Proposal of a Method for Calculating the Bond Work Index for Samples with Non-Standard Feed Particle Size Distribution

Abstract

1. Introduction

- Monitoring the influence of the initial particle size of the sample on the Bond Work Index values during the execution of the standard Bond test;

- Defining a model for determining the Bond Work Index for standard particle size samples based on the known Bond Work Index value for a non-standard particle size sample;

- Testing the accuracy of the model using results from laboratory experiments and available data from the reviewed literature.

2. Materials and Methods

3. Results and Discussion

- First, Bond’s standard test is performed on a sample of non-standard PSD;

- Then, the obtained parameters (wi,ns and Fns) from the Bond test on the non-standard PSD sample are used to estimate the wi for the standard PSD sample, using Equation (2).

4. Conclusions

- The value of the Bond work index increases as the particle size of the raw material decreases. For samples with an upper size limit significantly smaller than the standard size, the Bond work index value is higher than the Bond work index value obtained for the standard-sized sample.

- A model for determining the Bond work index for standard-sized samples has been presented, provided the Bond work index for a non-standard-sized sample is known.

- The model is applicable only for a closing screen size (P100) of 75 µm.

- The presented model was then tested on all available data found in the literature to verify the accuracy and validity of the model.

- When determining the Bond work index for a standard particle size sample, if the Bond work index value for a non-standard particle size sample on a 75 µm closing screen size is known, Equation (2) should be used, as it provides more reliable results.

- When determining the Bond work index for a standard particle size sample, if the Bond work index value for a non-standard particle size sample on a closing screen size of 149 µm is known, the model of Magdalinovic et al. [44] should be used, as it is currently the only model tested on a closing screen size of 149 µm.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

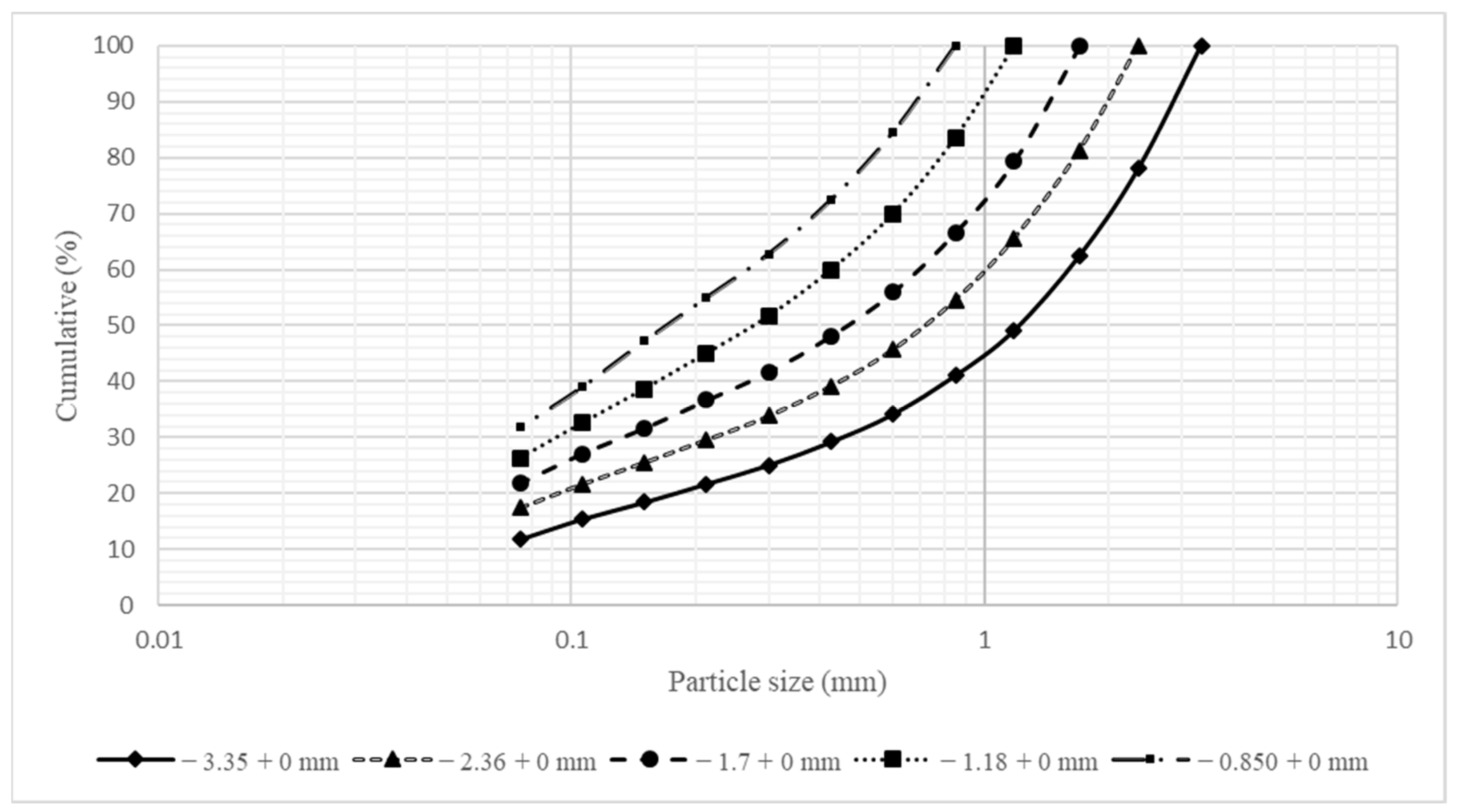

| Particle Size (mm) | Class Size in mm (%) | ||||

|---|---|---|---|---|---|

| −3.35 + 0 | −2.36 + 0 | −1.70 + 0 | −1.18 + 0 | −0.850 + 0 | |

| −3.35 + 2.36 | 21.95 | ||||

| −2.36 + 1.70 | 15.55 | 18.74 | |||

| −1.70 + 1.18 | 13.35 | 16.72 | 20.64 | ||

| −1.18 + 0.850 | 8.10 | 9.99 | 12.74 | 16.42 | |

| −0.850 + 0.600 | 6.90 | 8.86 | 10.69 | 13.64 | 15.51 |

| −0.600 + 0.425 | 4.95 | 6.51 | 7.80 | 9.99 | 12.02 |

| −0.425 + 0.300 | 4.14 | 5.33 | 6.46 | 8.28 | 9.68 |

| −0.300 + 0.212 | 3.37 | 4.26 | 5.02 | 6.66 | 7.82 |

| −0.212 + 0.150 | 3.26 | 4.04 | 5.00 | 6.39 | 7.75 |

| −0.150 + 0.106 | 3.01 | 3.87 | 4.56 | 6.07 | 8.23 |

| −0.106 + 0.075 | 3.62 | 4.23 | 5.27 | 6.25 | 7.20 |

| −0.075 + 0.00 | 11.80 | 17.45 | 21.82 | 26.30 | 31.79 |

| ∑ | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

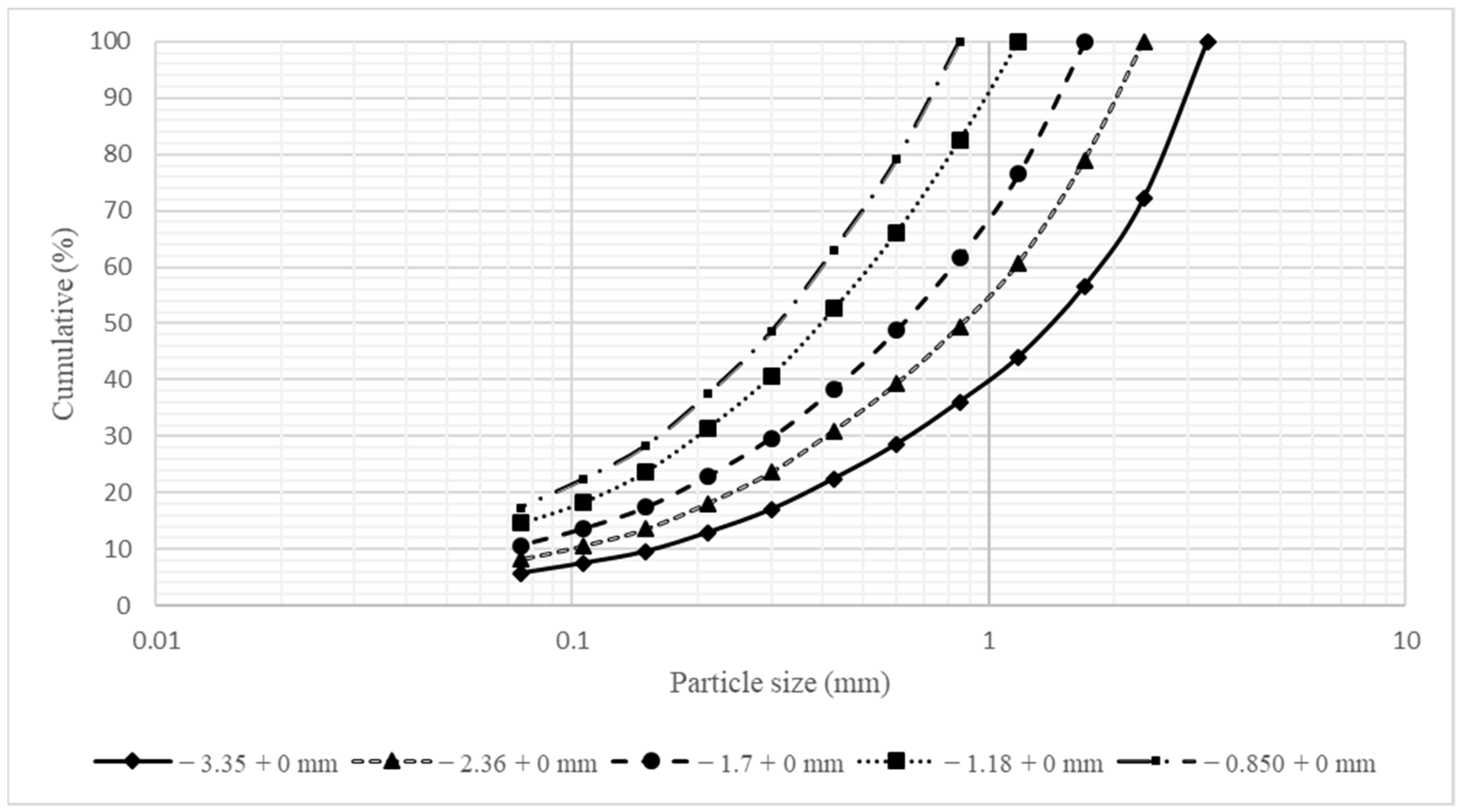

| Particle Size (mm) | Class Size in mm (%) | ||||

|---|---|---|---|---|---|

| −3.35 + 0 | −2.36 + 0 | −1.70 + 0 | −1.18 + 0 | −0.850 + 0 | |

| −3.35 + 2.36 | 27.77 | ||||

| −2.36 + 1.70 | 15.60 | 21.08 | |||

| −1.70 + 1.18 | 12.59 | 18.24 | 23.42 | ||

| −1.18 + 0.850 | 7.99 | 11.28 | 14.83 | 17.54 | |

| −0.850 + 0.600 | 7.52 | 10.18 | 12.98 | 16.40 | 20.91 |

| −0.600 + 0.425 | 6.10 | 8.28 | 10.36 | 13.47 | 16.02 |

| −0.425 + 0.300 | 5.45 | 7.39 | 8.76 | 11.94 | 14.62 |

| −0.300 + 0.212 | 4.05 | 5.46 | 6.73 | 9.21 | 10.95 |

| −0.212 + 0.150 | 3.39 | 4.57 | 5.55 | 7.76 | 9.25 |

| −0.150 + 0.106 | 2.08 | 3.00 | 3.78 | 5.46 | 5.93 |

| −0.106 + 0.075 | 1.77 | 2.39 | 2.92 | 3.68 | 5.02 |

| −0.075 + 0.00 | 5.69 | 8.13 | 10.67 | 14.54 | 17.30 |

| ∑ | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| Particle Size (mm) | Class Size in mm (%) | ||||

|---|---|---|---|---|---|

| −3.35 + 0 | −2.36 + 0 | −1.70 + 0 | −1.18 + 0 | −0.850 + 0 | |

| −3.35 + 2.36 | 29.92 | ||||

| −2.36 + 1.70 | 17.28 | 23.84 | |||

| −1.70 + 1.18 | 14.10 | 19.64 | 24.71 | ||

| −1.18 + 0.850 | 8.24 | 11.63 | 15.34 | 23.05 | |

| −0.850 + 0.600 | 7.38 | 10.22 | 13.14 | 18.60 | 23.14 |

| −0.600 + 0.425 | 5.18 | 7.39 | 10.20 | 13.29 | 16.76 |

| −0.425 + 0.300 | 4.33 | 6.19 | 8.32 | 10.45 | 13.55 |

| −0.300 + 0.212 | 2.96 | 4.36 | 6.00 | 7.00 | 9.71 |

| −0.212 + 0.150 | 2.44 | 3.76 | 4.84 | 6.00 | 8.04 |

| −0.150 + 0.106 | 1.72 | 2.59 | 3.10 | 4.23 | 5.64 |

| −0.106 + 0.075 | 1.47 | 2.28 | 3.14 | 3.79 | 4.98 |

| −0.075 + 0.00 | 4.98 | 8.10 | 11.21 | 13.59 | 18.18 |

| ∑ | 100.00 | 100.00 | 100.00 | 100.00 | 100.00 |

| Sample | Class Size (mm) | P100 = 75 µm | |

|---|---|---|---|

| F80 (μm) | wi (kWh/t) | ||

| Zeolite | −3.35 + 0 | 2440 | 9.834 |

| −2.36 + 0 | 1652 | 10.010 | |

| −1.70 + 0 | 1090 | 10.197 | |

| −1.18 + 0 | 727 | 10.371 | |

| −0.850 + 0 | 544 | 10.572 | |

| Dacite | −3.35 + 0 | 2646 | 17.800 |

| −2.36 + 0 | 1729 | 18.130 | |

| −1.70 + 0 | 1253 | 18.333 | |

| −1.18 + 0 | 807 | 18.827 | |

| −0.850 + 0 | 609 | 19.196 | |

| Basalt | −3.35 + 0 | 2609.1 | 21.098 |

| −2.36 + 0 | 1800.1 | 21.659 | |

| −1.70 + 0 | 1278 | 21.951 | |

| −1.18 + 0 | 892 | 22.352 | |

| −0.850 + 0 | 633 | 22.874 | |

References

- Bond, F.C. The third theory of comminution. Trans. Am. Inst. Min. Metall. Eng. 1952, 193, 484–494. [Google Scholar]

- Napier-Munn, T.; Morell, S.; Morrison, R.; Kojovic, T. Mineral Comminution Circuits: Their Operation and Optimisation, 2nd ed.; Julius Kruttschnitt Mineral Research Centre, The University of Queensland: Queensland, Australia, 1999; p. 413. [Google Scholar]

- Haffez, G.S.A. Correlation between bond work index and mechanical properties of some saudi ores. J. Eng. Sci. 2012, 40, 271–280. [Google Scholar]

- Gupta, V.K. Understanding production of fines in batch ball milling for mill scale-up design using the population balance model. Adv. Powder Technol. 2018, 29, 2035–2047. [Google Scholar]

- Mosher, J.B.; Tague, C.B. Conduct and precision of Bond grindability testing. Miner. Eng. 2001, 14, 1187–1197. [Google Scholar]

- Jankovic, A.; Suthers, S.; Wills, T.; Valery, W. Evaluation of dry grinding using HPGR in closed circuit with an airclassifier. Miner. Eng. 2015, 71, 133–138. [Google Scholar]

- Bond, F.C. Standard grindability test tabulated. Trans. Am. Inst. Min. Metall. Eng. 1949, 183, 313–329. [Google Scholar]

- Bond, F.C. Crushing grinding calculation part I and II. Br. Chem. Eng. 1961, 6, 378–385, 543–548. [Google Scholar]

- Nikolić, V.; García, G.G.; Coello-Velázquez, L.A.; Menéndez-Aguado, M.J.; Trumić, M.; Trumić, S.M. A Review of Alternative Procedures to the Bond Ball Mill Standard Grindability Test. Metals 2021, 11, 1114. [Google Scholar] [CrossRef]

- Nikolić, V.; Ferradal, P.S.; Pierres, J.M.; Menéndez-Aguado, J.M.; Trumić, M. Methods for Estimating the Bond Work Index for Ball Mills. Minerals 2024, 14, 1264. [Google Scholar] [CrossRef]

- Berry, T.F.; Bruce, R.W. A simple method of determining the grindability of ores. Can. Min. J. 1966, 87, 63–65. [Google Scholar]

- Smith, R.W.; Lee, K.H. A comparison of data from Bond type simulated closed circuit and batch type grindability tests. Trans. Metallur. Soc. AIME 1968, 241, 91–99. [Google Scholar]

- Kapur, P.C. Analysis of the Bond grindability test. Trans. Inst. Min. Metallur. 1970, 79, 103–107. [Google Scholar]

- Horst, W.E.; Bassarear, J.H. Use of simplified ore grindability technique to evaluate plant performance. Trans. Metallur. Soc. AIME 1977, 260, 348–351. [Google Scholar]

- Karra, V.K. Simulation of Bond grindability tests. CIM Bull. 1981, 74, 195–199. [Google Scholar]

- Mular, A.L.; Jergensen, G.V. Design and Installation of Comminution Circuits; Society of Mining Engineers of the American Institute of Mining, Metallurgical, and Petroleum Engineers, Inc.: New York, NY, USA, 1982; p. 1022. [Google Scholar]

- Magdalinović, N. A procedure for rapid determination of the Bond work index. Int. J. Miner. Process. 1989, 27, 125–132. [Google Scholar]

- Magdalinović, N. Abbreviated test for quick determination of Bond’s Work index. J. Min. Metallur. 2003, 39, 1–10. [Google Scholar]

- Ahmadi, R.; Shahsavari, S. Procedure for determination of ball Bond work index in the commercial operations. Miner. Eng. 2009, 22, 104–106. [Google Scholar] [CrossRef]

- Ford, E.; Sithole, V. A Comparison of Test Procedures for Estimating the Bond Ball Work Index on Zambian/DRC Copper-Cobalt Ores and Evaluation of Suitability for Use in Geometallurgical Studies. In Proceedings of the Copper Cobalt Africa, Incorporating the 8th Southern African Base Metals Conference, Livingstone, Zambia, 6–8 July 2015; pp. 65–68. [Google Scholar]

- Todorovic, D.; Trumic, M.; Andric, L.; Milosevic, V.; Trumic, M. A quick method for bond work index approximate value determination. Physicochem. Probl. Miner. Process. 2017, 53, 321–332. [Google Scholar]

- Lewis, K.A.; Pearl, M.; Tucker, P. Computer Simulation of the Bond Grindability test. Miner. Eng. 1990, 3, 199–206. [Google Scholar] [CrossRef]

- Aksani, B.; Sönmez, B. Simulation of bond grindability test by using cumulative based kinetic model. Miner. Eng. 2000, 13, 673–677. [Google Scholar] [CrossRef]

- Ciribeni, V.; Bertero, R.; Tello, A.; Puerta, M.; Avellá, E.; Paez, M.; Menéndez-Aguado, J.M. Application of the Cumulative Kinetic Model in the Comminution of Critical Metal Ores. Metals 2020, 10, 925. [Google Scholar]

- Camalan, M. A computational algorithm coupled with a particle selection routine for the simulation of the Bond locked-cycle test. Miner. Eng. 2022, 176, 107345. [Google Scholar]

- Rodríguez-Torres, I.; Tuzcu, E.T.; Andrade-Martínez, J.; Rosales-Marín, G. Estimation methodology for Bond ball mill work index experiment output via mathematical modeling. Miner. Eng. 2023, 201, 108186. [Google Scholar]

- Yap, R.F.; Sepulveda, J.L.; Jauregui, R. Determination of the Bond work index using an ordinary batch ball mill. In Design and Installation of Comminution Circuits; Mular, A.L., Jergensen, G.V., Eds.; AIME: New York, NY, USA, 1982; pp. 176–203. [Google Scholar]

- Nematollahi, H. New size laboratory ball mill for Bond work index determination. Miner. Eng. 1994, 46, 352–353. [Google Scholar]

- Menéndez-Aguado, J.M.; Dzioba, B.R.; Coello-Valazquez, A.L. Determination of work index in a common laboratory mill. Miner. Metall. Process. 2005, 22, 173–176. [Google Scholar]

- Mucsi, G. Fast test method for the determination of the grindability of fine materials. Chem. Eng. Res. Des. 2008, 86, 395–400. [Google Scholar] [CrossRef]

- Swain, R.; Rao, R.B. Alternative Approaches for Determination of Bond Work Index on Soft Friable Partially Laterised Khondalite Rocks of Bauxite Mine Waste Materials. J. Miner. Mater. Charact. Eng. 2009, 8, 729–743. [Google Scholar]

- Saeidi, N.; Noaparast, M.; Azizi, D.; Aslani, S.; Ramadi, A. A developed approach based on grinding time to determine ore comminution properties. J. Miner. Environ. 2013, 4, 105–112. [Google Scholar]

- Mwanga, A.; Rosenkranz, J.; Lamberg, P. Development and experimental validation of the Geometallurgical Comminution Test (GCT). Miner. Eng. 2017, 108, 109–114. [Google Scholar]

- Lvov, V.V.; Chitalov, L.S.; Struk, G.V.; Rakov, A.V. Research of the MSL-14K mill applicability to determine the Bond ball mill work index, MIAB. Min. Informational Anal. Bull. 2022, 6, 290–303. (In Russian) [Google Scholar] [CrossRef]

- Arellano-Piña, R.; Sanchez-Ramirez, E.A.; Pérez-Garibay, R.; Gutiérrez-Pérez, V.H. Bond’s work index estimation using non-standard ball mills. Physicochem. Probl. Miner. Process. 2023, 59, 172458. [Google Scholar]

- Tüzün, M.A. Wet bond mill test. Miner. Eng. 2001, 14, 369–373. [Google Scholar]

- Deniz, V.; Sütçü, N.; Umucu, Y. The effect of circulating load and test sieve size on the Bond work index based on natural amorphous silica. In Proceedings of the 18th International Mining Congress and Exhibition of Turkey-IMCET, Antalya, Turkey, 10–13 June 2003; pp. 517–522, ISBN 975-395-605-3. [Google Scholar]

- Josefin, Y.; Doll, A.G. Correction of Bond Ball Mill Work Index Test for Closing Mesh Sizes, Procemin-Geomet 2018. In Proceedings of the 14th International Mineral Processing Conference & 5th International Seminar on Geometallurgy, Santiago, Chile, 28–30 November 2018; pp. 1–12. [Google Scholar]

- Ciribeni, V.; Menéndez-Aguado, J.M.; Bertero, R.; Tello, A.; Avellá, E.; Paez, M.; Coello-Velázquez, A.L. Unveiling the Link between the Third Law of Comminution and the Grinding Kinetics Behaviour of Several Ores. Metals 2021, 11, 1079. [Google Scholar] [CrossRef]

- García, G.G.; Oliva, J.; Guasch, E.; Anticoi, H.; Coello-Velázquez, A.L.; Menéndez-Aguado, J.M. Variability Study of Bond Work Index and Grindability Index on Various Critical Metal Ores. Metals 2021, 11, 970. [Google Scholar] [CrossRef]

- García, G.G.; Coello-Velázquez, A.L.; Pérez, B.F.; Menéndez-Aguado, J.M. Variability of the Ball Mill Bond’s Standard Test in a Ta Ore Due to the Lack of Standardization. Metals 2021, 11, 1606. [Google Scholar] [CrossRef]

- Nikolić, V.; Trumić, M. A new approach to the calculation of bond work index for finer samples. Miner. Eng. 2021, 165, 106858. [Google Scholar]

- Nikolić, V.; Doll, A.; Trumić, M. A new methodology to obtain a corrected Bond ball mill work index valid with non-standard feed size. Miner. Eng. 2022, 188, 107822. [Google Scholar]

- Magdalinovic, N.; Trumic, M.; Trumic, G.; Magdalinovic, S.; Trumic, M. Determination of the Bond work index on samples of non-standard size. Int. J. Miner. Process. 2012, 114-117, 48–50. [Google Scholar]

- Stamboliadis, E.T. A contribution to the relationship of energy and particle size in the comminution of brittle particulate materials. Miner. Eng. 2002, 15, 707–713. [Google Scholar]

- Andrić, L.; Trumić, M.; Trumić, M.; Nikolić, V. Micronization of zeolite in vibration mill. Recycl. Sustain. Dev. 2018, 11, 63–71. [Google Scholar]

| wi [kWh/t] | 10–17 | 18–20 | >21 |

| k | 1.47 | 1.48 | 1.49 |

| Sample | Class Size (mm) | Fns (μm) | P100 = 75 μm | wi (kWh/t) | wi,c (kWh/t) | Δ (%) | |

|---|---|---|---|---|---|---|---|

| wi,ns (kWh/t) | k | ||||||

| Zeolite | −2.36 + 0 | 1652 | 10.010 | 1.47 | 9.834 | 9.863 | −0.29 |

| −1.70 + 0 | 1090 | 10.197 | 9.841 | −0.07 | |||

| −1.18 + 0 | 727 | 10.371 | 9.827 | +0.07 | |||

| −0.850 + 0 | 544 | 10.572 | 9.854 | −0.20 | |||

| Dacite | −2.36 + 0 | 1729 | 18.130 | 1.48 | 17.800 | 17.784 | +0.09 |

| −1.70 + 0 | 1253 | 18.333 | 17.696 | +0.58 | |||

| −1.18 + 0 | 807 | 18.827 | 17.777 | +0.13 | |||

| −0.850 + 0 | 609 | 19.196 | 17.873 | −0.41 | |||

| Basalt | −2.36 + 0 | 1800.1 | 21.659 | 1.49 | 21.098 | 21.145 | −0.22 |

| −1.70 + 0 | 1278 | 21.951 | 21.067 | +0.15 | |||

| −1.18 + 0 | 892 | 22.352 | 21.069 | +0.14 | |||

| −0.850 + 0 | 633 | 22.874 | 21.195 | −0.46 | |||

| Sample | Ref. | Class Size (mm) | Fns (μm) | P100 = 75 μm | wi (kWh/t) | wi,c (kWh/t) | Δ (%) | Δ2 | |

|---|---|---|---|---|---|---|---|---|---|

| wi,ns (kWh/t) | k | ||||||||

| Zeolite | −2.36 + 0 | 1652 | 10.01 | 1.47 | 9.834 | 9.86 | −0.29 | 0.084 | |

| −1.70 + 0 | 1090 | 10.20 | 9.84 | −0.07 | 0.005 | ||||

| −1.18 + 0 | 727 | 10.37 | 9.83 | +0.07 | 0.0049 | ||||

| −0.850 + 0 | 544 | 10.57 | 9.85 | −0.20 | 0.040 | ||||

| Dolomite | [44] | −2.356 + 0 | 1662 | 12.91 | 12.70 | 12.72 | −0.16 | 0.026 | |

| −1.651 + 0 | 1090 | 13.16 | 12.70 | 0.00 | 0.000 | ||||

| −1.168 + 0 | 727 | 13.38 | 12.65 | +0.39 | 0.152 | ||||

| −0.833 + 0 | 544 | 13.69 | 12.76 | −0.47 | 0.221 | ||||

| Cu ore | [44] | −2.356 + 0 | 1729 | 15.70 | 15.67 | 15.51 | +1.02 | 1.040 | |

| −1.651 + 0 | 1253 | 15.84 | 15.39 | +1.79 | 3.204 | ||||

| −1.168 + 0 | 807 | 16.19 | 15.39 | +1.79 | 3.204 | ||||

| −0.833 + 0 | 609 | 16.79 | 15.74 | −0.45 | 0.202 | ||||

| Dacite | −2.36 + 0 | 1729 | 18.13 | 1.48 | 17.80 | 17.78 | +0.09 | 0.008 | |

| −1.70 + 0 | 1253 | 18.33 | 17.70 | +0.58 | 0.336 | ||||

| −1.18 + 0 | 807 | 18.83 | 17.78 | +0.13 | 0.017 | ||||

| −0.850 + 0 | 609 | 19.20 | 17.87 | −0.41 | 0.168 | ||||

| Basalt | −2.36 + 0 | 1800.1 | 21.66 | 1.49 | 21.10 | 21.14 | −0.22 | 0.048 | |

| −1.70 + 0 | 1278 | 21.95 | 21.07 | +0.15 | 0.022 | ||||

| −1.18 + 0 | 892 | 22.35 | 21.07 | +0.14 | 0.020 | ||||

| −0.850 + 0 | 633 | 22.87 | 21.20 | −0.46 | 0.212 | ||||

| Quartzite | [44] | −2.356 + 0 | 1790 | 23.17 | 22.63 | 22.61 | +0.09 | 0.001 | |

| −1.651 + 0 | 1240 | 23.52 | 22.54 | +0.40 | 0.160 | ||||

| −1.168 + 0 | 870 | 24.14 | 22.73 | −0.44 | 0.194 | ||||

| −0.833 + 0 | 610 | 24.72 | 22.86 | −1.02 | 1.040 | ||||

| Sum | 10.4173 | ||||||||

| 0.66 | |||||||||

| Sample | Ref. | Class Size (mm) | Fns (μm) | wi,ns (kWh/t) | wi (kWh/t) | wi,cM (kWh/t) | Δ (%) | Δ2 |

|---|---|---|---|---|---|---|---|---|

| Zeolite | −2.36 + 0 | 1652 | 10.01 | 9.83 | 9.93 | −0.98 | 0.96 | |

| −1.70 + 0 | 1090 | 10.20 | 10.14 | −3.11 | 9.67 | |||

| −1.18 + 0 | 727 | 10.37 | 10.12 | −2.91 | 8.47 | |||

| −0.850 + 0 | 544 | 10.57 | 9.79 | +0.45 | 0.20 | |||

| Dolomite | [44] | −2.356 + 0 | 1662 | 12.91 | 12.70 | 12.91 | −1.65 | 2.72 |

| −1.651 + 0 | 1090 | 13.16 | 13.04 | −2.68 | 7.18 | |||

| −1.168 + 0 | 727 | 13.38 | 12.94 | −1.89 | 3.57 | |||

| −0.833 + 0 | 544 | 13.69 | 12.85 | −1.18 | 1.39 | |||

| Cu ore | [44] | −2.356 + 0 | 1729 | 15.70 | 15.67 | 15.69 | −0.13 | 0.02 |

| −1.651 + 0 | 1253 | 15.84 | 15.69 | −0.13 | 0.02 | |||

| −1.168 + 0 | 807 | 16.19 | 15.72 | −0.32 | 0.10 | |||

| −0.833 + 0 | 609 | 16.79 | 15.78 | −0.70 | 0.49 | |||

| Dacite | −2.36 + 0 | 1729 | 18.13 | 17.80 | 18.09 | −1.63 | 2.66 | |

| −1.70 + 0 | 1253 | 18.33 | 18.19 | −2.19 | 4.80 | |||

| −1.18 + 0 | 807 | 18.83 | 18.35 | −3.09 | 9.55 | |||

| −0.850 + 0 | 609 | 19.20 | 18.81 | −5.67 | 32.15 | |||

| Basalt | −2.36 + 0 | 1800.1 | 21.66 | 21.10 | 21.52 | −2.00 | 4.00 | |

| −1.70 + 0 | 1278 | 21.95 | 21.85 | −3.56 | 12.67 | |||

| −1.18 + 0 | 892 | 22.35 | 22.05 | −4.51 | 20.34 | |||

| −0.850 + 0 | 633 | 22.87 | 21.90 | −3.80 | 14.44 | |||

| Quartzite | [44] | −2.356 + 0 | 1790 | 23.17 | 22.63 | 23.16 | −2.34 | 5.48 |

| −1.651 + 0 | 1240 | 23.52 | 23.39 | −3.36 | 11.29 | |||

| −1.168 + 0 | 870 | 24.14 | 23.64 | −4.46 | 19.89 | |||

| −0.833 + 0 | 610 | 24.72 | 23.46 | −3.67 | 13.47 | |||

| Sum | 185.53 | |||||||

| 2.78 | ||||||||

| Sample | Ref. | Class Size (mm) | Fns (μm) | wi,ns (kWh/t) | wi (kWh/t) | wi,cM (kWh/t) | Δ (%) | Δ2 |

|---|---|---|---|---|---|---|---|---|

| Dolomite | [44] | −2.356 + 0 | 1662 | 9.77 | 9.82 | 9.56 | +2.65 | 7.023 |

| −1.651 + 0 | 1090 | 10.59 | 9.91 | −0.92 | 0.846 | |||

| −1.168 + 0 | 727 | 11.44 | 9.94 | −1.22 | 1.488 | |||

| −0.833 + 0 | 544 | 12.19 | 9.83 | −0.10 | 0.010 | |||

| Cu ore | [44] | −2.356 + 0 | 1729 | 15.86 | 15.32 | 15.43 | −0.72 | 0.518 |

| −1.651 + 0 | 1253 | 16.46 | 15.43 | −0.72 | 0.518 | |||

| −1.168 + 0 | 807 | 17.42 | 15.33 | −0.07 | 0.005 | |||

| −0.833 + 0 | 609 | 18.93 | 15.11 | +1.37 | 1.877 | |||

| Quartzite | [44] | −2.356 + 0 | 1790 | 18.92 | 19.00 | 18.61 | −2.05 | 4.203 |

| −1.651 + 0 | 1240 | 19.13 | 18.25 | +3.95 | 15.603 | |||

| −1.168 + 0 | 870 | 20.61 | 18.67 | +1.74 | 3.028 | |||

| −0.833 + 0 | 610 | 23.30 | 19.37 | −1.95 | 3.803 | |||

| Sum | 38.922 | |||||||

| 1.80 | ||||||||

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nikolić, V.; Pierres, J.M.; Calvo, M.S.; Menéndez-Aguado, J.M.; Trumić, M.; Trumić, M.S.; Milošević, V. Proposal of a Method for Calculating the Bond Work Index for Samples with Non-Standard Feed Particle Size Distribution. Minerals 2025, 15, 358. https://doi.org/10.3390/min15040358

Nikolić V, Pierres JM, Calvo MS, Menéndez-Aguado JM, Trumić M, Trumić MS, Milošević V. Proposal of a Method for Calculating the Bond Work Index for Samples with Non-Standard Feed Particle Size Distribution. Minerals. 2025; 15(4):358. https://doi.org/10.3390/min15040358

Chicago/Turabian StyleNikolić, Vladimir, Jesus Medina Pierres, Maria Sanchez Calvo, Juan M. Menéndez-Aguado, Milan Trumić, Maja S. Trumić, and Vladan Milošević. 2025. "Proposal of a Method for Calculating the Bond Work Index for Samples with Non-Standard Feed Particle Size Distribution" Minerals 15, no. 4: 358. https://doi.org/10.3390/min15040358

APA StyleNikolić, V., Pierres, J. M., Calvo, M. S., Menéndez-Aguado, J. M., Trumić, M., Trumić, M. S., & Milošević, V. (2025). Proposal of a Method for Calculating the Bond Work Index for Samples with Non-Standard Feed Particle Size Distribution. Minerals, 15(4), 358. https://doi.org/10.3390/min15040358