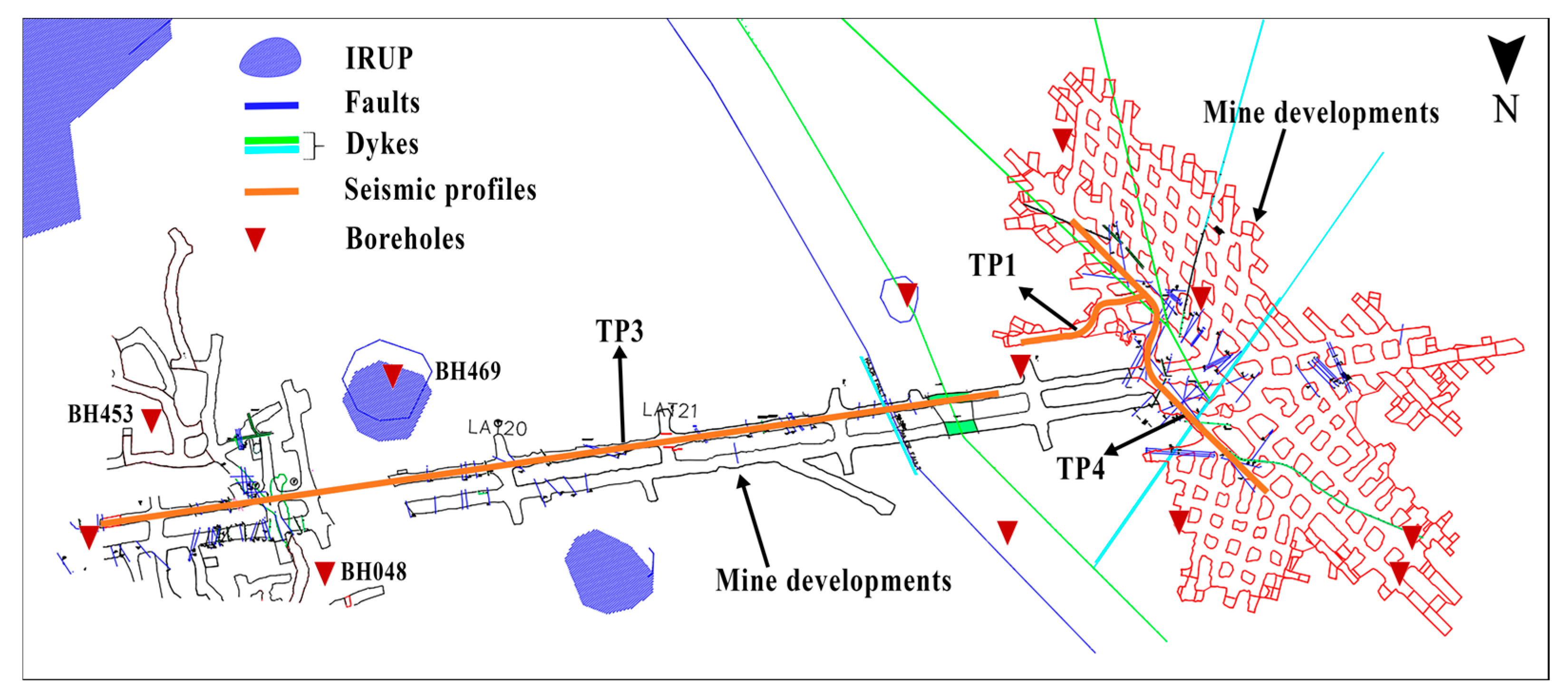

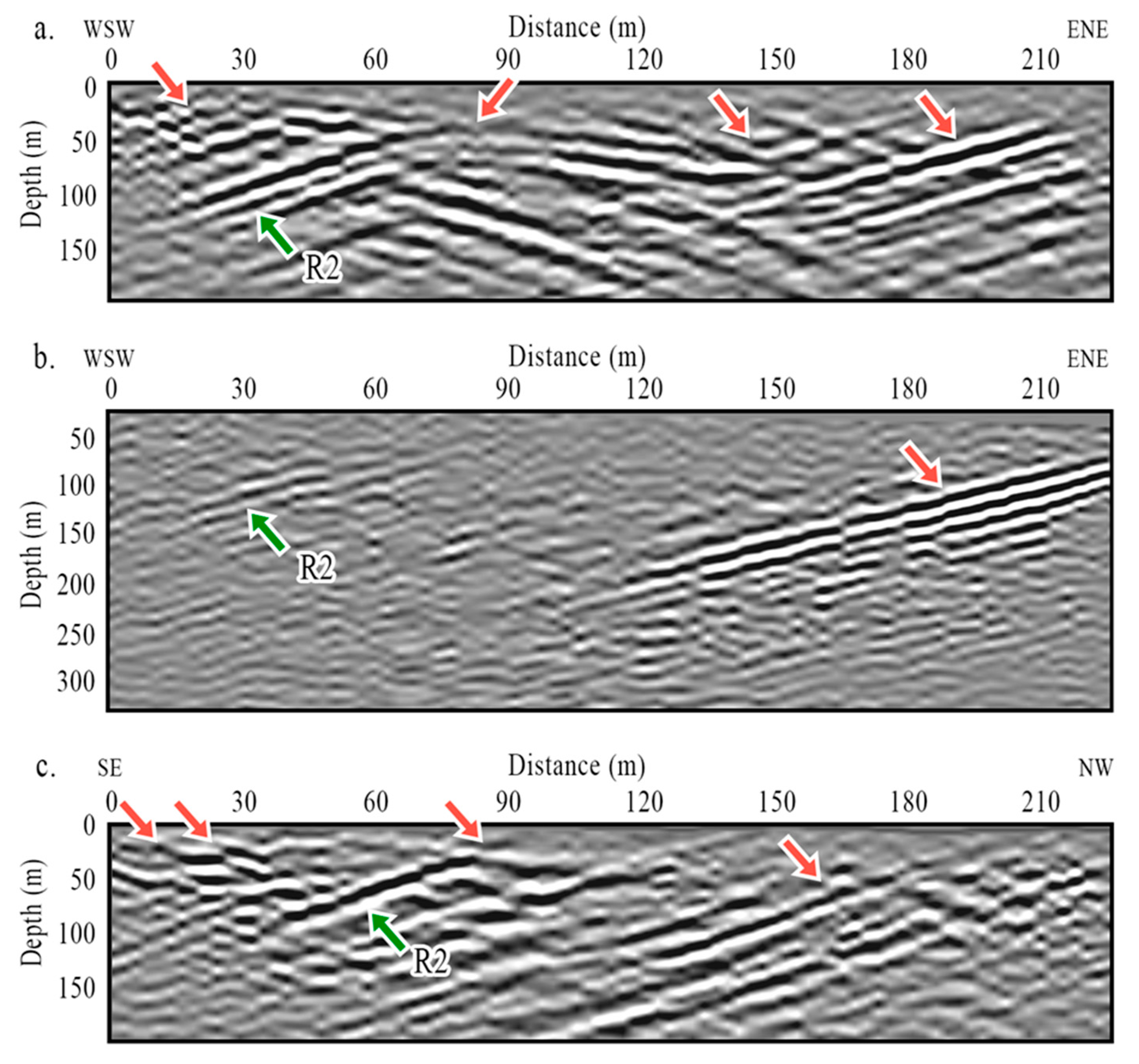

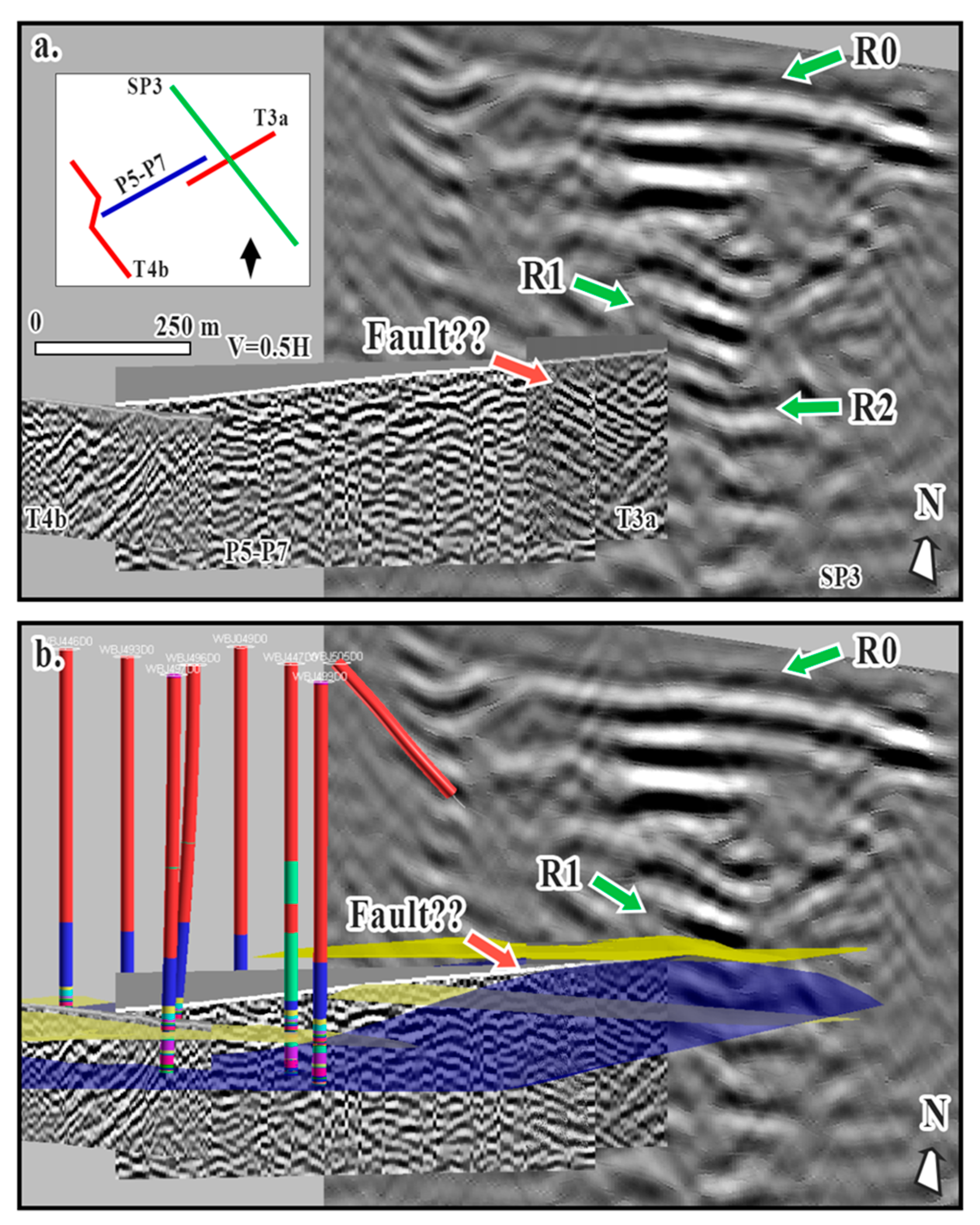

3.1. In-Mine Seismics

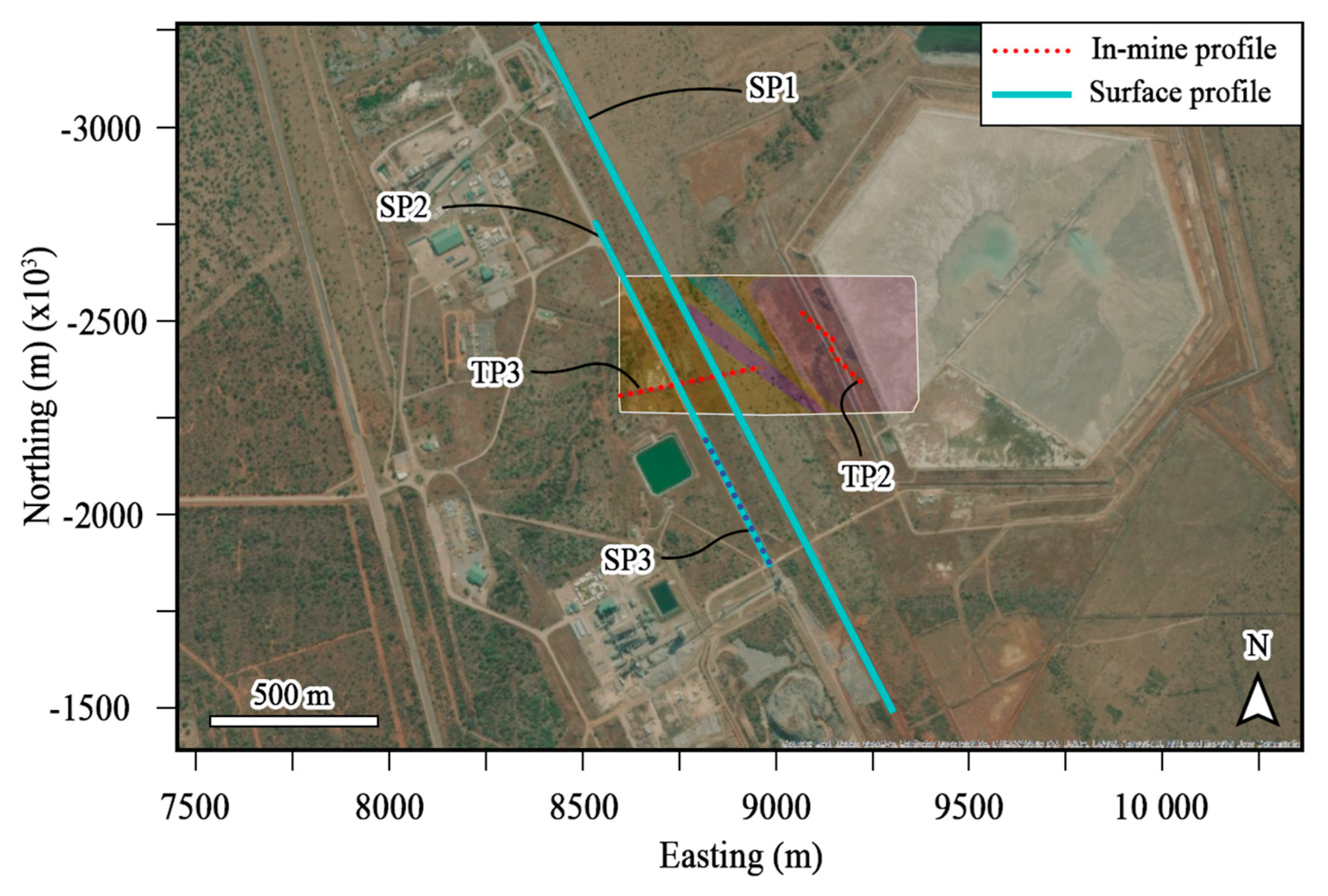

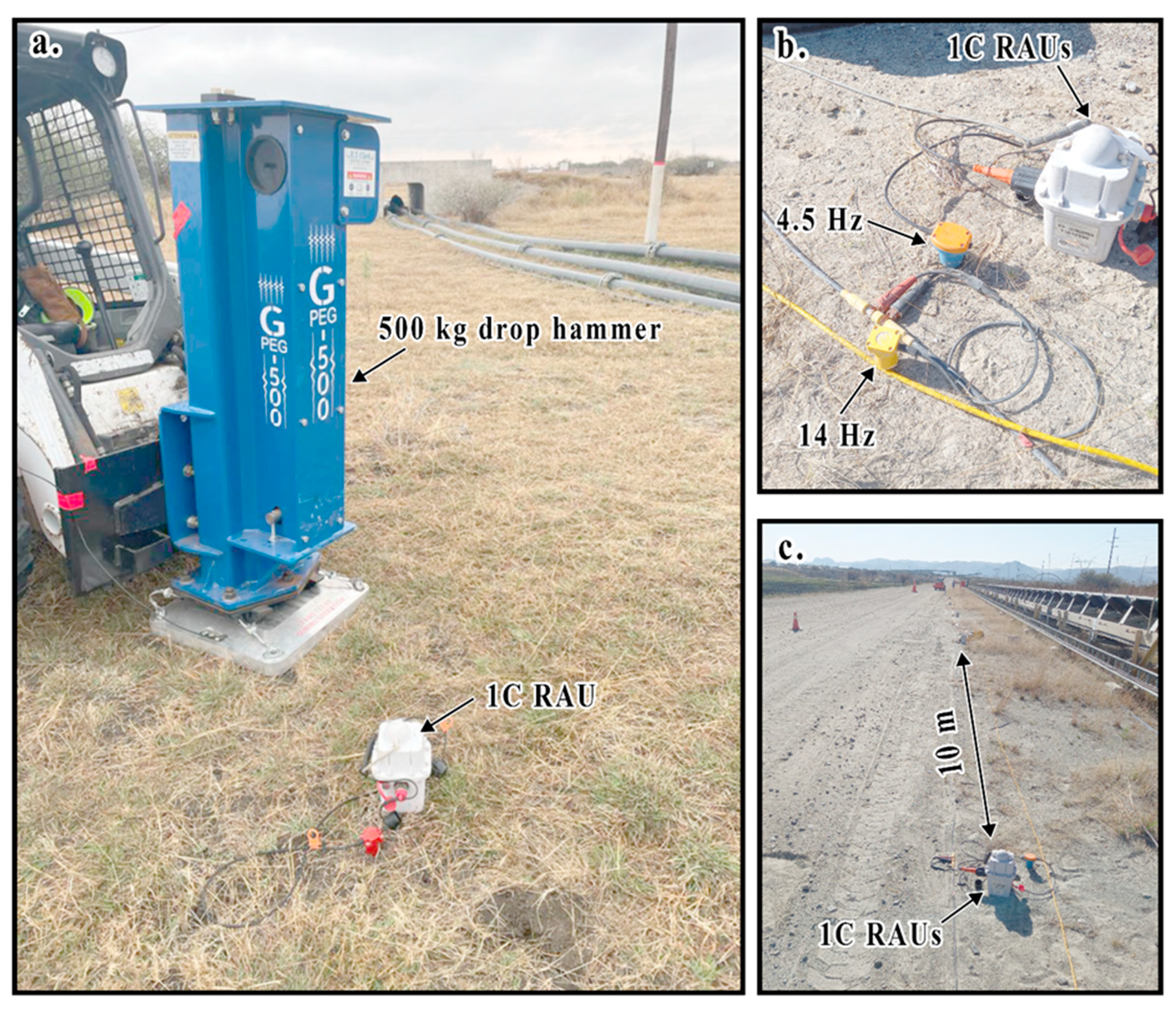

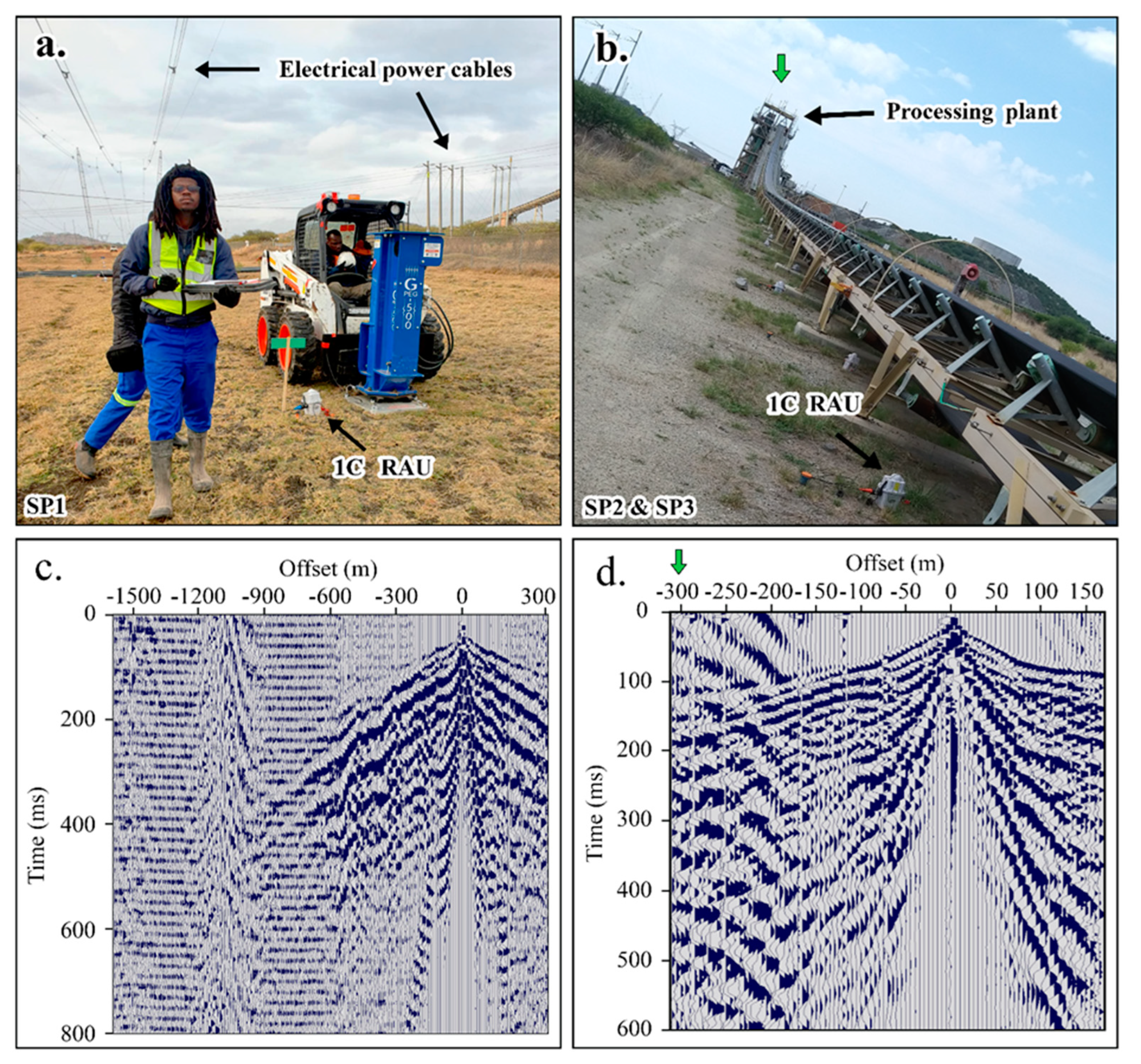

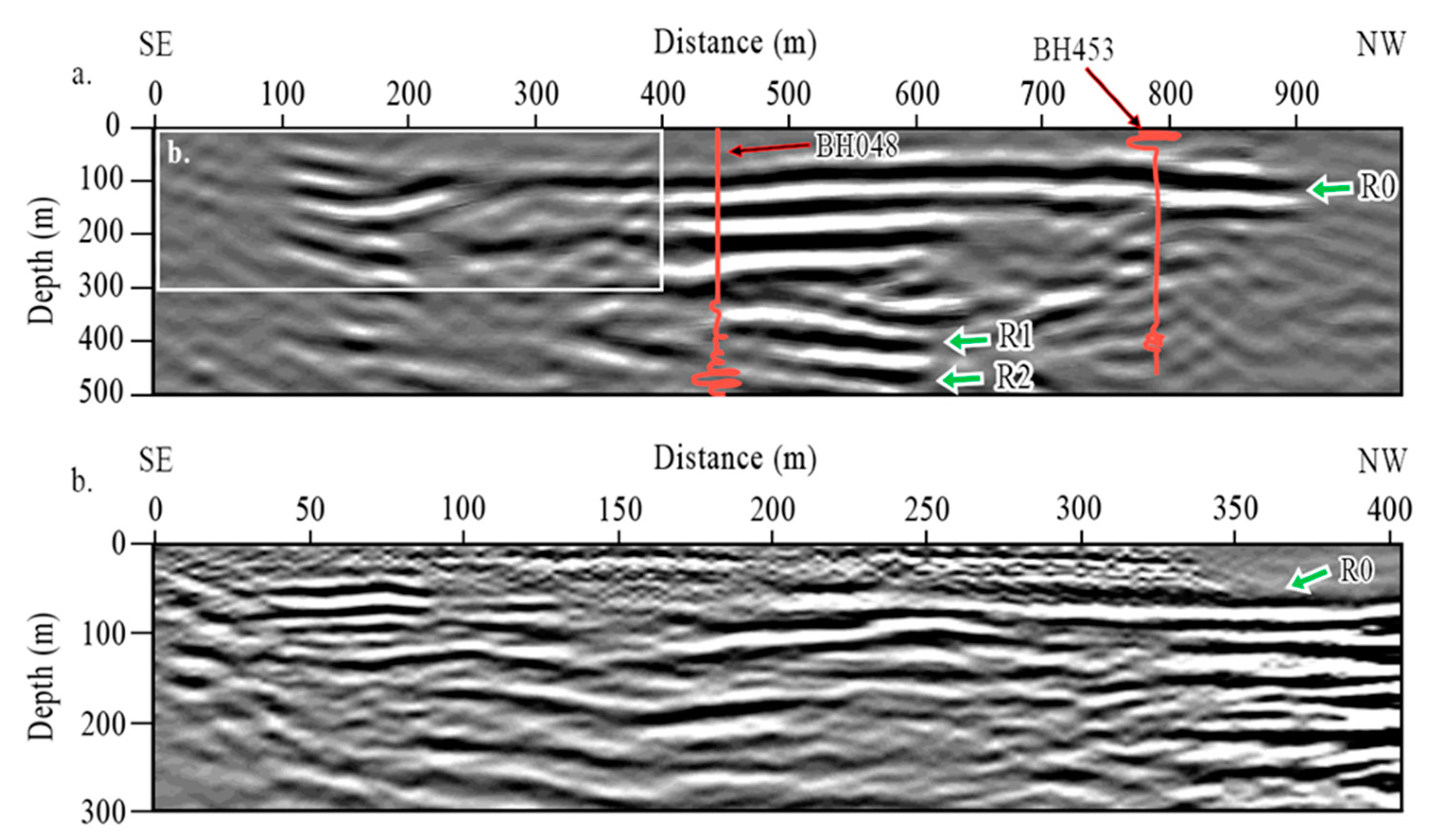

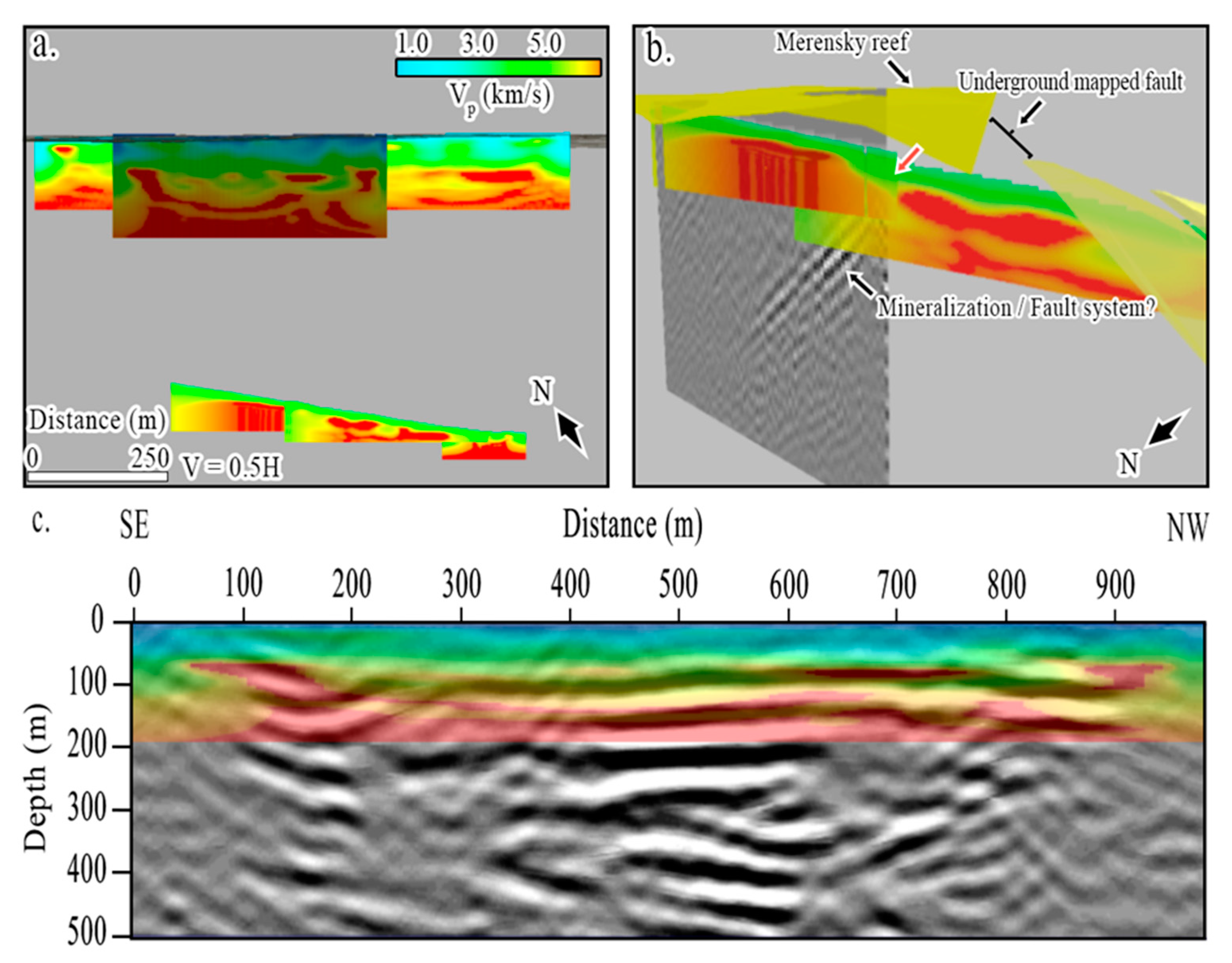

3.2. Surface Seismics

4. Data Processing

5. One-Dimensional (1D) and Two-Dimensional (2D) Modeling and Borehole Data

6. Results, Interpretation, and Discussion

7. Two-Dimensional High-Resolution Seismic in Noisy Mining Environment

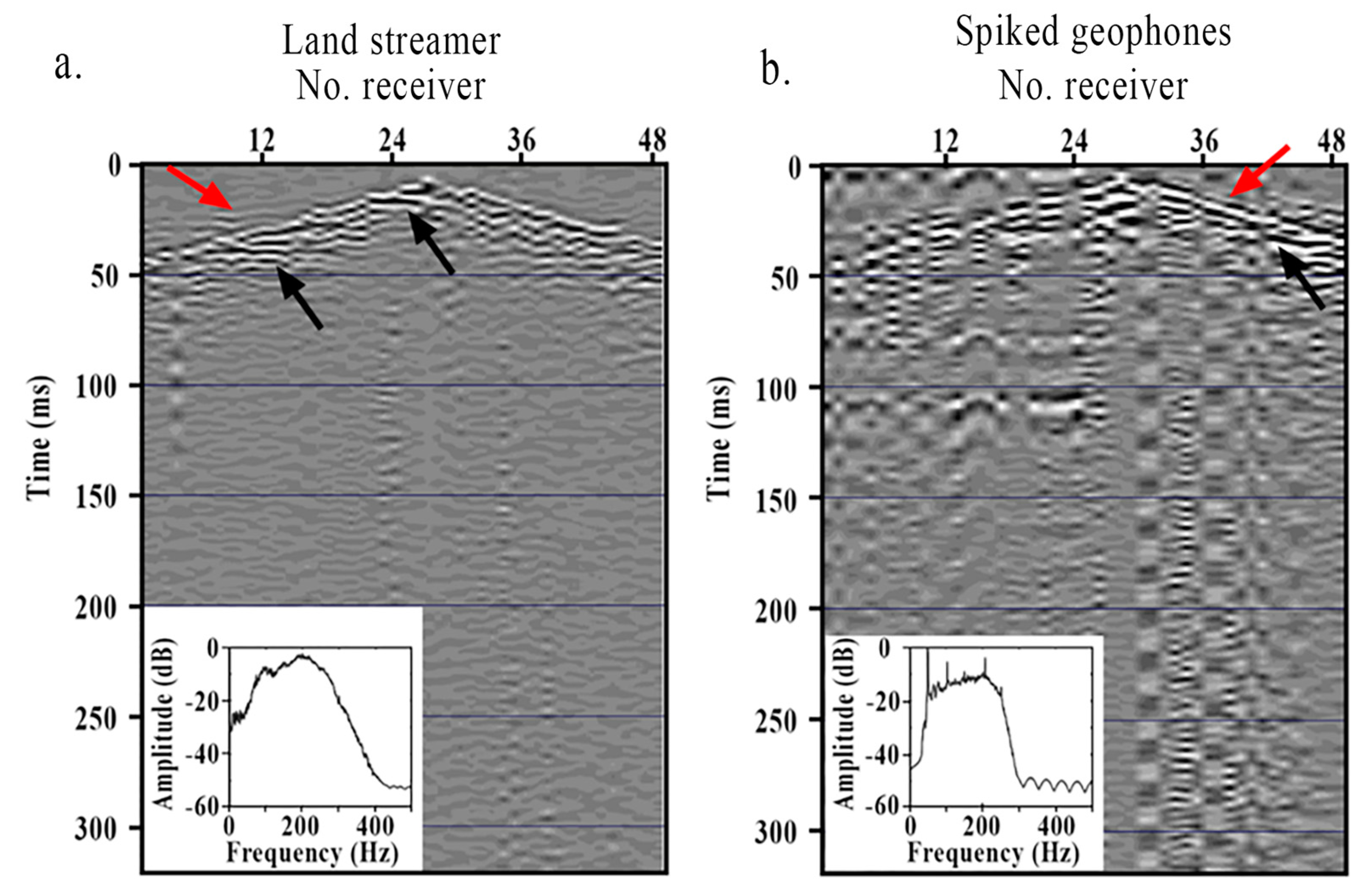

7.1. Sensors and Seismic Source

7.2. Mineral Exploration

8. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ediriweera, A.; Wiewiora, A. Barriers and Enablers of Technology Adoption in the Mining Industry. Resour. Policy 2021, 73, 102188. [Google Scholar] [CrossRef]

- Upstill, G.; Hall, P. Innovation in the Minerals Industry: Australia in a Global Context. Resour. Policy 2006, 31, 137–145. [Google Scholar] [CrossRef]

- Juhlin, C.; Lindgren, J.; Collini, B. Interpretation of Seismic Reflection and Borehole Data from Precambrian Rocks in the Dala Sandstone Area, Central Sweden. First Break 1991, 9, 24–36. [Google Scholar] [CrossRef]

- Eaton, D.W.; Milkereit, B.; Salisbury, M.H. Hardrock Seismic Exploration; Geophysical developments series; Society of Exploration Geophysicists: Tulsa, OK, USA, 2003; ISBN 978-1-56080-114-6. [Google Scholar]

- Ahmadi, O.; Juhlin, C.; Malehmir, A.; Munck, M. High-Resolution 2D Seismic Imaging and Forward Modeling of a Polymetallic Sulfide Deposit at Garpenberg, Central Sweden. Geophysics 2013, 78, B339–B350. [Google Scholar] [CrossRef]

- Malehmir, A.; Manzi, M.; Draganov, D.; Weckmann, U.; Auken, E. Introduction to the Special Issue on “Cost-Effective and Innovative Mineral Exploration Solutions”. Geophys. Prospect. 2020, 68, 3–6. [Google Scholar] [CrossRef]

- Manzi, M.S.D.; Cooper, G.R.J.; Malehmir, A.; Durrheim, R.J. Improved Structural Interpretation of Legacy 3D Seismic Data from Karee Platinum Mine (South Africa) through the Application of Novel Seismic Attributes. Geophys. Prospect. 2020, 68, 145–163. [Google Scholar] [CrossRef]

- Malehmir, A.; Bellefleur, G.; Juhlin, C.; Milkereit, B. Seismic Methods In Mineral Exploration And Mine Planning—Introduction. Geophysics 2012, 77, WC1–WC2. [Google Scholar] [CrossRef]

- Brodic, B.; Malehmir, A.; Pacheco, N.B.M.; Juhlin, C.; Carvalho, J.; Dynesius, L.; Van Den Berg, J.; de Kunder, R.; Donoso, G.; Sjölund, T.; et al. Innovative Seismic Imaging Of VMS Deposits, Neves-Corvo, Portugal: Part I—In-Mine Array. Geophysics 2021, 86, 1–76. [Google Scholar] [CrossRef]

- Scheiber-Enslin, S.E.; Manzi, M. Integration of 3D Reflection Seismics and Magnetic Data for Deep Platinum Mine Planning and Risk Mitigation: A Case Study from Bushveld Complex, South Africa. Explor. Geophys. 2018, 49, 928–939. [Google Scholar] [CrossRef]

- Rapetsoa, M.K.; Manzi, M.S.D.; Westgate, M.; Sihoyiya, M.; James, I.; Onyebueke, E.; Kubeka, P.; Durrheim, R.J.; Kgarume, T. Cost-effective In-mine Seismic Experiments to Image Platinum Deposits and Associated Geological Structures at Maseve Platinum Mine, South Africa. Near Surf. Geophys. 2022, 20, 572–589. [Google Scholar] [CrossRef]

- Sehoole, L.; Manzi, M.; Zhang, S. Application of 3D Seismic to Enhance Mapping of Potholes in the Western Bushveld Complex, South Africa; European Association of Geoscientists & Engineers: Utrecht, The Netherlands, 2018; Volume 2018, pp. 1–3. [Google Scholar] [CrossRef]

- Ledwaba, L.S.; Scheepers, J.; Durrheim, R.J. Rockburst damage mechanism at impala platinum mine. In Proceedings of the Second Southern Hemisphere International Rock Mechanics Symposium SHIRMS, Sun City, South Africa, 15–17 May 2012. [Google Scholar]

- Basson, I.J. Cumulative Deformation and Original Geometry of the Bushveld Complex. Tectonophysics 2019, 750, 177–202. [Google Scholar] [CrossRef]

- Brodic, B.; Malehmir, A.; Bastani, M.; Mehta, S.; Juhlin, C.; Lundberg, E.; Wang, S. Multi-Component Digital-Based Seismic Landstreamer and Boat-Towed Radio-Magnetotelluric Acquisition Systems for Improved Subsurface Characterization in the Urban Environment. First Break 2017, 35, 41–47. [Google Scholar] [CrossRef]

- Malehmir, A.; Maries, G.; Bäckström, E.; Schön, M.; Marsden, P. Developing Cost-Effective Seismic Mineral Exploration Methods Using A Landstreamer And A Drophammer. Sci. Rep. 2017, 7, 10325. [Google Scholar] [CrossRef] [PubMed]

- Markovic, M.; Maries, G.; Malehmir, A.; Von Ketelhodt, J.; Bäckström, E.; Schön, M.; Marsden, P. Deep Reflection Seismic Imaging Of Iron-Oxide Deposits In The Ludvika Mining Area Of Central Sweden. Geophys. Prospect. 2020, 68, 7–23. [Google Scholar] [CrossRef]

| Profiles | TP1 | TP3a | TP3b | TP4b |

|---|---|---|---|---|

| Survey parameters | ||||

| Acquisition type | Fixed straight line | Fixed straight line | Fixed straight line | Fixed crooked line |

| Acquisition system | Geometrics Geode | Geometrics Geode | Geometrics Geode | Geometrics Geode |

| Receiver frequency | 4.5 Hz | 4.5 Hz | 14 Hz | 4.5 Hz |

| No. of receivers | 24 | 48 | 48 | 48 |

| Receiver spacing | 2 | 5 m | 5 m | 5 m |

| Source | 6.3 kg sledgehammer | |||

| No. of source positions | 26 | 50 | 50 | 50 |

| Source spacing | 1 m | 2 m | 2 m | 2 m |

| Profile length | 48 m | 235 m | 235 m | 235 m |

| Recording length | 500 ms | 500 ms | 500 ms | 500 ms |

| Sampling interval | 1 ms | 1 ms | 1 ms | 1 ms |

| Profiles | SP1 | SP2 | SP3 |

|---|---|---|---|

| Survey parameters | |||

| Acquisition type | Fixed straight line | Fixed straight line | Fixed crooked line |

| Acquisition system | Sercel UNITE | Sercel UNITE | Geometrics Geode |

| Receiver frequency | 4.5 Hz | 4.5 Hz | 14 Hz |

| No. of receivers | 198 | 101 | 96 |

| Receiver spacing | 10 m | 10 | 5 m |

| Source | 500 kg G-PEG drop hammer | ||

| No. of source position | 198 | 101 | 35 |

| Source spacing | 10 m | 10 m | 10 m |

| Profile length | 1970 m | 1000 m | 475 |

| Recording length | 500 ms | 500 ms | 500 ms |

| Sampling interval | 2 ms | 2 ms | 2 ms |

| 2D Processing Flow | |

|---|---|

| 1. | Read SEG-Y data |

| 2. | Edit traces, geometry setup TP1: crooked CDP 1 m bin size TP3a-b: crooked CDP 2.5 m bin size TP4b: crooked CDP 2.5 m bin size |

| 3. | Pick first breaks |

| 4. | SNAWT: surface noise attenuation |

| 5. | Refraction and elevation corrections TP1: datum 537 m below msl, replacement velocity 5000 m/s TP3a-b: datum 635 m below msl, replacement velocity 5200 m/s TP4b: datum: 537 m below msl, replacement velocity 5000 m/s |

| 6. | Band-pass filtering: 16–80–250–300 Hz |

| 7. | Deconvolution: 60 ms filter length, 1 ms gap |

| 8. | Remove first arrivals |

| 9. | NMO corrections: 70% stretch mute, 20 ms taper |

| 10. | f–k filter: surgical muting |

| 11. | Velocity analysis |

| 12. | Stack TP1: constant velocity 6000 m/s TP3a-b: constant velocity 6500 m/s TP4b: constant velocity 6000 m/s |

| 13. | Post-stack coherency enhancement Spectral weighting 50 100 150 200 250 Hz Semblance-smoothing |

| 14. | Time-to-depth conversion using 6000 m/s and 6500 m/s |

| 2D Processing Flow | |

|---|---|

| 1. | Prepare SEG-Y |

| 2. | Geometry setup SP1: crooked CDP 5 m bin size SP2: crooked CDP 5 m bin size SP3: crooked CDP 2.5 m bin size |

| Remove 50 Hz noise: adaptive notch filter at 50 Hz | |

| 3. | Pick first breaks |

| 4. | Refraction and elevation corrections SP1: datum 1091 m above msl, replacement velocity 4500 m/s SP2: datum 1084 m above msl, replacement velocity 4500 m/s SP3: datum: 1090 m above msl, replacement velocity 4500 m/s |

| 5. | SNAWT: surface noise attenuation |

| 6. | Band-pass filtering: 10–20–100–150 Hz |

| 7. | Surface wave attenuation |

| 8. | Deconvolution: spiking, 60 ms filter length |

| 9. | Remove first arrivals energy |

| 10. | NMO corrections: 70% stretch mute, 20 ms taper |

| 11. | f–k filter: surgical muting |

| 12. | Velocity analysis |

| 13. | Stack SP1: constant velocity 6000 m/s SP2: constant velocity 600 m/s SP3: constant velocity 6000 m/s |

| 14. | Post-stack coherency enhancement Fx deconvolution Semblance-smoothing FK filtering |

| 15. | Time-to-depth conversion |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rapetsoa, M.; Manzi, M.; James, I.; Sihoyiya, M.; Durrheim, R.; Pienaar, M. Innovative Seismic Imaging of the Platinum Deposits, Maseve Mine: Surface and In-Mine. Minerals 2024, 14, 913. https://doi.org/10.3390/min14090913

Rapetsoa M, Manzi M, James I, Sihoyiya M, Durrheim R, Pienaar M. Innovative Seismic Imaging of the Platinum Deposits, Maseve Mine: Surface and In-Mine. Minerals. 2024; 14(9):913. https://doi.org/10.3390/min14090913

Chicago/Turabian StyleRapetsoa, Moyagabo, Musa Manzi, Ian James, Mpofana Sihoyiya, Raymond Durrheim, and Michelle Pienaar. 2024. "Innovative Seismic Imaging of the Platinum Deposits, Maseve Mine: Surface and In-Mine" Minerals 14, no. 9: 913. https://doi.org/10.3390/min14090913