1. Introduction

The green agenda has directly influenced the research for higher efficiency of all-electric machines design and applications. Even though three-phase machine configuration has been and is still the standard choice for industrial applications, in the past decades, machines with a higher number of phases (

), namely multiphase machines, have appeared as an exciting alternative [

1]. Multiphase machines have several advantages compared with classical ones, such as better current/power per phase distribution [

2], lower torque ripple than three-phase machines [

3] and intrinsic fault-tolerance capabilities [

4]. This is why multiphase systems can be found in electric boats, electric vehicles, railway traction, more electric aircraft, and wind power generation systems [

3,

5]. Some commercial examples include Dana six-phase and nine-phase electric trucks [

6], and, in Ref. [

7], a three-phase dual induction machine was selected as a suitable candidate for a belt-driven starter generator designed for 48 V mini-hybrid propulsion systems, and most recently, electrified propulsion engineering consultancy, Drive System Design (DSD) has developed a power-dense Electric Drive Unit (EDU) designed for a global Tier 1 supplier. Based on six-phase permanent magnet machines, the power-train will be used in a range of medium to heavy-duty commercial vehicle applications, such as city buses and delivery vans, when it reaches the market in 2024 [

8]. Another application is “The USS Zumwalt”, a US Navy full-electric propulsion ship powered by General Electric [

9].

However, since multiphase machines are relatively new in the market, they lack mass production. Consequently, they must be developed for specific applications, usually from the stator windings of a commercial three-phase machine [

10]. It should be noted that multiphase drive systems used for these machines protect against failures since, by increasing the number of phases (

), the possibility of a failure occurring is 12% compared to a conventional three-phase system [

11]. Still, with the increase in the number of phases, there is a greater degree of freedom for the operation against faults, with open winding being the most common problem. The absorbed current is distributed to the other phases when losing a phase. Regarding copper losses, as the number of phases increases, a decrease in copper losses was demonstrated [

11].

Concerning the design process of multiphase machines, a method for designing stator windings with any number of phases was proposed in [

12]. A procedure for evaluating the parameters of a five-phase induction motor, which can also be applied to other multiphase motors with a higher number of phases, is presented in [

13]. Meanwhile, ref. [

14] describes an approach to design a six-phase motor, and in [

15], specific problems related to the design of motors with a different number of phases are summarized, and results of the analysis are verified experimentally on a nine-phase asynchronous motor test bench. In ref. [

16], a six-phase starting generator is presented and compared with a three-phase model. Similarly, ref. [

17] compares, using finite element analysis, the performance of a nine-phase induction motor (IM) against a three-phase motor.

Even though several papers reported the winding design for multiphase machines, they are explained in a general way. This work proposes a straightforward procedure for constructing nine-phase IM stator windings from a three-phase IM without special requirements. The primary purpose is to help researchers who want to get involved in the multiphase machines field to quickly design a nine-phase topology, which falls within the category of multi-three-phase machines. A comparison between the efficiency of the commercial three-phase motor and the developed nine-phase redesign is made to obtain the reduction of power losses due to the windings quantitatively.

The rest of this work is organized as follows,

Section 2 describes the characteristics of the three-phase motor, and

Section 3 shows the analysis and design of the nine-phase IM. Then,

Section 4 presents the experimental results, and

Section 5 summarizes the conclusions.

2. Multi-Three-Phase Machines

Multi-three-phase machines have several independent sets to produce a unified electromagnetic field. The term “sets” is adopted to designate each three-phase winding it has. Therefore, a multi-three-phase machine consists of two or more three-phase winding and construction parameters are determined considering the number of stator slots (K), the number of poles (), and the number of phases (q) that these machines will have.

2.1. Multi-Three-Phase Winding

Multi-three-phase machines are generally made up of three-phase sets of three phases separated by

from each other. The stator winding arrangement is defined in the same way as for three-phase IM, that is, by the winding to be used, whether it concentric or eccentric, or if has one or two layers [

14].

Regardless of the type of machine (synchronous or induction), multiphase machines can be classified into two well-differentiated groups: machines with a prime number of phases and machines with an even or odd number of phases.

If the machine has a prime number of phases , every two consecutive phases will be offset by and will have a single isolated neutral point;

If the machines have an even or odd number of phases , they can have h sets of windings, each with q phases and can have one or h isolated neutral points. If the windings are three-phase sets , the machine under analysis is a multi-three-phase IM .

The multi-three-phase is the preferred configuration in many current applications because it resembles well-known three-phase machine topologies [

18]. On the other hand, some critical points to consider that influence the winding arrangement of a nine-phase IM from a three-phase one are listed below:

The power of the IM used is vital since, at higher power (from 5 HP), the dimension of slots is larger. They can therefore accommodate a more significant number of coils;

The number of stator slots must be a multiple of the number of phases of the machine to be designed;

The number of poles can be different from the initial one. Adding more poles will depend exclusively on the capacity of the machine and the chosen winding;

The winding design will consider the one that presents minor difficulties for its arrangement and distribution inside the slots. This is at the discretion of the designer.

In

Table 1, it can be seen which are the ideal values for the number of phases and poles proposed as a function of the number of slots the motor has, considering a simple arrangement (consequent poles to a layer) in the choice of the winding to be used.

It can be seen in

Table 1 that, for the same number of slots, by increasing the number of phases, the machine may have fewer poles, and this is due to the design limits that occur at the time of rewinding it. In the case of the design of a nine-phase IM, it is possible to make it with two poles and four poles in armatures whose number of slots is equal to 36. As for the design of one with two poles, there are more possibilities for more types of windings than the one with four poles, and the same would happen with one with six phases. As the number of poles increases, less space is available, and so is the design variety [

19].

2.2. Topology

Multiphase motors can be arranged in two types: symmetrical and asymmetrical. Each one has its characteristics that are considered for the design of the winding of these machines. They can be AC or DC, synchronous or asynchronous, with a symmetrical or asymmetrical configuration between the phases. These machines are commonly designed in a symmetrical arrangement because it entails fewer difficulties for their control. It is necessary to mention that their control will be through frequency power converters [

20].

2.2.1. Symmetrical

The sets can be arranged as symmetric if the spacial change between two consecutive phase windings is

. Therefore, the set of phases for the case of a symmetrical nine-phase IM would be distributed by

between sets around the circumference of the stator as shown in

Figure 1, maintaining the phase shift within each three-phase set at

electrical at all times [

18].

2.2.2. Asymmetrical

In the case of asymmetric nine-phase IMs, the three-phase windings are distributed in such a way that they are displaced by

between the phase windings and

between phases of the same assembly, as occurs in a motor with a symmetric configuration, as shown in

Figure 2. Thus, the spacial change between the corresponding phases of the windings is

[

18].

2.3. Calculations for AC Windings Applied to Nine-Phase IM

Two types of windings are usually used for the design and winding of electric motors: concentric and eccentric. At the same time, these are subdivided into concentric windings by consequent poles, concentric windings by poles, imbricated eccentric windings, and corrugated eccentric windings. Depending on the type, they can be made with single or two layers. They can be even, odd, or fractional integers [

14].

A 380 V, 4 poles, 5 HP three-phase squirrel cage IM with 36 slots in the stator and 44 slots in the rotor was used in this paper. Some parameters were delimited for constructing the nine-phase motor winding:

The power is equal to or close to that of a three-phase IM;

The same number of poles is maintained;

The windings are of asymmetric type.

Calculation Process

Known IM variables for calculations are:

Number of slots: ;

Number of poles: ;

Number of phases: .

- 1.

First, the value of

is determined:

being

an odd integer value. The design of windings by consequent poles is chosen. By taking into account the possibility of winding either a single layer or two layers, we proceed as follows:

- 2.

Concentric windings:

Two layers:

where

B is the total number of coils. From here, calculations are developed in a single layer because it allows us to correctly take advantage of the available slots to distribute the coils.

- 3.

Total number of groups (

G):

- 4.

The number of coils that make up each group (

) is calculated:

- 5.

- 6.

Finally, the distance between phases (

) is determined:

As the calculation has now been carried out, the winding distribution for the new nine-phase IM with asymmetrical topology is presented in

Figure 3:

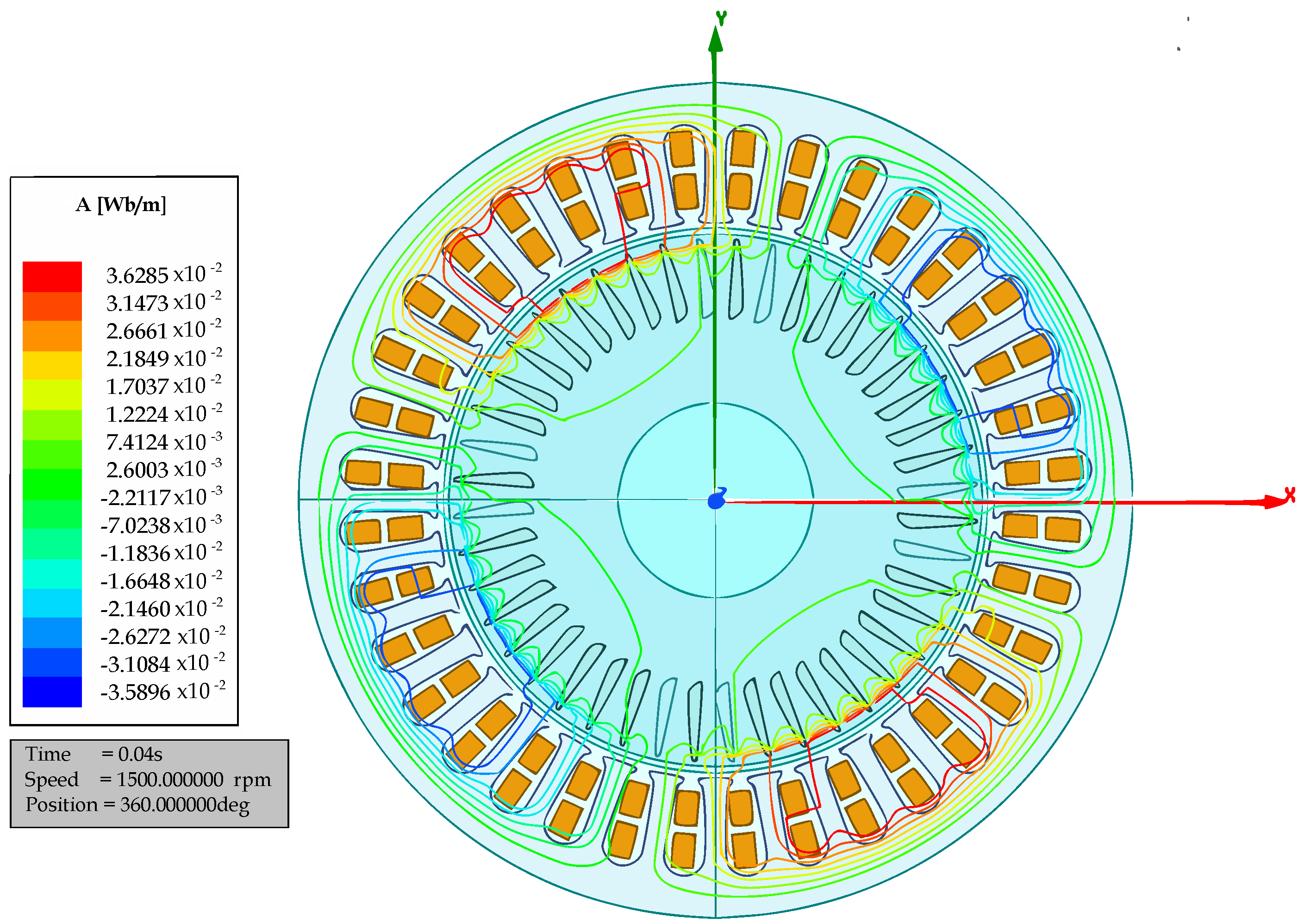

4. Experimental Results

This section presents the results from tests carried out on the three-phase IM before being modified and on the nine-phase IM after being rewound to determine its performance. With these results, a comparison was made to point out their differences and similarities.

Figure 9 depicts the experimental platform including the three-phase power source based on a varivolt, the oscilloscope, and the machine. Lastly,

Figure 10 and

Figure 11 present pictures of the experimental setup to perform the parameters tests, including current and voltage probes.

4.1. Original Three-Phase IM Results

Several tests were performed to obtain the three-phase IM’s electrical parameters. These tests are named non-load test, locked-rotor test, and DC-test [

21].

Table 5 presents the obtained values for these tests applied to the three-phase IM. Then,

Table 6 shows the electrical parameters for the three-phase IM, which were calculated through the obtained values.

4.2. Rewound Nine-Phase IM Results

In this section, the results through the tests carried out on the new asymmetrical nine-phase IM are presented in

Table 7,

Table 8 and

Table 9. The tests consist of the same performed for the three-phase IM. Measurements of the nine-phase IM were carried out independently for the three-phase sets. Electrical parameters of the nine-phase IM are described in

Table 10.

At last,

Figure 12 and

Figure 13 show the measured voltage and current in the oscilloscope for the non-load and locked rotor test of the nine-phase IM.

4.3. Comparative Analysis-Discussion

This section discusses a comparative analysis between both designs, the three-phase IM and the rewound asymmetrical nine-phase IM. First,

Figure 14 shows the equivalent circuit per phase for both IMs.

Figure 15 and

Figure 16 present a comparative view between both IMs in terms of power, phase current, and phase voltage.

Considering nominal currents for both three-phase and nine-phase IM, which are

A and

A, respectively, and the electrical parameters from the equivalent circuit from

Figure 17, a similar condition in terms of efficiency can be estimated.

In nominal conditions, the three-phase IM consumes approximately 4500 VAR and has 1560 W power losses. On the other hand, the nine-phase IM consumes 3370 VAR and has 1280 W of power losses in total. This gives approximately 25% reactive power minimization and a reduction of 18% in terms of power losses.

On the other hand, note that the nine-phase IM possesses higher leakage, higher magnetizing inductance, and higher resistance. Consequently, it acts as a low pass filter with a lower cutoff frequency, making it more versatile to power sources based on power electronics with high-frequency harmonics generating torque ripple-producing vibrations. It is worth noting that now that the IM has become a multiphase machine, it has gained the ability to post-fault operations, making it more suitable for critical applications.