Deep Learning in the State of Charge Estimation for Li-Ion Batteries of Electric Vehicles: A Review

Abstract

:1. Introduction

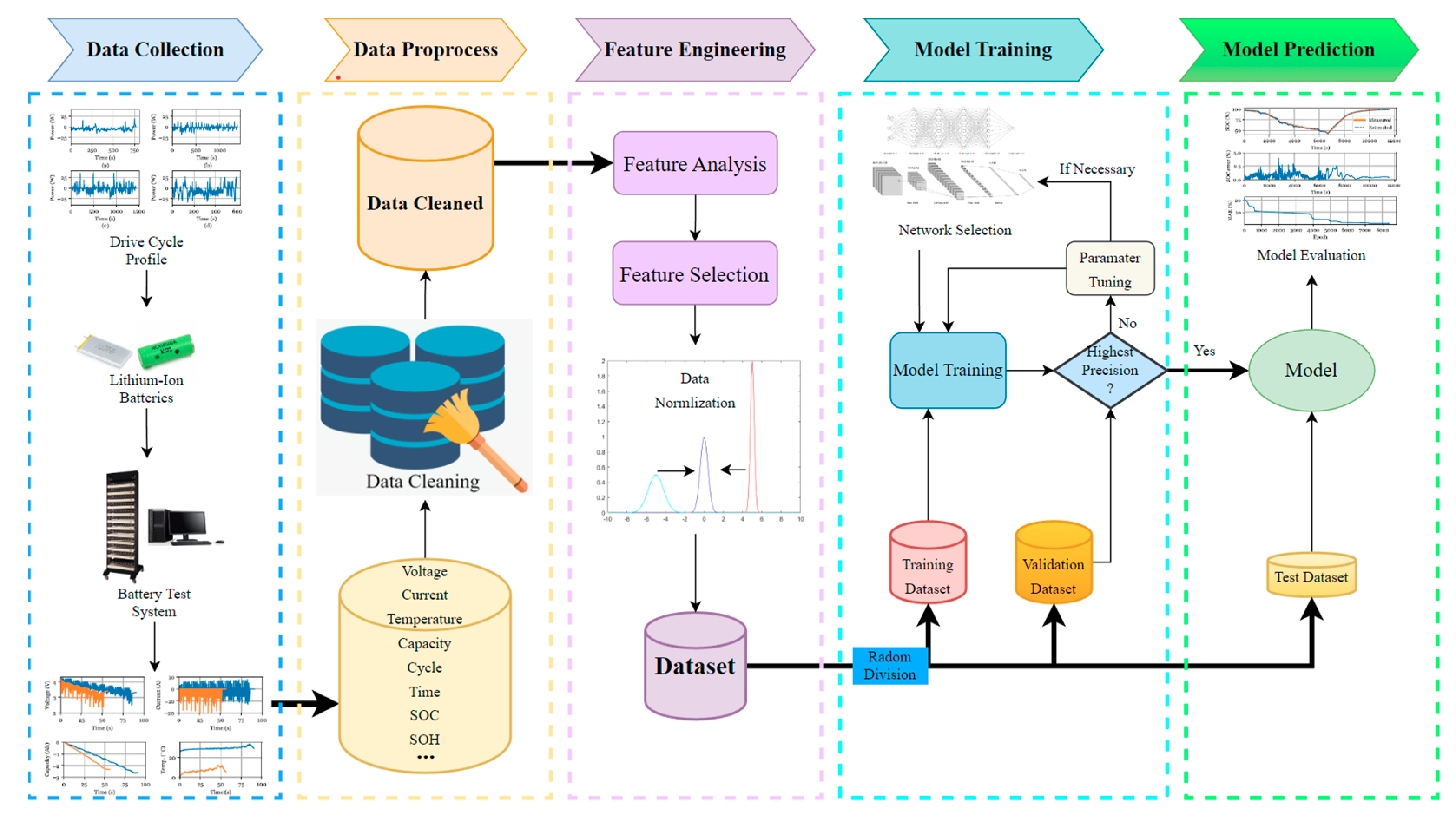

2. Process of SOC Estimation Using the Deep Learning Method

3. Li-Ion Battery Dataset

4. Deep Learning Neural Network Structure in SOC Estimation

4.1. Single Structure

4.1.1. MLP Type—DNN

4.1.2. Convolutional Type—TCN

4.1.3. Recurrent Type—LSTM

4.1.4. Recurrent Type—GRU

4.2. Hybrid Structure

4.2.1. 1D-CNN + LSTM

4.2.2. 1D-CNN + GRU + FC

4.2.3. NN + Filter Algorithm

4.3. Trans Structure

4.3.1. Transfer Learning

4.3.2. Transformer

5. Evaluation and Future Development

- Data: Due to the different battery types, battery parameters, and battery manufacturers for different electric vehicles, the SOC of the lithium battery that provides power cannot be generalized by a model. The failure and life cycle testing of lithium batteries take a long time and have a significant time cost. Generally, scientific research institutions or colleges and universities conduct battery parameter tests, so the quantity and quality of data obtained are limited. At present, models trained by deep learning can only achieve high accuracy under certain operating conditions or certain temperatures. For a general model, the amount of data is far from enough, and to maximize the utilization ratio of Li-ion cell data, there are some methods that can be used: (1) Time series data augmentation: the Li-ion data can be further augmented because they are the time series data, and several methods can be found in the paper [91], and in the state of charge for the Li-ion battery estimation problem, adding noise is the simple and effective method, which can be found in the paper [89]. (2) Creation of new variables based on original data, which can be created by some variables such as the derivation of voltage, current, and temperature based on voltage, current, and temperature; in addition, variables should be created according to the science of Li-ions. (3) Transfer of the model from the different Li-ion datasets: to improve the precision of SOC estimation, the model can be frozen or fine-tuned in a neural network layer to accomplish the target learning tasks; furthermore, when the amount of data is sufficient, the pre-trained models such as GPT-3 and BERT can be applied to the Li-ion SOC estimation problem.

- Computing power: Most electric vehicles generally have an in-vehicle computing platform with high-cost performance and low computing power and power consumption as the “brain” of the electronic and electrical equipment due to cost or power consumption reasons. To speed up the training, most of the deep learning is currently based on special processing units, such as graphic processing units and tensor processing units. For accelerated operations, however, these special computing units are designed without considering power consumption and cannot be directly used for onboard computing power platforms for electric vehicles. In addition, at present, all lithium battery SOC estimation based on deep learning is to test the battery separately under simulated driving conditions and to conduct offline training according to the obtained data. On-board training is carried out on the data measured by the sensors in the environment.

- Interpretability: Previously, there was no recognized scientific explanation for machine learning in computer science; nowadays, it is only used as a black box. This feature results in a lack of stability and interpretability compared with traditional methods. There is no fixed solution to the situation that does not meet expectations, so it sometimes takes a long time.

6. Conclusions

- High-quality data: Some public lithium battery data sets may not meet the actual needs due to reasons such as models or unexpected situations. From the actual needs, it may be necessary to re-test the lithium battery. In the next step, the SOC test of the lithium battery should be considered. Establishing a set of accepted testing methods or standards, which may be an efficient way to generate high-quality data at scale, can avoid duplication of testing, reduce testing time, and improve data quality.

- Computer science: Most of the existing deep learning-based lithium battery SOC estimation research uses neural networks that have made breakthroughs in the field of computer science as a method to migrate to this problem. In the future, we can focus on breakthrough research results in the field of computer science, which can be studied by referring to relevant theories and algorithms; the relevant science of battery chemistry can be used as a priori knowledge to construct the characteristics related to the state parameters of lithium batteries.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- International Energy Agency (IEA). 2021. Available online: https://www.iea.org (accessed on 27 September 2021).

- Latif, A.; Paul, M.; Das, D.C.; Hussain, S.M.S.; Ustun, T.S. Price Based Demand Response for Optimal Frequency Stabilization in ORC Solar Thermal Based Isolated Hybrid Microgrid under Salp Swarm Technique. Electronics 2020, 9, 2209. [Google Scholar] [CrossRef]

- Ng, M.-F.; Zhao, J.; Yan, Q.; Conduit, G.J.; Seh, Z.W. Predicting the state of charge and health of batteries using data-driven machine learning. Nat. Mach. Intell. 2020, 2, 161–170. [Google Scholar] [CrossRef] [Green Version]

- Chemali, E.; Preindl, M.; Malysz, P.; Emadi, A. Electrochemical and Electrostatic Energy Storage and Management Systems for Electric Drive Vehicles: State-of-the-Art Review and Future Trends. IEEE J. Emerg. Sel. Top. Power Electron. 2016, 4, 1117–1134. [Google Scholar] [CrossRef]

- Whittingham, M.S. Ultimate Limits to Intercalation Reactions for Lithium Batteries. Chem. Rev. 2014, 114, 11414–11443. [Google Scholar] [CrossRef]

- Hannan, M.A.; Lipu, M.H.; Hussain, A.; Mohamed, A. A review of lithium-ion battery state of charge estimation and man-agement system in electric vehicle applications: Challenges and recommendations. Renew. Sustain. Energy Rev. 2017, 78, 834–854. [Google Scholar] [CrossRef]

- Hoke, A.; Brissette, A.; Smith, K.; Pratt, A.; Maksimovic, D. Accounting for Lithium-Ion Battery Degradation in Electric Vehicle Charging Optimization. IEEE J. Emerg. Sel. Top. Power Electron. 2014, 2, 691–700. [Google Scholar] [CrossRef]

- How, D.N.T.; Hannan, M.A.; Lipu, M.S.H.; Ker, P.J.; Mansor, M.; Sahari, K.S.M.; Muttaqi, K.M. SOC Estimation Using Deep Bidirectional Gated Recurrent Units with Tree Parzen Estimator Hyperparameter Optimization. IEEE Trans. Ind. Appl. 2022, 58, 6629–6638. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Hussain, A.; Saad, M.H.M.; Ayob, A.; Hannan, M.A. Improved recurrent NARX neural network model for state of charge estimation of lithium-ion battery using pso algorithm. In Proceedings of the IEEE Symposium on Computer Applications and Industrial Electronics (ISCAIE), Penang, Malaysia, 28–29 April 2018; pp. 354–359. [Google Scholar] [CrossRef]

- Doyle, M.; Fuller, T.F.; Newman, J. Modeling of Galvanostatic Charge and Discharge of the Lithium/Polymer/Insertion Cell. J. Electrochem. Soc. 1993, 140, 1526–1533. [Google Scholar] [CrossRef]

- Fuller, T.F.; Doyle, M.; Newman, J. Simulation and Optimization of the Dual Lithium Ion Insertion Cell. J. Electrochem. Soc. 1994, 141, 1–10. [Google Scholar] [CrossRef]

- Corno, M.; Bhatt, N.; Savaresi, S.M.; Verhaegen, M. Electrochemical Model-Based State of Charge Estimation for Li-Ion Cells. IEEE Trans. Control Syst. Technol. 2014, 23, 117–127. [Google Scholar] [CrossRef]

- Hu, X.; Li, S.; Peng, H. A comparative study of equivalent circuit models for Li-ion batteries. J. Power Sources 2012, 198, 359–367. [Google Scholar] [CrossRef]

- Huria, T.; Ludovici, G.; Lutzemberger, G. State of charge estimation of high power lithium iron phosphate cells. J. Power Sources 2014, 249, 92–102. [Google Scholar] [CrossRef]

- Nejad, S.; Gladwin, D.; Stone, D. A systematic review of lumped-parameter equivalent circuit models for real-time estimation of lithium-ion battery states. J. Power Sources 2016, 316, 183–196. [Google Scholar] [CrossRef] [Green Version]

- Plett, G.L. Extended Kalman filtering for battery management systems of LiPB-based HEV battery packs: Part 3. State and parameter estimation. J. Power Sources 2004, 134, 277–292. [Google Scholar] [CrossRef]

- Schweppe, F.C.; Wildes, J. Power system static-state estimation, Part I: Exact model. IEEE Trans. Power Appar. Syst. 1970, 1, 120–125. [Google Scholar] [CrossRef] [Green Version]

- Charkhgard, M.; Zarif, M.H. Design of adaptive H∞ filter for implementing on state-of-charge estimation based on battery state-of-charge-varying modelling. IET Power Electron. 2015, 8, 1825–1833. [Google Scholar] [CrossRef]

- Han, J.; Kim, D.; Sunwoo, M. State-of-charge estimation of lead-acid batteries using an adaptive extended Kalman filter. J. Power Sources 2009, 188, 606–612. [Google Scholar] [CrossRef]

- He, H.; Xiong, R.; Zhang, X.; Sun, F.; Fan, J. State-of-Charge Estimation of the Lithium-Ion Battery Using an Adaptive Extended Kalman Filter Based on an Improved Thevenin Model. IEEE Trans. Veh. Technol. 2011, 60, 1461–1469. [Google Scholar] [CrossRef]

- Shrivastava, P.; Soon, T.K.; Bin Idris, M.Y.I.; Mekhilef, S. Overview of model-based online state-of-charge estimation using Kalman filter family for lithium-ion batteries. Renew. Sustain. Energy Rev. 2019, 113, 109233. [Google Scholar] [CrossRef]

- Xiong, R.; He, H.; Sun, F.; Zhao, K. Evaluation on State of Charge Estimation of Batteries with Adaptive Extended Kalman Filter by Experiment Approach. IEEE Trans. Veh. Technol. 2012, 62, 108–117. [Google Scholar] [CrossRef]

- Sun, F.; Hu, X.; Zou, Y.; Li, S. Adaptive unscented Kalman filtering for state of charge estimation of a lithium-ion battery for electric vehicles. Energy 2011, 36, 3531–3540. [Google Scholar] [CrossRef]

- Zahid, T.; Xu, K.; Li, W.; Li, C.; Li, H. State of charge estimation for electric vehicle power battery using advanced machine learning algorithm under diversified drive cycles. Energy 2018, 162, 871–882. [Google Scholar] [CrossRef]

- Burgos, C.; Sáez, D.; Orchard, M.E.; Cárdenas, R. Fuzzy modelling for the state-of-charge estimation of lead-acid batteries. J. Power Sources 2015, 274, 355–366. [Google Scholar] [CrossRef]

- Sheng, H.; Xiao, J. Electric vehicle state of charge estimation: Nonlinear correlation and fuzzy support vector machine. J. Power Sources 2015, 281, 131–137. [Google Scholar] [CrossRef]

- Li, I.-H.; Wang, W.-Y.; Su, S.-F.; Lee, Y.-S. A merged fuzzy neural network and its applications in battery state-of-charge esti-mation. IEEE Trans. Energy Convers. 2007, 22, 697–708. [Google Scholar] [CrossRef]

- Xu, L.; Wang, J.; Chen, Q. Kalman filtering state of charge estimation for battery management system based on a stochastic fuzzy neural network battery model. Energy Convers. Manag. 2012, 53, 33–39. [Google Scholar] [CrossRef]

- Lipu, M.S.H.; Hannan, M.A.; Hussain, A.; Ayob, A.; Saad, M.H.M.; Muttaqi, K.M. State of Charge Estimation in Lithium-Ion Batteries: A Neural Network Optimization Approach. Electronics 2020, 9, 1546. [Google Scholar] [CrossRef]

- Meng, J.; Luo, G.; Ricco, M.; Swierczynski, M.; Stroe, D.-I.; Teodorescu, R. Overview of Lithium-Ion Battery Modeling Methods for State-of-Charge Estimation in Electrical Vehicles. Appl. Sci. 2018, 8, 659. [Google Scholar] [CrossRef] [Green Version]

- Thiruvonasundari, D.; Deepa, K. Electric vehicle battery modelling methods based on state of charge–review. J. Green Eng. 2020, 10, 24–61. [Google Scholar]

- Zhou, W.; Zheng, Y.; Pan, Z.; Lu, Q. Review on the Battery Model and SOC Estimation Method. Processes 2021, 9, 1685. [Google Scholar] [CrossRef]

- Jongerden, M.; Haverkort, B. Battery modeling. Enschede 2008, 38, 1–18. [Google Scholar]

- Satyan, P.A.; Sutar, R. A Survey on Data-Driven Methods for State of Charge Estimation of Battery. In Proceedings of the International Conference on Electronics and Sustainable Communication Systems (ICESC), Coimbatore, India, 2–4 July 2020; pp. 996–1004. [Google Scholar]

- Lipu, M.H.; Hannan, M.; Hussain, A.; Ayob, A.; Saad, M.H.; Karim, T.F.; How, D.N. Data-driven state of charge estimation of lithium-ion batteries: Algorithms, implementation factors, limitations and future trends. J. Clean. Prod. 2020, 277, 124110. [Google Scholar] [CrossRef]

- Nasiri, F.; Ooka, R.; Haghighat, F.; Shirzadi, N.; Dotoli, M.; Carli, R.; Scarabaggio, P.; Behzadi, A.; Rahnama, S.; Afshari, A.; et al. Data Analytics and Information Technologies for Smart Energy Storage Systems: A State-of-the-Art Review. Sustain. Cities Soc. 2022, 84, 104004. [Google Scholar] [CrossRef]

- Ali, M.U.; Zafar, A.; Nengroo, S.H.; Hussain, S.; Alvi, M.J.; Kim, H.-J. Towards a Smarter Battery Management System for Electric Vehicle Applications: A Critical Review of Lithium-Ion Battery State of Charge Estimation. Energies 2019, 12, 446. [Google Scholar] [CrossRef] [Green Version]

- How, D.N.T.; Hannan, M.A.; Lipu, M.S.H.; Ker, P.J. State of Charge Estimation for Lithium-Ion Batteries Using Model-Based and Data-Driven Methods: A Review. IEEE Access 2019, 7, 136116–136136. [Google Scholar] [CrossRef]

- Vidal, C.; Malysz, P.; Kollmeyer, P.; Emadi, A. Machine Learning Applied to Electrified Vehicle Battery State of Charge and State of Health Estimation: State-of-the-Art. IEEE Access 2020, 8, 52796–52814. [Google Scholar] [CrossRef]

- Jumper, J.; Evans, R.; Pritzel, A.; Green, T.; Figurnov, M.; Ronneberger, O.; Tunyasuvunakool, K.; Bates, R.; Žídek, A.; Potapenko, A.; et al. Highly accurate protein structure prediction with AlphaFold. Nature 2021, 596, 583–589. [Google Scholar] [CrossRef] [PubMed]

- LeCun, Y.; Bengio, Y.; Hinton, G. Deep learning. Nature 2015, 52, 436–444. [Google Scholar] [CrossRef]

- Hunt, G. USABC Electric Vehicle Battery Test Procedures Manual; United States Department of Energy: Washington, DC, USA, 1996.

- Shi, W.; Jiang, J.; Zhang, W.; Li, X.; Jiang, J. A Study on the Driving Cycle for the Life Test of Traction Battery in Electric Buses. Automot. Eng. 2013, 35, 138–142. [Google Scholar]

- NASA. PCoE Datasets. Available online: https://ti.arc.nasa.gov/tech/dash/groups/pcoe/prognostic-data-repository/ (accessed on 30 September 2021).

- Saha, B.; Goebel, K. NASA Ames Prognostics Data Repository; NASA Ames: Moffett Field, CA, USA, 2007. Available online: http://ti.arc.nasa.gov/project/prognostic-data-repository (accessed on 30 September 2021).

- CALCE. Center for Advanced Life Cycle Engineering Battery Research Group. Available online: https://web.calce.umd.edu/batteries/data.htm (accessed on 30 September 2021).

- Attia, P.M.; Grover, A.; Jin, N.; Severson, K.A.; Markov, T.M.; Liao, Y.-H.; Chen, M.H.; Cheong, B.; Perkins, N.; Yang, Z.; et al. Closed-loop optimization of fast-charging protocols for batteries with machine learning. Nature 2020, 578, 397–402. [Google Scholar] [CrossRef] [Green Version]

- Severson, K.A.; Attia, P.M.; Jin, N.; Perkins, N.; Jiang, B.; Yang, Z.; Chen, M.H.; Aykol, M.; Herring, P.K.; Fraggedakis, D.; et al. Data-driven prediction of battery cycle life before capacity degradation. Nat. Energy 2019, 4, 383–391. [Google Scholar] [CrossRef] [Green Version]

- Kollmeyer, P. Panasonic 18650PF Li-ion Battery Data; Elsevier: Madison, WI, USA, 2018; Volume 51. [Google Scholar]

- Kollmeyer, P.; Skells, M. Turnigy Graphene 5000mAh 65C li-Ion Battery Data; Elsevier: Madison, WI, USA, 2020; Volume 1. [Google Scholar]

- Kollmeyer, P.; Vidal, C.; Naguib, M.; Skells, M. Lg 18650HG2 li-Ion Battery Data and Example Deep Neural Network xEV SOC Estimator Script; Elsevier: Madison, WI, USA, 2020; Volume 3. [Google Scholar]

- Zhang, X.; Wang, Y.; Yang, D.; Chen, Z. Behavior data of battery and battery pack SOC estimation under different working conditions. Data Brief 2016, 9, 737–740. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Liu, C.; Pan, R.; Chen, Z. Experimental data of lithium-ion battery and ultracapacitor under DST and UDDS profiles at room temperature. Data Brief 2017, 12, 161–163. [Google Scholar] [CrossRef] [PubMed]

- Hawkins, D.M. The problem of overfitting. J. Chem. Inf. Comput. Sci. 2004, 44, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Chemali, E.; Kollmeyer, P.J.; Preindl, M.; Emadi, A. State-of-charge estimation of Li-ion batteries using deep neural networks: A machine learning approach. J. Power Sources 2018, 400, 242–255. [Google Scholar] [CrossRef]

- Shrivastava, P.; Soon, T.K.; Bin Idris, M.Y.; Mekhilef, S.; Adnan, S.B.R.S. Lithium-ion battery state of energy estimation using deep neural network and support vector regression. In Proceedings of the 2021 IEEE 12th Energy Conversion Congress & Exposition-Asia (ECCE-Asia), Singapore, 24–27 May 2021; pp. 2175–2180. [Google Scholar] [CrossRef]

- How, D.N.T.; Hannan, M.A.; Lipu, M.S.H.; Sahari, K.S.M.; Ker, P.J.; Muttaqi, K.M. State-of-Charge Estimation of Li-Ion Battery in Electric Vehicles: A Deep Neural Network Approach. IEEE Trans. Ind. Appl. 2020, 56, 5565–5574. [Google Scholar] [CrossRef]

- Kashkooli, A.G.; Fathiannasab, H.; Mao, Z.; Chen, Z. Application of Artificial Intelligence to State-of-Charge and State-of-Health Estimation of Calendar-Aged Lithium-Ion Pouch Cells. J. Electrochem. Soc. 2019, 166, A605–A615. [Google Scholar] [CrossRef] [Green Version]

- Lecun, Y.; Bottou, L.; Bengio, Y.; Haffner, P. Gradient-based learning applied to document recognition. Proc. IEEE 1998, 86, 2278–2324. [Google Scholar] [CrossRef] [Green Version]

- Kiranyaz, S.; Ince, T.; Hamila, R.; Gabbouj, M. Convolutional neural networks for patient-specific ECG classification. In Proceedings of the 2015 37th Annual International Conference of the IEEE Engineering in Medicine and Biology Society (EMBC), Milan, Italy, 25–29 August 2015; pp. 2608–2611. [Google Scholar]

- Bai, S.; Kolter, J.Z.; Koltun, V. An empirical evaluation of generic convolutional and recurrent networks for sequence modeling. arXiv 2018, arXiv:1803.01271. [Google Scholar]

- He, K.; Zhang, X.; Ren, S.; Sun, J. Deep residual learning for image recognition. In Proceedings of the IEEE Conference on Computer Vision and Pattern Recognition, Las Vegas, NV, USA, 27–30 June 2016; pp. 770–778. [Google Scholar]

- Hannan, M.A.; How, D.N.T.; Lipu, M.S.H.; Ker, P.J.; Dong, Z.Y.; Mansur, M.; Blaabjerg, F. SOC Estimation of Li-ion Batteries with Learning Rate-Optimized Deep Fully Convolutional Network. IEEE Trans. Power Electron. 2020, 36, 7349–7353. [Google Scholar] [CrossRef]

- Hochreiter, S.; Schmidhuber, J. Long short-term memory. Neural Comput. 1997, 9, 1735–1780. [Google Scholar] [CrossRef] [PubMed]

- Cho, K.; van Merriënboer, B.; Gulcehre, C.; Bahdanau, D.; Bougares, F.; Schwenk, H.; Bengio, Y. Learning phrase representations using RNN encoder-decoder for statistical machine translation. In Proceedings of the 2014 Conference on Empirical Methods in Natural Language Processing (EMNLP), Doha, Qatar, 25–29 October 2014; pp. 1724–1734. [Google Scholar]

- Chaoui, H.; Ibe-Ekeocha, C.C. State of Charge and State of Health Estimation for Lithium Batteries Using Recurrent Neural Networks. IEEE Trans. Veh. Technol. 2017, 66, 8773–8783. [Google Scholar] [CrossRef]

- Chemali, E.; Kollmeyer, P.J.; Preindl, M.; Ahmed, R.; Emadi, A.; Kollmeyer, P. Long Short-Term Memory Networks for Accurate State-of-Charge Estimation of Li-ion Batteries. IEEE Trans. Ind. Electron. 2018, 65, 6730–6739. [Google Scholar] [CrossRef]

- Cui, S.; Yong, X.; Kim, S.; Hong, S.; Joe, I. An LSTM-Based Encoder-Decoder Model for State-of-Charge Estimation of Lithium-Ion Batteries. In Computer Science On-line Conference 2020; Springer: Cham, Switzerland, 2020; pp. 178–188. [Google Scholar] [CrossRef]

- Andréasson, J.; Straight, S.D.; Moore, T.A.; Moore, A.L.; Gust, D. Molecular all-photonic encoder−Decoder. J. Am. Chem. Soc. 2008, 130, 11122–11128. [Google Scholar] [CrossRef] [Green Version]

- Wong, K.L.; Bosello, M.; Tse, R.; Falcomer, C.; Rossi, C.; Pau, G. Li-Ion Batteries State-of-Charge Estimation Using Deep LSTM at Various Battery Specifications and Discharge Cycles. In Proceedings of the GoodIT ’21: Conference on Information Technology for Social Good, Rome, Italy, 9–11 September 2021; pp. 85–90. [Google Scholar] [CrossRef]

- Du, Z.; Zuo, L.; Li, J.; Liu, Y.; Shen, H.T. Data-Driven Estimation of Remaining Useful Lifetime and State of Charge for Lithium-Ion Battery. IEEE Trans. Transp. Electrif. 2021, 8, 356–367. [Google Scholar] [CrossRef]

- Yang, F.; Song, X.; Xu, F.; Tsui, K.-L. State-of-Charge Estimation of Lithium-Ion Batteries via Long Short-Term Memory Network. IEEE Access 2019, 7, 53792–53799. [Google Scholar] [CrossRef]

- Wan, E.A.; Van Der Merwe, R. The unscented Kalman filter for nonlinear estimation. In Proceedings of the IEEE 2000 Adaptive Systems for Signal Processing, Communications, and Control Symposium (Cat. No. 00EX373), Lake Louise, AB, Canada, 4 October 2000; pp. 153–158. [Google Scholar]

- Yang, F.; Li, W.; Li, C.; Miao, Q. State-of-charge estimation of lithium-ion batteries based on gated recurrent neural network. Energy 2019, 175, 66–75. [Google Scholar] [CrossRef]

- Hannan, M.A.; How, D.N.T.; Bin Mansor, M.; Lipu, M.S.H.; Ker, P.J.; Muttaqi, K.M. State-of-Charge Estimation of Li-ion Battery Using Gated Recurrent Unit with One-Cycle Learning Rate Policy. IEEE Trans. Ind. Appl. 2021, 57, 2964–2971. [Google Scholar] [CrossRef]

- Javid, G.; Basset, M.; Abdeslam, D.O. Adaptive online gated recurrent unit for lithium-ion battery SOC estimation. In Proceedings of the IECON 2020 the 46th Annual Conference of the IEEE Industrial Electronics Society, Singapore, 18–21 October 2020; pp. 3583–3587. [Google Scholar]

- Xiao, B.; Liu, Y. Accurate State-of-Charge Estimation Approach for Lithium-Ion Batteries by Gated Recurrent Unit with Ensemble Optimizer. IEEE Access 2019, 7, 54192–54202. [Google Scholar] [CrossRef]

- Yang, K.; Tang, Y.; Zhang, S.; Zhang, Z. A deep learning approach to state of charge estimation of lithium-ion batteries based on dual-stage attention mechanism. Energy 2022, 244, 123233. [Google Scholar] [CrossRef]

- Song, X.; Yang, F.; Wang, D.; Tsui, K.-L. Combined CNN-LSTM Network for State-of-Charge Estimation of Lithium-Ion Batteries. IEEE Access 2019, 7, 88894–88902. [Google Scholar] [CrossRef]

- Huang, Z.; Yang, F.; Xu, F.; Song, X.; Tsui, K.-L. Convolutional Gated Recurrent Unit–Recurrent Neural Network for State-of-Charge Estimation of Lithium-Ion Batteries. IEEE Access 2019, 7, 93139–93149. [Google Scholar] [CrossRef]

- Chen, Z.; Zhao, H.; Shu, X.; Zhang, Y.; Shen, J.; Liu, Y. Synthetic state of charge estimation for lithium-ion batteries based on long short-term memory network modeling and adaptive H-Infinity filter. Energy 2021, 228, 120630. [Google Scholar] [CrossRef]

- Yang, F.; Zhang, S.; Li, W.; Miao, Q. State-of-charge estimation of lithiumion batteries using LSTM and UKF. Energy 2020, 201, 117664. [Google Scholar] [CrossRef]

- Shu, X.; Li, G.; Zhang, Y.; Shen, S.; Chen, Z.; Liu, Y. Stage of Charge Estimation of Lithium-Ion Battery Packs Based on Improved Cubature Kalman Filter with Long Short-Term Memory Model. IEEE Trans. Transp. Electrif. 2020, 7, 1271–1284. [Google Scholar] [CrossRef]

- Ni, Z.; Yang, Y.; Xiu, X. Battery State of Charge Estimation Using Long Short-Term Memory Network and Extended Kalman Filter. In Proceedings of the 2020 39th Chinese Control Conference (CCC), Shenyang, China, 27–29 July 2020; pp. 5778–5783. [Google Scholar] [CrossRef]

- Bian, C.; Yang, S.; Miao, Q. Cross-Domain State-of-Charge Estimation of Li-Ion Batteries Based on Deep Transfer Neural Network with Multiscale Distribution Adaptation. IEEE Trans. Transp. Electrif. 2020, 7, 1260–1270. [Google Scholar] [CrossRef]

- Liu, Y.; Li, J.; Zhang, G.; Hua, B.; Xiong, N. State of Charge Estimation of Lithium-Ion Batteries Based on Temporal Convolutional Network and Transfer Learning. IEEE Access 2021, 9, 34177–34187. [Google Scholar] [CrossRef]

- Bengio, Y. Deep learning of representations for unsupervised and transfer learning. Proc. ICML Workshop Unsupervised Transf. Learn. 2012, 27, 17–36. [Google Scholar]

- Vaswani, A.; Shazeer, N.; Parmar, N.; Uszkoreit, J.; Jones, L.; Gomez, A.N.; Kaiser, Ł.; Polosukhin, I. Attention is all you need. Adv. Neural Inf. Process. Syst. 2017, 30, 1–13. [Google Scholar]

- Hannan, M.A.; How, D.N.T.; Lipu, M.S.H.; Mansor, M.; Ker, P.J.; Dong, Z.Y.; Sahari, K.S.M.; Tiong, S.K.; Muttaqi, K.M.; Mahlia, T.M.I.; et al. Deep learning approach towards accurate state of charge estimation for lithium-ion batteries using self-supervised transformer model. Sci. Rep. 2021, 11, 19541. [Google Scholar] [CrossRef] [PubMed]

- Shen, H.; Zhou, X.; Wang, Z.; Wang, J. State of charge estimation for lithium-ion battery using Transformer with immersion and invariance adaptive observer. J. Energy Storage 2021, 45, 103768. [Google Scholar] [CrossRef]

- Wen, Q.; Sun, L.; Yang, F.; Song, X.; Gao, J.; Wang, X.; Xu, H. Time Series Data Augmentation for Deep Learning: A Survey. arXiv 2020, arXiv:2002.12478. [Google Scholar]

| Dataset | Battery | Data | Ambient Temperature | Number of Battery | Refs |

|---|---|---|---|---|---|

| NASA-PCoE | 2 Ah 18650 | Voltage, Current, Temperature | 43 °C, 4 °C, 4 °C | 34 | [45] |

| CALCE | 1.1 Ah, LiCoO2 1.5 Ah, LiCoO2 1.35 Ah, LiCoO2 2.4 Ah, LiFePO4 2.23 Ah, LiFePO4 2.3 Ah, LNMC | Current, Voltage Charge Capacity, Discharge Capacity, Charge Energy, Discharge Energy, dV/dt | 50 °C, 45 °C, 40 °C, 30 °C, 25 °C, 20 °C, 0 °C, −5 °C, −10 °C, −40 °C | 144 (1.5 Ah, LiCoO2) | [46] |

| Toyota–MIT–Stanford | 1.1 Ah, LiFePO4 | Temperature, Current, Voltage, Charge, Discharge Capacity, Per-cycle Measurements of Capacity, Internal Resistance, and Charge Time | 30 °C | 124 | [47] |

| 224 | [48] | ||||

| Panasonic 18650PF | 2.9 Ah, NCA Panasonic 18650PF | Voltage, Current, Capacity, Energy, Temperature | 25 °C, 10 °C, 0 °C, −10 °C, −20 °C | 1 | [49] |

| Turnigy Graphene | 5 Ah, Turnigy Graphene | Voltage, Current, Time, Power | 40 °C, 25 °C, 10 °C, 0 °C,−10 °C, −20 °C | 1 | [50] |

| LG 18650HG2 | 3 Ah, LG HG2 | Voltage, Current, Power, Battery Case Temperature | 1 | [51] | |

| IFP-1865140 | 10 Ah, LiFePO4 | Voltage, Current, Capacity | 25 °C | 3 | [52] |

| IFP-1665130 | Voltage, Current, Time | 4 | [53] |

| Neural Network | Refs | Dataset | Input Variables | Error | |

|---|---|---|---|---|---|

| Single Structure | DNN | [55] | [49] | MAE: 0.61%, RMSE: 0.78%, MAX (25 °C): 2.38% | |

| [56] | Undisclosed | RMSE: 2.0527, MAE: 0.00421 | |||

| [57] | [46] | RMSE: 3.68%, MAE: 0.13% | |||

| [58] | Undisclosed | MSE: 0.0247% | |||

| TCN | [63] | [49] | (25 °C) RMSE: 0.85, MAE: 0.70, MAX (25 °C): 2.96 (−20~25 °C) RMSE: 2.00, MAE: 1.55, MAX (25 °C): 7.63 | ||

| LSTM | [66] | Undisclosed | RMSE: 0.4127~0.7012 RMSE: 0.4127~0.5476 | ||

| [67] | [49] | RMSE: 0.7%, MAE: 0.6%, MAX (25 °C): 2.6% | |||

| [68] | [46] | RMSE: 0.45~1.89%, MAE: 0.37~1.48% | |||

| [70] | [51], Undisclosed | RMSE: 1.57~2.89%, MAE: 1.17~2.22% | |||

| [71] | [45], Undisclosed | RMSE: 0.731~1.860%, MAE: 0.608~1.165% | |||

| [72] | Undisclosed | RMSE: 1.07~1.39%, MAE: 0.94~2.45% | |||

| GRU | [74] | Undisclosed | RMSE < 3.5%, MAE < 2.5% | ||

| [75] | [46] | RMSE: 0.65%, MAE: 0.46%; RMSE: 0.75%, MAE: 0.52% | |||

| [76] | [46] | RMSE: 0.84~1.08% | |||

| [77] | [46] | RMSE: 0.55~2.45%, MAE: 0.42~1.77% | |||

| [78] | Undisclosed | RMSE < 1.5%, MAE < 0.6% | |||

| Hybrid Structure | 1D-CNN + LSTM | [79] | Undisclosed | RMSE: 0.54~1.38%, MAE: 0.33~0.87% | |

| 1D-CNN + GRU + FC | [80] | Undisclosed | RMSE: 0.0098~0.0211, MAE: 0.0078~0.0168 | ||

| LSTM + UKF | [82] | Undisclosed | RMSE: 0.93%, MAE: 0.82% | ||

| LSTM + CKF | [83] | Undisclosed | MAE < 2% | ||

| LSTM + EKF | [84] | [46,49] | RMSE: 0.48% | ||

| LSTM + AHIF | [81] | Undisclosed | RMSE: 0.22~1.09%, MAX: 0.89~2%, MAE: 0.21~1.18% | ||

| Trans Structure | Transfer learning | [85] | [46,49] | RMSE: 0.49~1.57%, MAE: 0.39~1.32%RMSE: 0.49~1.57%, MAE: 0.39~1.32% | |

| [86] | [49,50] | (25 °C) RMSE: 0.36~1.02%, MAE: 0.26~0.61% | |||

| Transformer | [89] | [51] | RMSE: 0.9056%, MAE: 0.4459% | ||

| [90] | [46] | (50 °C) RMSE: 0.54%, MAE: 0.49% | |||

| Neural Network | Advantage | Disadvantage | |

|---|---|---|---|

| Single | DNN | Unlimited data input dimensions | Prone to overfitting and local optimum problems |

| 1D-CNN | Extraction of time series data features | Lower precision when this is the only method used | |

| TCN | Handling of time series data | Lower robustness | |

| LSTM | Longer historical time series data can be linked, can alleviate the problem of gradient disappearance and gradient explosion | Many calculation parameters, large capacity storage, and long training time | |

| GRU | Fewer computing parameters | Long training time | |

| Hybrid | 1D-CNN + X + Y + … | Combining the advantages of multiple neural networks | Relatively complex model |

| NN + Filter Algorithm | Merge the advantages of neural network and filter algorithm | Large capacity storage, long process time, and complex structure | |

| Trans | Transferlearning | Transfer feature of source data to target data | Hard to know which part can be used as knowledge for transfer in the target learning task. |

| Transformer | Achieve the data feature connection | Higher calculation complexity, computing power requirements, and data demand | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, D.; Zhong, C.; Xu, P.; Tian, Y. Deep Learning in the State of Charge Estimation for Li-Ion Batteries of Electric Vehicles: A Review. Machines 2022, 10, 912. https://doi.org/10.3390/machines10100912

Zhang D, Zhong C, Xu P, Tian Y. Deep Learning in the State of Charge Estimation for Li-Ion Batteries of Electric Vehicles: A Review. Machines. 2022; 10(10):912. https://doi.org/10.3390/machines10100912

Chicago/Turabian StyleZhang, Dawei, Chen Zhong, Peijuan Xu, and Yiyang Tian. 2022. "Deep Learning in the State of Charge Estimation for Li-Ion Batteries of Electric Vehicles: A Review" Machines 10, no. 10: 912. https://doi.org/10.3390/machines10100912