Calculating the Load Distribution and Contact Stress of the Disposable Harmonic Drive under Full Load

Abstract

:1. Introduction

2. Calculation of Backlash Generated for HDs with No Load

2.1. Design Scheme of Disposable Harmonic Gears

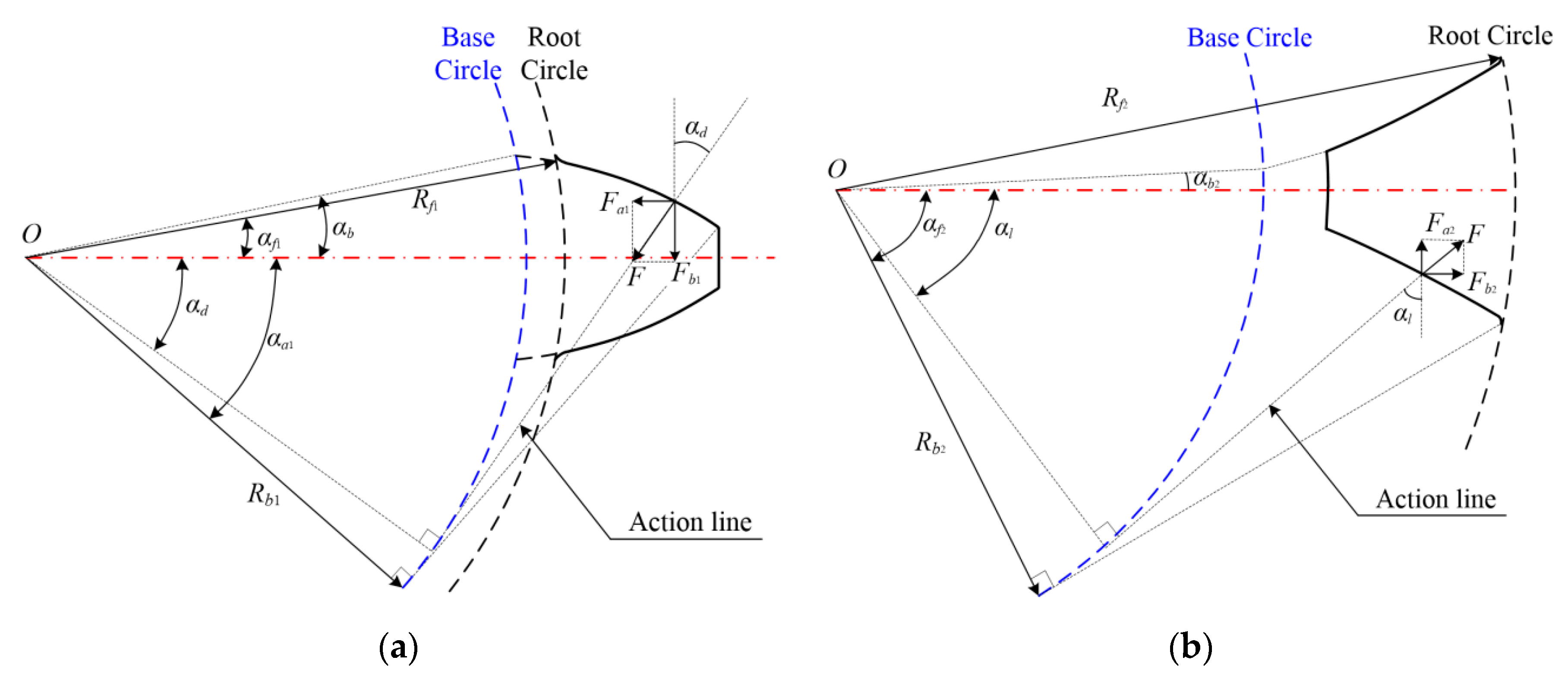

2.2. Calculation of the Backlash Associated with the Involute Profile Harmonic Gear under No Load

3. Load Distribution Calculation of the Harmonic Flexible Wheel

4. Tooth Surface Contact Stress Calculation of the Harmonic Flexible Wheel

5. Finite Element Analysis of the Disposable HD

6. Conclusions

- (1)

- The minimum no-load backlash of the disposable HD occurs at the long axis center of the wave generator. In addition, the minimum and maximum no-load backlashes of the disposable HD in the meshing area are smaller than those of the conventional HD.

- (2)

- Due to different structures, the flexibility of the disposable HD is higher than that of the conventional HD. The load distribution and contact stress of the disposable HD are smaller in the meshing area.

- (3)

- The maximum contact stress of the disposable HD is smaller than the yield strength of the flexible wheel. The disposable harmonic gear can be used for short-time operations under full load.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Taghirad, H.D.; Be’langer, P.R. Modeling and Parameter Identification of Harmonic Drive Systems. J. Dyn. Syst.-T 1998, 120, 439–444. [Google Scholar] [CrossRef]

- Ma, D.; Rao, P.; Yan, S. Kinematics Analysis of Meshed Teeth Pairs of Harmonic Drive Gears Considering the Load Effect Using Computer Vision. In Proceedings of the Automation and Robotics of the 5th International Conference on Control, Beijing, China, 19–22 April 2019; pp. 212–217. [Google Scholar]

- Vivet, M.; Mundo, D.; Tamarozzi, T.; Desmet, W. An analytical model for accurate and numerically efficient tooth contact analysis under load, applied to face-milled spiral bevel gears. Mech. Mach. Theory 2018, 130, 137–156. [Google Scholar] [CrossRef]

- Thomas, B.; Sankaranarayanasamy, K.; Ramachandra, S. Search method applied for gear tooth bending stress prediction in normal contact ratio asymmetric spur gears. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 203–210. [Google Scholar] [CrossRef]

- Mohammed, J.K.; Khdir, Y.K.; Kasab, S.Y. Contact stress analysis of spur gear under the different rotational speed by theoretical and finite element method. Acad. J. Nawroz Univ. 2018, 7, 213–222. [Google Scholar] [CrossRef]

- Wen, Q.; Du, Q.; Zhai, X. An analytical method for calculating the tooth surface contact stress of spur gears with tip relief. Int. J. Mech. Sci. 2019, 151, 170–180. [Google Scholar] [CrossRef]

- Sato, T.; Umezawa, K.; Ishikawa, J. Effects of contact ratio and profile correction of spur gears on the rotational vibration. Trans. JSME Sec. C 1983, 49, 448–455. [Google Scholar] [CrossRef]

- Liou, C.H.; Lin, H.H.; Oswald, F.B. Effect of contact ratio on spur gear dynamic load with no tooth profile modifications. J. Mech. Des. 1996, 118, 439–443. [Google Scholar] [CrossRef]

- Lin, H.H.; Lee, C.W.; Oswaid, F.B.; Townsend, D.P. Townsend, Computer-aided design of high-contact-ratio gears for minimum dynamic load and stress. J. Mech. Des. 1993, 115, 171–178. [Google Scholar] [CrossRef]

- Kahraman, A.; Blankenship, G.W. Gear dynamics experiments, part-2: Effect of involute contact ratio. Power Transm. Gearing Conf. 1996, 88, 381–396. [Google Scholar]

- Li, S.T. Gear contact model and loaded tooth contact analysis of a three-dimensional, thin-rimmed gear. J. Mech. Des. 2002, 124, 511–517. [Google Scholar] [CrossRef]

- Li, S.T. Deformation and Bending Stress Analysis of a Three-dimensional, Thin-rimmed Gear. J. Mech. Des. 2002, 124, 129–135. [Google Scholar] [CrossRef]

- Ravivarman, R.; Palaniradja, K.; Sekar, R.P. Evolution of balanced root stress and tribological properties in high contact ratio spur gear drive. Mech. Mach. Theory 2018, 126, 491–513. [Google Scholar] [CrossRef]

- Wang, Y.; Ren, S.; Li, Y. Design and manufacturing of a novel high contact ratio internal gear with a circular arc contact path. Int. J. Mech. Sci. 2019, 153, 143–153. [Google Scholar] [CrossRef]

- Huang, K.; Yi, Y.; Xiong, Y. Nonlinear dynamics analysis of high contact ratio gears system with multiple clearances. J. Braz. Soc. Mech. Sci. Eng. 2020, 42, 98. [Google Scholar] [CrossRef]

- Jia, C.; Fang, Z. Design and analysis of double-crowned high-contact-ratio cylindrical gears considering the load sharing of the multi-pair contact. Mech. Mach. Theory 2019, 131, 92–114. [Google Scholar] [CrossRef]

- Sun, X.; Han, L.; Wang, J. Tooth modification and loaded tooth contact analysis of China Bearing Reducer. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2019, 233, 6240–6261. [Google Scholar] [CrossRef]

- Rama, T.; Clement, C.D. Study on the quality and tooth root load carrying capacity of the high contact ratio asymmetrical gear tooth machined using WCEDM process. Mater. Manuf. Process. 2020, 35, 1352–1361. [Google Scholar]

- Yifan, H.F.; Zhao, Z.F.; Ma, H. Effects of tooth modification on the dynamic characteristics of thin-rimmed gears under surface wear. Mech. Mach. Theory 2020, 150, 103870. [Google Scholar]

- Donghui, M.; Jianing, W.; Liu, T. Deformation analysis of the flexspline of harmonic drive gears considering the driving speed effect using laser sensors. Sci. China Technol. Sci. 2017, 60, 1175–1187. [Google Scholar]

- Dong, H.M. Elastic deformation characteristic of the flexible wheel in harmonic drive. In ASME/IFToMM International Conference on Reconfigurable Mechanisms and Robots (ReMAR); IEEE: London, UK, 2009; pp. 363–369. [Google Scholar]

- Dong, H.M.; Zhu, Z.D.; Zhou, W.D. Dynamic Simulation of Harmonic Gear Drives Considering Tooth Profiles Parameters Optimization. J. Comput. 2012, 7, 1429–1436. [Google Scholar] [CrossRef] [Green Version]

- Chen, X.X.; Lin, S.Z.; Xing, J.Z. Deformation of flexible wheel under transmission force in harmonic drive. Adv. Mat. Res. 2010, 97–101, 3536–3539. [Google Scholar]

- Chen, X.X.; Liu, Y.S.; Xing, J.Z. A novel method based on mechanical analysis for the stretch of the neutral line of the flexible wheel cup of a harmonic drive. Mech. Mach. Theory 2014, 76, 189–196. [Google Scholar] [CrossRef]

- Chen, X.X.; Liu, Y.S.; Xing, J.Z. Neutral line of flexible wheel in harmonic driver. J. Mech. Eng. 2014, 50, 1–19. [Google Scholar] [CrossRef]

- Kayabasi, O.; Erzincanli, F. Shape optimization of tooth profile of a flexible wheel for a HD by finite element modeling. Mater. Des. 2007, 28, 441–447. [Google Scholar] [CrossRef]

- Chen, X.; Liu, Y.; Xing, J. The parametric design of double-circular-arc tooth profile and its influence on the functional backlash of HD. Mech. Mach. Theory 2014, 73, 1–24. [Google Scholar] [CrossRef]

- Le, K.X.; Quan, Y.X.; Zhou, G.R. Theoretical calculation of space dynamic meshing loads in harmonic gear drive. J. Zhejiang Univ. 1995, 2, 219–229. [Google Scholar]

- Zou, C.; Tao, T.; Jiang, G. Deformation and stress analysis of short flexible wheel in the HD system with load. In Proceedings of the 2013 IEEE International Conference on Mechatronics and Automation, Takamatsu, Japan, 4–7 August 2013; pp. 676–680. [Google Scholar]

- Sahoo, V.; Maiti, R. Evidence of secondary tooth contact in HD, with involute toothed gear pair, through experimental and finite element analyses of stresses in flex-gear cup. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2018, 232, 341–357. [Google Scholar] [CrossRef]

- Routh, B.; Maiti, R.; Ray, A.K. An investigation on secondary force contacts of tooth pairs in conventional HDs with involute toothed gear set. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2016, 230, 622–638. [Google Scholar] [CrossRef]

- Yang, C.; Hu, Q.; Liu, Z. Analysis of the Partial Axial Load of a Very Thin-Walled Spur-Gear (Flexible wheel) of a HD. Int. J. Precis. Eng. Man. 2020, 30, 1–13. [Google Scholar]

- Sahoo, V.; Maiti, R. Load sharing by tooth pairs in involute toothed HD with conventional wave generator cam. Meccanica 2018, 53, 373–394. [Google Scholar] [CrossRef]

- Sahoo, V.; Mahanto, B.S.; Maiti, R. Stresses in flex gear of a novel HD with and without pay load. Aust. J. Mech. Eng. 2020, 1, 1–15. [Google Scholar] [CrossRef]

- Xie, J.R. The meshing analysis method of the harmonic gear drive with the elliptical cam wave generator. Opt. Precis. Eng. 1980, 3, 33–40. [Google Scholar]

- Kokhanovskii, G.I.; Polenov, V.S.; Spiridonov, V.V. Calculating the stress and strain state of the flexible wheel of a wave toothed transmission. Sov. Appl. Mech. 1973, 9, 1355–1358. [Google Scholar] [CrossRef]

- Polenov, V.S. Investigation of the stress-strain state of flexible elements in wave drives. Sov. Appl. Mech. 1981, 17, 34–39. [Google Scholar] [CrossRef]

| The Conventional HD | The Disposable HD | |||

|---|---|---|---|---|

| Parameter | Flexible Wheel | Rigid Wheel | Flexible Wheel | Rigid Wheel |

| Number of teeth Z | 200 | 202 | 200 | 202 |

| Module m (mm) | 0.16 | 0.16 | 0.16 | 0.16 |

| Teeth width L (mm) | 10 | 10 | 10 | 10 |

| Modification coefficient | 2.3 | 2.0 | 2.7 | 2.85 |

| Total length l (mm) | 35 | 10 | ||

| Pressure angle α0 (°) | 20 | 20 | ||

| Transmission ratio | 100 | 100 | ||

| Flexible Wheel | Rigid Wheel and Wave Generator | |

|---|---|---|

| Material | 40CrNiMoA | 45Steel |

| Density ρ (kg/m3) | 7850 | 7870 |

| Young’s modulus E (MPa) | 211,000 | 209,000 |

| Poisson’s ratio ν | 0.3 | 0.27 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhang, Y.; Wang, G.; Pan, X.; Li, Y. Calculating the Load Distribution and Contact Stress of the Disposable Harmonic Drive under Full Load. Machines 2022, 10, 96. https://doi.org/10.3390/machines10020096

Zhang Y, Wang G, Pan X, Li Y. Calculating the Load Distribution and Contact Stress of the Disposable Harmonic Drive under Full Load. Machines. 2022; 10(2):96. https://doi.org/10.3390/machines10020096

Chicago/Turabian StyleZhang, Yuxin, Guanglin Wang, Xudong Pan, and Yuefeng Li. 2022. "Calculating the Load Distribution and Contact Stress of the Disposable Harmonic Drive under Full Load" Machines 10, no. 2: 96. https://doi.org/10.3390/machines10020096