Toward Viable Industrial Solid Residual Waste Recycling: A Review of Its Innovative Applications and Future Perspectives

Abstract

1. Introduction

2. Generation, Types, and Production Amounts of ISRW

2.1. Coal Ashes

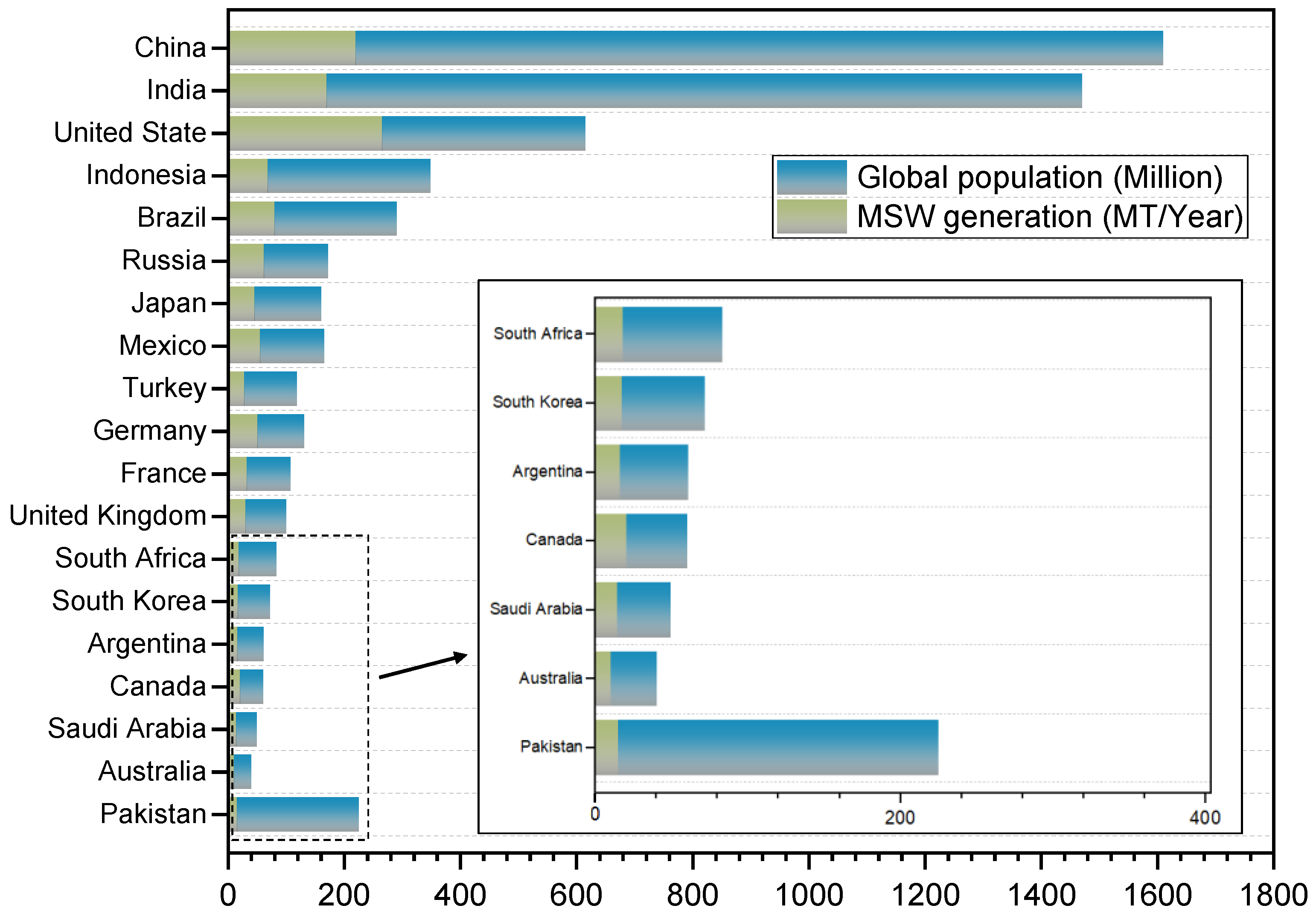

2.2. Municipal Solid Residual Waste (MSRW)

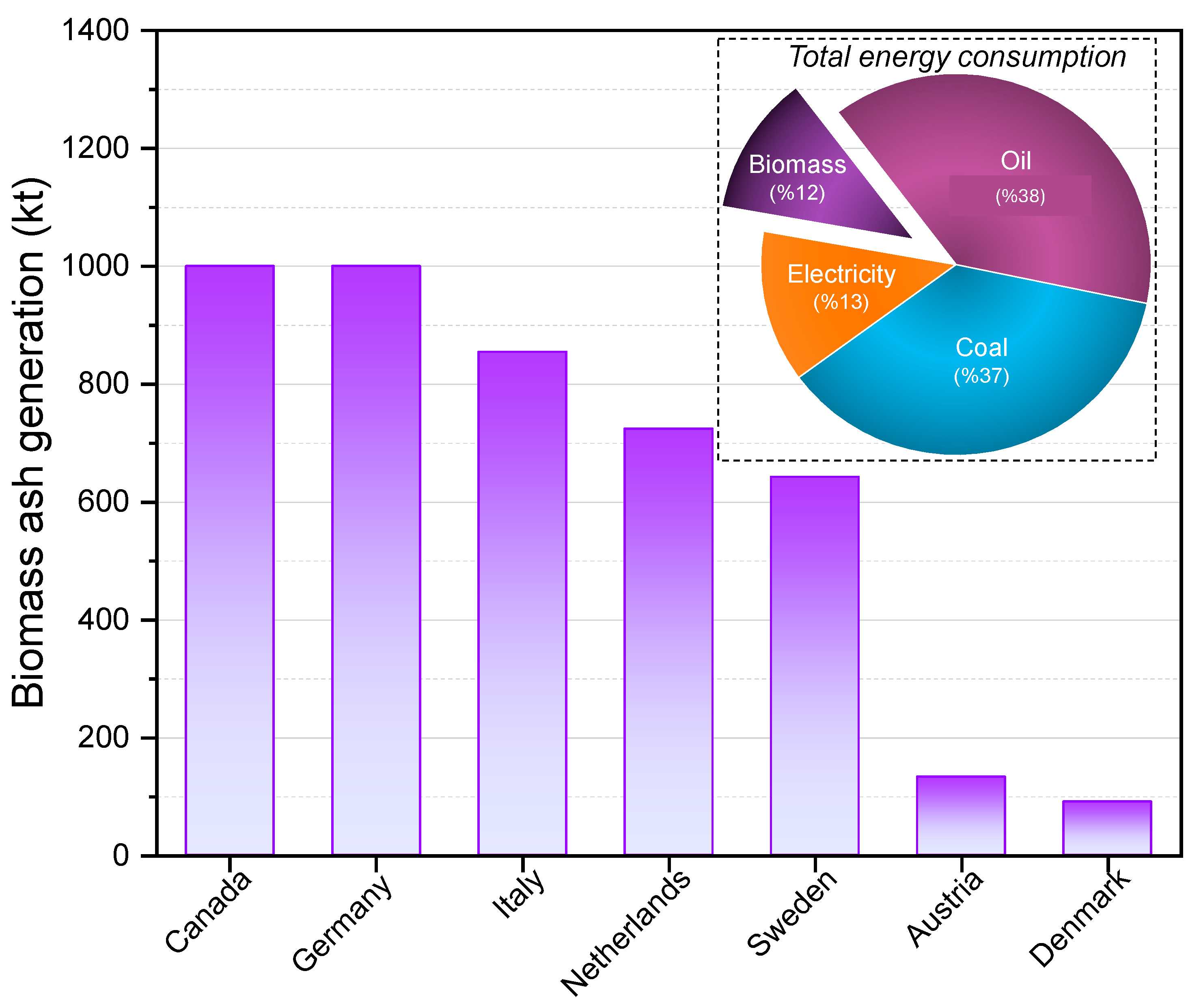

2.3. Biomass Ashes

3. Properties of Industrial Solid Ashes

3.1. Characteristics of C-FA and C-BA

3.2. Characteristics of MSRW-FA and MSRW-BA

3.3. Features of B-FA and B-BA

4. Management of ISRW from Industrial Waste-to-Energy Conversion Processes

4.1. Cement and Concrete Production

4.2. Brick and Ceramic Production

4.3. Road Construction

4.4. Soil Upgrading

5. Advanced Techniques for the Management of Industrial Ashes

6. Legal Regulations for Ash Management

7. Conclusions

- ➢

- Increasing energy demand and consumption induce large amounts of ISRW every year, depending on the type of fuel used and the characteristics of the raw material processed.

- ➢

- ISRWs are notable for their heterogeneous structure and multicomponent organic and inorganic materials. These wastes may contain high levels of oxides and heavy metals, making them potential pollutants. Consequently, many ISWs are classified as hazardous wastes worldwide. Therefore, the comprehensive identification and characterization of ISWs are critical for sustainable management strategies.

- ➢

- ISRWs are widely used in different construction applications, especially in concrete and cement. In addition, due to the rich content and strong physical properties of ISRWs, zeolite is utilized in different fields like adsorbents, glass, and soil improvement.

- ➢

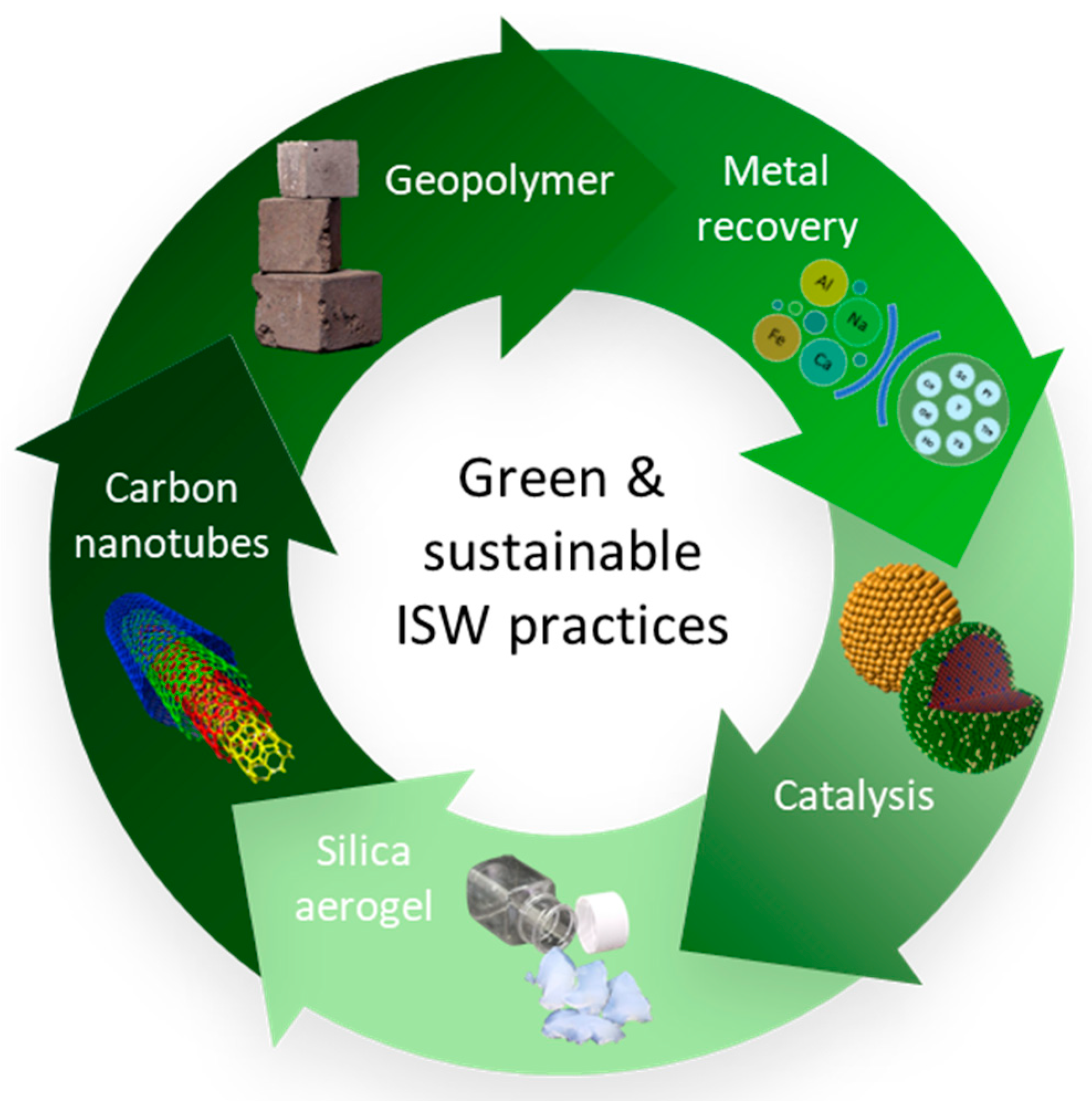

- Today, ISRWs are aimed to be transformed into products with high economic/commercial value compared to traditional methods. For example, ISRWs can be used in different fields such as geopolymers as an innovative and green alternative to cement, aerogel as insulation, and nanotubes as a chemical energy basis.

- ➢

- A multitude of legislation and regulations exist to facilitate the sustainable management of ISRW, though these vary considerably by country/region. The aim of these legislation and regulations is to identify safe management strategies for ISRWs. The efficacy of legislation hinges on the cooperation and implementation rate of ISRW producers, local governments, municipalities, and other relevant organizations.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, X.; Bai, C.; Qiao, Y.; Wang, X.; Yang, K.; Colombo, P. Preparation, properties and applications of fly ash-based porous geopolymers: A review. J. Clean. Prod. 2022, 359, 132043. [Google Scholar] [CrossRef]

- Aktar, M.A.; Alam, M.M.; Al-Amin, A.Q. Global economic crisis, energy use, CO2 emissions, and policy roadmap amid COVID-19. Sustain. Prod. Consum. 2021, 26, 770–781. [Google Scholar] [CrossRef] [PubMed]

- Johnsson, F.; Kjärstad, J.; Rootzén, J. The threat to climate change mitigation posed by the abundance of fossil fuels. Clim. Policy 2019, 19, 258–274. [Google Scholar] [CrossRef]

- Loth, E.; Qin, C.; Simpson, J.G.; Dykes, K. Why we must move beyond LCOE for renewable energy design. Adv. Appl. Energy 2022, 8, 100112. [Google Scholar] [CrossRef]

- Al-Ghouti, M.A.; Khan, M.; Nasser, M.S.; Al-Saad, K.; Heng, O.E. Recent advances and applications of municipal solid wastes bottom and fly ashes: Insights into sustainable management and conservation of resources. Environ. Technol. Innov. 2021, 21, 101267. [Google Scholar] [CrossRef]

- Nie, Y.; Li, J.; Wang, C.; Huang, G.; Fu, J.; Chang, S.; Li, H.; Ma, S.; Yu, L.; Cui, X.; et al. A fine-resolution estimation of the biomass resource potential across China from 2020 to 2100. Resour. Conserv. Recycl. 2022, 176, 105944. [Google Scholar] [CrossRef]

- Faisal, S.; Zaky, A.; Wang, Q.; Huang, J.; Abomohra, A. Integrated marine biogas: A promising approach towards sustainability. Fermentation 2022, 8, 520. [Google Scholar] [CrossRef]

- Sua-Iam, G.; Makul, N. Utilization of coal-and biomass-fired ash in the production of self-consolidating concrete: A literature review. J. Clean. Prod. 2015, 100, 59–76. [Google Scholar] [CrossRef]

- Karmakar, A.; Daftari, T.; Sivagami, K.; Chandan, M.R.; Shaik, A.H.; Kiran, B.; Chakraborty, S. A comprehensive insight into Waste to Energy conversion strategies in India and its associated air pollution hazard. Environ. Technol. Inno. 2023, 29, 103017. [Google Scholar] [CrossRef]

- Sanjuán, M.Á.; Argiz, C. A ten-year study on alkali content of coal fly ash. Fuels 2022, 3, 365–374. [Google Scholar] [CrossRef]

- Cruz, N.C.; Silva, F.C.; Tarelho, L.A.; Rodrigues, S.M. Critical review of key variables affecting potential recycling applications of ash produced at large-scale biomass combustion plants. Resour. Conserv. Recycl. 2019, 150, 104427. [Google Scholar] [CrossRef]

- Zhai, J.; Burke, I.T.; Stewart, D.I. Beneficial management of biomass combustion ashes. Renew. Sustain. Energy Rev. 2021, 151, 111555. [Google Scholar] [CrossRef]

- Kalisz, S.; Kibort, K.; Mioduska, J.; Lieder, M.; Małachowska, A. Waste management in the mining industry of metals ores, coal, oil and natural gas-A review. J. Environ. Manag. 2022, 304, 114239. [Google Scholar] [CrossRef] [PubMed]

- Able, C.; Rellergert, D.; Mazzoni, V.; Grol, E. Assessment of combustion residual leachate volume, composition, and treatment costs. J. Hazard. Mater. 2023, 457, 131731. [Google Scholar] [CrossRef]

- Munawar, M.A.; Khoja, A.H.; Naqvi, S.R.; Mehran, M.T.; Hassan, M.; Liaquat, R.; Dawood, U.F. Challenges and opportunities in biomass ash management and its utilization in novel applications. Renew. Sustain. Energy Rev. 2021, 150, 111451. [Google Scholar] [CrossRef]

- Hoang, A.T.; Varbanov, P.S.; Nižetić, S.; Sirohi, R.; Pandey, A.; Luque, R.; Ng, K.H. Perspective review on Municipal Solid Waste-to-energy route: Characteristics, management strategy, and role in circular economy. J. Clean. Prod. 2022, 359, 131897. [Google Scholar] [CrossRef]

- Voshell, S.; Mäkelä, M.; Dahl, O. A review of biomass ash properties towards treatment and recycling. Renew. Sustain. Energy Rev. 2018, 96, 479–486. [Google Scholar] [CrossRef]

- Wang, N.; Sun, X.; Zhao, Q.; Yang, Y.; Wang, P. Leachability and adverse effects of coal fly ash: A review. J. Hazard. Mater. 2020, 396, 122725. [Google Scholar] [CrossRef]

- Fan, X.; Yuan, R.; Gan, M.; Ji, Z.; Sun, Z. Subcritical hydrothermal treatment of municipal solid waste incineration fly ash: A review. Sci. Total Environ. 2022, 865, 160745. [Google Scholar] [CrossRef]

- Asl, S.M.H.; Ghadi, A.; Baei, M.S.; Javadian, H.; Maghsudi, M.; Kazemian, H. Porous catalysts fabricated from coal fly ash as cost-effective alternatives for industrial applications: A review. Fuel 2018, 217, 320–342. [Google Scholar]

- Zhang, Y.; Wang, L.; Chen, L.; Ma, B.; Zhang, Y.; Ni, W.; Tsang, D.C. Treatment of municipal solid waste incineration fly ash: State-of-the-art technologies and future perspectives. J. Hazard. Mater. 2021, 411, 125132. [Google Scholar] [CrossRef] [PubMed]

- Yao, Z.T.; Ji, X.S.; Sarker, P.K.; Tang, J.H.; Ge, L.Q.; Xia, M.S.; Xi, Y.Q. A comprehensive review on the applications of coal fly ash. Earth-Sci. Rev. 2015, 141, 105–121. [Google Scholar] [CrossRef]

- Bhatt, A.; Priyadarshini, S.; Mohanakrishnan, A.A.; Abri, A.; Sattler, M.; Techapaphawit, S. Physical, chemical, and geotechnical properties of coal fly ash: A global review. Case Stud. Constr. Mater. 2019, 11, e00263. [Google Scholar] [CrossRef]

- Oruji, S.; Brake, N.A.; Guduru, R.K.; Nalluri, L.; Günaydın-Şen, Ö.; Kharel, K.; Saeed, R.; Seyedsaeid, H.; Ingram, E. Mitigation of ASR expansion in concrete using ultra-fine coal bottom ash. Constr. Build. Mater. 2019, 202, 814–824. [Google Scholar] [CrossRef]

- Belviso, C. State-of-the-art applications of fly ash from coal and biomass: A focus on zeolite synthesis processes and issues. Prog. Energy Combust. Sci. 2018, 65, 109–135. [Google Scholar] [CrossRef]

- Das, S.; Gaustad, G.; Sekar, A.; Williams, E. Techno-economic analysis of supercritical extraction of rare earth elements from coal ash. J. Clean. Prod. 2018, 189, 539–551. [Google Scholar] [CrossRef]

- Gollakota, A.R.; Volli, V.; Shu, C.M. Progressive utilisation prospects of coal fly ash: A review. Sci. Total Environ. 2019, 672, 951–989. [Google Scholar] [CrossRef]

- Almeida, C.M.; Ghica, M.E.; Duraes, L. An overview on alumina-silica-based aerogels. Adv. Colloid Interface Sci. 2020, 282, 102189. [Google Scholar] [CrossRef]

- Le Ping, K.K.; Cheah, C.B.; Liew, J.J.; Siddique, R.; Tangchirapat, W.; Johari, M.A.B.M. Coal bottom ash as constituent binder and aggregate replacement in cementitious and geopolymer composites: A review. J. Build. Eng. 2022, 52, 104369. [Google Scholar] [CrossRef]

- Saint Akadiri, S.; Alola, A.A.; Olasehinde-Williams, G.; Etokakpan, M.U. The role of electricity consumption, globalization and economic growth in carbon dioxide emissions and its implications for environmental sustainability targets. Sci. Total Environ. 2020, 708, 134653. [Google Scholar] [CrossRef]

- Ritchie, H.; Rosado, P.; Roser, M. Energy. Published online at OurWorldInData.org. Available online: https://ourworldindata.org/global-energy-200-years (accessed on 31 July 2024).

- Energy Institute. Statistical Review of World Energy, 73rd Edition. Available online: https://www.energyinst.org/statistical-review#regional-overview (accessed on 31 July 2024).

- Heubaum, H.; Biermann, F. Integrating global energy and climate governance: The changing role of the International Energy Agency. Energy Policy 2015, 87, 229–239. [Google Scholar] [CrossRef]

- Alhassan, A.; Ozturk, I.; Al-Zyoud, M.F.; Bekun, F.V. Coal consumption-environmental sustainability nexus in developed and developing major coal-consuming economies. Heliyon 2024, 10, e25619. [Google Scholar] [CrossRef] [PubMed]

- British Petroleum—BP. Statistical Review of World Energy 2022. Available online: http://www.bp.com/ (accessed on 31 July 2024).

- Al-Mulali, U.; Ozturk, I. The investigation of environmental Kuznets curve hypothesis in the advanced economies: The role of energy prices. Renew. Sustain. Energy Rev. 2016, 54, 1622–1631. [Google Scholar] [CrossRef]

- Rafieizonooz, M.; Mirza, J.; Salim, M.R.; Hussin, M.W.; Khankhaje, E. Investigation of coal bottom ash and fly ash in concrete as replacement for sand and cement. Constr. Build. Mater. 2016, 116, 15–24. [Google Scholar] [CrossRef]

- Rafieizonooz, M.; Khankhaje, E.; Rezania, S. Assessment of environmental and chemical properties of coal ashes including fly ash and bottom ash, and coal ash concrete. J. Build. Eng. 2022, 49, 104040. [Google Scholar] [CrossRef]

- Mathapati, M.; Amate, K.; Prasad, C.D.; Jayavardhana, M.L.; Raju, T.H. A review on fly ash utilization. Mater. Today Proc. 2022, 50, 1535–1540. [Google Scholar] [CrossRef]

- Meena, A.; Singh, N.; Singh, S.P. High-volume fly ash self-consolidating concrete with coal bottom ash and recycled concrete aggregates: Fresh, mechanical and microstructural properties. J. Build. Eng. 2023, 63, 105447. [Google Scholar] [CrossRef]

- Darmansyah, D.; You, S.J.; Wang, Y.F. Advancements of coal fly ash and its prospective implications for sustainable materials in Southeast Asian countries: A re-view. Renew. Sustain. Energy Rev. 2023, 188, 113895. [Google Scholar] [CrossRef]

- Valeev, D.; Bobylev, P.; Osokin, N.; Zolotova, I.; Rodionov, I.; Salazar-Concha, C.; Verichev, K. A review of the alumina production from coal fly ash, with a focus in Russia. J. Clean. Prod. 2022, 363, 132360. [Google Scholar] [CrossRef]

- Zierold, K.M.; Odoh, C. A review on fly ash from coal-fired power plants: Chemical composition, regulations, and health evidence. Rev. Environ. Health 2020, 35, 401–418. [Google Scholar] [CrossRef]

- Nsiah-Gyambibi, R.; Sokama-Neuyam, Y.A.; Boakye, P.; Ampomah, W.; Aggrey, W.N.; Wang, S. Valorization of coal fly ash (CFA): A multi-industry review. Int. J. Environ. Sci. Technol. 2023, 20, 12807–12822. [Google Scholar] [CrossRef]

- Naveenkumar, R.; Iyyappan, J.; Pravin, R.; Kadry, S.; Han, J.; Sindhu, R.; Baskar, G. A strategic review on sustainable approaches in municipal solid waste management and energy recovery: Role of artificial intelligence, economic stability and life cycle assessment. Bioresour. Technol. 2023, 379, 129044. [Google Scholar] [CrossRef] [PubMed]

- Kaza, S.; Yao, L.; Bhada-Tata, P.; Van Woerden, F. What a waste 2.0: A global snapshot of solid waste management to 2050. World Bank Publications: Washington, DC, USA, 2018. [Google Scholar]

- Maalouf, A.; Mavropoulos, A. Re-assessing global municipal solid waste generation. Waste Manag. Res. 2023, 41, 936–947. [Google Scholar] [CrossRef] [PubMed]

- Assi, A.; Bilo, F.; Federici, S.; Zacco, A.; Depero, L.E.; Bontempi, E. Bottom ash derived from municipal solid waste and sewage sludge co-incineration: First results about characterization and reuse. Waste Manag. 2020, 116, 147–156. [Google Scholar] [CrossRef] [PubMed]

- Kumar, V.; Garg, N. The chemical and physical origin of incineration ash reactivity in cementitious systems. Resour. Conserv. Recycl. 2022, 177, 106009. [Google Scholar] [CrossRef]

- Šyc, M.; Simon, F.G.; Hykš, J.; Braga, R.; Biganzoli, L.; Costa, G.; Grosso, M. Metal recovery from incineration bottom ash: State-of-the-art and recent developments. J. Hazard. Mater. 2020, 393, 122433. [Google Scholar] [CrossRef]

- Xia, Y.; He, P.; Shao, L.; Zhang, H. Metal distribution characteristic of MSWI bottom ash in view of metal recovery. J. Environ. Sci. 2017, 52, 178–189. [Google Scholar] [CrossRef]

- Saravanan, A.; Kumar, P.S.; Nhung, T.C.; Ramesh, B.; Srinivasan, S.; Rangasamy, G. A review on biological methodologies in municipal solid waste management and landfilling: Resource and energy recovery. Chemosphere 2022, 309, 136630. [Google Scholar] [CrossRef]

- Raja, W.; Brahmbhatt, J. Conversion of municipal solid waste into hydrochar using hydrothermal carbonization. Int. J. Emerg. Technol. Innov. Res. 2021, 8, 593–599. [Google Scholar]

- Natarajan, R.; Al Fazari, F.; Al Saadi, A. Municipal waste water treatment by natural coagulant assisted electrochemical technique-Parametric effects. Environ. Technol. Inno. 2018, 10, 71–77. [Google Scholar] [CrossRef]

- Xiao, S.; Dong, H.; Geng, Y.; Francisco, M.J.; Pan, H.; Wu, F. An overview of the municipal solid waste management modes and innovations in Shanghai, China. Environ. Sci. Pollut. Res. Int. 2020, 27, 29943–29953. [Google Scholar] [CrossRef] [PubMed]

- Xu, J.; Li, R.; Shi, Y.; Deng, Y. Life cycle assessment-based optimization approaches for sustainable disposal of municipal solid waste. Sustain. Cities Soc. 2022, 79, 103665. [Google Scholar] [CrossRef]

- Pandit, A.; Nakagawa, Y.; Timilsina, R.R.; Kotani, K.; Saijo, T. Taking the perspectives of future generations as an effective method for achieving sustainable waste management. Sustain. Prod. Consum. 2021, 27, 1526–1536. [Google Scholar] [CrossRef]

- Lassi, U.; Sarkar, A. Introduction to waste biomass processing and valorization. In Processing of Biomass Waste; Elsevier: Amsterdam, The Netherlands, 2024; Volume 5, pp. 1–8. [Google Scholar]

- International Renewable Energy Agency—IRENA. The Fourth IRENA Policy Talk 2022: Sustainable Bioenergy for the Energy Transition; International Renewable Energy Agency: Masdar City, United Arab Emirates, 2022. [Google Scholar]

- World Bioenergy Association—WBA. Biomass Supply Chains: Harvesting & Collection. Pre-Treatment and Upgrading, Storage, Transportation and Handling; World Bioenergy Association: Stockholm, Sweden, 2018. [Google Scholar]

- World Bioenergy Association—WBA. Global Biomass Potential Towards 2035; World Bioenergy Association: Stockholm, Sweden, 2016. [Google Scholar]

- Żukowski, W.; Jankowski, D.; Wrona, J.; Berkowicz-Płatek, G. Combustion behavior and pollutant emission characteristics of polymers and biomass in a bubbling fluidized bed reactor. Energy 2023, 263, 125953. [Google Scholar] [CrossRef]

- IEA. Bioenergy. Options for Increased Use of Ash from Biomass Combustion and Cofiring. 2018. Available online: https://www.ieabioenergy.com/blog/publications/options-for-increased-use-of-ash-from-biomass-combustion-and-co-firing/ (accessed on 31 July 2024).

- Binal, A.; Bas, B.; Karamut, O.R. Improvement of the strength of Ankara Clay with self-cementing high alkaline fly ash. Procedia Eng. 2016, 161, 374–379. [Google Scholar] [CrossRef][Green Version]

- Ranjbari, M.; Esfandabadi, Z.S.; Quatraro, F.; Vatanparast, H.; Lam, S.S.; Aghbashlo, M.; Tabatabaei, M. Biomass and organic waste potentials towards implementing circular bio-economy platforms: A systematic bibliometric analysis. Fuel 2022, 318, 123585. [Google Scholar] [CrossRef]

- Pintana, P.; Tippayawong, N. Predicting ash deposit tendency in thermal utilization of biomass. Eng. J. 2016, 20, 15–24. [Google Scholar] [CrossRef]

- Shahbaz, M.; Yusup, S.; Al-Ansari, T.; Inayat, A.; Inayat, M.; Zeb, H.; Alnarabiji, M.S. Characterization and reactivity study of coal bottom ash for utilization in biomass gasification as an adsorbent/catalyst for cleaner fuel production. Energy Fuel 2019, 33, 11318–11327. [Google Scholar] [CrossRef]

- Rex, A.; Kitnasamy, D.; Lokuge, W.; Wang, H. Opportunities in Australia to promote the beneficial use of coal combustion products in construction. Addit. Cem. Mater. 2016, 5, 12–18. [Google Scholar]

- Al Biajawi, M.I.; Embong, R.; Muthusamy, K.; Ismail, N.; Obianyo, I.I. Recycled coal bottom ash as sustainable materials for cement replacement in cementitious Composites: A review. Constr. Build. Mater. 2022, 338, 127624. [Google Scholar] [CrossRef]

- Yang, I.H.; Park, J.; Dinh Le, N.; Jung, S. Strength Properties of high-strength concrete containing coal bottom ash as a replacement of aggregates. Adv. Mater. Sci. Eng. 2020, 16, 4246396. [Google Scholar] [CrossRef]

- Sanjuán, M.Á. Coal bottom ash natural radioactivity in building materials. Adv. Toxic. Constr. Build. 2022, 6, 207–224. [Google Scholar]

- ASTM, C618-17; Standard Specification for Coal Fly Ash and Raw or Calcined Natural Pozzolan for Use in Concrete. ASTM International: West Conshohocken, PA, USA, 2012.

- Hanjitsuwan, S.; Phoo-ngernkham, T.; Damrongwiriyanupap, N. Comparative study using Portland cement and calcium carbide residue as a promoter in bottom ash geopolymer mortar. Constr. Build. Mater. 2017, 133, 128–134. [Google Scholar] [CrossRef]

- Abdullah, M.J.; Beddu, S.; Abd Manan, T.S.B.; Syamsir, A.; Naganathan, S.; Kamal, N.L.M.; Rasdi, N.W. The strength and thermal properties of concrete containing water absorptive aggregate from well-graded bottom ash (BA) as partial sand replacement. Constr. Build. Mater. 2022, 339, 127658. [Google Scholar] [CrossRef]

- Onaizi, A.M.; Tang, W.; Amran, M.; Liu, Y.; Sajjad, U.; Alhassan, M. Towards increased adoption of furnace bottom ash as sustainable building materials: Characterization, standardization, and applications. J. Build. Eng. 2023, 82, 108274. [Google Scholar] [CrossRef]

- Muthusamy, K.; Rasid, M.H.; Jokhio, G.A.; Budiea, A.M.A.; Hussin, M.W.; Mirza, J. Coal bottom ash as sand replacement in concrete: A review. Constr. Build. Mater. 2020, 236, 117507. [Google Scholar] [CrossRef]

- Mukherjee, A.B.; Zevenhoven, R.; Bhattacharya, P.; Sajwan, K.S.; Kikuchi, R. Mercury flow via coal and coal utilization by-products: A global perspective. Resour. Conserv. Recycl. 2008, 52, 571–591. [Google Scholar] [CrossRef]

- Lin, K.L.; Lin, W.T.; Chen, S.C.; Sprince, A. Study on the cementation and engineering properties of ternary eco-binder mortar containing pulverized coal fly ash mixed with circulating fluidized bed co-fired fly ash. J CO2 Util. 2024, 83, 102787. [Google Scholar] [CrossRef]

- Pandian, N.S. Fly ash characterization with reference to geotechnical applications. J. Indian Inst. Sci. 2004, 84, 189. [Google Scholar]

- Amran, M.; Fediuk, R.; Murali, G.; Avudaiappan, S.; Ozbakkaloglu, T.; Vatin, N.; Karelina, M.; Klyuev, S.; Gholampour, A. Fly ash-based eco-efficient concretes: A comprehensive review of the short-term properties. Materials 2021, 14, 4264. [Google Scholar] [CrossRef]

- Gao, K.; Iliuta, M.C. Trends and advances in the development of coal fly ash-based materials for application in hydrogen-rich gas production: A review. J. Energy Chem. 2022, 73, 485–512. [Google Scholar] [CrossRef]

- Dou, X.; Ren, F.; Nguyen, M.Q.; Ahamed, A.; Yin, K.; Chan, W.P.; Chang, V.W.C. Review of MSWI bottom ash utilization from perspectives of collective characterization, treatment and existing application. Renew. Sustain. Energy Rev. 2017, 79, 24–38. [Google Scholar] [CrossRef]

- Dhir, R.K.; De Brito, J.; Lynn, C.J.; Silva, R.V. Chapter 3—Municipal solid waste composition, incineration, processing and management of bottom ashes. Sustain. Constr. Mater. 2018, 5, 31–90. [Google Scholar]

- Bernasconi, D.; Caviglia, C.; Destefanis, E.; Agostino, A.; Boero, R.; Marinoni, N.; Pavese, A. Influence of speciation distribution and particle size on heavy metal leaching from MSWI fly ash. Waste Manag. 2022, 138, 318–327. [Google Scholar] [CrossRef] [PubMed]

- Cristelo, N.; Segadães, L.; Coelho, J.; Chaves, B.; Sousa, N.R.; de Lurdes Lopes, M. Recycling municipal solid waste incineration slag and fly ash as precursors in low-range alkaline cements. Waste Manag. 2020, 104, 60–73. [Google Scholar] [CrossRef] [PubMed]

- Gao, X.; Yuan, B.; Yu, Q.L.; Brouwers, H.J.H. Characterization and application of municipal solid waste incineration (MSWI) bottom ash and waste granite powder in alkali activated slag. J. Clean. Prod. 2017, 164, 410–419. [Google Scholar] [CrossRef]

- Tsydenova, O.; Bengtsson, M. Chemical hazards associated with treatment of waste electrical and electronic equipment. Waste Manag. 2011, 31, 45–58. [Google Scholar] [CrossRef]

- Themelis, N.J.; Kim, Y.H. Material and energy balances in a large-scale aerobic bioconversion cell. Waste Manag. Res. 2002, 20, 234–242. [Google Scholar] [CrossRef]

- Wang, K.; Tester, J.W. Sustainable management of unavoidable biomass wastes. Green Energy Resour. 2023, 1, 100005. [Google Scholar] [CrossRef]

- Agrela, F.; Cabrera, M.; Morales, M.M.; Zamorano, M.; Alshaaer, M. Biomass fly ash and biomass bottom ash. In New Trends in Eco-Efficient and Recycled Concrete; Elsevier: Amsterdam, The Netherlands, 2019; Volume 3, pp. 23–58. [Google Scholar]

- Odzijewicz, J.I.; Wołejko, E.; Wydro, U.; Wasil, M.; Jabłońska-Trypuć, A. Utilization of ashes from biomass combustion. Energies 2022, 15, 9653. [Google Scholar] [CrossRef]

- da Costa, T.P.; Quinteiro, P.; Tarelho, L.A.; Arroja, L.; Dias, A.C. Life cycle assessment of woody biomass ash for soil amelioration. Waste Manag. 2020, 101, 126–140. [Google Scholar] [CrossRef] [PubMed]

- Vassilev, S.V.; Baxter, D.; Andersen, L.K.; Vassileva, C.G. An overview of the composition and application of biomass ash. Part 1. Phase–mineral and chemical composition and classification. Fuel 2013, 105, 40–76. [Google Scholar] [CrossRef]

- Modolo, R.E.; Silva, T.; Senff, L.; Tarelho, L.A.C.; Labrincha, J.A.; Ferreira, V.M.; Silva, L. Bottom ash from biomass combustion in BFB and its use in adhesive-mortars. Fuel Proces. Technol. 2015, 129, 192–202. [Google Scholar] [CrossRef]

- Sklivaniti, V.; Tsakiridis, P.E.; Katsiotis, N.S.; Velissariou, D.; Pistofidis, N.; Papageorgiou, D.; Beazi, M. Valorisation of woody biomass bottom ash in Portland cement: A characterization and hydration study. J. Environ. Chem. Eng. 2017, 5, 205–213. [Google Scholar] [CrossRef]

- Vamvuka, D.; Kakaras, E. Ash properties and environmental impact of various biomass and coal fuels and their blends. Fuel Proces. Technol. 2011, 92, 570–581. [Google Scholar] [CrossRef]

- European Biomass Industry Association. EUBIA. Biomass Ash Characteristics and Utilization; European Biomass Industry Association: Brussels, Belgium, 2024. [Google Scholar]

- Chen, B.; Perumal, P.; Illikainen, M.; Ye, G. A review on the utilization of municipal solid waste incineration (MSWI) bottom ash as a mineral resource for construction materials. J. Build. Eng. 2023, 71, 106386. [Google Scholar] [CrossRef]

- Wang, C.; Xu, G.; Gu, X.; Gao, Y.; Zhao, P. High value-added applications of coal fly ash in the form of porous materials: A review. Ceram. Int. 2021, 47, 22302–22315. [Google Scholar] [CrossRef]

- Ukwattage, N.L.; Ranjith, P.G.; Bouazza, M. The use of coal combustion fly ash as a soil amendment in agricultural lands (with comments on its potential to improve food security and sequester carbon. Fuel 2013, 109, 400–408. [Google Scholar] [CrossRef]

- Silva, F.C.; Cruz, N.C.; Tarelho, L.A.; Rodrigues, S.M. Use of biomass ash-based materials as soil fertilisers: Critical review of the existing regulatory framework. J. Clean. Prod. 2019, 214, 112–124. [Google Scholar] [CrossRef]

- Jamalimoghadam, M.; Vakili, A.H.; Keskin, I.; Totonchi, A.; Bahmyari, H. Solidification and utilization of municipal solid waste incineration ashes: Advancements in alkali-activated materials and stabilization techniques, a review. J. Environ. Manag. 2024, 367, 122014. [Google Scholar] [CrossRef]

- Zhang, Z.; Zhao, C.; Rao, Y.; Yu, C.; Luo, Z.; Zhao, H.; Wang, X.; Wu, C.; Wang, Q. Solidification/stabilization and risk assessment of heavy metals in municipal solid waste incineration fly ash: A review. Sci. Total Environ. 2023, 892, 164451. [Google Scholar] [CrossRef] [PubMed]

- Chen, D.; Zhang, Y.; Xu, Y.; Nie, Q.; Yang, Z.; Sheng, W.; Qian, G. Municipal solid waste incineration residues recycled for typical construction materials—A review. RSC Adv. 2022, 12, 6279–6291. [Google Scholar] [CrossRef] [PubMed]

- Olatoyan, O.J.; Kareem, M.A.; Adebanjo, A.U.; Olawale, S.O.A.; Alao, K.T. Potential use of biomass ash as a sustainable alternative for fly ash in concrete production: A review. Hybrid Adv. 2023, 4, 100076. [Google Scholar] [CrossRef]

- Liu, Z.; Deng, P.; Zhang, Z. Application of silica-rich biomass ash solid waste in geopolymer preparation: A review. Constr. Build. Mater. 2022, 356, 129142. [Google Scholar] [CrossRef]

- Razzak, S.A. Municipal solid and plastic waste derived high-performance biochar production: A comprehensive review. J. Anal. Appl. Pyrol. 2024, 15, 106622. [Google Scholar] [CrossRef]

- Khaobang, C.; Kathongthung, N.; Phitsuwan, P.; Sitthichirachat, P.; Wibowo, H.; Areeprasert, C. In-situ adsorptive pyrolysis of e-waste using coal and rice husk fly ash as alternative adsorbents for energy and precious metal recovery by solvent extraction. J. Anal. Appl. Pyrol. 2024, 179, 106465. [Google Scholar] [CrossRef]

- Salahshoor, S.; Afzal, S. Subsurface technologies for hydrogen production from fossil fuel resources: A review and techno-economic analysis. Int. J. Hydrogen Energy 2022, in press. [CrossRef]

- Sánchez, A.S.; Junior, E.P.; Gontijo, B.M.; de Jong, P.; dos Reis Nogueira, I.B. Replacing fossil fuels with renewable energy in islands of high ecological value: The cases of Galápagos, Fernando de Noronha, and Príncipe. Renew. Sustain. Energy Rev. 2023, 183, 113527. [Google Scholar] [CrossRef]

- Liu, Y.; Huang, Y. Assessing the interrelationship between fossil fuels resources and the biomass energy market for achieving a sustainable and green economy. Resour. Policy 2024, 88, 104397. [Google Scholar] [CrossRef]

- Arifin, M.H.; Kayode, J.S.; Ismail, M.K.I.; Abdullah, A.M.; Embrandiri, A.; Nazer, N.S.M.; Azmi, A. Environmental hazard assessment of industrial and municipal waste materials with the applications of RES2-D method and 3-D Oasis Montaj modeling: A case study at Kepong, Kuala Lumpur, Peninsula Malaysia. J. Hazard. Mater. 2021, 406, 124282. [Google Scholar] [CrossRef]

- Chowdhury, A.; Naz, A.; Chowdhury, A. Waste to resource: Applicability of fly ash as landfill geoliner to control ground water pollution. Mater. Today Proc. 2022, 60, 8–13. [Google Scholar] [CrossRef]

- Srivastava, R.R.; Rajak, D.K.; Ilyas, S.; Kim, H.; Pathak, P. Challenges, regulations, and case studies on sustainable management of industrial waste. Minerals 2022, 13, 51. [Google Scholar] [CrossRef]

- He, D.; Hu, H.; Jiao, F.; Zuo, W.; Liu, C.; Xie, H.; Wang, X. Thermal separation of heavy metals from municipal solid waste incineration fly ash: A review. Chem. Eng. J. 2023, 467, 143344. [Google Scholar] [CrossRef]

- Ahmaruzzaman, M.A. Review on the utilization of fly ash. Prog. Energy Combust. Sci. 2010, 36, 327–363. [Google Scholar] [CrossRef]

- Gartner, E. Industrially interesting approaches to low CO2 cements. Cem. Concr. Res. 2004, 34, 1489–1498. [Google Scholar] [CrossRef]

- Behera, S.K.; Mishra, D.P.; Singh, P.; Mishra, K.; Mandal, S.K.; Ghosh, C.N.; Kumar, R.; Mandal, P.K. Utilization of mill tailings, fly ash and slag as mine paste backfill material: Review and future perspective. Constr. Build. Mater. 2021, 309, 125120. [Google Scholar] [CrossRef]

- Sari, M.; Yilmaz, E.; Kasap, T.; Guner, N.U. Strength and microstructure evolution in cemented mine backfill with low and high pH pyritic tailings: Effect of mineral admixtures. Constr. Build. Mater. 2022, 328, 127109. [Google Scholar] [CrossRef]

- Fan, Y.; Zhao, Q.; Wang, D. Comparing Permeability and drying shrinkage of the concrete containing mineral admixtures under the equal strength grade. Minerals 2022, 12, 1477. [Google Scholar] [CrossRef]

- Li, Z.; Zhao, J.; Qiu, X. Recycling of coal gasification fine ash as a cement cleaning substitute: Performance, microstructure, and sustainability assessment of blended cement. J. Clean. Prod. 2024, 465, 142756. [Google Scholar] [CrossRef]

- Bocullo, V.; Vaičiukynienė, D.; Gečys, R.; Daukšys, M. Effect of ordinary Portland cement and water glass on the properties of alkali activated fly ash concrete. Minerals 2019, 10, 40. [Google Scholar] [CrossRef]

- Sun, Q.; Cai, C.; Zhang, S.; Tian, S.; Li, B.; Xia, Y.; Sun, Q. Study of localized deformation in geopolymer cemented coal gangue-fly ash backfill based on the digital speckle correlation method. Constr. Build. Mater. 2019, 215, 321–331. [Google Scholar] [CrossRef]

- Kim, J.E.; Seo, J.; Yang, K.H.; Kim, H.K. Cost and CO2 emission of concrete incorporating pretreated coal bottom ash as fine aggregate: A case study. Constr. Build. Mater. 2023, 408, 133706. [Google Scholar] [CrossRef]

- Gouda, K.N.; Babu, V. Utilizing coal ash as partial replacement in place of cement to produce concrete. Mater. Today Proc. 2023, in press. [CrossRef]

- Chindasiriphan, P.; Meenyut, B.; Orasutthikul, S.; Jongvivatsakul, P.; Tangchirapat, W. Influences of high-volume coal bottom ash as cement and fine aggregate replacements on strength and heat evolution of eco-friendly high-strength concrete. J. Build. Eng. 2023, 65, 105791. [Google Scholar] [CrossRef]

- Falaciński, P.; Szarek, Ł. Potential use of municipal waste incineration ash as a hardening slurry ingredient. Minerals 2022, 12, 655. [Google Scholar] [CrossRef]

- Weiksnar, K.D.; Marks, E.J.; Deaderick, M.J.; Meija-Ruiz, I.; Ferraro, C.C.; Townsend, T.G. Impacts of advanced metals recovery on municipal solid waste incineration bottom ash: Aggregate characteristics and performance in Portland limestone cement concrete. Waste Manag. 2024, 187, 70–78. [Google Scholar] [CrossRef]

- Sun, X.; Li, J.; Zhao, X.; Zhu, B.; Zhang, G. A review on the management of municipal solid waste fly ash in American. Procedia Environ. Sci. 2016, 31, 535–540. [Google Scholar] [CrossRef]

- Simões, J.R.; Silva, P.R.D.; Silva, R.V. Binary mixes of self-compacting concrete with municipal solid waste incinerator bottom ash. Appl. Sci. 2021, 11, 6396. [Google Scholar] [CrossRef]

- Danish, A.; Karadag, O.; Bilir, T.; Ozbakkaloglu, T. Valorization of biomass ashes in the production of cementitious composites: A comprehensive review of properties and performance. Constr. Build. Mater. 2023, 405, 133244. [Google Scholar] [CrossRef]

- Liu, B.; Wang, S.; Jia, W.; Ying, H.; Lu, Z.; Hong, Z. The Effect of RHA as a supplementary cementitious material on the performance of PCM aggregate concrete. Buildings 2024, 14, 2150. [Google Scholar] [CrossRef]

- Ranatunga, K.S.; del Rey Castillo, E.; Toma, C.L. Evaluation of the optimal concrete mix design with coconut shell ash as a partial cement replacement. Constr. Build. Mater. 2023, 401, 132978. [Google Scholar] [CrossRef]

- Du, Y.; Pundienė, I.; Pranckevičienė, J.; Kligys, M.; Girskas, G.; Korjakins, A. A review of biomass wood ash in alkali-activated materials: Treatment, application, and outlook. J. Compos. Sci. 2024, 8, 161. [Google Scholar] [CrossRef]

- Muthusamy, K.; Rasid, M.H.; Isa, N.N.; Hamdan, N.H.; Jamil, N.A.S.; Budiea, A.M.A.; Ahmad, S.W. Mechanical properties and acid resistance of oil palm shell lightweight aggregate concrete containing coal bottom ash. Mater. Today Proc. 2021, 41, 47–50. [Google Scholar] [CrossRef]

- Mukhtar, A.; Qazi, A.U.; Khan, Q.S.; Munir, M.J.; Kazmi, S.M.S.; Hameed, A. Feasibility of using coal ash for the production of sustainable bricks. Sustainability 2022, 14, 6692. [Google Scholar] [CrossRef]

- Abbas, S.; Hameed, R.; Baig, M.A.; Kashif, M.; Shaukat, S. Mechanical performance of coal ash based interlocking bricks wall panel: A sustainable and viable solution. J. Build. Eng. 2024, 95, 110288. [Google Scholar] [CrossRef]

- Eliche-Quesada, D.; Sandalio-Pérez, J.A.; Martínez-Martínez, S.; Pérez-Villarejo, L.; Sánchez-Soto, P.J. Investigation of use of coal fly ash in eco-friendly construction materials: Fired clay bricks and silica-calcareous non fired bricks. Ceram. Int. 2018, 44, 4400–4412. [Google Scholar] [CrossRef]

- Pandey, V.; Panda, S.K.; Singh, V.K. Preparation and characterization of high-strength insulating porous bricks by reusing coal mine overburden waste, red mud and rice husk. J. Clean. Prod. 2024, 469, 143134. [Google Scholar] [CrossRef]

- Otitoju, T.A.; Okoye, P.U.; Chen, G.; Li, Y.; Okoye, M.O.; Li, S. Advanced ceramic components: Materials, fabrication, and applications. J. Ind. Eng. Chem. 2020, 85, 34–65. [Google Scholar] [CrossRef]

- Valderrama, D.M.A.; Cuaspud, J.A.G.; Taniolo, N.; Boccaccini, A.R. Glass-ceramic materials obtained by sintering of vitreous powders from industrial waste: Production and properties. Constr. Mater. 2021, 1, 63–79. [Google Scholar] [CrossRef]

- Luo, Y.; Ma, S.; Liu, C.; Zhao, Z.; Zheng, S.; Wang, X. Effect of particle size and alkali activation on coal fly ash and their role in sintered ceramic tiles. J. Eur. Ceram. Soc. 2017, 37, 1847–1856. [Google Scholar] [CrossRef]

- Xing, J.; Tang, Q.; Gan, M.; Ji, Z.; Fan, X.; Sun, Z.; Chen, X.; Jing, Q. Preparation of glass ceramic by low-temperature melting of municipal solid waste incineration fly ash and municipal sludge. Mater. Lett. 2024, 359, 135962. [Google Scholar] [CrossRef]

- Kim, K.; Kim, K.; Kim, M. Characterization of municipal solid-waste incinerator fly ash, vitrified using only end-waste glass. J. Clean. Prod. 2021, 318, 128557. [Google Scholar] [CrossRef]

- Wang, Y.; Huang, X.; Wang, W.; Wu, T. The distribution pattern and leaching toxicity of heavy metals in glass ceramics from MSWI fly ash and andesite tailings. Toxics 2022, 10, 774. [Google Scholar] [CrossRef] [PubMed]

- Kazmi, S.M.; Abbas, S.; Saleem, M.A.; Munir, M.J.; Khitab, A. Manufacturing of sustainable clay bricks: Utilization of waste sugarcane bagasse and rice husk ashes. Constr. Build. Mater. 2016, 120, 29–41. [Google Scholar] [CrossRef]

- Carrasco, B.; Cruz, N.; Terrados, J.; Corpas, F.A.; Pérez, L. An evaluation of bottom ash from plant biomass as a replacement for cement in building blocks. Fuel 2014, 118, 272–280. [Google Scholar] [CrossRef]

- Terrones-Saeta, J.M.; Suárez-Macías, J.; Iglesias-Godino, F.J.; Corpas-Iglesias, F.A. Study of the incorporation of biomass bottom ashes in ceramic materials for the manufacture of bricks and evaluation of their leachates. Materials 2020, 13, 2099. [Google Scholar] [CrossRef]

- Buritatum, A.; Suddeepong, A.; Horpibulsuk, S.; Akkharawongwhatthana, K.; Yaowarat, T.; Hoy, M.; Arulrajah, A. Improved performance of asphalt concretes using bottom ash as an alternative aggregate. Sustainability 2022, 14, 7033. [Google Scholar] [CrossRef]

- Ohenoja, K.; Pesonen, J.; Yliniemi, J.; Illikainen, M. Utilization of fly ashes from fluidized bed combustion: A review. Sustainability 2020, 12, 2988. [Google Scholar] [CrossRef]

- Yoo, B.S.; Park, D.W.; Vo, H.V. Evaluation of asphalt mixture containing coal ash. Transp. Res. Procedia 2016, 14, 797–803. [Google Scholar] [CrossRef]

- Vaitkus, A.; Škulteckė, J.; Šernas, O. A test road with unbound base and sub-base course from MSWI bottom ash mixtures. Buildings 2023, 13, 1311. [Google Scholar] [CrossRef]

- Ascher, S.; Watson, I.; Wang, X.; You, S. Township-based bioenergy systems for distributed energy supply and efficient household waste re-utilisation: Techno-economic and environmental feasibility. Energy 2019, 181, 455–467. [Google Scholar] [CrossRef]

- Ding, Y.; Xi, Y.; Gao, H.; Wang, J.; Wei, W.; Zhang, R. Porosity of municipal solid waste incinerator bottom ash effects on asphalt mixture performance. J. Clean. Prod. 2022, 369, 133344. [Google Scholar] [CrossRef]

- Tahami, S.A.; Arabani, M.; Mirhosseini, A.F. Usage of two biomass ashes as filler in hot mix asphalt. Constr. Build. Mater. 2018, 170, 547–556. [Google Scholar] [CrossRef]

- Xue, Y.; Wu, S.; Cai, J.; Zhou, M.; Zha, J. Effects of two biomass ashes on asphalt binder: Dynamic shear rheological characteristic analysis. Constr. Build. Mater. 2014, 56, 7–15. [Google Scholar] [CrossRef]

- Turan, C.; Javadi, A.A.; Vinai, R.; Beig Zali, R. Geotechnical characteristics of fine-grained soils stabilized with fly ash, a review. Sustainability 2022, 14, 16710. [Google Scholar] [CrossRef]

- Ahmad, S.; Ghazi, M.S.A.; Syed, M.; Al-Osta, M.A. Utilization of fly ash with and without secondary additives for stabilizing expansive soils: A review. Res. Eng. 2024, 22, 102079. [Google Scholar] [CrossRef]

- Masto, R.E.; Sengupta, T.; George, J.; Ram, L.C.; Sunar, K.K.; Selvi, V.A.; Sinha, A.K. The impact of fly ash amendment on soil carbon. Energy Sour. Part A Rec. Util. Environ. Eff. 2014, 36, 554–562. [Google Scholar] [CrossRef]

- Liang, S.; Chen, J.; Guo, M.; Feng, D.; Liu, L.; Qi, T. Utilization of pretreated municipal solid waste incineration fly ash for cement-stabilized soil. Waste Manag. 2020, 105, 425–432. [Google Scholar] [CrossRef]

- Pocienė, O.; Šlinkšienė, R. Buckwheat husks, ash and biomass for sustainable plant fertilization and soil improvement. Proceedings 2023, 92, 53. [Google Scholar] [CrossRef]

- Wang, S.; Liu, B.; Zhang, Q.; Wen, Q.; Lu, X.; Xiao, K.; Zhang, S. Application of geopolymers for treatment of industrial solid waste containing heavy metals: State-of-the-art review. J. Clean. Prod. 2023, 390, 136053. [Google Scholar] [CrossRef]

- Amran, Y.M.; Alyousef, R.; Alabduljabbar, H.; El-Zeadani, M. Clean production and properties of geopolymer concrete; A review. J. Clean. Prod. 2020, 251, 119679. [Google Scholar] [CrossRef]

- Madirisha, M.M.; Dada, O.R.; Ikotun, B.D. Chemical Fundamentals of Geopolymers in Sustainable Construction. Mater. Today Sustain. 2024, 15, 100842. [Google Scholar] [CrossRef]

- You, S.; Ho, S.W.; Li, T.; Maneerung, T.; Wang, C.H. Techno-economic analysis of geopolymer production from the coal fly ash with high iron oxide and calcium oxide contents. J. Hazard. Mater. 2019, 361, 237–244. [Google Scholar] [CrossRef] [PubMed]

- Shehata, N.; Sayed, E.T.; Abdelkareem, M.A. Recent progress in envi-ronmentally friendly geopolymers: A review. Sci. Total Environ. 2021, 762, 143166. [Google Scholar] [CrossRef] [PubMed]

- Reddy, M.Y.; Harihanandh, M. Experimental studies on strength and durability of alkali activated slag and coal bottom ash based geopolymer concrete. Mater. Today Proc. 2023; in press. [Google Scholar]

- Yatsenko, E.A.; Trofimov, S.V.; Goltsman, B.M.; Li, W.; Smoliy, V.A.; Ryabova, A.V.; Izvarin, A.I. Study on the curing and foaming of surfactant-modified geopolymer gels based on ash and slag waste from coal combustion. Gels 2023, 10, 19. [Google Scholar] [CrossRef]

- Davidovits, J. Geopolymer Chemistry and Application, 3rd ed.; Institute Geopolymer: Saint-Quentin, France, 2011; ISBN 9782951482050. [Google Scholar]

- Kumar, S.; Kumar, R. Mechanical activation of fly ash: Effect on reaction, structure and properties of resulting geopolymer. Ceram. Int. 2011, 37, 533–541. [Google Scholar] [CrossRef]

- Szabó, R.; Mucsi, G. Effect of SiO2, Al2O3 and Na2O content and fly ash fineness on the structure and mechanical properties of fly ash based geopolymer. Recycl. Sustain. Dev. 2019, 12, 61–68. [Google Scholar] [CrossRef]

- Mucsi, G.; Kumar, S.; Csőke, B.; Kumar, R.; Molnár, Z.; Rácz, Á.; Debreczeni, Á. Control of geopolymer properties by grinding of land filled fly ash. Int. J. Miner. Process. 2015, 143, 50–58. [Google Scholar] [CrossRef]

- Lan, T.; Meng, Y.; Ju, T.; Chen, Z.; Du, Y.; Deng, Y.; Jiang, J. Synthesis and application of geopolymers from municipal waste incineration fly ash (MSWI FA) as raw ingredient-A review. Resour. Conserv. Recycl. 2022, 182, 106308. [Google Scholar] [CrossRef]

- Lu, N.; Ran, X.; Pan, Z.; Korayem, A.H. Use of municipal solid waste incineration fly ash in geopolymer masonry mortar manufacturing. Materials 2022, 15, 8689. [Google Scholar] [CrossRef] [PubMed]

- Liang, D.; Yan, J.; Wang, F.; Lv, G. The long-term leaching behavior of heavy metals in geopolymers and Portland cement bricks containing MSWI fly ash: A comparative study. J. Environ. Chem. Eng. 2024, 12, 112894. [Google Scholar] [CrossRef]

- Hossain, S.S.; Roy, P.K.; Bae, C.J. Utilization of waste rice husk ash for sustainable geopolymer: A review. Constr. Build. Mater. 2021, 310, 125218. [Google Scholar] [CrossRef]

- Oti, J.; Adeleke, B.O.; Mudiyanselage, P.R.; Kinuthia, J. A comprehensive performance evaluation of GGBS-based geopolymer concrete activated by a rice husk ash-synthesized sodium silicate solution and sodium hydroxide. Recycling 2024, 9, 23. [Google Scholar] [CrossRef]

- Huseien, G.F.; Hussein, Z.J.; Kubba, Z.; Mikhail Nikolaevich, B.; Mirza, J. Improved bond strength performance of geopolymer mortars: Role of high volume ground blast furnace slag, fly ash, and palm oil fuel ash incorporation. Minerals 2023, 13, 1096. [Google Scholar] [CrossRef]

- Hamada, H.M.; Jokhio, G.A.; Yahaya, F.M.; Humada, A.M.; Gul, Y. The present state of the use of palm oil fuel ash (POFA) in concrete. Constr. Build. Mater. 2018, 175, 26–40. [Google Scholar] [CrossRef]

- European Commission—EC. European Commission Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability 1; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Thomas, B.S.; Dimitriadis, P.; Kundu, C.; Vuppaladadiyam, S.S.V.; Raman, R.S.; Bhattacharya, S. Extraction and Separation of Rare Earth Elements from coal and coal fly ash: A review on fundamental understanding and on-going engineering advancements. J. Environ. Chem. Eng. 2024, 15, 112769. [Google Scholar] [CrossRef]

- Grabias-Blicharz, E.; Franus, W. A Critical review on mechanochemical processing of fly ash and fly ash-derived materials. Sci. Total Environ. 2023, 860, 160529. [Google Scholar] [CrossRef]

- Vassilev, S.V.; Vassileva, C.G. Contents and associations of rare earth elements and yttrium in biomass ashes. Fuel 2020, 262, 116525. [Google Scholar] [CrossRef]

- Yesenchak, R.; Sharma, S.; Maxwell, A.E. Modes of occurrence, elemental relationships, and economic viability of rare earth elements in west virginia coals: A statistical approach. Minerals 2022, 12, 1060. [Google Scholar] [CrossRef]

- Mehr, J.; Haupt, M.; Skutan, S.; Morf, L.; Adrianto, L.R.; Weibel, G.; Hellweg, S. The environmental performance of enhanced metal recovery from dry municipal solid waste incineration bottom ash. Waste Manag. 2021, 119, 330–341. [Google Scholar] [CrossRef] [PubMed]

- Funari, V.; Ghani, J.; Mantovani, L. Resource recovery from municipal solid waste incineration bottom ash. In Treatment and Utilization of Combustion and Incineration Residues; Elsevier: Amsterdam, The Netherlands, 2024; Volume 3, pp. 511–531. [Google Scholar]

- Li, S.; Ji, B.; Zhang, W. A review on the thermochemical treatments of biomass: Implications for hydrochar production and rare earth element recovery from hyperaccumulators. Chemosphere 2023, 342, 140140. [Google Scholar] [CrossRef] [PubMed]

- Perämäki, S.E.; Tiihonen, A.J.; Väisänen, A.O. Occurrence and recovery potential of rare earth elements in Finnish peat and biomass combustion fly ash. J. Geochem. Explor. 2019, 201, 71–78. [Google Scholar] [CrossRef]

- Boruah, J.S.; Chowdhury, D. Advances in carbon nanomaterial–clay nanocomposites for diverse applications. Minerals 2022, 13, 26. [Google Scholar] [CrossRef]

- Magrez, A.; Seo, J.W.; Smajda, R.; Mionić, M.; Forró, L. Catalytic CVD synthesis of carbon nanotubes: Towards high yield and low temperature growth. Materials 2010, 3, 4871–4891. [Google Scholar] [CrossRef]

- Dhore, V.G.; Rathod, W.S.; Patil, K.N. Synthesis and characterization of high yield multiwalled carbon nanotubes by ternary catalyst. Mater. Today Proc. 2018, 5, 3432–3437. [Google Scholar] [CrossRef]

- Ayeleru, O.O.; Dlova, S.; Akinribide, O.J.; Ntuli, F.; Kupolati, W.K.; Marina, P.F.; Blencowe, A.; Olubambi, P.A. Challenges of plastic waste generation and management in sub-Saharan Africa: A review. Waste Manag. 2020, 110, 24–42. [Google Scholar] [CrossRef]

- Makgabutlane, B.; Maubane-Nkadimeng, M.S.; Coville, N.J.; Mhlanga, S.D. Plastic-fly ash waste composites reinforced with carbon nanotubes for sustainable building and construction applications: A review. Results Chem. 2022, 4, 100405. [Google Scholar] [CrossRef]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Chitriv, S.P.; Saini, V.; Ratna, D. Carbon nanotubes synthesis over coal ash based catalysts using polypropylene waste via CVD process: Influence of catalyst and reaction temperature. J. Environ. Manag. 2024, 366, 121881. [Google Scholar] [CrossRef]

- Ren, X.; Hussain, M.I.; Chang, Y.; Ge, C. State-of-the-Art review on amorphous carbon nanotubes: Synthesis, structure, and application. Int. J. Molec. Sci. 2023, 24, 17239. [Google Scholar] [CrossRef] [PubMed]

- Aliyu, A.; Kariim, I.; Abdulkareem, S.A. Effects of aspect ratio of multi-walled carbon nanotubes on coal washery waste water treatment. J. Environ. Manag. 2017, 202, 84–93. [Google Scholar] [CrossRef]

- Thambiliyagodage, C.J.; Ulrich, S.; Araujo, P.T.; Bakker, M.G. Catalytic graphitization in nanocast carbon monoliths by iron, cobalt and nickel nanoparticles. Carbon 2018, 134, 452–463. [Google Scholar] [CrossRef]

- Santos, A.C.; Cruz, C.; Font, E.; French, D.; Guedes, A.; Moreira, K.; Valentim, B. Physicochemical properties of Fe-bearing phases from commercial Colombian coal ash. Minerals 2023, 13, 1055. [Google Scholar] [CrossRef]

- Xu, M.X.; Wu, Y.C.; Ji, H.W.; Meng, X.X.; Di, J.Y.; Lu, Q. Preparation of coal fly ash supported high-temperature SCR catalyst by a novel alkali-acid combined activation. Cataly. Comm. 2023, 180, 106711. [Google Scholar] [CrossRef]

- Luo, S.; Guo, M.Z.; Ling, T.C. Mechanical and microstructural performances of fly ash blended cement pastes with mixing CO2 during fresh stage. Constr. Build. Mater. 2022, 358, 129444. [Google Scholar] [CrossRef]

- Suescum-Morales, D.; Silva, R.V.; Bravo, M.; Jiménez, J.R.; Fernández-Rodríguez, J.M.; de Brito, J. Effect of incorporating municipal solid waste incinerated bottom ash in alkali-activated fly ash concrete subjected to accelerated CO2 curing. J. Clean. Prod. 2022, 370, 133533. [Google Scholar] [CrossRef]

- Fu, J.; Liu, K.; Li, H.; Hu, J.; Liu, M. Bimetallic atomic site catalysts for CO2 reduction reactions: A review. Environ. Chem. Lett. 2022, 15, 243–262. [Google Scholar] [CrossRef]

- Garba, M.D.; Usman, M.; Khan, S.; Shehzad, F.; Galadima, A.; Ehsan, M.F.; Ghanem, A.S.; Humayun, M. CO2 towards fuels: A review of catalytic conversion of carbon dioxide to hydrocarbons. J. Environ. Chem. Eng. 2021, 9, 104756. [Google Scholar] [CrossRef]

- Wang, C.; Bai, L.; Xu, H.; Qin, S.; Li, Y.; Zhang, G. A review of high-temperature aerogels: Composition, mechanisms, and properties. Gels 2024, 10, 286. [Google Scholar] [CrossRef]

- Gu, J.; Liu, L.; Zhu, R.; Song, Q.; Yu, H.; Jiang, P.; Sai, H. Recycling coal fly ash for super-thermal-insulating aerogel fiber preparation with simultaneous Al2O3 extraction. Molecules 2023, 28, 7978. [Google Scholar] [CrossRef] [PubMed]

- Minju, N.; Nair, B.N.; Savithri, S. Sodium silicate-derived aerogels: Effect of processing parameters on their applications. RSC Adv. 2021, 11, 15301–15322. [Google Scholar]

- Hou, H.; Zhang, S.; Guo, D.; Su, L.; Xu, H. Synergetic benefits of pollution and carbon reduction from fly ash resource utilization—Based on the life cycle perspective. Sci. Total Environ. 2023, 903, 166197. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Chen, Z.; Zhang, J.; Liu, Y.; Chen, L.; Yang, M.; Osman, A.I.; Farghali, M.; Liu, E.; Hassan, D.; et al. Municipal solid waste management challenges in developing regions: A comprehensive review and future perspectives for Asia and Africa. Sci. Total Environ. 2024, 930, 172794. [Google Scholar] [CrossRef] [PubMed]

- Santos, S.M.; Gonçalves, M.; Brito, P.; Nobre, C. Waste-derived chars: A comprehensive review. Waste 2024, 2, 218–239. [Google Scholar] [CrossRef]

- Zare, M.; Nasategay, F.; Gomez, J.A.; Moayedi Far, A.; Sattarvand, J. A review of tailings dam safety monitoring guidelines and systems. Minerals 2024, 14, 551. [Google Scholar] [CrossRef]

- Lemly, A.D. An urgent need for an EPA standard for disposal of coal ash. Environ. Pollut. 2014, 191, 253–255. [Google Scholar] [CrossRef]

- Ministry of Commerce People’s Republic of China (MOFCOM). Law of the People’s Republic of China on Prevention and Control of Environmental Pollution by Solid Waste. 2007. Available online: http://www.mofcom.gov.cn/ (accessed on 12 September 2024).

- National Development and Reform Commission (NDRC). 2023. Available online: https://www.ndrc.gov.cn/ (accessed on 12 September 2024).

- Ministry of Ecology and Environment (MEE). 2023. Available online: https://www.mee.gov.cn/ (accessed on 12 September 2024).

- Environmental Protection Agency (EPA) Final Rule. Hazardous and solid waste management system; disposal of coal combustion residuals from electric utilities. Fed. Register. 2015, 80, 38950–39122.

- Resource Conservation and Recovery Act (RCRA). Summary of the Resource Conservation and Recovery Act. 1976, 42 U.S.C. §6901. Available online: https://www.epa.gov/ (accessed on 12 September 2024).

- Jambhulkar, H.P.; Shaikh, S.M.S.; Kumar, M.S. Fly ash toxicity, emerging issues and possible implications for its exploitation in agriculture; Indian scenario: A review. Chemosphere 2018, 213, 333–344. [Google Scholar] [CrossRef]

- Ministry of Environment, Forest and Climate Change. The Hazardous Substances Management Division (HSMD). 2021. Available online: https://moef.gov.in/ (accessed on 12 September 2024).

- Industrial Emission Directive (IED). Directive 2010/75/EU of the European Parliament and of the Council of 24 November 2010 on Industrial Emissions (Integrated Pollution Prevention and Control). Available online: http://data.europa.eu/eli/dir/2010/75/2011-01-06 (accessed on 12 September 2024).

- Waste Framework Directive (WFD). Directive 2008/98/EC of the European Parliament and of the Council of 19 November 2008 on Waste and Repealing Certain Directives. Available online: http://data.europa.eu/eli/dir/2008/98/2018-07-05 (accessed on 12 September 2024).

- The Landfill Directive (LD). Council Directive 1999/31/EC of 26 April 1999 on the Landfill of Waste. Available online: http://data.europa.eu/eli/dir/1999/31/2018-07-04 (accessed on 12 September 2024).

- Environmental Justice Australia. Unearthing Australia’s Toxic Coal Ash Legacy (How the Regulation of Toxic Coal Ash Waste Is Failing Australian Communities). 2019. Available online: https://envirojustice.org.au/ (accessed on 12 September 2024).

| C-FA | C-BA | |

|---|---|---|

| Physical Features | ||

| Color | Reddish-tan/black | Dark grey/black |

| Specific gravity (no unit) | 1.9–2.6 | 1.39–2.6 |

| Specific surface, Ss | 5–10 (m2/g) | 93–600 (m2/kg) |

| Apparent density (g/cm3) | 2.1–3.0 | - |

| Max. dry density (g/cc) | 0.9–1.6 | - |

| Optimum water content (%) | 18.0–38.0 | 11.61–32.23 |

| Grain size (µm) | 1–100 | >100 |

| Porosity (%) | 30–65 | - |

| pH | 1.2–12.5 (most are alkaline) | - |

| Fineness modulus | - | 1.8–5.6 |

| Water content, ω (%) | - | 1.0–28.9 |

| Chemical Features | (%) | (%) |

| SiO2 Al2O3 Fe2O3 CaO MgO SO3 Na2O K2O | 39.08 10.58 2.71 30.80 11.61 2.11 0.42 0.17 | 51.51 18.7 9.5 5.08 0.93 0.14 0.52 2.56 |

| Physical Features | MSRW-FA | MSRW-BA |

|---|---|---|

| Color Density (g/cm3) | Gray to light brown 0.7–1.5 | Dark gray to black 1.0–2.5 |

| Particle Size | <100 µm | 0.1–50 mm |

| LOI | 1%–10% | 1%–5% |

| Specific Gravity | 2.2–2.8 | 2.0–2.5 |

| Chemical Features | (%) | (%) |

| SiO2 Al2O3 Fe2O3 CaO SO3 Na2O K2O | 3.25 2.31 0.39 38.70 4.59 11.57 8.35 | 19.12 12.04 9.31 43.12 2.40 2.36 0.85 |

| Physical Features | B-FA | B-BA | ||

|---|---|---|---|---|

| Color | Gray or light brown | Dark gray or black | ||

| Density (g/cm3) Particle size Porosity Hygroscopicity | 0.6–1.2 1–100 µm High Tendency to absorb moisture | 1.5–2.0 0.1–50 mm Low Less tendency to absorb moisture | ||

| Chemical Features | Rice husk (%) | Corn cobs (%) | Olive plant (%) | Forest biomass (%) |

| SiO2 | 94.38 | 27.65 | 6.84 | 72.20 |

| Al2O3 Fe2O3 | 0.21 0.22 | 2.49 1.55 | 2.73 1.39 | 3.32 0.78 |

| CaO | 0.97 | 13.19 | 31.41 | 17.16 |

| SO3 | 0.92 | 7.14 | - | - |

| K2O | - | - | 12.31 | 0.75 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Keskin, T.; Yilmaz, E.; Kasap, T.; Sari, M.; Cao, S. Toward Viable Industrial Solid Residual Waste Recycling: A Review of Its Innovative Applications and Future Perspectives. Minerals 2024, 14, 943. https://doi.org/10.3390/min14090943

Keskin T, Yilmaz E, Kasap T, Sari M, Cao S. Toward Viable Industrial Solid Residual Waste Recycling: A Review of Its Innovative Applications and Future Perspectives. Minerals. 2024; 14(9):943. https://doi.org/10.3390/min14090943

Chicago/Turabian StyleKeskin, Tugba, Erol Yilmaz, Tugrul Kasap, Muhammet Sari, and Shuai Cao. 2024. "Toward Viable Industrial Solid Residual Waste Recycling: A Review of Its Innovative Applications and Future Perspectives" Minerals 14, no. 9: 943. https://doi.org/10.3390/min14090943

APA StyleKeskin, T., Yilmaz, E., Kasap, T., Sari, M., & Cao, S. (2024). Toward Viable Industrial Solid Residual Waste Recycling: A Review of Its Innovative Applications and Future Perspectives. Minerals, 14(9), 943. https://doi.org/10.3390/min14090943