Optimization Approaches and Techniques for Automotive Alternators: Review Study

Abstract

:1. Introduction

2. Optimization Methods

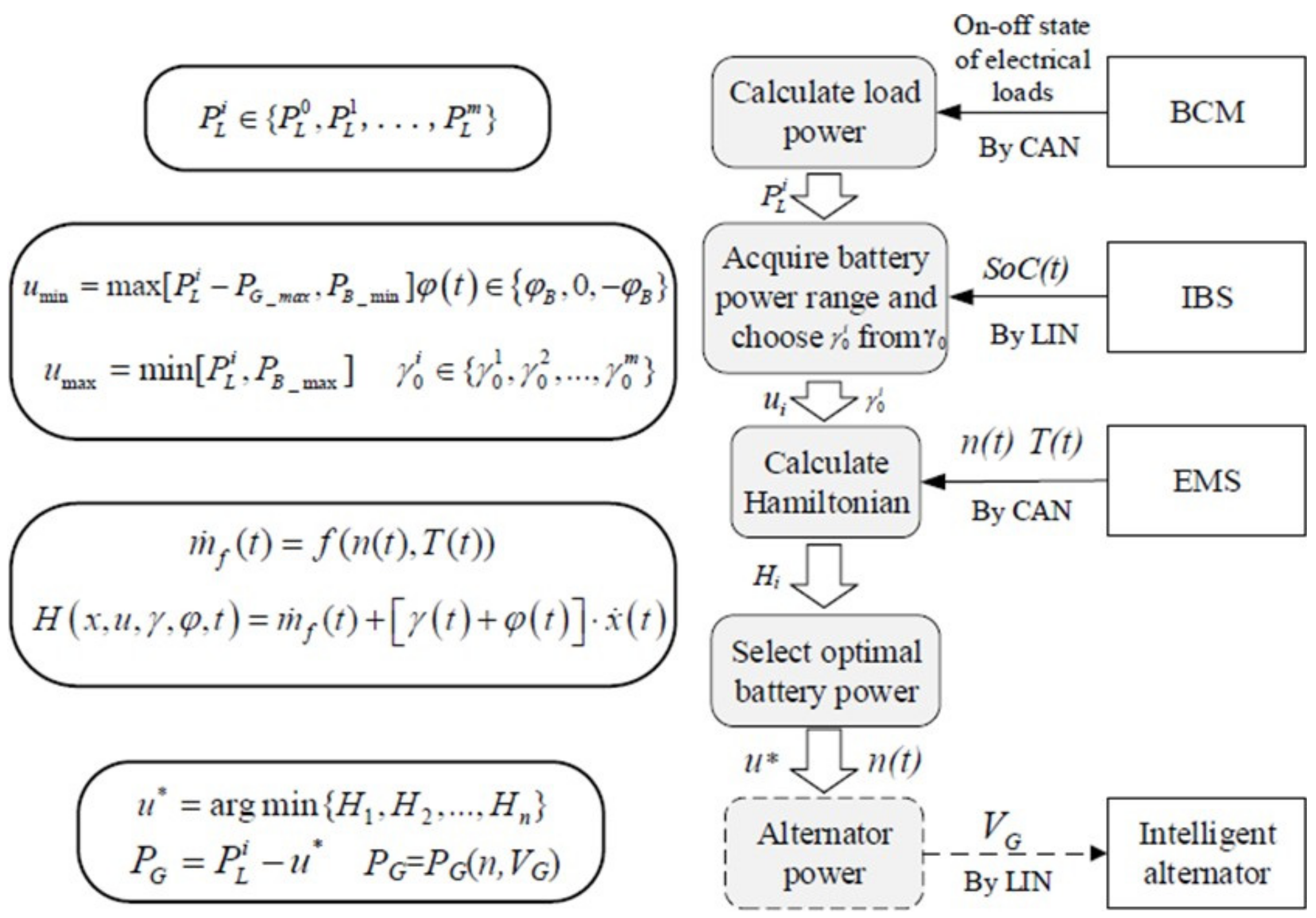

2.1. Pontryagin’s Minimum Principle (PMP)

2.2. Optimal Power Distribution (OPD)

2.3. Equivalent Consumption Minimization Strategy (ECMS)

2.4. Model Predictive Controller (MPC) and Modified Dynamic Programming (DP)

2.5. Teaching-Learning-Based Optimization (TLBO)

2.6. DCR (Driving Cycle Recognition) and ELP (Electrical Load Perception) Algorithms

2.7. Multi-Objective Optimization Approach

2.8. Quadratic Optimization

2.9. Convex Optimization Algorithm

2.10. Real-Time Energy Management Strategy (R-EMS)

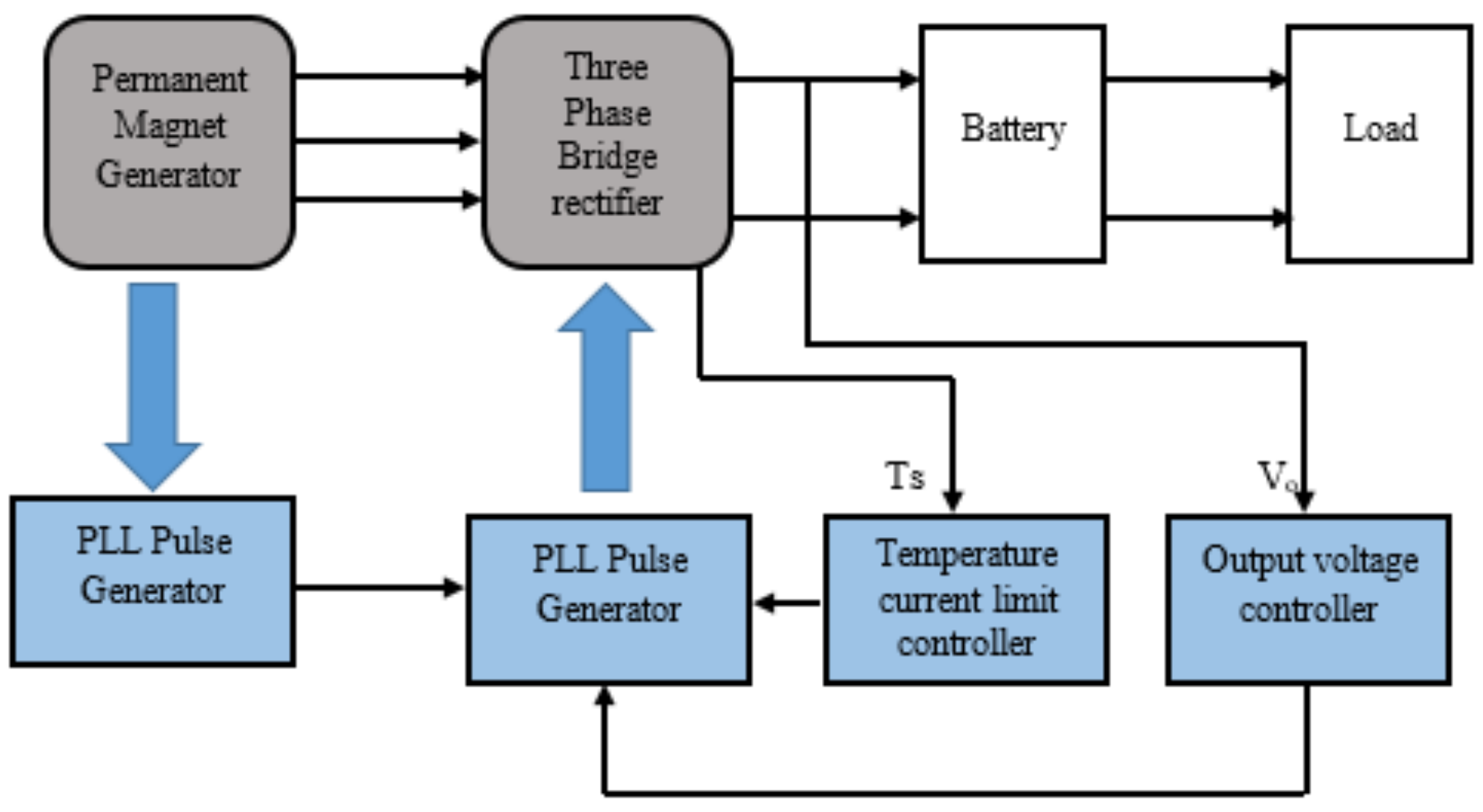

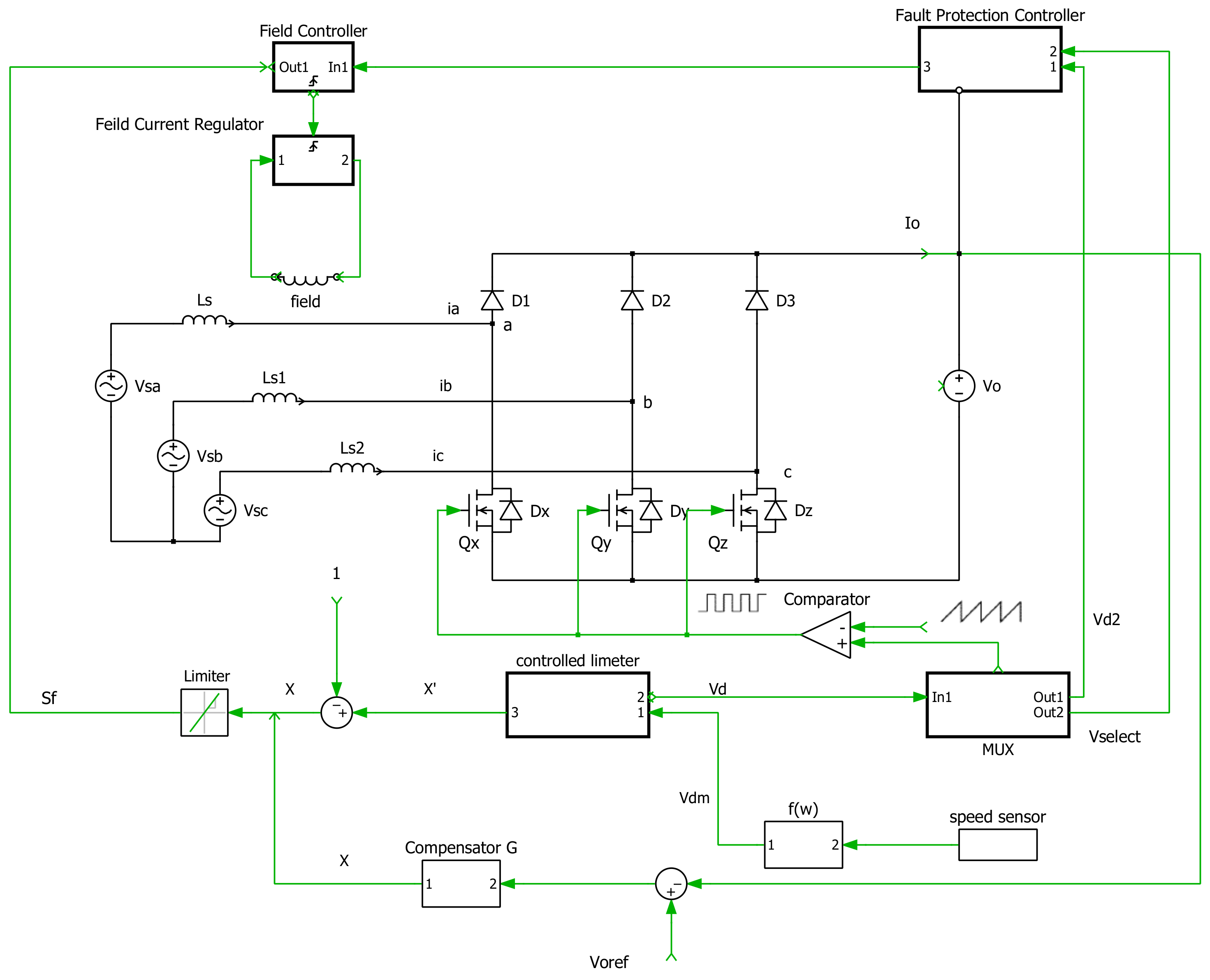

3. Optimization Using Power Electronic Techniques

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Mazlan, R.K.; Dan, R.M.; Zakaria, M.Z.; Hamid, A.H.A. Experimental study on the effect of alternator speed to the car charging system. MATEC Web Conf. 2016, 90, 1076. [Google Scholar] [CrossRef] [Green Version]

- Ali, H.; Sulaiman, E.; Aziz, R.; Jenal, M.; Ahmad, M.Z.; Khan, F. Review of Double Stator Flux switching machines with various arrangements of excitation sources. Alex. Eng. J. 2021, 60, 4393–4410. [Google Scholar] [CrossRef]

- Chiara, F.; Canova, M. A review of energy consumption, management, and recovery in automotive systems, with considerations of future trends. Proc. Inst. Mech. Eng. Part D J. Automob. Eng. 2013, 227, 914–936. [Google Scholar] [CrossRef]

- Gecha, V.Y.; Goncharov, V.I.; Chirkin, V.G.; Shirinskii, S.V.; Petrichenko, D.A. Linear Alternator with Reciprocating Mover: Review of Designs and Machine Types. Biosci. Biotechnol. Res. Asia 2015, 12, 409–418. [Google Scholar] [CrossRef]

- Kamalakannan, C.; Kamaraj, V.; Paramasivam, S.; Paranjothi, S.R. Switched Reluctance Machine in Automotive Applications A Technology Status Review. In Proceedings of the 1st International Conference on Electrical Energy Systems, Chennai, India, 3–5 January 2011; pp. 187–197. [Google Scholar] [CrossRef]

- Li, S.; Zhang, S.; Habetler, T.G.; Harley, R.G. Modeling, Design Optimization, and Applications of Switched Reluctance Machines—A Review. IEEE Trans. Ind. Appl. 2019, 55, 2660–2681. [Google Scholar] [CrossRef]

- Rahman, S.A.; Masjuki, H.; Kalam, M.; Abedin, M.; Sanjid, A.; Sajjad, H. Impact of idling on fuel consumption and exhaust emissions and available idle-reduction technologies for diesel vehicles—A review. Energy Convers. Manag. 2013, 74, 171–182. [Google Scholar] [CrossRef]

- Reddy, K.J.; Natarajan, S. Energy sources and multi-input DC-DC converters used in hybrid electric vehicle applications—A review. Int. J. Hydrogen Energy 2018, 43, 17387–17408. [Google Scholar] [CrossRef]

- Boldea, I. Automobile Electrification Trends: A Review. In Proceedings of the 2007 International Aegean Conference on Electrical Machines and Power Electronics, Bodrum, Turkey, 10–12 September 2007; pp. 369–377. [Google Scholar] [CrossRef]

- Saponara, S.; Lee, C.H.; Wang, N.X.; Kirtley, J.L. Electric Drives and Power Chargers: Recent Solutions to Improve Performance and Energy Efficiency for Hybrid and Fully Electric Vehicles. IEEE Veh. Technol. Mag. 2020, 15, 73–83. [Google Scholar] [CrossRef]

- Gathadi, P.; Bhole, A. Electric Motors and Rotor Position Detection Techniques of Integrated Starter Alternator for HEV: A Review. In Proceedings of the 2018 International Conference on Current Trends towards Converging Technologies (ICCTCT), Coimbatore, India, 1–3 March 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Enang, W.; Bannister, C. Modelling and control of hybrid electric vehicles (A comprehensive review). Renew. Sustain. Energy Rev. 2017, 74, 1210–1239. [Google Scholar] [CrossRef] [Green Version]

- Waldman, C.; Gurusubramanian, S.; Fiorentini, L.; Canova, M. A model-based supervisory energy management strategy for a 12 V vehicle electrical system. Control Eng. Pr. 2015, 44, 20–30. [Google Scholar] [CrossRef] [Green Version]

- Wang, Y.; Hu, H.; Zhang, L.; Zhang, N.; Sun, X. Real-Time Vehicle Energy Management System Based on Optimized Distribution of Electrical Load Power. Appl. Sci. 2016, 6, 285. [Google Scholar] [CrossRef] [Green Version]

- Couch, J.; Fiorentini, L.; Canova, M. An ECMS-Based Approach for the Energy Management of a Vehicle Electrical System. IFAC Proc. Vol. 2013, 46, 115–120. [Google Scholar] [CrossRef]

- Koot, M.; Kessels, J.T.; de Jager, B.; Heemels, W.P.M.H.; van den Bosch, P.P.J.; Steinbuch, M. Energy management strategies for vehicular electric power systems. IEEE Trans. Veh. Technol. 2005, 54, 771–782. [Google Scholar] [CrossRef]

- Han, Z.; Hu, Y.; Sun, P.; Chen, H. Model Predictive Control of Diesel Engine Start-Stop Control in an HEV. In Proceedings of the 36th Chinese Control Conference (CCC), Dalian, China, 26–28 July 2017. [Google Scholar] [CrossRef]

- Chatterjee, S.; Mukherjee, V. PID controller for automatic voltage regulator using teaching–learning based optimization technique. Int. J. Electr. Power Energy Syst. 2016, 77, 418–429. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, N.; Wu, Y.; Liu, B.; Wu, Y. A strategy of electrical energy management for internal combustion engine vehicle based on driving cycle recognition and electrical load perception. Adv. Mech. Eng. 2018, 10, 1687814018809236. [Google Scholar] [CrossRef]

- Winter, M.; Taube, J.; Herzog, H.-G. Simulation-Based Optimization of an Energy Management for Automotive Power Nets. In Proceedings of the IEEE International Conference on Electrical Systems for Aircraft, Railway, Ship Propulsion and Road Vehicles & International Transportation Electrification Conference (ESARS-ITEC), Nottingham, UK, 7–9 November 2018 ; pp. 1–5. [Google Scholar] [CrossRef]

- Xia, C.; Du, Z.; Zhang, C. A Single-Degree-of-Freedom Energy Optimization Strategy for Power-Split Hybrid Electric Vehicles. Energies 2017, 10, 896. [Google Scholar] [CrossRef] [Green Version]

- Marinkov, S.; Murgovski, N.; de Jager, B. Convex Modeling and Optimization of a Vehicle Powertrain Equipped with a Generator-Turbine Throttle Unit. IEEE Trans. Control Syst. Technol. 2016, 25, 1–14. [Google Scholar] [CrossRef]

- Wu, J.; Ruan, J.; Zhang, N.; Walker, P.D. An Optimized Real-Time Energy Management Strategy for the Power-Split Hybrid Electric Vehicles. IEEE Trans. Control Syst. Technol. 2018, 27, 1194–1202. [Google Scholar] [CrossRef]

- Fan, B.S.M. Multidisciplinary Optimization of Hybrid Electric Vehicles: Component Sizing and Power Management Logic. Ph.D. Thesis, University of Waterloo, Waterloo, ON, Canada, 2011; pp. 1–146. Available online: http://resonance.uwaterloo.ca/p/alumni/thesis/b-fan-T.pdf (accessed on 26 May 2019).

- Rodrigues, G.S.L.; Oliveira, A.C.; Lima, A.M.N. Combining Model-Based and Extremum Seeking Control for Fast Tracking the Maximum Power Point of Lundell Alternator. In Proceedings of the 15th Brazilian Power Electronics Conference and 5th IEEE Southern Power Electronics Conference (COBEP/SPEC), Santos, Brazil, 1–4 December 2019; pp. 1–6. [Google Scholar] [CrossRef]

- Toloue, S.F.; Moallem, M. A Multi-Surface Sliding-Mode Extremum Seeking Controller for Alternator Maximum Power Point Tracking. In Proceedings of the IECON 2015 - 41st Annual Conference of the IEEE Industrial Electronics Society, Yokohama, Japan, 9–12 November 2015; pp. 001501–001506. [Google Scholar] [CrossRef]

- Tolue, S.F.; Moallem, M. Multivariable Sliding-Mode Extremum Seeking Control with Application to Alternator Maximum Power Point Tracking. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 229–234. [Google Scholar] [CrossRef]

- Toloue, S.F.; Moallem, M. Multivariable Sliding-Mode Extremum Seeking Control with Application to MPPT of an Alternator-Based Energy Conversion System. IEEE Trans. Ind. Electron. 2017, 64, 6383–6391. [Google Scholar] [CrossRef]

- Liaw, C.Z. A High Power Interior Permanent Magnet Alternator for Automotive Applications. 2013. Available online: https://digital.library.adelaide.edu.au/dspace/bitstream/2440/83587/8/02whole.pdf (accessed on 23 February 2022).

- Liaw, C.-Z.; Whaley, D.; Soong, W.; Ertugrul, N. Investigation of inverterless control of interior permanent-magnet alternators. IEEE Trans. Ind. Appl. 2006, 42, 536–544. [Google Scholar] [CrossRef] [Green Version]

- Liaw, C.; Soong, W.; Ertugrul, N. Closed-Loop Control and Performance of an Inverterless Interior PM Automotive Alternator. In Proceedings of the International Conference on Power Electronics and Drives Systems, Kuala Lumpur, Malaysia, 28 November–1 December 2005; Voulme 1, pp. 343–348. [Google Scholar] [CrossRef]

- Liaw, C.-Z.; Soong, W.L.; Welchko, B.A.; Ertugrul, N. Uncontrolled Generation in Interior Permanent-Magnet Machines. IEEE Trans. Ind. Appl. 2005, 41, 945–954. [Google Scholar] [CrossRef] [Green Version]

- Liaw, C.; Soong, W.; Ertugrul, N. Low-Speed Output Power Improvement of an Interior PM Automotive Alternator. In Proceedings of the Conference Record of the 2006 IEEE Industry Applications Conference Forty-First IAS Annual Meeting, Tampa, FL, USA, 8–12 October 2006; Volume 1, pp. 27–34. [Google Scholar] [CrossRef]

- Ilončiak, J.; Struharnanský, Ľ.; Kuchta, J. Modular Concept of Auxiliary Converters for Diesel Electric Locomotives. Procedia Eng. 2017, 192, 359–364. [Google Scholar] [CrossRef]

- Henry, R.R.; Lequesne, B.; Chen, S.; Ronning, J.J.; Xue, Y. Belt-Driven Starter-Generator for Future 42-Volt Systems; (No. 2001-01-0728); SAE Technical Paper; SAE International: Warrendale, PA, USA, 2001. [Google Scholar]

- Naidu, M.; Walters, J. A 4-kW 42-V induction-machine-based automotive power generation system with a diode bridge rectifier and a PWM inverter. IEEE Trans. Ind. Appl. 2003, 39, 1287–1293. [Google Scholar] [CrossRef]

- Naidu, M.; Henry, R.; Boules, N. A 3.4 kW, 42 V High Efficiency Automotive Power Generation System; SAE International: Warrendale, PA, USA, 2000. [Google Scholar] [CrossRef]

- Caricchi, F.; Crescimbini, F.; Santini, E.; Solero, L. High-efficiency low-volume starter/alternator for automotive applications. In Proceedings of the Conference Record of the 2000 IEEE Industry Applications Conference. Thirty-Fifth IAS Annual Meeting and World Conference on Industrial Applications of Electrical Energy (Cat. No. 00CH37129), Rome, Italy, 8–12 October 2000; Volume 1. [Google Scholar]

- El-Hasan, T.S. Development of Automotive Permanent Magnet Alternator with Fully Controlled AC/DC Converter. Energies 2018, 11, 274. [Google Scholar] [CrossRef] [Green Version]

- Liang, F.; Miller, J.; Zarei, S. A control scheme to maximize output power of a synchronous alternator in a vehicle electrical power generation system. In Proceedings of the IAS ‘96. Conference Record of the 1996 IEEE Industry Applications Conference Thirty-First IAS Annual Meeting, San Diego, CA, USA, 6–10 October 1996. [Google Scholar] [CrossRef]

- Lovelace, E.; Jahns, T.; Lang, J.H. Impact of saturation and inverter cost on interior PM synchronous machine drive optimization. IEEE Trans. Ind. Appl. 2000, 36, 723–729. [Google Scholar] [CrossRef]

- Perreault, D.; Caliskan, V. Automotive Power Generation and Control. IEEE Trans. Power Electron. 2004, 19, 618–630. [Google Scholar] [CrossRef]

- Rivas, J.M.; Perreault, D.J.; Keim, T.A. Performance Improvement of Alternators with Switched-Mode Rectifiers. IEEE Trans. Energy Convers. 2004, 19, 561–568. [Google Scholar] [CrossRef]

- Rivas, J. Output Power Increase at Idle Speed in Alternators. Ph.D. Thesis, Massachusetts Institute of Technology, Cambridge, MA, USA, 2003. [Google Scholar]

- Sarafianos, D.; Logan, T.G.; McMahon, R.A.; Flack, T.J.; Pickering, S. Alternator Loss Breakdown and Use of Alternative Rectifier Diodes for Improvement of Vehicle Electrical Power System Efficiency. In Proceedings of the 16th International Power Electronics and Motion Control Conference and Exposition, Antalya, Turkey, 21–24 September 2014; pp. 502–507. [Google Scholar] [CrossRef]

- Soong, W.; Ertugrul, N. Inverterless High-Power Interior Permanent-Magnet Automotive Alternator. IEEE Trans. Ind. Appl. 2004, 40, 1083–1091. [Google Scholar] [CrossRef]

- Sarafianos, D.; Llano, D.X.; Ghosh, S.S.; McMahon, R.A.; Pickering, S.; Flack, T.J. Control Strategy for a Multiphase Lundell-Alternator/Active-Rectifier System in 14 V Automotive Power Systems. IEEE Trans. Transp. Electrif. 2019, 5, 347–355. [Google Scholar] [CrossRef]

- Hassan, G.; Perreault, D.; Keim, T. Design of Dual-Output Alternators with Switched-Mode Rectification. IEEE Trans. Power Electron. 2005, 20, 164–172. [Google Scholar] [CrossRef]

- Wan, J.; Zeng, X.; Li, Z.; Li, L.; Yang, Y.; Zhao, Y.; Li, Z.; Zhang, B. A Novel Synchronous Rectification with Directly Frequency Tracking for Automotive Alternator. IEEE Trans. Ind. Electron. 2021, 69, 2216–2226. [Google Scholar] [CrossRef]

| Item No. | Year | Status |

|---|---|---|

| 1 | Before the 1960s | Only the ignition was the primary load for the battery and the alternator. |

| 2 | After the 1960s | The power requirement of upper-class automobiles has climbed from less than 500 W. |

| 3 | In the 2000 year | More than 2 kW and will continue to rise. |

| 4 | In the coming decade | An accelerated growth to around 10 kW. |

| Researchers | Algorithm | Enhancement | Disadvantages |

|---|---|---|---|

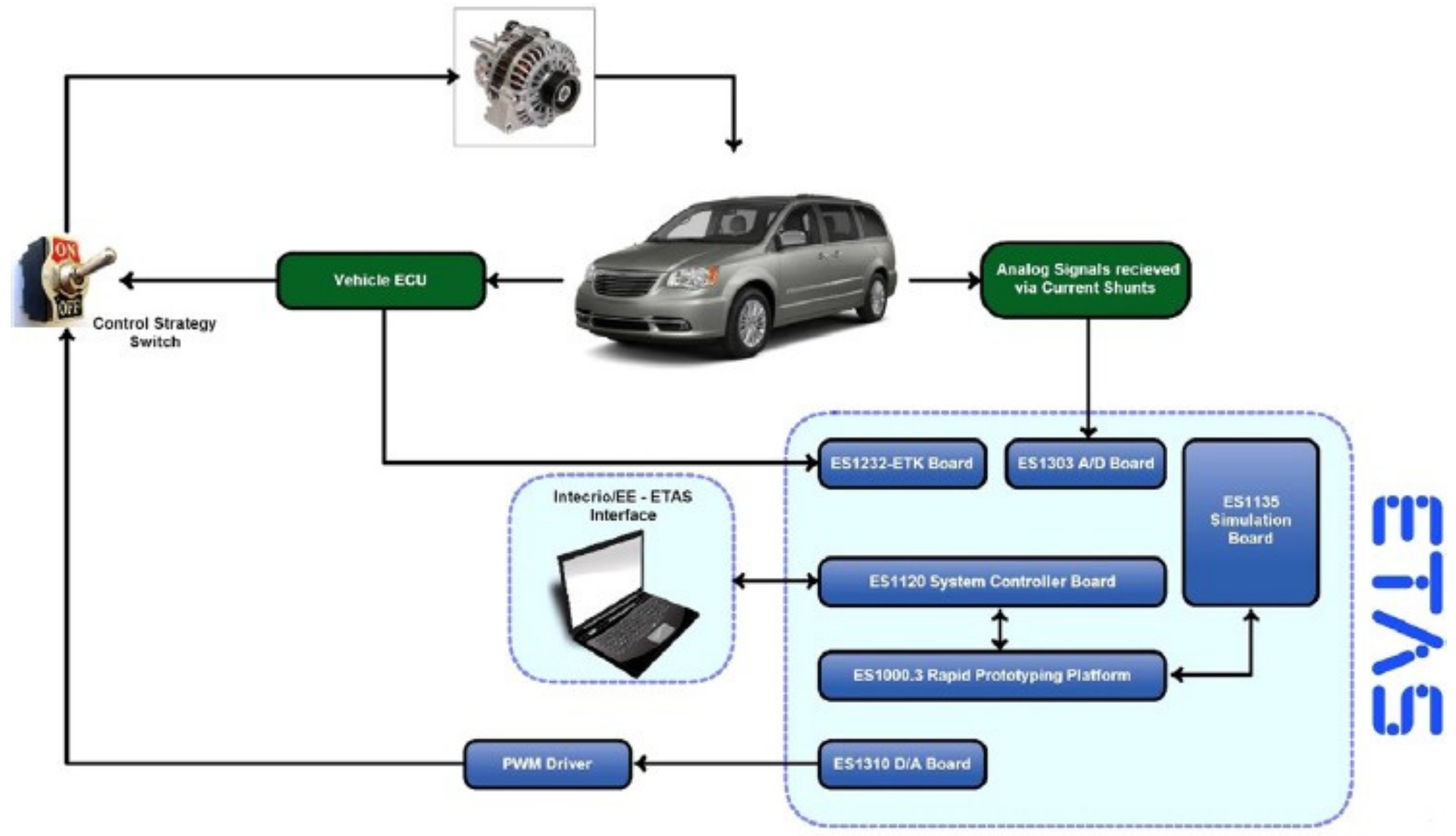

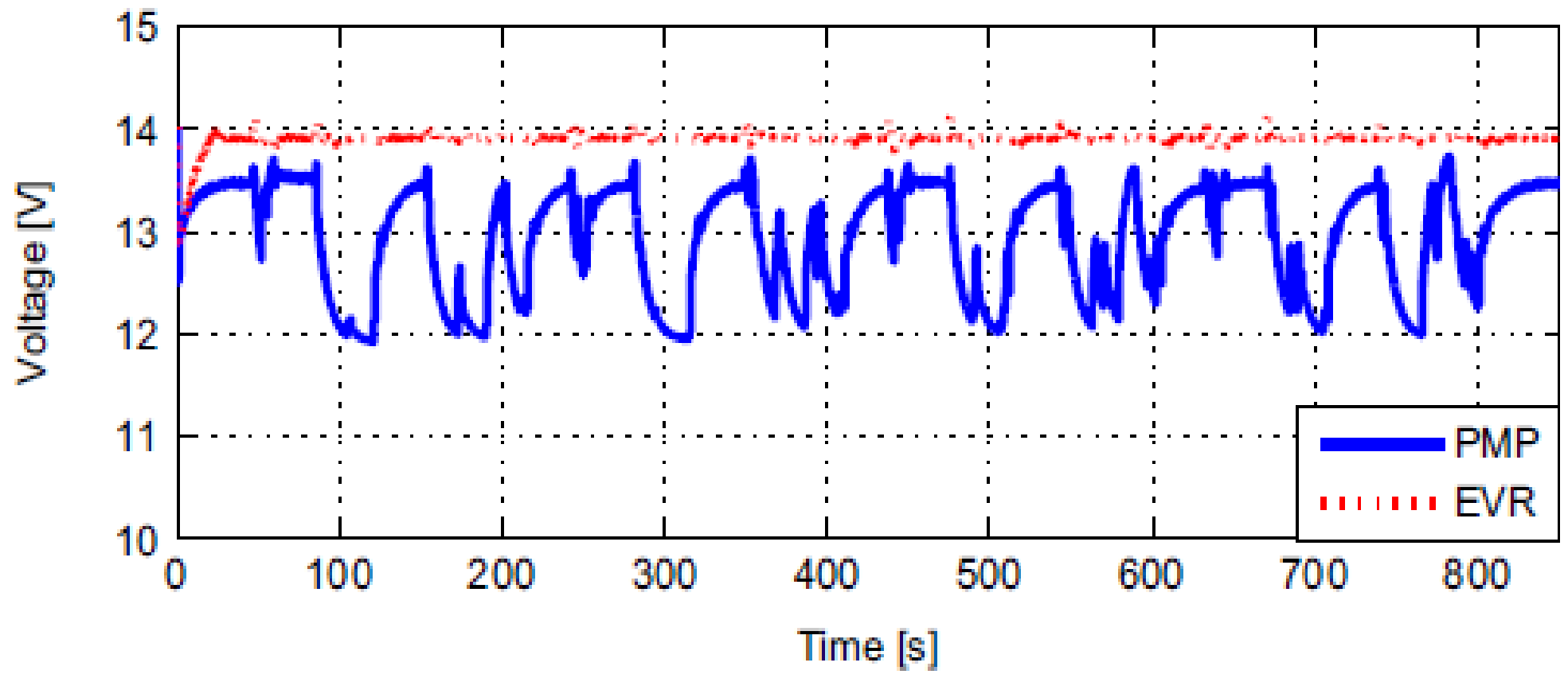

| Waldman et al., 2015, [13] | PMP and global, optimum controller | 2.1% reduction in fuel. Small voltage and current fluctuation enhanced the battery lifetime. | Limited field current range and did not deal with the output voltage control. The output voltage has more ripple content as compared with EVR technology. It is not applied in the real world; it is only used in ECU software. The alternator type is not specified in this work. |

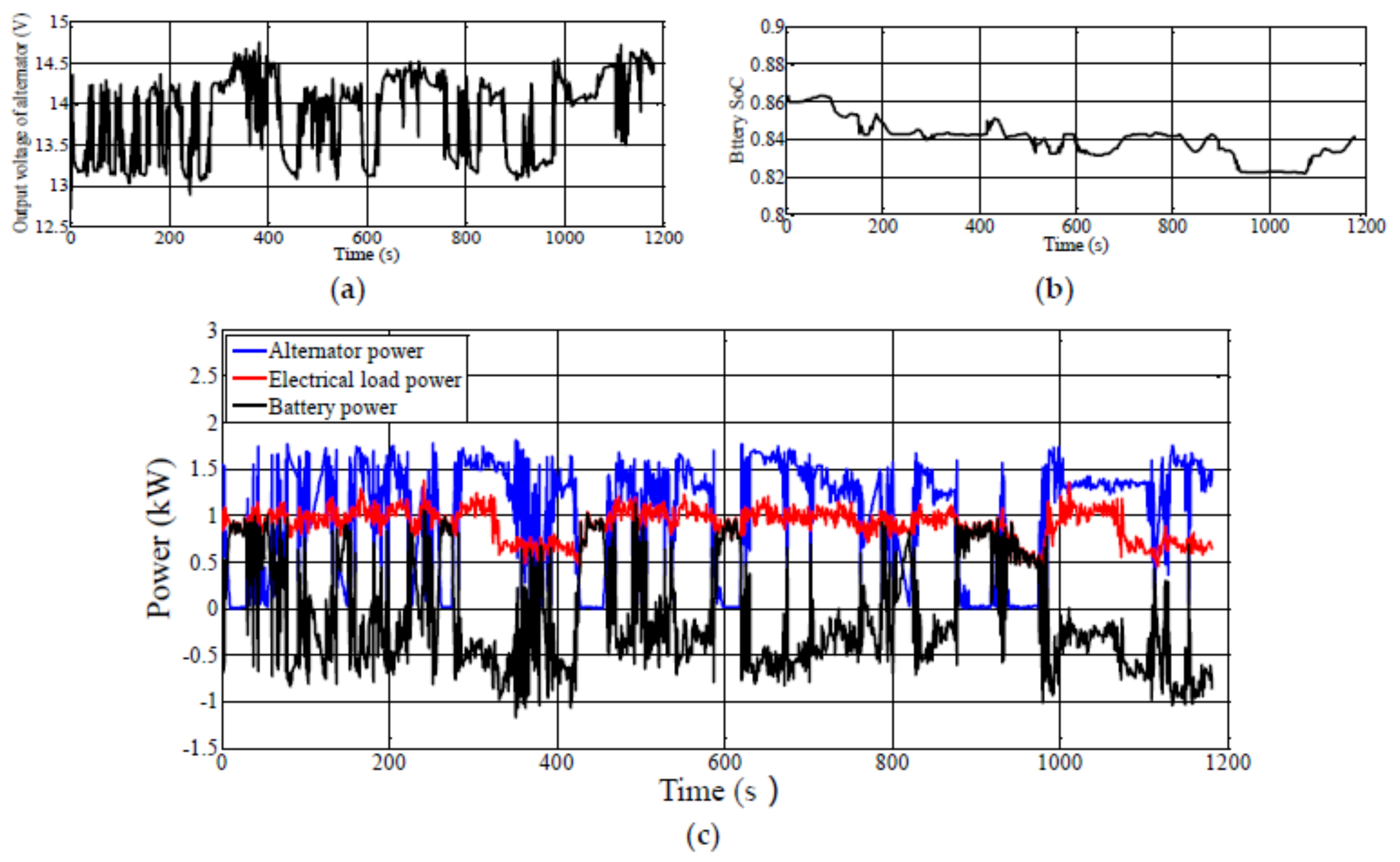

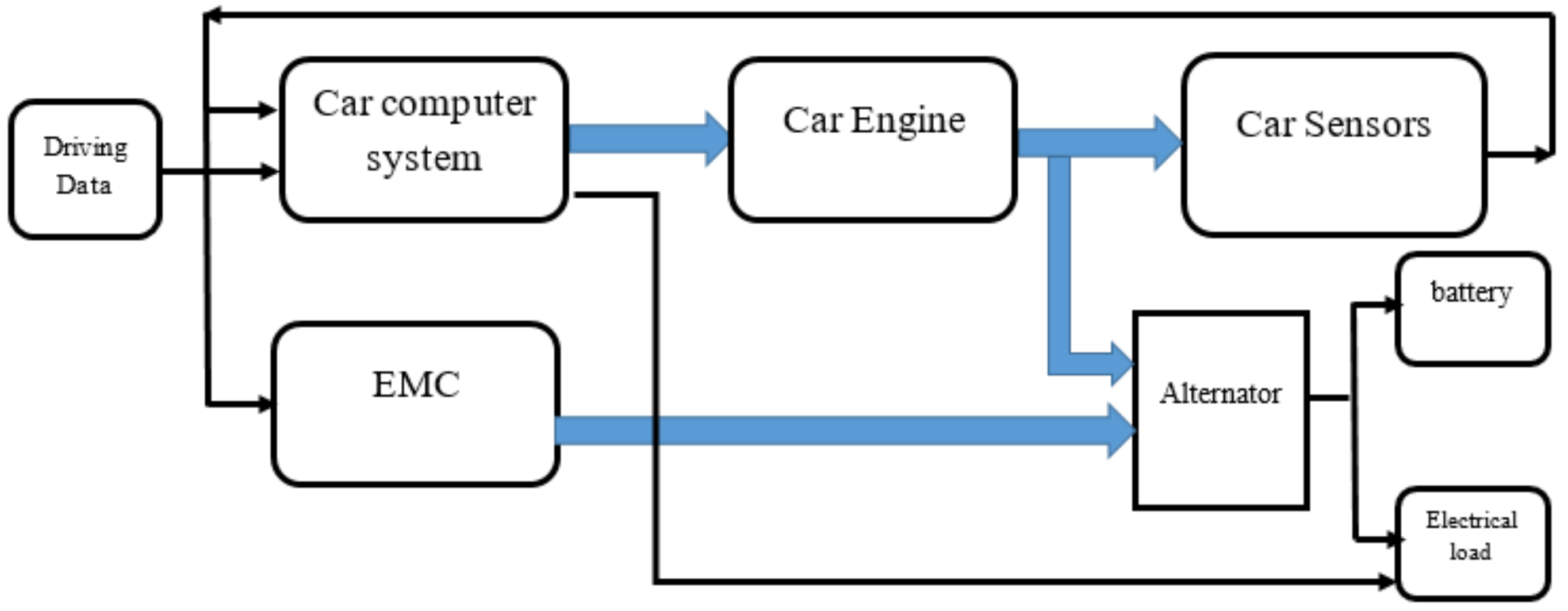

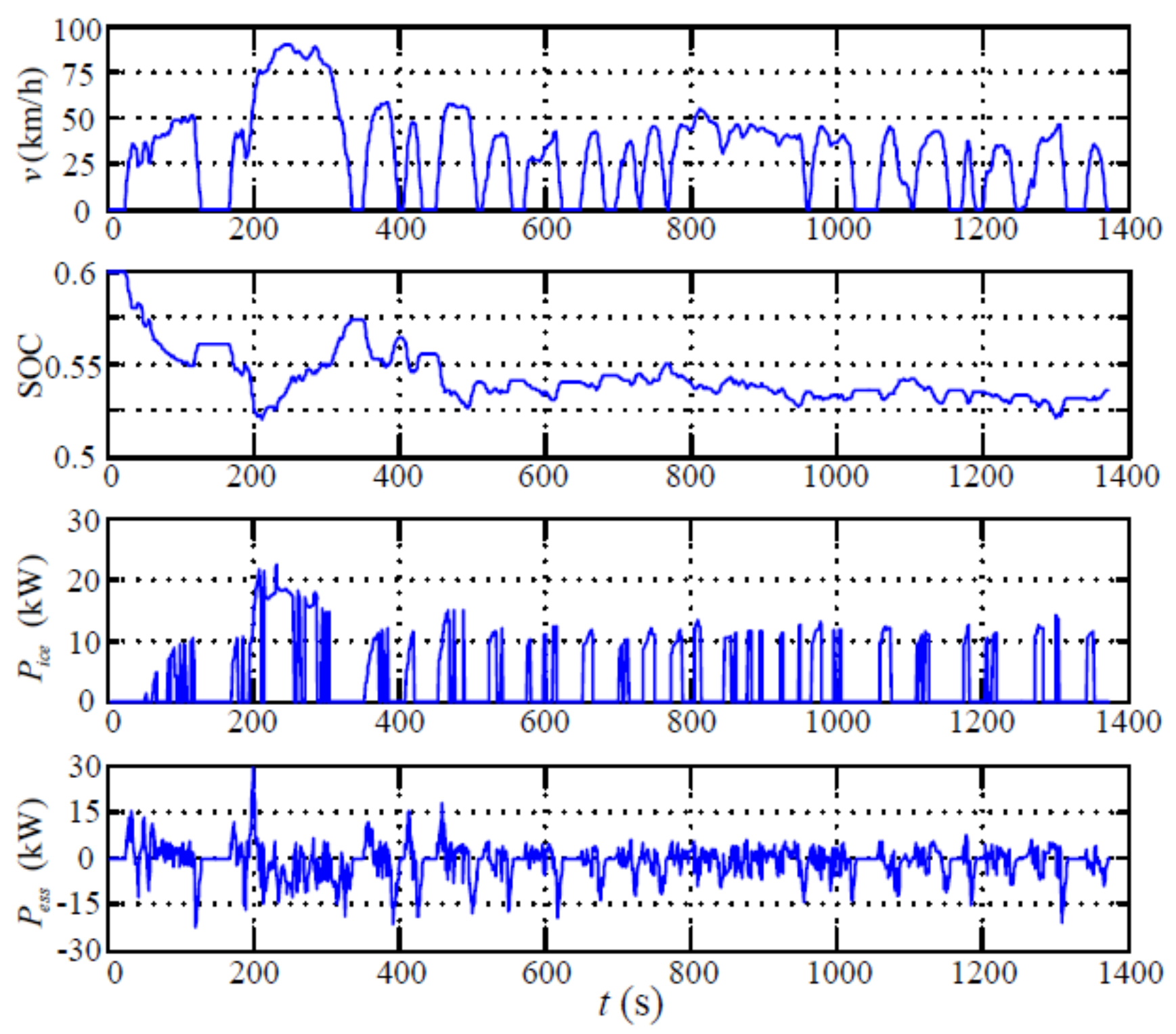

| Wang et al., 2016, [14] | OPD | Real-time appropriate strategy. 1.7% fuel reduction. It is applied in real life to passenger vehicles (designed by Hella (Lippstadt)), and the Bosch alternator is used in this work. | Complex approach needing complex calculations. The alternator type is not specified in this work, the work is only a simulation, and it is not applied in the real world. |

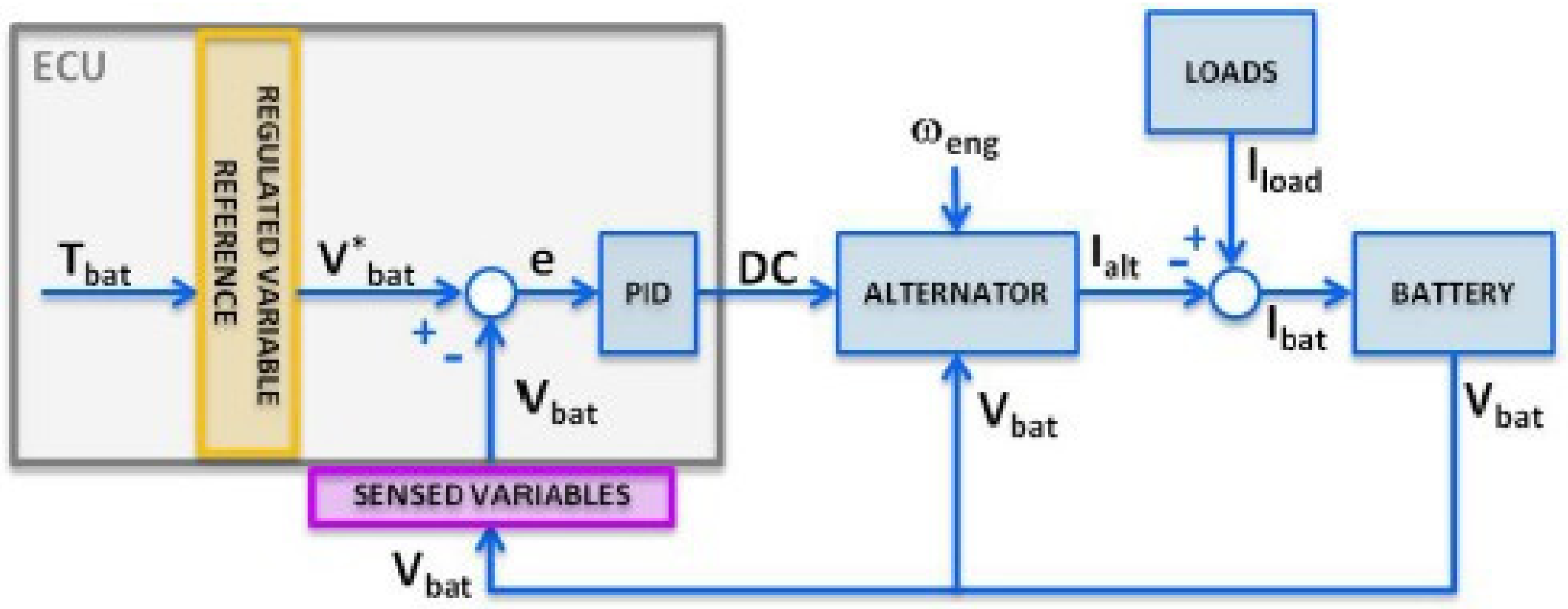

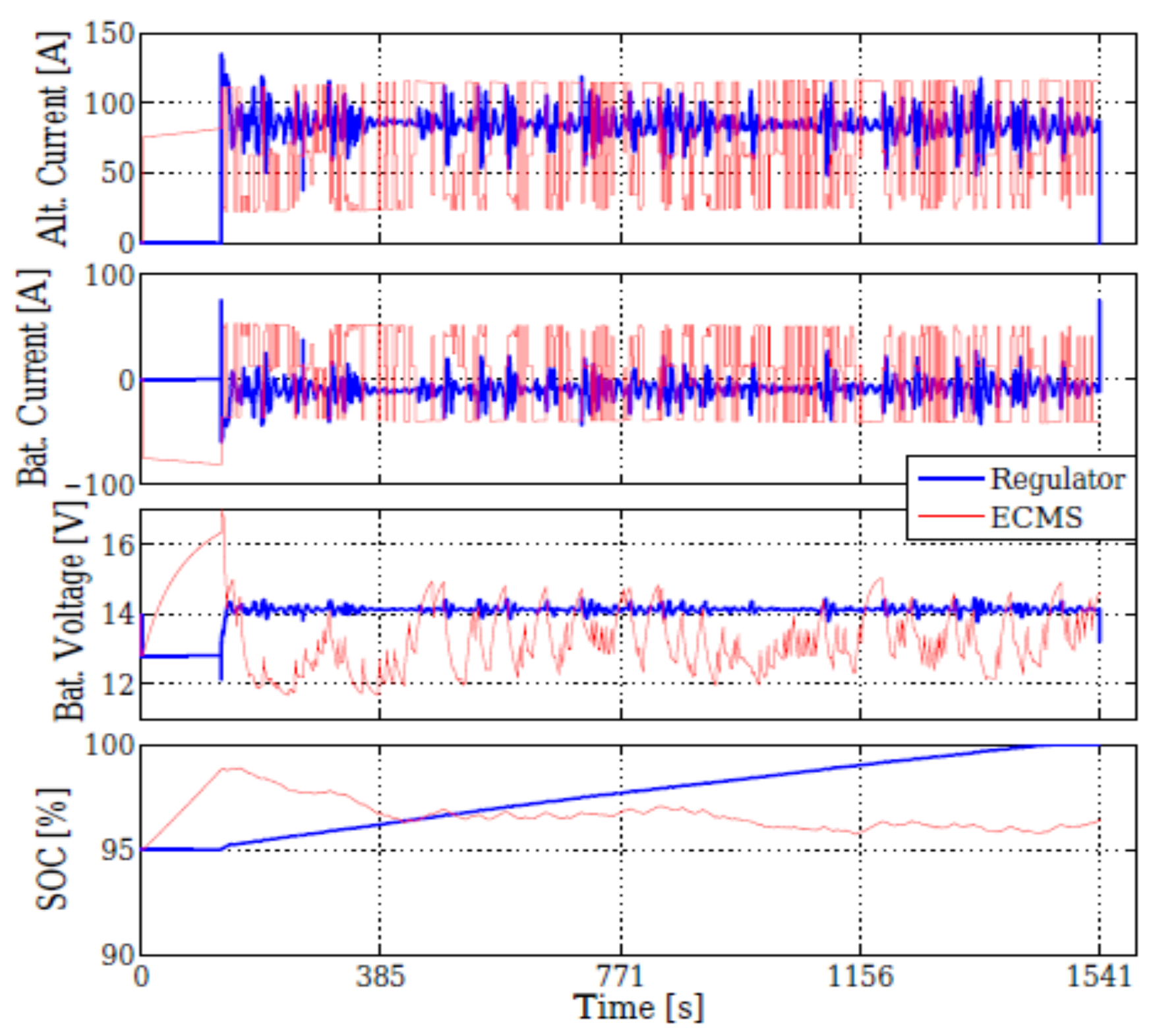

| Couch, Fiorentini, and Canova, 2013, [15] | ECMS | Ensures a current harmony between the alternator, load, and battery currents and reduces the fuel in average percentages of 1.5% and 25%, respectively. | The action is limited to the field current variation, and the ECMS leads to a 100 to 300% increase in the overall battery consumption, which may influence durability. The type of the alternator is not specified, and this strategy is not applied in the real world. |

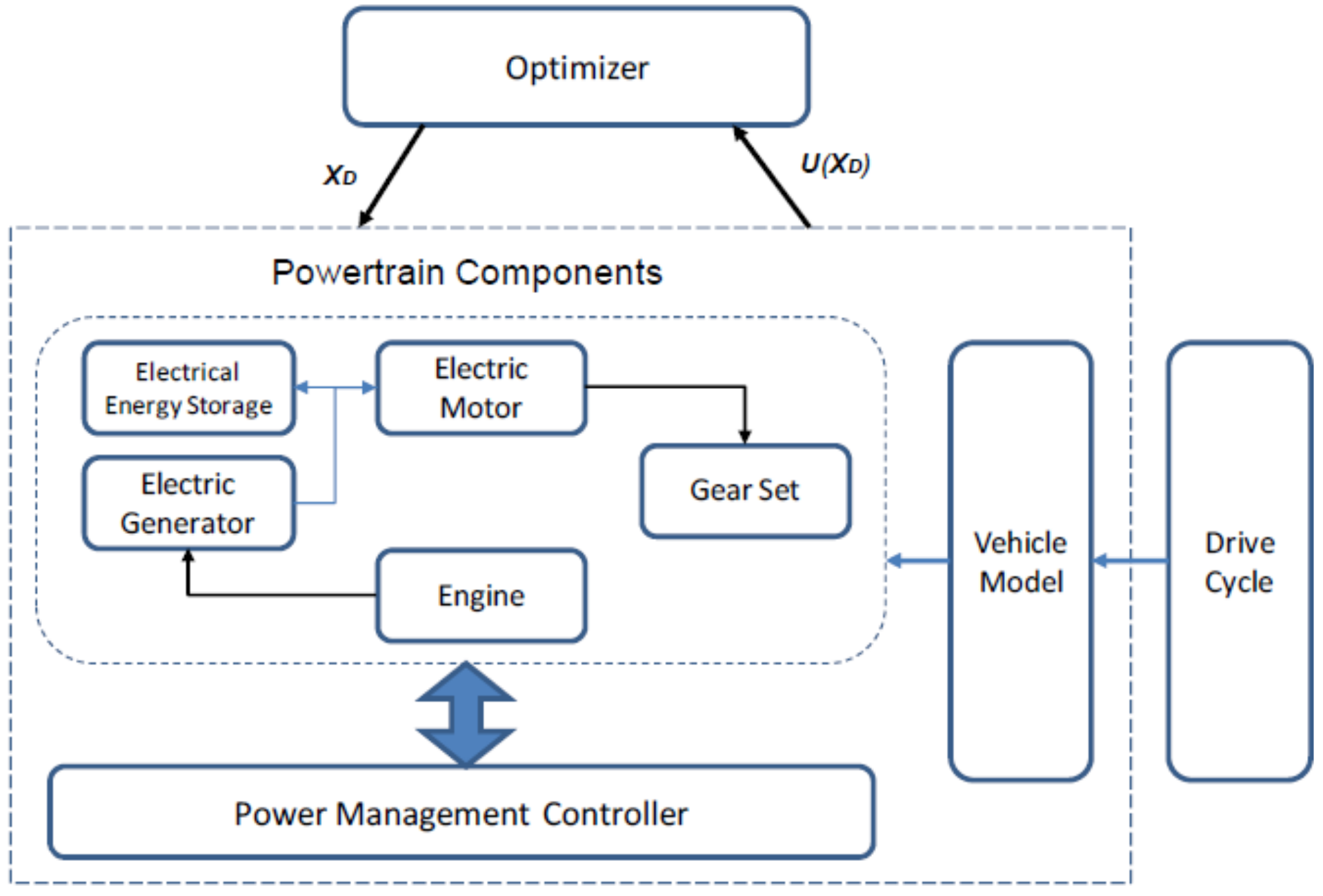

| Koot et al., 2005, [16] | Modified DP | Reduction in fuel use of 2%, significant emissions reductions. It can be applied quickly and smoothly. | No experimental work is achieved to verify the results for the proposed algorithm. The type of the alternator is not specified (only the general term for integrated starter/alternator), and this strategy is not applied in the real world. |

| Han et al., 2017, [17] | MPC | Smooth and fast starting time for the alternator-based engine (0.3 s). The results demonstrate that the engine can start rapidly with minimal speed oscillations. | No experimental work is achieved to verify the results for the proposed algorithm, it is only a comparison between Matlab and AMESim software, and it is not applied in the real world. The type of the alternator is not specified. Only a general belt starter/alternator term is used. |

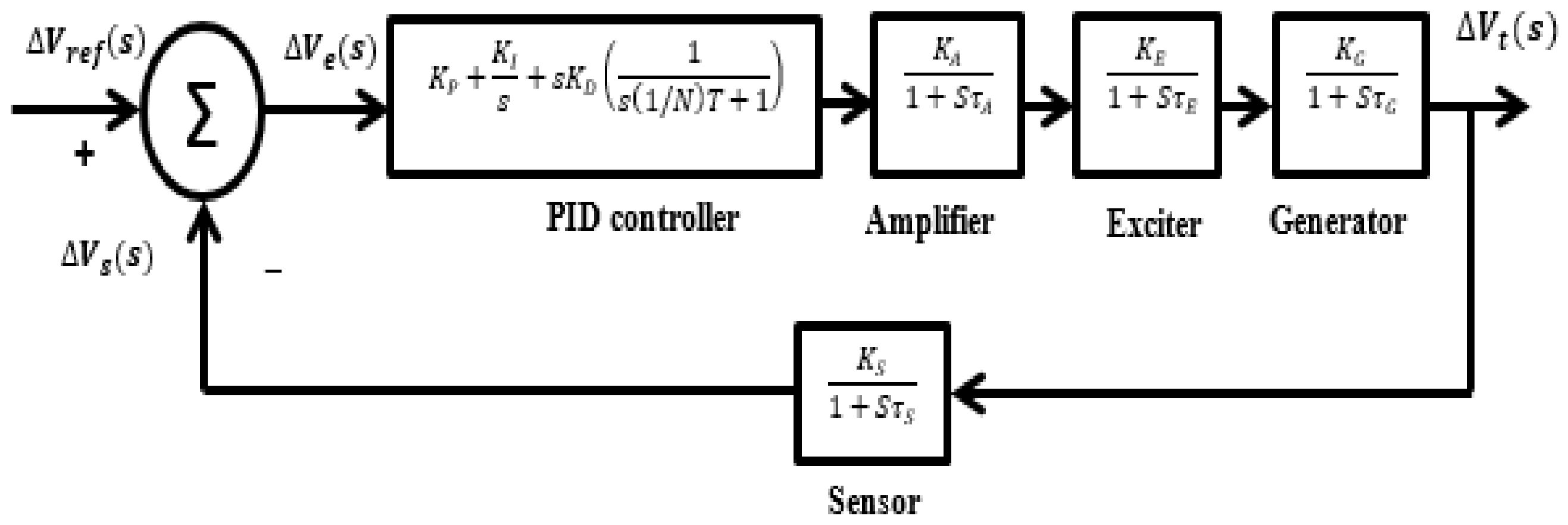

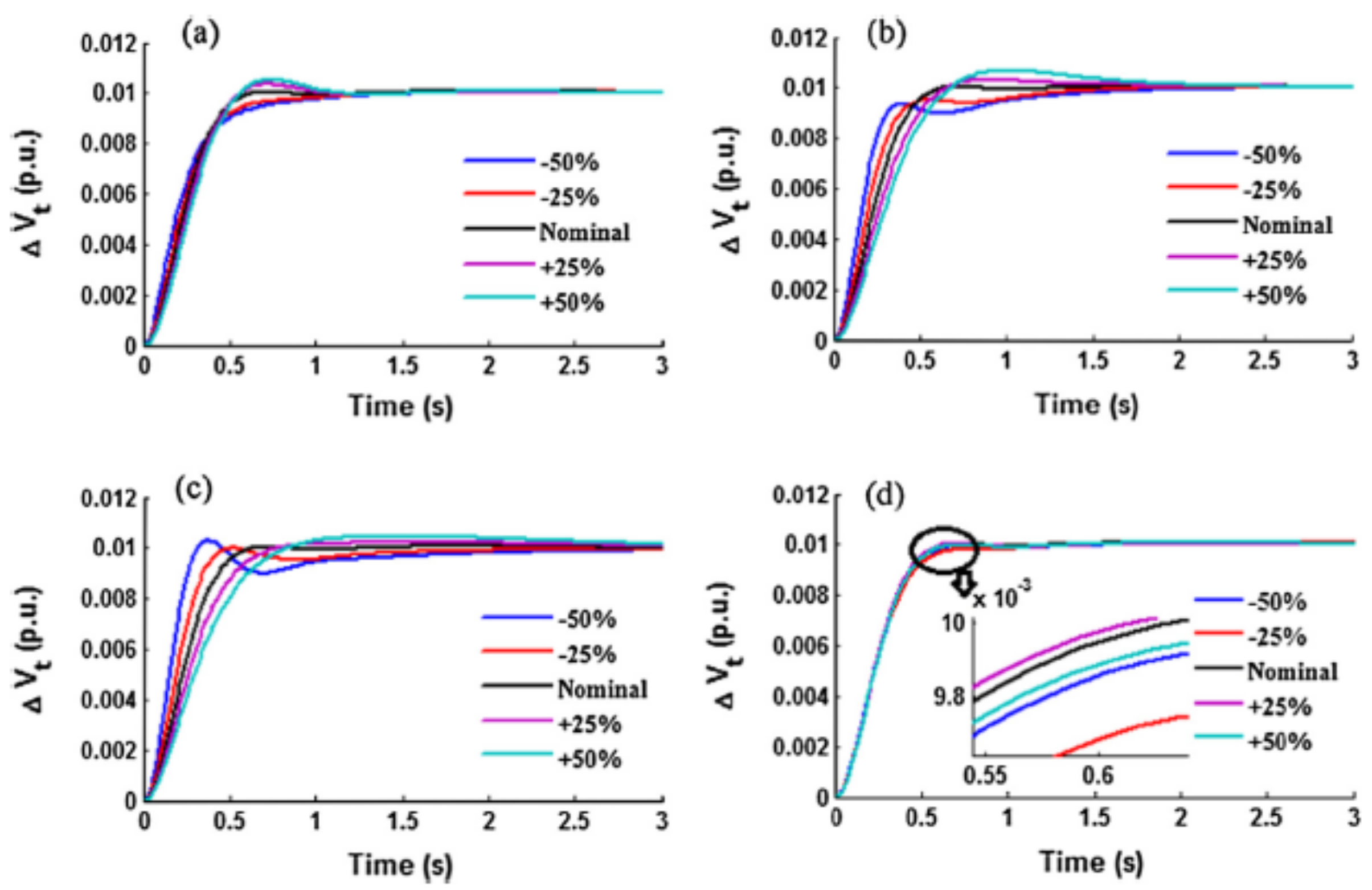

| Chatterjee and Mukherjee, 2016, [18] | TLBO | Good voltage response can be implemented online. Simulation results demonstrate that the TLBO-based PID controller is a vital AVR optimization tool. | It only controls the field current of the alternator. No practical work is introduced in this paper, and also the alternator type is not specified. |

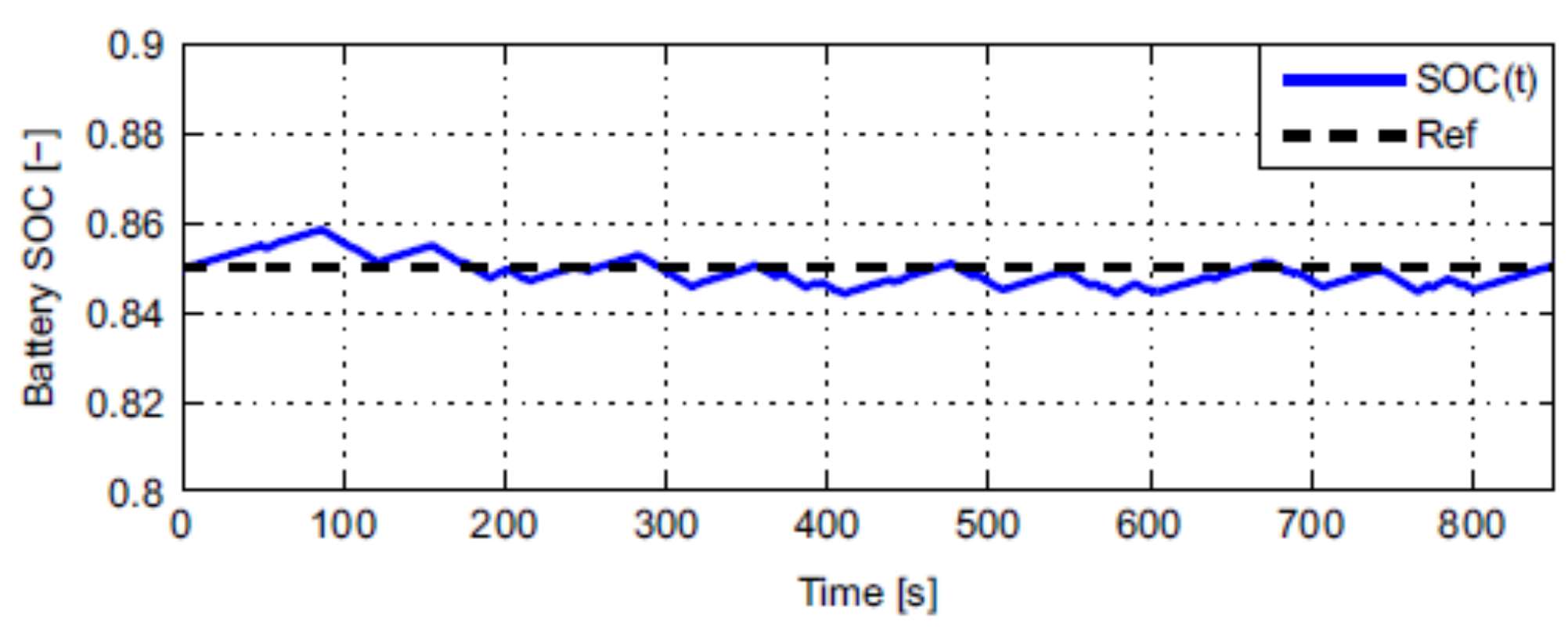

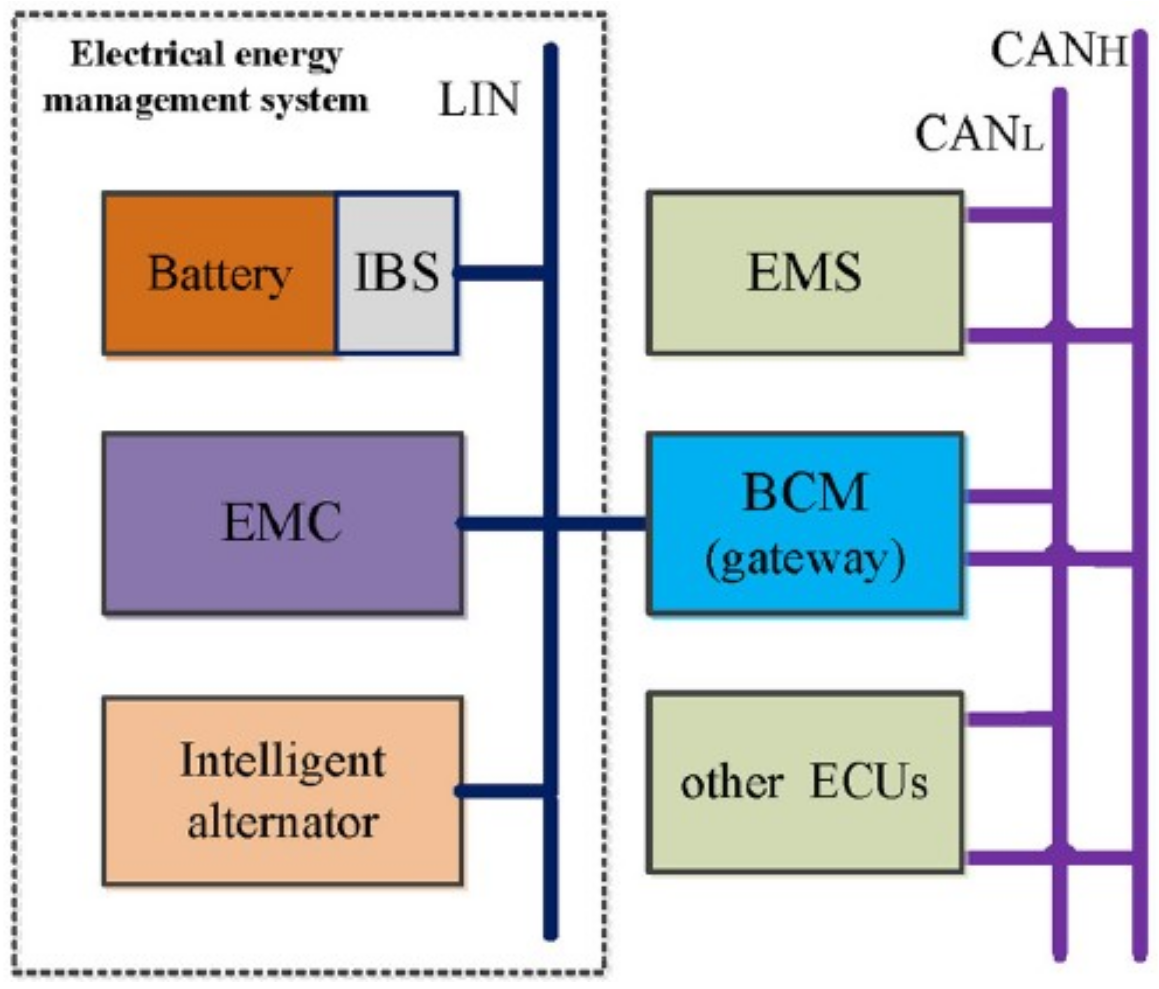

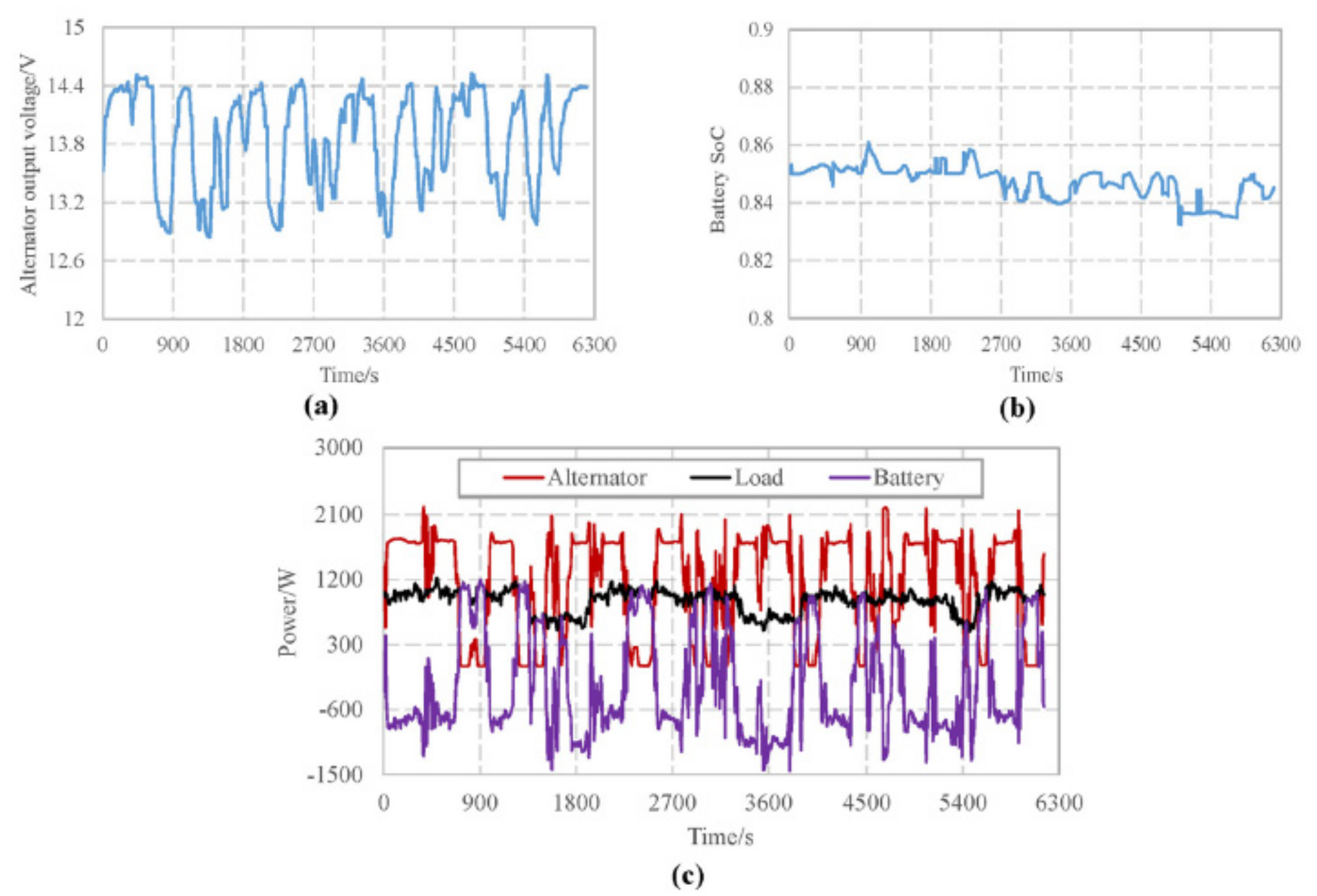

| Wang et al., 2018, [19] | DCR and ELP | Stable load power and 1.6% reduction in fuel. The experimental result is obtained depending on real vehicles and alternator parameters. | Fluctuation of battery SOC and high computational complexity. The alternator type is not mentioned in work (only the term intelligent alternator). |

| Winter, Taube, and Herzog, 2018, [20] | Multi-Objective | Select the desired system behavior and discover high-effect parameters. | Simulation work only. Alternator type is not mentioned in the work, and the work is not applied in the real world car. |

| Xia, Du, and Zhang, 2017, [21] | Quadratic optimization | The optimization index deals with the battery SOC and fuel reduction simultaneously. Fuel consumption is reduced by 3.7%. Toyota Prius parameters are used as a vehicle in this work. | Simulation work only, two motor-generator set is used, and it needs extra components and cost. Alternator type is not mentioned in this work. |

| Marinkov, Murgovski, and Jager, 2017, [22] | Convex Optimization | Price is reduced by about 8.1%, Can implement online. Only a real-world driving cycle is used. | It is only simulation work, numerical analysis, and lowers fuel reduction. The alternator type is not mentioned in this work. |

| Wu et al., 2019, [23] | R-EMS | Significant effect on the SOC for the battery and fuel consumption for the engine. Real-time driving cycles are used. | These devices have low efficiency, less than 50%, and the alternator has a high output at the idle speed, but it is down at high rates. The alternator type is not specified. |

| Fan, 2011, [24] | MDO | Reduced size for the system components, fast response. As indicated by the GM Impala, the Parameters of Denso are used in this work as a real word alternator. | It needs extra components; finally, the work is only a simulation, not a real-time one. |

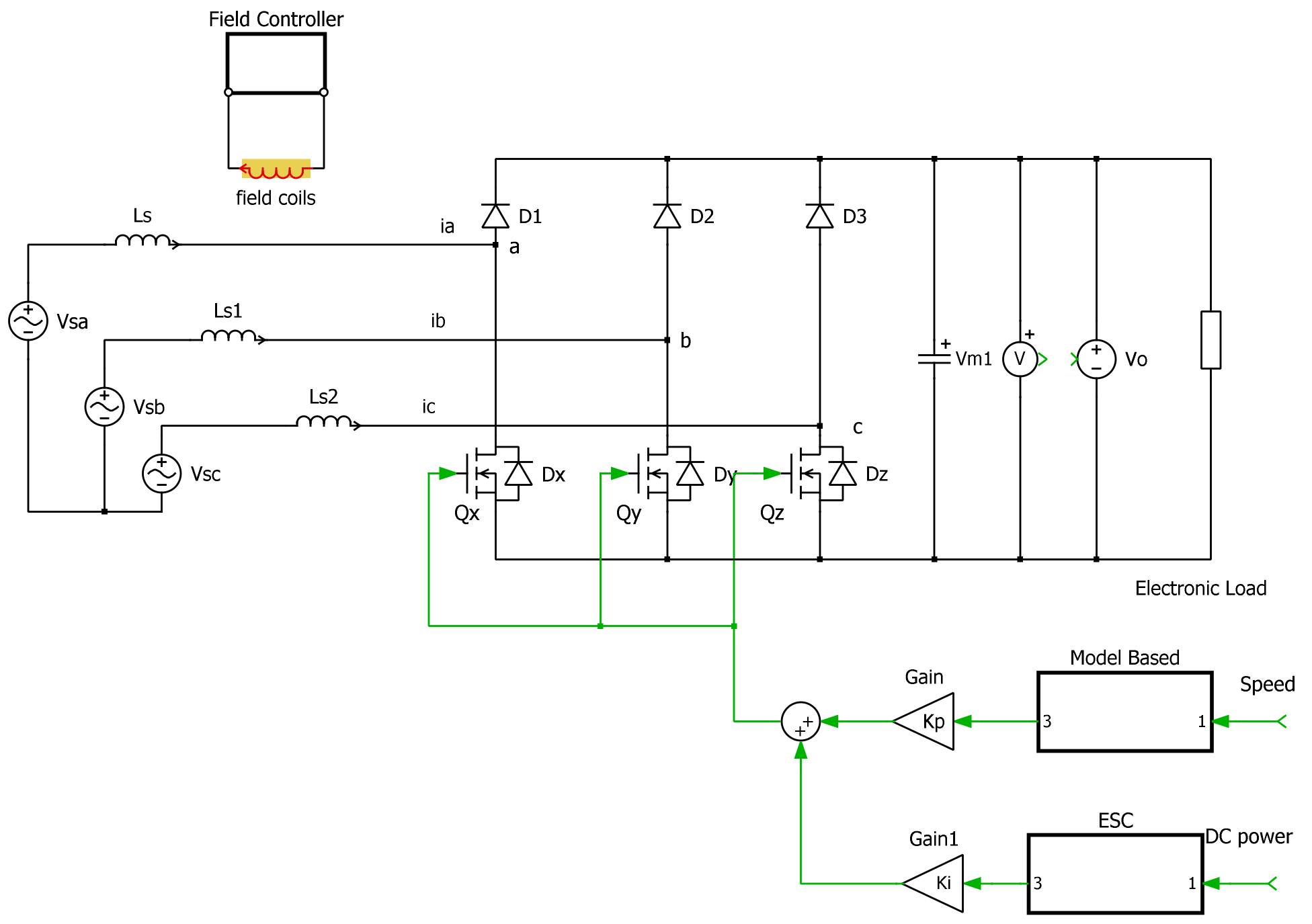

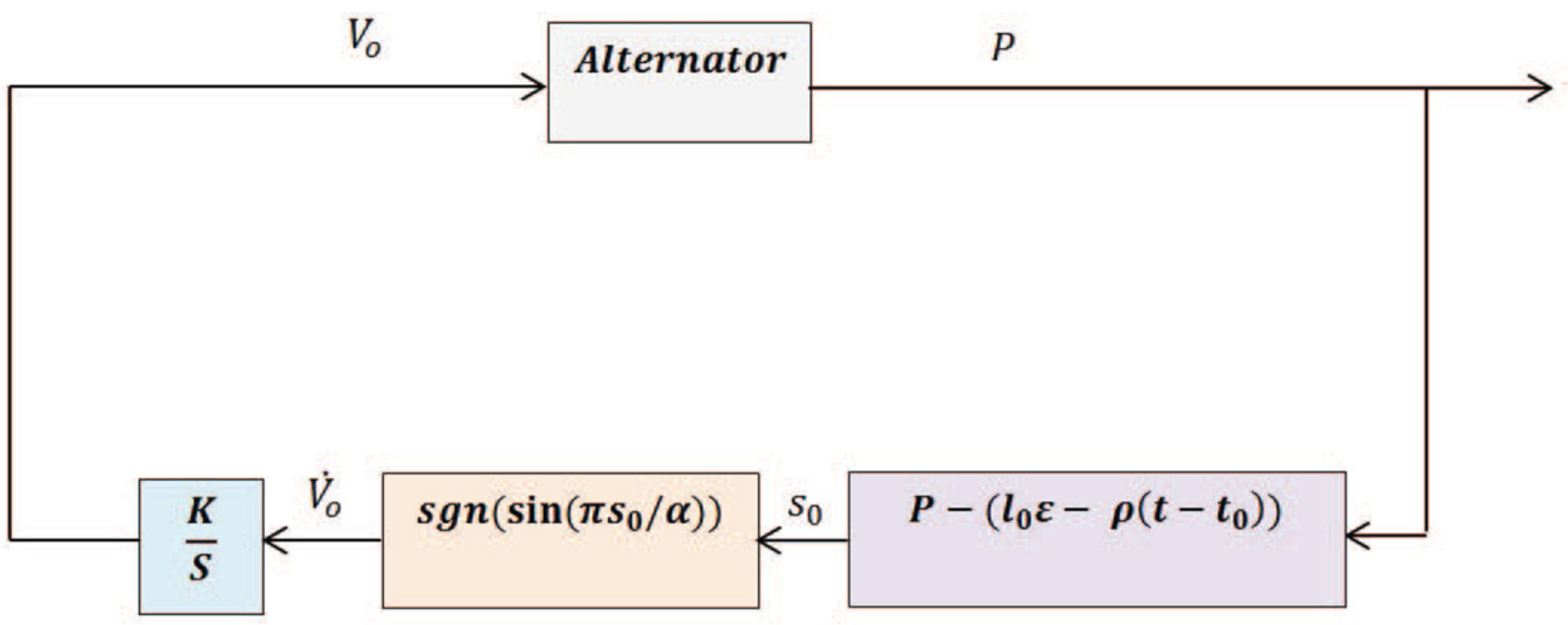

| Lins Rodrigues, Cunha Oliveira, and Nogueira Lima, 2019, [25] | Model-based Extremum Seeking | Real-time applicable hybrid optimization, fast, high accuracy, and good enhancement in power in 6–7%. An automotive Lundell alternator is used in this work. | Simulation work only. |

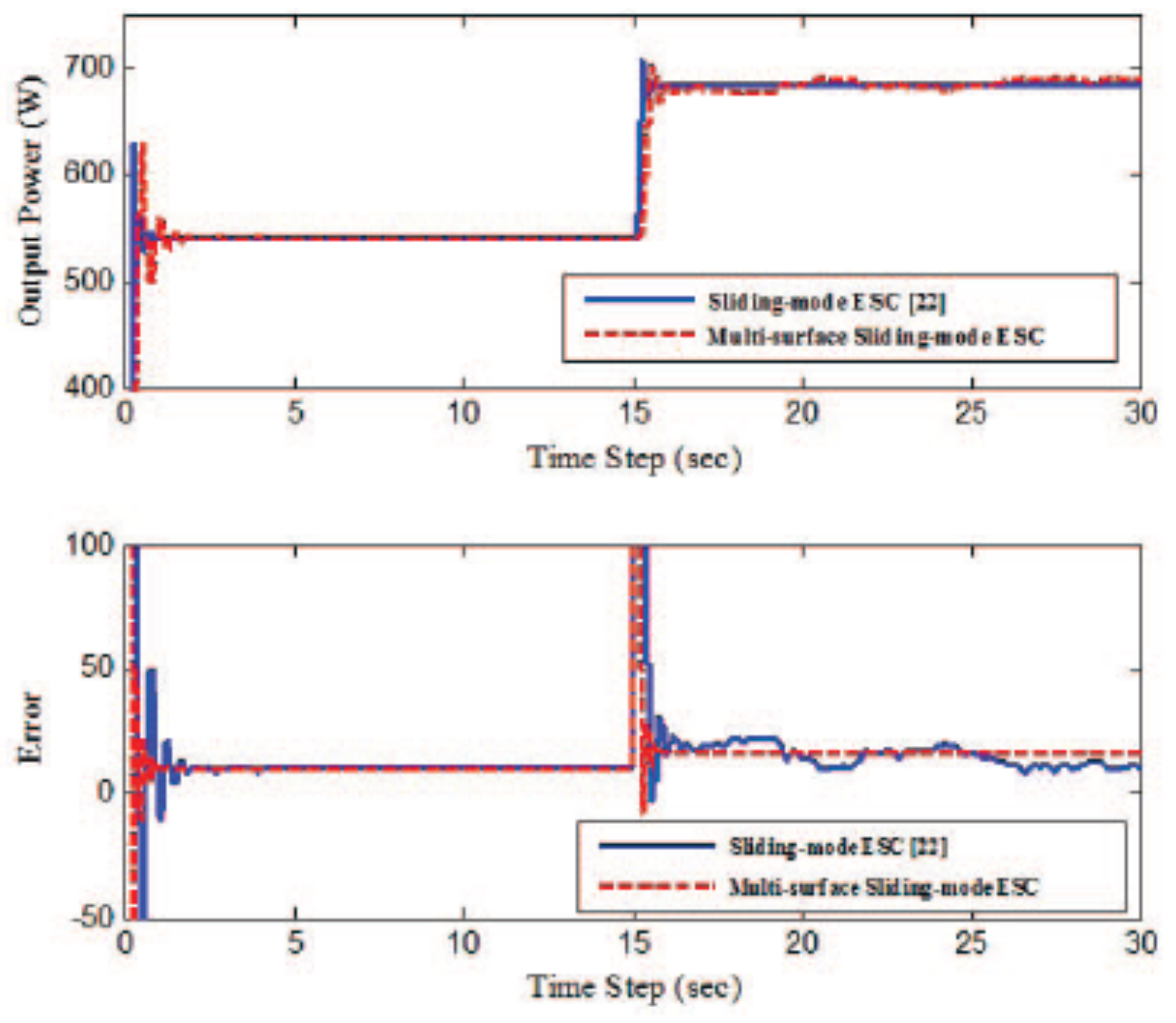

| Toloue and Moallem, 2015, [26] | Sliding mode multi-surface | High efficiency, smooth, fast, and robust performance. In addition, this method has less fluctuation, increasing the precision for speed performance. Parameters of the Lundell alternator are used in this work. | Simulation works only and has high computational complexity. |

| Tolue and Moallem 2016, [27] | Multivariable Sliding-mode Extremum Seeking | Fast and precise convergence and robust performance in the face of disturbances and uncertainties. The parameters of the Lundell alternator are used. | Simulation work only. |

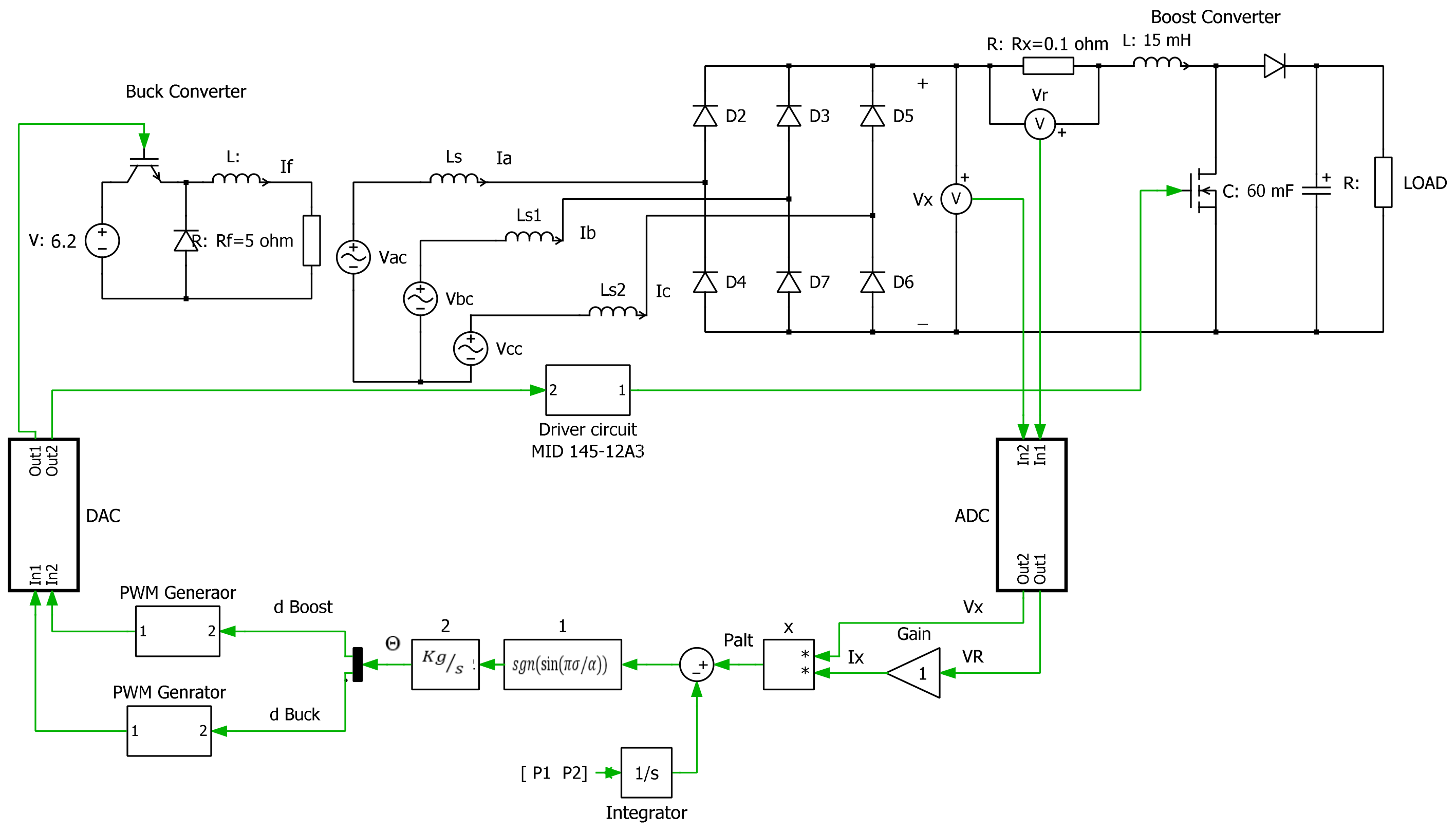

| Tolue and Moallem 2017, [28] | Experimental MVESC (Multivariable Sliding-mode Extremum Seeking) | Advantages in robust performance, speed, and accuracy. The system is used in the real-world railway industry. The alternator type is remanufactured ACDelco 334-2224A | Compacted system and expensive. It needs ADC and DAC and tow choppers. |

| Researchers | Algorithm | Enhancement | Disadvantages |

|---|---|---|---|

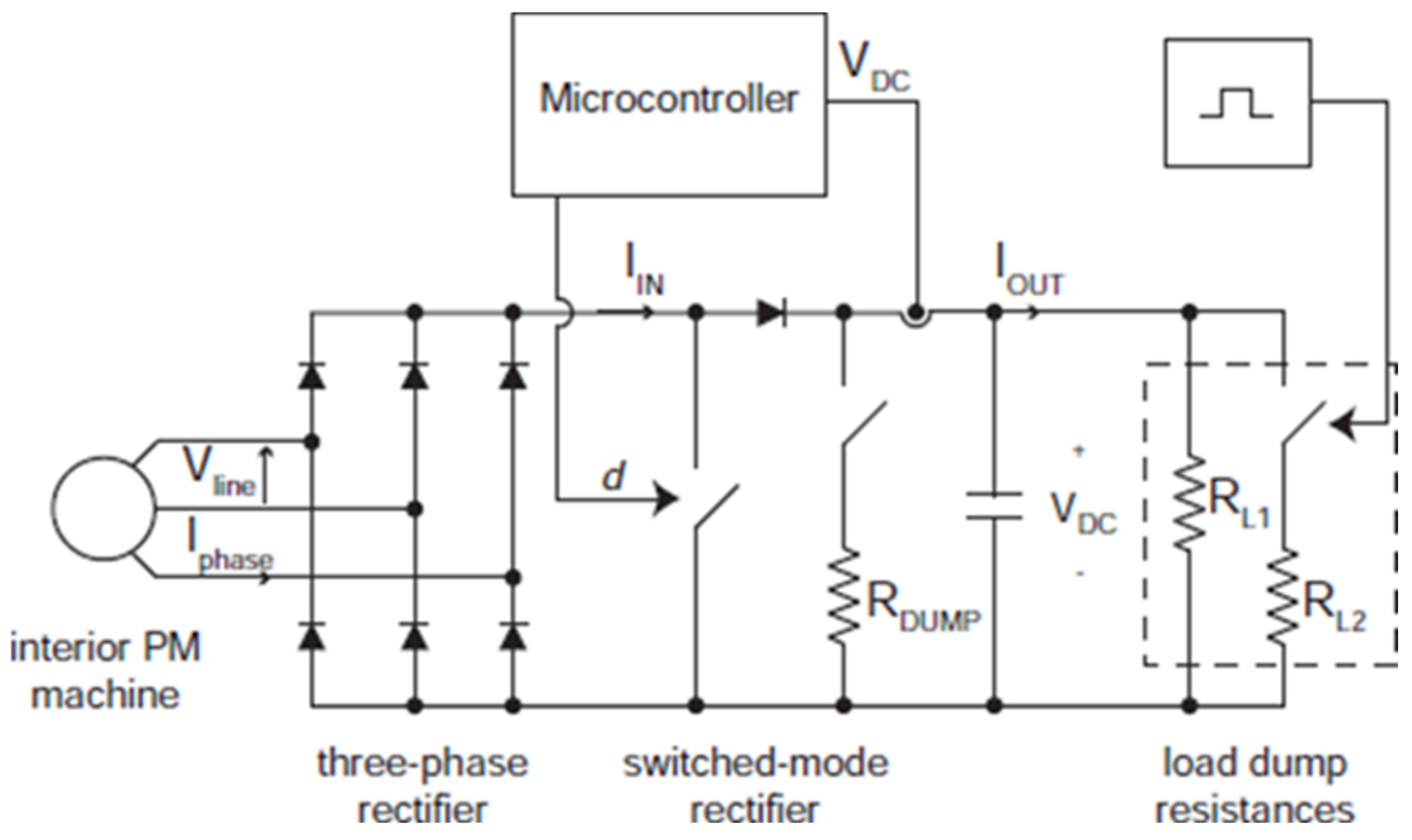

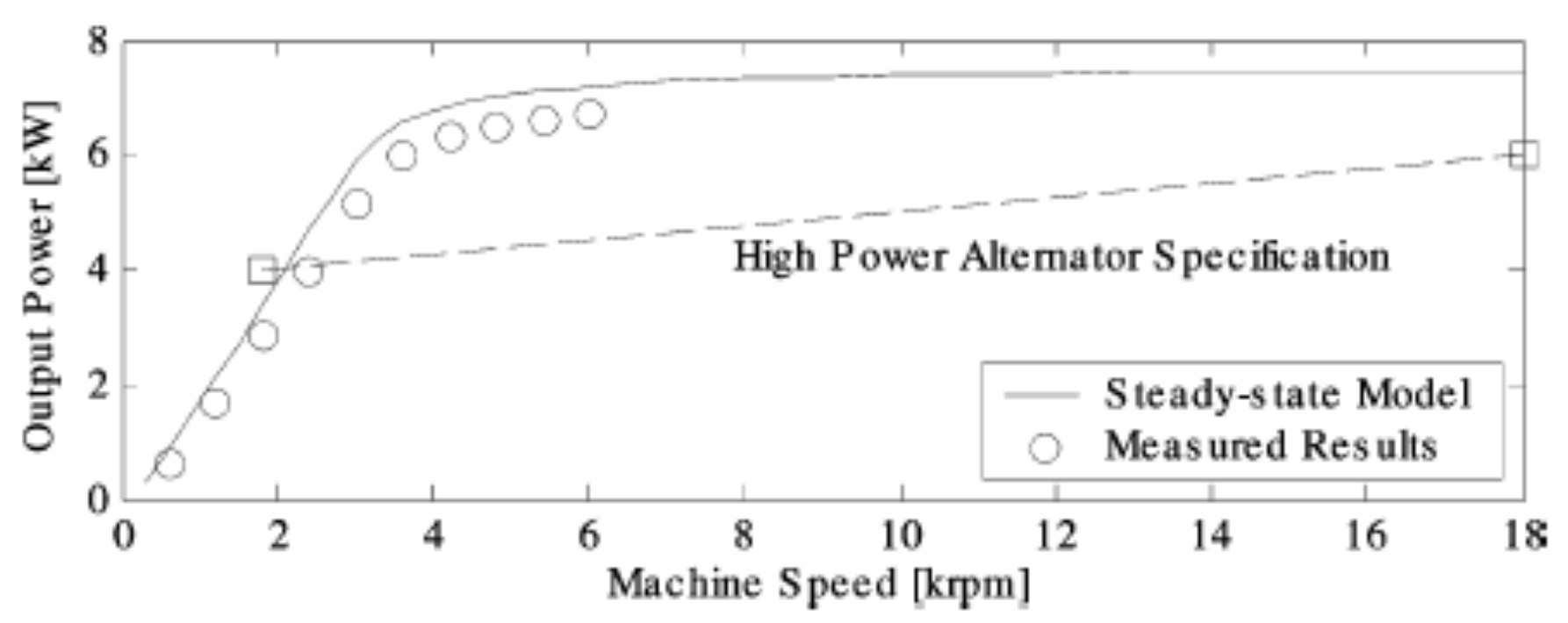

| C.-Z. Liaw, 2013, [29] | SMR | Improved the output power by 66%, high efficiency is obtained at low speeds, and finally, acceptable voltage fluctuation is measured. The type of the alternator is interior PM. This work is experimental. | No investigation has been made for the alternator performance at higher speeds. The accuracy of the proposed system is affected by the rectifier’s presence. |

| Henry et al., 2001, [35] | Inverter and DC/DC converter | The net efficiency was in the range of (73–79%). | The complex controller provides an output power of about 4 kW, but at high speed, this power was reduced to half at 4000 rpm, for example. |

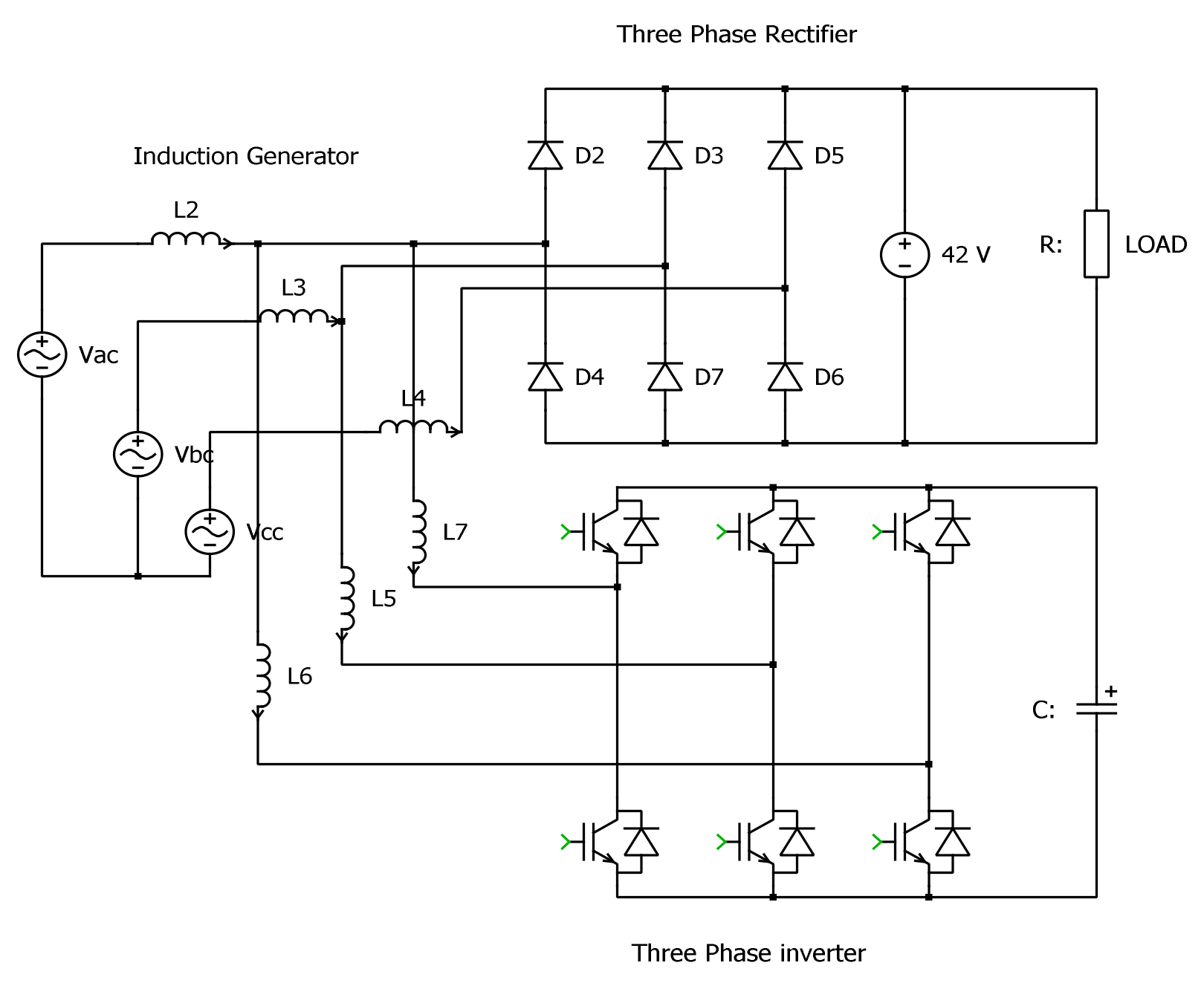

| Naidu and Walters, 2003, [36] | Diode rectifier and voltage source PWM inverter | High efficacy at low speeds, but an excellent transient response for the controller was optioned. An induction generator is used as the power source in this work | It has lower efficiency at full speed, needing a complex controller. Not applied in the real world, and the work is a simulation only. |

| Naidu, Henry, and Boules, 2000, [37] | SCR rectifier | The obtained power was high at full speed, and the efficiency was 71%. A real-world Delphi R&D PM alternator is used in this work. | It used a complex controller. |

| El-Hasan, 2018, [38] | Full controlled AC to DC convertor | High efficiency is optioned (94%) and good voltage regulation. Axial-flux PM(AFPM) S/A alternator is used in a real LGA 340 OHC Lombardini engine. | The system suffered from temperature rise when the load was 49 A. |

| Liang, Miller, and Zarei, 1996, [40] | Six-step inverter | Output increased by 43%, and a good response was obtained. The salient pole Lundell alternator is the alternator type used in this work. | The system suffers from a high fluctuating of the output voltage. Experimental work is present but not used in the real world. |

| Perreault and Caliskan, 2004, [42] | Half-bridge SMR | They increase the output power linearly from 1 kW at idle speed (1800 rpm) to about 4 kW (6000 rpm). Lundell alternator is used in this work. | The system has low energy and efficiency at low speeds. |

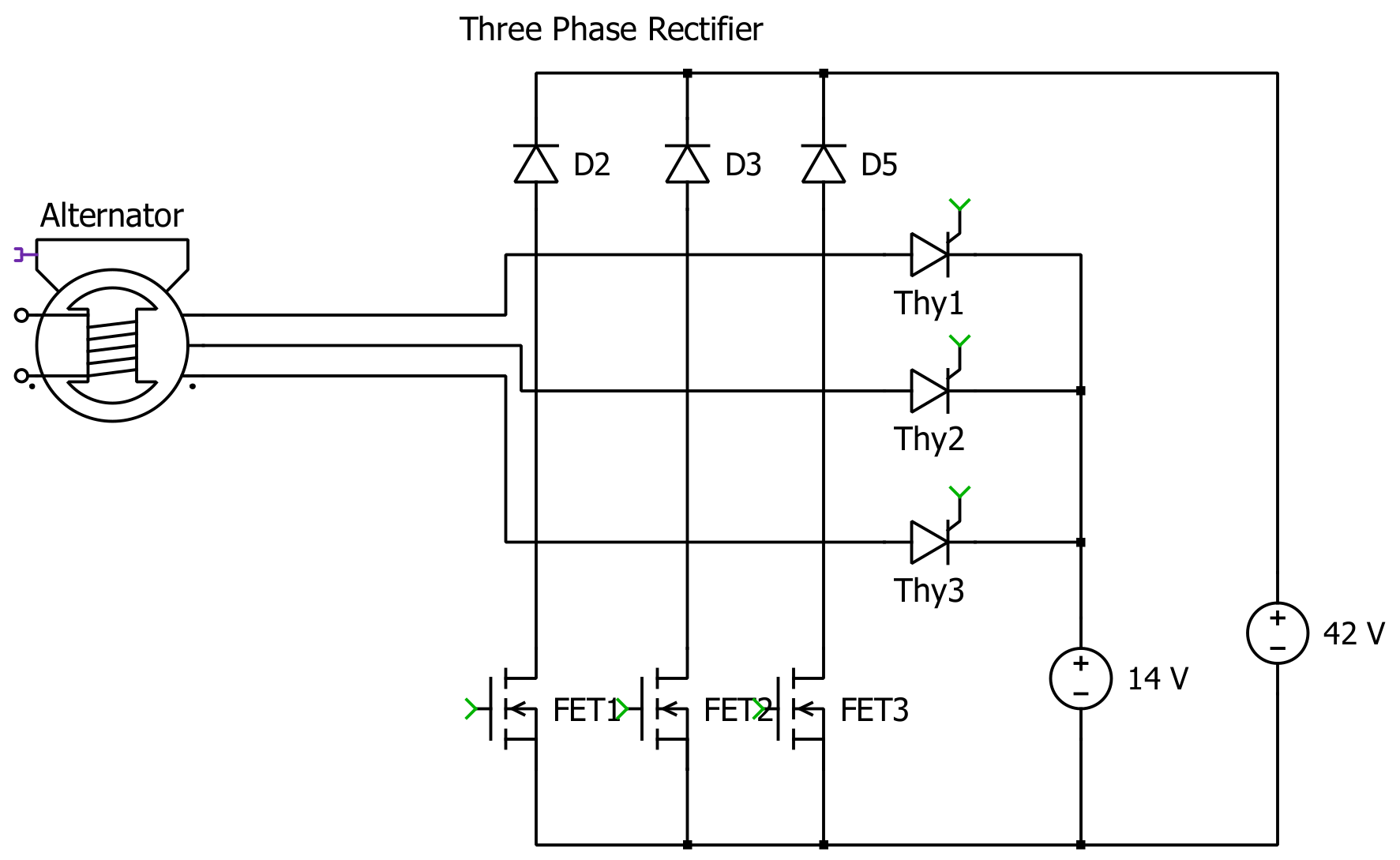

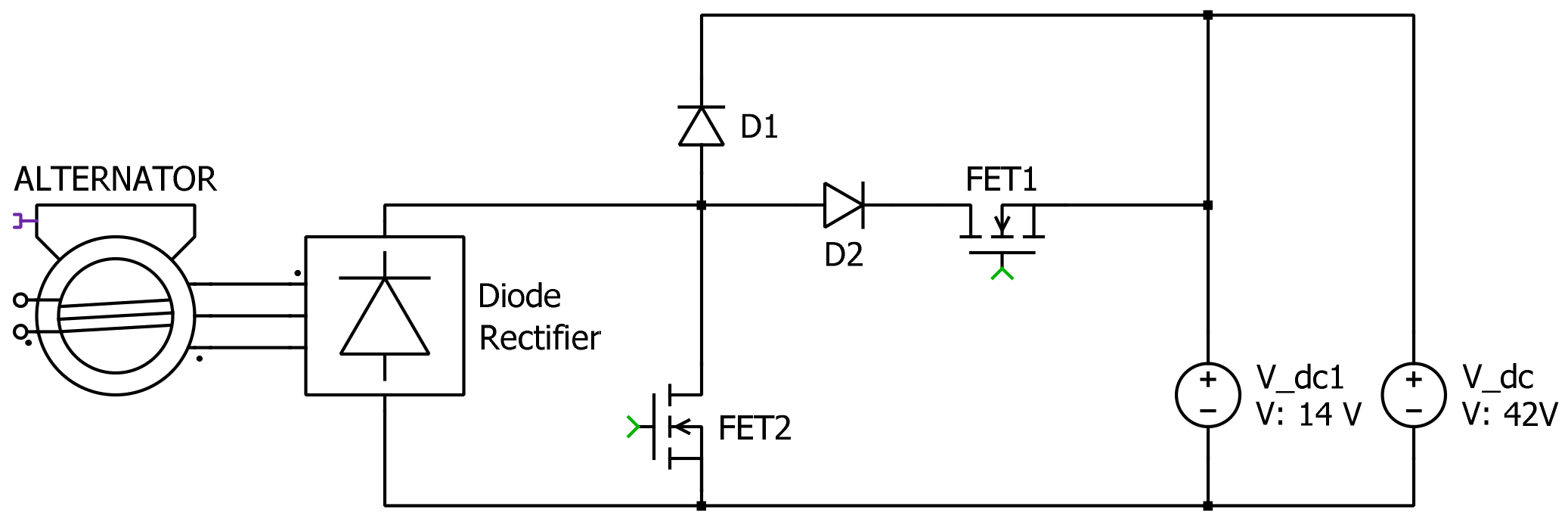

| Hassan, Perreault, and Keim, 2005, [48] | Dual output SMR | Results indicated a good response and performance for the proposed combination. Slandered Lundell alternator (14-V 65/130 A) is used in this work. It is used as an experimental setup to verify the proposed system. | Complex circuit, and it needs an axillary control device. It works only on the alternator’s output, not on the regulating of the field current. |

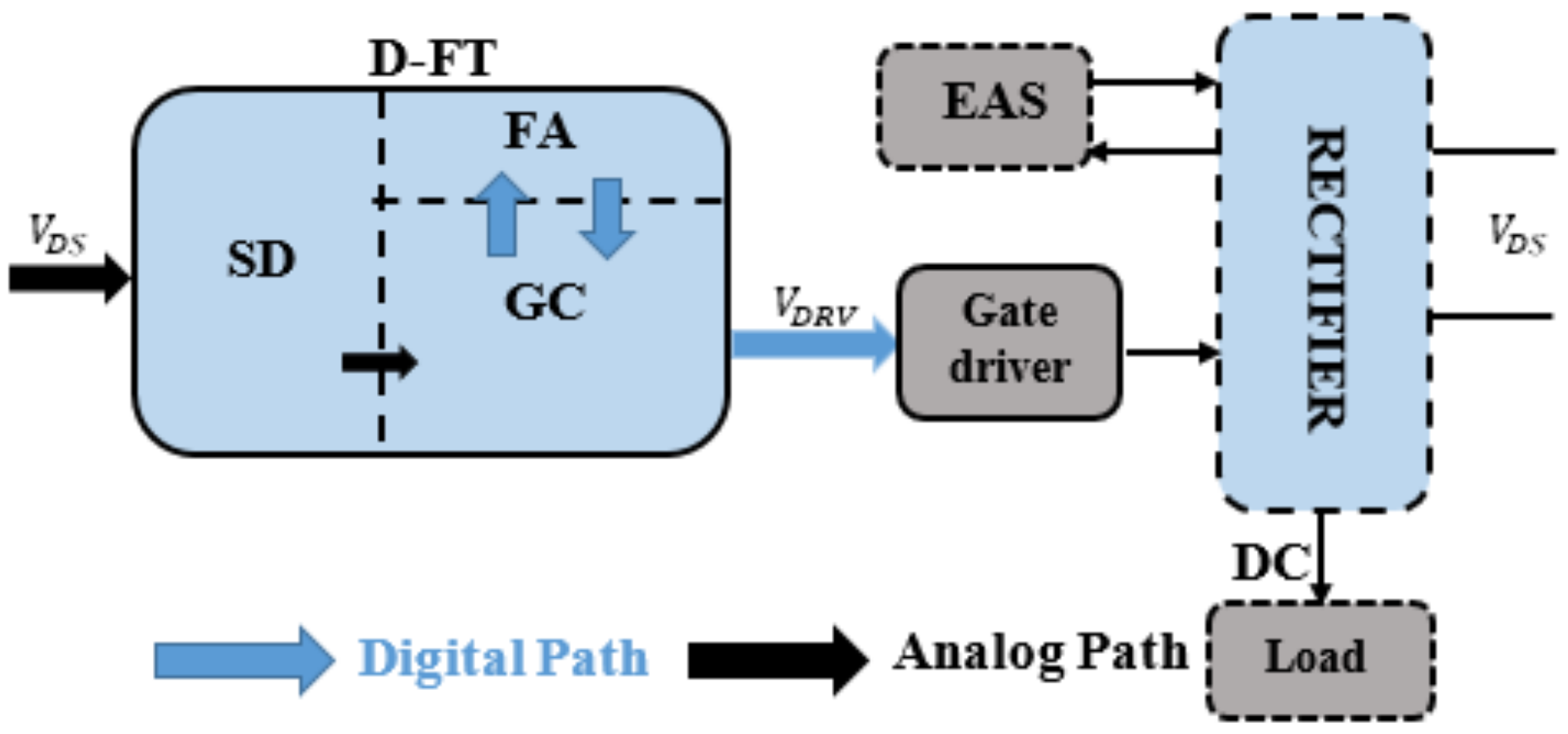

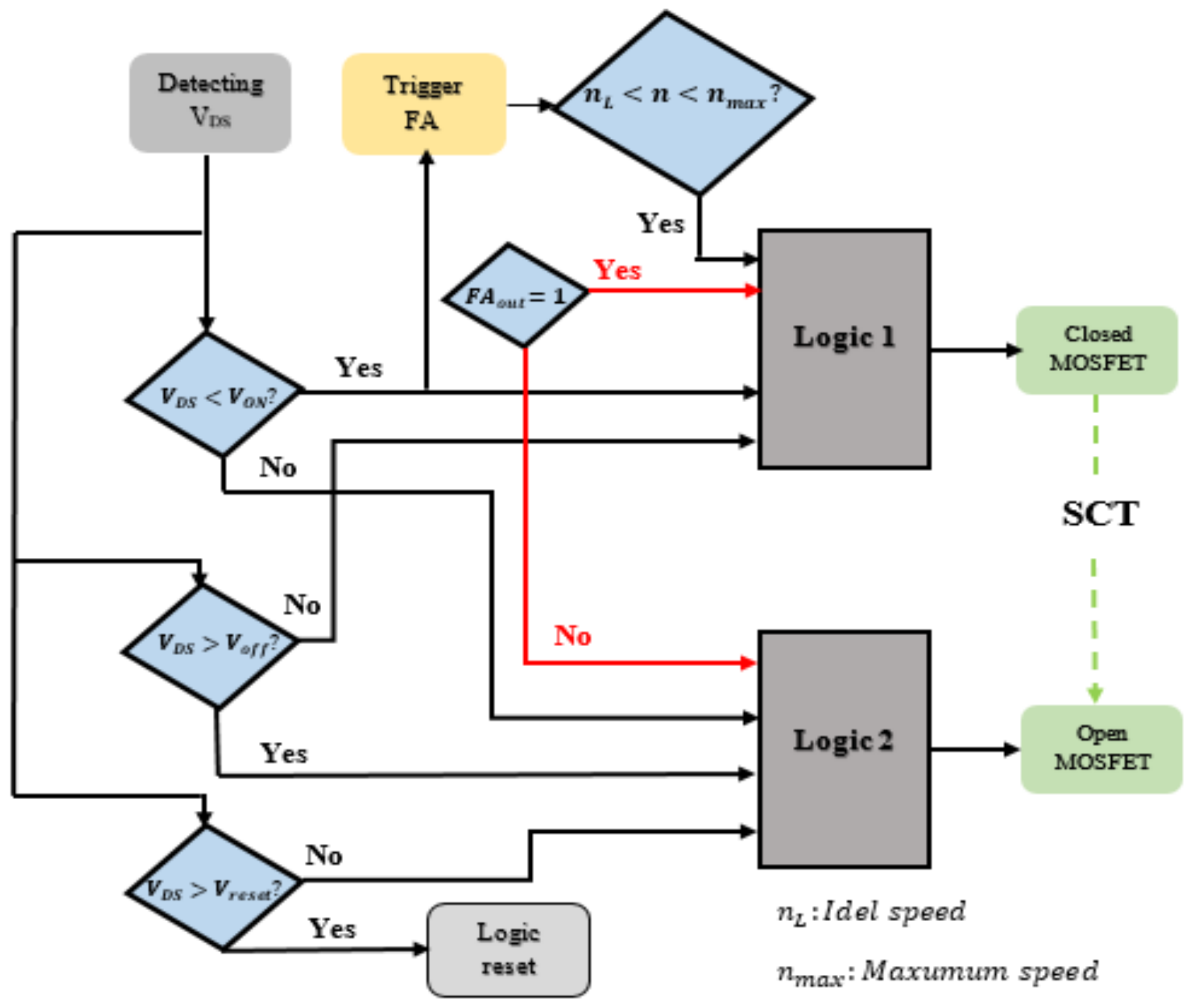

| J. Wan, 2022, [49] | D-FTSR | A novel approach to tracking the engine speed to control the alternator output frequency enhanced alternator efficiency by 8% and can be applicable in a wide range of alternators. The work is verified using an experimental setup. | It controls only the rectifier output and does not deal with the field voltage control. The type of the alternator is not specified in this work. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mahmood, O.T.; Wan Hasan, W.Z.; Ismail, L.I.; Shafie, S.; Azis, N.; Norsahperi, N.M.H. Optimization Approaches and Techniques for Automotive Alternators: Review Study. Machines 2022, 10, 478. https://doi.org/10.3390/machines10060478

Mahmood OT, Wan Hasan WZ, Ismail LI, Shafie S, Azis N, Norsahperi NMH. Optimization Approaches and Techniques for Automotive Alternators: Review Study. Machines. 2022; 10(6):478. https://doi.org/10.3390/machines10060478

Chicago/Turabian StyleMahmood, Omar Talal, Wan Zuha Wan Hasan, Luthffi Idzhar Ismail, Suhaidi Shafie, Norhafiz Azis, and Nor Mohd Haziq Norsahperi. 2022. "Optimization Approaches and Techniques for Automotive Alternators: Review Study" Machines 10, no. 6: 478. https://doi.org/10.3390/machines10060478

APA StyleMahmood, O. T., Wan Hasan, W. Z., Ismail, L. I., Shafie, S., Azis, N., & Norsahperi, N. M. H. (2022). Optimization Approaches and Techniques for Automotive Alternators: Review Study. Machines, 10(6), 478. https://doi.org/10.3390/machines10060478