Influence of Particle Size in Talc Suppression by a Galactomannan Depressant

Abstract

:1. Introduction

2. Experimental

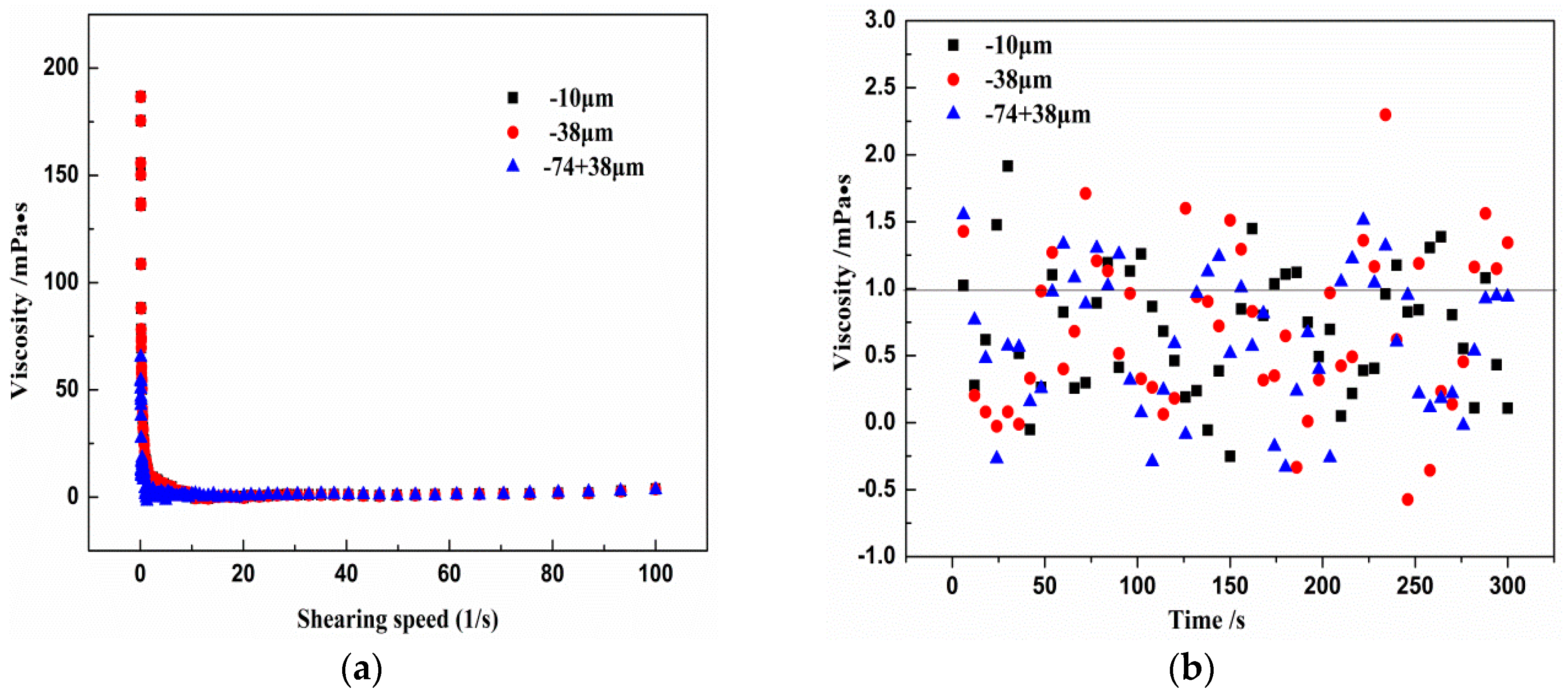

2.1. Samples and Reagents

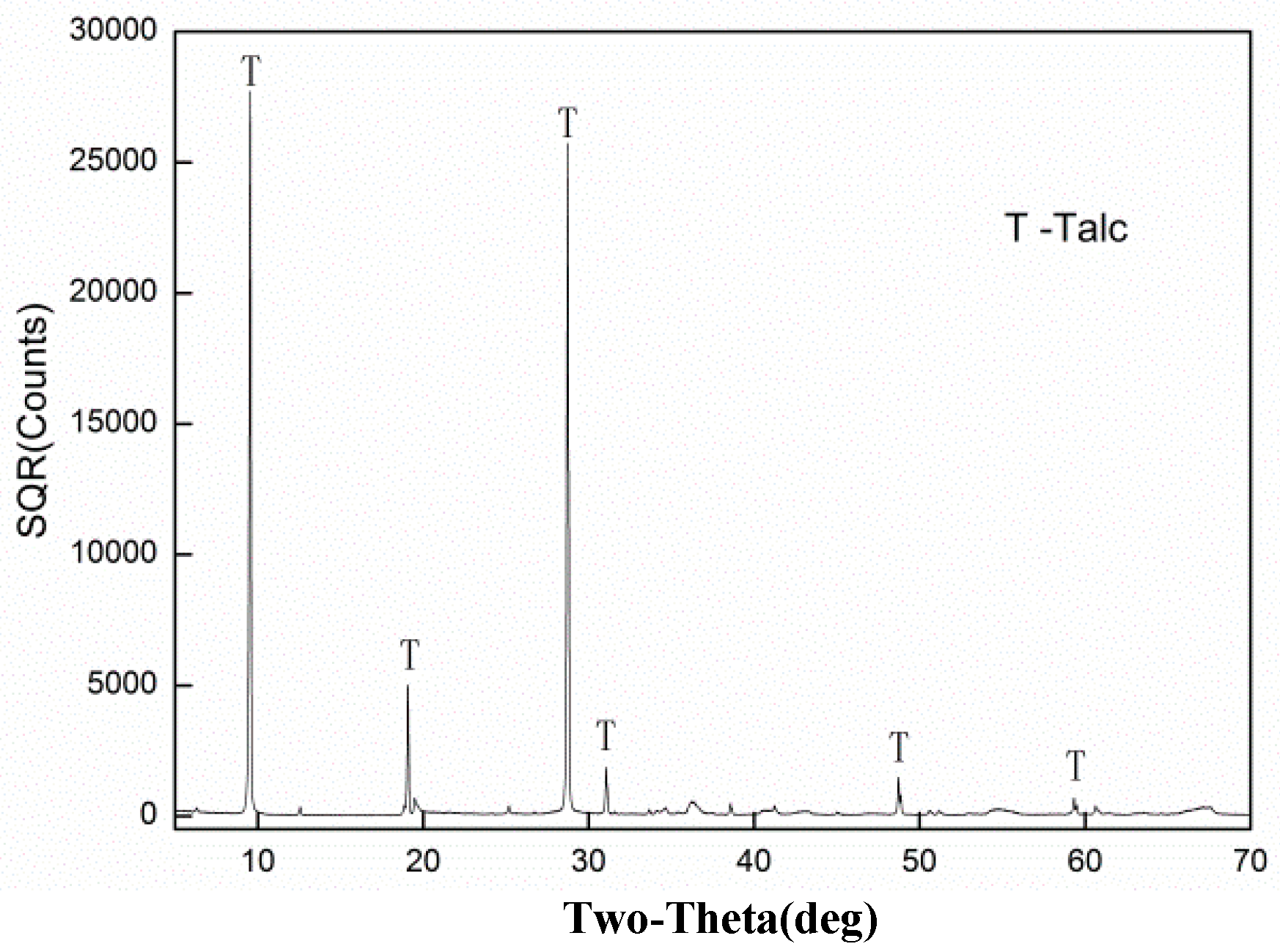

2.1.1. Samples

2.1.2. Reagents

2.2. Experiments

2.2.1. Micro-Flotation Tests

2.2.2. Determination of Modified Flotation Rate Constant

2.2.3. Recovery by Entrainment

2.2.4. Laser Particle Size Experiments

2.2.5. Adsorption Tests

2.2.6. Advancing Contact Angle Measurement

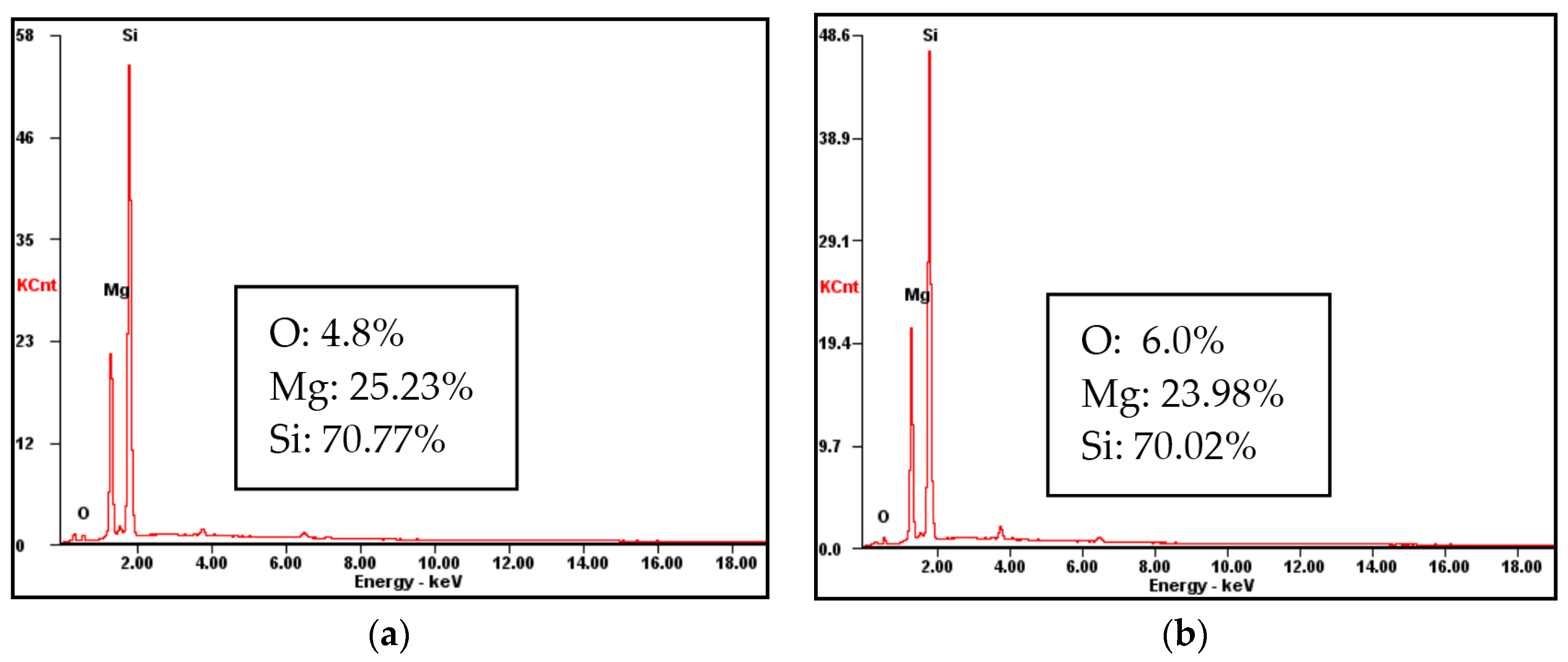

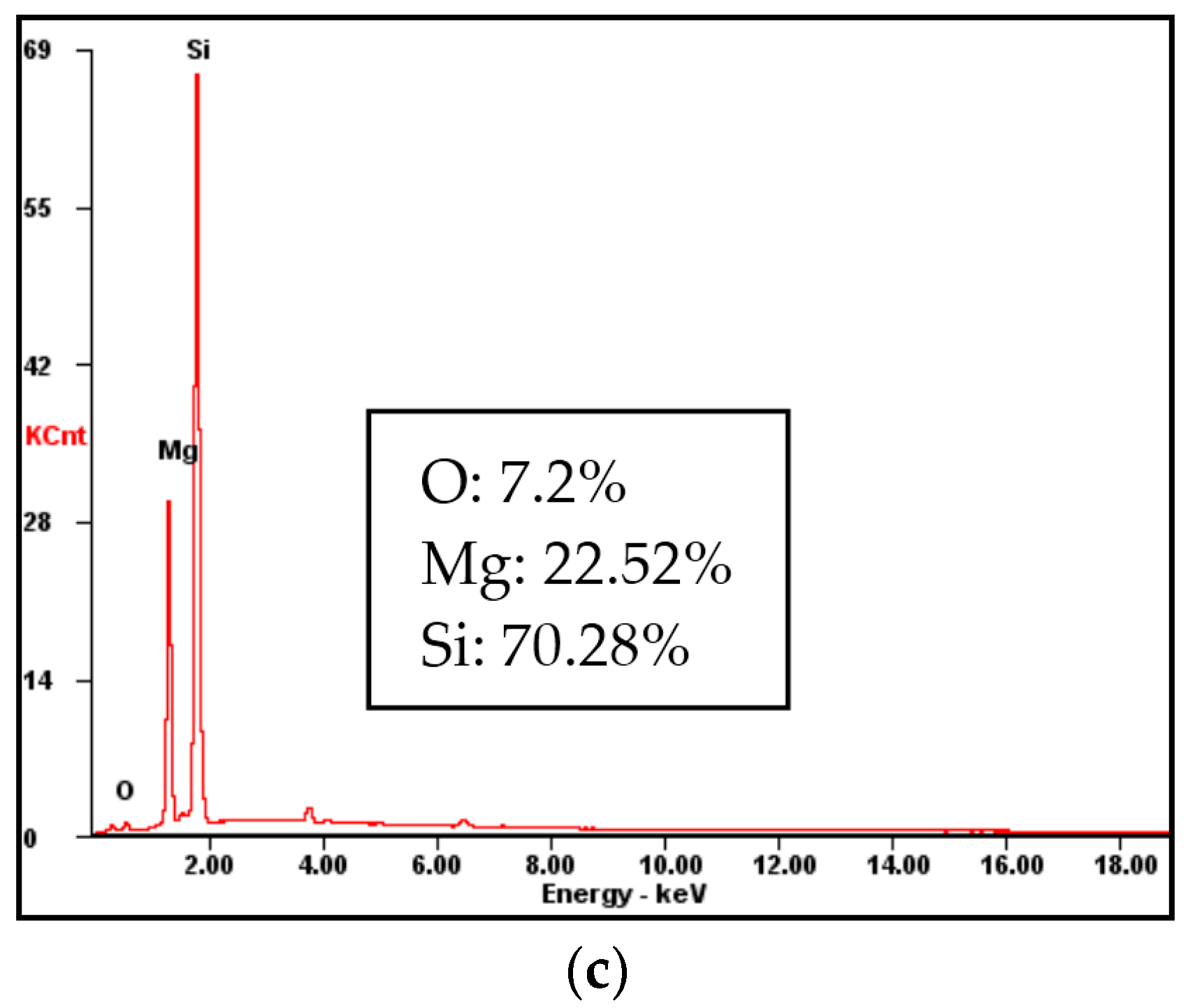

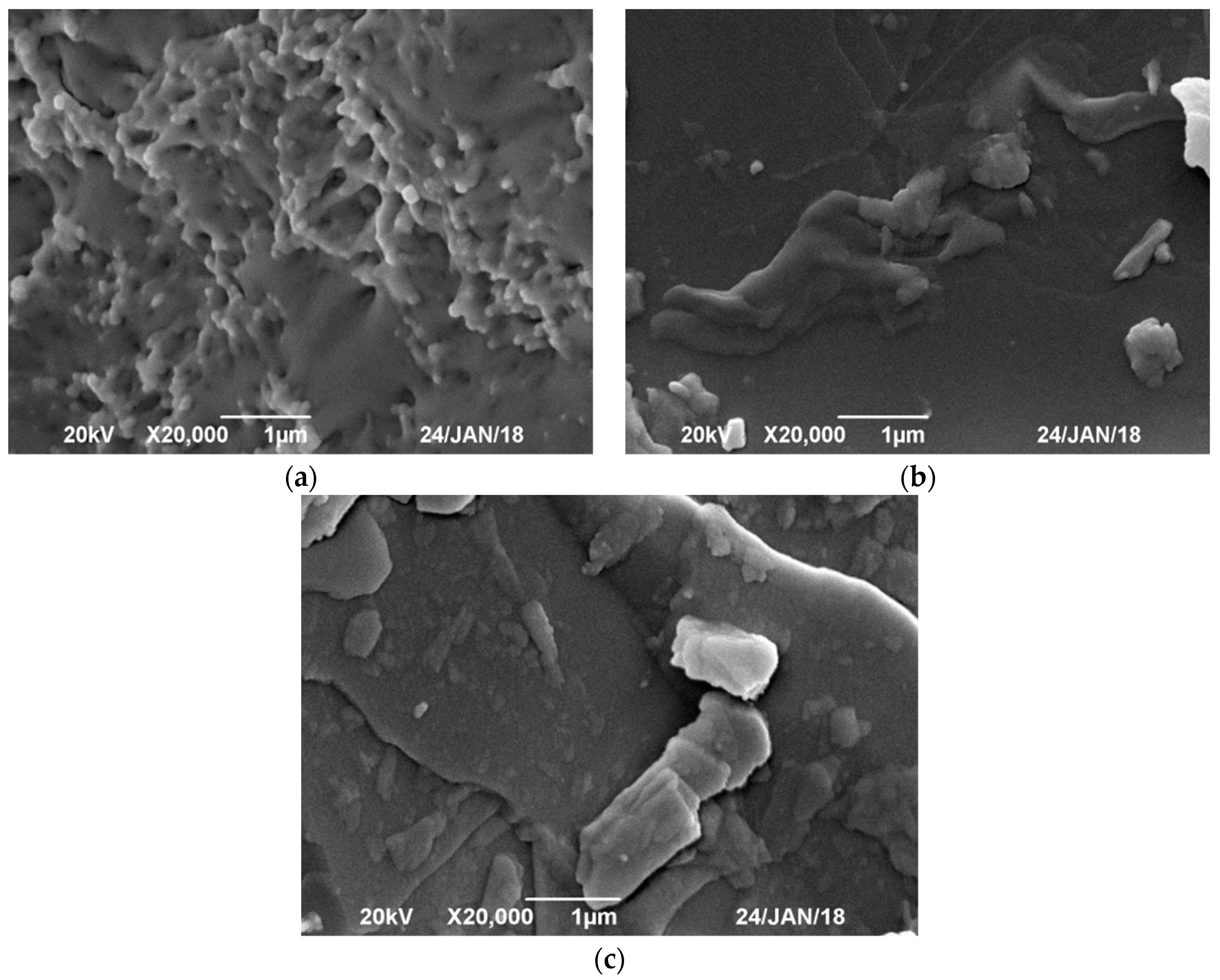

2.2.7. Scanning Electron Microscopy and Energy Dispersive X-ray Spectrometry Analysis

3. Results and Discussions

3.1. Comparision of Different Depressants

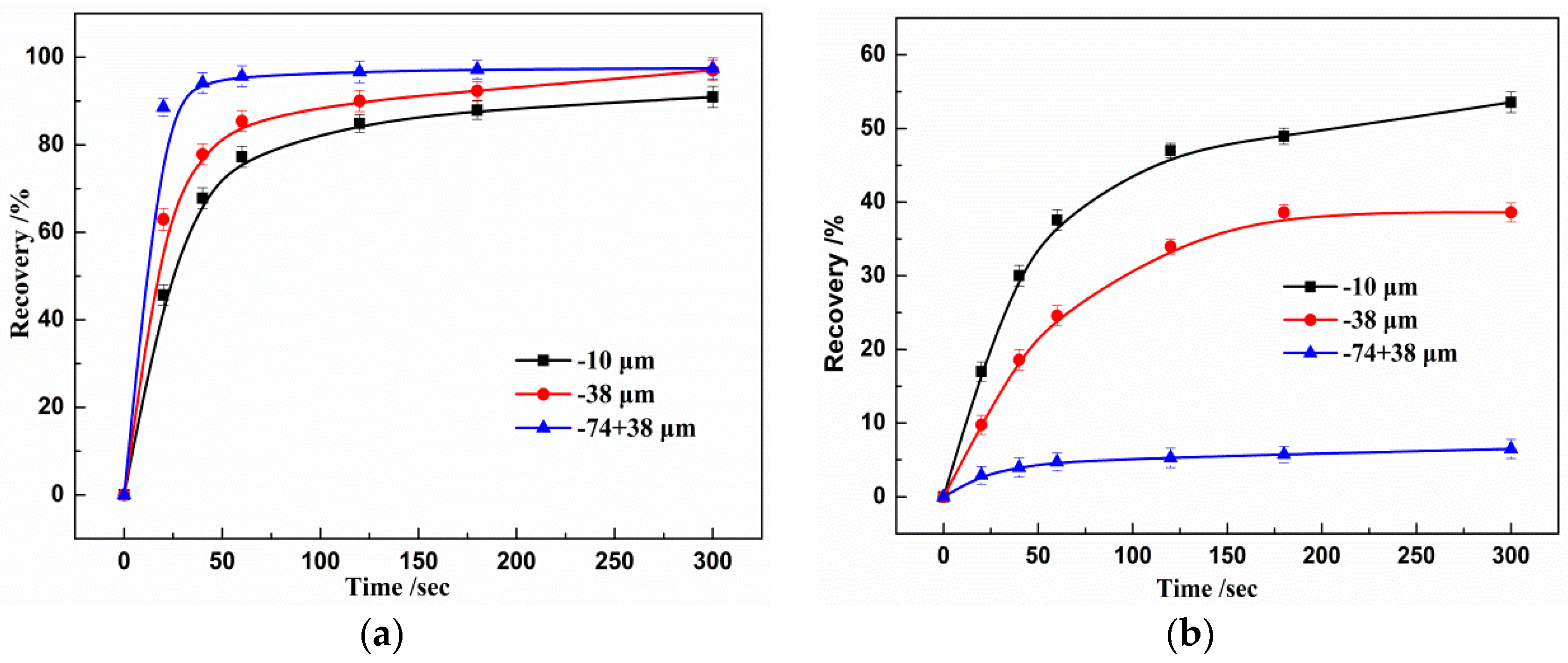

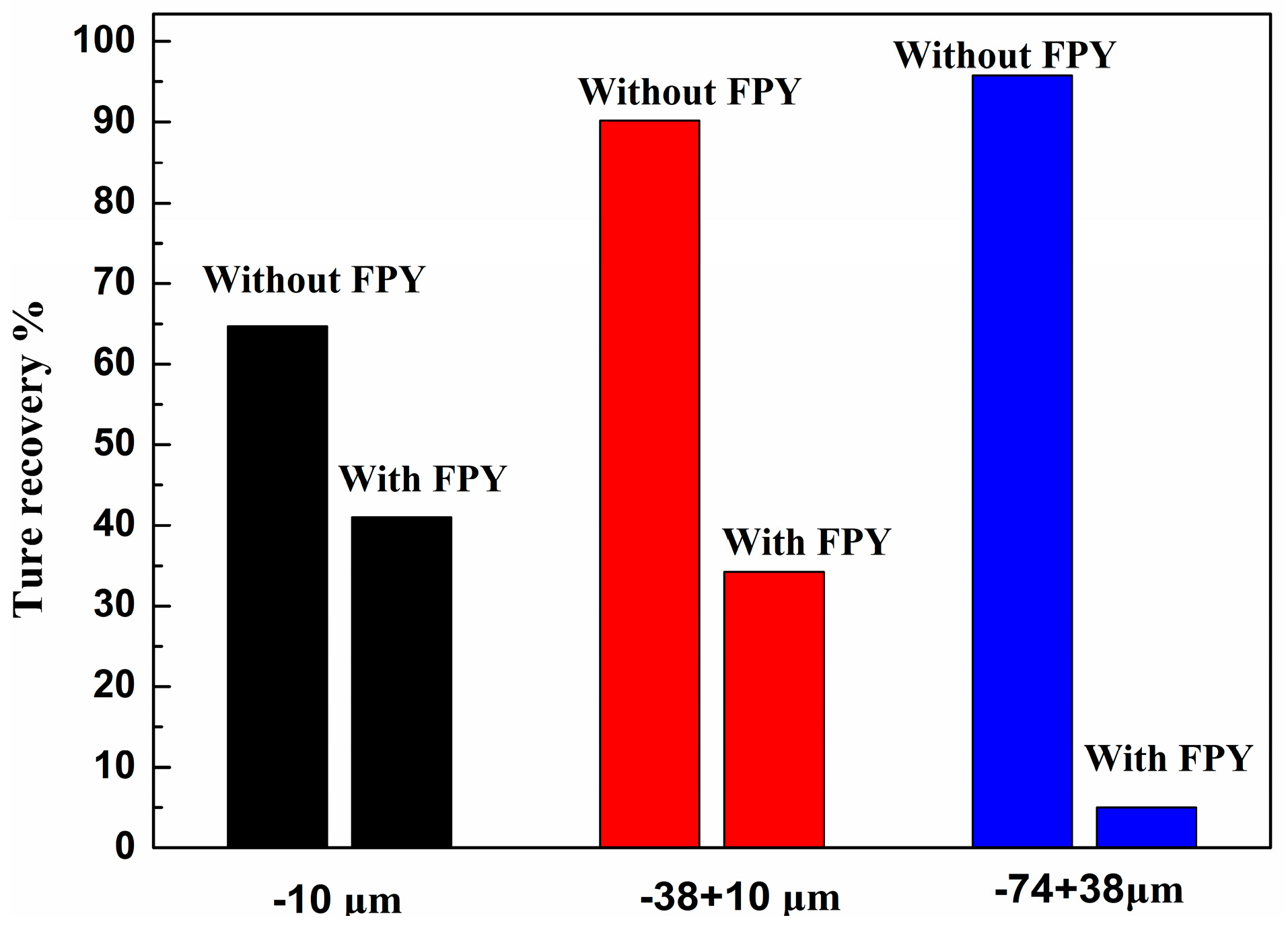

3.2. Flotation of Independent Size Fraction

3.3. Recovery by Entrainment Analysis

3.4. Contact Angle Variation with Particle Size

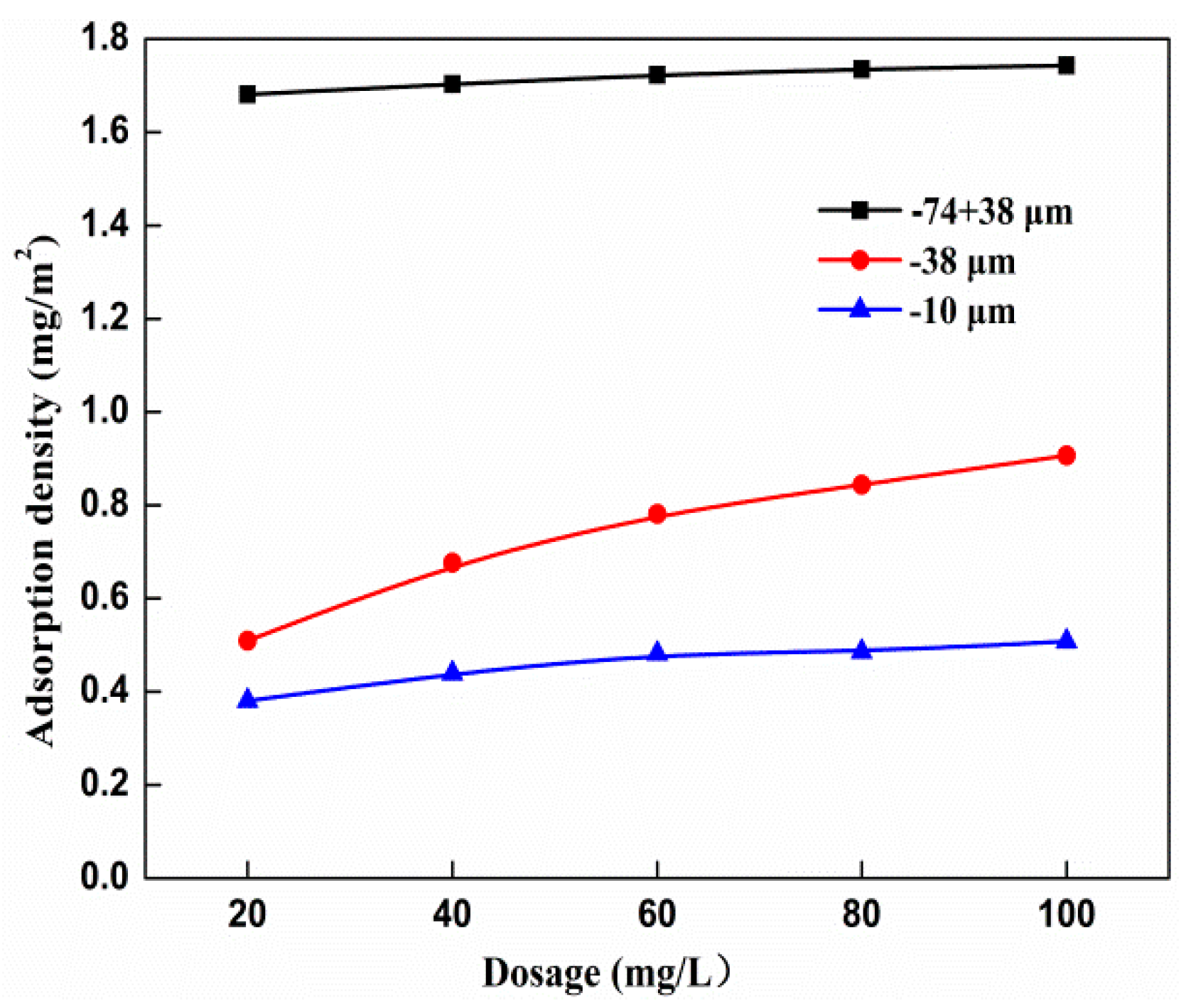

3.5. Adsorption Studies

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Gomes, L.M.B.; Oliveira, J.F. The Control of natural floatability of talc with carboxymethyl cellulose and aluminium chloride. In Fine Particles Processing Flotation, Proceedings of the 17th International Mineral Processing, Dresden, Germany, 23–28 September 1991; Bergakademie Freiberg: Freiberg, Germany, 1991; Volume 2, p. 353. [Google Scholar]

- Morris, G.E.; Fornasiero, D.; Ralston, J. Polymer depressants at the talc–water interface: Adsorption isotherm, micro-flotation and electromagnetic studies. Int. J. Miner. Process. 2002, 67, 211–227. [Google Scholar] [CrossRef]

- Horvat, S.; Sobisch, T.; Lerche, D. Determination of the particle surface properties (hansen solubility parameters) for talc-based pigment by multisample analytical centrifugation. In Proceedings of the 11th Zsigmondy-Colloquium of the Kolloid-Gesellschaft e.V., Bielefeld, Germany, 2–4 March 2015. [Google Scholar]

- Wang, J.; Somasundaran, P.; Nagaraj, D.R. Adsorption mechanism of guar gum at solid–liquid interfaces. Miner. Eng. 2005, 18, 77–81. [Google Scholar] [CrossRef]

- Yetgin, S.H.; Unal, H.; Mimaroglu, A. Influence of foam agent content and talc filler on the microcellular and mechanical properties of injection molded polypropylene and yalc filled polypropylene composite foams. J. Cell. Plast. 2014, 50, 563–576. [Google Scholar] [CrossRef]

- Xu, L.; Wu, H.; Dong, F.; Wang, L.; Wang, Z.; Xiao, J. Flotation and adsorption of mixed cationic/anionic collectors on muscovite mica. Miner. Eng. 2013, 41, 41–45. [Google Scholar] [CrossRef]

- Zhao, K.L.; Gu, G.H.; Wang, H.; Wang, C.L.; Wang, X.H.; Luo, C. The Influence of Depressant Foenum-Graecum on the Flotation of a Sulfide Ore Which Contains Hydrophobic Gangue. Int. J. Miner. Process. 2015, 141, 68–76. [Google Scholar] [CrossRef]

- Beattie, D.A.; Le, H.; Kaggwa, G.B.N.; Ralston, J. The effect of polysaccharides and polyacrylamides on the depression of talc and the flotation of sulfide minerals. Miner. Eng. 2006, 19, 598–608. [Google Scholar] [CrossRef]

- Zhou, X.; Feng, B. The Effect of polyether on the separation of pentlandite and serpentine. J. Mater. Res. Technol. 2015, 4, 429–433. [Google Scholar] [CrossRef]

- Chen, Z.; Gu, G.; Li, S.; Wang, C.; Zhu, R. The effect of seaweed glue in the separation of copper molybdenum sulphide ore by flotation. Minerals 2018, 8, 41. [Google Scholar] [CrossRef]

- Paroles, L.A.S.; Merwe, R.V.D.; Groenmeyer, G.V.; Harris, P.J. The influence of metal cations on the behavior of carboxymethyl celluloses as talc depressants. Colloids Surf. A Physicochem. Eng. Asp. 2008, 317, 109–115. [Google Scholar] [CrossRef]

- Grządka, E. Influence of surfactants on the adsorption and elektrokinetic properties of the system: Guar gum/manganese dioxide. Cellulose 2013, 20, 1313–1328. [Google Scholar] [CrossRef]

- Mhlanga, S.S.; O’Connor, C.T.; Mcfadzean, B. A study of the relative adsorption of guar onto pure minerals. Miner. Eng. 2012, 36, 172–178. [Google Scholar] [CrossRef]

- Mierczynska-Vasilev, A.; Beattie, D.A. The effect of impurities and cleavage characteristics on talc hydrophobicity and polymer adsorption. Int. J. Miner. Process. 2013, 118, 34–42. [Google Scholar] [CrossRef]

- Deng, W.; Xu, L.; Tian, J.; Hu, Y.; Han, Y. Flotation and adsorption of a new polysaccharide depressant on pyrite and talc in the presence of a pre-adsorbed xanthate collector. Minerals 2017, 7, 40. [Google Scholar] [CrossRef]

- Zhao, K.; Yan, W.; Wang, X.; Hui, B.; Gu, G. The flotation separation of pyrite from pyrophyllite using oxidized guar gum as depressant. Int. J. Miner. Process. 2017, 161, 78–82. [Google Scholar] [CrossRef]

- Rath, R.K.; Subramanian, S.; Laskowski, J.S. Adsorption of dextrin and guar gum onto talc. A comparative study. Langmuir 1997, 13, 6260–6266. [Google Scholar] [CrossRef]

- Jiang, J.X.; Jian, H.L.; Zhu, L.W.; Zhang, W.M. Development and Application of the Functional Polysaccharide Gum; China Light Industry Press: Beijing, China, 2012; pp. 5–90. [Google Scholar]

- Zhou, B.; Wang, Y.; Li, B.; Li, J.; Lv, G.Y.; Mei, T.; Cui, B.; Fan, J.S. Preparation and characterization of konjac glucomannan-based cation exchange resin. Carbohydr. Polym. 2012, 87, 1877–1880. [Google Scholar] [CrossRef]

- He, F.; Zhang, Z.; Cui, M.; Liu, L.; Xue, Q. Soft rot disease alters soil characteristics and root-associated, culturable microbial community of Amorphophallus konjac. J. Gen. Plant Pathol. 2017, 84, 44–57. [Google Scholar] [CrossRef]

- Ghasemi, S.N.; Fallah, S.; Pokhrel, L.R.; Rostamnejadi, A. Natural amelioration of zinc oxide nanoparticle toxicity in fenugreek (Trigonella foenum-gracum) by arbuscular mycorrhizal (Glomus intraradices) secretion of glomalin. Plant Physiol. Biochem. 2017, 112, 227–238. [Google Scholar] [CrossRef] [PubMed]

- Xia, L.Y.; Hong, Z.; Liu, G.Y. Utilization of soluble starch as a depressant for the reverse flotation of diaspore from kaolinite. Miner. Eng. 2009, 22, 560–565. [Google Scholar] [CrossRef]

- Peng, H.; Wu, D.; Abdall, M.; Luo, W.; Jiao, W. Study of the effect of sodium sulfide as a selective depressor in the separation of chalcopyrite and molybdenite. Minerals 2017, 7, 51. [Google Scholar] [CrossRef]

- Trahar, W.J. A rational interpretation of the role of particle size in flotation. Int. J. Miner. Process. 1981, 8, 289–327. [Google Scholar] [CrossRef]

- Bu, X.; Xie, G.; Peng, Y. Interaction of fine, medium, and coarse particles in coal fines flotation. Energy Sources Part A Recovery Utiliz. Environ. Effects 2017, 39, 1–7. [Google Scholar]

- Wills, B.A.; Napier-Munn, T. Wills’ Mineral Processing Technology: An Introduction to the Practical Aspects of Ore Treatment and Mineral Recovery, 7th ed.; Butterworth-Heinemann: Oxford, UK, 2006; p. 444. [Google Scholar]

- Bu, X.; Xie, G.; Peng, Y.; Ge, L.; Ni, C. Kinetics of Flotation. Order of Process, Rate Constant Distribution and Ultimate Recovery. Physicochem. Probl. Min. Process. 2017, 53, 342–365. [Google Scholar]

- Bournival, G.; Ata, S.; Jameson, G.J. The influence of submicron particles and salt on the recovery of coarse particles. Miner. Eng. 2014, 69, 146–153. [Google Scholar] [CrossRef]

- Albijanic, B.; Subasinghe, N.; Park, C.H. Flotation kinetic models for fixed and variable pulp chemical conditions. Miner. Eng. 2015, 78, 66–68. [Google Scholar] [CrossRef]

- Lynch, A.J.; Johnson, N.W.; Manlapig, E.V.; Thorne, C.G. Mineral and Coal Flotation Circuits: Their Simulation and Control; Elsevier: Amsterdam, The Netherlands, 1981; pp. 71–75. [Google Scholar]

- Muganda, S. Influence of particle size and contact angle on the flotation of chalcopyrite in a laboratory batch flotation cell. Int. J. Miner. Process. 2011, 98, 150–162. [Google Scholar] [CrossRef]

- Harris, M.C.; Runge, K.C.; Whiten, W.J.; Morrison, R.D. JKSimFloat as a practical tool for flotation process design and optimisation. In Proceedings of the Mineral Processing Plant Design Practice and Control Conference, Vancouver, BC, Canada, 20–24 October 2002; Society for Mining Metallurgy & Exploration: Englewood, CO, USA, 2002; pp. 31–40. [Google Scholar]

- Savassi, O.N.; Alexander, D.J.; Franzidis, J.P.; Manlapig, E.V. An empirical model for entrainment in industrial flotation plants. Miner. Eng. 1998, 11, 243–256. [Google Scholar] [CrossRef]

- Wang, L.; Runge, K.; Peng, Y.; Vos, C. An empirical model for the degree of entrainment in froth flotation based on particle size and density. Miner. Eng. 2016, 98, 187–193. [Google Scholar] [CrossRef]

- Washburn, E.W. The dynamics of capillary flow. Phys. Rev. 1921, 3, 273–283. [Google Scholar] [CrossRef]

- Crawford, R.; Koopal, L.K.; Ralston, J. Contact angles on particles and plates. Colloids Surf. 1987, 27, 57–64. [Google Scholar] [CrossRef]

- Galet, L.; Patry, S.; Dodds, J. Determination of the wettability of powders by the Washburn capillary rise method with bed preparation by a centrifugal packing technique. J. Colloid Interface Sci. 2010, 346, 470–475. [Google Scholar] [CrossRef] [PubMed]

- Burt, M.W.G.; Fewtrell, C.A. The preparation of powder beds by a centrifugal compaction technique. In Particle Size Analysis; Groves, M.J., Wyatt-Sargent, J.L., Eds.; Society for Analytical Chemistry: London, UK, 1970; pp. 321–338. [Google Scholar]

- Jackson, P.V.; Hunt, J.A.; Doherty, P.J.; Cannon, A.; Gilson, P. Hydrophilicity of 3-D biomaterials: The Washburn equation. J. Mater. Sci. 2004, 15, 507–511. [Google Scholar] [CrossRef]

- Wan, H.; Yang, W.; Cao, W.; He, T.; Liu, Y. The interaction between Ca2+ and molybdenite edges and its effect on molybdenum flotation. Minerals 2017, 7, 141. [Google Scholar] [CrossRef]

- Zhao, K.; Gu, G.; Wang, C.; Rao, X.; Wang, X. The effect of a new polysaccharide on the depression of talc and the flotation of a nickel–copper sulfide ore. Miner. Eng. 2015, 77, 99–106. [Google Scholar] [CrossRef]

- Alvarez-Silva, M.; Wiese, J.; O’Connor, C.T. An investigation into the role of froth height and depressant dosage in the recovery of chromite in the flotation of UG2 ore using a laboratory column. Miner. Eng. 2014, 55, 125–131. [Google Scholar] [CrossRef]

- Rahman, R.M.; Ata, S.; Jameson, G.J. The effect of flotation variables on the recovery of different particle size fractions in the froth and the pulp. Int. J. Miner. Process. 2012, 106–109, 70–77. [Google Scholar] [CrossRef]

- Ye, J.; Hongmin, L. Study on the ultra-fine modified air pulverization of talcum. In Proceedings of the China Plastics Processing Industry Association Talcum Powder Application Symposium in Plastics, Changsha, China, 23 May 2005; pp. 110–114. [Google Scholar]

| Element | MgO | SiO2 | TiO2 | K2O | Fe2O3 | Na2O | NiO | CaO |

|---|---|---|---|---|---|---|---|---|

| Grade (mass fraction)/% | 30.43 | 57.15 | 3.26 | 0.65 | 0.58 | 0.32 | 0.29 | 0.17 |

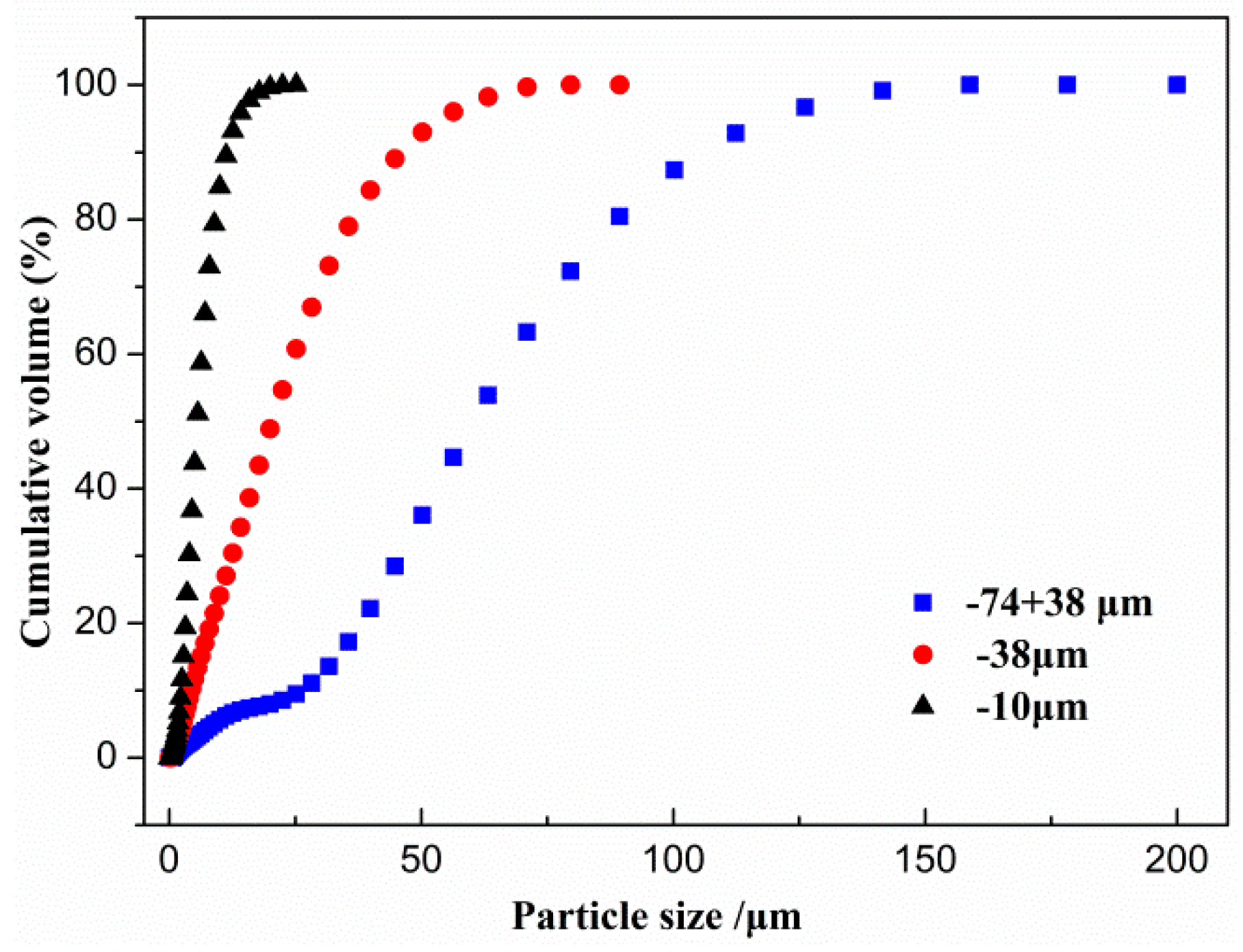

| Size Fraction/μm | d10/μm | d50/μm | d90/μm | Mean Size/μm |

|---|---|---|---|---|

| −74 + 38 | 29.577 | 67.679 | 118.4446 | 70.767 |

| −38 | 4.924 | 22.966 | 51.579 | 25.985 |

| −10 | 2.647 | 6.211 | 12.813 | 7.096 |

| Parameter | Size Fraction | |||||

|---|---|---|---|---|---|---|

| Without FPY | With FPY | |||||

| −10 μm | −38 μm | −74 + 38 μm | −10 μm | −38 μm | −74 + 38 μm | |

| R2 | 0.999 | 0.996 | 0.999 | 0.995 | 0.999 | 0.997 |

| 88.11 | 92.39 | 96.41 | 51.93 | 41.00 | 6.33 | |

| K/min−1 | 0.0362 | 0.0536 | 0.1235 | 0.0207 | 0.0149 | 0.0240 |

| Km/min−1 | 0.032 | 0.050 | 0.119 | 0.011 | 0.006 | 0.002 |

| Conditions | Size Fraction | di (μm) | Rw (%) | ENTi | Rent.i (%) |

|---|---|---|---|---|---|

| Without FPY | −10 μm | 7.096 | 61.289 | 0.4283 | 26.25 |

| −38 μm | 25.985 | 61.433 | 0.1113 | 6.84 | |

| −74 + 38 μm | 70.767 | 54.518 | 0.0305 | 1.66 | |

| With FPY | −10 μm | 11.150 | 43.707 | 0.2867 | 12.53 |

| −38 μm | 31.39 | 50.077 | 0.0880 | 4.41 | |

| −74 μm | 70.791 | 49.232 | 0.0305 | 1.50 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Gu, G.; Li, S.; Song, S.; Wang, C. Influence of Particle Size in Talc Suppression by a Galactomannan Depressant. Minerals 2018, 8, 122. https://doi.org/10.3390/min8040122

Chen Z, Gu G, Li S, Song S, Wang C. Influence of Particle Size in Talc Suppression by a Galactomannan Depressant. Minerals. 2018; 8(4):122. https://doi.org/10.3390/min8040122

Chicago/Turabian StyleChen, Zhixiang, Guohua Gu, Shuangke Li, Siyu Song, and Chongqing Wang. 2018. "Influence of Particle Size in Talc Suppression by a Galactomannan Depressant" Minerals 8, no. 4: 122. https://doi.org/10.3390/min8040122

APA StyleChen, Z., Gu, G., Li, S., Song, S., & Wang, C. (2018). Influence of Particle Size in Talc Suppression by a Galactomannan Depressant. Minerals, 8(4), 122. https://doi.org/10.3390/min8040122