Mechanism Design and Experimental Verification of Novel Automatic Balance Equipment for a Rope-Type Elevator

Abstract

:1. Introduction

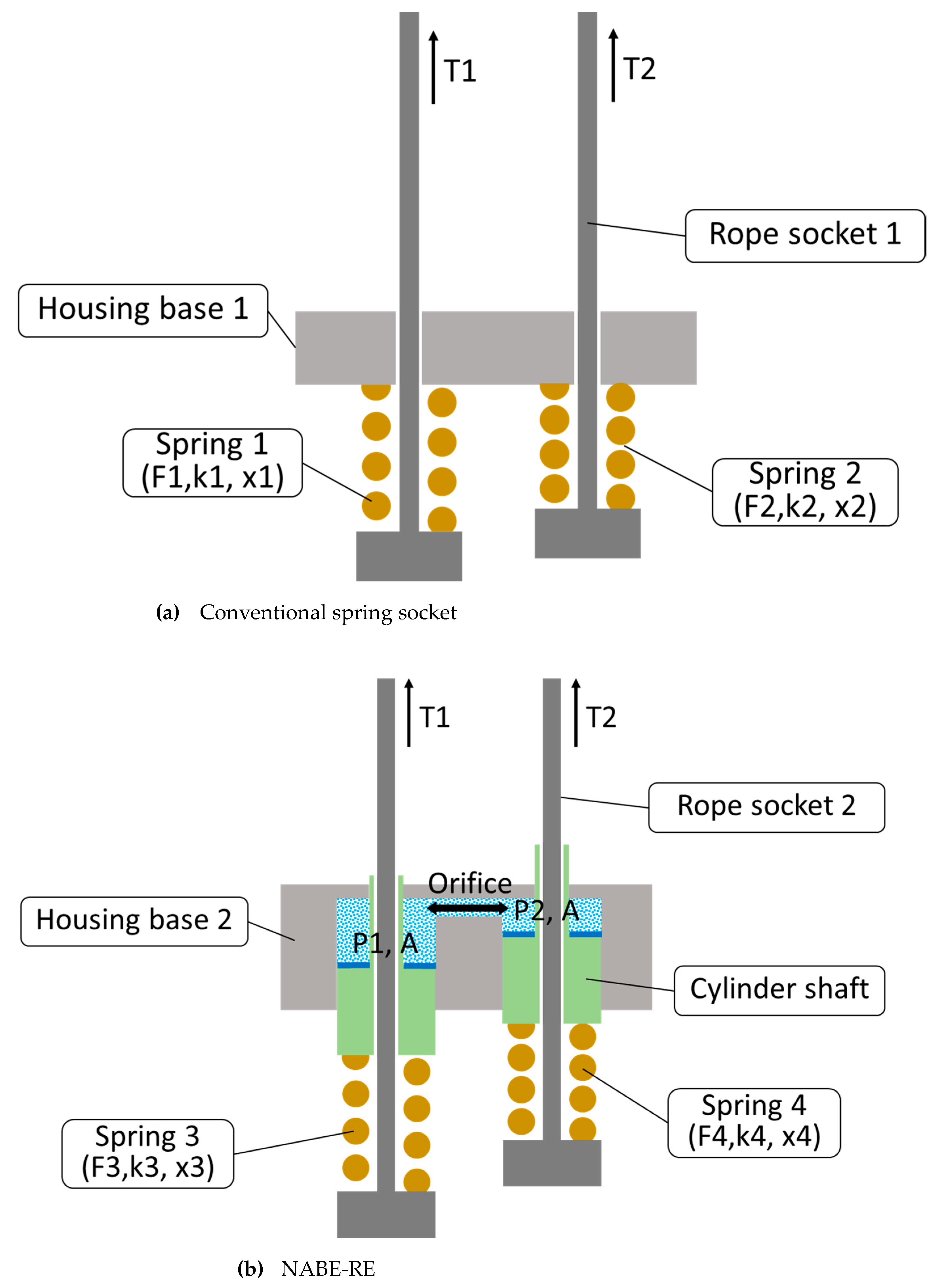

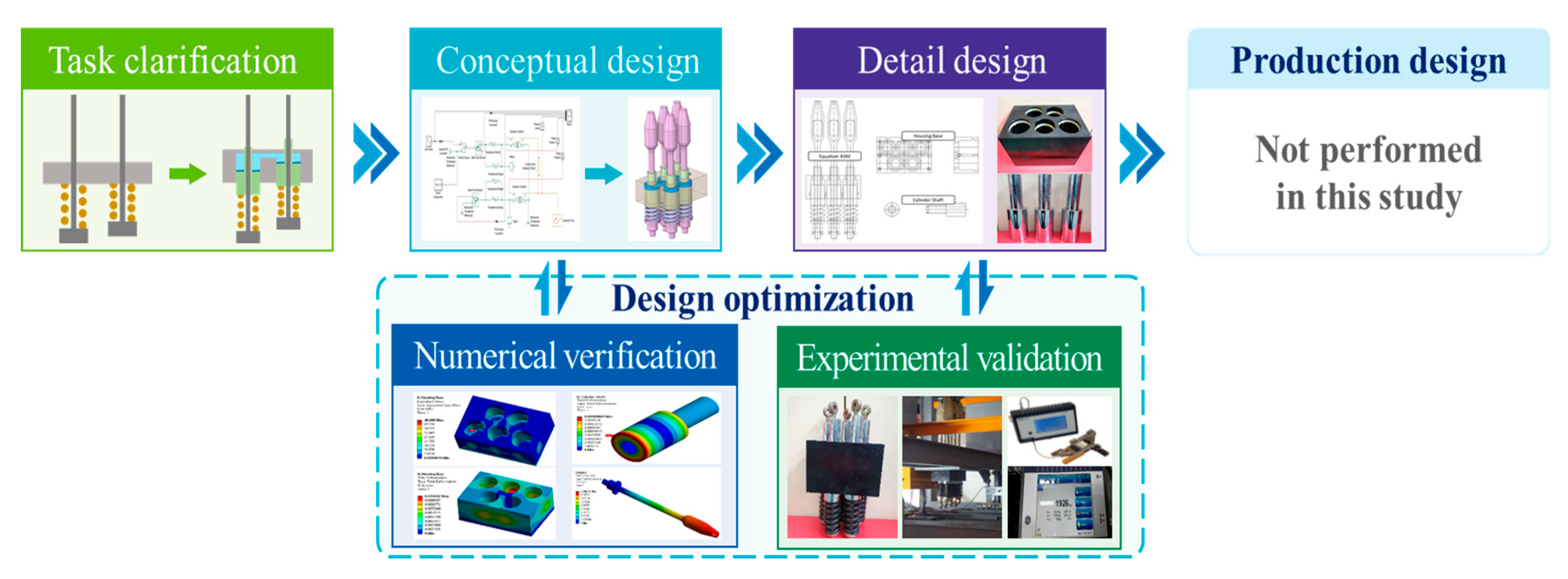

2. Mechanism Design

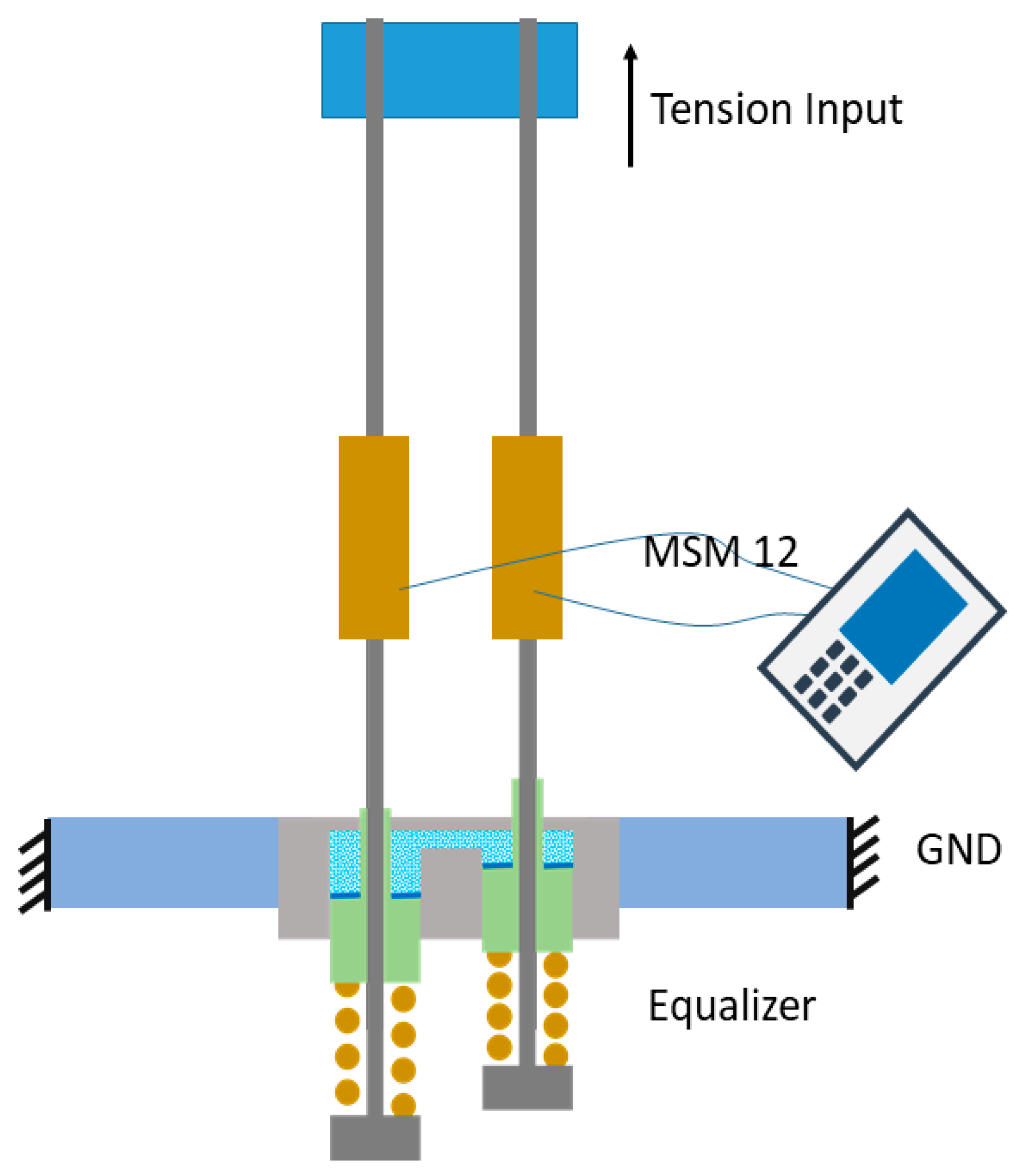

2.1. Operating Principle

2.2. Kinematic Verification

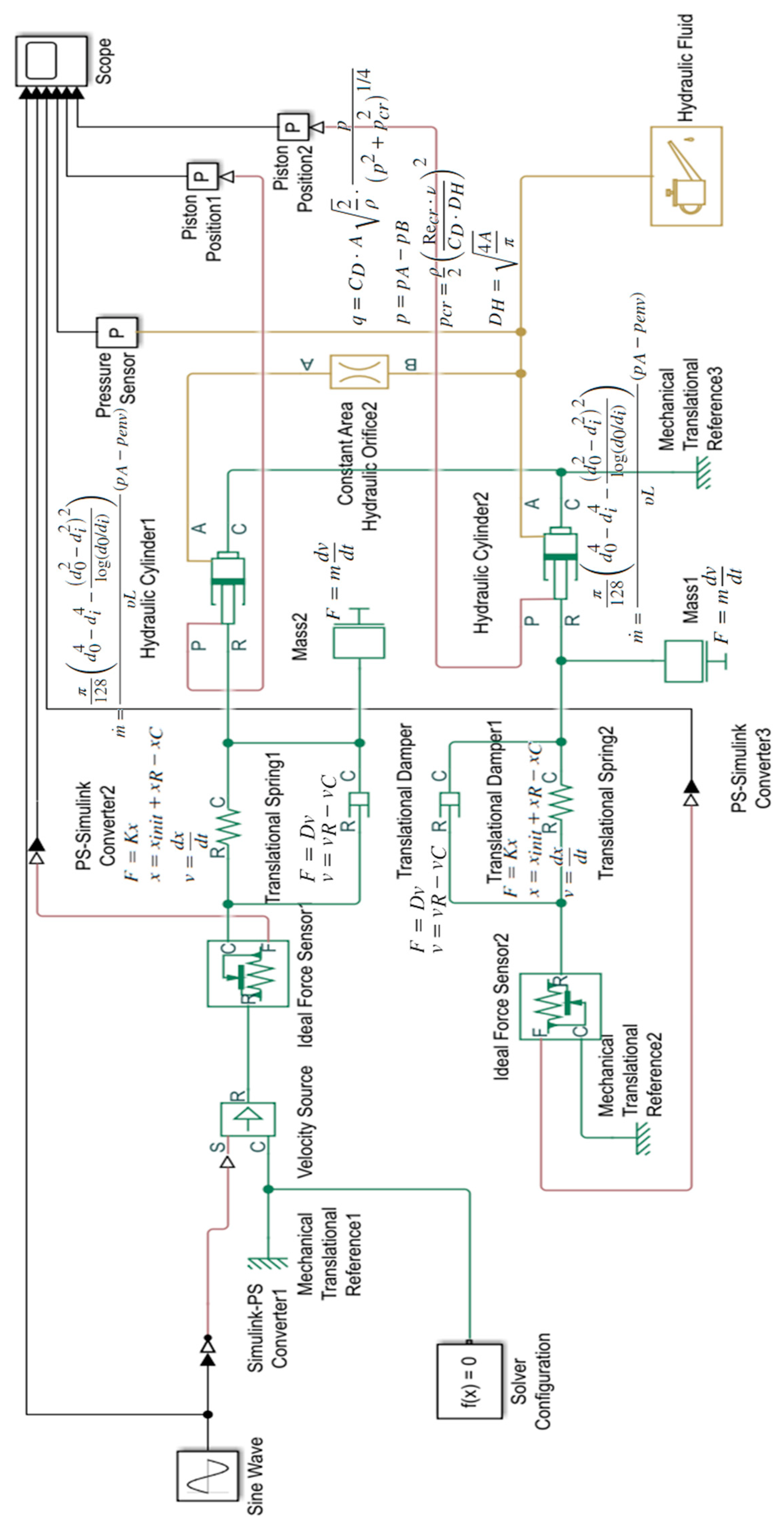

2.2.1. Modeling and Investigation Methods

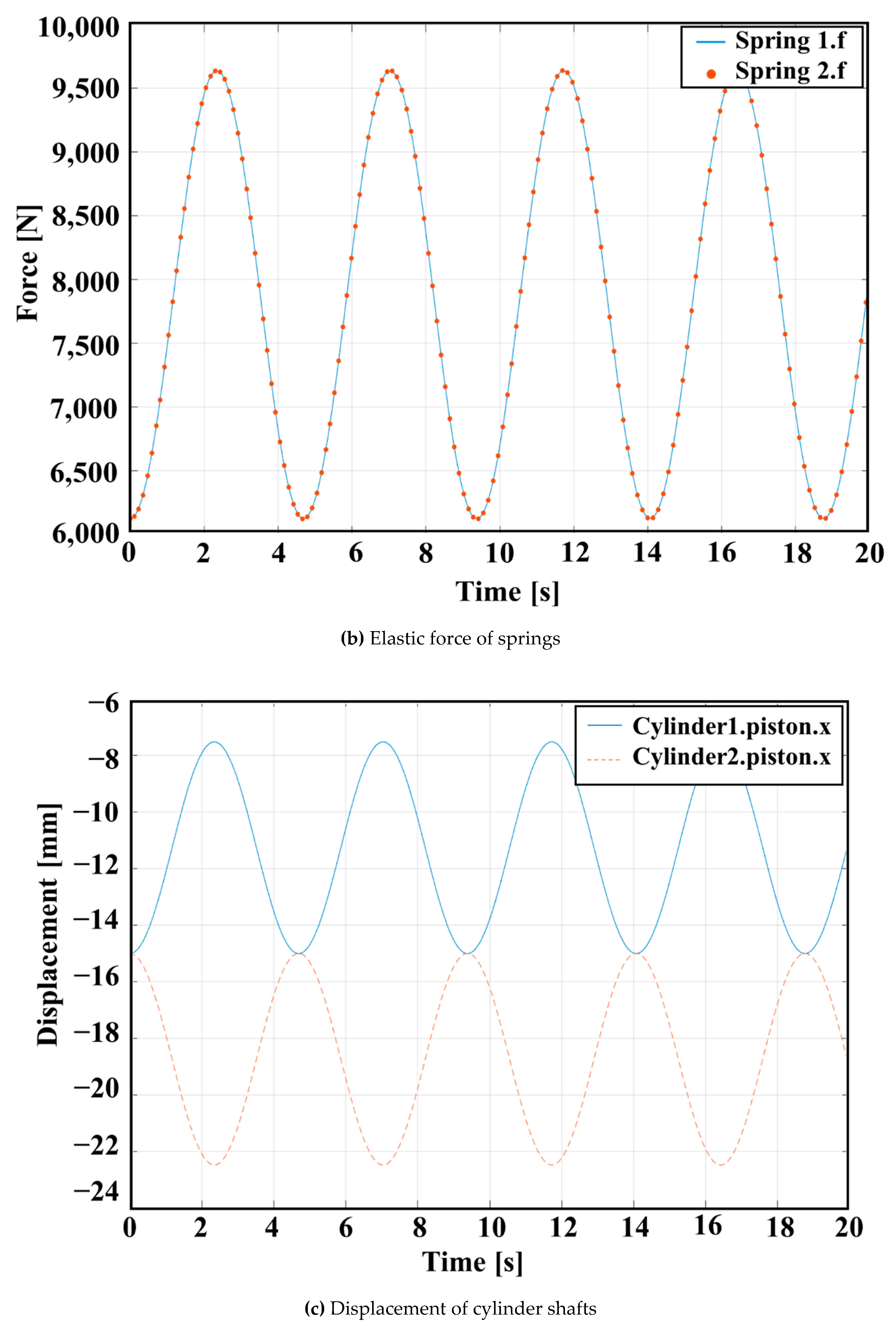

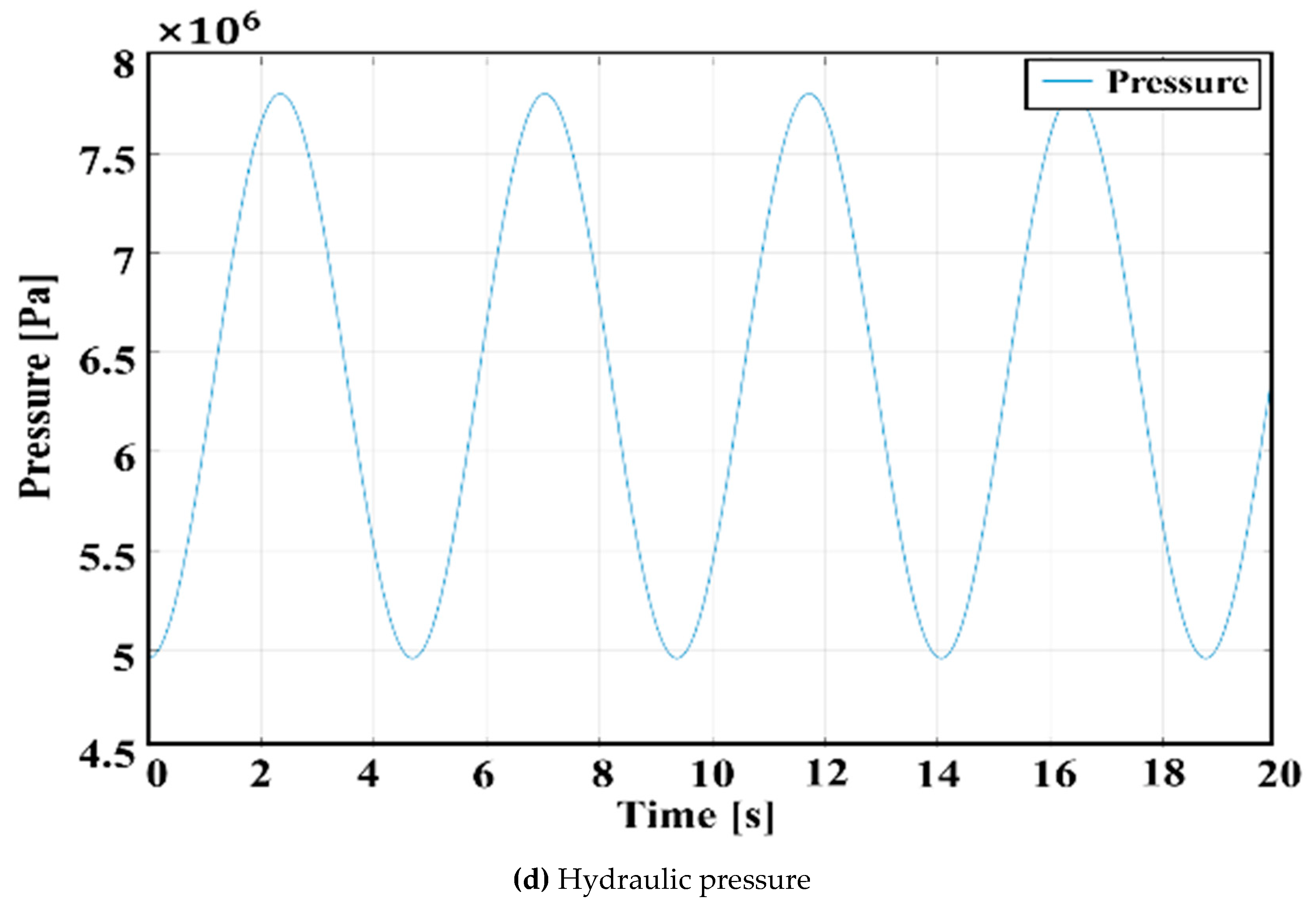

2.2.2. Simulation Results and Discussion

3. Verification of NABE-RE

3.1. Numerical Investigation of Structural Stability

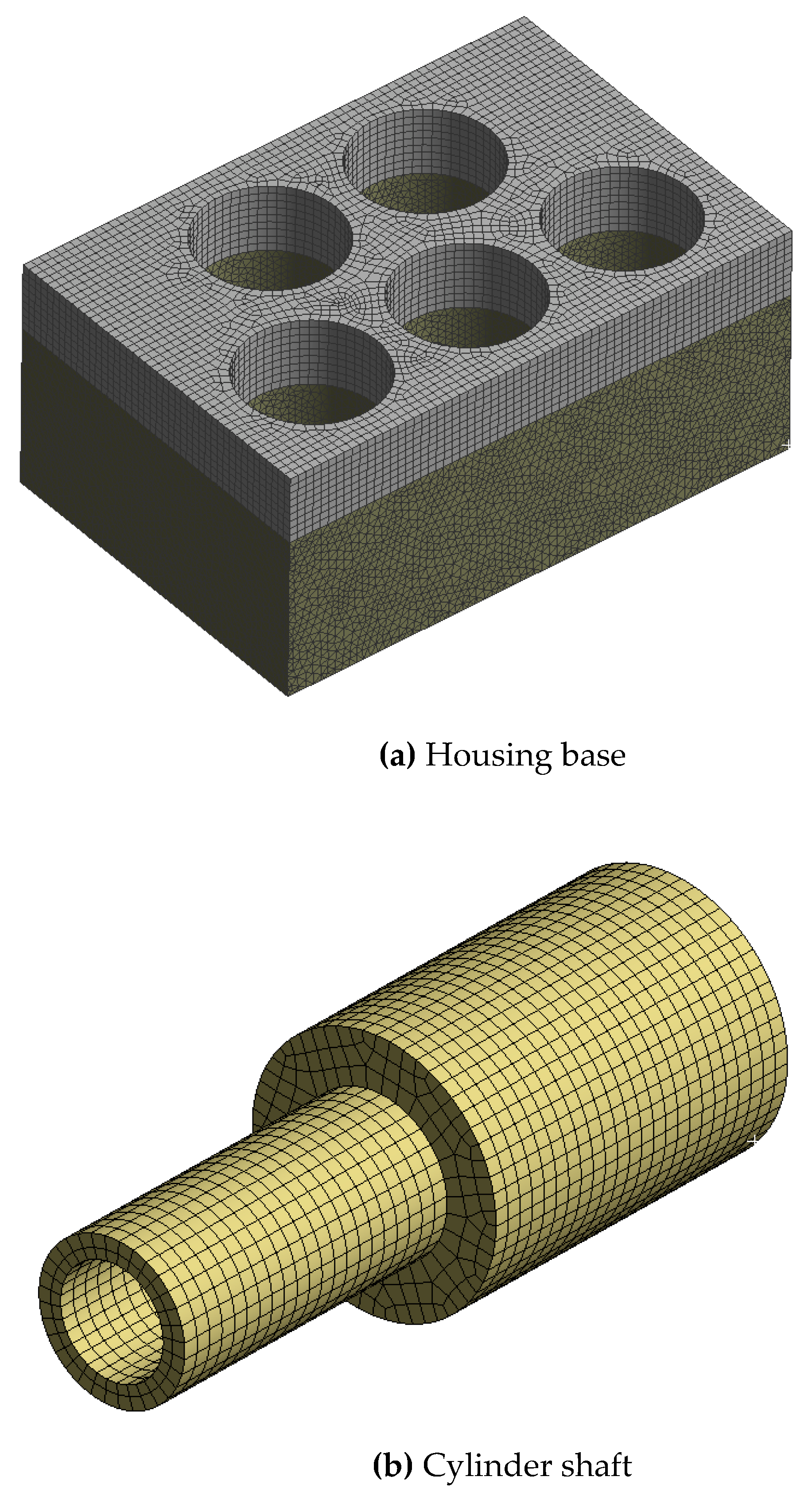

3.1.1. Modeling and Investigation Methods

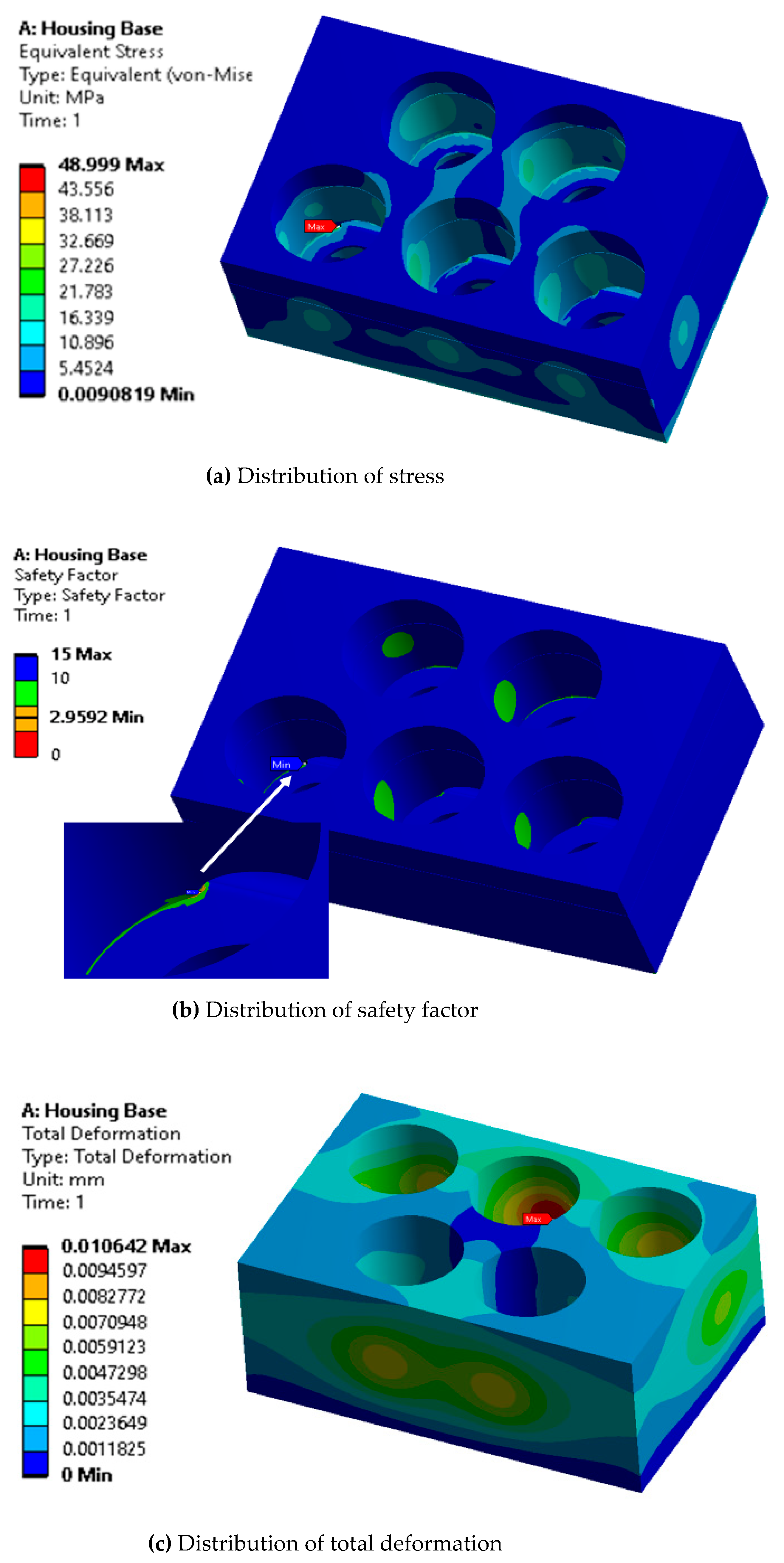

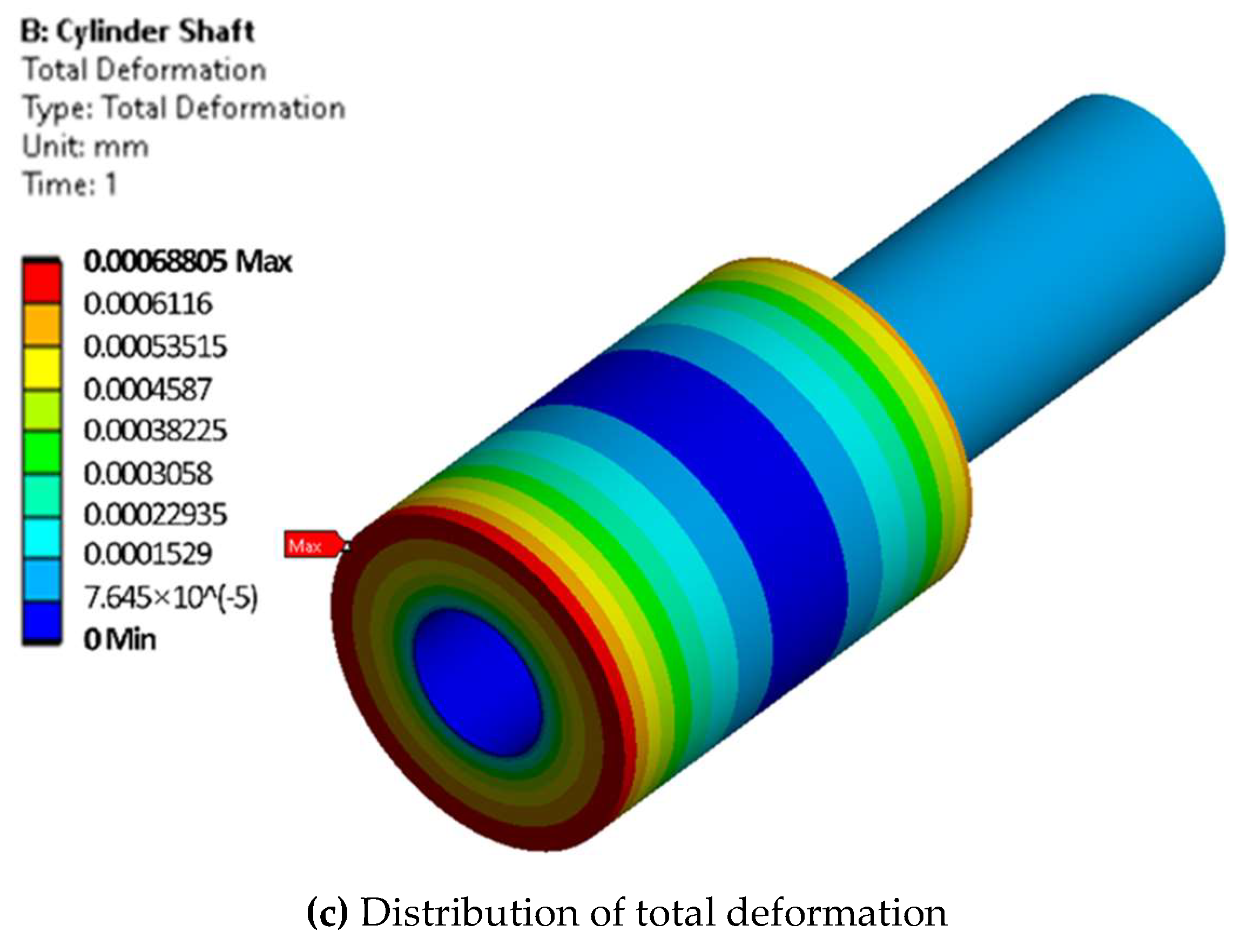

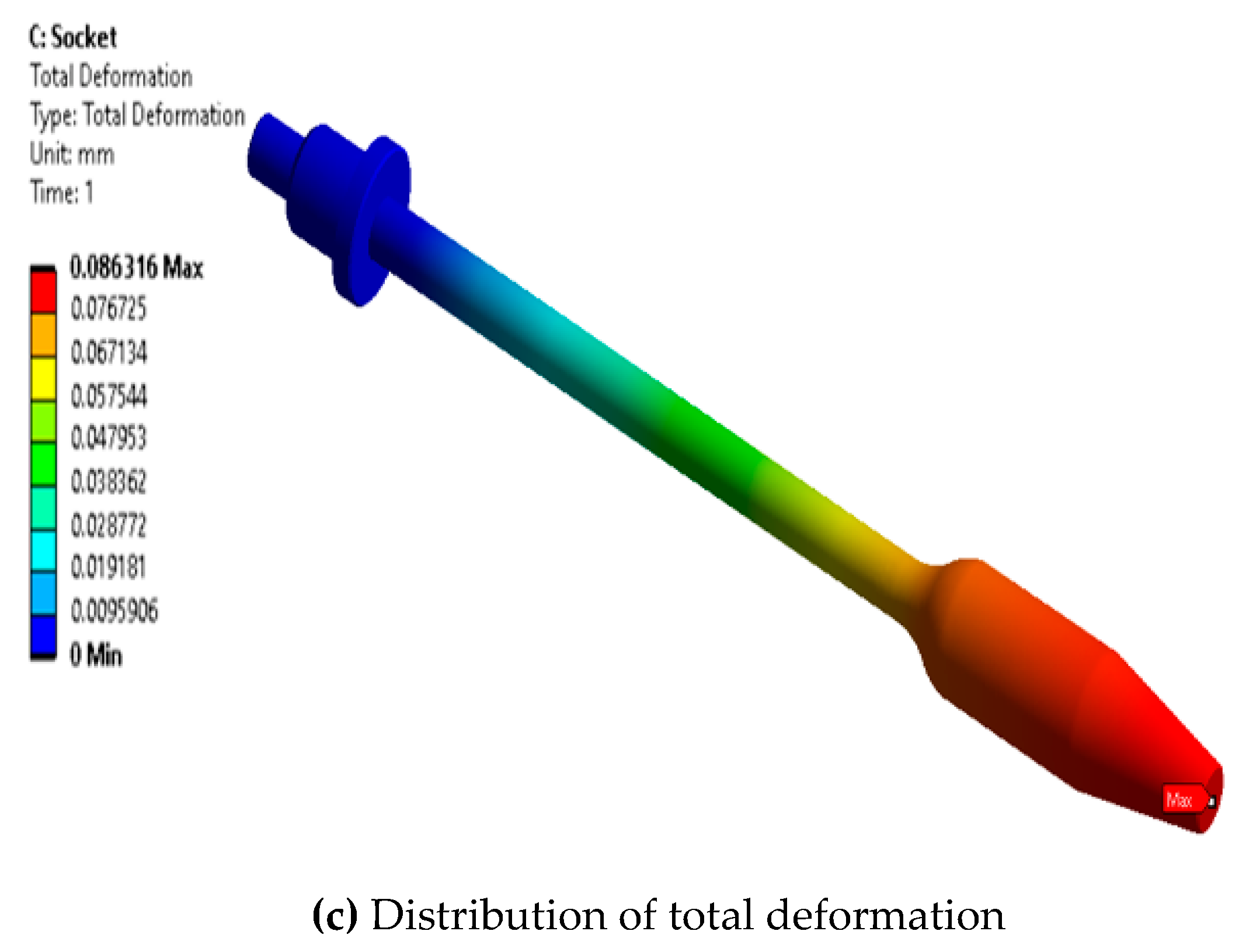

3.1.2. Results and Discussion

3.2. Experimental Validation

3.2.1. Experimental Investigation Methods

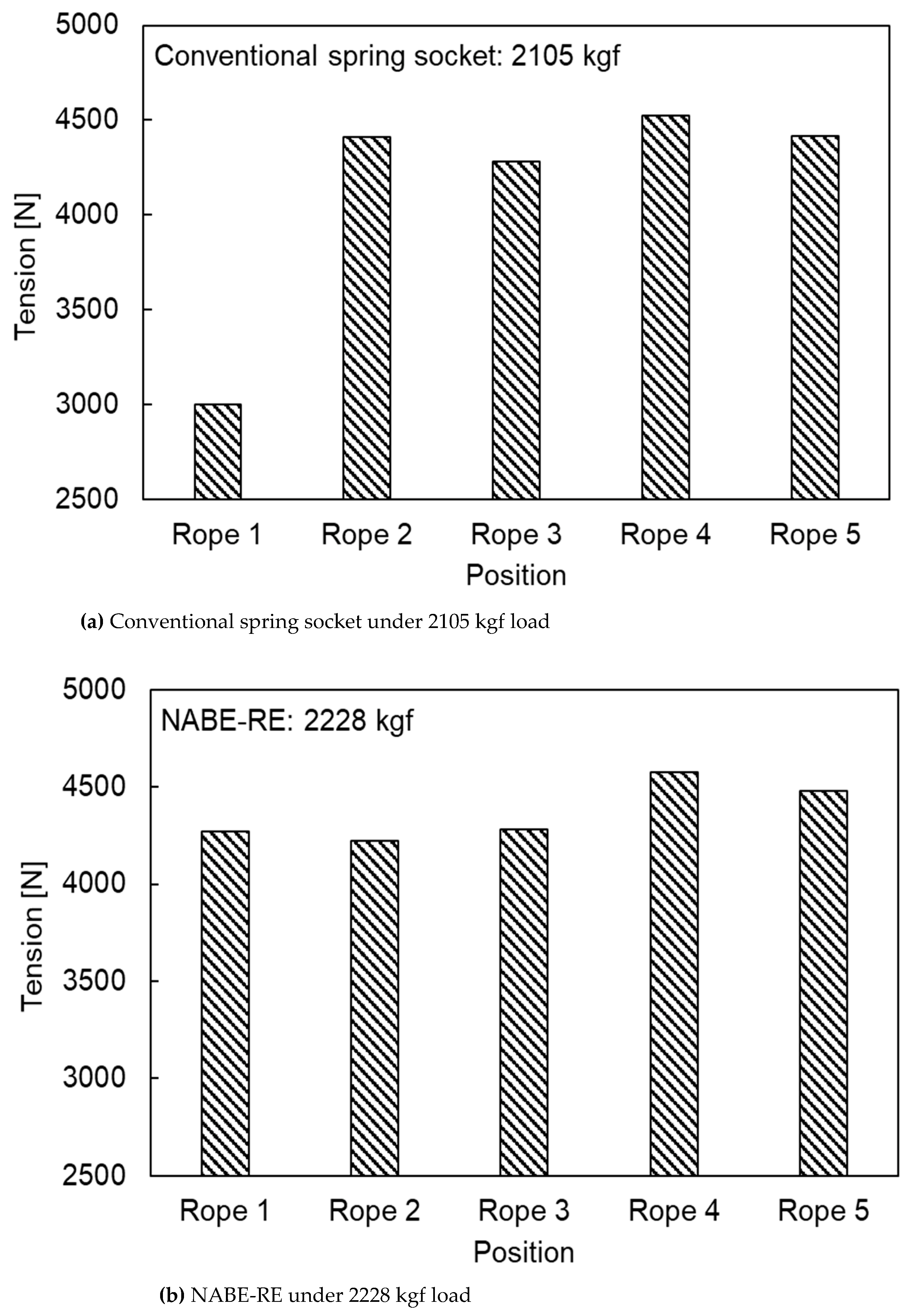

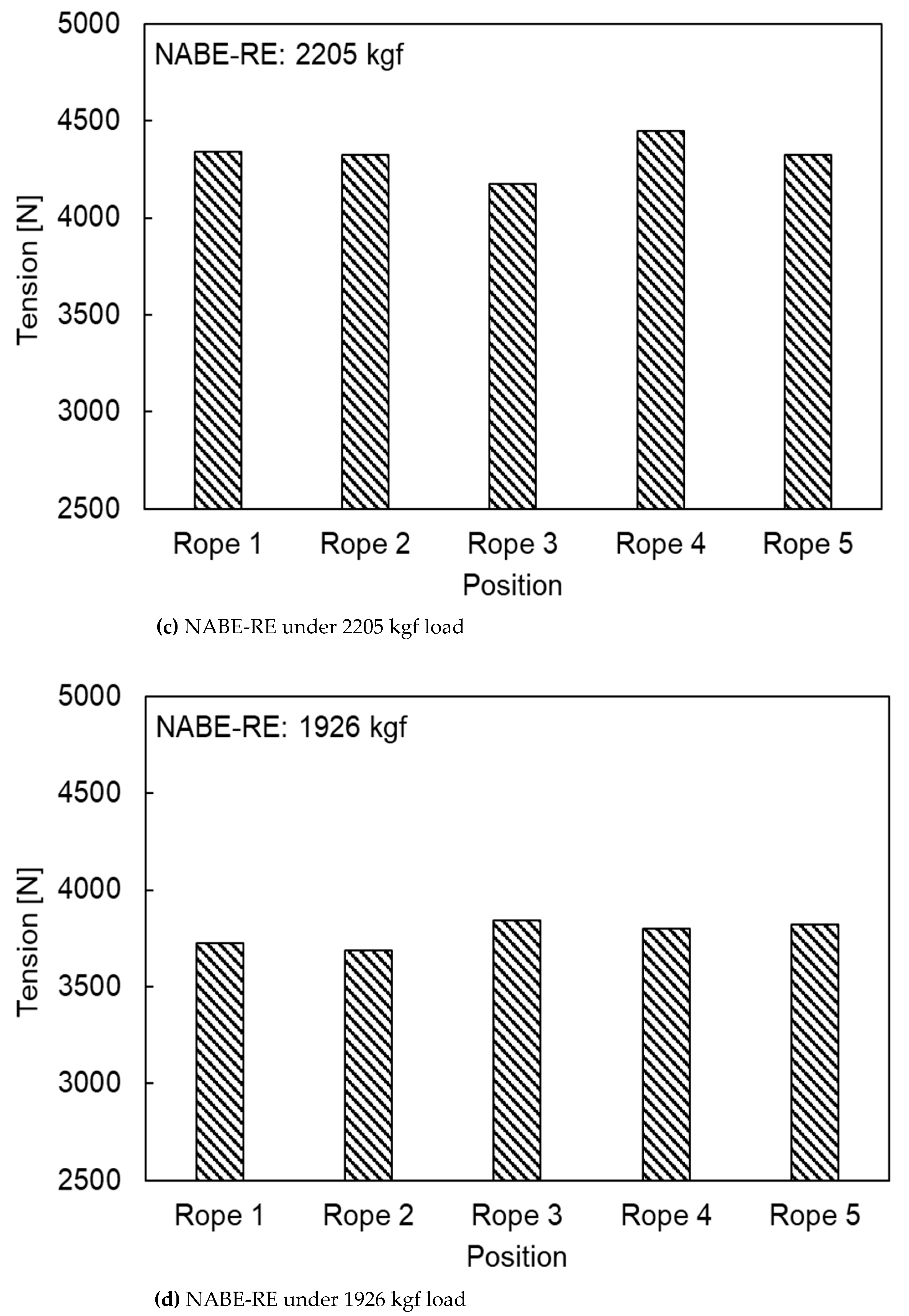

3.2.2. Results and Discussion

4. Conclusions

- (1)

- The operating principle of the automatic tension balancing function of the NABE-RE mechanism was explained. To verify the kinematic validity of the mechanism, numerical investigation was performed using Simscape. From the kinematic simulation results, it can be seen that, when the cylinder shaft 1 is pushed a certain distance, the cylinder shaft 2 moves in the opposite direction with the same travel distance. This happens because the movement of shaft 1 increases the pressure inside the hydraulic system, which pushes cylinder shaft 2 to move in the opposite direction. The results of the high stiffness springs that showed the existence of the same force at both the input and output sides sufficiently demonstrate the automatic tension balancing function of the proposed mechanism. Based on the same kinematics, it can be determined that the mechanism can also be applied to elevator designs with multiple ropes.

- (2)

- The NABE-RE design with five ropes was selected to obtain an optimal structural stability for the design. The structural stability analyses of the core components (housing base, cylinder shaft and rope socket) based on the finite element method were performed. In the pre-processing of the simulation, the boundary conditions were set considering the actual load and the required safety factor. Different meshing methods were applied in the divided model with a shared topology to obtain a more efficient and accurate calculation. The results showed that the safety factor of all components was more than 2.0 and the maximum amount of deformation was also within the allowable value, which verifies that the structural stability of the proposed NABE-RE meets the design requirements.

- (3)

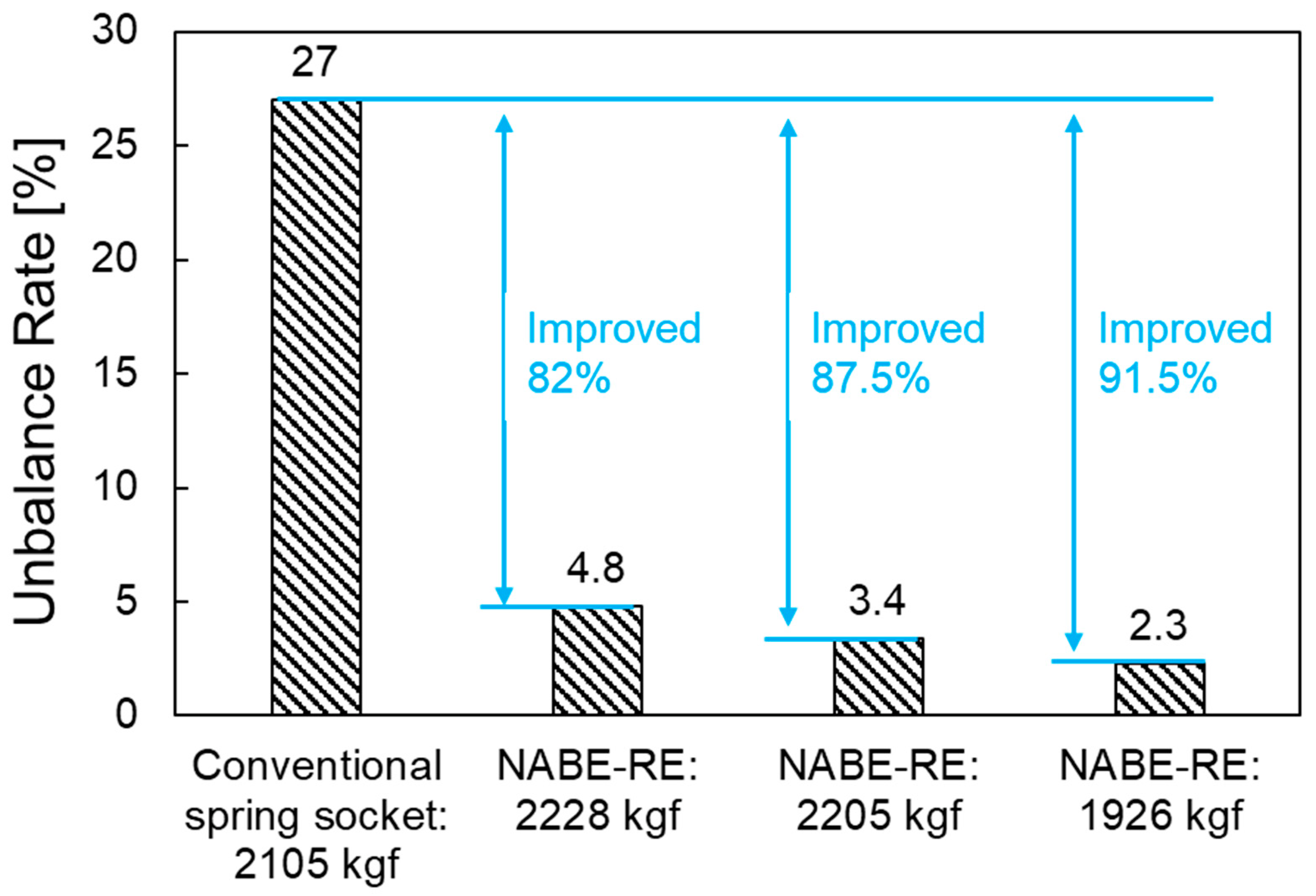

- A prototype of the numerically verified NABE-RE with five ropes was produced and the automatic tension balancing function was confirmed through the rope tension comparison experiments. When using the conventional spring socket, the maximum difference in rope tensions was 1521 N and the unbalance rate was more than 27%. When the NABE-RE was installed, a maximum difference between rope tensions of 353 N was measured under the total rope tension of 2228 kgf and the unbalance ratio was calculated to be about 4.8%. The minimum unbalance ratio of 2.3% was observed under the 1926 kgf loading condition. It was also observed that the smaller the total rope tension, the smaller the tension unbalance ratio between ropes. Therefore, it was confirmed that the proposed NABE-RE can reduce the difference of tensions between the different ropes to improve the unbalance ratio by more than 82% as compared to the conventional spring socket. The test results verified that the automatic tension balancing function of the proposed NABE-RE sufficiently meets the target of limiting the unbalance ratio to less than 10%.

- (4)

- The experimental results show that the unbalance rate of each rope in the elevator system significantly decreased by up to 91.5% after installing the NABE-RE. This fully validates the effectiveness of NABE-RE in balancing each rope’s tension and also proves that the proposed mechanism design meets the anticipated objective. However, the experiment in this study only evaluated the rope tension and was unable to confirm the dynamics and ride comfort of the elevator system installed by NABE-RE. Further research and product development are required for compatibility validation taking into account the entire elevator system and a number of NABE-RE products for different elevator models. The innovative design and research methodologies proposed in this study offer a crucial theoretical foundation for the technological advancement of the elevator industry and indicate the direction of future research to address the issues of elevator harshness and vibration durability. The design processes can be used to study a variety of mechanisms and offer effective design concepts for studying and creating new mechanisms.

Author Contributions

Funding

Conflicts of Interest

References

- Blokus, A.; Kołowrocki, K. Reliability and maintenance strategy for systems with aging-dependent components. Qual. Reliab. Eng. Int. 2019, 35, 2709–2731. [Google Scholar] [CrossRef]

- Chang, L.; Wei, S.; Xu, K.; Liu, J.; Li, T. An improved image denoising method based on contourlet transform and NeighShrink algorithm. Int. J. Comput. Appl. Technol. 2018, 57, 94. [Google Scholar] [CrossRef]

- Ryu, H.-M.; Kim, S.-Y.; Sul, S.-K.; Kwon, T.-S.; Kim, K.; Shim, Y.-S.; Seok, K.-R. Dynamic load simulator for high-speed elevator system. In Proceedings of the Power Conversion Conference-Osaka 2002 (Cat. No. 02TH8579), Osaka, Japan, 2–5 April 2002; Volume 2, pp. 885–889. [Google Scholar]

- Liu, S.; Sun, Y.; Ma, W.; Xie, F.; Jiang, X.; He, L.; Kang, Y. A New Signal Processing Method Based on Notch Filtering and Wavelet Denoising in Wire Rope Inspection. J. Nondestr. Eval. 2019, 38, 39. [Google Scholar] [CrossRef]

- Lee, Y.; Kim, T.S.; Cho, H.; Sung, D.K.; Choi, B.D. Performance analysis of an elevator system during up-peak. Math. Comput. Model. 2009, 49, 423–431. [Google Scholar] [CrossRef]

- Nguyen, X.T.; Miura, N.; Sone, A. Optimal design of control device to reduce elevator ropes responses against earthquake excitation using Genetic Algorithms. J. Adv. Mech. Des. Syst. Manuf. 2019, 13, JAMDSM0038. [Google Scholar] [CrossRef] [Green Version]

- Onur, Y. Theoretical investigation of rope strand subjected to axial tensile load. Int. Rev. Appl. Sci. Eng. 2019, 10, 1–5. [Google Scholar] [CrossRef]

- Peng, Q.; Jiang, A.; Yuan, H.; Huang, G.; He, S.; Li, S. Study on Theoretical Model and Test Method of Vertical Vibration of Elevator Traction System. Math. Probl. Eng. 2020, 2020, 8518024. [Google Scholar] [CrossRef] [Green Version]

- Boyko, A.; Volyanskaya, Y. Development of the gearless electric drive for the elevator lifting mechanism. East.-Eur. J. Enterp. Technol. 2018, 4, 72–80. [Google Scholar] [CrossRef] [Green Version]

- Onur, Y.A.; Aycan, O. Theoretical and experimental investigation of effects of failures on the tensile endurance of elevator ropes. Mater. Werkst. 2019, 50, 706–717. [Google Scholar] [CrossRef]

- Rostami, J.; Tse, P.; Yuan, M. Detection of broken wires in elevator wire ropes with ultrasonic guided waves and tone-burst wavelet. Struct. Health Monit. 2019, 19, 147592171985591. [Google Scholar] [CrossRef]

- Santo, D.R.; Balthazar, J.M.; Tusset, A.M.; Piccirilo, V.; Brasil, R.; Silveira, M. On nonlinear horizontal dynamics and vibrations control for high-speed elevators. J. Vibrat. Control. 2018, 24, 825–838. [Google Scholar] [CrossRef] [Green Version]

- Gerstenmeyer, S.; Peters, R. Safety distance control for multi-car lifts. Build. Serv. Eng. Res. Technol. 2016, 37, 730–754. [Google Scholar] [CrossRef]

- Taehoon, K.; Dongmin, L.; Minsu, C.; Hyunsu, L.; Myungdo, L.; Hunhee, C.; Kyung-In, K. Simulation-Based Lift Planning Model for the Lift Transfer Operation System. J. Constr. Eng. Manag. 2020, 146, 04020098. [Google Scholar]

- Van, L.D.; Lin, Y.B.; Wu, T.H.; Lin, Y.C. An Intelligent Elevator Development and Management System. IEEE Syst. J. 2020, 14, 3015–3026. [Google Scholar] [CrossRef]

- Wang, X.; Günay, S.; Lu, W. Seismic analysis of the rail-counterweight system in elevators considering the stiffness of rail brackets. Adv. Struct. Eng. 2020, 24, 1369433220974777. [Google Scholar] [CrossRef]

- Cao, G.; Cai, X.; Wang, N.; Peng, W.; Li, J. Dynamic Response of Parallel Hoisting System under Drive Deviation between Ropes with Time-Varying Length. Shock Vibrat. 2017, 2017, 6837697. [Google Scholar] [CrossRef] [Green Version]

- Kwon, D.; Kim, J.; Park, S.; Kwon, I.; DeVries, K.L.; Park, J. Damage sensing, mechanical and interfacial properties of resins suitable for new CFRP rope for elevator applications. Compos. Part B: Eng. 2019, 157, 259–265. [Google Scholar] [CrossRef]

- Yang, D.; Kim, K.; Kwak, M.; Lee, S. Dynamic modeling and experiments on the coupled vibrations of building and elevator ropes. J. Sound Vibrat. 2017, 390, 164–191. [Google Scholar] [CrossRef]

- Zhang, Q.; Hou, T.; Zhang, R.; Liu, J. Time-Varying Characteristics of the Longitudinal Vibration of a High-Speed Traction Elevator Lifting System. Int. J. Acoust. Vib. 2020, 25, 153–161. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, Y.; Hou, T.; Zhang, R. Dynamic analysis of high-speed traction elevator and traction car–rope time-varying system. Noise Vib. Worldw. 2019, 50, 37–45. [Google Scholar] [CrossRef]

- Zhang, Q.; Yang, Z.; Wang, C.; Yang, Y.; Zhang, R. Intelligent control of active shock absorber for high-speed elevator car. Proc. Inst. Mech. Eng. Part C 2019, 233, 3804–3815. [Google Scholar] [CrossRef]

- Zhao, Y.; Pan, J.; Huang, Z.; Miao, Y.; Jiang, J.; Wang, Z. Analysis of vibration monitoring data of an onshore wind turbine under different operational conditions. Eng. Struct. 2020, 205, 110071. [Google Scholar] [CrossRef]

- Nguyen, X.T.; Miura, N.; Sone, A. Analysis and control of vibration of ropes in a high-rise elevator under earthquake excitation. Earthq. Eng. Eng. Vib. 2019, 18, 447–460. [Google Scholar] [CrossRef]

- Kim, D.; Kim, G. A Study on the Development of an Elevator Rope Tension Automatic Equalizer. J. Korean Soc. Manuf. Process Eng. 2020, 19, 60–66. [Google Scholar] [CrossRef]

- Qin, Z.; Wu, Y.; Huang, A.; Lyu, S.; Sutherland, J. Theoretical Design of a Novel Vibration Energy Absorbing Mechanism for Cables. Appl. Sci. 2020, 10, 5309. [Google Scholar] [CrossRef]

- Fujiwara, E.; Cordeiro, C. Model-Based Design and Simulation of Paraxial Ray Optics Systems. Appl. Sci. 2020, 10, 8278. [Google Scholar] [CrossRef]

- Kulshrestha, A.; Mahela, O.; Gupta, M.; Khan, B.; Haes Alhelou, H.; Siano, P. Hybridization of Stockwell Transform and Wigner Distribution Function to Design Transmission Line Protection Scheme. Appl. Sci. 2020, 10, 7985. [Google Scholar] [CrossRef]

- Qin, Z.; Zhang, Q.; Wu, Y.T.; Eizad, A.; Lyu, S.K. Experimentally Validated Geometry Modification Simulation for Improving Noise Performance of CVT Gearbox for Vehicles. Int. J. Precis. Eng. Manuf. 2019, 20, 1969–1977. [Google Scholar] [CrossRef]

- Qin, Z.; Wu, Y.T.; Eizad, A.; Lee, K.H.; Lyu, S.K. Design and evaluation of two-stage planetary gearbox for special-purpose industrial machinery. J. Mech. Sci. Technol. 2019, 33, 5943–5950. [Google Scholar] [CrossRef]

- Qin, Z.; Wu, Y.T.; Eizad, A.; Jeon, N.S.; Kim, D.S.; Lyu, S.K. A Study on Simulation Based Validation of Optimized Design of High Precision Rotating Unit for Processing Machinery. Int. J. Precis Eng. Manuf. 2019, 20, 1601–1609. [Google Scholar] [CrossRef]

- Qin, Z.; Tang, X.; Wu, Y.-T.; Lyu, S.-K. Advancement of Tidal Current Generation Technology in Recent Years: A Review. Energies 2022, 15, 8042. [Google Scholar] [CrossRef]

- Qin, Z.; Son, H.I.; Lyu, S.K. Design of anti-vibration mounting for 140A class alternator for vehicles. J. Mech. Sci. Technol. 2018, 32, 5233–5239. [Google Scholar] [CrossRef]

- Corte, W.; Van Meirvenne, K.; Boel, V.; Taerwe, L. Design of Anchorage Zones of Pretensioned Concrete Girders: A Comparison of Nonlinear 3D FEM Results with Measurements on a Full Scale Beam. Appl. Sci. 2020, 10, 8221. [Google Scholar] [CrossRef]

- Fiorineschi, L.; Papini, S.; Pugi, L.; Rindi, A.; Rotini, F. Systematic design of a new gearbox for concrete mixers. J. Eng. Des. Technol. 2020, 18, 2017–2042. [Google Scholar] [CrossRef]

- Zheng, P.; Lin, T.J.; Chen, C.H.; Xu, X. A systematic design approach for service innovation of smart product-service systems. J. Clean. Prod. 2018, 201, 657–667. [Google Scholar] [CrossRef]

- Bakker, T.; Bontsema, J.; Müller, J. Systematic design of an autonomous platform for robotic weeding. J. Terramech. 2010, 47, 63–73. [Google Scholar] [CrossRef]

- Rotini, F.; Becattini, N.; Borgianni, Y.; Fiorineschi, L. Editorial for the Special Issue “Requirements in Design Processes: Open Issues, Relevance and Implications”. Appl. Sci. 2022, 12, 10109. [Google Scholar] [CrossRef]

| Parameters | Value |

|---|---|

| Elastic coefficient of the high stiffness spring [kgf/mm] | 48 |

| Structural damping of the high stiffness spring [N/(m/s)] | 0.02 |

| Preload value of the high stiffness spring [mm] | 13.0 |

| Area of the hydraulic piston presented to the hydraulic pressure [mm2] | 1235.3 |

| Initial position of the two hydraulic cylinder shafts [mm] | 15.0 |

| Total stroke of the two cylinders [mm] | 30.0 |

| Load on each rope [kgf] | 260 |

| Density of the hydraulic oil [kg/m3] | 844.4 |

| Viscosity of the hydraulic oil [cSt] | 15.9869 |

| Part Name | Material | Yield Strength | Ultimate Strength | Poisson’s Ratio | Density |

|---|---|---|---|---|---|

| Housing Base | AL-6063 T5 | 145 MPa | 185 MPa | 0.33 | 2770 kg/m3 |

| Cylinder Shaft | S45C | 580 MPa | 680 MPa | 0.29 | 7850 kg/m3 |

| Rope socket | SS41 | 245 MPa | 510 MPa | 0.30 | 7850 kg/m3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Qin, Z.; Wu, Y.; Cong, J.; Lyu, S.-K. Mechanism Design and Experimental Verification of Novel Automatic Balance Equipment for a Rope-Type Elevator. Machines 2022, 10, 1180. https://doi.org/10.3390/machines10121180

Qin Z, Wu Y, Cong J, Lyu S-K. Mechanism Design and Experimental Verification of Novel Automatic Balance Equipment for a Rope-Type Elevator. Machines. 2022; 10(12):1180. https://doi.org/10.3390/machines10121180

Chicago/Turabian StyleQin, Zhen, Yuting Wu, Jianchen Cong, and Sung-Ki Lyu. 2022. "Mechanism Design and Experimental Verification of Novel Automatic Balance Equipment for a Rope-Type Elevator" Machines 10, no. 12: 1180. https://doi.org/10.3390/machines10121180

APA StyleQin, Z., Wu, Y., Cong, J., & Lyu, S.-K. (2022). Mechanism Design and Experimental Verification of Novel Automatic Balance Equipment for a Rope-Type Elevator. Machines, 10(12), 1180. https://doi.org/10.3390/machines10121180