Multi-Analogy Innovation Design Based on Digital Twin

Abstract

1. Introduction

- A multi-analogy innovation design method is proposed by combining analogy theory, DT, DCC and TRIZ.

- The currently proposed M-AID process model improves the practical feasibility of innovative schemes through DT to integrate data pertinent to customer requirements, the manufacturing process, etc, in the design process.

- The currently proposed model improves design efficiency, shortens the design cycle, and saves resources for product innovation process.

2. Related Works

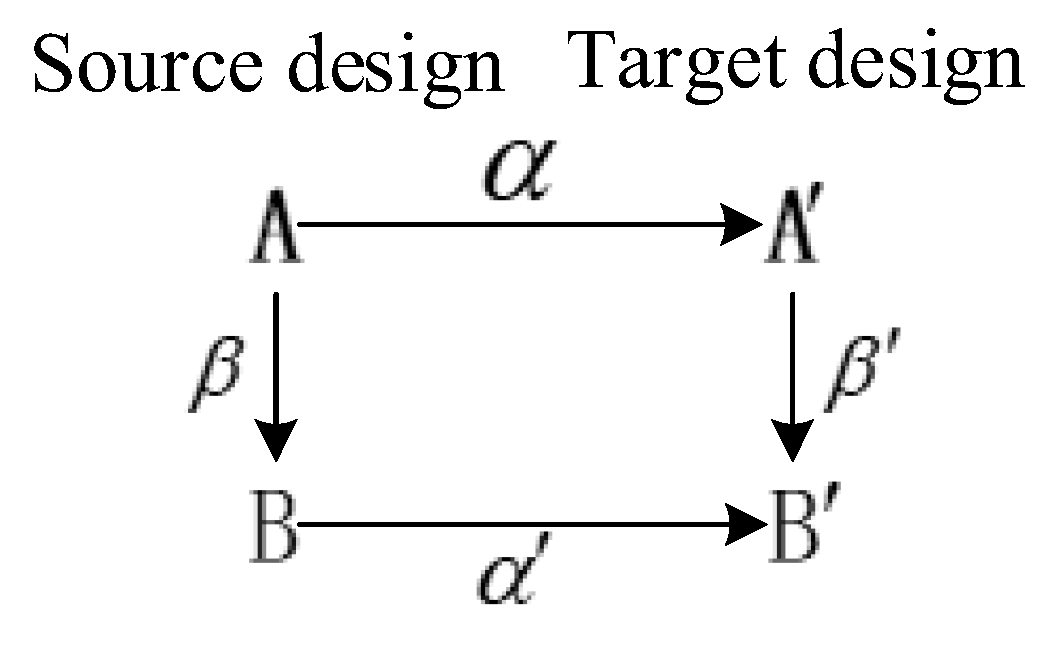

2.1. Analogy Design

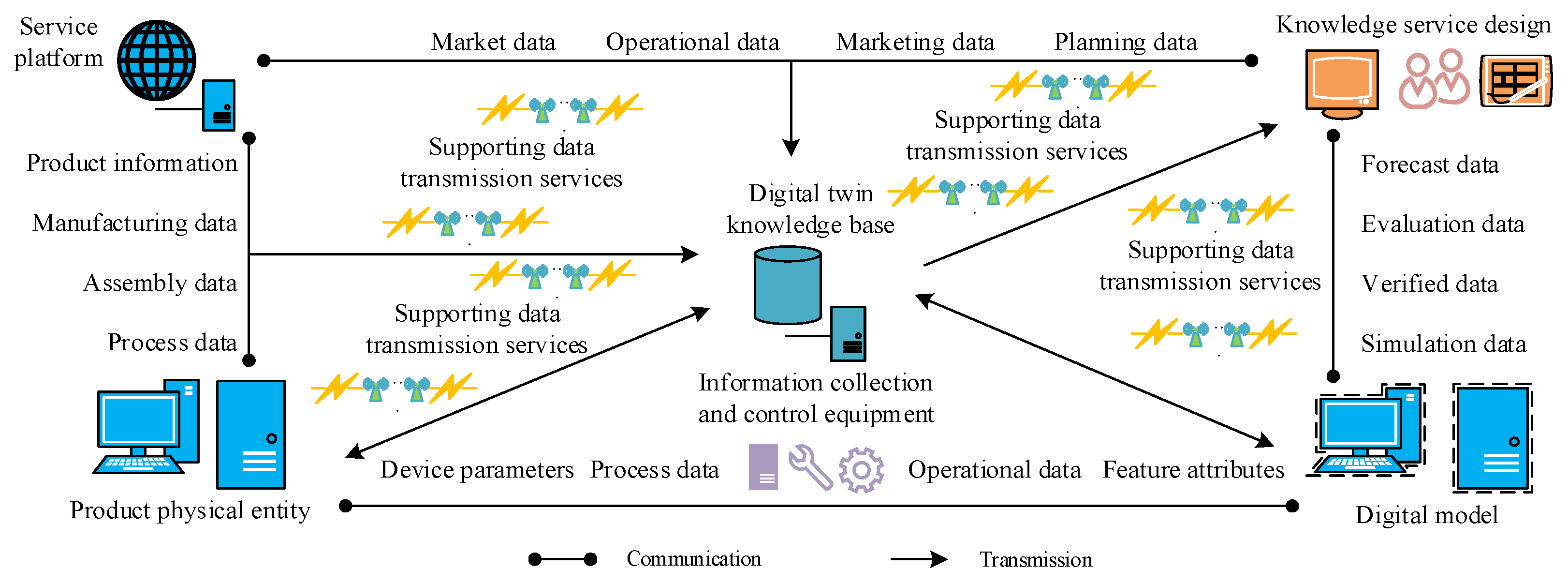

2.2. Digital Twin Knowledge Base

- (1)

- Create a geometric model of product digital twin.

- (2)

- Construct a static size of the virtual space entity using data of existing physical static components. Sensors installed in the entity can provide real-time update data of dynamic components in the entity.

- (3)

- Integrate environmental constraints into the simulation platform and upload and save entity data through the transport layer (ZigBee, WiFi, Ethernet, etc.).

- (1)

- Corresponding data are transmitted to a data conversion unit through the transmission layer, and the required data are filtered to reduce the data processing volume, and thus improve running speed.

- (2)

- By establishing an index, data information is transmitted to a corresponding database storage unit and the information is classified and stored to facilitate subsequent calls.

2.3. Theory of Inventive Problem Solving

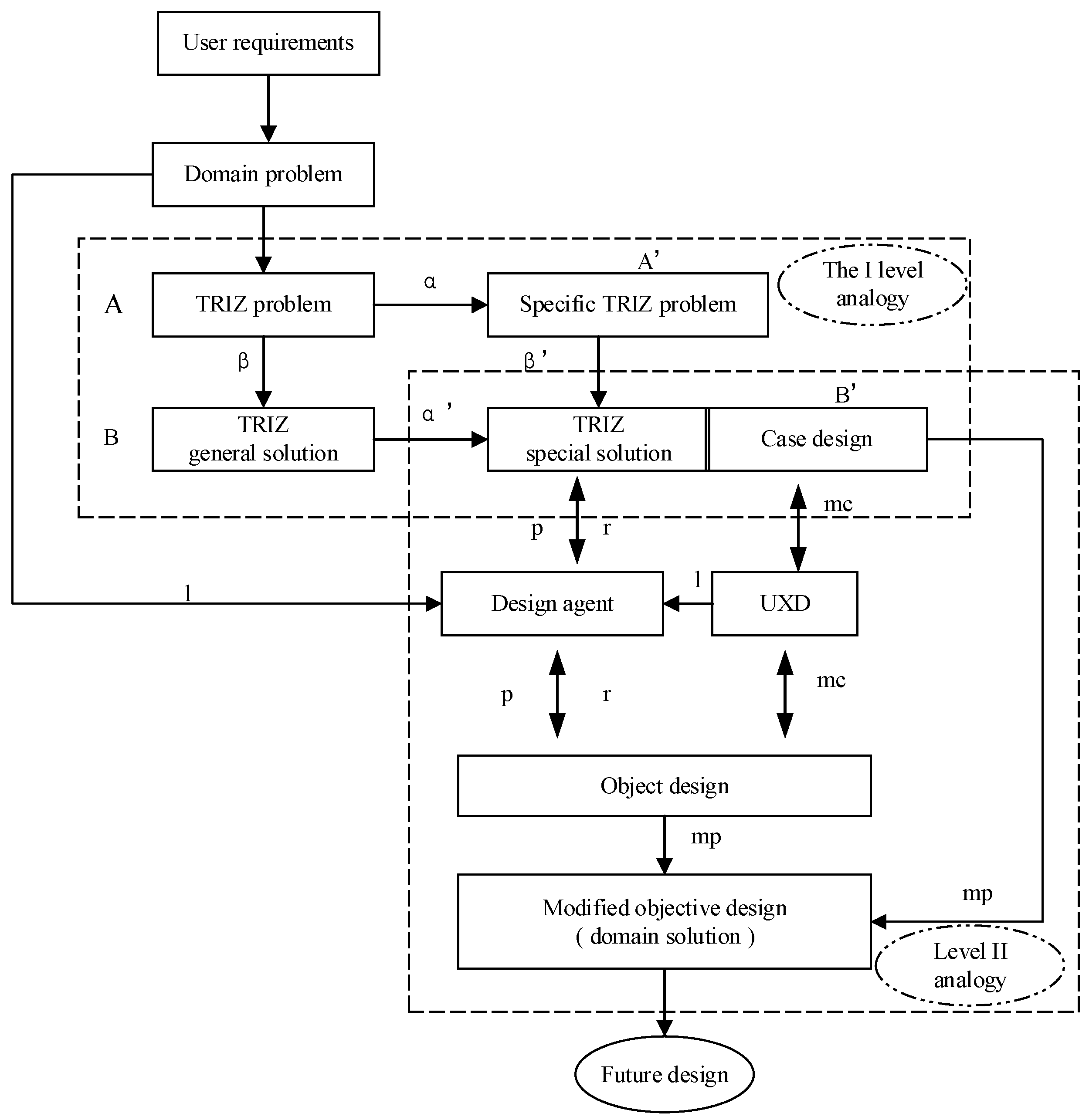

3. Framework and Process Model of Multi-Analogy Innovation Design

3.1. Framework of Multi-Analogy Innovation Design

- Obtaining a reference source system by analogy for the design target;

- Constructing a digital system of the reference source system through analogy between knowledge base of digital twin and patent library;

- Analyzing conditions and environments of source system for specific product functions and digital system;

- Integrating real and digital systems and solving complexity problems that arise during the integration of multiple specific systems through complexity analogy;

- Using TRIZ tools to solve problems in the system for design solutions for the target product.

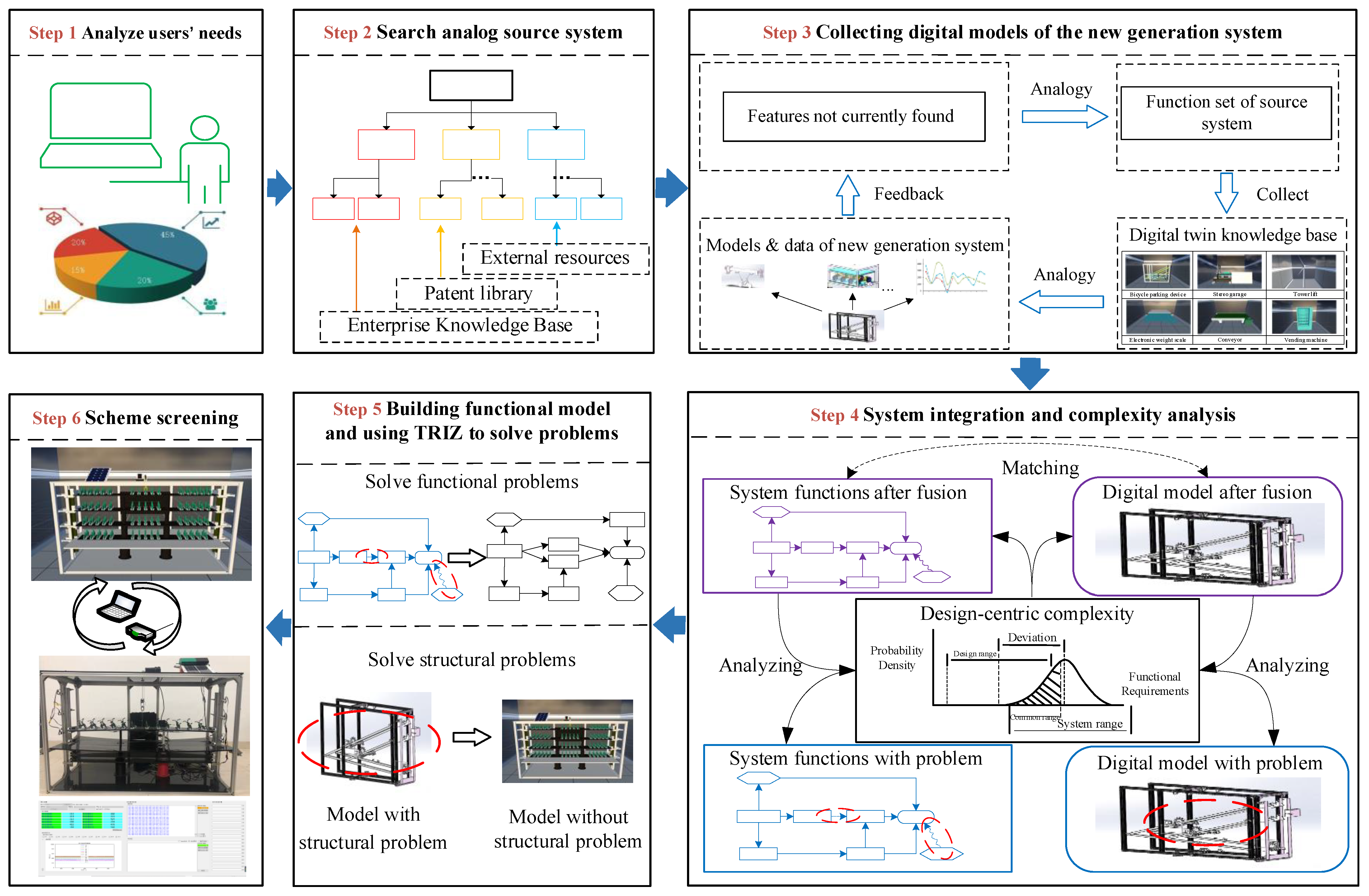

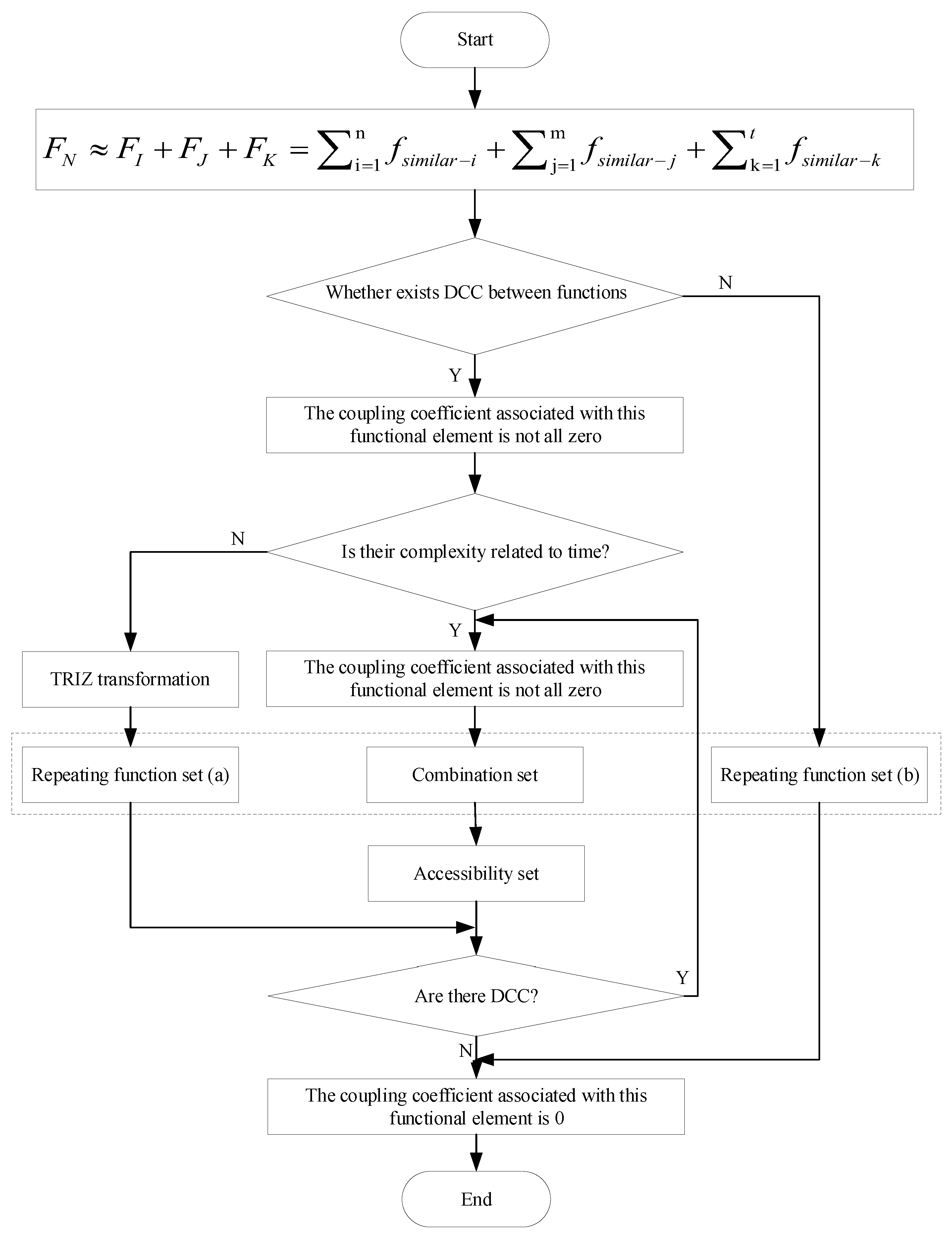

3.2. Process Model of Multi-Analogy Innovation Design

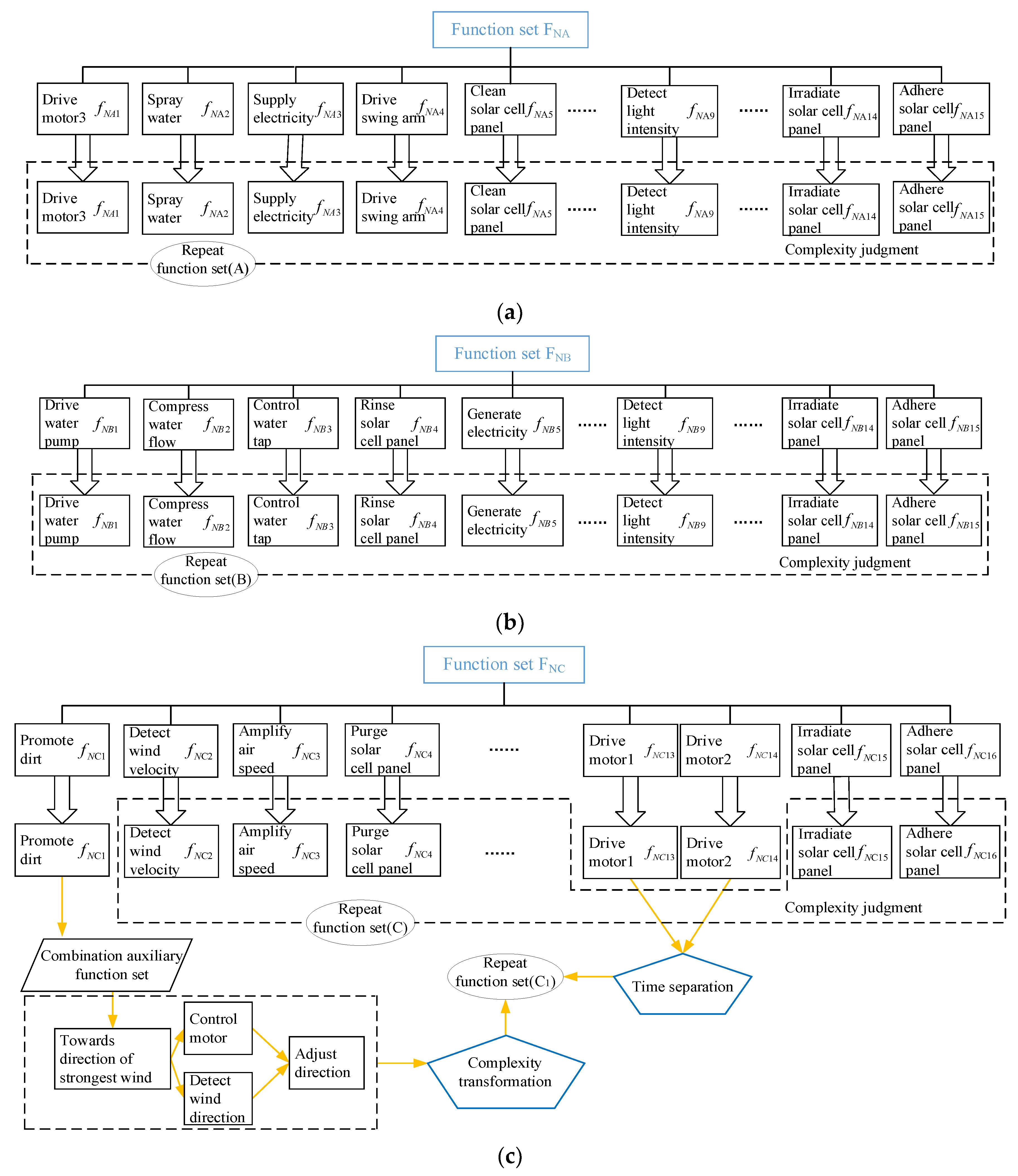

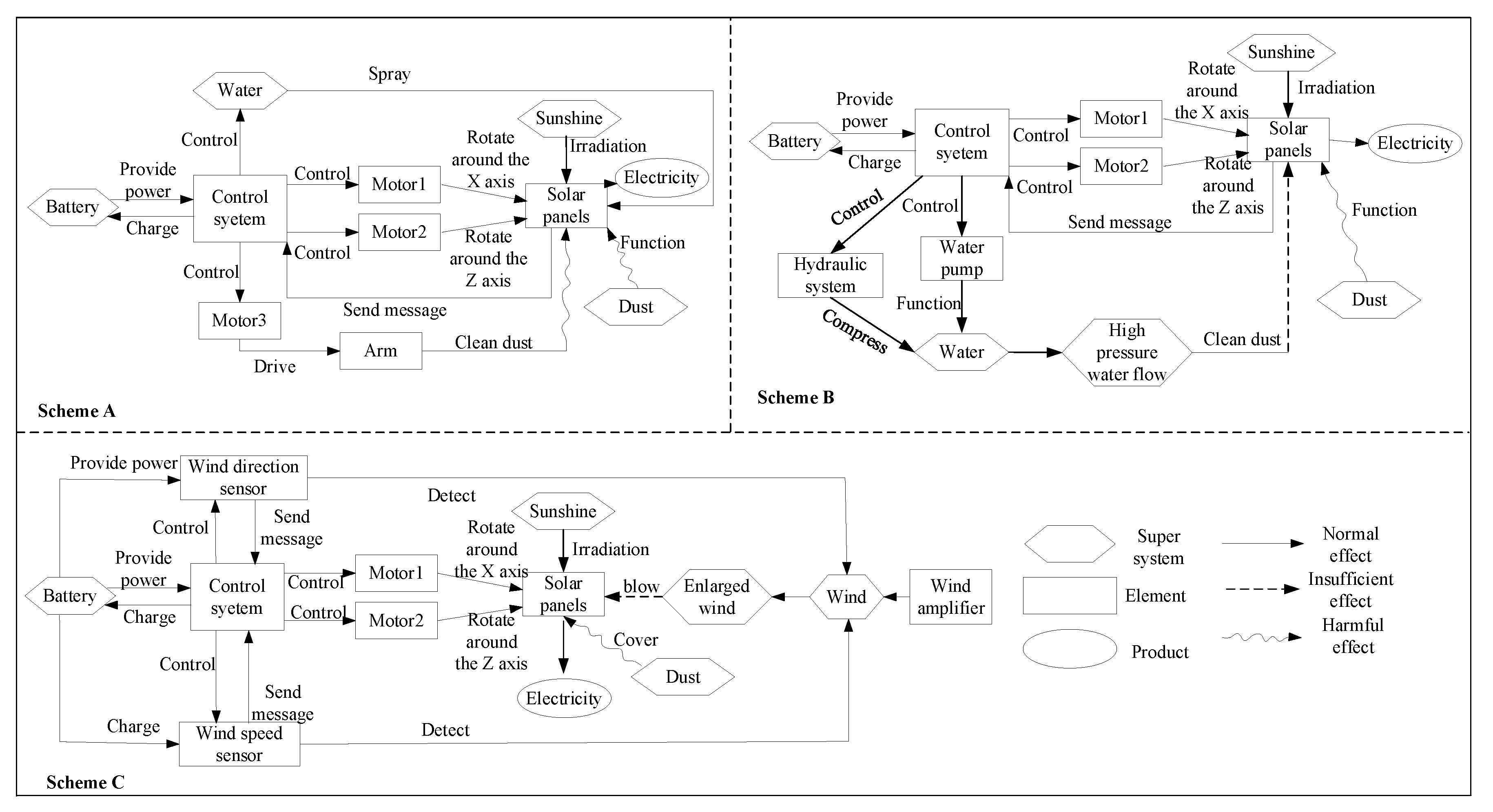

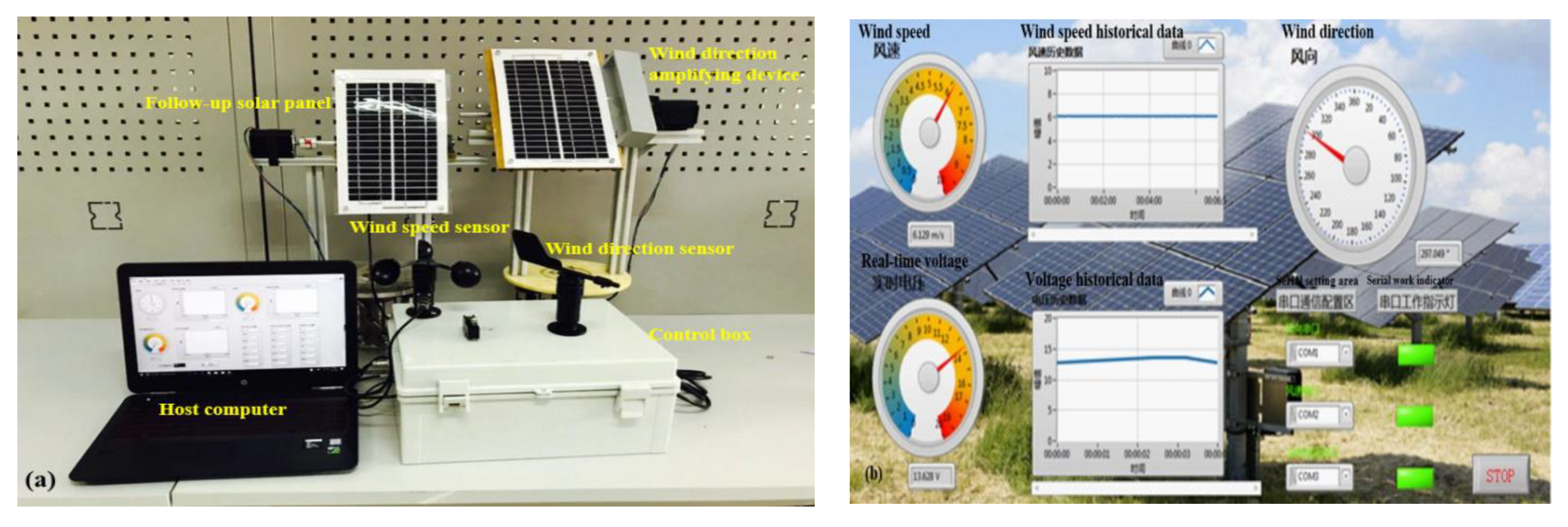

4. Case Study

5. Evaluation of the Currently Proposed Method and Solution

5.1. Discussion of Design Solution

5.2. Discussion of Method

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| M-AID | Multi-analogy innovation design |

| DCC | Design-centric complexity |

| TRIZ | Theory of Inventive Problem Solving |

| DT | Digital twin |

| ABD | Analogy-based design |

| S-B-F | Structure–Behavior–Function |

| V | Verb |

| N | Noun |

| A | Act |

| T | Target |

| EO | Execution object |

| Fi, i = 1, 2, 3,… | Function |

| Ai, i = 1, 2, 3,… | Act |

| Ti, i = 1, 2, 3,… | Target |

| EOi, i = 1, 2, 3,… | Execution object |

| vi, i = 1, 2, 3,… | Flow rate of the fluid in the device |

Appendix A

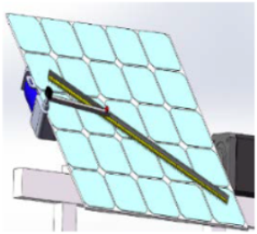

| 1 | Drive | Motor 3 | Control system | Drive | Motor 3 |

| 2 | Spray | Water | Control system | Spray | Water |

| 3 | Supply | Electrical energy | Cell | Provide power | Control system |

| 4 | Drive | Swing arm | Mechanical structure | Drive | Swing arm |

| 5 | Clean | Solar cell panel | Swing arm | Clean | Solar cell panel |

| 6 | Generate | Electricity | Solar cell panel | Generate | Electricity |

| 7 | Depot | Electricity | Cell | Depot | Electricity |

| 8 | Supply | Electricity | Cell | Provide power | Light sensor |

| 9 | Detect | Light intensity | Light sensor | Detect | Sunlight |

| 10 | Rotate horizontally | Solar cell panel | Horizontal motor | Rotate horizontally | Solar cell panel |

| 11 | Rotate vertically | Solar cell panel | Vertical motor | Rotate vertically | Solar cell panel |

| 12 | Drive | Motor 1 | Control system | Drive | Motor 1 |

| 13 | Drive | Motor 2 | Control system | Drive | Motor 2 |

| 14 | Irradiate | Solar cell panel | Sunlight | Irradiate | Solar cell panel |

| 15 | Adhere | Solar cell panel | Dirt | Adhere | Solar cell panel |

| 1 | Drive | Water pump | Control system | Drive | Water pump |

| 2 | Compress | Water flow | Control system | Compress | Water flow |

| 3 | Control | Water tap | Control system | Control | Water tap |

| 4 | Rinse | Solar cell panel | Compressed water | Rinse | Solar cell panel |

| 5 | Generate | Electricity | Solar cell panel | Generate | Electricity |

| 6 | Depot | Electricity | Cell | Depot | Electricity |

| 7 | Supply | Electricity | Sell | Provide power | Light sensor |

| 8 | Supply | Electricity | Cell | Provide power | Control system |

| 9 | Detect | Light intensity | Light sensor | Detect | Sunlight |

| 10 | Rotate horizontally | Solar cell panel | Horizontal motor | Rotate horizontally | Solar cell panel |

| 11 | Rotate vertically | Solar cell panel | Vertical motor | Rotate vertically | Solar cell panel |

| 12 | Drive | Motor1 | Control system | Drive | Motor1 |

| 13 | Drive | Motor2 | Control system | Drive | Motor2 |

| 14 | Irradiate | Solar cell panel | Sunlight | Irradiate | Solar cell panel |

| 15 | Adhere | Solar cell panel | dirt | Adhere | Solar cell panel |

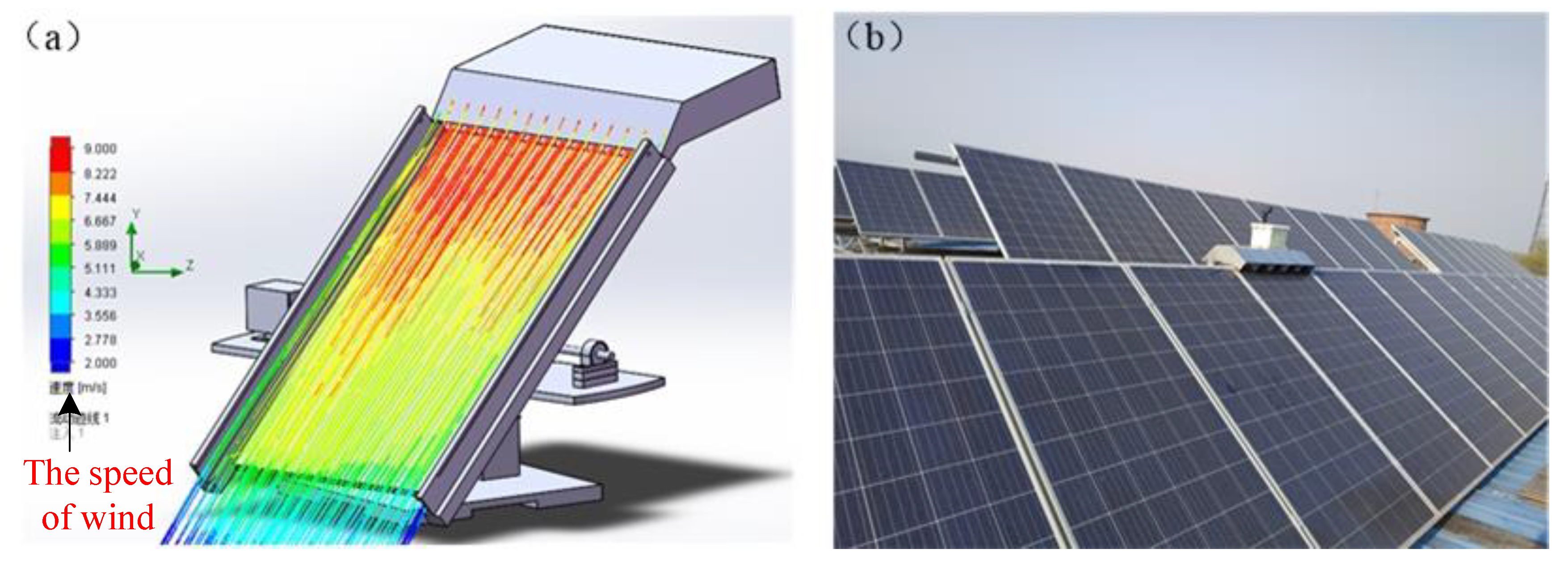

| 1 | Promote | Dirt | Air | Promote | Dirt |

| 2 | Detect | Wind velocity | Wind speed sensor | Detect | Wind velocity |

| 3 | Amplify | Air speed | Air amplifier | Amplify | Air |

| 4 | Purge | Solar cell panel | Amplified wind | Purge | Solar cell panel |

| 5 | Detect | Direction of wind | Direction sensor | Detect | Direction of wind |

| 6 | Generate | Electricity | Solar cell panel | Generate | Electricity |

| 7 | Depot | Electricity | Cell | Depot | Electricity |

| 8 | Supply | Electricity | Cell | Provide power | Light sensor |

| 9 | Supply | Electricity | Cell | Provide power | Control system |

| 10 | Detect | Light intensity | Light sensor | Detect | Sunlight |

| 11 | Rotate horizontally | Solar cell panel | Vertical motor | Rotate horizontally | Solar cell panel |

| 12 | Rotate vertically | Solar cell panel | Horizontal motor | Rotate vertically | Solar cell panel |

| 13 | Drive | Motor 1 | Control system | Drive | Motor 1 |

| 14 | Drive | Motor 2 | Control system | Drive | Motor 2 |

| 15 | Irradiate | Solar cell panel | Sunlight | Irradiate | Solar cell panel |

| 16 | Adhere | Solar cell panel | Dirt | Adhere | Solar cell panel |

Appendix B

Appendix C

| Level | Wind Speed (m/s) | (km/h) | Phenomenon on the Ground | Height of the Waves (m) |

|---|---|---|---|---|

| 0 | 0.0–0.2 | <1 | Smoke moves straight up. | 0.0 |

| 1 | 0.3–1.5 | 1–5 | Smoke is blown away by the wind. | 0.1 |

| 2 | 1.6–3.3 | 6–11 | Leaves rustle loudly. | 0.2 |

| 3 | 3.4–5.4 | 12–19 | Branches swing. | 0.6 |

| 4 | 5.5–7.9 | 20–28 | Dust, paper, and sand are blown up by the wind. | 1.0 |

| 5 | 8.0–10.7 | 29–38 | Small trees sway. | 2.0 |

| 6 | 10.8–13.8 | 39–49 | It is difficult to lift umbrellas. | 3.0 |

| 7 | 13.9–17.1 | 50–61 | It is difficult to walk. | 4.0 |

| 8 | 17.2–20.7 | 62–74 | Tree branches are blown away. | 5.5 |

| 9 | 20.8–24.4 | 75–88 | Tiles are blown away. | 7.0 |

| 10 | 24.5–28.4 | 89–102 | Trees are uprooted. | 9.0 |

| 11 | 28.5–32.6 | 103–117 | Major damage is inflicted. | 11.5 |

Appendix D

Appendix E

| Number | V0 (V) | V1 (V) | V2 (V) | η% |

|---|---|---|---|---|

| 1 | 12.44 | 11.13 | 11.76 | 48.09 |

| 2 | 11.76 | 11.13 | 11.45 | 50.79 |

| 3 | 12.04 | 11.35 | 11.71 | 52.17 |

| 4 | 12.21 | 10.95 | 11.59 | 50.79 |

| 5 | 11.83 | 11.29 | 11.57 | 51.85 |

| 6 | 12.14 | 11.08 | 11.65 | 53.77 |

| 7 | 12.11 | 11.12 | 11.67 | 55.56 |

| 8 | 11.83 | 11.13 | 11.52 | 55.71 |

| 9 | 12.11 | 11.04 | 11.61 | 53.27 |

| 10 | 12.08 | 11.15 | 11.68 | 56.99 |

| 11 | 12.24 | 11.14 | 11.77 | 57.27 |

| 12 | 12.16 | 10.94 | 11.66 | 59.02 |

| 13 | 11.94 | 10.21 | 11.26 | 60.69 |

| 14 | 12.32 | 10.62 | 11.74 | 65.88 |

| 15 | 12.06 | 10.84 | 11.65 | 66.39 |

| 16 | 12.03 | 11.31 | 11.73 | 58.33 |

References

- Liu, X.; Luo, L.; Chen, L.; Li, J. Research on Bio-inspired Design Based on C-K Theory for Product Innovation. J. Mech. Eng. 2020, 56, 207. [Google Scholar]

- Fu, K.; Chan, J.; Cagan, J.; Kotovsky, K.; Schunn, C.; Wood, K. The meaning of “near” and “far”: The impact of structuring design databases and the effect of distance of analogy on design output. J. Mech. Design 2013, 135, 021007. [Google Scholar] [CrossRef]

- Christensen, B.T.; Schunn, C.D. The relationship of analogical distance to analogical function and preinventive structure: The case of engineering design. Mem. Cogn. 2007, 35, 29–38. [Google Scholar] [CrossRef]

- Qian, L.; Gero, J.S. Function–behavior–structure paths and their role in analogy-based design. AI EDAM 1996, 10, 289–312. [Google Scholar] [CrossRef]

- Liu, X.; Tan, R.; Yao, L. Application research on integrated process model for the conceptual design of product innovation. Chin. J. Mech. Eng. 2008, 44, 154–162. [Google Scholar] [CrossRef]

- Goel, A.K.; Bhatta, S.R. Use of design patterns in analogy-based design. Adv. Eng. Inform. 2004, 18, 85–94. [Google Scholar] [CrossRef]

- Zhang, P.; Nie, Z.; Dong, Y.; Zhang, Z.; Yu, F.; Tan, R. Smart concept design based on recessive inheritance in complex electromechanical system. Adv. Eng. Inform. 2019, 43, 101010. [Google Scholar] [CrossRef]

- Glaessgen, E.; Stargel, D. The digital twin paradigm for future NASA and US Air Force vehicles. In Proceedings of the 53rd AIAA/ASME/ASCE/AHS/ASC Structures, Structural Dynamics and Materials Conference 20th AIAA/ASME/AHS Adaptive Structures Conference 14th AIAA, Honolulu, HI, USA, 23–26 April 2012; p. 1818. [Google Scholar]

- Wagner, C.; Grothoff, J.; Epple, U.; Drath, R.; Malakuti, S.; Gruner, S.; Hoffmeister, M.; Zimermann, P. The role of the Industry 4.0 asset administration shell and the digital twin during the life cycle of a plant. In Proceedings of the 2017 22nd IEEE International Conference on Emerging Technologies and Factory Automation (ETFA), Limassol, Cyprus, 12–15 September 2017; pp. 1–8. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems; Springer: Cham, Switzerland, 2017; pp. 85–113. [Google Scholar]

- Tao, F.; Sui, F.; Liu, A.; Qi, Q.; Zhang, M.; Song, B.; Guo, Z.; Lu, S.C.-Y.; Nee, A.Y.C. Digital twin-driven product design framework. Int. J. Prod. Res. 2019, 57, 3935–3953. [Google Scholar] [CrossRef]

- Singh, V.; Willcox, K.E. Engineering Design with Digital Thread. AIAA J. 2018, 56, 4515–4528. [Google Scholar] [CrossRef]

- Moyne, J.; Qamsane, Y.; Balta, E.C.; Kovalenko, I.; Faris, J.; Barton, K.; Tilbury, D.M. A Requirements Driven Digital Twin Framework: Specification and Opportunities. IEEE Access 2020, 8, 107781–107801. [Google Scholar] [CrossRef]

- Jia, L.; Peng, Q.; Tan, R.; Zhu, X. Analogical stimuli retrieval approach based on R-SBF ontology model. J. Eng. Des. 2019, 30, 599–624. [Google Scholar] [CrossRef]

- Liu, X.M.; Huang, S.P.; Wang, J.H.; Lin, G. Conceptual design based on TRIZ & function analogy for product innovation. J. Mech. Eng. 2016, 52, 34–42. [Google Scholar]

- Dunbar, K.; Baker, L.M. Goals, analogy, and the social constraints of scientific discovery. Behav. Brain Sci. 1994, 17, 538–539. [Google Scholar] [CrossRef]

- Tan, R.; Zhang, R.; Liu, F.; Yang, B.-J. Two stages analogy-based conceptual design based on TRIZ. Comput. Integr. Manuf. Syst. 2006, 12, 328. [Google Scholar]

- Jia, L.-Z.; Wu, C.-L.; Zhu, X.-H.; Tan, R.-H. Design by Analogy: Achieving More Patentable Ideas from One Creative Design. Chin. J. Mech. Eng. 2018, 31, 37. [Google Scholar] [CrossRef]

- Moreno, D.P.; Blessing, L.T.; Yang, M.C.; Hernández, A.A.; Wood, K.L. Overcoming design fixation: Design by analogy studies and nonintuitive findings. Artif. Intell. Eng. Des. Anal. Manuf. 2016, 30, 185–199. [Google Scholar] [CrossRef]

- Murphy, J.; Fu, K.; Otto, K.; Yang, M.; Jensen, D.; Wood, K. Function Based Design-by-Analogy: A Functional Vector Approach to Analogical Search. J. Mech. Des. 2014, 136, 101102. [Google Scholar] [CrossRef]

- Zhang, H.; Yan, Q.; Wen, Z. Information modeling for cyber-physical production system based on digital twin and AutomationML. Int. J. Adv. Manuf. Technol. 2020, 107, 1927–1945. [Google Scholar] [CrossRef]

- Tao, F.; Liu, W.; Liu, J.; Liu, X.; Liu, Q.; Qu, T.; Hu, T.; Zhang, Z.; Xiang, F.; Xu, W.; et al. Digital twin and its potential application exploration. Comput. Integr. Manuf. Syst. 2018, 24, 1–18. [Google Scholar]

- Tao, F.; Liu, W.; Zhang, M.; Hu, T.; Qi, Q.; Zhang, H.; Sui, F.; Wang, T.; Xu, H.; Huang, Z.; et al. Five-dimension digital twin model and its ten applications. Comput. Integr. Manuf. Syst. 2019, 25, 1–18. [Google Scholar]

- Wu, C.; Zhou, Y.; Pessôa, M.V.P.; Peng, Q.; Tan, R. Conceptual digital twin modeling based on an integrated five-dimensional framework and TRIZ function model. J. Manuf. Syst. 2020, 58, 79–93. [Google Scholar] [CrossRef]

- Fourgeau, E.; Gomez, E.; Adli, H.; Fernandes, C.; Hagege, M. System engineering workbench for multi-views systems methodology with 3DEXPERIENCE Platform. The Aircraft Radar Use Case. In Advances in Intelligent Systems and Computing; Springer: Cham, Switzerland, 2016; pp. 269–270. [Google Scholar]

- Wang, Y.; Wang, S.; Yang, B.; Zhu, L.; Liu, F. Big data driven Hierarchical Digital Twin Predictive Remanufacturing paradigm: Architecture, control mechanism, application scenario and benefits. J. Clean. Prod. 2019, 248, 119299. [Google Scholar] [CrossRef]

- Erkoyuncu, J.A.; del Amo, I.F.; Ariansyah, D.; Bulka, D.; Vrabič, R.; Roy, R. A design framework for adaptive digital twins. CIRP Ann. 2020, 69, 145–148. [Google Scholar] [CrossRef]

- Dong, Y.; Tan, R.; Zhang, P.; Peng, Q.; Shao, P. Product redesign using functional backtrack with digital twin. Adv. Eng. Inform. 2021, 49, 101361. [Google Scholar] [CrossRef]

- Nie, Z.; Zhang, P.; Wang, F.; Wang, Z. Sustainable innovation pathway for mechanical products by inducing characteristic parameters. Adv. Eng. Inform. 2021, 49, 101349. [Google Scholar] [CrossRef]

- Zhang, J.S.; Wang, Q.F.; Zhong, Y.F.; Wan, L. Configuration-oriented product modelling and knowledge management for made-to-order manufacturing enterprises. Int. J. Adv. Manuf. Technol. 2005, 25, 41–52. [Google Scholar]

- Lim, K.Y.H.; Zheng, P.; Chen, C.-H.; Huang, L. A digital twin-enhanced system for engineering product family design and optimization. J. Manuf. Syst. 2020, 57, 82–93. [Google Scholar] [CrossRef]

- Zhou, G.; Zhang, C.; Li, Z.; Ding, K.; Wang, C. Knowledge-driven digital twin manufacturing cell towards intelligent manufacturing. Int. J. Prod. Res. 2019, 58, 1034–1051. [Google Scholar] [CrossRef]

- Xiao, F.; Zhang, W.; Wang, D.; Peng, K.; Qian, F. System architecture and applications for overall design of solid rocket motor based on digital twin. Comput. Integr. Manuf. Syst. 2019, 25, 1405–1418. [Google Scholar]

- Chinkatham, T.; Cavallucci, D. Early feasibility evaluation of Solution Concepts in an Inventive Design Method Framework: Approach and support tool. Comput. Ind. 2015, 67, 1–16. [Google Scholar] [CrossRef]

- Baldussu, A.; Cascini, G. About Integration Opportunities between TRIZ and Biomimetics for Inventive Design. Procedia. Eng. 2015, 131, 3–13. [Google Scholar] [CrossRef]

- Borgianni, Y.; Cascini, G.; Rotini, F. Preliminary Studies on Human Approaches to Inventive Design Tasks with a TRIZ Perspective. Procedia Eng. 2015, 131, 39–49. [Google Scholar] [CrossRef]

- Frillici, F.S.; Fiorineschi, L.; Cascini, G. Linking TRIZ to Conceptual Design Engineering Approaches. Procedia Eng. 2015, 131, 1031–1040. [Google Scholar] [CrossRef]

- Rousselot, F.; Zanni-Merk, C.; Cavallucci, D. Towards a formal definition of contradiction in inventive design. Comput. Ind. 2012, 63, 231–242. [Google Scholar] [CrossRef]

- Yan, W.; Liu, H.; Zanni-Merk, C.; Cavallucci, D. IngeniousTRIZ: An automatic ontology-based system for solving inventive problems. Knowl.-Based Syst. 2015, 75, 52–65. [Google Scholar] [CrossRef]

- Yan, W.; Liu, H.; Liu, Y.; Wang, J.; Zanni-Merk, C.; Cavallucci, D.; Yan, X.; Zhang, L. Latent semantic extraction and analysis for TRIZ-based inventive design. Eur. J. Ind. Eng. 2018, 12, 661–681. [Google Scholar] [CrossRef]

- Sheu, D.-L.D.; Chiu, M.-C.; Cayard, D. The 7 pillars of TRIZ philosophies. Comput. Ind. Eng. 2020, 146, 106572. [Google Scholar] [CrossRef]

- Sauli, S.A.; Ishak, M.R.; Mustapha, F.; Yidris, N.; Hamat, S. Hybridization of TRIZ and CAD-analysis at the conceptual design stage. Int. J. Comput. Integr. Manuf. 2019, 32, 890–899. [Google Scholar] [CrossRef]

- Kandukuri, S.; Günay, E.E.; Al-Araidah, O.; Kremer, G.E.O. Inventive solutions for remanufacturing using additive manufacturing: ETRIZ. J. Clean. Prod. 2021, 305, 126992. [Google Scholar] [CrossRef]

- Leon, N. The future of computer-aided innovation. Comput. Ind. 2009, 60, 539–550. [Google Scholar] [CrossRef]

- Hüsig, S.; Kohn, S. Computer aided innovation—State of the art from a new product development perspective. Comput. Ind. 2009, 60, 551–562. [Google Scholar] [CrossRef]

- Cugini, U.; Cascini, G.; Muzzupappa, M.; Nigrelli, V. Integrated Computer-Aided Innovation: The PROSIT approach. Comput. Ind. 2009, 60, 629–641. [Google Scholar] [CrossRef]

- Flores, R.L.; Belaud, J.P.; Negny, S.; Le Lann, J.M. Open computer aided innovation to promote innovation in process engineering. Chem. Eng. Res. Des. 2015, 103, 90–107. [Google Scholar] [CrossRef][Green Version]

- Zhang, J.; Tan, R.; Zhang, Z. Research on the integration of product concept design and particular design driven by CAI technology. J. Mech. Eng. 2016, 52, 47–57. [Google Scholar] [CrossRef]

- Zhang, H.G. Innovative Design-Systematic Innovation Based on TRIZ; China Machine Press: Beijing, China, 2017; pp. 79–80. [Google Scholar]

- Frey, D.D.; Jahangir, E.; Engelhardt, F. Computing the Information Content of Decoupled Designs. Res. Eng. Des. 2000, 12, 90–102. [Google Scholar] [CrossRef]

- Suh, N.P. Complexity in engineering. CIRP Ann. 2005, 54, 46–63. [Google Scholar] [CrossRef]

- Zhang, P.; Li, X.; Nie, Z.; Yu, F.; Liu, W. A Trimming Design Method Based on Bio-Inspired Design for System Innovation. Appl. Sci. 2021, 11, 4060. [Google Scholar] [CrossRef]

| Evaluation Conditions | Complexity 1 | Effect 2 | Consumption Resource 3 | Economy 4 | Constraint Condition 5 | S |

|---|---|---|---|---|---|---|

| Weight w | 0.10 | 0.30 | 0.10 | 0.25 | 0.25 | |

| Value ranges q | −1 × n (number of functions) | 1 to 4 (poor) | −1 × (1 to 4) (poor) | 1 to 4 (poor) | −1 × n (number of constraints) | |

| 5 to 8 (general) | −1 × (5 to 8) (general) | 5 to 8 (general) | ||||

| 9 to 10 (good) | −1 × (9 to 10) (higher) | 9 to 10 (good) |

| 11 | Generate | Electricity | Generate | Electricity | Solar cell panel |

| 12 | Depot | Electricity | Depot | Electricity | Cell |

| 13 | Supply | Electricity | Provide power | Light sensor | Cell |

| 14 | Supply | Electricity | Provide power | Control system | Cell |

| 15 | Monitor | Direction | Detect | Sunlight | Light sensor |

| 16 | Rotate horizontally | Cell panel | Rotate horizontally | Solar cell panel | Horizontal motor |

| 17 | Rotate vertically | Cell panel | Rotate vertically | Solar cell panel | Vertical motor |

| 18 | Drive | Motor1 | Drive | Motor1 | Control system |

| 19 | Drive | Motor2 | Drive | Motor2 | Control system |

| Scheme | Problem | TRIZ General Questions | TRIZ General Solution | TRIZ Special Solution | Scheme Drawing |

|---|---|---|---|---|---|

| A | The goal is to remove as much dust as possible, but too much friction will wear out the surface of the battery panel. | Improve parameter: Loss of substance Deterioration parameter: Object-generated harmful factors | 22: Turning harmful into beneficial 30: Flexible shells or thin films 33: Homogeneity 40: Composite materials | Select 30th invention principle to get specific plan: Change material of brush and improve brushing method to rolling erasing. |  |

| B | To clean the battery panel, the position of the high-pressure water gun needs to be changed, but this will lead to more complex devices. | Improve parameter: Ease of operation Deterioration parameter: Device complexity | 12: Equipotentiality 17: Another dimension 26: Copying 32: Color modification | Select the 26th invention principle to get a specific plan: Increase the baffle to change the direction of water flow. |  |

| C | For the system to use wind energy in the direction where wind energy is the greatest, it cannot be in the direction where light energy is best absorbed. | The hope is to face the direction of the strongest light but also to maximize the use of wind energy | Taking out-Separation | Improve structure so that direction of the wind amplifying device can be adjusted independently. |  |

| Evaluation Conditions | Weight | Scheme A | Scheme B | Scheme C |

|---|---|---|---|---|

| Complexity | 0.1 | −15 | −15 | −16 |

| Effect | 0.3 | 7 | 8 | 5 |

| Consumption resource | 0.1 | −4 | −6 | −1 |

| Economy | 0.25 | 4 | 6 | 7 |

| Constraint condition | 0.25 | −2 | −3 | −1 |

| S | —— | 0.7 | 1.05 | 1.3 |

| Aspects | Manual Dust Removal | High Pressure-Water Dust Removal | Waterless Robot Dust Removal | Natural Wind Dust Removal |

|---|---|---|---|---|

| Applicable scene | Small or home solar panels | Solar panels in areas with abundant water resources | Solar panels in rainy or low-rain areas | Solar power sites in a windy and less rainy area of the northwest |

| Energy used for dust removal | Water | Water | Mechanical energy | Natural energy |

| Automaticity | Low | Medium | High | High |

| Effect of dust removal | Very good | Good | Good | Good |

| Cost | High labor cost | High cost | Extremely high cost | Low cost |

| Advantages and Disadvantages | ||||

| Advantages | Very good dust removal effect | Good dust removal effect | Good dust removal effect less using water | Good dust removal effect without water |

| Disadvantages | Involves the use of cleaning agents, which may cause secondary pollution of the environment | Requires a lot of water resources, resulting in waste of resources | Involves high construction cost, high maintenance cost, expensive lease, and high driver cost | The effect of dust removal is unstable restricted by wind |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nie, Z.; Cao, G.; Zhang, P.; Peng, Q.; Zhang, Z. Multi-Analogy Innovation Design Based on Digital Twin. Machines 2022, 10, 652. https://doi.org/10.3390/machines10080652

Nie Z, Cao G, Zhang P, Peng Q, Zhang Z. Multi-Analogy Innovation Design Based on Digital Twin. Machines. 2022; 10(8):652. https://doi.org/10.3390/machines10080652

Chicago/Turabian StyleNie, Zifeng, Guozhong Cao, Peng Zhang, Qingjin Peng, and Zhimin Zhang. 2022. "Multi-Analogy Innovation Design Based on Digital Twin" Machines 10, no. 8: 652. https://doi.org/10.3390/machines10080652

APA StyleNie, Z., Cao, G., Zhang, P., Peng, Q., & Zhang, Z. (2022). Multi-Analogy Innovation Design Based on Digital Twin. Machines, 10(8), 652. https://doi.org/10.3390/machines10080652