Effect of Inlet Condition on the Performance Curve of a 10 MW Supercritical Carbon Dioxide Centrifugal Compressor

Abstract

:1. Introduction

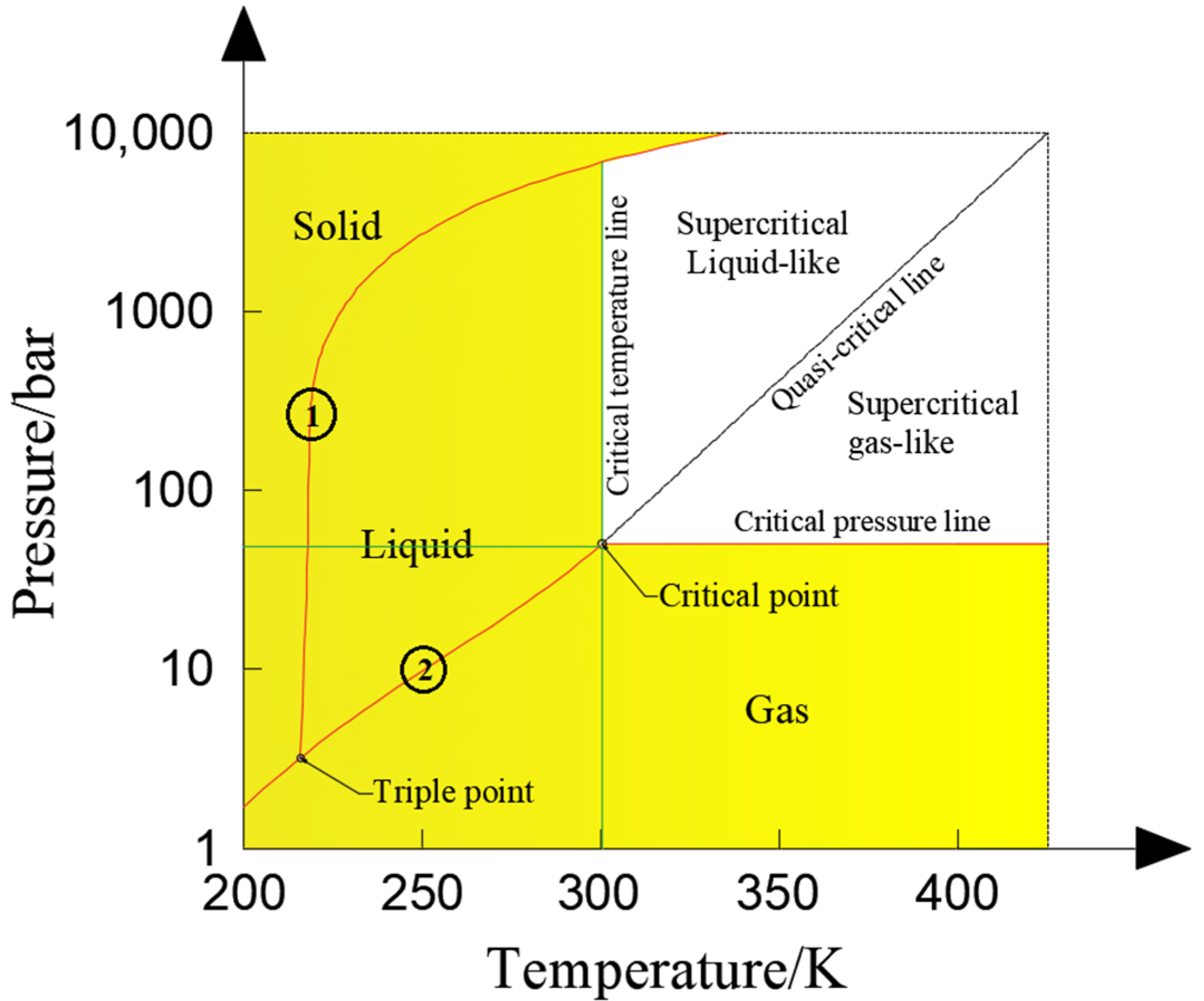

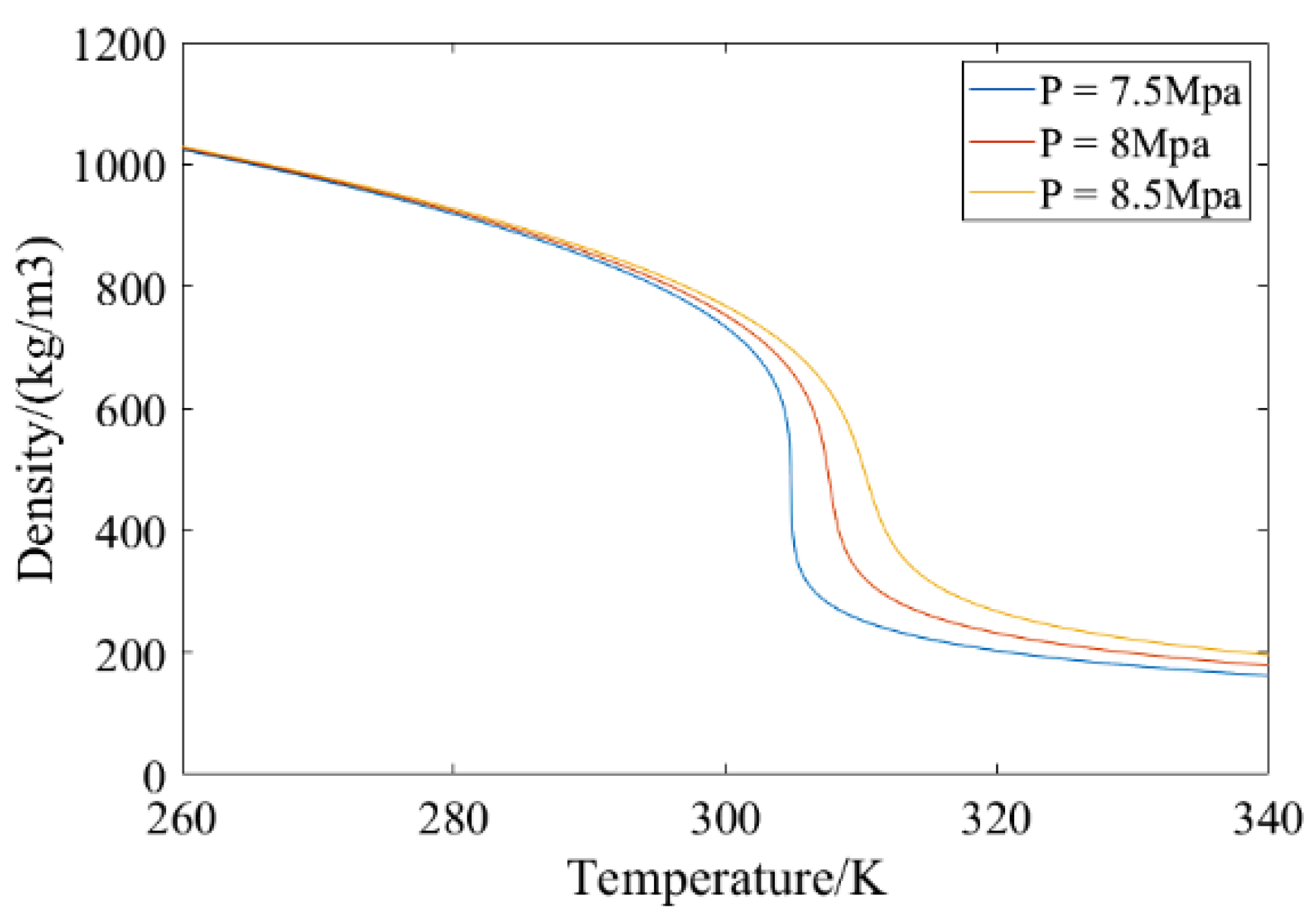

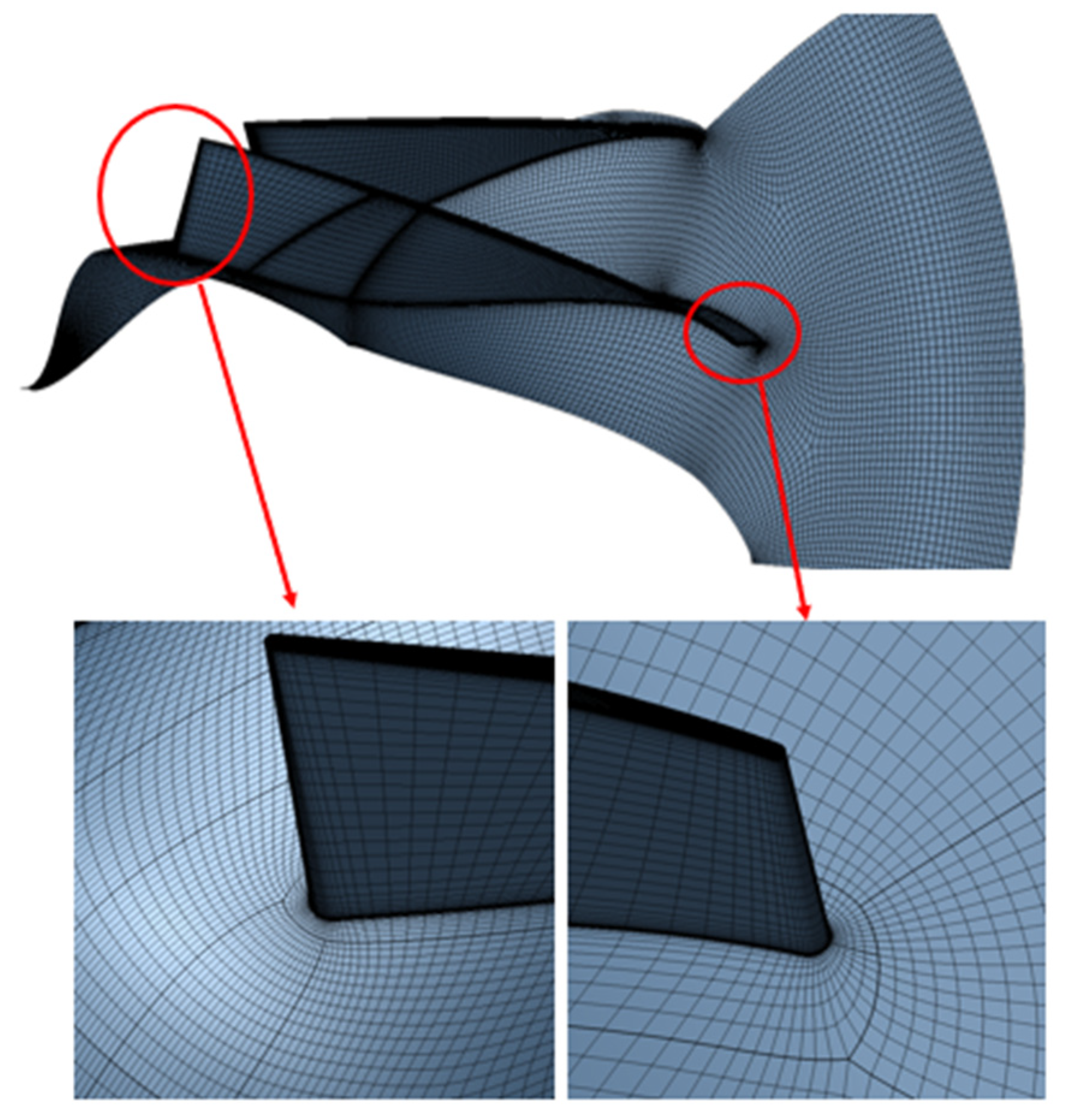

2. Thermophysical Property of S-CO2 near the Critical Point

3. Geometric Model and Numerical Setup

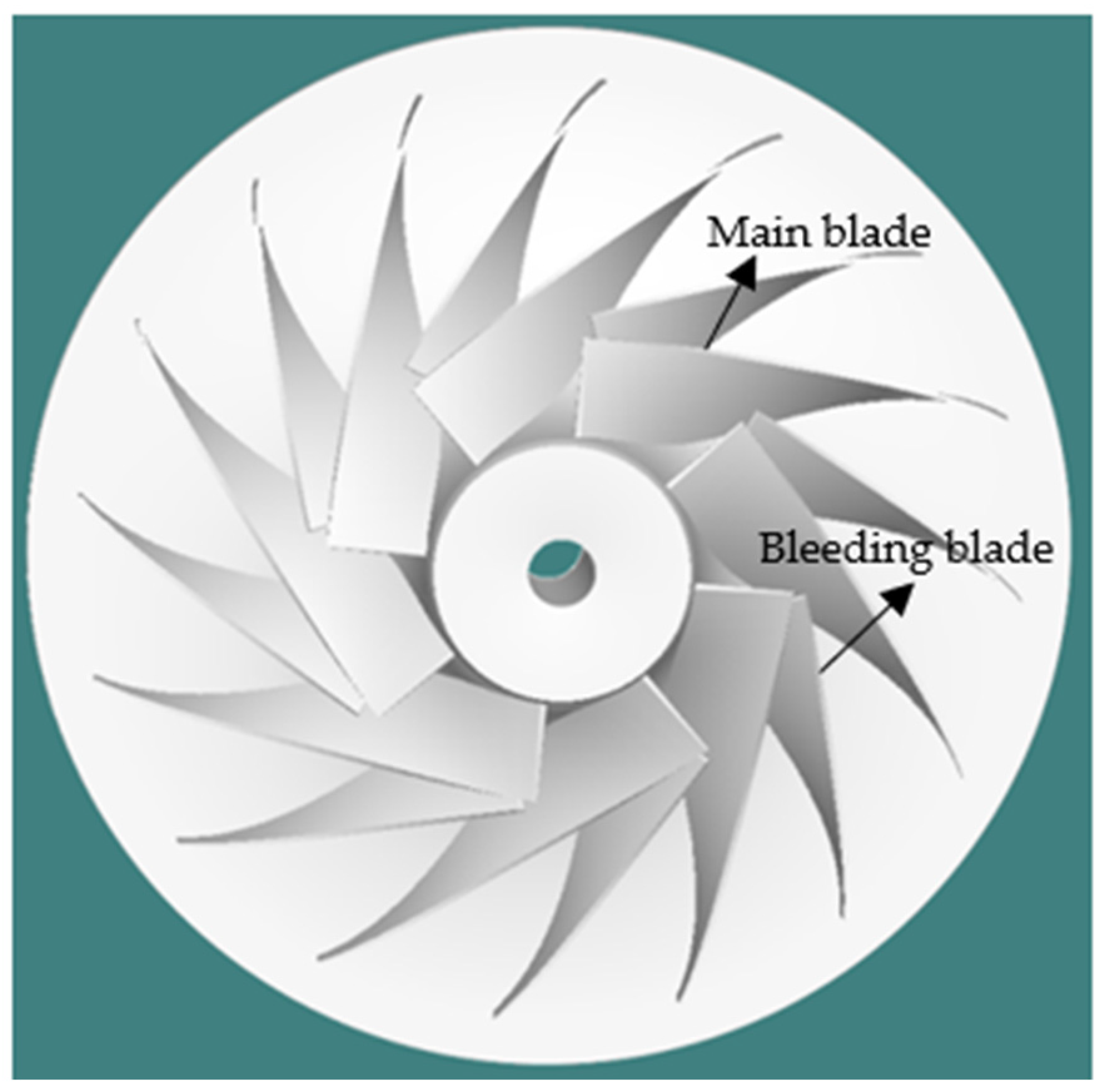

3.1. Geometric Model of the 10 MW Centrifugal Compressor

3.2. Resolution Verification of Thermophysical Properties

3.3. Numerical Method and Validation

4. Result and Discussion

4.1. Performance Prediction at the Nominal Inlet Condition

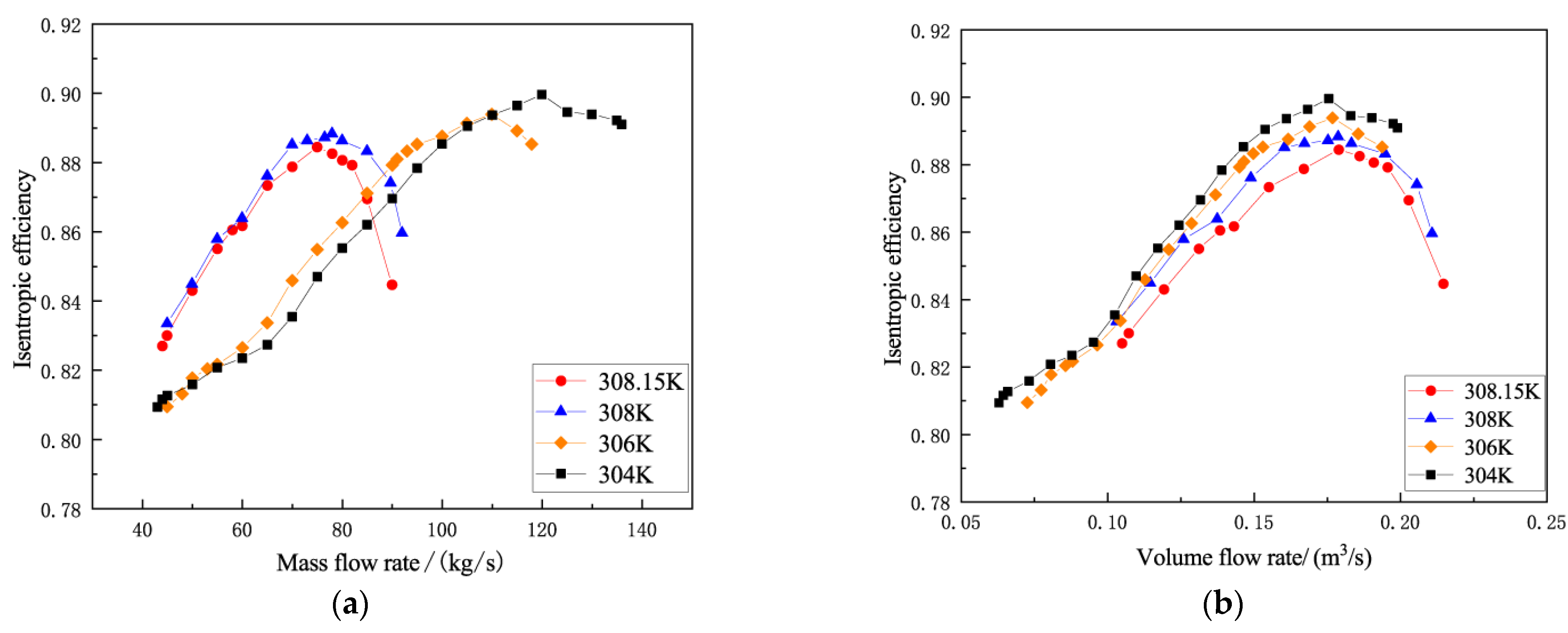

4.2. The Influence of Inlet Temperature

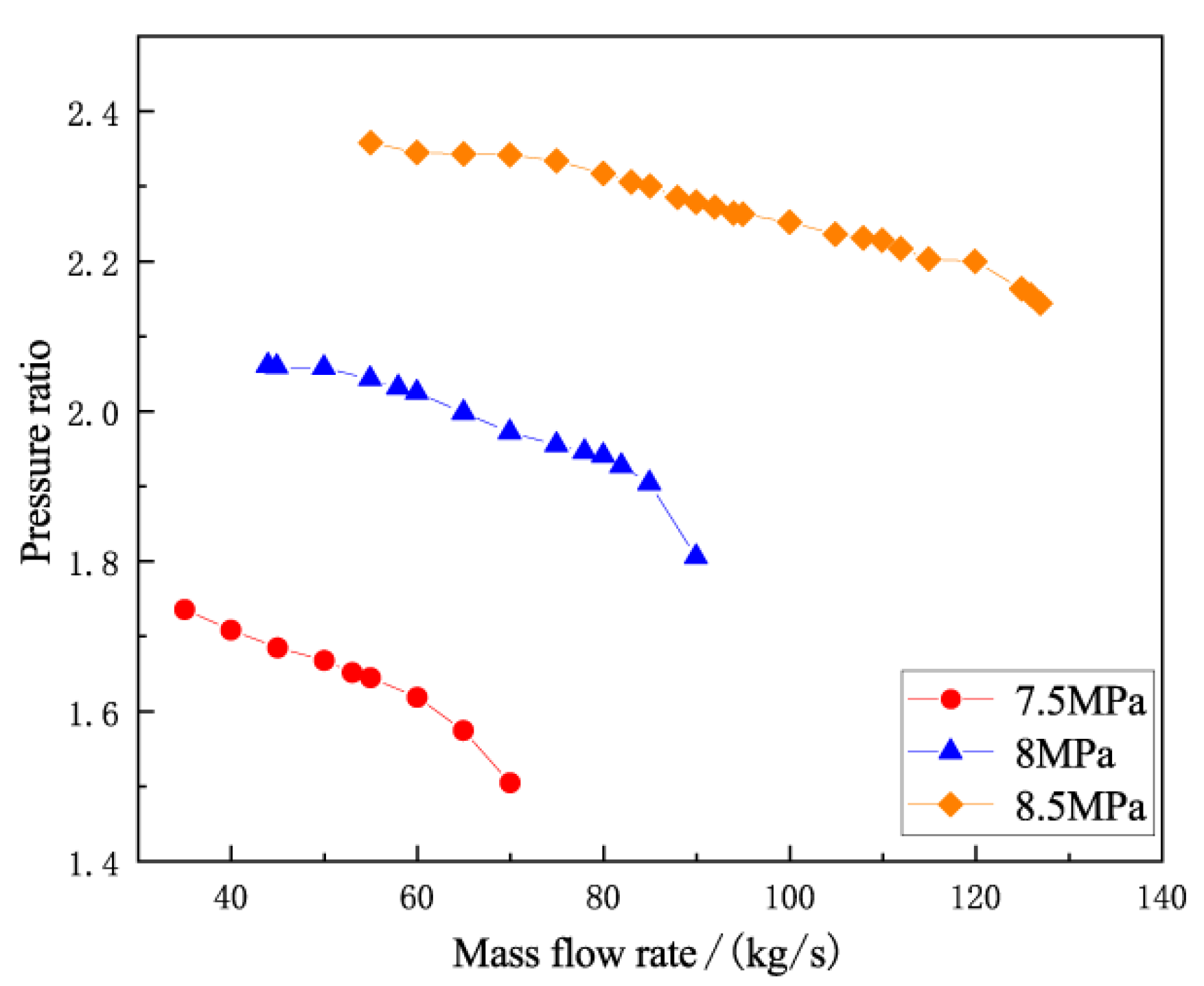

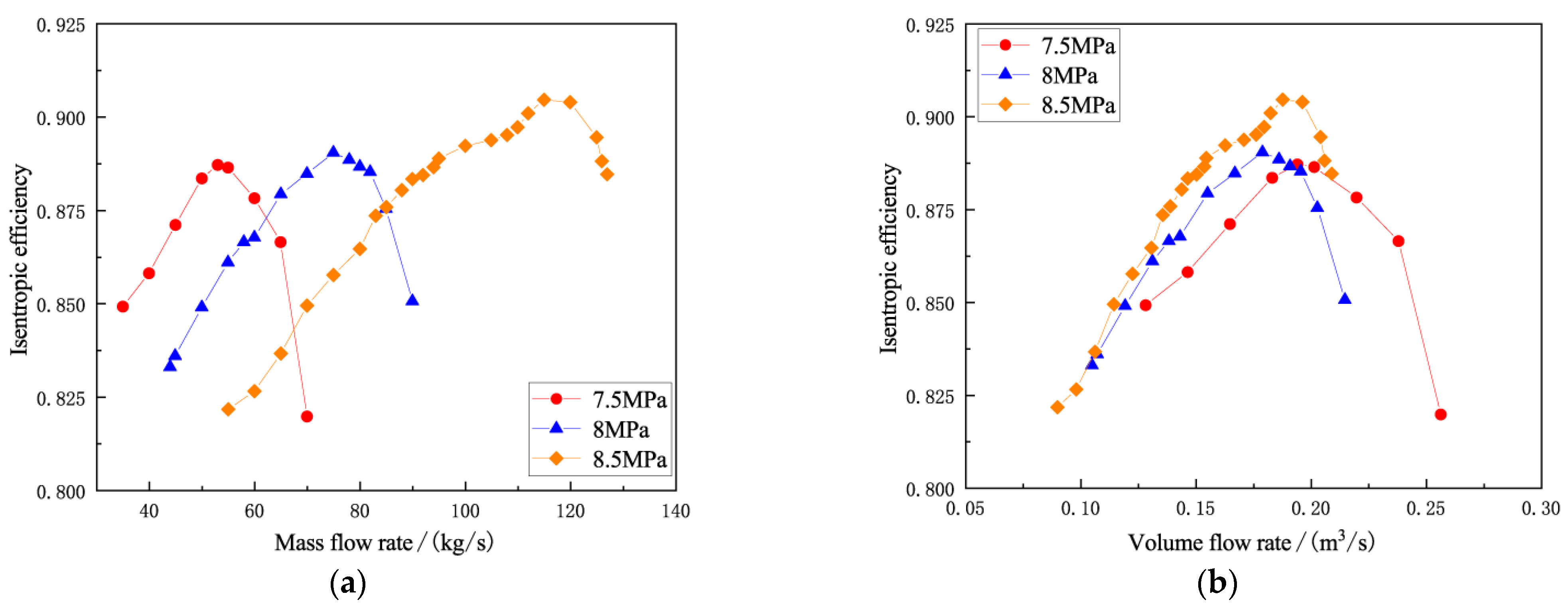

4.3. The Influence of Inlet Pressure

5. Conclusions

- (1)

- The higher pressure ratio of the S-CO2 centrifugal compressor can be obtained at a lower inlet temperature or a higher inlet pressure, mainly attributed to the smaller compressibility factor of CO2 at the compressor inlet;

- (2)

- When the inlet state of CO2 approaches the liquid-like phase, i.e., the inlet temperature decreases, or the inlet pressure decreases, the S-CO2 centrifugal compressor has a higher isentropic efficiency under the same volumetric flow rate;

- (3)

- Compared with the gas-like state, the wider surge margin but a narrower chocking margin occur for the S-CO2 centrifugal compressor at the inlet liquid-like state.

Author Contributions

Funding

Conflicts of Interest

References

- Angelino, G. Carbon dioxide condensation cycles for power production. J. Eng. Power 1968, 90, 287–295. [Google Scholar] [CrossRef]

- Feher, E.G. The supercritical thermodynamic power cycle. Energy Convers. 1968, 8, 85–90. [Google Scholar] [CrossRef]

- Clementoni, E.M.; Cox, T.L. Effect of compressor inlet pressure on cycle performance for a supercritical carbon dioxide Brayton cycle. In Proceedings of the ASME Turbo Expo 2018, Oslo, Norway, 11–15 June 2018. [Google Scholar]

- Wright, S.A.; Radel, R.F.; Vernon, M.E.; Rochau, G.E.; Pickard, P.S. Operation and Analysis of a Supercritical CO2 Brayton Cycle; Report: SAND2010-0171; Sandia National Laboratories: Albuquerque, NM, USA; Livermore, CA, USA, 2010. [Google Scholar]

- Ahn, Y.; Lee, J.; Kim, S.G.; Lee, J.I.; Cha, J.E.; Lee, S.W. Design consideration of supercritical CO2 power cycle integral experiment loop. Energy 2015, 86, 115–127. [Google Scholar] [CrossRef]

- Lewis, J.; Clementoni, E.M.; Cox, T.L. Effect of compressor inlet temperature on cycle performance for a supercritical carbon dioxide Brayton cycle. In Proceedings of the 6th sCO2 Power cycle symposium, Pittsburgh, PA, USA, 27–29 March 2018. [Google Scholar]

- Zhu, Y.M.; Jiang, Y.Y.; Liang, S.Q.; Guo, C.H.; Guo, Y.X.; Gao, F.; Xia, H.F. Experimental research progress of supercritical carbon dioxide Brayton cycle compress. Therm. Power Gener. 2020, 49, 11–20. [Google Scholar]

- Chen, H.X.; Zhuge, W.L.; Zhang, Y.J.; Liu, H.D. Effect of compressor inlet condition on supercritical carbon dioxide compressor performance. In Proceedings of the ASME Turbo Expo 2019, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Liu, X.H.; Teng, J.F.; Yang, J.; Sun, X.F.; Sun, D.K.; He, C.; Du, J. Calculation of stall margin enhancement with micro-tip injection in an axial compressor. J. Fluids Eng. 2019, 141, 081109. [Google Scholar] [CrossRef]

- Zhang, L.; He, R.Y.; Wang, X.; Zhang, Q.; Wang, S.L. Study on static and dynamic characteristics of an axial fan with abnormal blade under rotating stall conditions. Energy 2019, 170, 305–325. [Google Scholar] [CrossRef]

- Zhang, L.; He, R.Y.; Wang, S.L.; Zhang, Q. A review of rotating stall in vaneless diffuser of centrifugal compressor. J. Therm. Sci. 2020, 29, 323–342. [Google Scholar] [CrossRef]

- Munroe, T.A.; Zaccaria, M.A.; Flaspohler, W.H. Fluent CFD steady-state predictions of a single stage centrifugal compressor with supercritical CO2 working fluid. In Proceedings of the sCO2 Power cycle symposium, New York, NY, USA, 29–30 April 2009. [Google Scholar]

- Pecnik, R.; Rinaldi, E.; Colonna, P. Computational fluid dynamics of a radial compressor operating with supercritical CO2. In Proceedings of the ASME Turbo Expo 2012, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar]

- Kim, S.G.; Ahn, Y.; Lee, J.; Lee, J.I.; Addad, Y.; Ko, B. Numerical investigation of a centrifugal compressor for supercritical CO2 as a working fluid. In Proceedings of the ASME Turbo Expo 2014, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Zhao, H.; Deng, Q.H.; Zheng, K.K.; Zhang, H.Z.; Feng, Z.P. Numerical investigation on the flow characteristics of a supercritical CO2 centrifugal compressor. In Proceedings of the ASME Turbo Expo 2014, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Zheng, K.K.; Zhao, H.; Feng, Z.P. Analysis of internal flow characteristics of supercritical carbon dioxide centrifugal compressor. J. Eng. Thermophys. 2015, 36, 985–988. [Google Scholar]

- Rindldi, E.; Pecnik, R.; Colonna, P. Computational fluid dynamic simulation of a supercritical CO2 compressor performance map. J. Eng. Gas Turbines Power 2015, 137, 072602. [Google Scholar] [CrossRef]

- Jiang, X.F.; Tian, Y.; Shao, W.W.; Xiao, Y.H. Numerical simulation of supercritical CO2 compressor characteristics. J. Aerosp. Power 2018, 33, 1685–1694. [Google Scholar]

- Wright, S.A.; Pickard, P.S.; Fuller, R.; Radel, R.F.; Vernon, M.E. Supercritical CO2 Brayton cycle power generation development program and initial test results. In Proceedings of the ASME 2009 Power Conference, Albuquerque, NM, USA, 21–23 July 2009. [Google Scholar]

- Rinaldi, E.; Pecnik, R.; Colonna, P. Numerical computation of the performance map of a supercritical CO2 radial compressor by means of three-dimensional CFD simulations. In Proceedings of the ASME Turbo Expo 2014, Düsseldorf, Germany, 16–20 June 2014. [Google Scholar]

- Monje, B. Design of Supercritical Carbon Dioxide Centrifugal Compressor. Ph.D. Thesis, University of Seville, Sevilla, Spain, 2014. [Google Scholar]

- Wang, W.Y. Research on the Flow Characteristics of Supercritical Carbon Dioxide Centrifugal Compressor. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2018. [Google Scholar]

- Fleming, D.; Holsschuh, T.; Conboy, T.; Rochau, G.; Fuller, R. Scaling considerations for a multi-megawatt class supercritical CO2 Brayton cycle and path forward for commercialization. In Proceedings of the ASME Turbo Expo 2012, Copenhagen, Denmark, 11–15 June 2012. [Google Scholar]

| Parameter | Specification | Parameter | Specification |

|---|---|---|---|

| Working fluid | CO2 | Inlet total temperature (K) | 308.15 |

| Rotating speed (r/min) | 16,500 | Inlet total pressure (MPa) | 8.0 |

| Mass flow rate (kg/s) | 75.0 | Pressure ratio | 2.0 |

| Parameter | Value | Parameter | Value |

|---|---|---|---|

| Inlet hub radius (mm) | 2.5 | Tip clearance (mm) | 0.4 |

| Inlet shroud radius (mm) | 43.76 | Inlet blade angle at tip (°) | 32 |

| Outlet shroud radius (mm) | 96.53 | Outlet blade angle at tip (°) | 46 |

| Blade height at outlet (mm) | 9.81 | Main blade number | 8 |

| Blade thickness (mm) | 1.0 | Bleeding blade number | 8 |

| Set | Pressure Range (MPa) | Temperature Range (K) | Resolution | Pressure Ratio | Isentropic Efficiency (%) |

|---|---|---|---|---|---|

| 1 | 0.005–800 | 216.59–2000 | 101 × 101 | 1.976 | 77.24 |

| 2 | 1–40 | 220–1000 | 101 × 101 | 1..979 | 86.78 |

| 3 | 1–40 | 220–1000 | 301 × 301 | 1.955 | 87.95 |

| 4 | 1–20 | 220–500 | 301 × 301 | 1.956 | 88.01 |

| Grid Number (Million) | Pressure Ratio | Isentropic Efficiency (%) |

|---|---|---|

| 0.81 | 1.789 | 83.12 |

| 1.35 | 1.963 | 87.16 |

| 1.62 | 2.032 | 89.33 |

| 1.93 | 2.035 | 89.38 |

| Inlet Total Temperature (K) | Inlet Total Pressure (MPa) | Compressibility Factor | Inlet Total Density (kg/m3) |

|---|---|---|---|

| 304.00 | 8.0 | 0.204 | 683.31 |

| 306.00 | 8.0 | 0.223 | 620.55 |

| 308.00 | 8.0 | 0.315 | 436.24 |

| 308.15 | 8.0 | 0.328 | 419.09 |

| Inlet Total Temperature (K) | Inlet Total Pressure (MPa) | Compressibility Factor | Inlet Total Density (kg/m3) |

|---|---|---|---|

| 308.15 | 7.5 | 0.472 | 272.97 |

| 308.15 | 8 | 0.328 | 419.09 |

| 308.15 | 8.5 | 0.239 | 612.12 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tong, Z.; Yang, X.; Shang, P.; Ma, J.; Zhang, Y.; Zhang, C. Effect of Inlet Condition on the Performance Curve of a 10 MW Supercritical Carbon Dioxide Centrifugal Compressor. Machines 2022, 10, 359. https://doi.org/10.3390/machines10050359

Tong Z, Yang X, Shang P, Ma J, Zhang Y, Zhang C. Effect of Inlet Condition on the Performance Curve of a 10 MW Supercritical Carbon Dioxide Centrifugal Compressor. Machines. 2022; 10(5):359. https://doi.org/10.3390/machines10050359

Chicago/Turabian StyleTong, Zhiting, Xiaomin Yang, Pengxu Shang, Jingyuan Ma, Yue Zhang, and Chao Zhang. 2022. "Effect of Inlet Condition on the Performance Curve of a 10 MW Supercritical Carbon Dioxide Centrifugal Compressor" Machines 10, no. 5: 359. https://doi.org/10.3390/machines10050359

APA StyleTong, Z., Yang, X., Shang, P., Ma, J., Zhang, Y., & Zhang, C. (2022). Effect of Inlet Condition on the Performance Curve of a 10 MW Supercritical Carbon Dioxide Centrifugal Compressor. Machines, 10(5), 359. https://doi.org/10.3390/machines10050359