Robust Estimation and Validation of Contact Parameters of Iron Ore for Transfer Chute Simulation

Abstract

:1. Introduction

1.1. Overview

1.2. Contact Models and Particle Model Selection in DEM

2. Methodology

2.1. Overview

2.2. Materials

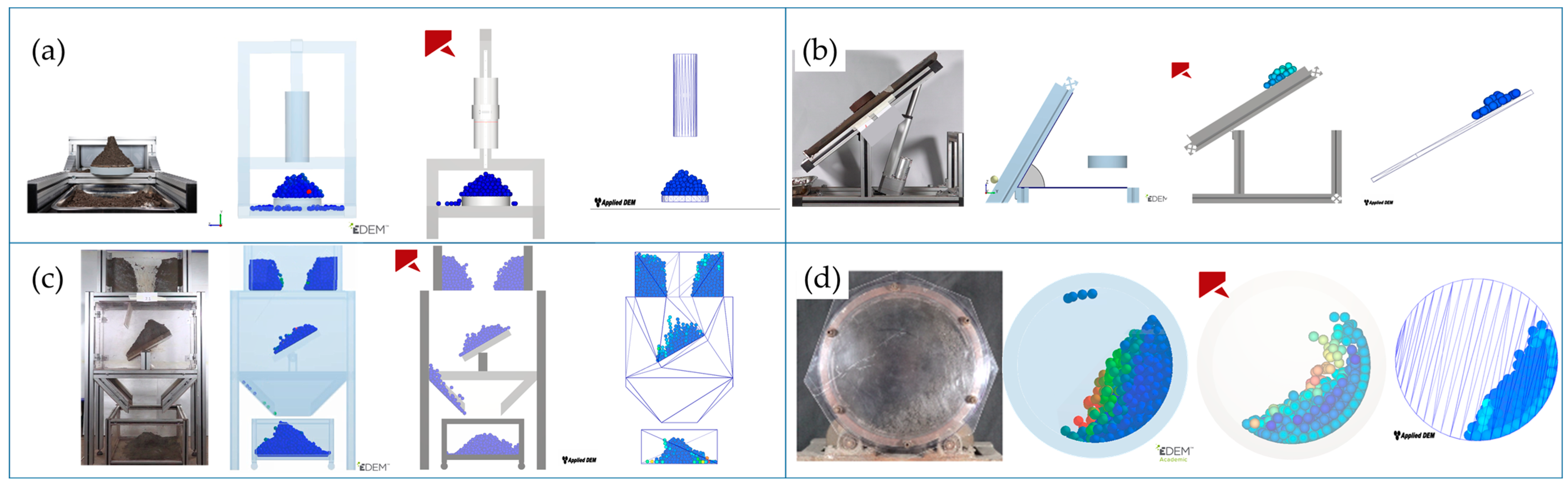

2.3. Bench-Scale Tests

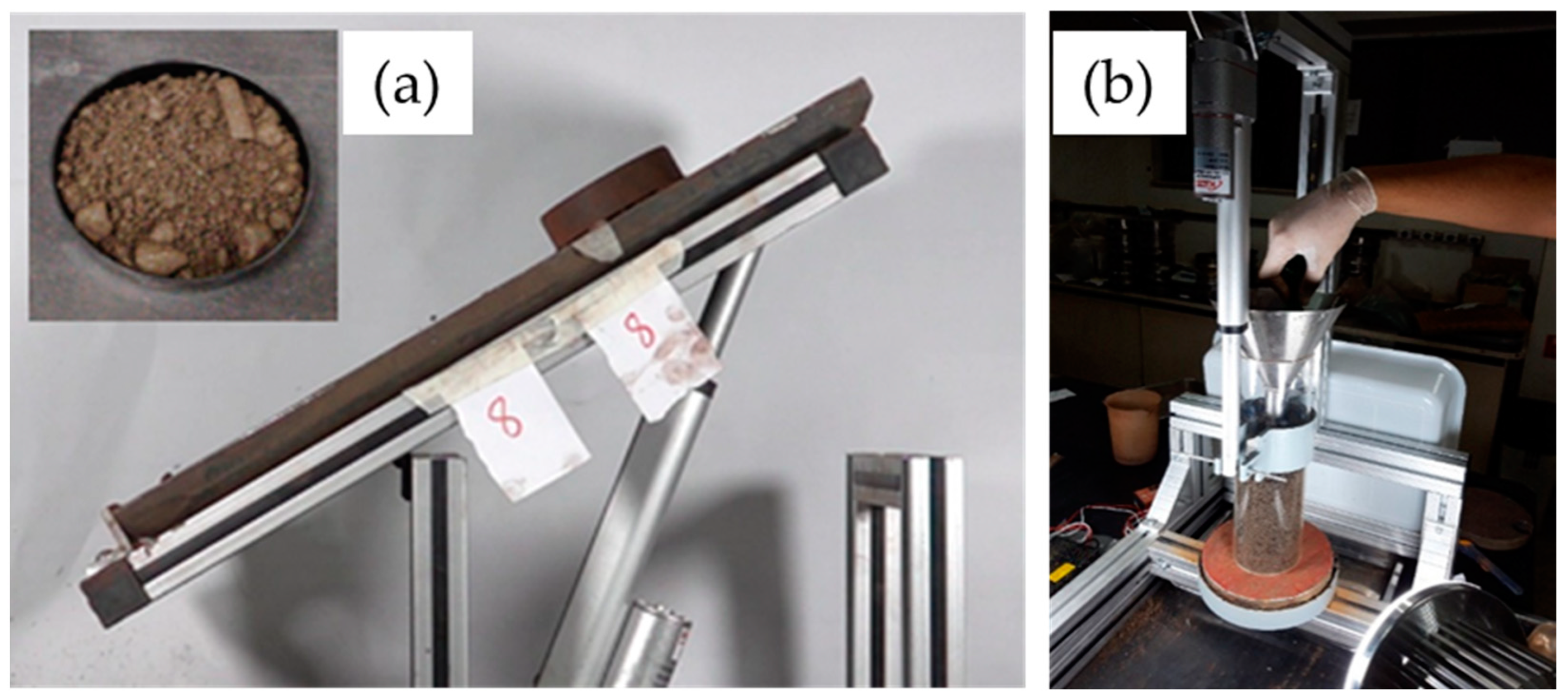

2.3.1. Inclined Plane Test

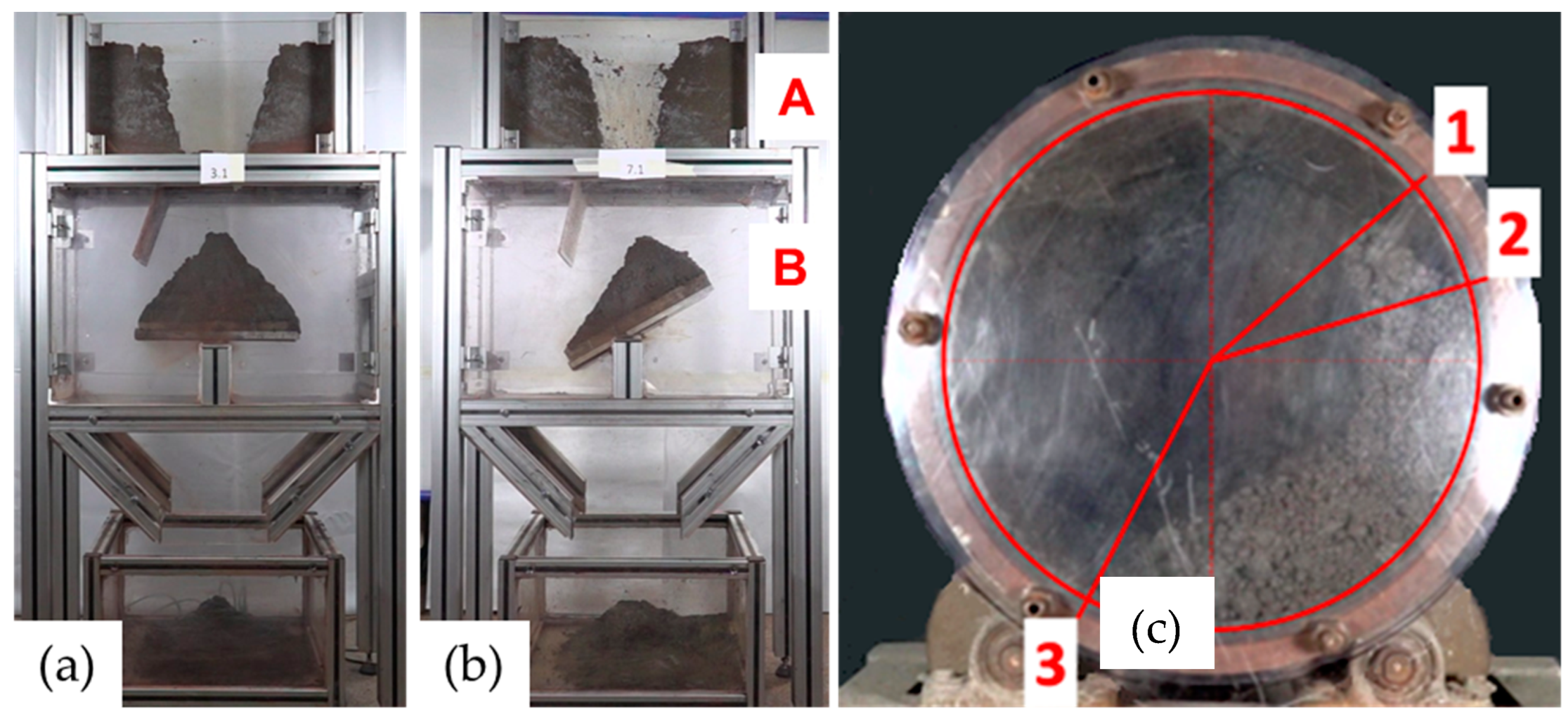

2.3.2. Slump Test

2.3.3. Drawdown Test

2.3.4. Tumbling Test

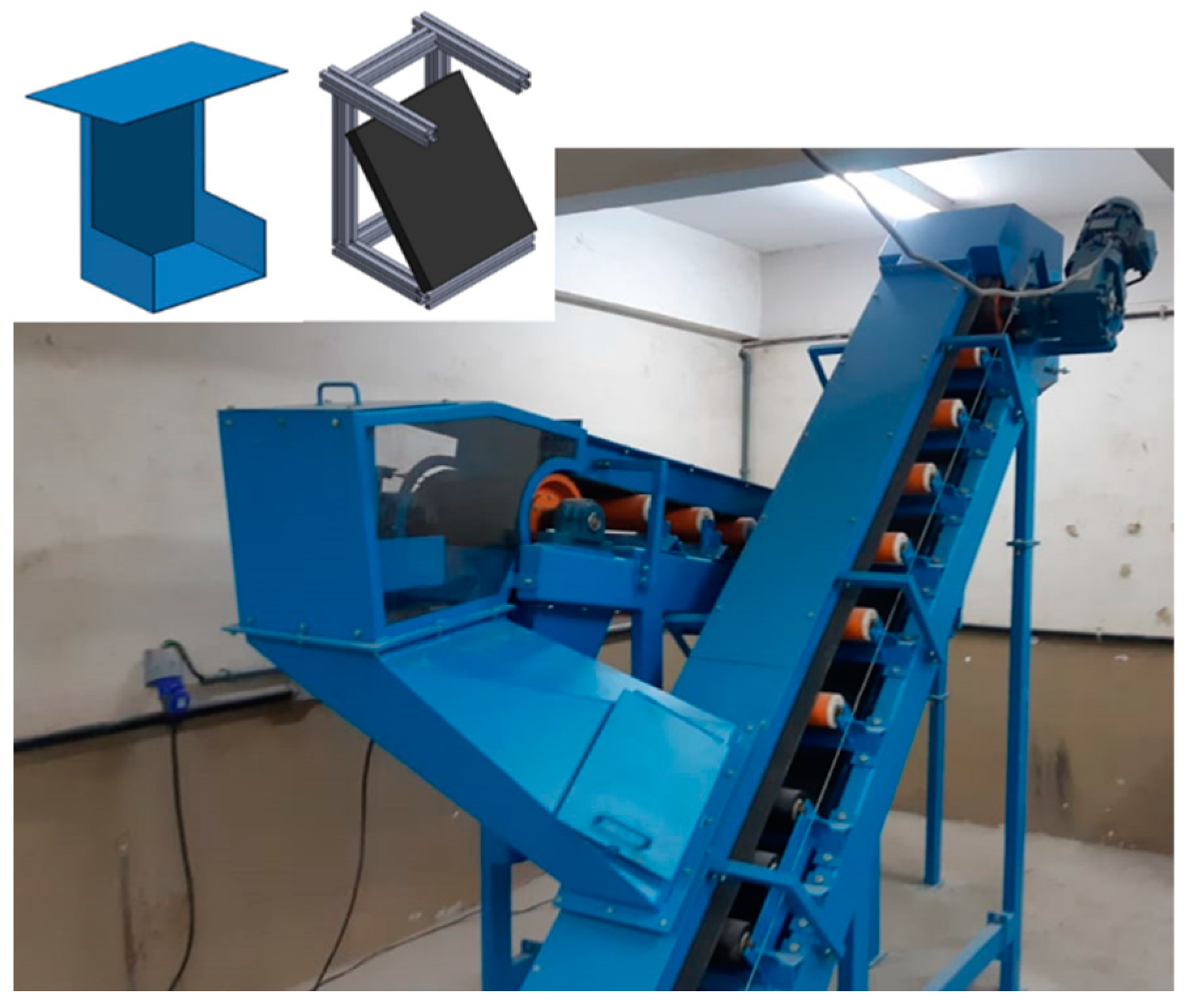

2.4. Pilot-Scale Tests

2.5. DEM Environment

2.6. Industrial-Scale Tests

3. Results and Discussion

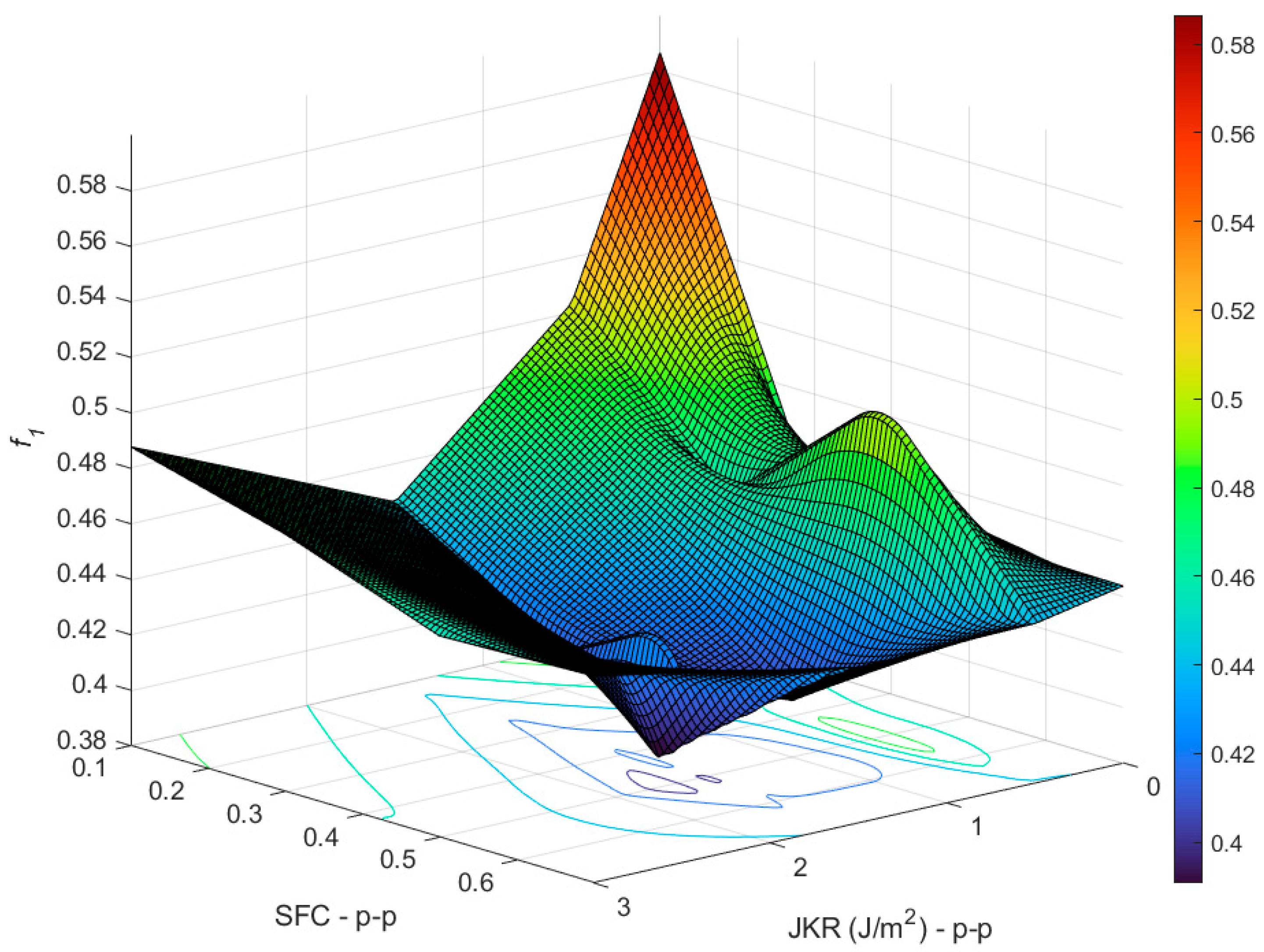

3.1. Bench-Scale Test Results

3.2. Pilot-Scale Tests

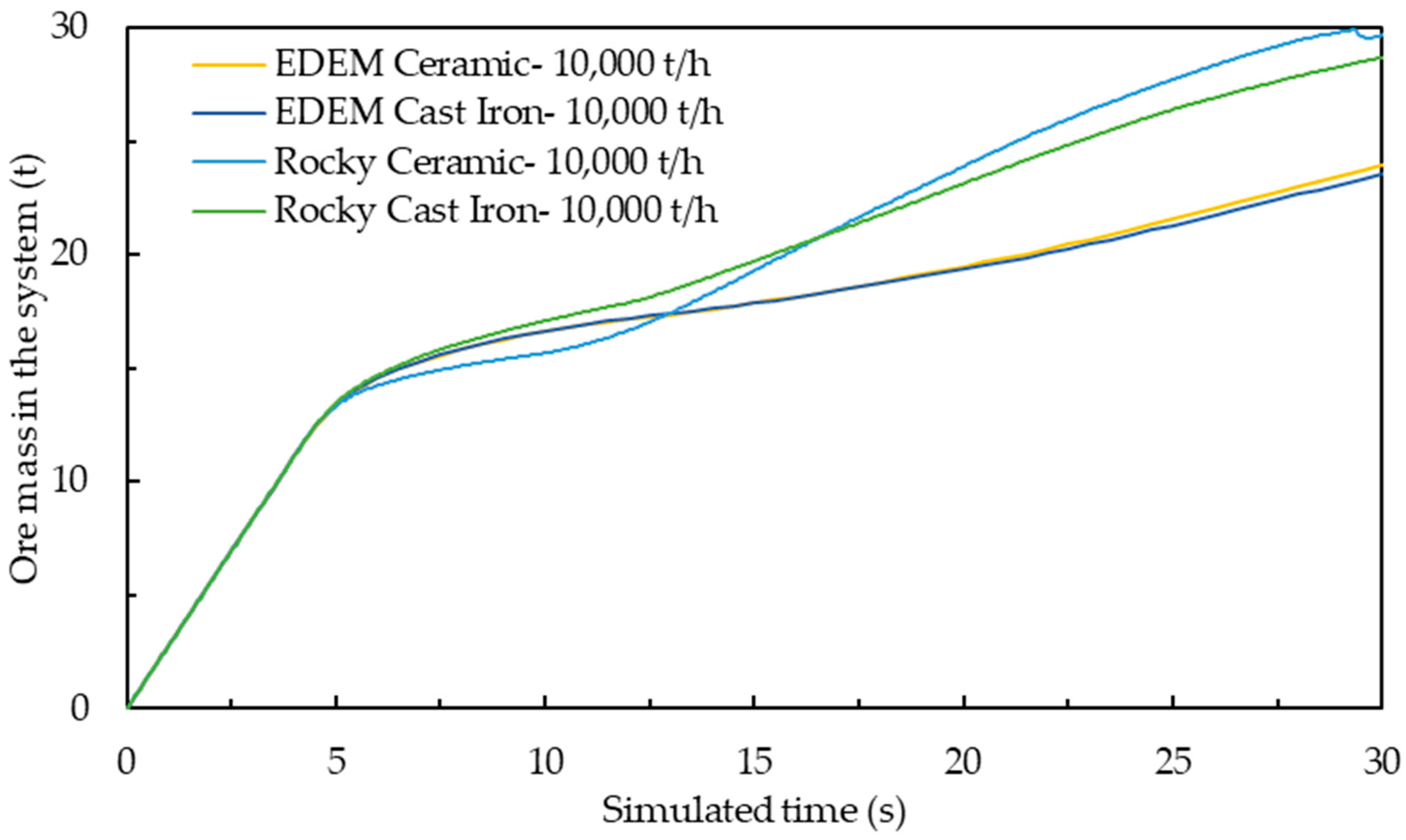

3.3. Industrial Chute Validation

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Simulation Number | Particle–Particle | Particle–Cast Iron | Objective Function— f (-) | Mass on Plate (kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (J/m2) | CoR (-) | SFC (-) | RFC (-) | (J/m2) | CoR (-) | SFC (-) | RFC (-) | ||||

| 1872 | 3.0 | 0.3 | 0.3 | 1.0 | 0 | 0.1 | 0.7 | 1.0 | 0.068 | 3.15 | |

| 1167 | 1.5 | 0.1 | 0.5 | 0.8 | 0 | 0.1 | 0.7 | 0.8 | 0.069 | 2.36 | |

| 1168 | 1.5 | 0.1 | 0.5 | 1.0 | 0 | 0.1 | 0.7 | 1.0 | 0.070 | 2.05 | |

| 0208 | 0 | 0.1 | 0.7 | 1.0 | 0 | 0.1 | 0.7 | 1.0 | 0.074 | 2.55 | |

| 1678 | 3.0 | 0.1 | 0.5 | 0.6 | 0 | 0.1 | 0.7 | 0.6 | 0.076 | 1.63 | |

| Simulation Number | Particle–Particle | Particle–Cast Iron | Objective Function— f (-) | Mass on Plate (kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (J/m2) | CoR (-) | SFC (-) | RFC (-) | (J/m2) | CoR (-) | SFC (-) | RFC (-) | ||||

| 1678 | 3.0 | 0.1 | 0.5 | 0.6 | 0 | 0.1 | 0.7 | 0.6 | 0.298 | 1.63 | |

| 1167 | 1.5 | 0.1 | 0.5 | 0.8 | 0 | 0.1 | 0.7 | 0.8 | 0.301 | 2.36 | |

| 0727 | 0.5 | 0.1 | 0.7 | 0.8 | 0.5 | 0.1 | 0.3 | 0.8 | 0.303 | 0.37 | |

| 0208 | 0.0 | 0.1 | 0.7 | 1.0 | 0 | 0.1 | 0.7 | 1.0 | 0.305 | 2.55 | |

| 1168 | 1.5 | 0.1 | 0.5 | 1.0 | 0 | 0.1 | 0.7 | 1.0 | 0.305 | 2.05 | |

References

- CEMA. Belt Conveyors for Bulk Materials, 7th ed.; CEMA: Bonita Springs, FL, USA, 2014. [Google Scholar]

- Swinderman, R.T.; Marti, A.D.; Goldbeck, L.J.; Marshall, D.; Strebel, M.G. Foundations™ The Practical Resource for Cleaner, Safer, More Productive Dust & Material Control, 4th ed.; Martin Engineering Company: Neponset, IL, USA, 2009. [Google Scholar]

- Benjamin, C.; Donecker, P.; Huque, S.; Rozentals, J. The Transfer Chute Design Manual for Conveyor Belt Systems; Conveyor Transfer Design Pty Ltd.: Spring Hill, QLD, Australia, 2015. [Google Scholar]

- Gavi, J. Solução em Transporte e Transferência de Materiais. Manual de Inspeção e Manutenção de Correias Transportadoras e seus Periféricos, 1st ed.; Vitória: Bios Editoração, Brasil, 2011. [Google Scholar]

- Cundall, P.A.; Strack, O.D.L. A discrete numerical model for granular assemblies. Géotechnique 1979, 29, 47–65. [Google Scholar] [CrossRef]

- Kessler, F.; Prenner, M. DEM—Simulation of Conveyor Transfer Chutes. FME Trans. 2009, 37, 185–192. [Google Scholar]

- Grima, A.; Hastie, D.; Curry, D.; Wypych, P.; Laroche, R. The Beginning of a New Era in Design: Calibrated Discrete Element Modelling. Aust. Bulk Handl. Rev. 2011, 16, 14–21. [Google Scholar]

- Mason, A. Improved Transfer Chute Design Using DEM Software to Predict Material Flow Behavior. Bachelor of Engineering (Mechanical) Dissertation, University of Southern Queensland, Toowoomba, QLD, Australia, 2016. [Google Scholar]

- Bharadwaj, R. Using DEM to Solve Bulk Material Handling Problems. Chem. Eng. Prog. 2012, 108, 54–58. [Google Scholar]

- Ilic, D.; Donohue, T.J. On the Design and Analysis of Transfer Chute Systems. In Proceedings of the XXVI Encontro Nacional de Tratamento de Minérios e Metalurgia Extrativa, Poços de Caldas, Brazil, 18–22 October 2015. [Google Scholar]

- Gröger, T.; Katterfeld, A. Discrete Element Simulation of Transfer Stations and Their Verification. Bulk Solids Handl. 2007, 27, 158–166. [Google Scholar]

- Rossow, J.; Coetzee, C.J. Discrete element modelling of a chevron patterned conveyor belt and a transfer chute. Powder Technol. 2021, 391, 77–96. [Google Scholar] [CrossRef]

- Coetzee, C.; Scheffler, O.C. Comparing particle shape representations and contact models for DEM simulation of bulk cohesive behaviour. Comput. Geotech. 2023, 159, 105449. [Google Scholar] [CrossRef]

- Scheffler, O.C.; Coetzee, C. DEM calibration for simulating bulk cohesive materials. Comput. Geotech. 2023, 161, 105476. [Google Scholar] [CrossRef]

- Katterfeld, A.; Donohue, T.; Ilic, D. Application of the Discrete Element Method in Mechanical Conveying of Bulk Materials. In Proceedings of the 7th International Conference for Conveying and Handling of Particulate Solids (CHoPS), Friedrichshafen, Germany, 10–13 September 2012. [Google Scholar]

- Ilic, D.; Ariff, F.M.; Sommer, K.; Santos, M.; Yuming, D. Application of DEM to Blending and Homogeneity Evaluation and Improvement in a Belt Conveyor Transfer Chute System. In Proceedings of the Ninth World Conference on Sampling and Blending (WCSB), Beijing, China, 6–9 May 2019. [Google Scholar]

- Weinhart, T.; Labra, C.; Luding, S.; Ooi, J.Y. Influence of coarse-graining parameters on the analysis of DEM simulations of silo flow. Powder Technol. 2016, 293, 138–148. [Google Scholar] [CrossRef]

- Chu, K.; Chen, J.; Yu, A. Applicability of a coarse-grained CFD–DEM model on dense medium cyclone. Miner. Eng. 2016, 90, 43–54. [Google Scholar] [CrossRef]

- Xu, L.; Wu, X.; Wang, S.; Bao, S. Multi-level coarse-grained discrete element method modeling of cylinder particle flow in a rotating drum. Particuology 2024, 88, 218–238. [Google Scholar] [CrossRef]

- Lommen, S.; Mohajeri, M.; Lodewijks, G.; Schott, D. DEM particle upscaling for large-scale bulk handling equipment and material interaction. Powder Technol. 2019, 352, 273–282. [Google Scholar] [CrossRef]

- Coetzee, C.J. Review: Calibration of the Discrete Element Method. Powder Technol. 2017, 310, 104–142. [Google Scholar] [CrossRef]

- Coetzee, C.J.; Scheffler, O.C. The calibration of dem parameters for the bulk modelling of cohesive materials. Processes 2022, 11, 5. [Google Scholar] [CrossRef]

- Carr, M.J.; Roessler, T.; Robinson, P.W.; Otto, H.; Richter, C.; Katterfeld, A.; Wheeler, C.A. Calibration procedure of Discrete Element Method (DEM) parameters for wet and sticky bulk materials. Powder Technol. 2023, 429, 118919. [Google Scholar] [CrossRef]

- Liu, Z.; Yuan, J.; Shen, J.; Hu, Y.; Chen, S. A new DEM calibration method for wet and stick materials based on the BP neural network. Powder Technol. 2024, 448, 120228. [Google Scholar] [CrossRef]

- Mohajeri, M.J.; Rhee, C.; Schott, D.L. Replicating cohesive and stress-history-dependent behavior of bulksolids: Feasibility and definiteness in DEM calibration procedure. Adv. Powder Technol. 2021, 32, 1532–1548. [Google Scholar] [CrossRef]

- Barrios, G.K.P.; de Carvalho, R.M.; Kwade, A.; Tavares, L.M. Contact Parameter Estimation for DEM Simulation of Iron Ore Pellet Handling. Powder Technol. 2013, 248, 84–93. [Google Scholar] [CrossRef]

- Roessler, T.; Katterfeld, A. Scaling of the angle of repose test and its influence on the calibration of DEM parameters using upscaled particles. Powder Technol. 2018, 330, 58–66. [Google Scholar] [CrossRef]

- Rackl, M.; Hanley, K.J. A Methodical Calibration Procedure for Discrete Element Models. Powder Technol. 2016, 307, 73–83. [Google Scholar] [CrossRef]

- You, Y.; Guo, J.; Li, G.; Lv, X.; Wu, S.; Li, Y.; Yang, R. Investigation the iron ore fine granulation effects and particle adhesion behavior in a horizontal high-shear granulator. Powder Technol. 2021, 394, 162–170. [Google Scholar] [CrossRef]

- Mohajeri, M.J.; de Kluijver, W.; Helmons, R.L.; van Rhee, C.; Schott, D.L. A validated co-simulation of grab and moist iron ore cargo: Replicating the cohesive and stress-history dependent behaviour of bulk solids. Adv. Powder Technol. 2021, 32, 1157–1169. [Google Scholar] [CrossRef]

- Ilic, D.; Roberts, A.; Wheeler, C. Modelling bulk solid interactions in transfer chutes: Accelerated flow. Chem. Eng. Sci. 2019, 209, 115197. [Google Scholar] [CrossRef]

- Magalhães, M.F.; Chieregati, A.C.; Ilic, D.; de Carvalho, R.M.; Lemos, M.G.; Delboni, H., Jr. Use of Discrete Element Modelling to evaluate the parameters of the sampling theory in the feed grade sampler of a sulphide gold plant. Minerals 2021, 11, 978. [Google Scholar] [CrossRef]

- Basu, S.; Chakrabarty, A.; Nag, S.; Behera, K.; Bandyopadhyay, B.; Grima, A.P.; Ghosh, P. Design modification of iron ore bearing transfer chute using discrete element method. Eng. Comput. 2021, 38, 3590–3607. [Google Scholar] [CrossRef]

- Kumar, R.; Jha, P.K.; Kishore, R.; Singh, R.K.; Subrahmanyam, T.V.S.; Chaurasiya, S.K.; Mangipudi, K.R.; Sahu, K.K. Analysing the flow of wet iron ore in an industrial transfer chute using discrete element method. Miner. Process. Extr. Metall. 2024, 133, 131–146. [Google Scholar] [CrossRef]

- Oliveira, G.P.; de Carvalho, R.M.; Machado, B.P. Simulação do carregamento de pelotas de minério de ferro em navios de porão conjugado com o método de elementos discretos. In Proceedings of the 37° Seminário de Logística–Proceedings, São Paulo, Brazil, 2–4 October 2018. [Google Scholar]

- Chen, W.; Roberts, A.; Katterfeld, A.; Wheeler, C. Modelling the stability of iron ore bulk cargoes during marine transport. Powder Technol. 2018, 326, 255–264. [Google Scholar] [CrossRef]

- Coetzee, C. Calibration of the discrete element method: Strategies for spherical and non-spherical particles. Powder Technol. 2020, 364, 851–878. [Google Scholar] [CrossRef]

- Roessler, T.; Richter, C.; Katterfeld, A.; Will, F. Development of a standard calibration procedure for the DEM parameters of cohesionless bulk materials–part I: Solving the problem of ambiguous parameter combinations. Powder Technol. 2019, 343, 803–812. [Google Scholar] [CrossRef]

- Weerasekara, N.S.; Powell, M.S.; Cleary, P.W.; Tavares, L.M.; Evertsson, M.; Morrison, R.D.; Quist, J.; Carvalho, R.M. Review The contribution of DEM to the science of comminution. Powder Technol. 2013, 248, 3–24. [Google Scholar] [CrossRef]

- Grima, A.P.; Wypych, P.W. Investigation into calibration of discrete element model parameters for scale-up and validation of particle–structure interactions under impact conditions. Powder Technol. 2011, 212, 198–209. [Google Scholar] [CrossRef]

- Hertz, H. Uber die Beruhrung fester elastischer Korper. J. Fur Die Reine Und Angew. Math. 1882, 92, 156–171. [Google Scholar] [CrossRef]

- Mindlin, R.D.; Deresiewicz, H. Elastic Spheres in Contact Under Varying Oblique Forces. J. Appl. Mech. 1953, 20, 327–344. [Google Scholar] [CrossRef]

- Carr, M.J.; Chen, W.; Williams, K.; Katterfeld, A. Comparative investigation on modelling wet and sticky material behaviours with a simplified JKR cohesion model and liquid bridging cohesion model in DEM. In Proceedings of the ICBMH 2016-12th International Conference on Bulk Materials Storage, Handling and Transportation, Proceedings, Darwin, Australia, 11–14 July 2016. [Google Scholar]

- Ucgul, M.; Fielke, J.M.; Saunders, C. Three-dimensional discrete element modelling (DEM) of tillage: Accounting for soil cohesion and adhesion. Biosyst. Eng. 2015, 129, 298–306. [Google Scholar] [CrossRef]

- Schulze, D. Powders and Bulk Solids: Behavior, Characterization, Storage and Flow; Springer: New York, NY, USA, 2007. [Google Scholar]

- Johnson, K.L.; Kendall, K.; Roberts, A.D. Surface energy and the contact of elastic solids. Proc. R. Soc. London. Ser. A Math. Phys. Sci. 1971, 324, 301–313. [Google Scholar]

- Ajmal, M.; Roessler, T.; Richter, C.; Katterfeld, A. Calibration of cohesive DEM parameters under rapid flow conditions and low consolidation stresses. Powder Technol. 2020, 374, 22–32. [Google Scholar] [CrossRef]

- DCS Computing. LIGGGHTS(R) PUBLIC Documentation. Version 3.X (2016), CFDEM Research. Available online: https://www.cfdem.com/media/DEM/docu/Manual.html (accessed on 10 December 2024).

- Huynh, T.Q.; Nguyen, T.T.; Indraratna, B. Evaluating cohesive models in discrete element simulation through drawdown test with new assessment perspectives. Powder Technol. 2024, 452, 120542. [Google Scholar] [CrossRef]

- Easo, L.A.; Wassgren, C.R. Comparison of liquid bridge volume models in DEM simulations. In Proceedings of the AIChE Annual Meeting Proceedings (Vol. 1), San Francisco, CA, USA, 3–8 November 2013. [Google Scholar]

- Govender, N.; Rajamani, R.; Wilke, D.N.; Wu, C.Y.; Khinast, J.; Glasser, B.J. Effect of particle shape in grinding mills using a GPU based DEM code. Miner. Eng. 2018, 129, 71–84. [Google Scholar] [CrossRef]

- Coetzee, C.J. Calibration of the discrete element method and the effect of particle shape. Powder Technol. 2016, 297, 50–70. [Google Scholar] [CrossRef]

- Zhou, H.; Hu, Z.; Chen, J.; Lv, X.; Xie, N. Calibration of DEM models for irregular particles based on experimental design method and bulk experiments. Powder Technol. 2018, 332, 210–223. [Google Scholar] [CrossRef]

- Wensrich, C.M.; Katterfeld, A. Rolling Friction as a Technique for Modelling Particle Shape in DEM. Powder Technol. 2012, 217, 409–417. [Google Scholar] [CrossRef]

- Ai, J.; Chen, J.F.; Rotter, J.M.; Ooi, J.Y. Assessment of Rolling Resistance Models in Discrete Element Simulations. Powder Technol. 2011, 206, 269–282. [Google Scholar] [CrossRef]

- 56. ASTM A532; Standard Specification for Abrasion-Resistant Cast Irons. ASTM, American Society for Testing and Materials: West Conshohocken, PA, USA, 2014.

- ABNT, Associação Brasileira de Normas Técnicas. NBR 17177: Transportadores Contínuos de Correia—Simulação do Escoamento de Granéis Sólidos em Chutes de Transferência Aplicando o Método dos Elementos Discretos (DEM)—Método para Calibração de Parâmetros de Contato—Padronização de Relatório de Simulação; ABNT, Associação Brasileira de Normas Técnicas: Rio de Janeiro, Brasil, 2024. [Google Scholar]

- Grima, A.; Wypych, P. Discrete Element Simulation of a Conveyor Impact-Plate Transfer: Calibration, Validation and Scale-Up. Aust. Bulk Handl. Rev. 2010, 3, 64–72. [Google Scholar]

- Ilic, D. Bulk Solid Interactions in Belt Conveying Systems. Doctor of Philosophy of Mechanical. Ph.D. Thesis, The University of Newcastle, Callaghan, NSW, Australia, 2013; p. 304. [Google Scholar]

- Mascarenhas, F.P.; Mesquita, A.L.A. Simulation of Transfer Chute Operation Using the Discrete Element Method. In Proceedings of the XXXIV Iberian Latin-American Congress on Computational Methods in Engineering (CILAMCE), Pirenópolis, Brazil, 10–13 November 2013. [Google Scholar]

- Coetzee, C.J. Particle Upscaling: Calibration and Validation of the Discrete Element Method. Powder Technol. 2019, 344, 487–503. [Google Scholar] [CrossRef]

- Li, C.; Honeyands, T.; O’dea, D.; Moreno-Atanasio, R. The Angle of Repose and Size Segregation of Iron Ore Granules: DEM Analysis and Experimental Investigation. Powder Technol. 2017, 320, 257–272. [Google Scholar] [CrossRef]

- Tsuji, Y.; Tanaka, T.; Ishida, T. Lagrangian numerical simulation of plug flow of cohesionless particles in a horizontal pipe. Powder Technol. 1992, 71, 239–250. [Google Scholar] [CrossRef]

- Mindlin, R.D. Compliance of Elastic Bodies in Contact. J. Appl. Mech. 1949, 16, 259–268. [Google Scholar] [CrossRef]

- Sakaguchi, H.; Ozaki, E.; Igarashi, T. Plugging of the flow of granular materials during the discharge from a silo. Int. J. Mod. Phys. B 1993, 7, 1949–1963. [Google Scholar] [CrossRef]

| Component | Fe | SiO2 | Al2O3 | P | Mn | Loss on Ignition |

|---|---|---|---|---|---|---|

| % | 56.85 | 14.42 | 1.50 | 0.053 | 0.170 | 2.18 |

| Software | EDEM 2022 | Rocky 4.2 | Contact Parameters |

|---|---|---|---|

| Normal force | Hertzian Spring Dashpot [63] | Hertzian Spring Dashpot [63] | CoR/SFC |

| Tangential Force | No-slip—Mindlin [64] | Mindlin–Deresiewicz [42] | |

| Adhesive Force | JKR—Johnson et al. [46] | JKR—Johnson et al. [46] | |

| Rolling friction | Standard—Type A [65] | Type C [55] | RFC |

| Restitution—CoR | Static Friction—SFC | Rolling Friction *—RFC | |

|---|---|---|---|

| 0.1 | 0 | 0.1 | 0.05 |

| 0.3 | 0.5 | 0.3 | 0.2 |

| 0.5 | 1.5 | 0.5 | 0.4 |

| - | 3.0 | 0.7 | 0.6 |

| Test | Objective Function | Weight |

|---|---|---|

| Repose angle | 1 | |

| Sliding angle | 3 | |

| Tumbling (15 rpm) * | 0.002 | |

| Tumbling (30 rpm) * | 0.002 | |

| Drawdown (horizontal) | 0.007 | |

| Drawdown (30°) | 0.007 |

| Test | Measurement | Surface | |||

|---|---|---|---|---|---|

| Cast Iron | Ceramic | ||||

| Mean | Standard Deviation | Mean | Standard Deviation | ||

| Slump | Repose angle (°) | 52.6 | 3.5 | 49.3 | 3.7 |

| Inclined angle | Sliding angle (°) | 36.1 | 1.6 | 33.7 | 1.9 |

| Drawdown | Mass on top section (%) | 62.64 | 2.32 | 62.64 | 2.32 |

| Drawdown | Mass on inclined plate (%) | 16.24 | 0.36 | 13.93 | 0.09 |

| Tumbling (15 rpm) | Foot angle (°) | 112 | 1 | - | - |

| Tumbling (15 rpm) | Detachment angle (°) | 15 | 1 | - | - |

| Tumbling (30 rpm) | Foot angle (°) | 114 | 1 | - | - |

| Tumbling (30 rpm) | Detachment angle (°) | 18 | 1 | - | - |

| Simulation Number | Particle–Particle | Particle–Cast Iron | Objective Function— f (-) | Mass on Plate (kg) * | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (J/m2) | CoR (-) | SFC (-) | RFC (-) | (J/m2) | CoR (-) | SFC (-) | RFC (-) | ||||

| 21,459 | 3.00 | 0.50 | 0.30 | 0.00 | 3.00 | 0.50 | 0.70 | 0.40 | 0.487 | 0.00 | |

| 36,867 | 1.75 | 0.30 | 0.50 | 0.94 | 0 | 0.10 | 0.70 | 0.60 | 0.506 | 0.94 | |

| 21,477 | 1.50 | 0.30 | 0.50 | 1.50 | 0 | 0.10 | 0.70 | 0.60 | 0.515 | 1.50 | |

| 36,881 | 1.50 | 0.30 | 0.50 | 1.84 | 0 | 0.10 | 0.70 | 0.65 | 0.520 | 1.84 | |

| 36,908 | 0.50 | 0.50 | 0.30 | 1.28 | 0 | 0.50 | 0.70 | 0.60 | 0.520 | 1.28 | |

| Simulation Number | Particle–Particle | Particle–Cast Iron | Objective Function— f (-) | Mass on Plate * (kg) | |||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| (J/m2) | CoR (-) | SFC (-) | RFC (-) | (J/m2) | CoR (-) | SFC (-) | RFC (-) | ||||

| 36,887 | 1.50 | 0.30 | 0.50 | 0.20 | 0.00 | 0.10 | 0.70 | 0.55 | 0.430 | 0.63 | |

| 36,907 | 1.50 | 0.30 | 0.50 | 0.20 | 0.00 | 0.10 | 0.70 | 0.60 | 0.431 | 1.50 | |

| 36,881 | 1.50 | 0.30 | 0.50 | 0.20 | 0.00 | 0.10 | 0.70 | 0.65 | 0.456 | 1.84 | |

| 36,886 | 1.50 | 0.30 | 0.50 | 0.20 | 0.00 | 0.10 | 0.70 | 0.45 | 0.456 | 0.18 | |

| 36,882 | 1.50 | 0.30 | 0.50 | 0.20 | 0.00 | 0.10 | 0.70 | 0.50 | 0.496 | 0.53 | |

| Software | Lining Surface | Particle–Particle | Particle–Geometry | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| JKR (J/m2) | Restitution | Static Friction | Rolling Friction | JKR (J/m2) | Restitution | Static Friction | Rolling Friction | |||

| EDEM | Cast iron | 1.50 | 0.30 | 0.50 | 0.20 | 0 | 0.10 | 0.70 | 0.65 | |

| EDEM | Ceramic | 1.50 | 0.30 | 0.50 | 0.20 | 0 | 0.10 | 0.70 | 0.45 | |

| Rocky | Cast iron | 0 | 0.10 | 0.70 | 1.00 | 0 | 0.10 | 0.70 | 1.00 | |

| Rocky | Ceramic | 0.50 | 0.10 | 0.70 | 0.80 | 0.50 | 0.10 | 0.30 | 0.80 | |

| BFA | - | 0.30 * | - | 0.30 | - | 0.03 * | - | 0.60 | - | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de Oliveira, G.P.; de Carvalho, R.M.; de Souza Almeida, H.P.; Tavares, L.M. Robust Estimation and Validation of Contact Parameters of Iron Ore for Transfer Chute Simulation. Minerals 2025, 15, 175. https://doi.org/10.3390/min15020175

de Oliveira GP, de Carvalho RM, de Souza Almeida HP, Tavares LM. Robust Estimation and Validation of Contact Parameters of Iron Ore for Transfer Chute Simulation. Minerals. 2025; 15(2):175. https://doi.org/10.3390/min15020175

Chicago/Turabian Stylede Oliveira, Guilherme Pereira, Rodrigo Magalhães de Carvalho, Henrique Peixoto de Souza Almeida, and Luís Marcelo Tavares. 2025. "Robust Estimation and Validation of Contact Parameters of Iron Ore for Transfer Chute Simulation" Minerals 15, no. 2: 175. https://doi.org/10.3390/min15020175

APA Stylede Oliveira, G. P., de Carvalho, R. M., de Souza Almeida, H. P., & Tavares, L. M. (2025). Robust Estimation and Validation of Contact Parameters of Iron Ore for Transfer Chute Simulation. Minerals, 15(2), 175. https://doi.org/10.3390/min15020175