Abstract

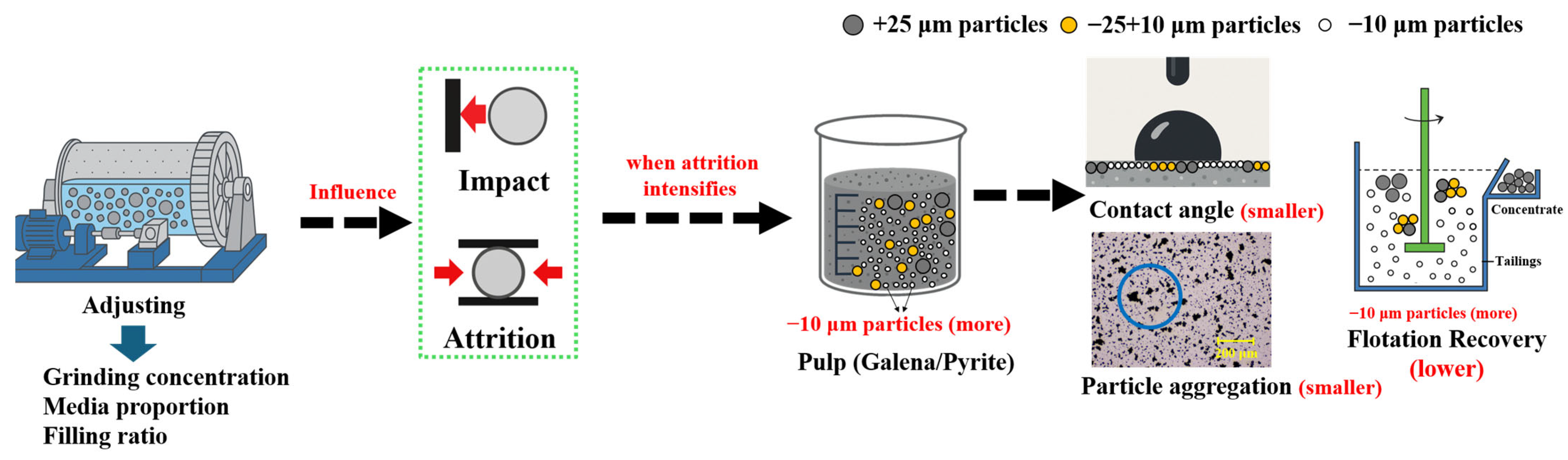

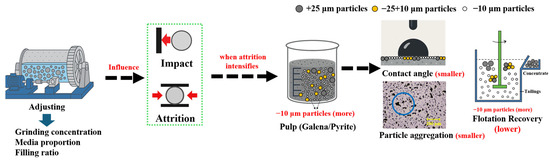

The processing of low-grade, lead-containing practical ores requires fine grinding to liberate galena and enhance flotation recovery. The ball mill is still one of the most common approaches used in industry for fine grinding. This study investigated the effect of the grinding parameters in a ball mill on the fine grinding product of galena and on flotation performance. The grinding product had a particle size below 30 μm, which was classified into +25 μm, −25 + 10 μm, and −10 μm fractions. Grinding experiments showed that modifications to the grinding concentration, media proportion, and filling ratio exerted significant effects on the yields of the +25 μm and −10 μm fractions. Flotation experiments showed that the yield of −10 μm particles negatively affected the flotation performance of galena. Discrete element method simulation results revealed that an increase in the motion velocity of the media group enhanced attrition effects during fine grinding, promoting the generation of −10 μm particles. The higher yield of −10 μm particles facilitated a smaller contact angle and smaller agglomerate size, resulting in lower recovery. To optimize the particle size distribution and improve fine-grained galena flotation recovery, it is essential to reduce the attrition of the grinding media on the mineral.

1. Introduction

Lead is recognized as a critical national strategic resource, playing an indispensable role in the electrical, mechanical, military, and metallurgical industries, and serves as a cornerstone of national economic development [1,2,3]. Galena, the most widely distributed lead-bearing mineral, is the primary raw material for lead metal production. As global demand for lead continues to rise, the recycling and utilization of microfine-grained galena resources have garnered increasing attention, with corresponding research efforts intensifying [4]. Fine grinding is a well-established technique for enhancing the liberation of microfine mineral particles and optimizing flotation recovery efficiency [5]. Given the growing emphasis on resource efficiency and technological innovation, investigating the impact of fine grinding on the flotation performance of microfine-grained galena is of significant scientific and practical importance.

Ball mills and stirred mills are commonly used equipment for fine ore grinding [5]. Although stirred mills have advantages, such as lower energy consumption and higher grinding efficiency compared to ball mills [6], the design and development of large-scale stirred mills within a short timeframe remain challenging due to structural limitations and material strength constraints [7]. Consequently, traditional ball mills remain the most widely used fine grinding equipment, due to their high throughput and simple structure [8]. Given their widespread application, investigating the effects of fine grinding in ball mill systems remains highly significant.

The surface properties of galena particles in the ball mill grinding product vary with particle size. Generally, the finer the galena particles, the more complex their surface properties [9,10,11]. It has been proven that under identical flotation reagent conditions, −25 μm galena particles are more soluble and oxidize more readily than +25 μm particles, enhancing their surface hydrophilicity [12], and that galena particles smaller than 10 µm are more affected by iron oxidation species from grinding media than those in the intermediate size range of −53 + 10 µm [13]. Therefore, in the fine grinding stage of galena, achieving an optimal particle size distribution is crucial for ensuring effective separation and enhancing flotation recovery [14,15], and it is essential to study the factors influencing the particle size distribution of galena grinding products. It has been established that the material composition [16,17], shape [18,19], and size [20] of the grinding media, along with variations in the mill mechanisms [21,22,23], directly impact the particle size distribution of fine-ground mineral products. Additionally, determining appropriate grinding parameters, such as the grinding concentration, media proportion, and filling ratio, is also critical for achieving the desired particle size distribution in fine-ground products, thereby ensuring optimal separation efficiency [24,25]. When adjusting the grinding parameters, the variation regularity of the particle size distribution of galena fine grinding products remains unclear and requires further investigation.

During the fine grinding stage, mineral particles are generally ground to below 30 μm [26]. This paper investigates galena with 65% of particles finer than 74 μm, which is ground to achieve a particle size below 30 μm in a ball mill system. The study examines the effects of the grinding parameters, including grinding concentration, media proportion, and filling ratio, on the particle size distribution of the fine-ground galena product. The variation in flotation recovery confirms the reliability of the analysis results for the changes in grinding product particle size distribution. The research findings provide new insights into how the grinding parameters affect the particle size distribution of galena during fine grinding, thus facilitating the recycling of fine-grained galena resources.

2. Materials and Methods

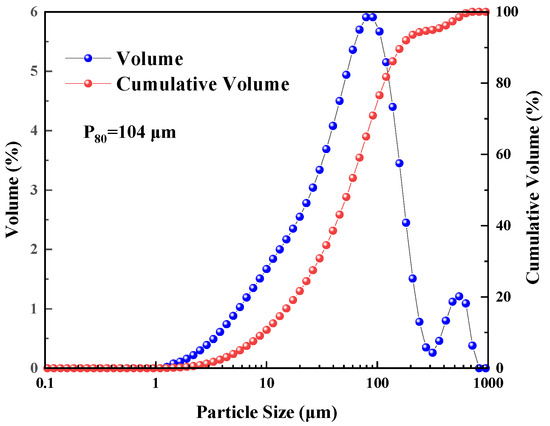

2.1. Pure Minerals

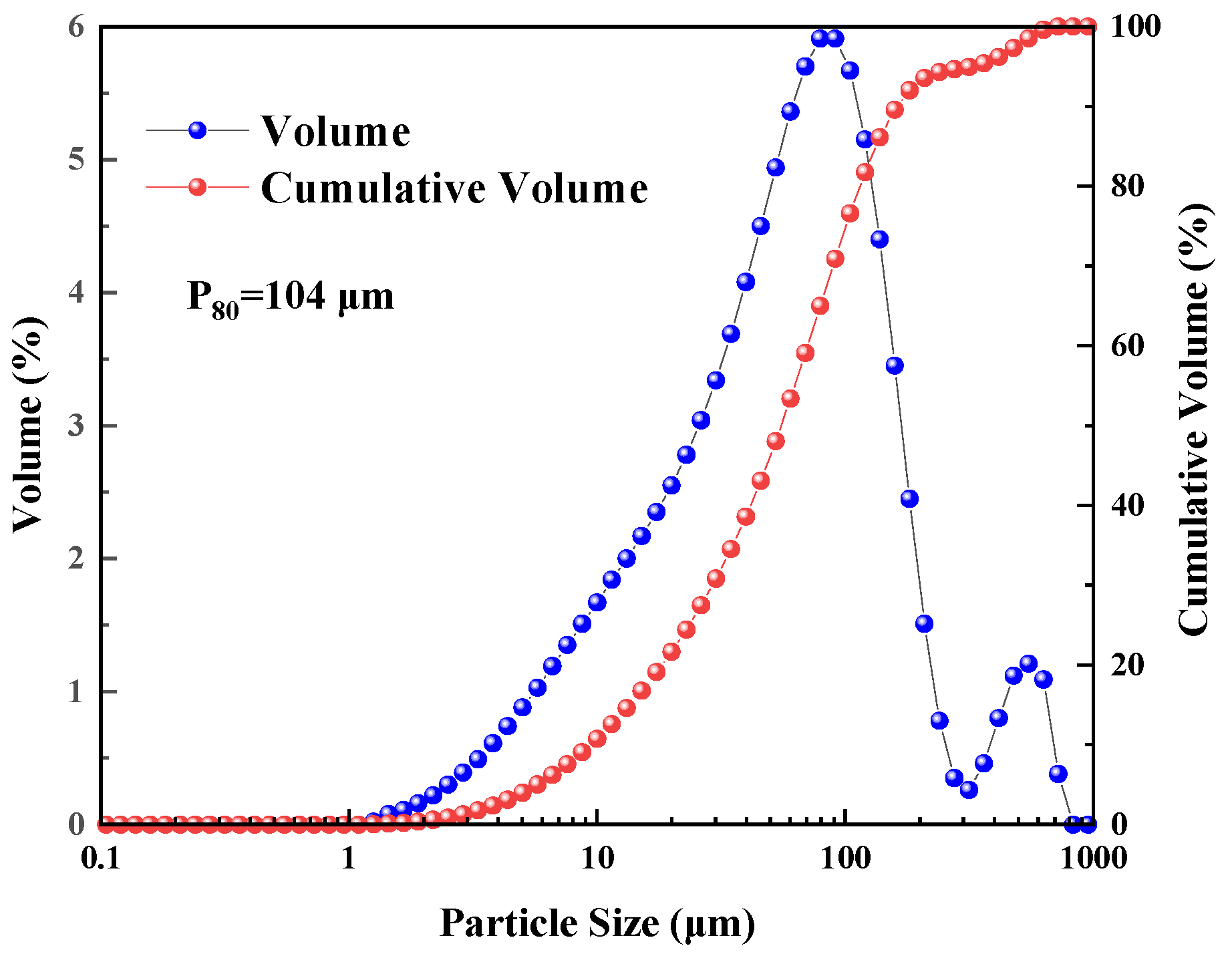

The galena sample used in this study was purchased from the Mingfa Mineral Specimen Company in Guangzhou, China and is sourced from a medium-low temperature hydrothermal deposit. The X-ray fluorescence (XRF) analysis, which was performed using an Axios mAX device made by PANalytical, which was located in Almelo, The Netherlands, showed that it contained 85.83% Pb, which meant that the purity of galena was 99.09%. Following hand selection, crushing, and grinding, the galena sample exhibited the particle size distribution shown in Figure 1, with 65% of the particles smaller than 74 μm. As shown in Figure 1, since the minerals were crushed below 200 μm in the crushing stage, and grinding in the grinding stage targeted minerals under 100 μm from the crushing product, the minerals in the 100–200 μm range were not ground. Thus, the laser particle size analysis results of galena showed a second peak, with the maximum particle size around 200 μm.

Figure 1.

The laser particle size analysis results of galena (the feed material for the grinding experiments).

2.2. Grinding Experiments

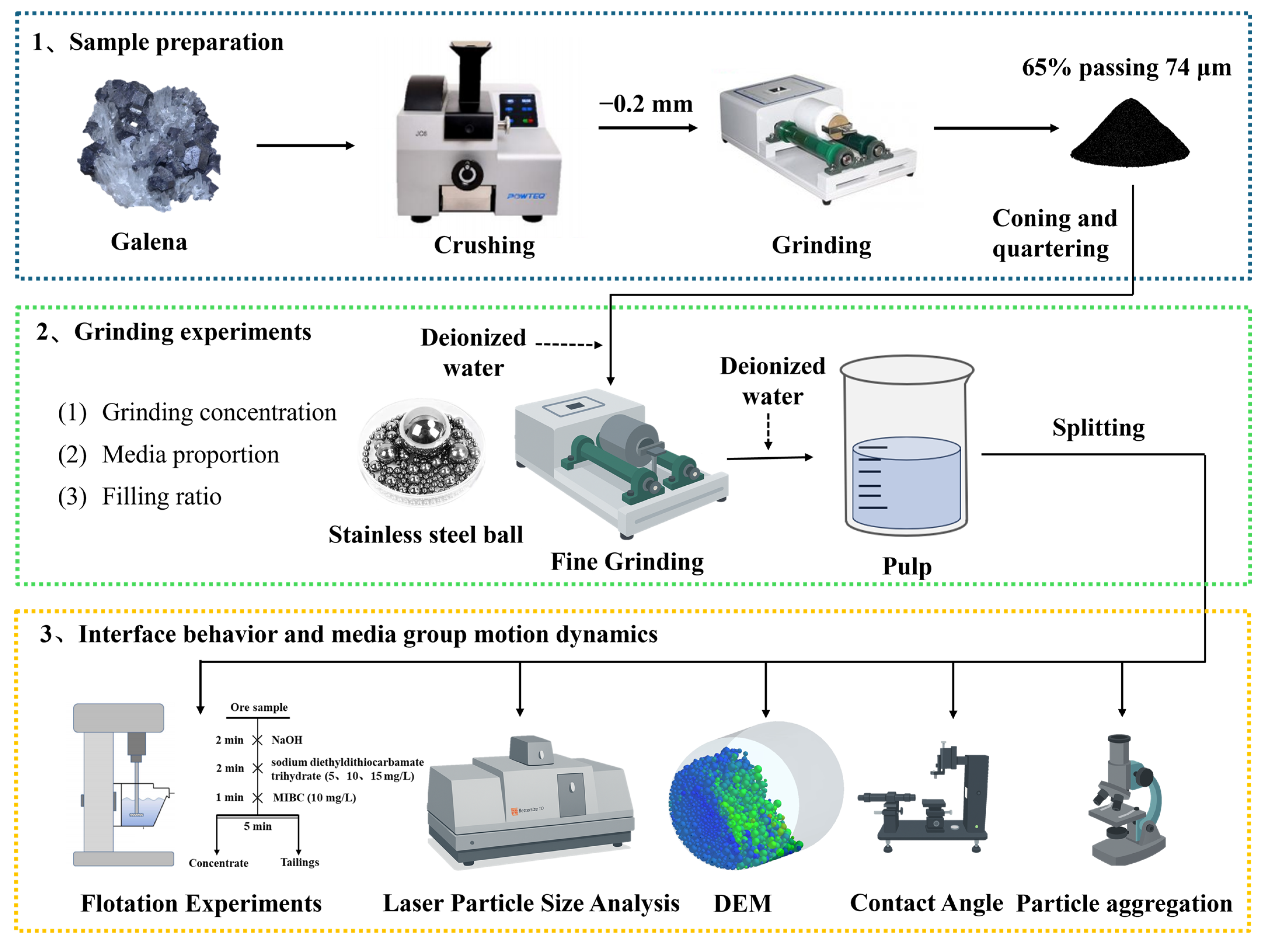

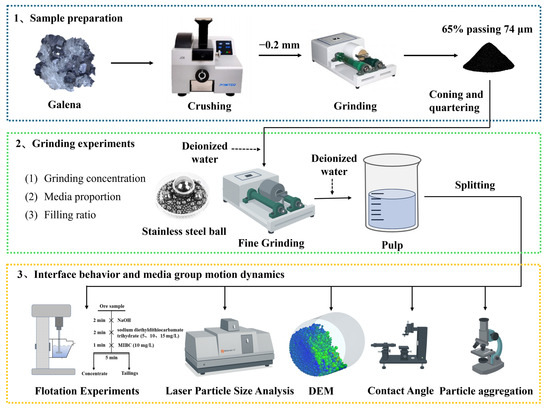

The experimental process is shown in Figure 2. Grinding experiments were conducted using a stainless-steel cylindrical mill with a grinding chamber size of 80 mm (D) × 100 mm (L). Literature reports have demonstrated that small-scale ball mill jars have been effectively utilized in laboratory settings to investigate the impact of grinding conditions on the properties of ground products and have consistently shown stable outcomes and well-defined trends [27]. For each test, 60 g of galena sample, deionized water and stainless-steel balls were placed in the ball mill, which had an effective volume of 500 mL, and ground for 10 min at a mill speed of 109 r/min; the critical speed of the mill is 149 r/min. The grinding parameters were set as detailed in Table 1. When 65% of the particles in the feed material are smaller than 74 μm, relevant research has demonstrated that in laboratory-scale tests, the fine grinding efficiency of minerals is optimal when the media sizes are selected as 5 mm, 3 mm, and 2 mm [28]. The grinding concentration is defined as the ratio of the mass of solids to the mass of pulp, which is equivalent to the ratio of the mass of solids to the sum of the mass of solids and the mass of water. The media proportion refers to the combination ratio of the grinding media of different sizes or types within a ball mill. The filling ratio is the percentage of the grinding media volume relative to the mill’s effective volume.

Figure 2.

Schematic diagram of the experimental process.

Table 1.

The grinding parameters and their values examined in the experiments.

Pre-tests were carried out to explore the grinding parameters appropriate to grind 60 g of galena samples to below 30 μm under the above-mentioned conditions of a mill speed of 109 r/min and a grinding time of 10 min. The results show that a grinding concentration of 67%, a media ratio of 4:4:2, and a filling ratio of 40% are required to achieve a grinding product size of less than 30 μm. Based on these conditions, the grinding concentration, media proportion, and filling ratio were successively varied to obtain the fine-ground products for each set of grinding parameters, which were then used for subsequent experiments and analysis. For example, when adjusting the grinding concentration, the media ratio was 4:4:2 and the filling ratio was 40%. When adjusting the media ratio, the grinding concentration was 67% and the filling ratio was 40%. When adjusting the filling ratio, the grinding concentration was 67% and the media ratio was 4:4:2.

2.3. Laser Particle Size Analysis

The particle size distribution of the fine-ground products was analyzed using a Mastersizer 2000 laser particle size analyzer manufactured by Malvern Instruments, located in Malvern, UK. During the experiments, 1 g of the sample was dispersed in 900 mL of water in a beaker. Dispersion was facilitated by a stirrer operating at 2500 rpm, and ultrasonic treatment was applied for 1 min. The average particle size was automatically calculated by the analyzer. In the laser particle size analysis experiments, multiple measurements were taken for the same sample. The average particle size and the yields of the three average particle size fractions were obtained after processing the particle size distribution data.

2.4. Flotation Experiments

In the flotation experiments, analytical grade NaOH, industrial-grade sodium diethyldithiocarbamate trihydrate, and analytical-grade methyl isobutyl carbinol (MIBC) were used as the pH adjusters, collectors, and frothers, respectively.

For each flotation experiment, 15 g of the fine-ground galena product was placed in a 140 mL flotation tank, and deionized water was added; the pulp density used during flotation was 15.79 wt.%. The mixture was stirred at 1992 rpm for 2 min. The slurry pH was adjusted to 9, followed by the sequential addition of the collector sodium diethyldithiocarbamate trihydrate at dosages of 5, 10, 15 g/Mg with two minutes of stirring and the frother MIBC at a dosage of 10 g/Mg with one minute of stirring. Flotation was conducted for 5 min. After flotation, the products were filtered, dried, weighed, and the galena recovery was calculated based on the weights of the concentrate and tailing products. The specific calculation formula is expressed as follows:

In the formula, ε denotes the galena recovery, m1 is the concentrate product weight, and m2 is the tailing product weight.

2.5. Discrete Element Simulation

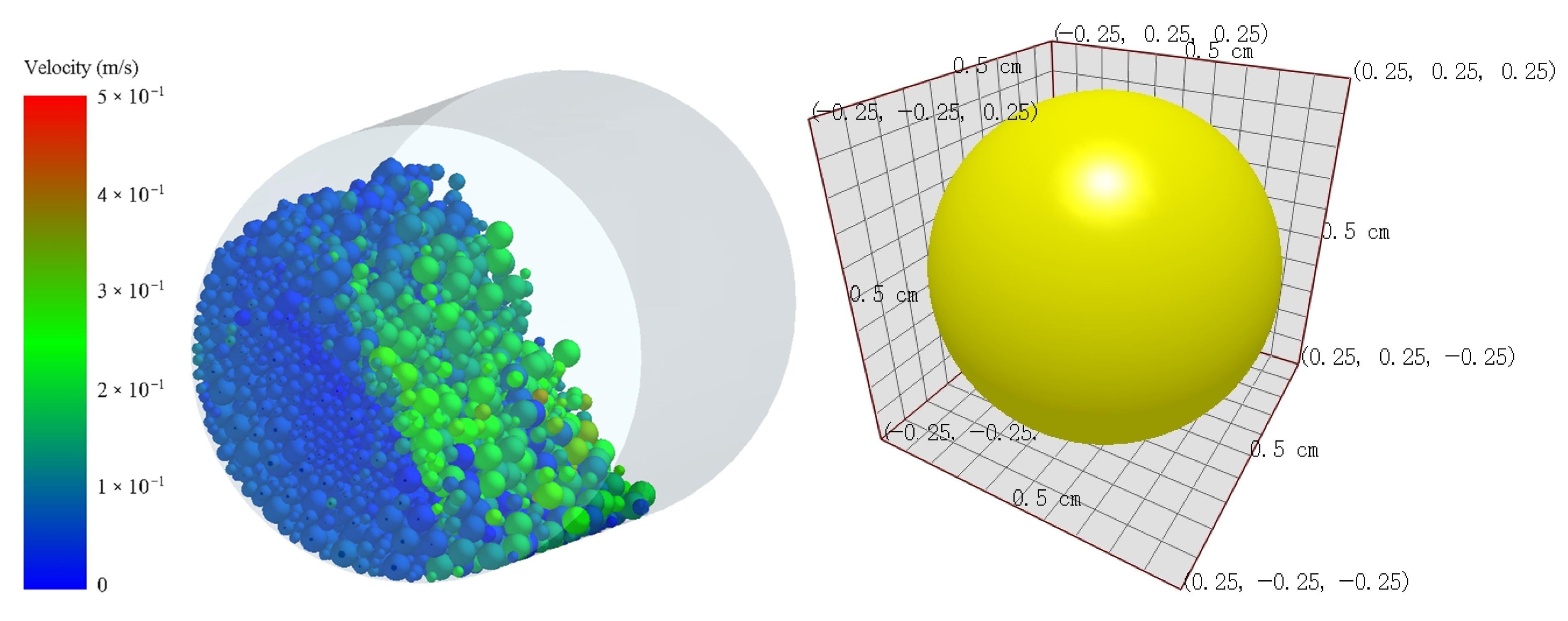

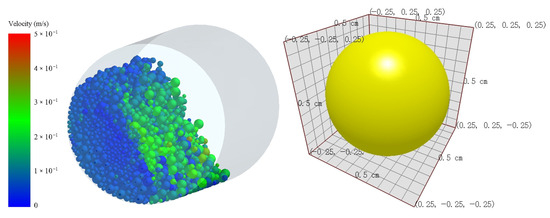

In this study, the grinding process in a ball mill was numerically simulated using the discrete element method (DEM) to elucidate the motion behavior of the grinding media and investigate the mechanisms by which the grinding parameters influence the fine-grinding efficiency of galena. The ball mill model and the reference model of the steel ball media used in the DEM simulation are shown in Figure 3. Figure 3 only shows the model of the 5 cm ball; models of the 3 cm and 2 cm balls were also used in the simulation, matching the actual grinding experiment. The Hertz–Mindlin (no slip) contact model was employed in the simulation, as it effectively predicts the motion state of the media group within the ball mill [29]. The particle contact parameters are listed in Table 2. Each simulation ran for a total duration of 5 s, divided into 50 time steps, with a step size of 0.1 s. This study utilized EDEM commercial software (EDEM 2022, Altair, Troy, MI, USA).

Figure 3.

The model used in the DEM simulations.

Table 2.

Particle contact parameters (derived from the manufacturer’s test report).

2.6. Contact Angle Measurements

After taking a sample identical to the feed for the flotation test from the finely ground product, it was mixed with deionized water and stirred in a beaker under the flotation reagent system with a collector dosage of 10 g/Mg at 1992 r/min, and when no collector was added, no treatment was performed. After stirring, the pulp was filtered and dried, and the dried product was then pressed into a smooth slice. A JC2000DM contact angle meter was used to measure the contact angle of the samples through the sessile drop method. In this method, a stable water droplet with a diameter of 3–4 mm was precisely deposited onto the slice surface using a microsyringe for contact angle measurement. Each sample was measured three times at different locations, and the average value was recorded.

2.7. Observation of Hydrophobic Agglomerates

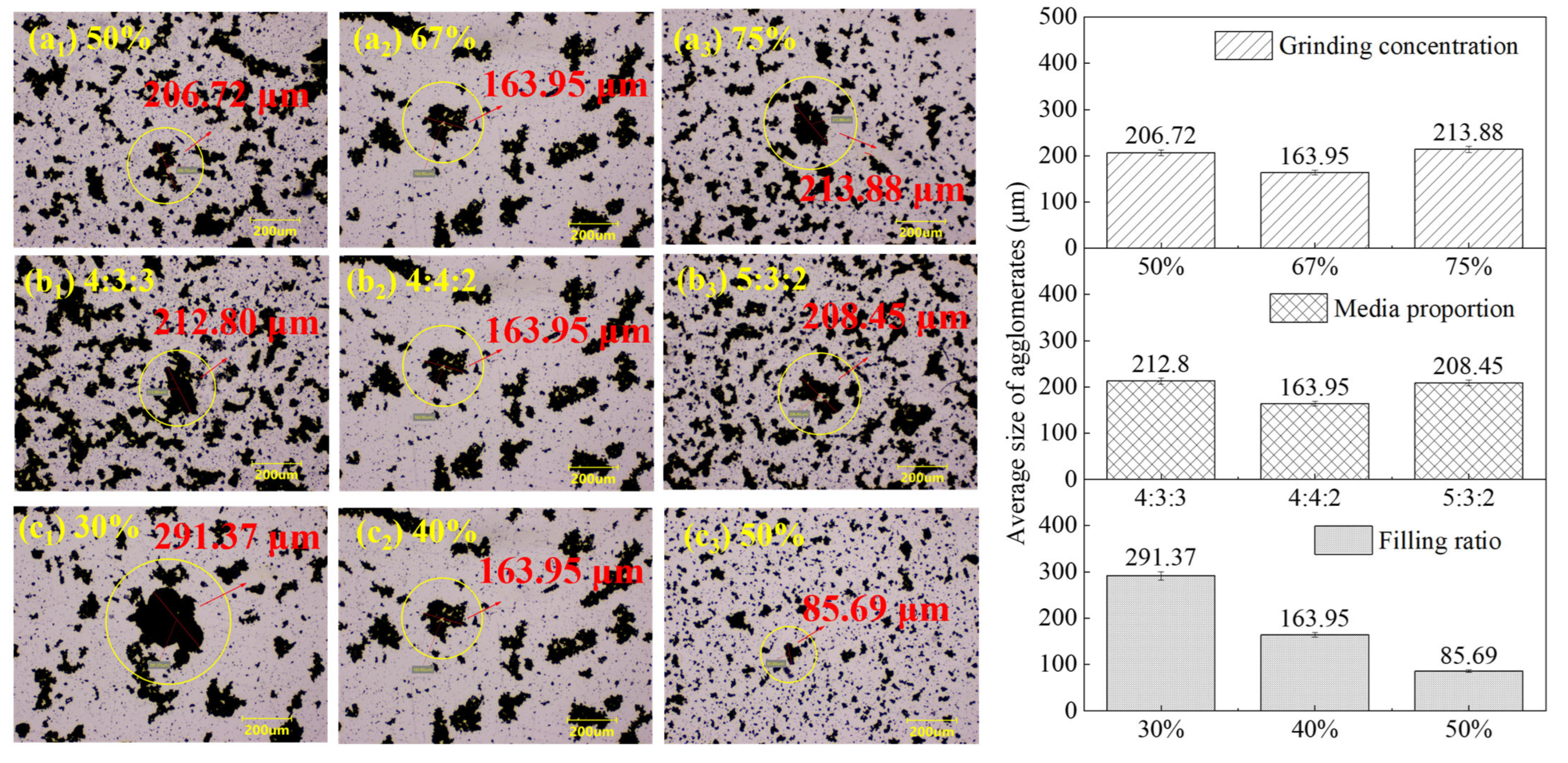

An optical microscope (OLYMPUS CX33, PLENIC-Pro, Hangzhou, China) was used to observe the aggregate particle size of the fine-ground galena products. After fine grinding, a 1 g sample was taken from the product and stirred with deionized water in a beaker under the flotation reagent system with a collector dosage of 10 g/Mg at 1992 r/min, and when no collector was added, no treatment was performed. After stirring, 1 mL of the pulp was extracted using a pipette and placed on a glass slide to ensure a uniform monolayer distribution of the aggregates. The slide was then placed under the optical microscope, and the sample was examined at 100× magnification. Subsequently, the average agglomerate size was analyzed using OPLENIC-Pro software (V1.95). In each stirring test, ten samples were observed for analysis and discussion to ensure data accuracy. The calculation of the average agglomerate size and error was based on the measurements of the largest agglomerate size during each of the ten observations. The photos that best represent the average agglomerate size were selected for presentation [30].

3. Results and Discussion

3.1. Particle Size Distribution of the Fine-Ground Galena Products

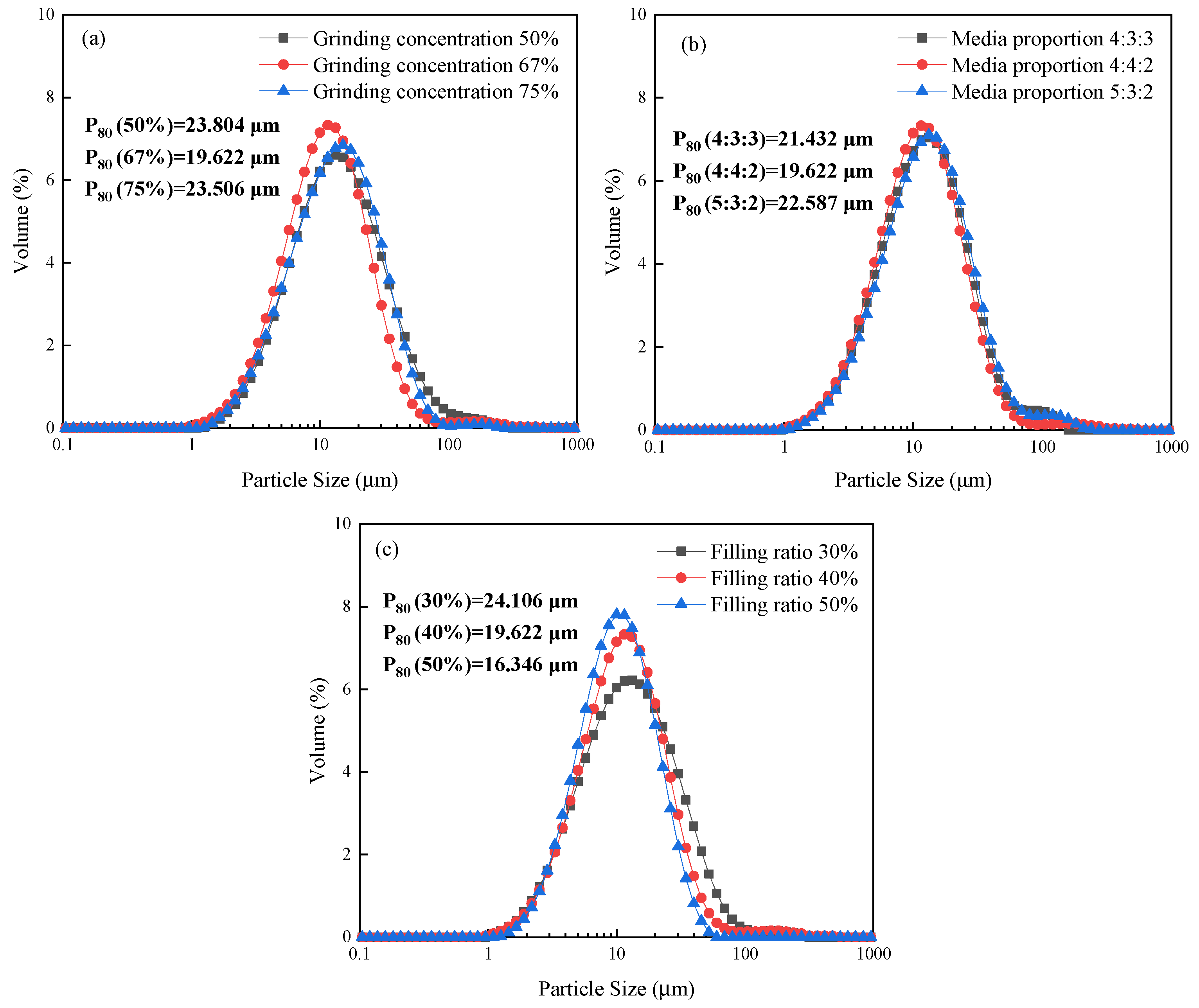

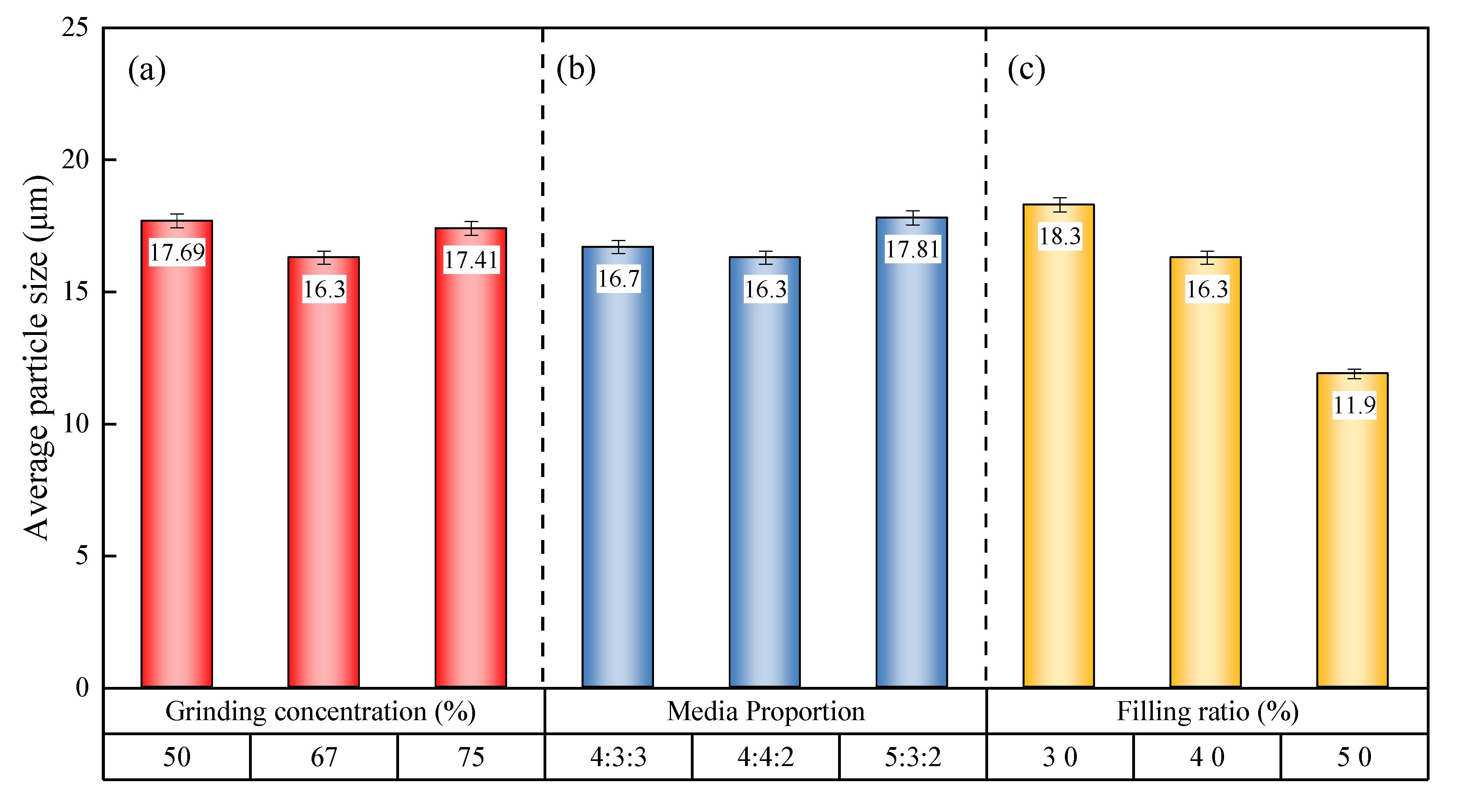

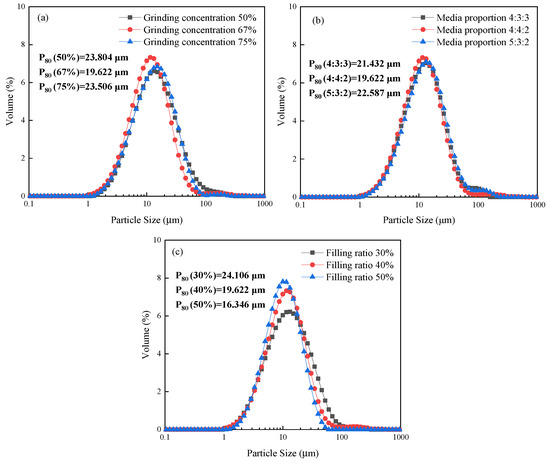

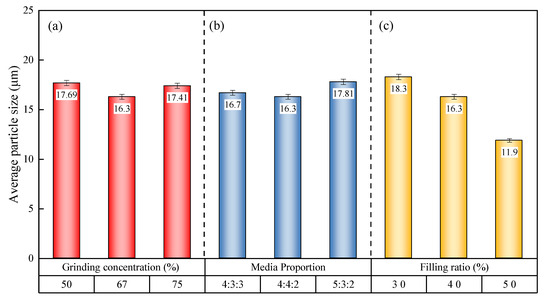

Figure 4 and Figure 5 present the particle size distribution curve and the average particle size of the fine-ground galena products under different grinding concentrations, media proportions, and filling ratios. As shown in Figure 5, when the grinding concentration increased from 50% to 75% or the media proportion shifted from 4:3:3 to 5:3:2, the average particle size of the fine-ground product initially decreased and then increased. This can be attributed to the fact that lower grinding concentrations and specific media proportions provide optimal grinding conditions. Low grinding concentrations reduce the buffer effect between grinding media, enhancing the impact and attrition forces on the galena particles. However, excessively high concentrations may lead to overloading, reducing the efficiency of energy transfer to the particles [24]. Similarly, the optimal media proportion (4:3:3) balances the impact and grinding actions of different media sizes. Deviating from this proportion disrupts the grinding dynamics, resulting in coarser particles at higher concentrations and specific media ratios. In contrast, increasing the filling ratio from 30% to 50% caused a gradual reduction in average particle size. A higher filling ratio increases the number of grinding media in the mill, leading to more frequent collisions and grinding actions on the galena particles. This results in more effective size reduction [31]. The shifts in the particle size distribution curves under various grinding process parameters shown in Figure 4 demonstrate well the reliability of the analysis results regarding changes in average particle size.

Figure 4.

Particle size distribution curve of the fine-ground galena products obtained from different (a) grinding concentration, (b) media proportion, and (c) filling ratio.

Figure 5.

Average particle size of the fine-ground galena products obtained from different (a) grinding concentration, (b) media proportion, and (c) filling ratio.

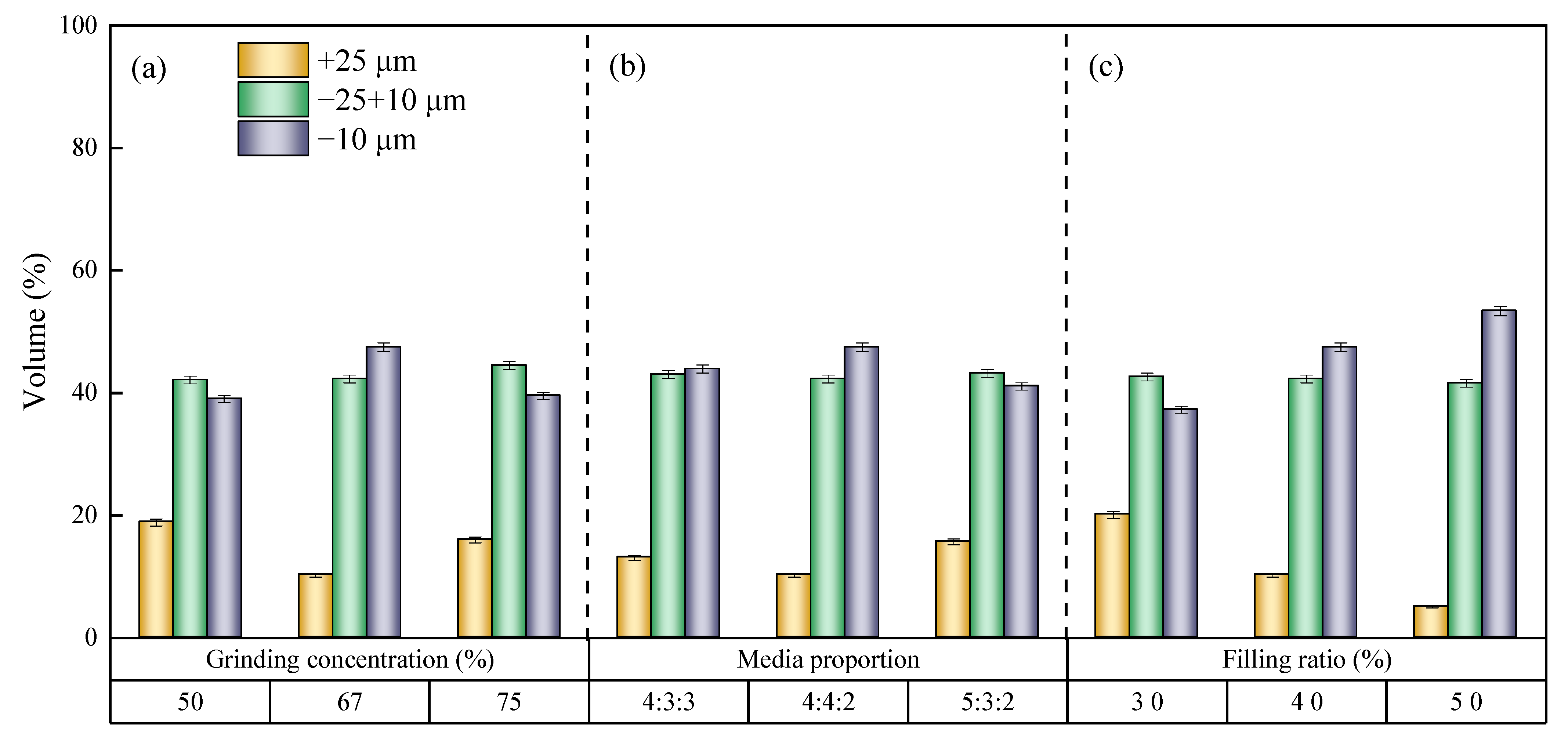

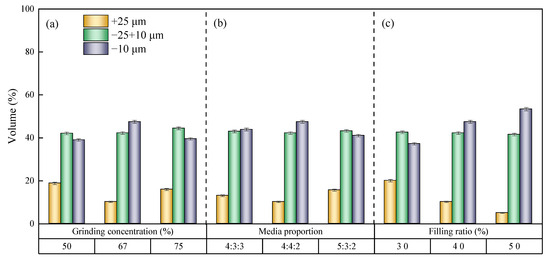

The influence of the grinding parameters on the particle size distribution of the fine-ground products was further explored. The fine-ground products with a particle size below 30 μm obtained under different grinding parameters were classified into +25 μm, −25 + 10 μm, and −10 μm fractions, and the yield of each size fraction was calculated, as shown in Figure 6. Figure 6 illustrates that as the grinding concentration increased from 50% to 75%, the yield of +25 μm particles initially decreased and then increased. This trend is consistent with the average particle size variation, indicating that moderate grinding intensities favor the reduction of coarse particles. The yield of −25 + 10 μm particles remained relatively stable, suggesting that this size fraction is less sensitive to changes in grinding concentration within the tested range. Meanwhile, the yield of −10 μm particles first increased and then decreased, indicating that both excessively high and low grinding concentrations are not conducive to the formation of fine particles. This is similar to the trend observed when the media proportion was adjusted from 4:3:3 to 5:3:2. This suggests that both the grinding concentration and media proportion significantly affect the grinding efficiency and particle size distribution [32]. When the filling ratio increased from 30% to 50%, the yield of +25 μm particles gradually decreased, the yield of −25 + 10 μm particles showed negligible variation, while the yield of −10 μm particles progressively increased. This indicates that higher filling ratios enhance grinding efficiency.

Figure 6.

Yield of each size fraction in the fine-ground galena products obtained from different (a) grinding concentration, (b) media proportion, and (c) filling ratio.

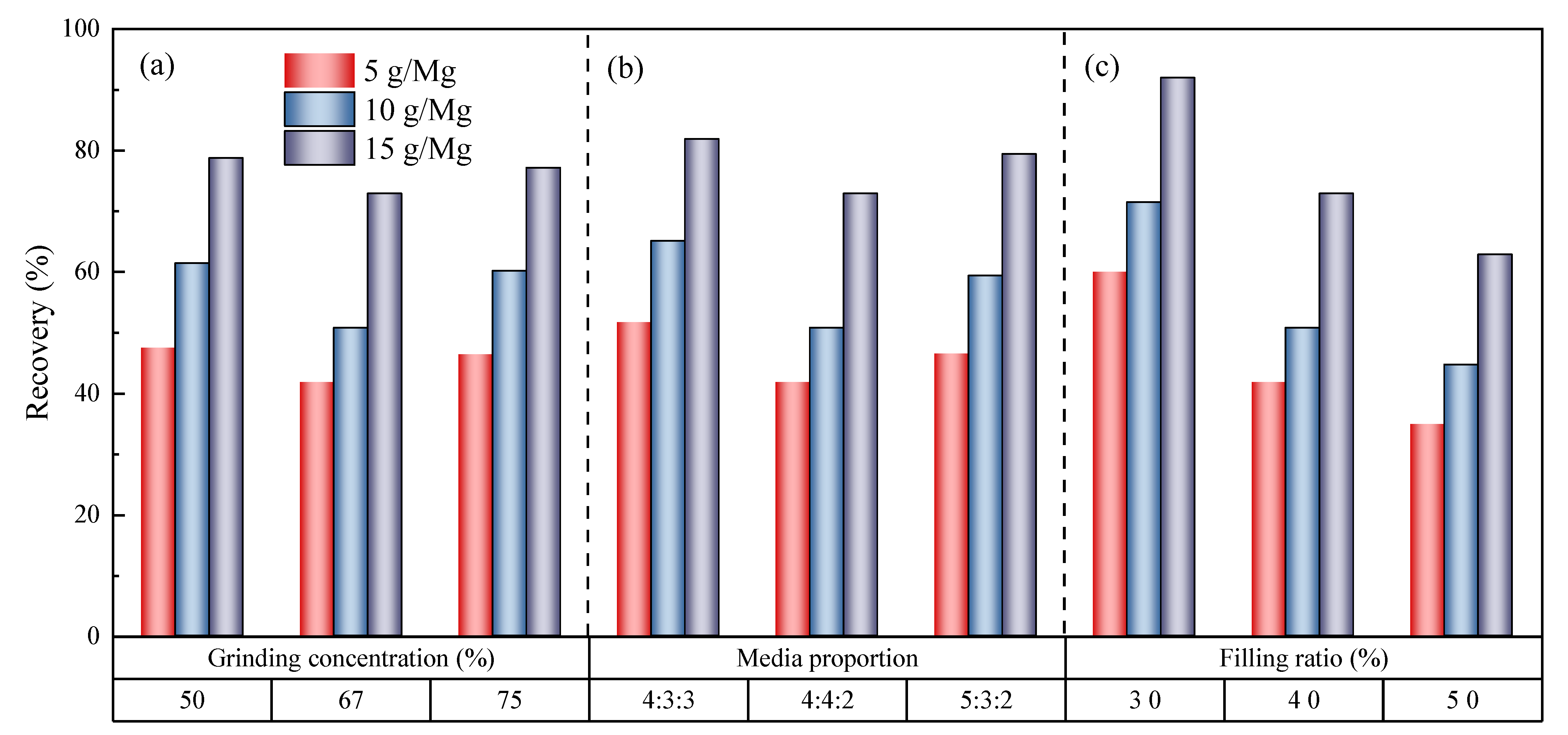

3.2. Flotation Experiments on the Fine-Ground Galena Products

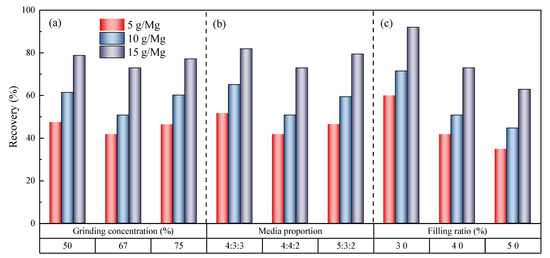

The recovery of the fine-ground galena products under different grinding parameters is shown in Figure 7. As Figure 7 shows, under a constant collector dosage, increasing grinding concentration from 50% to 75% initially decreased the galena recovery, followed by a subsequent increase, consistent with the variation observed when the media proportion was adjusted from 4:3:3 to 5:3:2. When the filling ratio increased from 30% to 50%, the galena recovery gradually declined. Combined with the particle size distribution analysis results, the variation in +25 μm particles, particularly the yield of −10 μm particles, significantly impacted galena recovery. Specifically, a higher yield of −10 μm particles led to lower galena recovery. When the filling rate reached 50%, the yield of −10 μm particles in the fine-ground product was highest at 53.38%, while the galena recovery was lowest. This indicates that the flotation performance is closely related to the particle size distribution of the ground products. Coarser particles (+25 μm) may not be sufficiently liberated, leading to lower flotation recovery. Finer particles (−10 μm) may increase the risk of over-pulverization, which can negatively affect flotation efficiency. The −25 + 10 μm fraction represents a balance between liberation and over-pulverization, making it the most suitable size range for optimal flotation performance. Therefore, understanding and controlling the particle size distribution through grinding parameters is crucial for optimizing the flotation process and achieving higher galena recovery and concentrate quality.

Figure 7.

The effect of different (a) grinding concentration, (b) media proportion, and (c) filling ratio on the recovery of the fine-ground galena products (the collector dosages were 5, 10, and 15 g/Mg).

3.3. Results of DEM

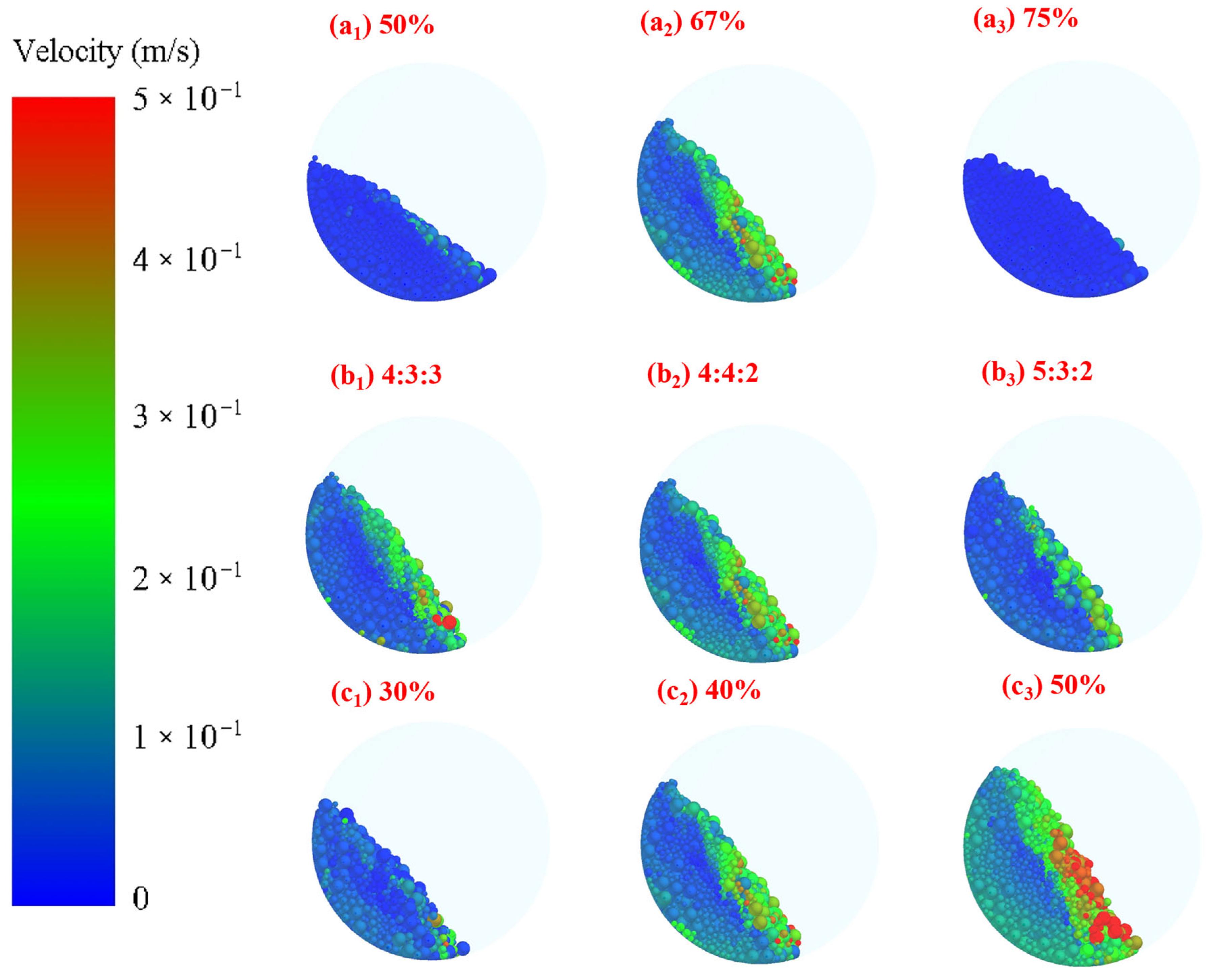

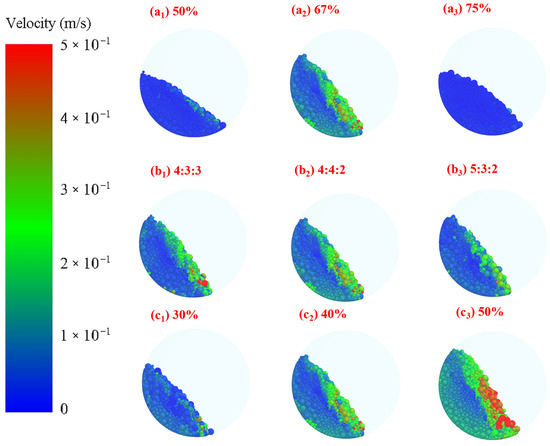

The motion state of the grinding media in the mill was analyzed using discrete element simulation to elucidate the influence of different grinding parameters on fine grinding performance in the grinding experiments [33,34]. The velocity cloud diagram of the media group is presented in Figure 8. Generally, a higher motion velocity of the media group corresponds to a larger effective grinding area, enhancing material breakage [35]. As shown in Figure 8, with increasing grinding concentration or adjusting the media proportion from 4:3:3 to 5:3:2, the motion velocity of the media group first increased and then decreased. In contrast, the motion velocity of the media group increased progressively with an increase in the filling ratio. At a filling ratio of 50%, the media group exhibited the highest motion velocity, resulting in the most effective crushing and grinding of materials. This phenomenon occurs because an increase in the filling rate leads to a greater overall media volume, raising the shoulder position of the media balls within the rotating cylinder. Consequently, the potential energy increases and is progressively converted into kinetic energy during descent, thereby increasing the motion velocity of the media balls [36].

Figure 8.

Velocity cloud of media group under different (a) grinding concentration, (b) media proportion, and (c) filling ratio.

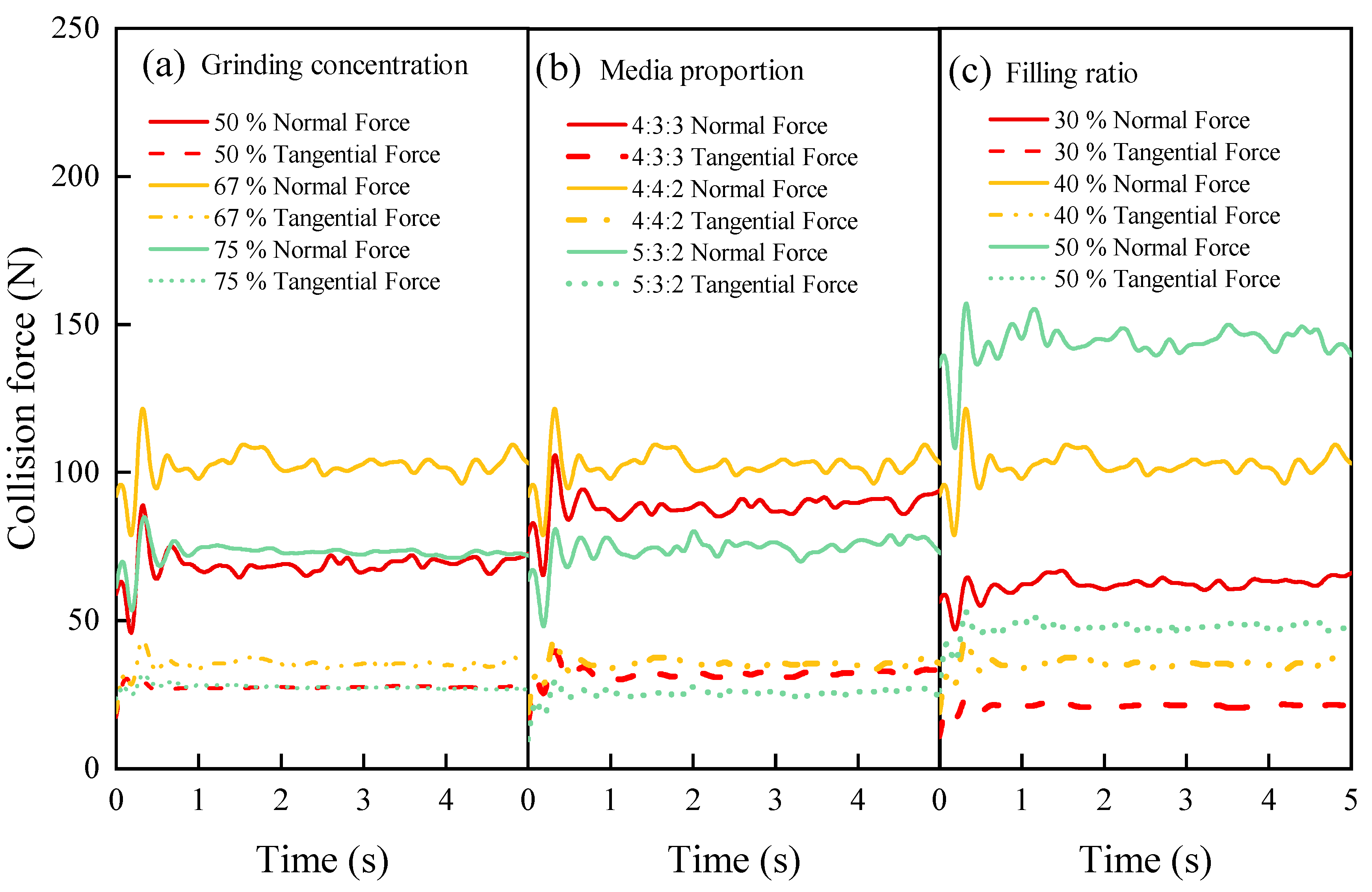

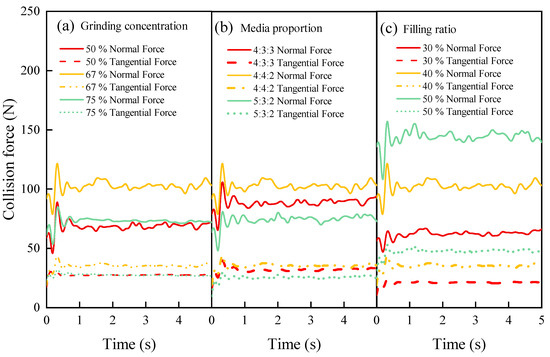

Under different grinding parameters, the normal and tangential forces of media collisions in the mill are shown in Figure 9. Generally, the normal force primarily facilitates impact breakage of the material, with the intensity of media impact determined by its magnitude. The tangential force primarily contributes to attrition. Among them, the grinding action primarily affects the yield of −10 μm particles in the grinding product, showing a positive correlation [37,38,39].

Figure 9.

The variation in normal and tangential collision forces with time of different (a) grinding concentration, (b) media proportion, and (c) filling ratio.

In Figure 9, adjustments to the grinding parameters altered the normal and tangential forces exerted by the grinding media on the minerals, thereby influencing both impact and attrition effects, which, in turn, affected the particle size distribution of the fine-ground products. It should be noted that during fine grinding in a ball mill, attrition is the primary mechanism. As the particle size of the mineral decreases, the grinding action exerted by the media on the mineral becomes stronger, while the impact action gradually weakens. However, the simulation results indicate that the normal force, which characterizes the impact action, is relatively large. This may be due to the higher mill speed, which causes some grinding media balls to be in a state of free fall. Additionally, since mineral particles were not included in the simulation and the effective contact area between media balls is small, grinding action is difficult to generate. Therefore, in the simulation results, the normal force representing the impact action is greater than the tangential force [36,40]. Nevertheless, when keeping other simulation conditions constant, the influence of the grinding process parameters on the tangential force, which characterizes the grinding action, can still be observed. Therefore, it can still be concluded that adjusting the grinding process parameters changes the grinding action, thereby affecting the particle size distribution of the finely ground product. The normal and tangential forces exerted by the media on the mineral exhibited a unimodal trend with increasing grinding concentration or when the media ratio was adjusted from 4:3:3 to 5:3:2; in contrast, both forces demonstrated a monotonic increase with rising filling rate. At a filling ratio of 50%, the normal and tangential forces reached their maximum values, resulting in the strongest impact and attrition effects exerted by the media on the minerals. This observation is consistent with Figure 4, Figure 5 and Figure 6, where the fine-ground galena products exhibited the smallest average particle size and the highest yield of −10 μm particles.

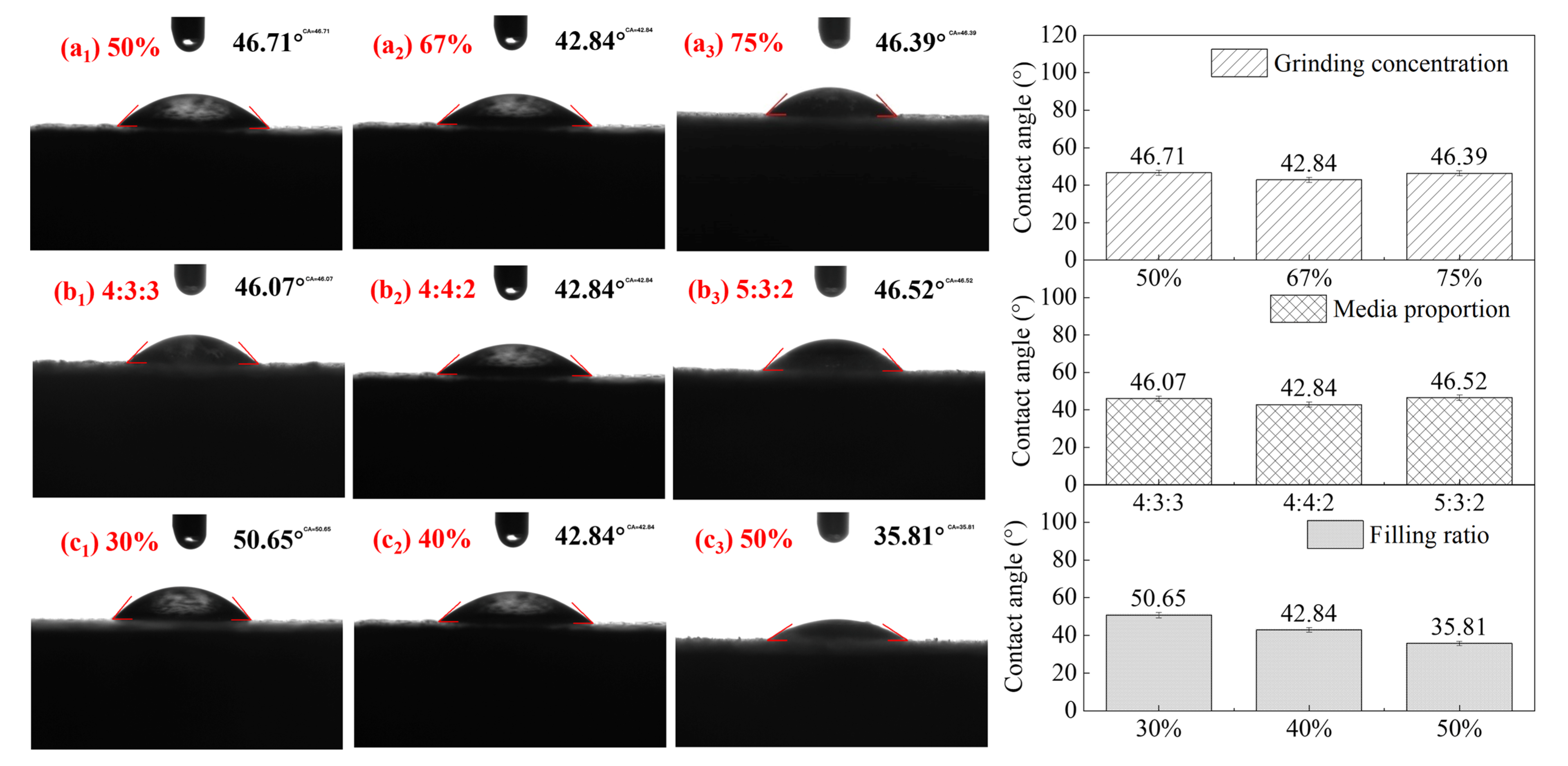

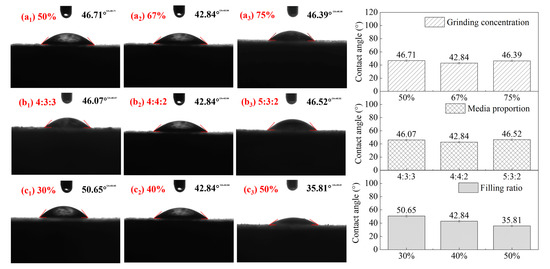

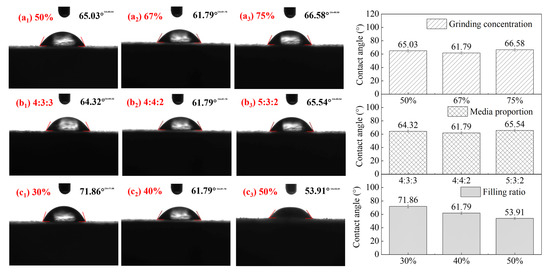

3.4. Contact Angle Analysis

The surface wettability of minerals varies with particle size [41,42,43], while grinding parameters influence the particle size distribution of the fine-ground galena product. As shown in Figure 10 and Figure 11, the contact angle values presented in the bar chart on the right, along with the error bars, are derived from three measurements taken at different locations on the sample. Each photo on the left is an exemplary photo of the three photos for each sample. The effects of the grinding parameters on the surface contact angle of galena are presented under two conditions: without a collector and with a collector dosage of 10 g/Mg. Based on the particle size distribution analysis results, Figure 10 and Figure 11, when the grinding parameters were adjusted, an increase in the yield of the −10 μm fraction in fine-ground galena products correlated with a smaller surface contact angle and lower galena recovery. Specifically, at a filling rate of 30%, the yield of the −10 μm fraction was minimized, while the galena surface contact angle was maximized, resulting in the highest galena recovery.

Figure 10.

Influence of (a) grinding concentration, (b) media proportion, and (c) filling rate on the surface contact angle of the fine-ground galena products (pH = 9, sodium diethyldithiocarbamate trihydrate = 0).

Figure 11.

Influence of (a) grinding concentration, (b) media proportion, and (c) filling rate on the surface contact angle of the fine-ground galena products (pH = 9, sodium diethyldithiocarbamate trihydrate = 10 g/Mg).

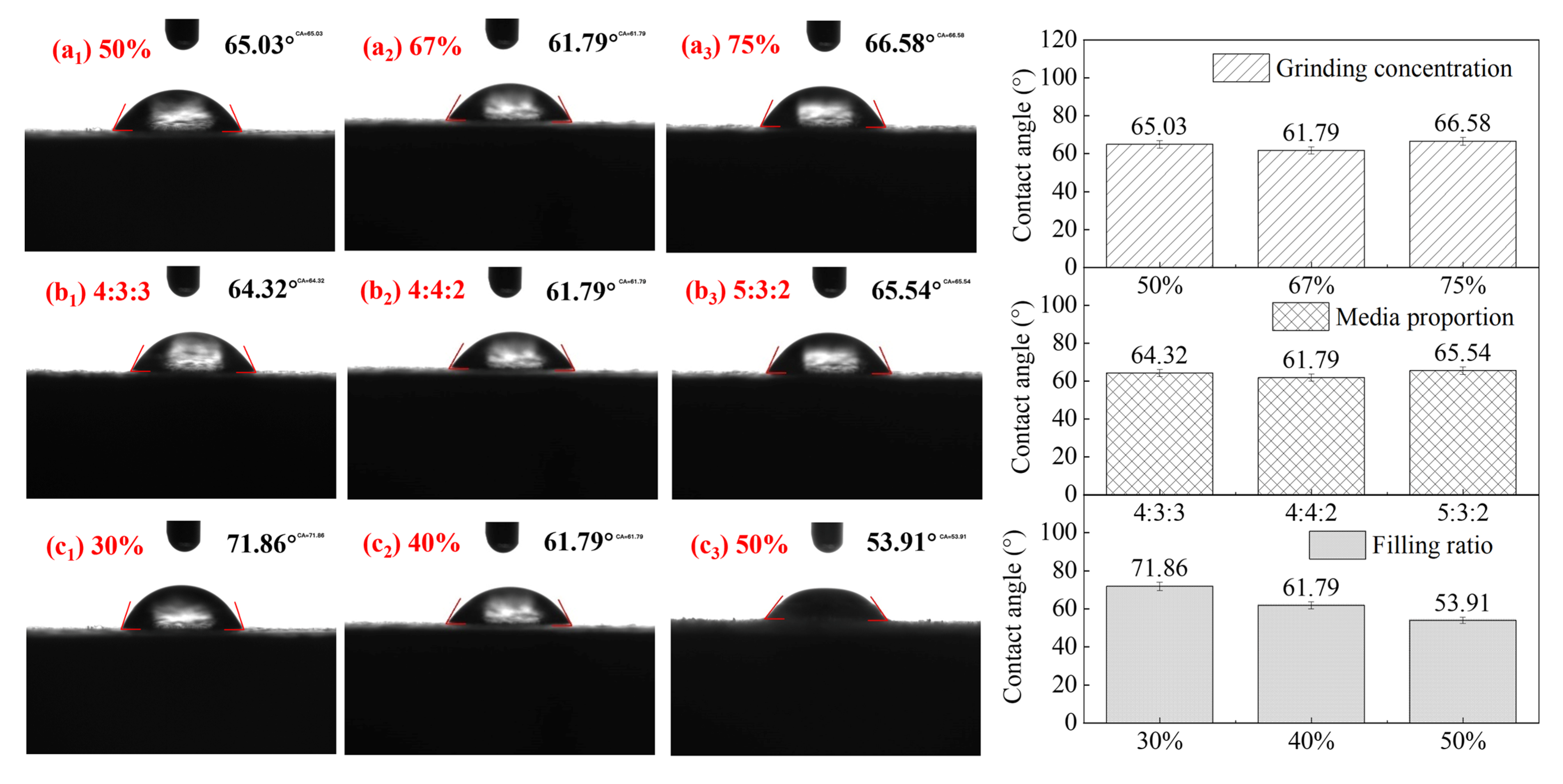

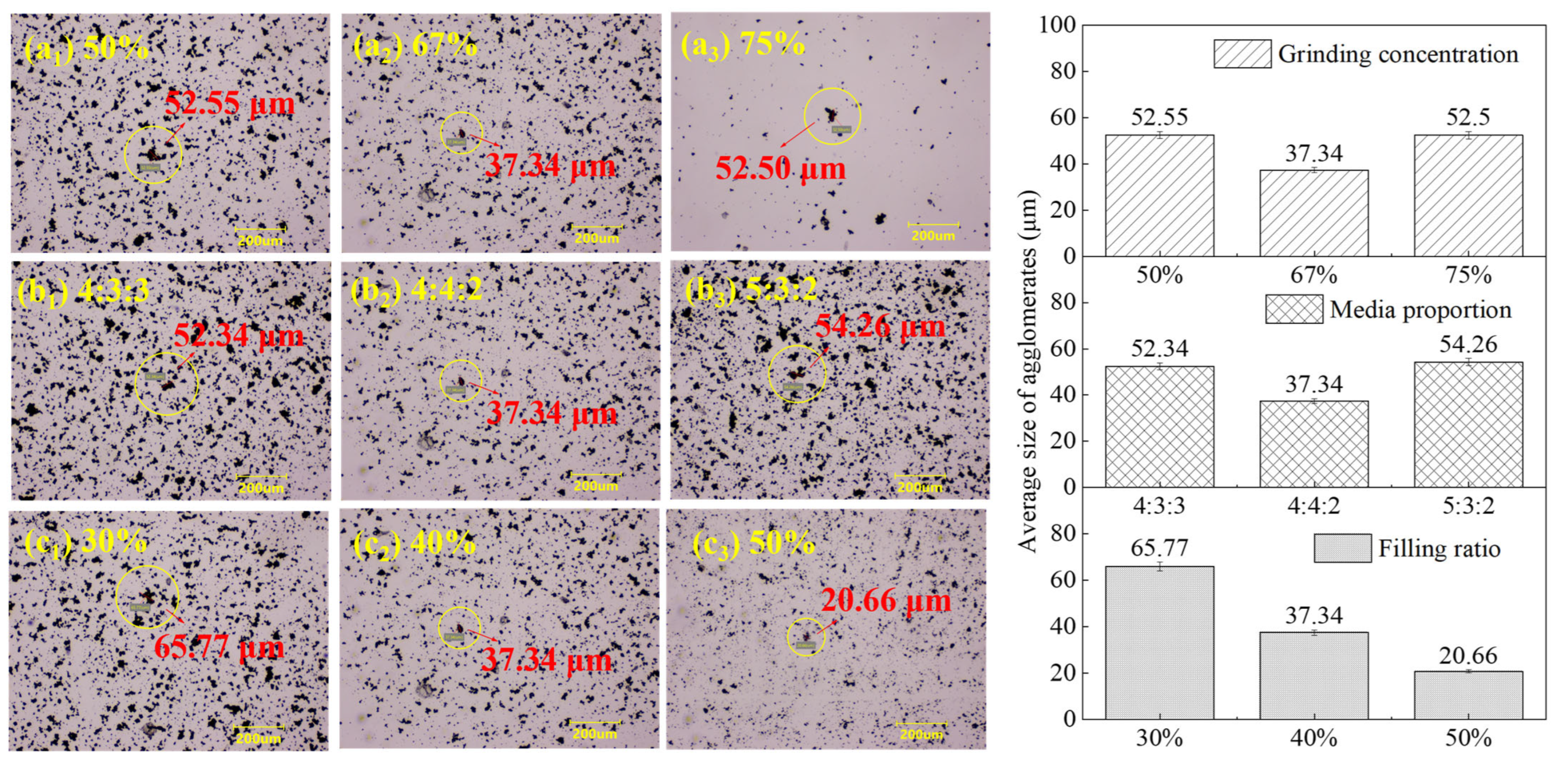

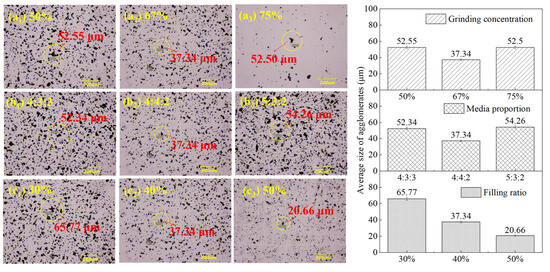

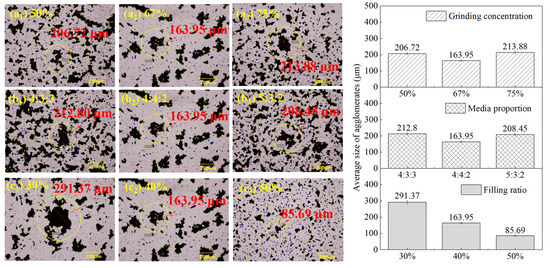

3.5. Hydrophobic Agglomeration

Due to variations in the surface wettability of minerals with different particle sizes, the agglomeration behavior of particles changes during flotation, with larger agglomerate size exhibiting better floatability [44,45]. The effects of the grinding parameters on the average agglomerate size of the fine-ground galena products, under conditions without a collector and with a collector dosage of 10 g/Mg, are shown in Figure 12 and Figure 13. The average agglomerate size values and error bars presented in the bar chart on the right are derived from the measurement of the largest agglomerate size during each of the ten observations. Each photo on the left is selected from ten observations of a single stirring experiment to best represent the average agglomerate size and the most representative agglomerates. Based on the particle size analysis, Figure 12 and Figure 13, when grinding parameters such as the grinding concentration, media proportion, and filling ratio were adjusted, the −10 μm yield in fine-ground galena products rose, the average agglomerate size decreased, and the galena recovery declined. Specifically, at a filling rate of 50%, the −10 μm yield peaked, the average agglomerate size was minimal, and the galena recovery was lowest.

Figure 12.

Influence of (a) grinding concentration, (b) media proportion, and (c) filling rate on the average agglomerate size of the fine-ground galena products (pH = 9, sodium diethyldithiocarbamate trihydrate = 0).

Figure 13.

Influence of (a) grinding concentration, (b) media proportion, and (c) filling rate on the average agglomerate size of the fine-ground galena products (pH = 9, sodium diethyldithiocarbamate trihydrate = 10 g/Mg).

3.6. Effects of Grinding Parameters on Particle Size Distribution and Recovery of the Fine-Ground Galena Products

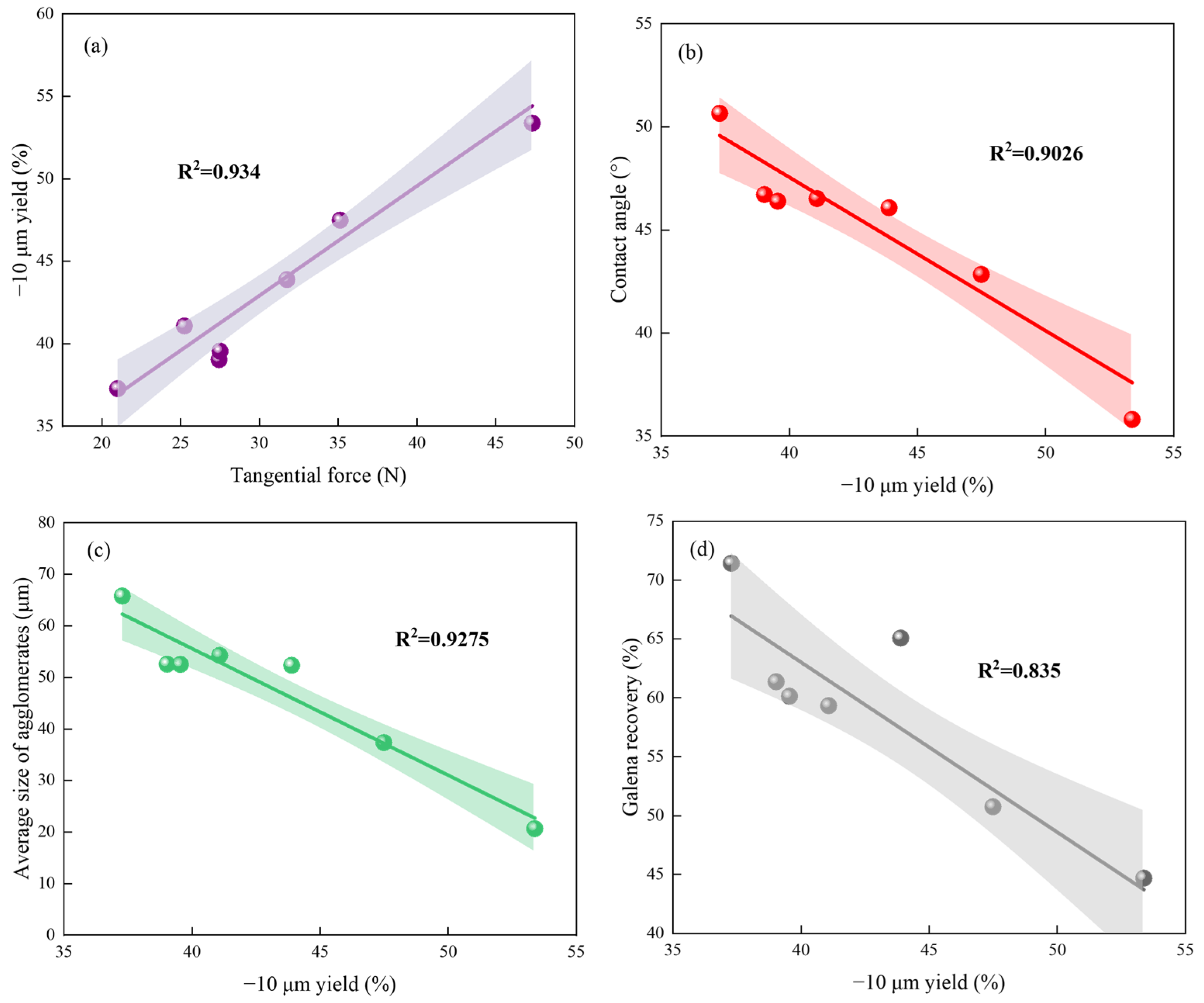

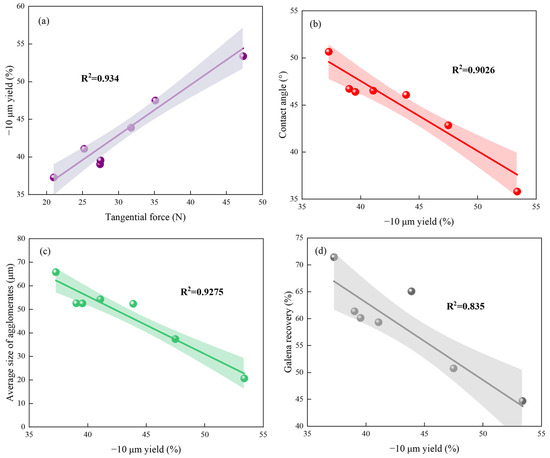

As can be seen from Figure 14, changes in the grinding parameters led to different tangential forces exerted by the media on minerals, influencing the generation of −10 µm particles (Figure 9), leading to differences in the average particle size, +25 µm yield, and particularly, the −10 µm yield of the fine-ground galena products (Figure 6), which ultimately influenced interfacial behaviors, such as the surface contact angle (Figure 10 and Figure 11), agglomeration (Figure 12 and Figure 13), and flotation (Figure 7). As shown in Figure 15, the yield of the −10 µm particle size fraction in the finely ground galena product shows a positive linear correlation with the tangential force, which characterizes the attrition, and a negative linear correlation with the contact angle of the mineral surface, the average aggregate size, and the galena recovery.

Figure 14.

Effects of grinding parameters on particle size distribution and recovery of the fine-ground galena products.

Figure 15.

Linear fitting results: (a) −10 µm yield vs. tangential force (plot in purple); (b) Contact angle and average aggregate size vs. −10 µm yield (plot in red); (c) Average aggregate size vs. −10 µm yield (plot in green); (d) Galena recovery vs. −10 µm yield (plot in gray).

4. Conclusions

The fine-ground product with a particle size below 30 μm was classified into three size fractions: +25 μm, −25 + 10 μm, and −10 μm. Changes in the grinding concentration, media proportion, and filling ratio significantly affected the yields of the +25 μm and −10 μm fractions, and the yield of the −25 + 10 µm particle size fraction remained relatively unchanged. When the filling rate increased from 30% to 50%, the yield of the +25 µm particle size fraction decreased by 15.04%, and the yield of the −10 µm particle size fraction increased by 16.10%. Discrete element simulation results revealed that increasing the motion velocity of the media group and enhancing attrition effects by adjusting the grinding parameters during fine grinding promoted the generation of −10 μm particles.

The −10 μm particle yield significantly affected mineral flotation behavior, with higher yields leading to lower galena recovery. Surface wettability and agglomeration analyses showed that the higher yield of −10 μm particles resulted in a smaller contact angle, smaller average agglomerate size, and lower galena recovery.

To achieve optimal particle size distribution and enhance fine-grained galena flotation recovery, thus promoting the effective recovery of micro-fine galena, it is essential to reduce the attrition of the grinding media on the mineral by adjusting the grinding parameters, such as by lowering the filling ratio. This minimizes galena overgrinding, lowers the −10 μm yield, and enhances flotation recovery. This provides some guidance for the industrial practice of reducing the yield of the −10 µm particle size fraction by adjusting the grinding process parameters.

Author Contributions

Conceptualization, G.G. and Y.W. (Yanhong Wang); methodology, G.G. and M.G.; formal analysis, Y.W. (Yanming Wu), S.Y. and Y.Y.; resources, G.G. and Y.W. (Yanhong Wang); data curation, M.G.; writing—original draft preparation, M.G.; writing—review and editing, G.G., Y.W. (Yanhong Wang) and J.C.; visualization, Q.L.; supervision, G.G.; project administration, G.G. and Y.W. (Yanhong Wang). All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Natural Science Foundation of China, grant number 52074358.

Data Availability Statement

The data obtained and analyzed within the frame of this study will be made available by the corresponding author upon reasonable request.

Conflicts of Interest

Authors Yuankun Yang, Shengli Yu and Yanming Wu were employed by the company Zijin Mining Group Co., Ltd. The remaining authors declare that the research was conducted in the absence of any commercial or financial relationships that could be construed as a potential conflict of interest.

References

- Nayak, A.; Jena, M.S.; Mandre, N.R. Beneficiation of Lead-Zinc Ores—A Review. Miner. Process. Extr. Metall. Rev. 2022, 43, 564–583. [Google Scholar] [CrossRef]

- Zhang, X.W.; Yang, L.S.; Li, Y.H.; Li, H.R.; Wang, W.Y.; Ye, B.X. Impacts of lead/zinc mining and smelting on the environment and human health in China. Environ. Monit. Assess. 2012, 184, 2261–2273. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Z.; Xie, F.; Wang, W. A Review on Lead Extraction from Ore and Spent Lead Paste by Hydrometallurgical Processes. Jom 2024, 76, 5569–5588. [Google Scholar] [CrossRef]

- Li, Q.K.; Du, S.Y.; Gu, G.H.; Wu, L.D.; Wang, Y.H. Utilizing the high intensity conditioning process with a multi-bladed impeller to enhance the flotation of fine-grained galena. Part. Sci. Technol. 2024, 42, 895–907. [Google Scholar] [CrossRef]

- Zhang, X.L.; Wei, H.Q.; Han, Y.X.; Zhou, Z.Y.; Li, W.B. Effect of different mills on the fine grinding characteristics and leaching behaviour of gold ore. Miner. Eng. 2024, 215, 108800. [Google Scholar] [CrossRef]

- Xiao, X.; Zhang, G.W.; Feng, Q.M.; Xiao, S.X.; Huang, L.L.; Zhao, X.; Li, Z.Q. The liberation effect of magnetite fine ground by vertical stirred mill and ball mill. Miner. Eng. 2012, 34, 63–69. [Google Scholar] [CrossRef]

- Kumar, A.; Sahu, R.; Tripathy, S.K. Energy-Efficient Advanced Ultrafine Grinding of Particles Using Stirred Mills—A Review. Energies 2023, 16, 5277. [Google Scholar] [CrossRef]

- Aleksandrova, T.N.; Orlova, A.V.; Taranov, V.A. Current Status of Copper-Ore Processing: A Review. Russ. J. Non-Ferr. Met. 2021, 62, 375–381. [Google Scholar] [CrossRef]

- Du, Y.; Tong, X.; Xie, X.; Lu, Y.; Hua, Z.; Zhang, W. Effects of pyrite on the flotation behavior and electrochemical interaction of different particle sizes of galena in the presence of diethyldithiocarbamate. Sep. Sci. Technol. 2021, 56, 2467–2474. [Google Scholar] [CrossRef]

- Peng, Y.; Grano, S. Dissolution of fine and intermediate sized galena particles and their interactions with iron hydroxide colloids. J. Colloid Interface Sci. 2010, 347, 127–131. [Google Scholar] [CrossRef]

- Peng, Y.J.; Grano, S.; Fornasiero, D.; Ralston, J. Control of grinding conditions in the flotation of galena and its separation from pyrite. Int. J. Miner. Process. 2003, 70, 67–82. [Google Scholar] [CrossRef]

- Lu, Y.L.; Tong, X.; Xie, X.; Yang, B.; Hua, Z.B. Effect of particle size on the oxidation and flotation behavior of galena particles. Physicochem. Probl. Miner. Process. 2019, 55, 208–216. [Google Scholar] [CrossRef]

- Peng, Y.J.; Grano, S. Effect of iron contamination from grinding media on the flotation of sulphide minerals of different particle size. Int. J. Miner. Process. 2010, 97, 1–6. [Google Scholar] [CrossRef]

- Guo, W.; Guo, K.Q.; Xing, Y.W.; Gui, X.H. A Comprehensive Review on Evolution Behavior of Particle Size Distribution During Fine Grinding Process for Optimized Separation Purposes. Miner. Process. Extr. Metall. Rev. 2024. [Google Scholar] [CrossRef]

- Miettinen, T.; Ralston, J.; Fornasiero, D. The limits of fine particle flotation. Miner. Eng. 2010, 23, 420–437. [Google Scholar] [CrossRef]

- Tong, J.Q.; Wu, C.B.; Wang, Y.H.; Tian, J.K.; Li, Z.Y.; Xie, F.; Yao, X.; Zeng, G.S. Effect on Fine Particles Output Characteristics of Ceramic Ball Grinding. Minerals 2023, 13, 1416. [Google Scholar] [CrossRef]

- Wu, C.B.; Chen, Z.L.; Liao, N.N.; Zeng, C.; Wang, Y.H.; Tian, J.K. Enhancing the Grinding Efficiency of a Magnetite Second-Stage Mill through Ceramic Ball Optimization: From Laboratory to Industrial Applications. Minerals 2024, 14, 160. [Google Scholar] [CrossRef]

- Matsanga, N.; Nheta, W.; Chimwani, N. A Review of the Grinding Media in Ball Mills for Mineral Processing. Minerals 2023, 13, 1373. [Google Scholar] [CrossRef]

- Shahbazi, B.; Jafari, M.; Parian, M.; Rosenkranz, J.; Chelgani, S.C. Study on the impacts of media shapes on the performance of tumbling mills—A review. Miner. Eng. 2020, 157, 106490. [Google Scholar] [CrossRef]

- Kutuk, S. Influence of milling parameters on particle size of ulexite material. Powder Technol. 2016, 301, 421–428. [Google Scholar] [CrossRef]

- Chen, X.M.; Peng, Y.J. The effect of regrind mills on the separation of chalcopyrite from pyrite in cleaner flotation. Miner. Eng. 2015, 83, 33–43. [Google Scholar] [CrossRef]

- Hacifazlioglu, H.; Korkmaz, A.V. Performance comparison of stirred media mill and ball (BOND) mill in bauxite grinding. Part. Sci. Technol. 2020, 38, 404–408. [Google Scholar] [CrossRef]

- Samanli, S.; Cuhadaroglu, D.; Kizgut, S. A Simulation Study of Laboratory Scale Ball and Vertical Stirred Mills. Part. Part. Syst. Charact. 2010, 26, 256–264. [Google Scholar] [CrossRef]

- Ma, S.J.; Li, H.J.; Shuai, Z.C.; Yang, J.L.; Deng, X.J.; Xu, W.Z. Research on Grinding Law and Grinding Parameters Optimization of Polymetallic Complex Ores. Minerals 2022, 12, 1283. [Google Scholar] [CrossRef]

- Yuan, C.F.; Wu, C.B.; Fang, X.; Liao, N.N.; Tong, J.Q.; Yu, C. Effect of Slurry Concentration on the Ceramic Ball Grinding Characteristics of Magnetite. Minerals 2022, 12, 1569. [Google Scholar] [CrossRef]

- Jankovic, A. Variables affecting the fine grinding of minerals using stirred mills. Miner. Eng. 2003, 16, 337–345. [Google Scholar] [CrossRef]

- Wang, C.; Deng, J.; Tao, L.M.; Sun, W.; Xiao, Q.F.; Gao, Z.Y. Enhanced flotation of chalcopyrite particles by grinding with short cylinder media. Miner. Eng. 2022, 188, 107827. [Google Scholar] [CrossRef]

- Partyka, T.; Yan, D. Fine grinding in a horizontal ball mill. Miner. Eng. 2007, 20, 320–326. [Google Scholar] [CrossRef]

- Zhao, S.; Evans, T.M.; Zhou, X. Effects of curvature-related DEM contact model on the macro- and micro-mechanical behaviours of granular soils. Geotechnique 2018, 68, 1085–1098. [Google Scholar] [CrossRef]

- Li, Q.; Zhou, J.; Wu, Y.; Yang, Y.; Wang, Y.; Gu, G.; Liu, B. Influence of the impeller structure and operating parameters of a high intensity conditioning system on the flotation of fine-grained pyrite. Miner. Eng. 2025, 228, 109363. [Google Scholar] [CrossRef]

- Yang, J.L.; Shuai, Z.C.; Zhou, W.T.; Ma, S.J. Grinding Optimization of Cassiterite-Polymetallic Sulfide Ore. Minerals 2019, 9, 134. [Google Scholar] [CrossRef]

- Yang, J.L.; Deng, X.J.; Xu, W.Z.; Li, H.J.; Ma, S.J. Study on the Grinding Law of Ball Media for Cassiterite-Polymetallic Sulfide Ore. Minerals 2022, 12, 270. [Google Scholar] [CrossRef]

- He, K.; Jia, M.P.; Sun, F.; Yang, Q.; Wu, B.; Li, X.B.; Meng, C. Simulation of Grinding Media Motion and Collisions in Wet-Operated Accelerator-Mill Using DEM Coupled with CFD. Minerals 2022, 12, 341. [Google Scholar] [CrossRef]

- Puga, A.M.; Govender, N.; Rajamani, R.K. Verification of Polyhedral DEM with Laboratory Grinding Mill Experiments. Kona Powder Part. J. 2022, 39, 208–218. [Google Scholar] [CrossRef]

- Cleary, P.W.; Owen, P. Effect of operating condition changes on the collisional environment in a SAG mill. Miner. Eng. 2019, 132, 297–315. [Google Scholar] [CrossRef]

- Fang, X.; Wu, C.B.; Liao, N.N.; Zhong, J.X.; Duan, X.Q.; Zhu, S.L.; Liu, A.J.; Xiao, K. Investigating the Influence of Medium Size and Ratio on Grinding Characteristics. Minerals 2024, 14, 875. [Google Scholar] [CrossRef]

- Xiaojing, Y.; Jinlin, Y.; Shaojian, M.; Runnan, G. Research on the characteristics of particles size for grinding products with a ball mill at low speed. J. Phys. Conf. Ser. 2021, 2044, 012040. [Google Scholar]

- Xiaojing, Y.; Shaojian, M.; Jinlin, Y.; Pengyan, Z. Crushing characteristics of different minerals by cylindrical ball mill in cascading motion state. J. Phys. Conf. Ser. 2021, 2044, 012142. [Google Scholar]

- Xiaojing, Y.; Shaojian, M.; Linling, J.; Runnan, G. Approach of establishing the grinding population balance kinetic model for cassiterite-polymetallic sulfide ore. Ferroelectrics 2021, 578, 66–80. [Google Scholar]

- Li, Q.; Wu, L.; Yang, Y.; Gu, G.; Wang, Y. The relationship among pyrite fine grinding by stirred ball mill and tumbling ball mill, the properties of the product and the flotation behavior. Miner. Eng. 2025, 229, 109401. [Google Scholar] [CrossRef]

- Gao, Z.Y.; Sun, W.; Hu, Y.H. Mineral cleavage nature and surface energy: Anisotropic surface broken bonds consideration. Trans. Nonferrous Met. Soc. China 2014, 24, 2930–2937. [Google Scholar] [CrossRef]

- Gao, Z.Y.; Sun, W.; Hu, Y.H.; Liu, X.W. Surface energies and appearances of commonly exposed surfaces of scheelite crystal. Trans. Nonferrous Met. Soc. China 2013, 23, 2147–2152. [Google Scholar] [CrossRef]

- Moon, K.S.; Fuerstenau, D.W. Surface crystal chemistry in selective flotation of spodumene (LiAl[SiO3]2) from other aluminosilicates. Int. J. Miner. Process. 2003, 72, 11–24. [Google Scholar] [CrossRef]

- Alvarez, A.; Gutierrez, L.; Laskowski, J.S. Use of polyethylene oxide to improve flotation of fine molybdenite. Miner. Eng. 2018, 127, 232–237. [Google Scholar] [CrossRef]

- Wan, H.; Qu, J.P.; Zhao, L.F.; Bu, X.Z. Improving the flotation performance of fine molybdenite using superhydrophobic magnetic carriers. Miner. Eng. 2025, 224, 109212. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).