Preserving Flake Size in an African Flake Graphite Ore Beneficiation Using a Modified Grinding and Pre-Screening Process

Abstract

:1. Introduction

2. Material and Methods

2.1. Materials

2.2. Analysis Methods

2.3. Experimental Tests

2.4. Grinding Damage Coefficient

3. Results and Discussion

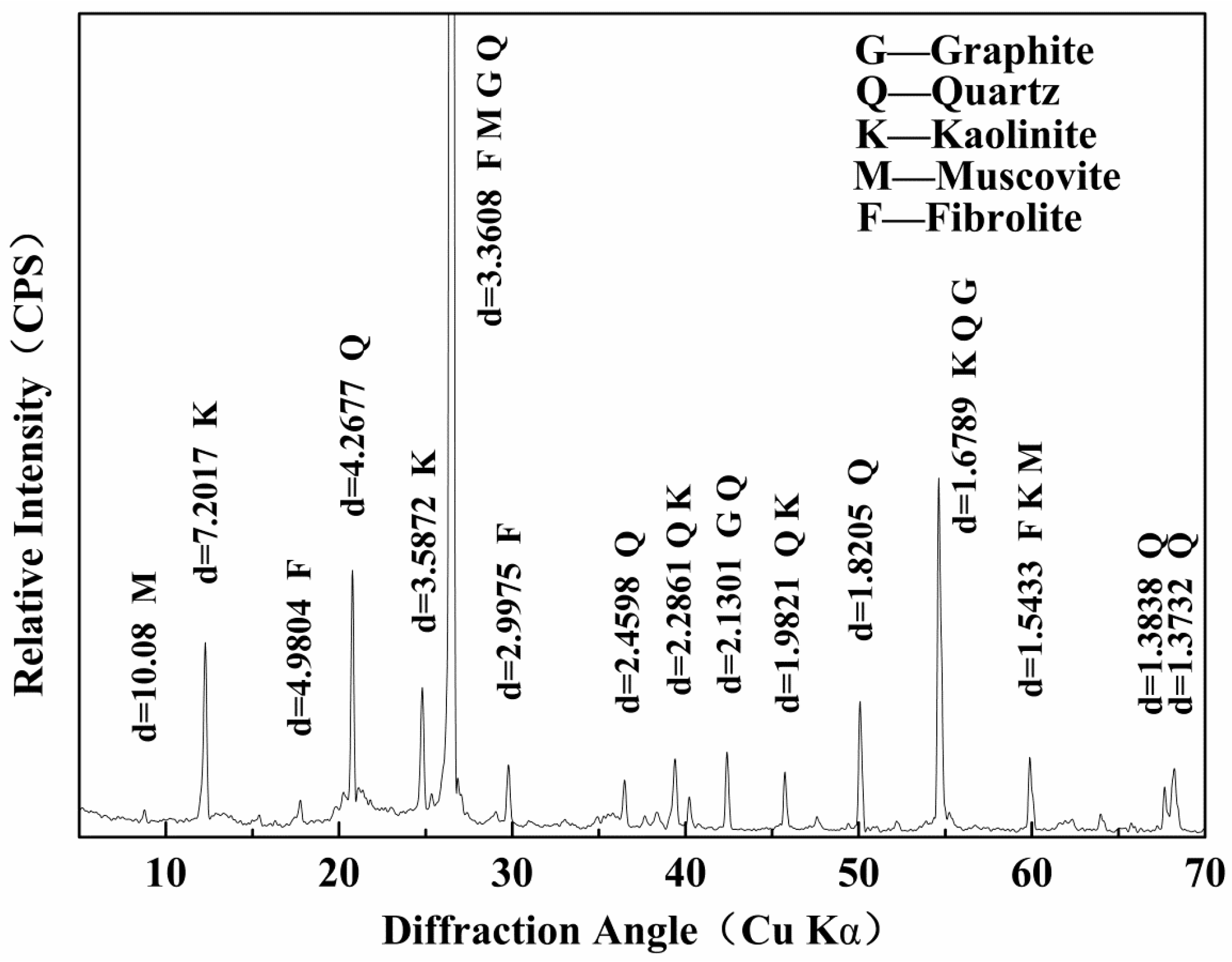

3.1. Mineralogy Study

3.2. Coarse Grinding

3.3. First Regrinding

3.4. Open Circuit Tests

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Inagaki, M.; Masahiro, T.; Kang, F.Y.; Zheng, Y.P.; Shen, W.C. Pore structure of exfoliated graphite—A report on a joint research project under the scientific cooperation program between NSFC and JSPS. New Carbon Mater. 2003, 18, 241–249. [Google Scholar]

- Luke, L.; Chang, Y. Industrial Mineralogy: Materials, Processes, and Uses; Prentice Hall: Upper Saddle River, NJ, USA, 2002. [Google Scholar]

- Crossley, P. Graphite—High-tech supply sharpens up. Ind. Miner. 2000, 398, 31–47. [Google Scholar]

- Acharya, B.C.; Rao, D.S.; Prakash, S.; Reddy, P.S.R.; Biswal, S.K. Processing of low grade graphite ores of Orissa, India. Miner. Eng. 1996, 9, 1165–1169. [Google Scholar] [CrossRef]

- Mitchell, C.J. Industrial Minerals Laboratory Manual: Flake Graphite; British Geological Survey: Nottingham, UK, 1992. [Google Scholar]

- Chehreh Chelgani, S.; Rudolph, M.; Kratzsch, R.; Sandmann, D.; Gutzmer, J. A review of graphite beneficiation techniques. Miner. Process. Extr. Metall. Rev. 2016, 37, 58–68. [Google Scholar] [CrossRef]

- Qiu, Y.; Yu, Y.; Zhang, L.; Qian, Y.; Ouyang, Z. An Investigation of Reverse Flotation Separation of Sericite from Graphite by Using a Surfactant: MF. Minerals 2016, 6, 57. [Google Scholar] [CrossRef]

- Weng, X.; Li, H.; Song, S.; Liu, Y. Reducing the Entrainment of Gangue Fines in Low Grade Microcrystalline Graphite Ore Flotation Using Multi-Stage Grinding-Flotation Process. Minerals 2017, 7, 38. [Google Scholar] [CrossRef]

- Wakamatsu, T.; Numata, Y. Flotation of graphite. Miner. Eng. 1991, 4, 975–982. [Google Scholar] [CrossRef]

- Vasumathi, N.; Kumar, V.T.V.; Nayak, B.; Rao, S.S.; Prabhaker, S.; Raju, B.G. Beneficiation of low grade graphite ore of eastern India by two-stage grinding and flotation. J. Min. Metall. A Min. 2014, 50, 9–17. [Google Scholar] [CrossRef]

- Tamashausky, A.V. Graphite. Am. Ceram. Soc. Bull. 1998, 77, 102–104. [Google Scholar]

- Asbury Carbons. Natural Flake Graphite. Available online: http://asbury.com/technical-presentations-papers/materials-in-depth/natural-flake-graphite (accessed on 5 June 2017).

- Bhima, R.R.; Patnaik, N. Preparation of high pure graphite by alkali digestion method. Scand. J. Metall. 2004, 33, 257–260. [Google Scholar] [CrossRef]

- Lu, X.J.; Forssberg, E. Preparation of high-purity and low-sulphur graphite from Woxna fine graphite concentrate by alkali roasting. Miner. Eng. 2002, 15, 755–757. [Google Scholar] [CrossRef]

- Wissler, M. Graphite and carbon powders for electrochemical applications. J. Power Sources 2006, 156, 142–150. [Google Scholar] [CrossRef]

- Xie, Z. Study on protecting flaky graphite concentration. China Non-Met. Min. Ind. Her. 2005, 1, 010. [Google Scholar]

- Long, Y.; Zhang, G.W.; Li, Z.Q.; Xiao, X. Research progress of the protecting large glaky graphite. China Non-Met. Min. Ind. Her. 2013, 2, 016. [Google Scholar]

- Yue, C. Study on the damage of large-scale flaky graphite and new grinding-flotation process. Non-Met. Mines 2002, 25, 36–37. [Google Scholar]

- Chen, X.; Peng, Y. The effect of regrind mills on the separation of chalcopyrite from pyrite in cleaner flotation. Miner. Eng. 2015, 83, 33–43. [Google Scholar] [CrossRef]

- Wills, B.A.; Finch, J. Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery; Butterworth-Heinemann: Oxford, UK, 2015. [Google Scholar]

- Long, Y.; Zhang, G.W.; Xiao, X.; Li, Z.Q. Grinding of Flake Graphite with Vertical Agitating Mill. Min. Metall. Eng. 2014, 34, 41–44. (In Chinese) [Google Scholar]

- Yue, C. Research on speed flotation of flake graphite. Non-Met. Mines 2007, 5, 018. [Google Scholar]

- Newcombe, B. Predicting plant scale flash flotation performance—Validation of laboratory methodology and applications for use. Miner. Eng. 2014, 57, 57–67. [Google Scholar] [CrossRef]

- Newcombe, B.; Bradshaw, D.; Wightman, E. Flash flotation and the plight of the coarse particle. Miner. Eng. 2012, 34, 1–10. [Google Scholar] [CrossRef]

- Qu, X.; Zhang, L.; Li, Q. Study on new technology to protect flake graphite by grading for grinding and floating. Non-Met. Mines 2015, 38, 53–55. [Google Scholar]

- Newcombe, B.; Wightman, E.; Bradshaw, D. The role of a flash flotation circuit in an industrial refractory gold concentrator. Miner. Eng. 2013, 53, 57–73. [Google Scholar] [CrossRef]

- He, P.; Zhang, L.; Deng, C. Selective Grinding and Floating Test on Flakey Graphite in Africa. Bull. Chin. Ceram. Soc. 2016, 9, 2826–2831. [Google Scholar]

- Sabih, A.; Radziszewski, P.; Mullany, I. Investigating grinding media differences in microstructure, hardness, abrasion and fracture toughness. Miner. Eng. 2017, 103, 43–53. [Google Scholar] [CrossRef]

- Yu, X.B.; Fang, H.P.; Xiao, Y.J.; Zhang, L.Y. Experimental study on purification of a fine-scaled graphite ore by flotation. Conserv. Util. Miner. Resour. 2000, 1, 003. [Google Scholar]

- Xie, G.Y.; Zhang, M.X.; Bian, B.X.; Fang, M.Q. Mineral Processing; China University of Mining and Technology Press: Xuzhou, China, 2001. [Google Scholar]

- Duan, X.X. Crushing and Grinding; Metallurgical Industry Press: Beijing, China, 2006. [Google Scholar]

- Zhang, G.F.; Feng, Q.M.; Chen, Q.Y.; Zhang, P.M. Study on grinding media of selective grinding of bauxite. J. Cent. South Univ. Sci. Technol. 2004, 4, 552–556. [Google Scholar]

- Feng, Q. Study on wet grinding parameters for producing ultra-fine graphite particles. China Non-Met. Min. Ind. Her. 2003, 6, 005. [Google Scholar]

- Xie, C.; Yuan, H. Research on concentration of large flake graphite with the filling-type flotation machine. Met. Mine 2010, 7, 018. [Google Scholar]

- Ravichandran, V.; Eswaraiah, C.; Manisankar, P. Beneficiation of low grade graphite ore deposits of Tamilnadu (India). Ultra Chem. 2012, 8, 159–168. [Google Scholar]

- Sun, Z.; Jia, F.; Li, Q. Study on Beneficiation Process of a Low Grade Graphite Ore in Inner Mongolia. Ind. Miner. Process. 2012, 9, 003. [Google Scholar]

- Vasumathi, N.; Kumar, T.V.V.; Ratchambigai, S.; Rao, S.S.; Raju, G.B. Flotation studies on low grade graphite ore from eastern India. Int. J. Min. Sci. Technol. 2015, 25, 415–420. [Google Scholar] [CrossRef]

- Nkwanyana, S.; Loveday, B. Addition of pebbles to a ball-mill to improve grinding efficiency. Miner. Eng. 2017, 103, 72–77. [Google Scholar] [CrossRef]

| Composition | SiO2 | Al2O3 | Fe2O3 | SO3 | K2O | TiO2 | P2O5 | BaO | MgO | CaO |

| Content/% | 60.93 | 13.21 | 4.13 | 4.01 | 0.94 | 0.57 | 0.40 | 0.15 | 0.14 | 0.10 |

| Composition | Na2O | SrO | Cr2O3 | ZrO2 | CuO | ZnO | Y2O3 | LOI | FC | |

| Content/% | 0.09 | 0.038 | 0.035 | 0.015 | 0.013 | 0.007 | 0.002 | 15.22 | 7.59 |

| Species | Graphite | Quartz | Kaolinite | Muscovite | Fibrolite | Limonite | Epidote | Others |

|---|---|---|---|---|---|---|---|---|

| Content/% | 7 | 50 | 23 | 8 | 5 | 3 | 2 | 2 |

| Media | Volume-Weight (g/cm3) | Specification (mm) | Mill Charge Volume (%) | |

|---|---|---|---|---|

| Coarse Grinding | Regrinding | |||

| Steel Ball | 4.5 | Φ10–25 | Φ5–10 | 40 |

| Steel Rod | 5.6 | Φ20 × 200 | Φ10 × 100 | 50 |

| Pebble | 1.6 | Φ10–30 | Φ5–15 | 50 |

| Size Fraction/μm | According to Particle Number | According to Distribution Rate | |||

|---|---|---|---|---|---|

| Particle Numbers/n | Particle Pumber Percentage/% | Cumulative Particle Number Percentage/% | Distribution Rate/% | Cumulative Distribution Rate/% | |

| +830 | 36 | 0.65 | 0.65 | 13.13 | 13.13 |

| −830 + 600 | 87 | 1.57 | 2.22 | 15.87 | 29.00 |

| −600 + 500 | 115 | 2.07 | 4.29 | 10.49 | 39.49 |

| −500 + 300 | 662 | 11.93 | 16.21 | 30.19 | 69.68 |

| −300 + 230 | 656 | 11.82 | 28.03 | 14.96 | 84.64 |

| −230 + 180 | 700 | 12.61 | 40.64 | 7.98 | 92.62 |

| −180 + 150 | 514 | 9.26 | 49.90 | 2.93 | 95.55 |

| −150 + 106 | 974 | 17.55 | 67.45 | 2.78 | 98.33 |

| −106 + 75 | 738 | 13.29 | 80.74 | 1.05 | 99.38 |

| −75 + 45 | 668 | 12.03 | 92.78 | 0.48 | 99.86 |

| −45 | 401 | 7.22 | 100.00 | 0.14 | 100.00 |

| Total | 5551 | 100.00 | 100.00 | ||

| Product | Conventional Open Circuit | Modified Open Circuit | ||||

|---|---|---|---|---|---|---|

| Yield/% | FC/% | Recovery/% | Yield/% | FC/% | Recovery/% | |

| Conc1 | 7.11 | 95.40 | 91.26 | 3.03 | 94.73 | 40.12 |

| Conc2 | 3.86 | 96.63 | 52.23 | |||

| CT1 | 5.12 | 3.79 | 2.61 | 6.05 | 0.40 | 0.34 |

| CT2 | 2.24 | 0.36 | 0.11 | 2.86 | 1.04 | 0.42 |

| CT3 | 1.14 | 1.99 | 0.30 | 0.94 | 3.19 | 0.42 |

| CT4 | 0.77 | 5.77 | 0.60 | 0.26 | 28.76 | 1.05 |

| CT5 | 0.28 | 13.64 | 0.52 | 0.11 | 39.19 | 0.54 |

| CT6 | 0.12 | 48.18 | 0.79 | - | - | - |

| Tailings | 83.21 | 0.34 | 3.80 | 82.89 | 0.42 | 4.87 |

| Total | 100.00 | 7.44 | 100.00 | 100.00 | 7.15 | 100.00 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, K.; Qiu, Y.; Zhang, L. Preserving Flake Size in an African Flake Graphite Ore Beneficiation Using a Modified Grinding and Pre-Screening Process. Minerals 2017, 7, 115. https://doi.org/10.3390/min7070115

Sun K, Qiu Y, Zhang L. Preserving Flake Size in an African Flake Graphite Ore Beneficiation Using a Modified Grinding and Pre-Screening Process. Minerals. 2017; 7(7):115. https://doi.org/10.3390/min7070115

Chicago/Turabian StyleSun, Kangkang, Yangshuai Qiu, and Lingyan Zhang. 2017. "Preserving Flake Size in an African Flake Graphite Ore Beneficiation Using a Modified Grinding and Pre-Screening Process" Minerals 7, no. 7: 115. https://doi.org/10.3390/min7070115

APA StyleSun, K., Qiu, Y., & Zhang, L. (2017). Preserving Flake Size in an African Flake Graphite Ore Beneficiation Using a Modified Grinding and Pre-Screening Process. Minerals, 7(7), 115. https://doi.org/10.3390/min7070115