Effect of Fiber Types and Dosages on the Properties of Modified Aluminum Dross–Coal Gangue-Based Foam Filling Materials

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

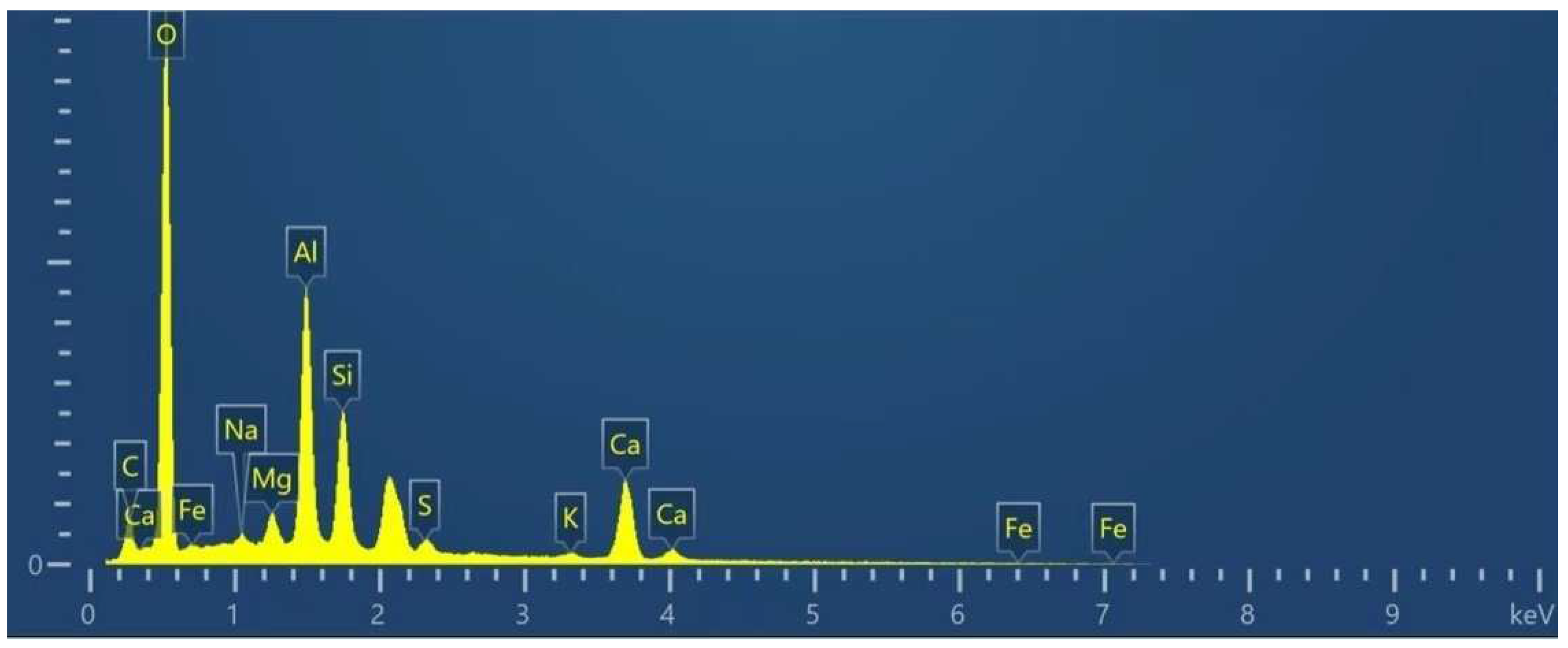

2.1.1. Aluminum Dross (AD)

2.1.2. Ordinary Portland Cement (OPC)

2.1.3. Coal Gangue (CG)

2.1.4. Fiber

2.2. Preparation of Blowing Agent and CFB Sample

2.3. Experimental Methods

2.3.1. Slump Test

2.3.2. Rheological Test

2.3.3. UCS Test

2.3.4. Scanning Electron Microscopy Test

2.3.5. Pore Test

3. Results and Discussion

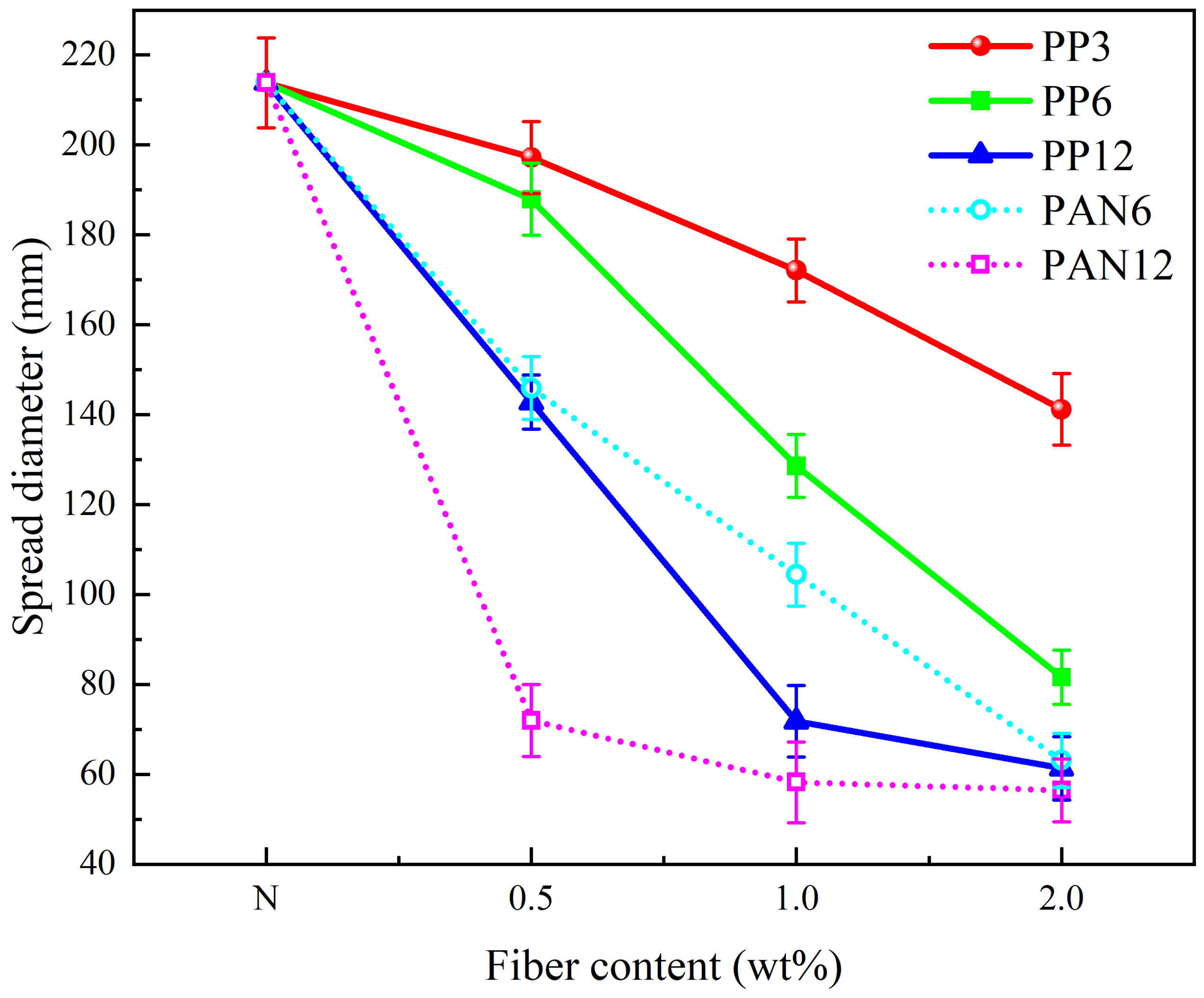

3.1. Slump Tests

3.2. Rheological Properties

3.2.1. Yield Stress

3.2.2. Apparent Viscosity

3.3. Mechanical Properties

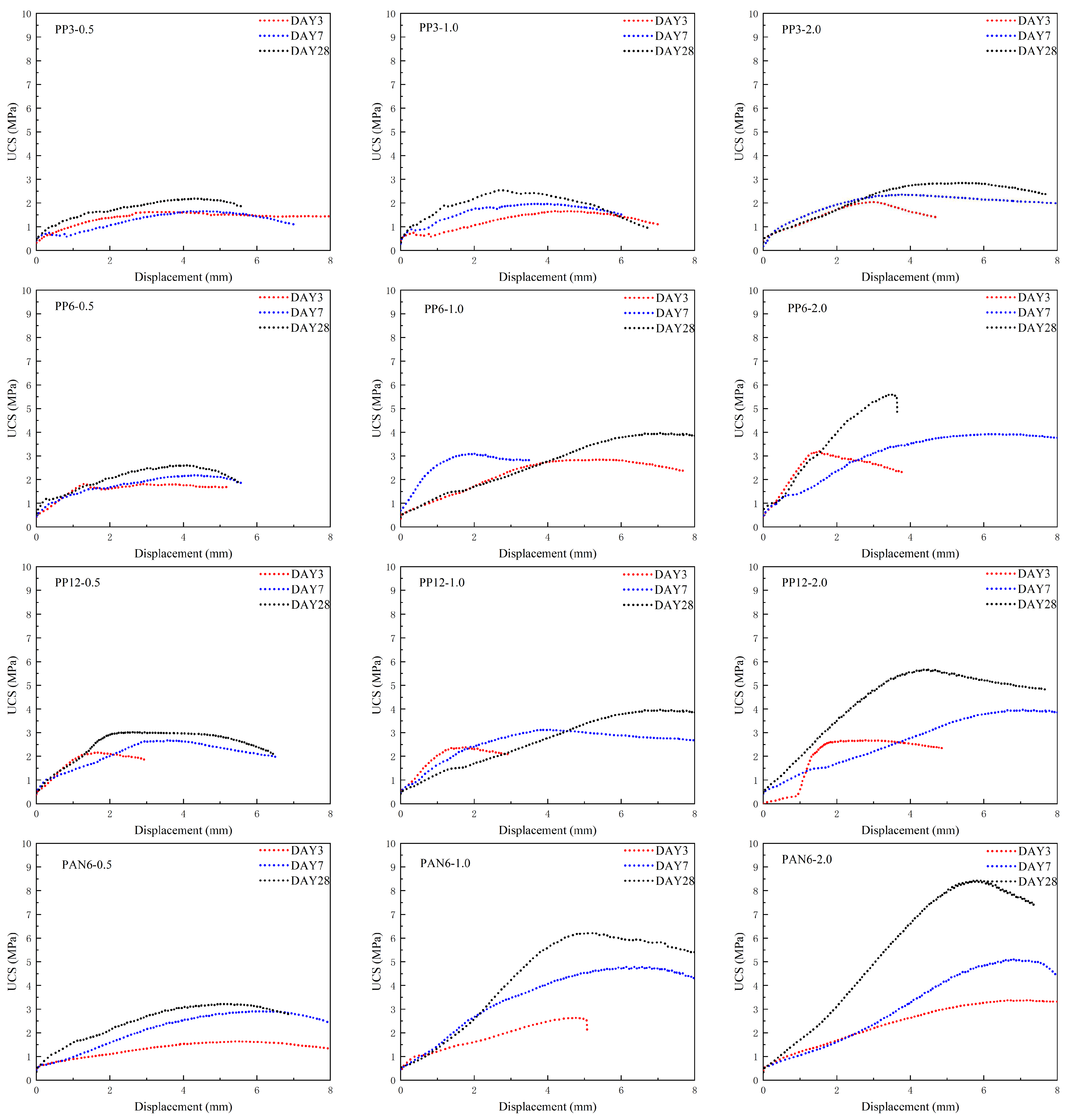

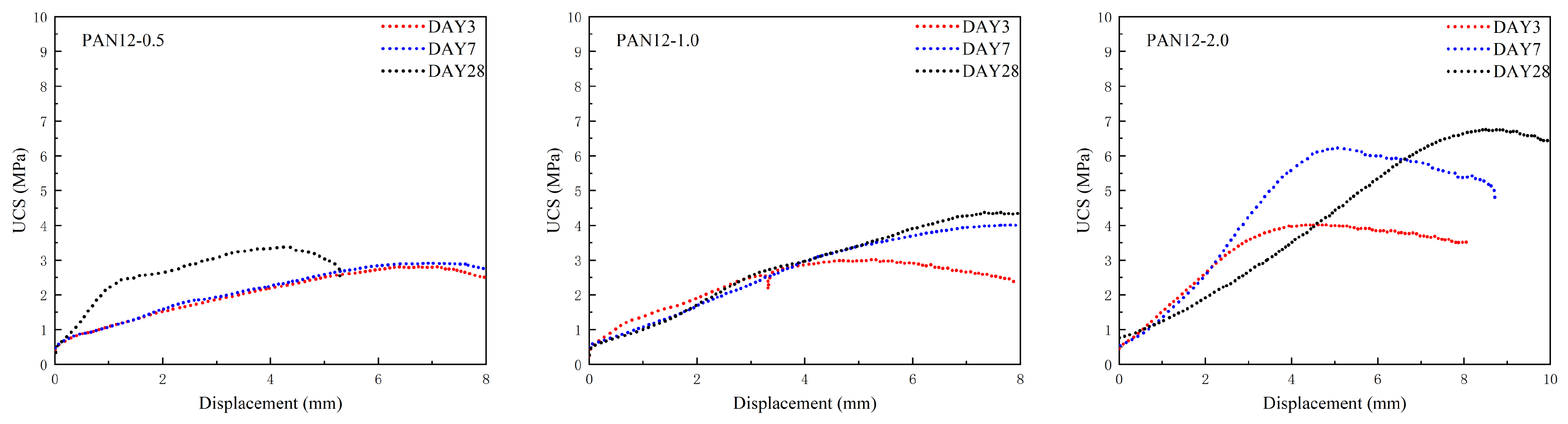

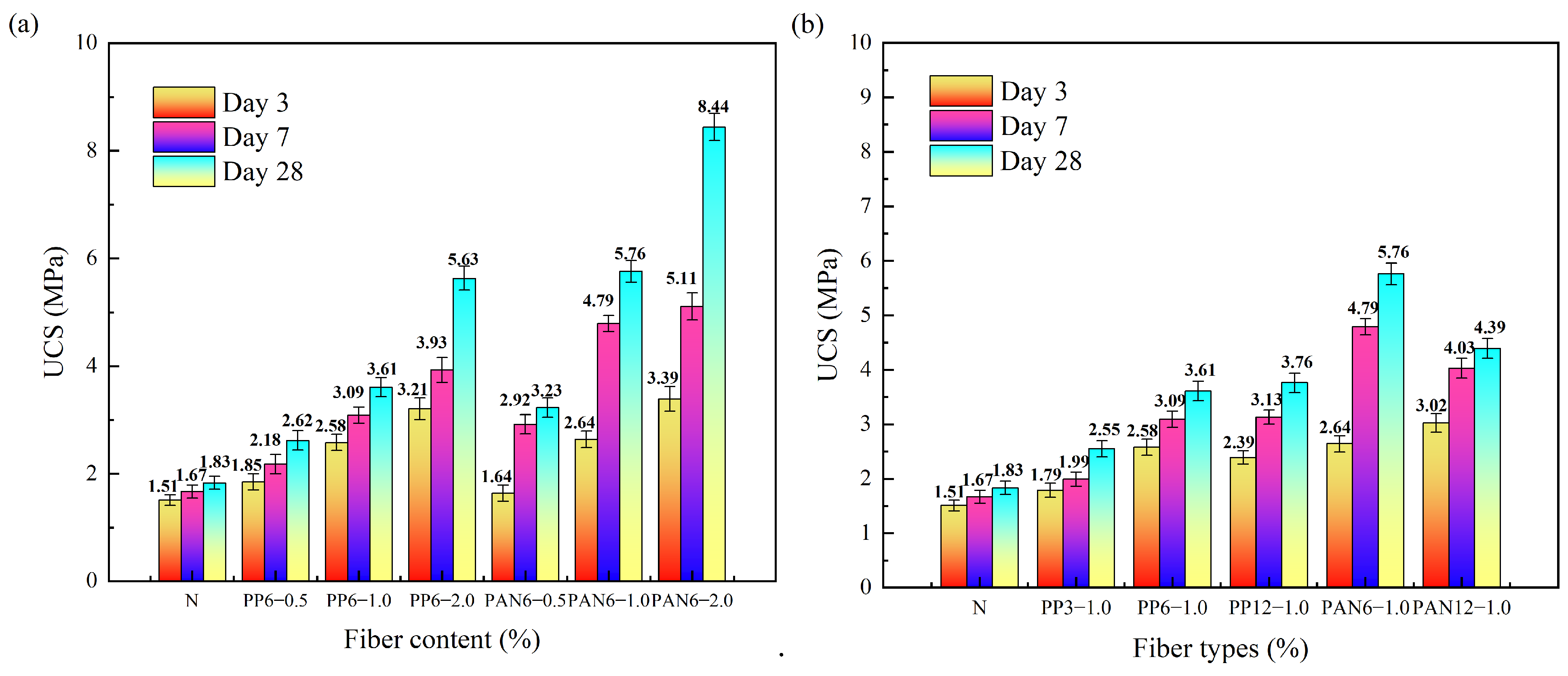

3.3.1. Uniaxial Compressive Strength Results

3.3.2. Analysis of Microstructure Behavior of Fiber-Reinforced CFB Samples

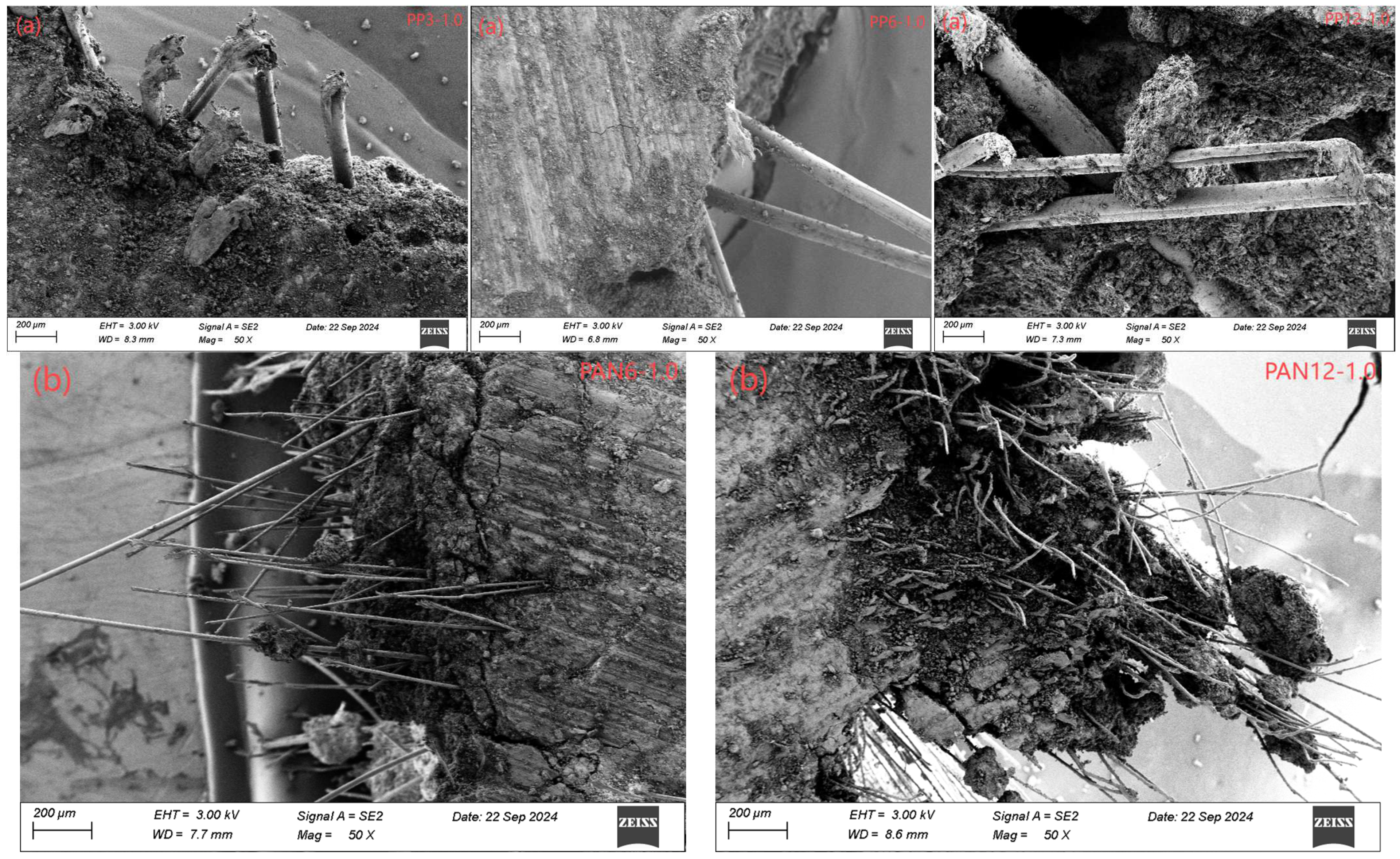

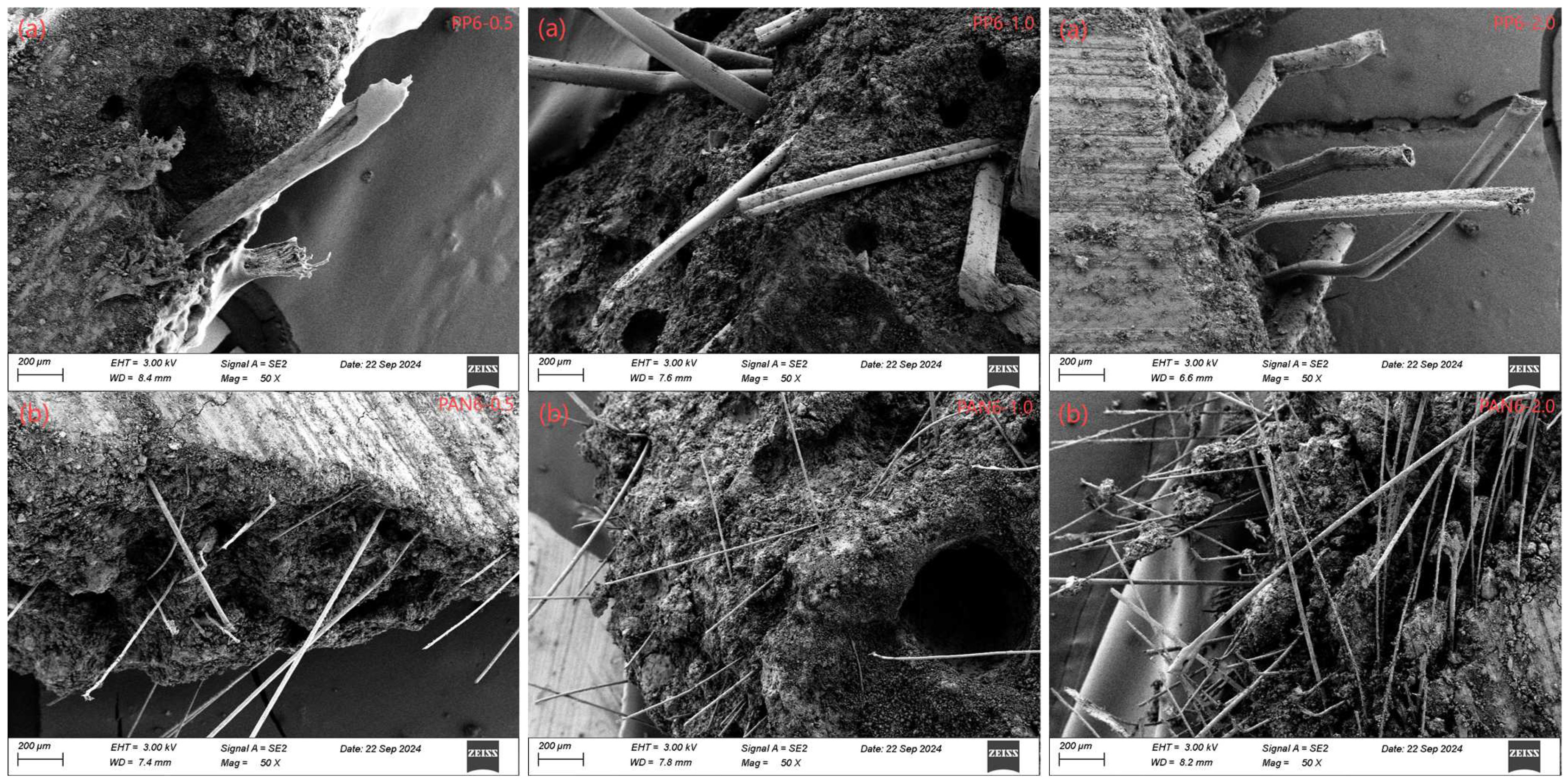

- Microstructural Characteristics and Fiber–Matrix Interactions

- 2.

- Fiber Pull-Out Mechanism

- 3.

- Impact of Fiber Content and Length

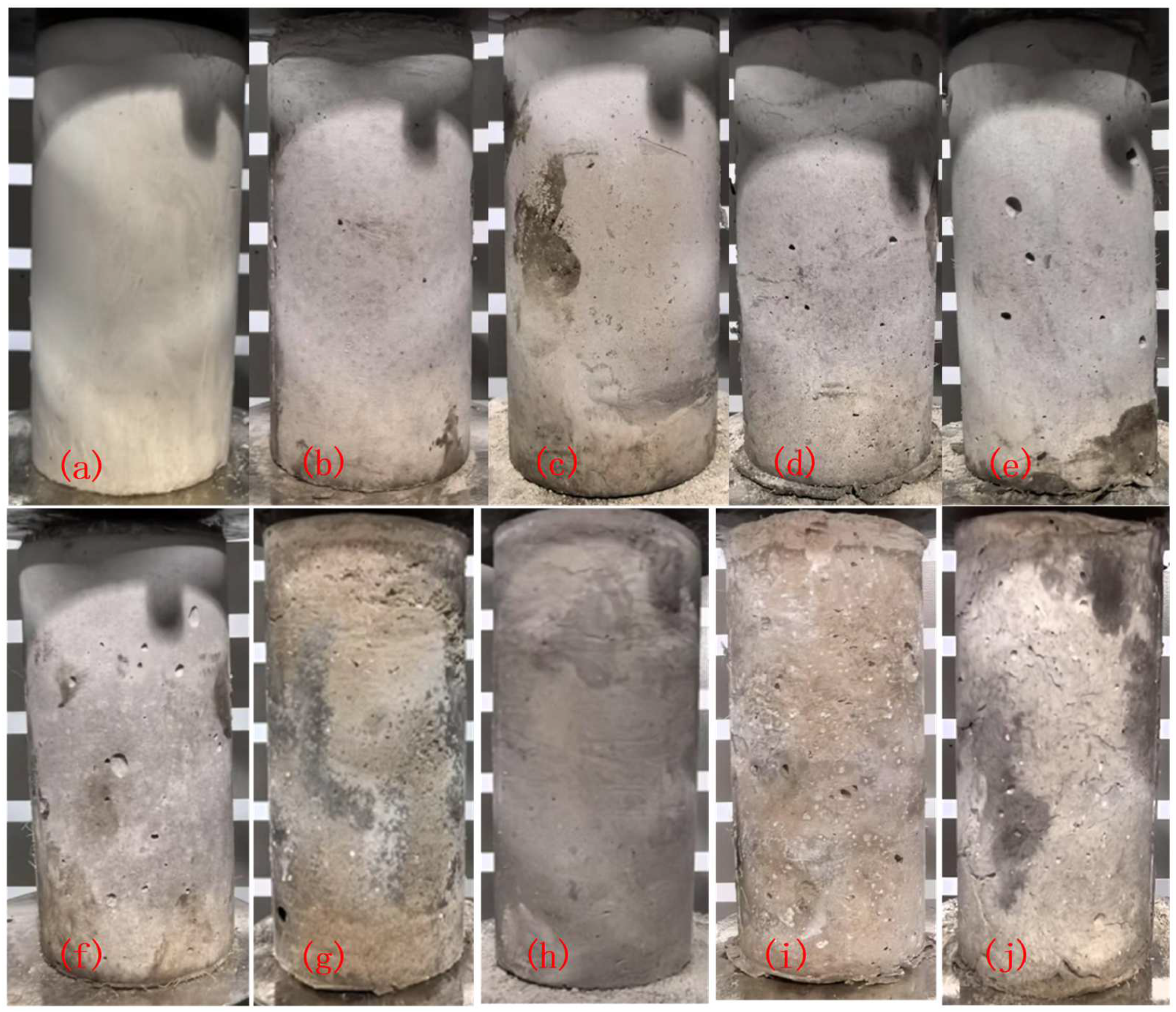

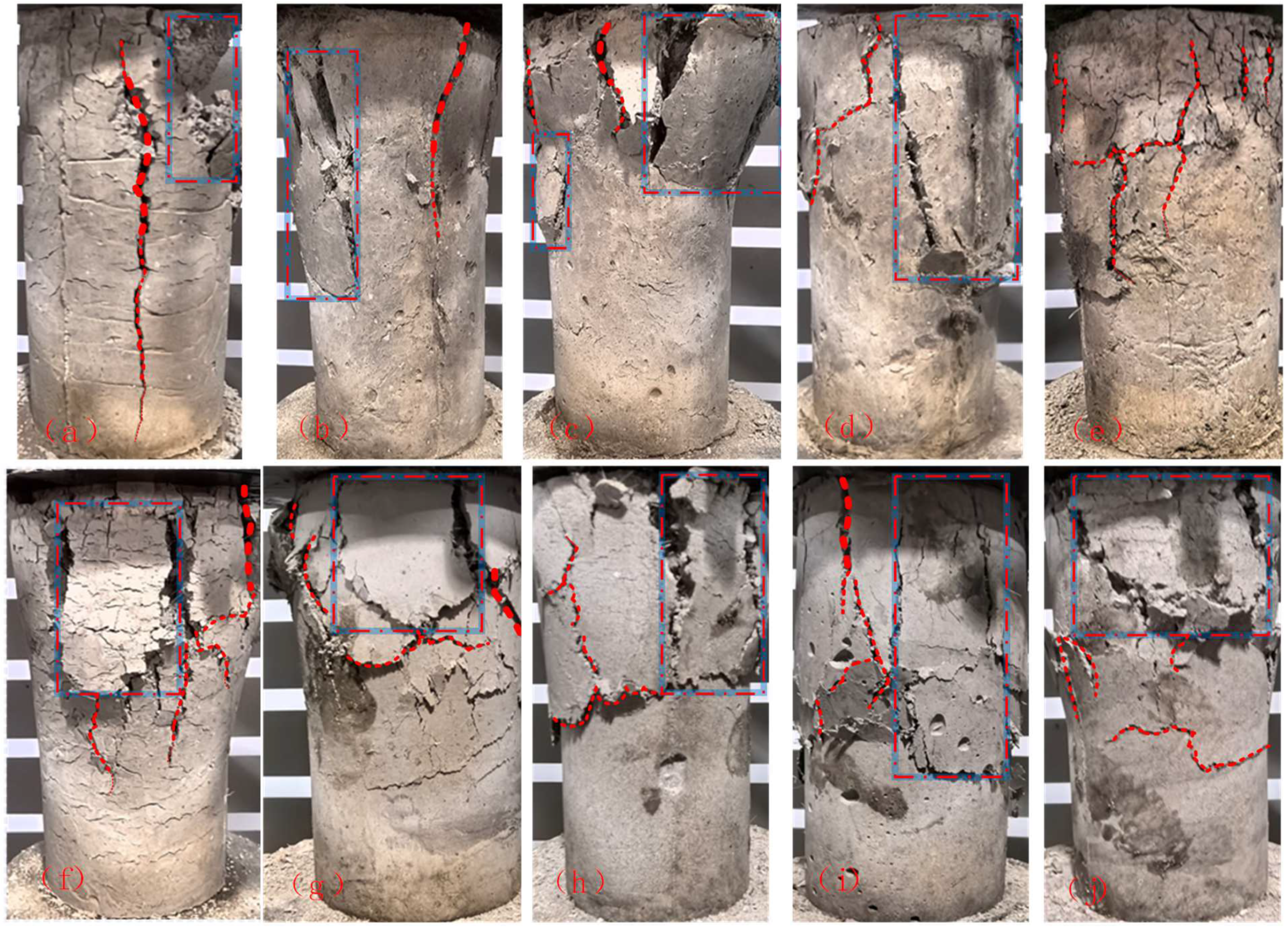

3.3.3. Failure Mode

3.3.4. Pore Distribution

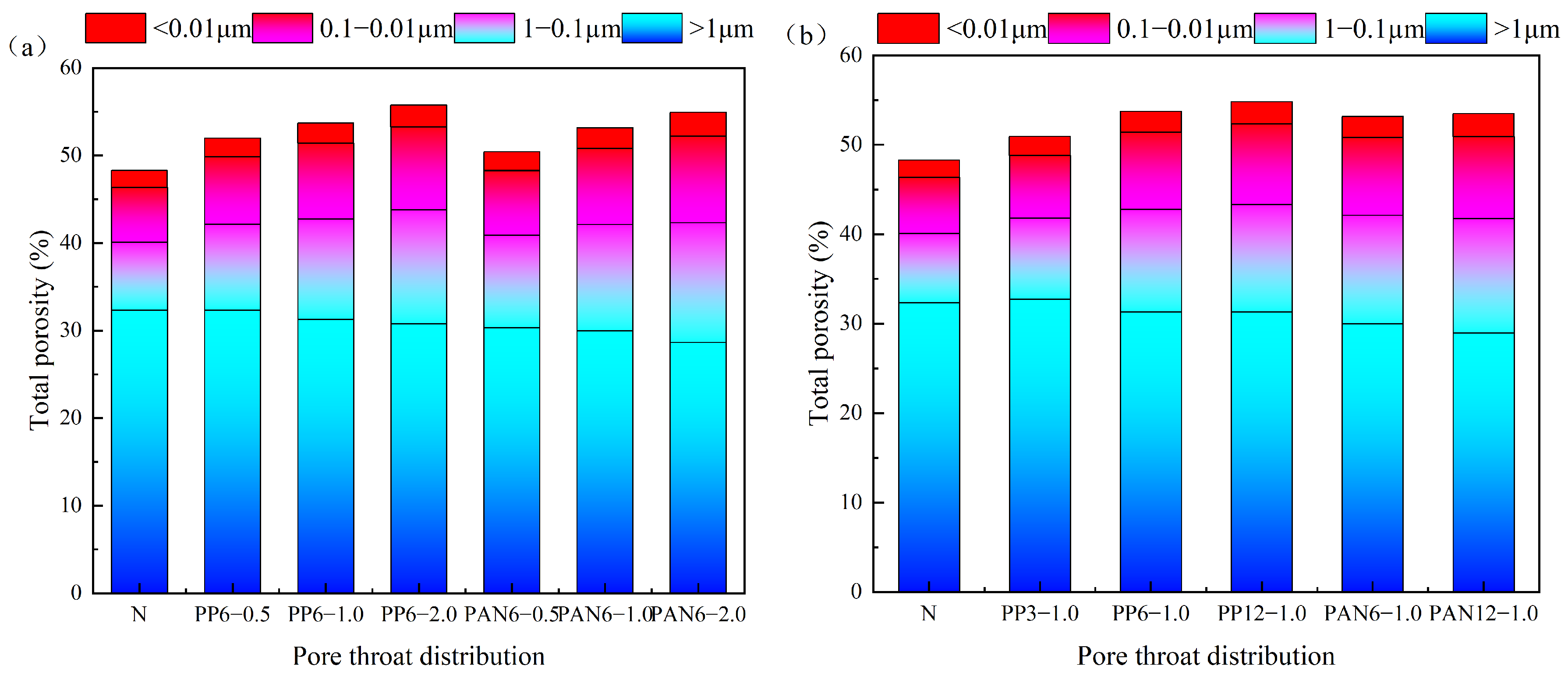

- Relationship Between Pore Size Distribution and Strength

- 2.

- Impact of Pore Evolution on Load-Bearing Capacity

- 3.

- Fiber Reinforcement and Pore Structure Optimization

3.3.5. Comparison with Conventional Filling Materials

4. Conclusions

- Influence on Flow and Pore Structure:

- 2.

- Enhancement of Strength and Failure Behavior:

- 3.

- Optimization of Fiber Parameters:

- 4.

- Economic Viability and Durability Considerations for Industrial Applications

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Li, Y.; Liu, H.; Su, L.; Chen, S.; Zhu, X.; Zhang, P. Developmental Features, Influencing Factors, and Formation Mechanism of Underground Mining–Induced Ground Fissure Disasters in China: A Review. Int. J. Environ. Res. Public Health 2023, 20, 3511. [Google Scholar] [CrossRef] [PubMed]

- Gao, R.; Bai, D.; Yu, B.; Tai, Y.; Meng, X.; Zhang, W. Ground fracturing of multi-strata for strong ground pressure control in extra-thick coal seams with hard roofs: Numerical simulation and case study. Eng. Fract. Mech. 2024, 303, 110129. [Google Scholar] [CrossRef]

- Chen, Q.; Zhang, Q.; Qi, C.; Fourie, A.; Xiao, C. Recycling phosphogypsum and construction demolition waste for cemented paste backfill and its environmental impact. J. Clean. Prod. 2018, 186, 418–429. [Google Scholar] [CrossRef]

- Kesimal, A.; Yilmaz, E.; Ercikdi, B. Evaluation of paste backfill mixtures consisting of sulphide-rich mill tailings and varying cement contents. Cem. Concr. Res. 2004, 34, 1817–1822. [Google Scholar] [CrossRef]

- Belem, T.; Benzaazoua, M. Design and application of underground mine paste backfill technology. Geotech. Geol. Eng. 2008, 26, 147–174. [Google Scholar] [CrossRef]

- Karaca, O.; Cameselle, C.; Reddy, K.R. Mine tailing disposal sites: Contamination problems, remedial options and phytocaps for sustainable remediation. Rev. Environ. Sci. Bio/Technol. 2018, 17, 205–228. [Google Scholar] [CrossRef]

- Fall, M.; Célestin, J.; Pokharel, M.; Touré, M. A contribution to understanding the effects of curing temperature on the mechanical properties of mine cemented tailings backfill. Eng. Geol. 2010, 114, 397–413. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, L.; Ren, F.; Qiu, J.; Ding, H. Rheological and mechanical properties of cemented foam backfill: Effect of mineral admixture type and dosage. Cem. Concr. Compos. 2020, 112, 103689. [Google Scholar] [CrossRef]

- Zhao, J.-W.; Wang, X.-M.; Peng, K.; Li, S. Utilization of Foaming Technology in Cemented Paste Backfill of High-Mud Superfine Unclassified Tailings. Adv. Mater. Sci. Eng. 2017, 2017, 6157869. [Google Scholar] [CrossRef]

- Hefni, M.; Hassani, F.; Nokken, M.; Kermani, M.; Vatne, D. Investigation into the development of foam mine fill. In Mine Fill 2014: Proceedings of the Eleventh International Symposium on Mining with Backfill; Australian Centre for Geomechanics: Perth, Australia, 2014; pp. 49–59. [Google Scholar]

- Tiberti, G.; Minelli, F.; Plizzari, G. Reinforcement optimization of fiber reinforced concrete linings for conventional tunnels. Compos. Part B Eng. 2014, 58, 199–207. [Google Scholar] [CrossRef]

- Meng, W.; Khayat, K.H. Improving flexural performance of ultra-high-performance concrete by rheology control of suspending mortar. Compos. Part B Eng. 2017, 117, 26–34. [Google Scholar] [CrossRef]

- Chun, B.; Yoo, D.-Y. Hybrid effect of macro and micro steel fibers on the pullout and tensile behaviors of ultra-high-performance concrete. Compos. Part B Eng. 2019, 162, 344–360. [Google Scholar] [CrossRef]

- Fu, C.; Ye, H.; Wang, K.; Zhu, K.; He, C. Evolution of mechanical properties of steel fiber-reinforced rubberized concrete (FR-RC). Compos. Part B Eng. 2019, 160, 158–166. [Google Scholar] [CrossRef]

- Bolat, H.; Şimşek, O.; Çullu, M.; Durmuş, G.; Can, Ö. The effects of macro synthetic fiber reinforcement use on physical and mechanical properties of concrete. Compos. Part B Eng. 2014, 61, 191–198. [Google Scholar] [CrossRef]

- Ateş, A. Mechanical properties of sandy soils reinforced with cement and randomly distributed glass fibers (GRC). Compos. Part B Eng. 2016, 96, 295–304. [Google Scholar] [CrossRef]

- Junior, A.N.; Ferreira, S.R.; Toledo Filho, R.D.; Fairbairn, E.d.M.R.; Dweck, J. Effect of early age curing carbonation on the mechanical properties and durability of high initial strength Portland cement and lime-pozolan composites reinforced with long sisal fibres. Compos. Part B Eng. 2019, 163, 351–362. [Google Scholar] [CrossRef]

- Consoli, N.C.; Thomé, A.; Girardello, V.; Ruver, C.A. Uplift behavior of plates embedded in fiber-reinforced cement stabilized backfill. Geotext. Geomembr. 2012, 35, 107–111. [Google Scholar] [CrossRef]

- Festugato, L.; Fourie, A.; Consoli, N.C. Cyclic shear response of fibre-reinforced cemented paste backfill. Géotech. Lett. 2013, 3, 5–12. [Google Scholar] [CrossRef]

- Chen, X.; Shi, X.; Zhou, J.; Chen, Q.; Li, E.; Du, X. Compressive behavior and microstructural properties of tailings polypropylene fibre-reinforced cemented paste backfill. Constr. Build. Mater. 2018, 190, 211–221. [Google Scholar] [CrossRef]

- Yi, X.; Ma, G.; Fourie, A. Centrifuge model studies on the stability of fibre-reinforced cemented paste backfill stopes. Geotext. Geomembr. 2018, 46, 396–401. [Google Scholar] [CrossRef]

- Yi, X.; Ma, G.; Fourie, A. Compressive behaviour of fibre-reinforced cemented paste backfill. Geotext. Geomembr. 2015, 43, 207–215. [Google Scholar] [CrossRef]

- Qi, C.; Fourie, A. Cemented paste backfill for mineral tailings management: Review and future perspectives. Miner. Eng. 2019, 144, 106025. [Google Scholar] [CrossRef]

- Ma, G.; Li, Z.; Yi, X.; Guo, L. Macro-meso experiment of fiber-reinforced cement paste filling material. Beijing Gongye Daxue Xuebao/J. Beijing Univ. Technol. 2016, 42, 406–412. [Google Scholar] [CrossRef]

- Li, J.; Jia, A.; Hou, X.; Wang, X.; Mao, Y.; Wang, W. Thermal co-treatment of aluminum dross and municipal solid waste incineration fly ash: Mineral transformation, crusting prevention, detoxification, and low-carbon cementitious material preparation. J. Environ. Manag. 2023, 329, 117090. [Google Scholar] [CrossRef]

- David, E.; Kopac, J. Hydrolysis of aluminum dross material to achieve zero hazardous waste. J. Hazard. Mater. 2012, 209, 501–509. [Google Scholar] [CrossRef]

- Li, L.; Wang, K.; Zhang, S.; Zhang, X.; Yin, K. Resource utilisation of hazardous aluminium dross and coal gangue for fibre-reinforced cemented foam backfill. J. Build. Eng. 2024, 91, 109736. [Google Scholar] [CrossRef]

- Shen, H.; Liu, B.; Ekberg, C.; Zhang, S. Harmless disposal and resource utilization for secondary aluminum dross: A review. Sci. Total Environ. 2021, 760, 143968. [Google Scholar] [CrossRef] [PubMed]

- Belem, T.; El Aatar, O.; Bussière, B.; Benzaazoua, M. Gravity-driven 1-D consolidation of cemented paste backfill in 3-m-high columns. Innov. Infrastruct. Solut. 2016, 1, 37. [Google Scholar] [CrossRef]

- Ouattara, D.; Belem, T.; Mbonimpa, M.; Yahia, A. Effect of superplasticizers on the consistency and unconfined compressive strength of cemented paste backfills. Constr. Build. Mater. 2018, 181, 59–72. [Google Scholar] [CrossRef]

- Shen, X.; Li, X.; Liu, L.; Chen, X.; Du, J. Research on Mechanical Properties of Steel-Polypropylene Fiber-Reinforced Concrete after High-Temperature Treatments. Appl. Sci. 2024, 14, 3861. [Google Scholar] [CrossRef]

- Bei-Xing, L.; Ming-xiang, C.; Fang, C.; Lu-ping, L. The mechanical properties of polypropylene fiber reinforced concrete. J. Wuhan Univ. Technol. Mater. Sci. Ed. 2004, 19, 68–71. [Google Scholar] [CrossRef]

- Song, M.; Song, N.; Zhang, Y.; Wang, J. Mechanical Properties of Polypropylene-Fiber-Reinforced High-Performance Concrete Based on the Response Surface Method. Adv. Mater. Sci. Eng. 2022, 2022, 9802222. [Google Scholar] [CrossRef]

- Ahn, H.; Wee, J.-H.; Kim, Y.M.; Yu, W.-R.; Yeo, S.-Y. Microstructure and mechanical properties of polyacrylonitrile precursor fiber with dry and wet drawing process. Polymers 2021, 13, 1613. [Google Scholar] [CrossRef]

- Wang, P.H.; Liu, J.; Li, R.Y. Physical modification of polyacrylonitrile precursor fiber: Its effect on mechanical properties. J. Appl. Polym. Sci. 1994, 52, 1667–1674. [Google Scholar] [CrossRef]

- Guo, Z.; Qiu, J.; Jiang, H.; Xing, J.; Sun, X.; Ma, Z. Flowability of ultrafine-tailings cemented paste backfill incorporating superplasticizer: Insight from water film thickness theory. Powder Technol. 2021, 381, 509–517. [Google Scholar] [CrossRef]

- Zhang, S.; Yang, L.; Qiu, J.; Hou, C.; Guo, Z. Fluidity and strength behaviors of cemented foam backfill: Effect of particle size distribution and foaming agent dosage. Bull. Eng. Geol. Environ. 2021, 80, 3177–3191. [Google Scholar] [CrossRef]

- Xu, S.; Suorineni, F.T.; Li, K.; Li, Y. Evaluation of the strength and ultrasonic properties of foam-cemented paste backfill. Int. J. Min. Reclam. Environ. 2017, 31, 544–557. [Google Scholar] [CrossRef]

- Qiu, J.; Guo, Z.; Yang, L.; Jiang, H.; Zhao, Y. Effects of packing density and water film thickness on the fluidity behaviour of cemented paste backfill. Powder Technol. 2020, 359, 27–35. [Google Scholar] [CrossRef]

- Jiang, H.; Qi, Z.; Yilmaz, E.; Han, J.; Qiu, J.; Dong, C. Effectiveness of alkali-activated slag as alternative binder on workability and early age compressive strength of cemented paste backfills. Constr. Build. Mater. 2019, 218, 689–700. [Google Scholar] [CrossRef]

- Yilmaz, E.; Belem, T.; Bussière, B.; Benzaazoua, M. Relationships between microstructural properties and compressive strength of consolidated and unconsolidated cemented paste backfills. Cem. Concr. Compos. 2011, 33, 702–715. [Google Scholar] [CrossRef]

- Mohamed, O.; Zuaiter, H. Fresh properties, strength, and durability of fiber-reinforced geopolymer and conventional concrete: A review. Polymers 2024, 16, 141. [Google Scholar] [CrossRef] [PubMed]

- Xu, W.-B.; Li, Q.-L.; Tian, M.-M. Strength and deformation properties of polypropylene fiber-reinforced cemented tailings backfill. Chin. J. Eng. 2019, 41, 1618–1626. [Google Scholar] [CrossRef]

- Chowdhry, G.; Chang, Y.M.; Frampton, J.P.; Kreplak, L. Polymer entanglement drives formation of fibers from stable liquid bridges of highly viscous dextran solutions. Soft Matter 2021, 17, 1873–1880. [Google Scholar] [CrossRef] [PubMed]

- Chen, X.; Shi, X.; Zhang, S.; Chen, H.; Zhou, J.; Yu, Z.; Huang, P. Fiber-reinforced cemented paste backfill: The effect of fiber on strength properties and estimation of strength using nonlinear models. Materials 2020, 13, 718. [Google Scholar] [CrossRef]

- Haruna, S.; Fall, M. Strength development of cemented tailings materials containing polycarboxylate ether-based superplasticizer: Experimental results on the effect of time and temperature. Can. J. Civ. Eng. 2021, 48, 429–442. [Google Scholar] [CrossRef]

- Hu, J.; Ren, Q.; Ding, X.; Jiang, Q. Trans-scale relationship analysis between the pore structure and macro parameters of backfill and slurry. R. Soc. Open Sci. 2019, 6, 190389. [Google Scholar] [CrossRef]

- Odler, I.; Rößler, M. Investigations on the relationship between porosity, structure and strength of hydrated Portland cement pastes. II. Effect of pore structure and of degree of hydration. Cem. Concr. Res. 1985, 15, 401–410. [Google Scholar] [CrossRef]

- Zhang, P.; Li, Q.-F. Effect of polypropylene fiber on durability of concrete composite containing fly ash and silica fume. Compos. Part B Eng. 2013, 45, 1587–1594. [Google Scholar] [CrossRef]

- Xue, G.; Yilmaz, E.; Song, W.; Yilmaz, E. Influence of fiber reinforcement on mechanical behavior and microstructural properties of cemented tailings backfill. Constr. Build. Mater. 2019, 213, 275–285. [Google Scholar] [CrossRef]

- Xu, W.; Li, Q.; Zhang, Y. Influence of temperature on compressive strength, microstructure properties and failure pattern of fiber-reinforced cemented tailings backfill. Constr. Build. Mater. 2019, 222, 776–785. [Google Scholar] [CrossRef]

| Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | Na2O | SO3 |

|---|---|---|---|---|---|---|---|---|

| Weight percentage (%) | 10.78 | 68.46 | 1.50 | 5.90 | 6.83 | 1.93 | 2.89 | 1.70 |

| Composition | Al | Si | Ca | Mg | Na | Ti | Fe | H |

|---|---|---|---|---|---|---|---|---|

| Weight percentage (%) | 64.78 | 9.01 | 7.54 | 7.36 | 3.84 | 2.07 | 1.87 | 3.53 |

| Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | Na2O | K2O |

|---|---|---|---|---|---|---|---|---|

| Weight percentage (%) | 18.691 | 7.399 | 2.597 | 65.544 | 3.037 | 0.604 | 0.296 | 0.576 |

| Composition | SiO2 | Al2O3 | Fe2O3 | CaO | MgO | TiO2 | Na2O | K2O |

|---|---|---|---|---|---|---|---|---|

| Weight percentage (%) | 62.82 | 22.81 | 5.49 | 1.47 | 1.44 | 1.42 | 1.07 | 3.48 |

| Composition | Si | Al | Fe | K | Ca | Mg | Ti | H |

|---|---|---|---|---|---|---|---|---|

| Weight percentage (%) | 56.52 | 23.23 | 7.39 | 5.56 | 2.03 | 1.67 | 1.53 | 0.44 |

| Fiber Type | Length (mm) | Density (g/cm3) | Tensile Strength (MPa) | Young’s Modulus (GPa) | Elongation Rate (%) |

|---|---|---|---|---|---|

| Polypropylene | 12 | 0.94 | 368 | 3.66 | 26 |

| Polyacrylonitrile | 12 | 0.94 | 759 | 4.89 | 32 |

| Test No. | Sample | OPC | CG | Foaming Agent Type and Dosage | Fiber Length | Fiber Content | Water/Solid Ratio |

|---|---|---|---|---|---|---|---|

| 1 | N | 65 | 25 | M2 (10%) | 0 | 0 | 0.5 |

| 2 | PP3-0.5 | 65 | 25 | M2 (10%) | 3 | 0.5 | 0.5 |

| 3 | PP3-1 | 65 | 25 | M2 (10%) | 3 | 1 | 0.5 |

| 4 | PP3-2 | 65 | 25 | M2 (10%) | 3 | 2 | 0.5 |

| 5 | PP6-0.5 | 65 | 25 | M2 (10%) | 6 | 0.5 | 0.5 |

| 6 | PP6-1 | 65 | 25 | M2 (10%) | 6 | 1 | 0.5 |

| 7 | PP6-2 | 65 | 25 | M2 (10%) | 6 | 2 | 0.5 |

| 8 | PP12-0.5 | 65 | 25 | M2 (10%) | 12 | 0.5 | 0.5 |

| 9 | PP12-1 | 65 | 25 | M2 (10%) | 12 | 1 | 0.5 |

| 10 | PP12-2 | 65 | 25 | M2 (10%) | 12 | 2 | 0.5 |

| 11 | PAN6-0.5 | 65 | 25 | M2 (10%) | 6 | 0.5 | 0.5 |

| 12 | PAN6-1 | 65 | 25 | M2 (10%) | 6 | 1 | 0.5 |

| 13 | PAN6-2 | 65 | 25 | M2 (10%) | 6 | 2 | 0.5 |

| 14 | PAN12-0.5 | 65 | 25 | M2 (10%) | 12 | 0.5 | 0.5 |

| 15 | PAN12-1 | 65 | 25 | M2 (10%) | 12 | 1 | 0.5 |

| 16 | PAN12-2 | 65 | 25 | M2 (10%) | 12 | 2 | 0.5 |

| Test No. | Bingham Model a,b | Test No. | Bingham Model |

|---|---|---|---|

| N | τ = 8.95 + 0.48 · γ˙ | N | τ = 8.95 + 0.48 · γ˙ |

| PP6-0.5 | τ = 10.85 + 0.52 · γ˙ | PP3-1.0 | τ = 12.64 + 0.68 · γ˙ |

| PP6-1.0 | τ = 14.25 + 0.71 · γ˙ | PP6-1.0 | τ = 14.25 + 0.71 · γ˙ |

| PP6-2.0 | τ = 24.25 + 0.76 · γ˙ | PP12-1.0 | τ = 17.90 + 0.82 · γ˙ |

| PAN6-0.5 | τ = 19.37 + 0.60 · γ˙ | PAN6-1.0 | τ = 22.96 + 0.79 · γ˙ |

| PAN6-1.0 | τ = 22.96 + 0.79 · γ˙ | PAN12-1.0 | τ = 28.52 + 0.98 · γ˙ |

| PAN6-2.0 | τ = 26.38 + 0.91 · γ˙ |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, K.; Wang, K.; Zhang, X.; Jiang, Y.; Zhang, S. Effect of Fiber Types and Dosages on the Properties of Modified Aluminum Dross–Coal Gangue-Based Foam Filling Materials. Minerals 2025, 15, 106. https://doi.org/10.3390/min15020106

Yin K, Wang K, Zhang X, Jiang Y, Zhang S. Effect of Fiber Types and Dosages on the Properties of Modified Aluminum Dross–Coal Gangue-Based Foam Filling Materials. Minerals. 2025; 15(2):106. https://doi.org/10.3390/min15020106

Chicago/Turabian StyleYin, Keyuan, Kai Wang, Xiaoqiang Zhang, Yulong Jiang, and Shiyu Zhang. 2025. "Effect of Fiber Types and Dosages on the Properties of Modified Aluminum Dross–Coal Gangue-Based Foam Filling Materials" Minerals 15, no. 2: 106. https://doi.org/10.3390/min15020106

APA StyleYin, K., Wang, K., Zhang, X., Jiang, Y., & Zhang, S. (2025). Effect of Fiber Types and Dosages on the Properties of Modified Aluminum Dross–Coal Gangue-Based Foam Filling Materials. Minerals, 15(2), 106. https://doi.org/10.3390/min15020106