Full-Scale Pore Structure and Fractal Dimension of the Longmaxi Shale from the Southern Sichuan Basin: Investigations Using FE-SEM, Gas Adsorption and Mercury Intrusion Porosimetry

Abstract

1. Introduction

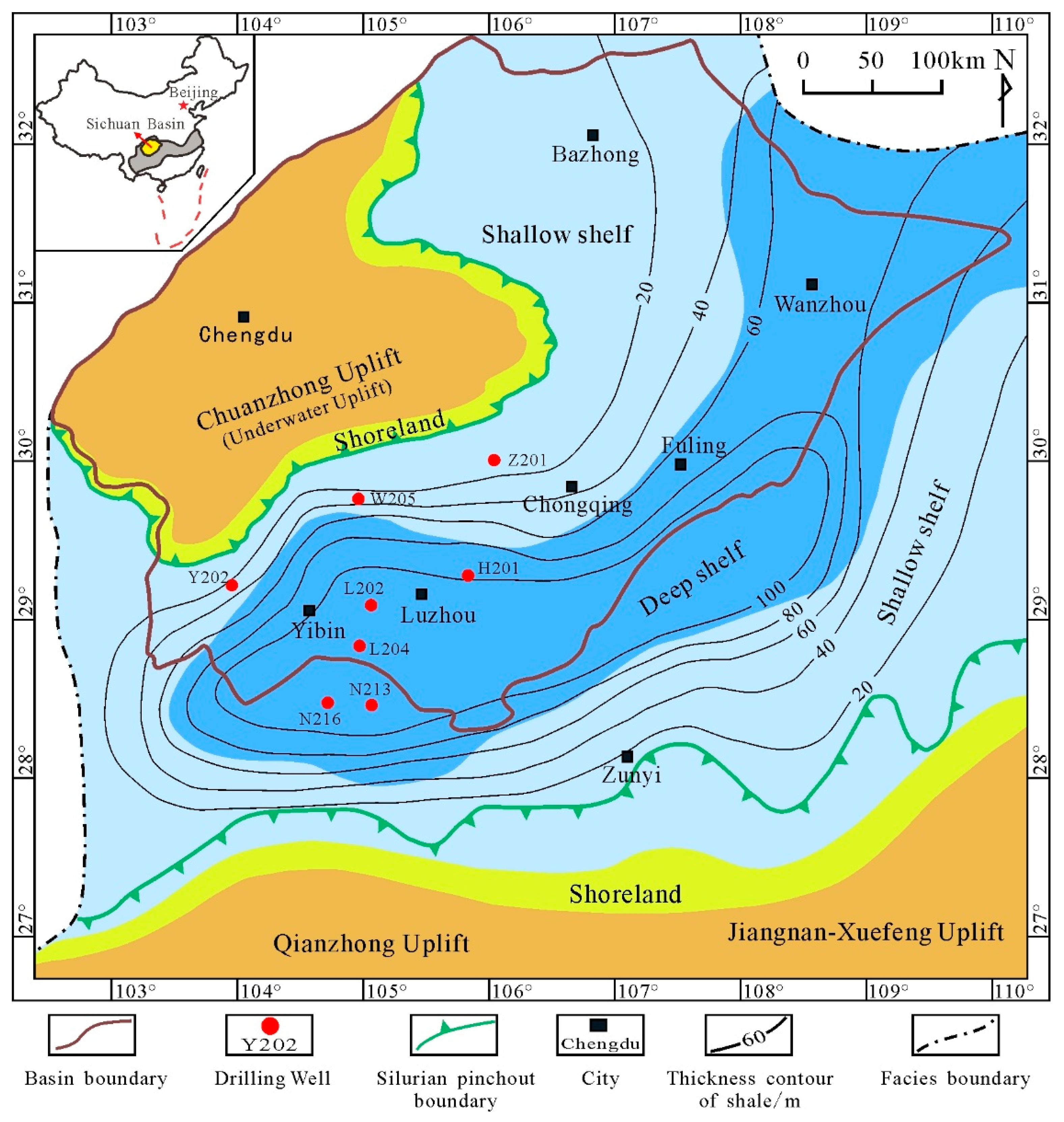

2. Geological Setting

3. Samples and Methods

3.1. Shale Samples

3.2. Organic Petrography and Mineralogy

3.3. FE-SEM Observation

3.4. Low-Pressure N2/CO2 Adsorption

3.5. HMIP Measurements

3.6. Fractal Method

4. Results

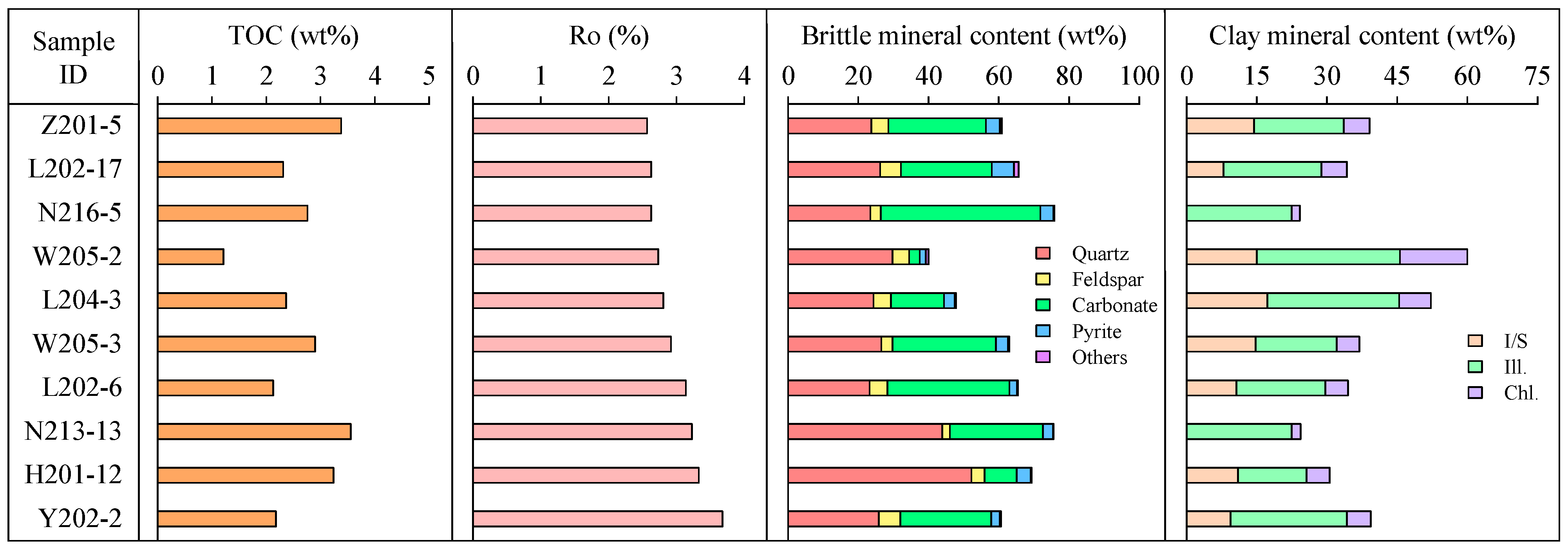

4.1. Organic Geochemistry and Mineral Composition

4.2. Pore Types and Morphologies

4.2.1. Interparticle Pores

4.2.2. Intraparticle Pores

4.2.3. Fracture Pores

4.2.4. Organic Matter Pores

4.3. Quantitative Analysis of Pore Structure

4.3.1. Pore Structure from CO2 Adsorption

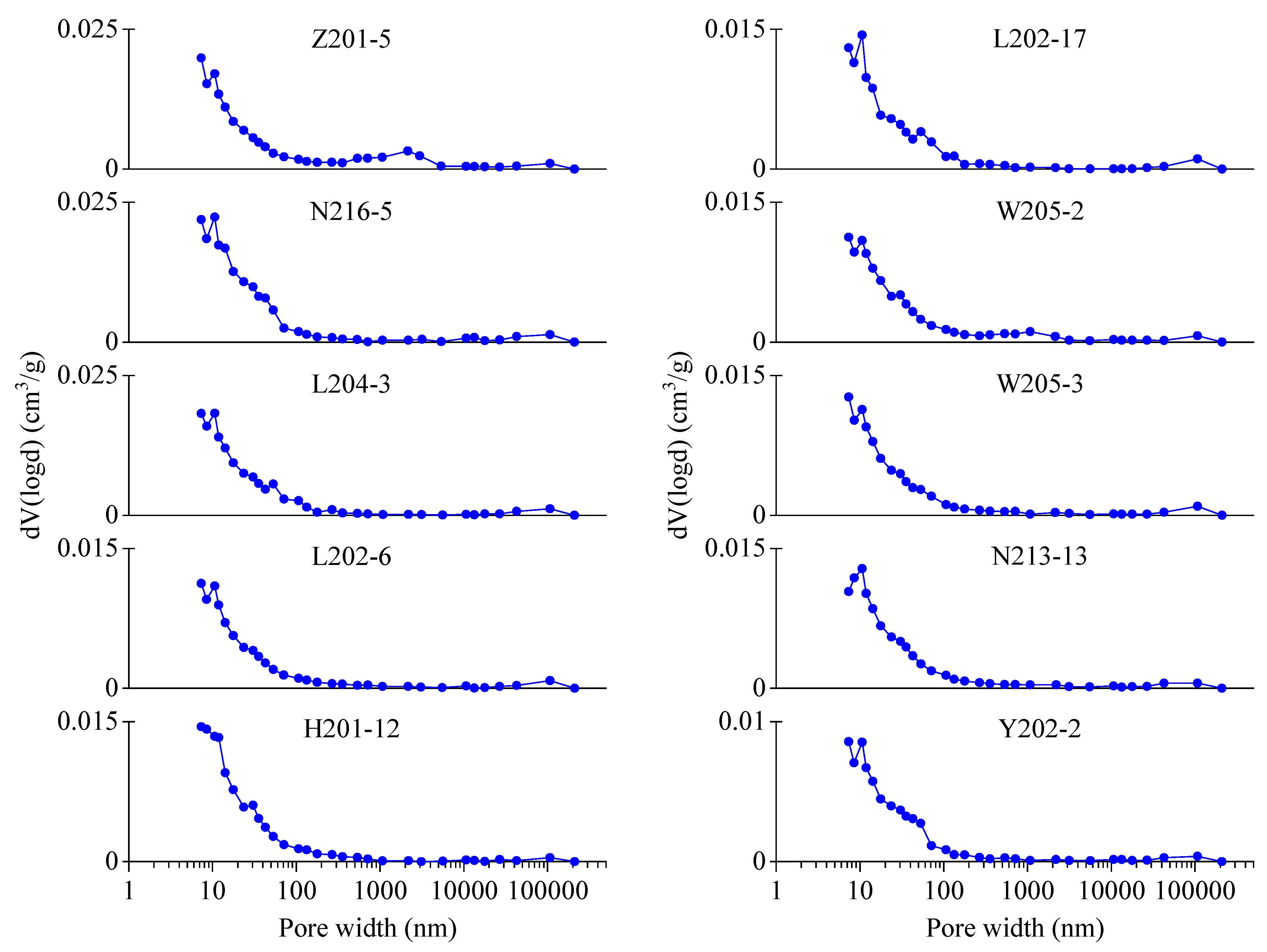

4.3.2. Pore Structure from N2 Adsorption

4.3.3. Pore Structure from HMIP

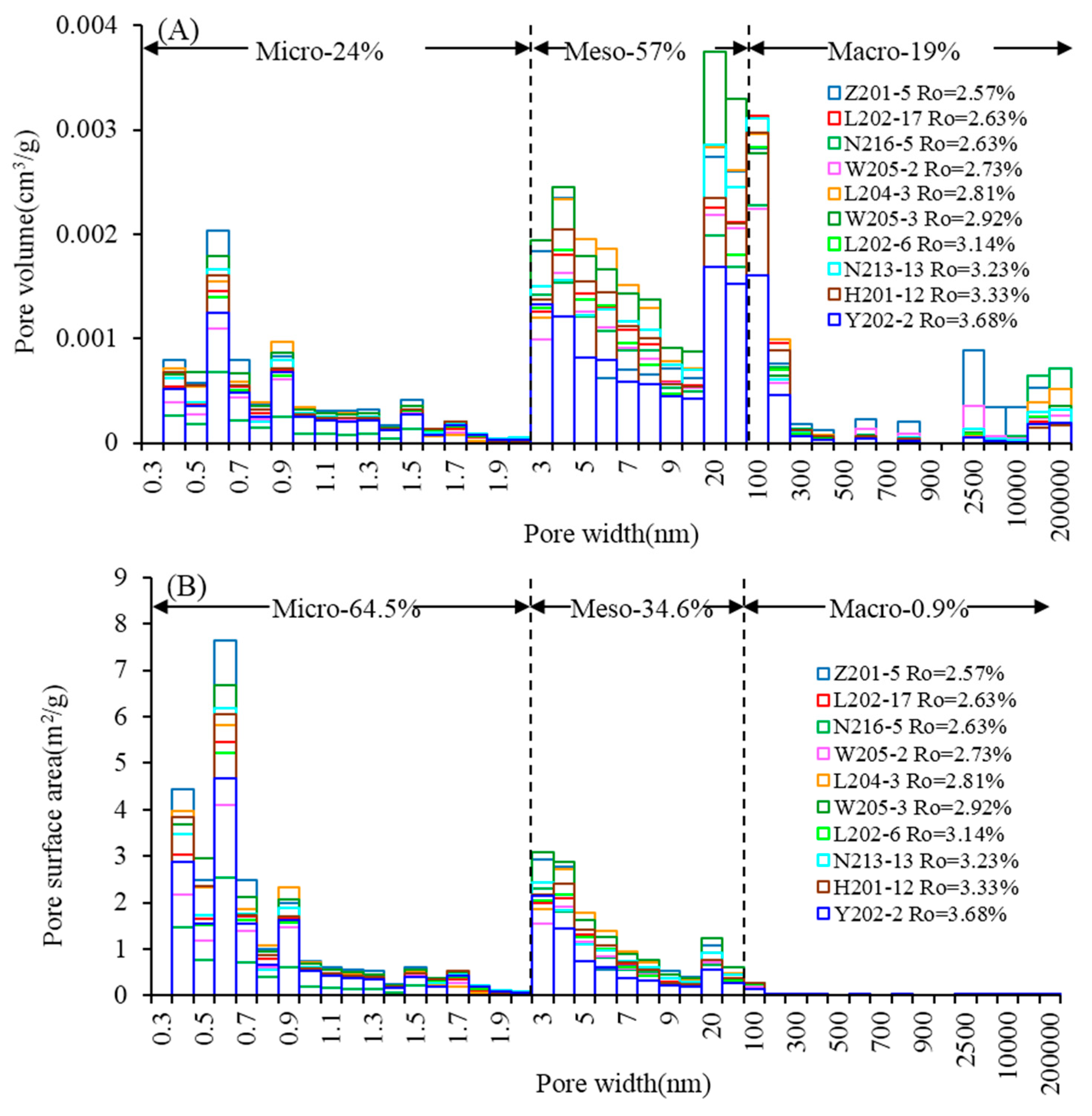

4.3.4. Full-Scale Pore Structure Characterization

4.4. Fractal Dimensions from N2 Adsorption Experiment

5. Discussion

5.1. Compositional Controls on Shale Pore Structure

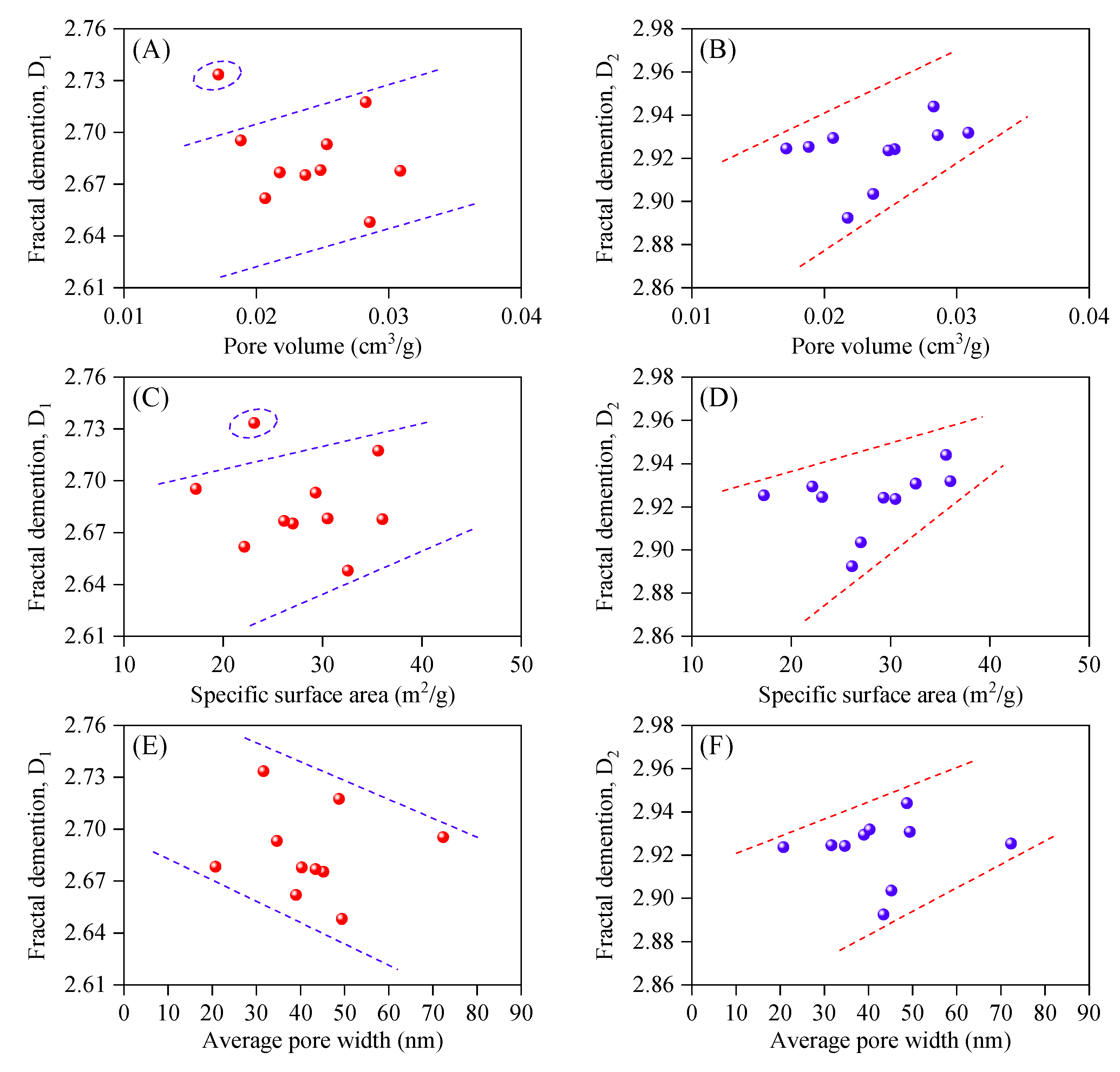

5.2. Correlations Between Pore Structure Parameters and Fractal Dimensions

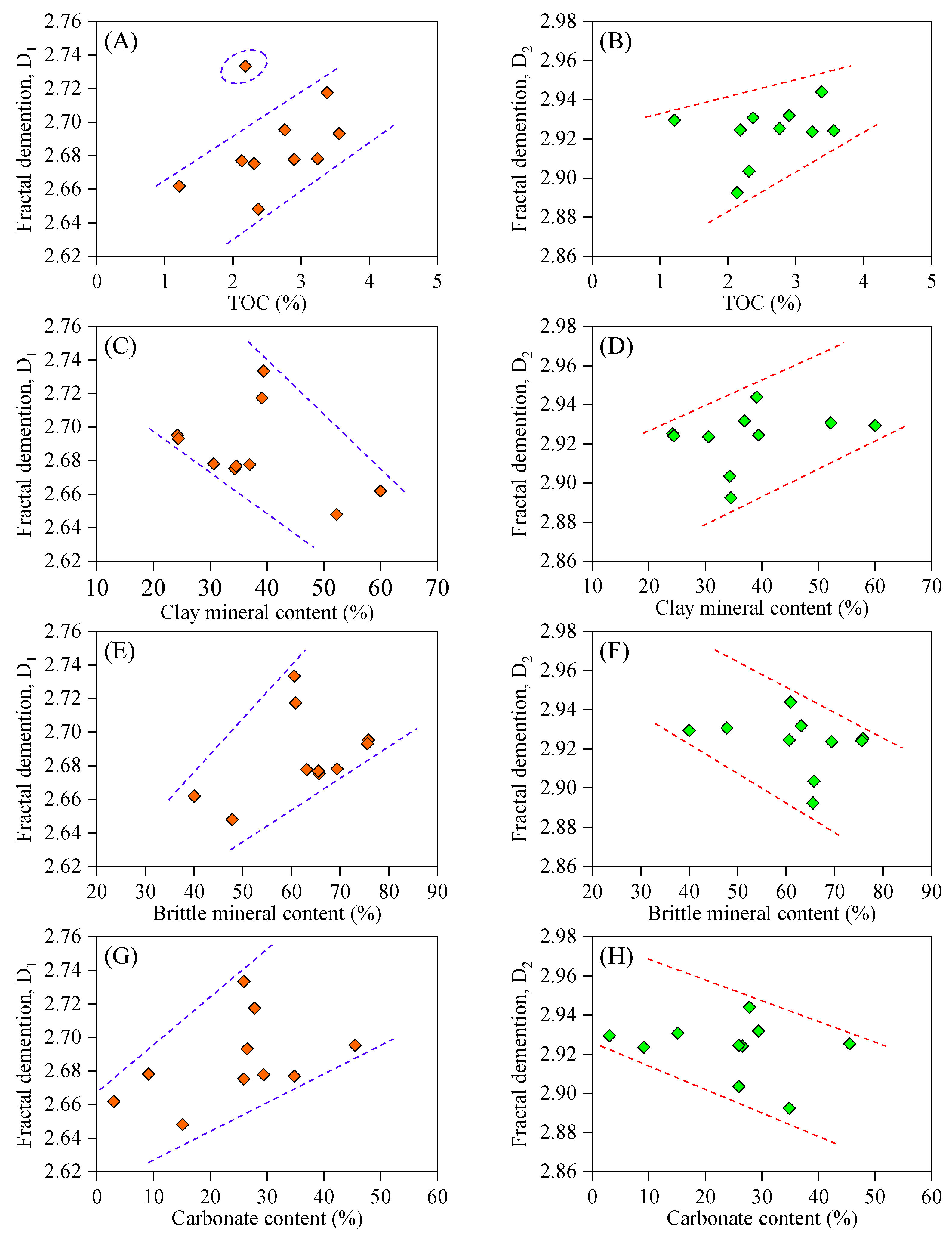

5.3. Factors Influencing Fractal Dimensions

6. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Curtis, J.B. Fractured shale-gas systems. AAPG Bull. 2002, 86, 1921–1938. [Google Scholar]

- Bernard, S.; Horsfield, B.; Schulz, H.-M.; Wirth, R.; Schreiber, A.; Sherwood, N. Geochemical evolution of organic-rich shales with increasing maturity: A STXM and TEM study of the Posidonia Shale (Lower Toarcian, northern Germany). Mar. Petrol. Geol. 2012, 31, 70–89. [Google Scholar] [CrossRef]

- Johnson, C.; Boersma, T. Energy (in)security in Poland the case of shale gas. Energy Policy 2013, 53, 389–399. [Google Scholar] [CrossRef]

- Zou, C.N.; Du, J.H.; Xu, C.C.; Wang, Z.C.; Zhang, B.M.; Wei, G.Q.; Wang, T.S.; Yao, G.S.; Deng, S.H.; Liu, J.L.; et al. Formation, distribution, resource potential, and discovery of Sinian-Cambrian giant gas field, Sichuan Basin, SW China. Petrol. Explor. Dev. 2014, 41, 306–325. [Google Scholar] [CrossRef]

- Zou, C.; Yang, Z.; Dai, J.; Dong, D.; Zhang, B.; Wang, Y.; Deng, S.; Huang, J.; Liu, K.; Yang, C.; et al. The characteristics and significance of conventional and unconventional Sinian–Silurian gas systems in the Sichuan Basin, central China. Mar. Petrol. Geol. 2015, 64, 386–402. [Google Scholar] [CrossRef]

- Hao, F.; Zou, H.Y.; Lu, Y.C. Mechanisms of shale gas storage: Implications for shale gas exploration in China. AAPG Bull. 2013, 97, 1325–1346. [Google Scholar] [CrossRef]

- Guo, X.; Li, Y.; Liu, R.; Wang, Q. Characteristics and controlling factors of micropore structures of the Longmaxi Shale in the Jiaoshiba area, Sichuan Basin. Nat. Gas Ind. B 2014, 1, 165–171. [Google Scholar] [CrossRef]

- Technically Recoverable Shale Oil. Shale Gas Resources: An Assessment of 137 Shale Formations in 41 Countries Outside the United States; Independent Statistics & Analysis and US Department of Energy: Washington, DC, USA, 2013.

- Ross, D.J.K.; Bustin, R.M. The importance of shale composition and pore structure upon gas storage potential of shale gas reservoirs. Mar. Petrol. Geol. 2009, 26, 916–927. [Google Scholar] [CrossRef]

- Zheng, X.; Zhang, B.; Sanei, H.; Bao, H.; Meng, Z.; Wang, C.; Li, K. Pore structure characteristics and its effect on shale gas adsorption and desorption behavior. Mar. Petrol. Geol. 2019, 100, 165–178. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Solano, N.; Bustin, R.M.; Bustin, A.M.M.; Chalmers, G.R.L.; He, L.; Melnichenko, Y.B.; Radlinski, A.P.; Blach, T.P. Pore structure characterization of North American shale gas reservoirs using USANS/SANS, gas adsorption, and mercury intrusion. Fuel 2013, 103, 606–616. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.F.; Liu, H.Q. Fractal characteristics of shales from a shale gas reservoir in the Sichuan Basin, China. Fuel 2014, 115, 378–384. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Hammes, U. Spectrum of pore types and networks in mudrocks and a descriptive classification for matrix-related mudrock pores. AAPG Bull. 2012, 96, 1071–1098. [Google Scholar] [CrossRef]

- Chalmers, G.R.; Bustin, R.M.; Power, I.M. Characterization of gas shale pore systems by porosimetry, pycnometry, surface area, and field emission scanning electron microscopy/transmission electron microscopy image analyses: Examples from the Barnett, Woodford, Haynesville, Marcellus, and Doig units. AAPG Bull. 2012, 96, 1099–1119. [Google Scholar]

- Yang, F.; Ning, Z.F.; Wang, Q.; Zhang, R.; Krooss, B.M. Pore structure characteristics of lower Silurian shales in the southern Sichuan Basin, China: Insights to pore development and gas storage mechanism. Int. J. Coal Geol. 2016, 156, 12–24. [Google Scholar] [CrossRef]

- Xiong, F.; Jiang, Z.; Li, P.; Wang, X.; Bi, H.; Li, Y.; Wang, Z.; Amooie, M.A.; Soltanian, M.R.; Moortgat, J. Pore structure of transitional shales in the Ordos Basin, NW China: Effects of composition on gas storage capacity. Fuel 2017, 206, 504–515. [Google Scholar] [CrossRef]

- Slatt, R.M.; O’Brien, N.R. Pore types in the Barnett and Woodford gas shales: Contribution to understanding gas storage and migration pathways in fine-grained rocks. AAPG Bull. 2011, 95, 2017–2030. [Google Scholar] [CrossRef]

- Loucks, R.G.; Reed, R.M.; Ruppel, S.C.; Jarvie, D.M. Morphology, Genesis, and Distribution of Nanometer-Scale Pores in Siliceous Mudstones of the Mississippian Barnett Shale. J. Sediment. Res. 2009, 79, 848–861. [Google Scholar] [CrossRef]

- Kuila, U.; McCarty, D.K.; Derkowski, A.; Fischer, T.B.; Topor, T.; Prasad, M. Nano-scale texture and porosity of organic matter and clay minerals in organic-rich mudrocks. Fuel 2014, 135, 359–373. [Google Scholar] [CrossRef]

- Sing, K.S.W.; Everett, D.H.; Haul, R.A.W.; Moscou, L.; Pierotti, R.A.; Rouquerol, J.; Siemieniewska, T. Reporting Physisorption Data for Gas/Solid Systems with Special Reference to the Determination of Surface Area and Porosity. Pure Appl. Chem. 1985, 57, 603–619. [Google Scholar] [CrossRef]

- Chalmers, G.R.L.; Bustin, R.M. The organic matter distribution and methane capacity of the lower Cretaceous strata of northeastern British Columbia, Canada. Int. J. Coal Geol. 2007, 70, 223–239. [Google Scholar] [CrossRef]

- Klaver, J.; Desbois, G.; Urai, J.L.; Littke, R. BIB-SEM study of the pore space morphology in early mature Posidonia Shale from the Hils area, Germany. Int. J. Coal Geol. 2012, 103, 12–25. [Google Scholar] [CrossRef]

- Klaver, J.; Desbois, G.; Littke, R.; Urai, J.L. BIB-SEM characterization of pore space morphology and distribution in postmature to overmature samples from the Haynesville and Bossier Shales. Mar. Petrol. Geol. 2015, 59, 451–466. [Google Scholar] [CrossRef]

- Tomutsa, L.; Silin, D.; Radmilovic, V. Analysis of chalk petrophysical properties by means of submicron-scale pore imaging and modeling. SPE Reserv. Eval. Eng. 2007, 10, 285–293. [Google Scholar] [CrossRef]

- Javadpour, F. Nanopores and Apparent Permeability of Gas Flow in Mudrocks (Shales and Siltstone). J. Can. Petrol. Technol. 2009, 48, 16–21. [Google Scholar] [CrossRef]

- Tiwari, P.; Deo, M.; Lin, C.L.; Miller, J.D. Characterization of oil shale pore structure before and after pyrolysis by using X-ray micro CT. Fuel 2013, 107, 547–554. [Google Scholar] [CrossRef]

- Clarkson, C.R.; Jensen, J.L.; Pedersen, P.K.; Freeman, M. Innovative methods for flow-unit and pore-structure analyses in a tight siltstone and shale gas reservoir. AAPG Bull. 2012, 96, 355–374. [Google Scholar] [CrossRef]

- Mastalerz, M.; He, L.L.; Melnichenko, Y.B.; Rupp, J.A. Porosity of Coal and Shale: Insights from Gas Adsorption and SANS/USANS Techniques. Energy Fuels 2012, 26, 5109–5120. [Google Scholar] [CrossRef]

- Bahadur, J.; Radlinski, A.P.; Melnichenko, Y.B.; Mastalerz, M.; Schimmelrnannv, A. Small-Angle and Ultrasmall-Angle Neutron Scattering (SANS/USANS) Study of New Albany Shale: A Treatise on Microporosity. Energy Fuels 2015, 29, 567–576. [Google Scholar] [CrossRef]

- Kuila, U.; Prasad, M. Specific surface area and pore-size distribution in clays and shales. Geophys. Prospect. 2013, 61, 341–362. [Google Scholar] [CrossRef]

- Hu, J.G.; Tang, S.H.; Zhang, S.H. Investigation of pore structure and fractal characteristics of the Lower Silurian Longmaxi shales in western Hunan and Hubei Provinces in China. J. Nat. Gas Sci. Eng. 2016, 28, 522–535. [Google Scholar] [CrossRef]

- Xu, H.; Zhou, W.; Zhang, R.; Liu, S.; Zhou, Q. Characterizations of pore, mineral and petrographic properties of marine shale using multiple techniques and their implications on gas storage capability for Sichuan Longmaxi gas shale field in China. Fuel 2019, 241, 360–371. [Google Scholar] [CrossRef]

- Sun, W.; Zuo, Y.; Wu, Z.; Liu, H.; Xi, S.; Shui, Y.; Wang, J.; Liu, R.; Lin, J. Fractal analysis of pores and the pore structure of the Lower Cambrian Niutitang shale in northern Guizhou province: Investigations using NMR, SEM and image analyses. Mar. Petrol. Geol. 2019, 99, 416–428. [Google Scholar] [CrossRef]

- Yang, R.; He, S.; Yi, J.Z.; Hu, Q.H. Nano-scale pore structure and fractal dimension of organic-rich Wufeng-Longmaxi shale from Jiaoshiba area, Sichuan Basin: Investigations using FE-SEM, gas adsorption and helium pycnometry. Mar. Petrol. Geol. 2016, 70, 27–45. [Google Scholar] [CrossRef]

- Mandelbrot, B.B. The Fractal Geometry of Nature; WH freeman: New York, NY, USA, 1983; Volume 173. [Google Scholar]

- Pfeiferper, P.; Avnir, D. Chemistry nonintegral dimensions between two and three. J. Chem. Phys. 1983, 79, 3369–3558. [Google Scholar]

- Dathe, A.; Eins, S.; Niemeyer, J.; Gerold, G. The surface fractal dimension of the soil–pore interface as measured by image analysis. Geoderma 2001, 103, 203–229. [Google Scholar] [CrossRef]

- Pyun, S.-I.; Rhee, C.-K. An investigation of fractal characteristics of mesoporous carbon electrodes with various pore structures. Electrochim. Acta 2004, 49, 4171–4180. [Google Scholar] [CrossRef]

- Sakhaee-Pour, A.; Li, W.F. Fractal dimensions of shale. J. Nat. Gas Sci. Eng. 2016, 30, 578–582. [Google Scholar] [CrossRef]

- Pfeifer, P.; Wu, Y.J.; Cole, M.W.; Krim, J. Multilayer adsorption on a fractally rough surface. Phys. Rev. Lett. 1989, 62, 1997–2000. [Google Scholar] [CrossRef]

- Qi, H.; Ma, J.; Wong, P.-Z. Adsorption isotherms of fractal surfaces. Colloids Surf. A Physicochem. Eng. Asp. 2002, 206, 401–407. [Google Scholar] [CrossRef]

- Yao, Y.; Liu, D.; Tang, D.; Tang, S.; Huang, W. Fractal characterization of adsorption-pores of coals from North China: An investigation on CH4 adsorption capacity of coals. Int. J. Coal. Geol. 2008, 73, 27–42. [Google Scholar] [CrossRef]

- Li, Y.; Wang, Z.; Pan, Z.; Niu, X.; Yu, Y.; Meng, S. Pore structure and its fractal dimensions of transitional shale: A cross-section from east margin of the Ordos Basin, China. Fuel 2019, 241, 417–431. [Google Scholar] [CrossRef]

- Dong, D.; Wang, Y.; Li, X.; Zou, C.; Guan, Q.; Zhang, C.; Huang, J.; Wang, S.; Wang, H.; Liu, H.; et al. Breakthrough and prospect of shale gas exploration and development in China. Nat. Gas Ind. B 2016, 3, 12–26. [Google Scholar] [CrossRef]

- Zhao, W.; Li, J.; Yang, T.; Wang, S.; Huang, J. Geological difference and its significance of marine shale gases in South China. Petrol. Explor. Dev. 2016, 43, 547–559. [Google Scholar] [CrossRef]

- Tian, H.; Pan, L.; Xiao, X.M.; Wilkins, R.W.T.; Meng, Z.P.; Huang, B.J. A preliminary study on the pore characterization of Lower Silurian black shales in the Chuandong Thrust Fold Belt, southwestern China using low pressure N-2 adsorption and FE-SEM methods. Mar. Petrol. Geol. 2013, 48, 8–19. [Google Scholar] [CrossRef]

- Wang, X.P.; Mou, C.L.; Wang, Q.Y.; Ge, X.Y.; Chen, X.W.; Zhou, K.K.; Liang, W. Diagenesis of black shale in Longmaxi Formation, southern Sichuan Basin and its periphery. Acta Pet. Sin. 2015, 36, 1035–1047, (In Chinese with English abstract). [Google Scholar]

- Yang, R.; He, S.; Hu, Q.; Hu, D.; Zhang, S.; Yi, J. Pore characterization and methane sorption capacity of over-mature organic-rich Wufeng and Longmaxi shales in the southeast Sichuan Basin, China. Mar. Petrol. Geol. 2016, 77, 247–261. [Google Scholar] [CrossRef]

- Chen, L.; Lu, Y.; Jiang, S.; Li, J.; Guo, T.; Luo, C. Heterogeneity of the Lower Silurian Longmaxi marine shale in the southeast Sichuan Basin of China. Mar. Petrol. Geol. 2015, 65, 232–246. [Google Scholar] [CrossRef]

- Yang, R.; Hao, F.; He, S.; He, C.C.; Guo, X.S.; Yi, J.Z.; Hu, H.Y.; Zhang, S.W.; Hu, Q.H. Experimental investigations on the geometry and connectivity of pore space in organic-rich Wufeng and Longmaxi shales. Mar. Petrol. Geol. 2017, 84, 225–242. [Google Scholar] [CrossRef]

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Determination of Total Organic Carbon in Sedimentary Rock; GB/T 19145-2003; GAQSIQ: Beijing, China, 2003.

- China National Petroleum Corporation. Method for Determination of Vitrinite Reflectance in Sedimentary Rocks; SY/T 5124-1995; China National Petroleum Corporation: Daqing, China, 1995. [Google Scholar]

- Schoenherr, J.; Littke, R.; Urai, J.L.; Kukla, P.A.; Rawahi, Z. Polyphase thermal evolution in the Infra-Cambrian Ara Group (South Oman Salt Basin) as deduced by maturity of solid reservoir bitumen. Org. Geochem. 2007, 38, 1293–1318. [Google Scholar] [CrossRef]

- China National Energy Administration. Analysis Method for Clay Minerals and Ordinary Non-Clay Minerals in Sedimentary Rocks by the X-ray Diffraction; SY/T 5163-2010; China National Energy Administration: Beijing, China, 2010.

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Pore Size Distribution and Porosity of Solid Materials by Mercury Porosimetry and Gas Adsorption-Part 3: Analysis of Micropores by Gas Adsorption; GB/T 21650.3-2011; GAQSIQ: Beijing, China, 2011.

- General Administration of Quality Supervision, Inspection and Quarantine of the People’s Republic of China. Determination of the Specific Surface Area of Solids by Gas Adsorption Using the BET Method; GB/T 19587-2017; GAQSIQ: Beijing, China, 2017.

- Han, Y.; Kwak, D.; Choi, S.; Shin, C.; Lee, Y.; Kim, H. Pore Structure Characterization of Shale Using Gas Physisorption: Effect of Chemical Compositions. Minerals 2017, 7, 66. [Google Scholar] [CrossRef]

- Yan, G.Y.; Wei, C.T.; Song, Y.; Zhang, J.J. Pore characteristics of organic-rich shale in the Carboniferous-Permian coal-bearing strata in Qinshui Basin. Energy Explor. Exploit. 2017, 35, 645–662. [Google Scholar] [CrossRef]

- Washburn, E.W. The Dynamics of Capillary Flow. Phys. Rev. 1921, 17, 273–283. [Google Scholar] [CrossRef]

- Gan, H.; Nandi, S.; Walker, P., Jr. Nature of the porosity in American coals. Fuel 1972, 51, 272–277. [Google Scholar] [CrossRef]

- Gregg, S.J.; Sing, K.S.W.; Salzberg, H. Adsorption surface area and porosity. J. Electrochem. Soc. 1967, 114, 279C. [Google Scholar] [CrossRef]

- Li, A.; Ding, W.L.; He, J.H.; Dai, P.; Yin, S.; Xie, F. Investigation of pore structure and fractal characteristics of organic-rich shale reservoirs: A case study of Lower Cambrian Qiongzhusi formation in Malong block of eastern Yunnan Province, South China. Mar. Petrol. Geol. 2016, 70, 46–57. [Google Scholar] [CrossRef]

- Wang, M.; Xue, H.T.; Tian, S.S.; Wilkins, R.W.T.; Wang, Z.W. Fractal characteristics of Upper Cretaceous lacustrine shale from the Songliao Basin, NE China. Mar. Petrol. Geol. 2015, 67, 144–153. [Google Scholar] [CrossRef]

- Li, Z.; Shen, X.; Qi, Z.; Hu, R. Study on the pore structure and fractal characteristics of marine and continental shale based on mercury porosimetry, N2 adsorption and NMR methods. J. Nat. Gas Sci. Eng. 2018, 53, 12–21. [Google Scholar] [CrossRef]

- Wilson, M.J.; Wilson, L.; Shaldybin, M.V. Clay mineralogy and unconventional hydrocarbon shale reservoirs in the USA. II. Implications of predominantly illitic clays on the physico-chemical properties of shales. Earth-Sci. Rev. 2016, 158, 1–8. [Google Scholar] [CrossRef]

- Mishra, S.; Mendhe, V.A.; Varma, A.K.; Kamble, A.D.; Sharma, S.; Bannerjee, M.; Kalpana, M.S. Influence of organic and inorganic content on fractal dimensions of Barakar and Barren Measures shale gas reservoirs of Raniganj basin, India. J. Nat. Gas Sci. Eng. 2018, 49, 393–409. [Google Scholar] [CrossRef]

- Shao, X.; Pang, X.; Li, H.; Hu, T.; Xu, T.; Xu, Y.; Li, B. Pore network characteristics of lacustrine shales in the Dongpu Depression, Bohai Bay Basin, China, with implications for oil retention. Mar. Petrol. Geol. 2018, 96, 457–473. [Google Scholar] [CrossRef]

- Tang, X.; Zhang, J.; Wang, X.; Yu, B.; Ding, W.; Xiong, J.; Yang, Y.; Wang, L.; Yang, C. Shale characteristics in the southeastern Ordos Basin, China: Implications for hydrocarbon accumulation conditions and the potential of continental shales. Int. J. Coal. Geol. 2014, 128–129, 32–46. [Google Scholar] [CrossRef]

- Gale, J.F.W.; Holder, J. Natural fractures in some US shales and their importance for gas production. In Geological Society, London, Petroleum Geology Conference Series; Geological Society of London: London, UK, 2010; Volume 7, pp. 1131–1140. [Google Scholar]

- Clarke, R. Basin focus: Maverick basin. Oil Gas Invest. 2007, 27, 87–90. [Google Scholar]

- Zeng, L.; Lyu, W.; Li, J.; Zhu, L.; Weng, J.; Yue, F.; Zu, K. Natural fractures and their influence on shale gas enrichment in Sichuan Basin, China. J. Nat. Gas Sci. Eng. 2016, 30, 1–9. [Google Scholar] [CrossRef]

- Han, H.; Zhong, N.; Ma, Y.; Huang, C.; Wang, Q.; Chen, S.; Lu, J. Gas storage and controlling factors in an over-mature marine shale: A case study of the Lower Cambrian Lujiaping shale in the Dabashan arc-like thrust–fold belt, southwestern China. J. Nat. Gas Sci. Eng. 2016, 33, 839–853. [Google Scholar] [CrossRef]

- Zhang, J.; Li, X.; Wei, Q.; Gao, W.; Liang, W.; Wang, Z.; Wang, F. Quantitative characterization of pore-fracture system of organic-rich marine-continental shale reservoirs: A case study of the Upper Permian Longtan Formation, Southern Sichuan Basin, China. Fuel 2017, 200, 272–281. [Google Scholar] [CrossRef]

- Yang, F.; Ning, Z.F.; Wang, Q.; Liu, H.Q. Pore structure of Cambrian shales from the Sichuan Basin in China and implications to gas storage. Mar. Petrol. Geol. 2016, 70, 14–26. [Google Scholar] [CrossRef]

- Zhang, J.Z.; Li, X.Q.; Xie, Z.Y.; Li, J.; Zhang, X.Q.; Sun, K.X.; Wang, F.Y. Characterization of microscopic pore types and structures in marine shale_ Examples from the Upper Permian Dalong formation, Northern Sichuan Basin, South China. J. Nat. Gas Sci. Eng. 2018, 59, 326–342. [Google Scholar] [CrossRef]

- Wang, Y.; Zhu, Y.M.; Wang, H.Y.; Feng, G.J. Nanoscale pore morphology and distribution of lacustrine shale reservoirs: Examples from the Upper Triassic Yanchang Formation, Ordos Basin. J. Energy Chem. 2015, 24, 512–519. [Google Scholar] [CrossRef]

- Liu, X.J.; Xiong, J.; Liang, L.X. Investigation of pore structure and fractal characteristics of organic-rich Yanchang formation shale in central China by nitrogen adsorption/desorption analysis. J. Nat. Gas Sci. Eng. 2015, 22, 62–72. [Google Scholar] [CrossRef]

- Chen, L.; Jiang, Z.; Liu, K.; Gao, F.; Wang, P. A Combination of N-2 and CO2 Adsorption to Characterize Nanopore Structure of Organic-Rich Lower Silurian Shale in the Upper Yangtze Platform, South China: Implications for Shale Gas Sorption Capacity. Acta Geol. Sin. Engl. 2017, 91, 1380–1394. [Google Scholar] [CrossRef]

- Ji, W.; Song, Y.; Jiang, Z.; Meng, M.; Liu, Q.; Chen, L.; Wang, P.; Gao, F.; Huang, H. Fractal characteristics of nano-pores in the Lower Silurian Longmaxi shales from the Upper Yangtze Platform, south China. Mar. Petrol. Geol. 2016, 78, 88–98. [Google Scholar] [CrossRef]

- Ji, W.; Song, Y.; Jiang, Z.; Wang, X.; Bai, Y.; Xing, J. Geological controls and estimation algorithms of lacustrine shale gas adsorption capacity: A case study of the Triassic strata in the southeastern Ordos Basin, China. Int. J. Coal. Geol. 2014, 134, 61–73. [Google Scholar] [CrossRef]

- Li, J.; Li, X.; Wu, K.; Wang, X.; Shi, J.; Yang, L.; Zhang, H.; Sun, Z.; Wang, R.; Feng, D. Water Sorption and Distribution Characteristics in Clay and Shale: Effect of Surface Force. Energy Fuels 2016, 30, 8863–8874. [Google Scholar] [CrossRef]

- Liang, L.X.; Xiong, J.; Liu, X.J. An investigation of the fractal characteristics of the Upper Ordovician Wufeng Formation shale using nitrogen adsorption analysis. J. Nat. Gas Sci. Eng. 2015, 27, 402–409. [Google Scholar] [CrossRef]

- Zhang, M.; Fu, X. Influence of reservoir properties on the adsorption capacity and fractal features of shales from Qinshui coalfield. J. Petrol. Sci. Eng. 2019, 177, 650–662. [Google Scholar] [CrossRef]

- Quirk, J.; Aylmore, L. Domains and Quasi-Crystalline Regions in Clay Systems 1. Soil Sci. Soc. Am. J. 1971, 35, 652–654. [Google Scholar] [CrossRef]

- Zhang, Y.F.; Yu, B.S.; Sun, M.D. Diagenesis and its effect on pores of the Niutitang Formation shale in southeast Chongqing, China. J. Chengdu Univ. Technol. (Sci. Technol. Ed.) 2017, 44, 48–56. [Google Scholar]

| Sample ID | Depth (m) | TOC (wt %) | Vitrinite Reflectance | Mineral Composition (wt %) | Clays Relative Content (wt %) | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Rb (%) | Ro (%) | Qtz. | Kfs. | Pl. | Cal. | Dol. | Sd. | Py. | Gp. | Clays | I/S | Ill. | Chl. | |||

| Z201-5 | 4355.4 | 3.38 | 2.45 | 2.57 | 23.7 | 0.3 | 4.6 | 6.4 | 21.4 | 0.6 | 3.9 | 39.1 | 37 | 49 | 14 | |

| L202-17 | 4298.3 | 2.31 | 2.51 | 2.63 | 26.2 | 0.4 | 5.5 | 9.8 | 16.1 | 0.7 | 6.3 | 0.7 | 34.3 | 23 | 61 | 16 |

| N216-5 | 2312.8 | 2.76 | 2.52 | 2.63 | 23.5 | 0.8 | 2.1 | 24.8 | 20.7 | 0.2 | 3.7 | 24.2 | 93 | 7 | ||

| W205-2 | 3681.6 | 1.21 | 2.62 | 2.73 | 29.8 | 0.3 | 4.4 | 1.8 | 1.2 | 0.8 | 1.7 | 60 | 25 | 51 | 24 | |

| L204-3 | 3795.0 | 2.37 | 2.71 | 2.81 | 24.3 | 1.6 | 3.4 | 6.6 | 8.5 | 0.4 | 3 | 52.2 | 33 | 54 | 13 | |

| W205-3 | 3697.9 | 2.90 | 2.82 | 2.92 | 26.5 | 0.3 | 3 | 19 | 10.4 | 0.5 | 3.4 | 36.9 | 40 | 47 | 13 | |

| L202-6 | 4248.4 | 2.13 | 3.05 | 3.14 | 23.2 | 0.7 | 4.4 | 16.3 | 18.5 | 0.3 | 2.1 | 34.5 | 31 | 55 | 14 | |

| N213-13 | 2567.5 | 3.56 | 3.15 | 3.23 | 43.9 | 0.2 | 2 | 11.2 | 15.3 | 0.2 | 2.8 | 24.4 | 92 | 8 | ||

| H201-12 | 4113.8 | 3.24 | 3.25 | 3.33 | 52.2 | 0.4 | 3.4 | 3.3 | 5.8 | 0.3 | 4 | 30.6 | 36 | 48 | 16 | |

| Y202-2 | 3484.8 | 2.18 | 3.62 | 3.68 | 25.8 | 0.4 | 5.8 | 10.3 | 15.6 | 0.4 | 2.3 | 39.4 | 24 | 63 | 13 | |

| Sample ID | P/P0: 0–0.5 | P/P0: 0.5–1.0 | ||||

|---|---|---|---|---|---|---|

| K1 | D1 = 3 + K1 | R2 | K2 | D2 = 3 + K2 | R2 | |

| Z201-5 | −0.2826 | 2.7174 | 0.9835 | −0.0561 | 2.9439 | 0.8881 |

| L202-17 | −0.3248 | 2.6752 | 0.9739 | −0.0965 | 2.9035 | 0.9559 |

| N216-5 | −0.3047 | 2.6953 | 0.9695 | −0.0747 | 2.9253 | 0.9290 |

| W205-2 | −0.3382 | 2.6618 | 0.9855 | −0.0706 | 2.9294 | 0.9113 |

| L204-3 | −0.3520 | 2.6480 | 0.9688 | −0.0693 | 2.9307 | 0.9310 |

| W205-3 | −0.3223 | 2.6777 | 0.9791 | −0.0682 | 2.9318 | 0.9081 |

| L202-6 | −0.3232 | 2.6768 | 0.9780 | −0.1076 | 2.8924 | 0.9920 |

| N213-13 | −0.3069 | 2.6931 | 0.9699 | −0.0759 | 2.9241 | 0.8111 |

| H201-12 | −0.3219 | 2.6781 | 0.9823 | −0.0764 | 2.9236 | 0.9329 |

| Y202-2 | −0.2666 | 2.7334 | 0.9793 | −0.0755 | 2.9245 | 0.9742 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, X.; Jiang, Z.; Jiang, S.; Chang, J.; Zhu, L.; Li, X.; Li, J. Full-Scale Pore Structure and Fractal Dimension of the Longmaxi Shale from the Southern Sichuan Basin: Investigations Using FE-SEM, Gas Adsorption and Mercury Intrusion Porosimetry. Minerals 2019, 9, 543. https://doi.org/10.3390/min9090543

Wang X, Jiang Z, Jiang S, Chang J, Zhu L, Li X, Li J. Full-Scale Pore Structure and Fractal Dimension of the Longmaxi Shale from the Southern Sichuan Basin: Investigations Using FE-SEM, Gas Adsorption and Mercury Intrusion Porosimetry. Minerals. 2019; 9(9):543. https://doi.org/10.3390/min9090543

Chicago/Turabian StyleWang, Xingmeng, Zhenxue Jiang, Shu Jiang, Jiaqi Chang, Lin Zhu, Xiaohui Li, and Jitong Li. 2019. "Full-Scale Pore Structure and Fractal Dimension of the Longmaxi Shale from the Southern Sichuan Basin: Investigations Using FE-SEM, Gas Adsorption and Mercury Intrusion Porosimetry" Minerals 9, no. 9: 543. https://doi.org/10.3390/min9090543

APA StyleWang, X., Jiang, Z., Jiang, S., Chang, J., Zhu, L., Li, X., & Li, J. (2019). Full-Scale Pore Structure and Fractal Dimension of the Longmaxi Shale from the Southern Sichuan Basin: Investigations Using FE-SEM, Gas Adsorption and Mercury Intrusion Porosimetry. Minerals, 9(9), 543. https://doi.org/10.3390/min9090543