Study on the Factors Affecting the Wheel–Rail Lateral Impact of the Forepart of the Curved Switch Rail

Abstract

:1. Introduction

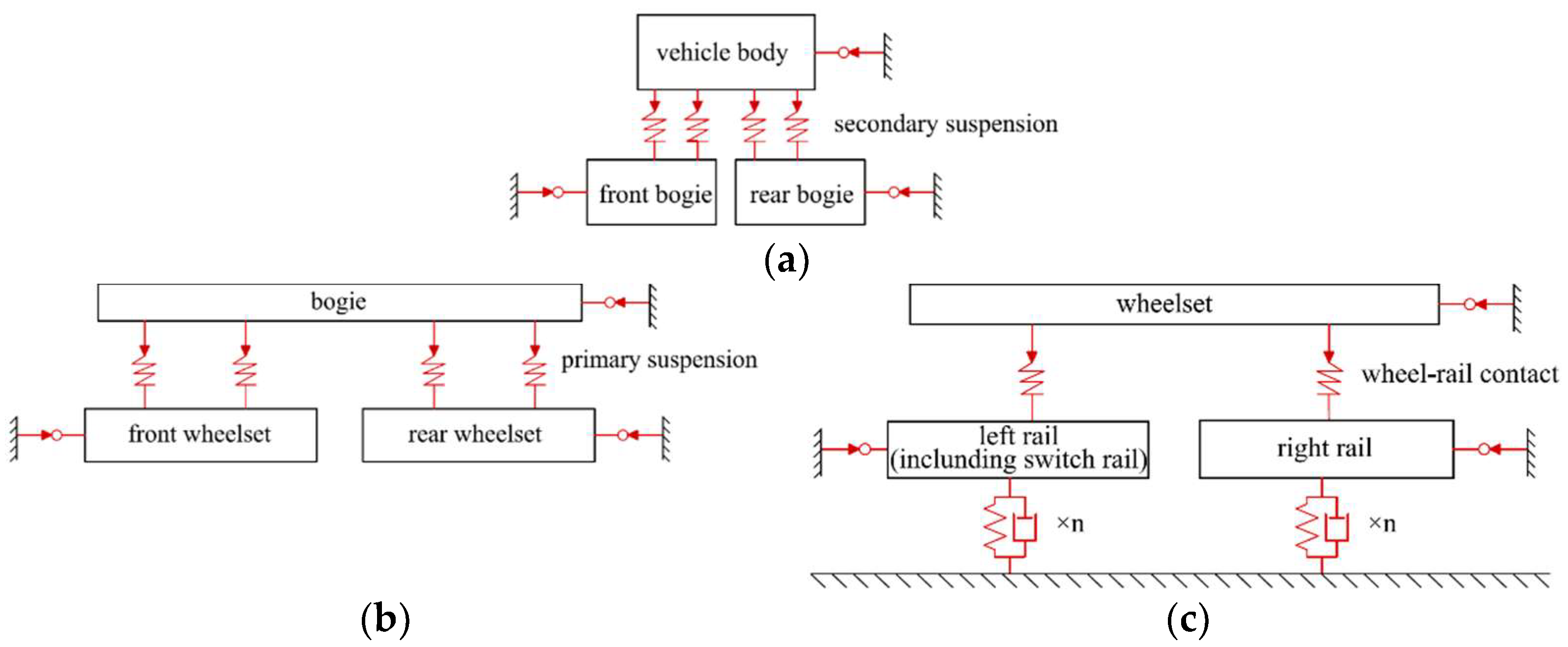

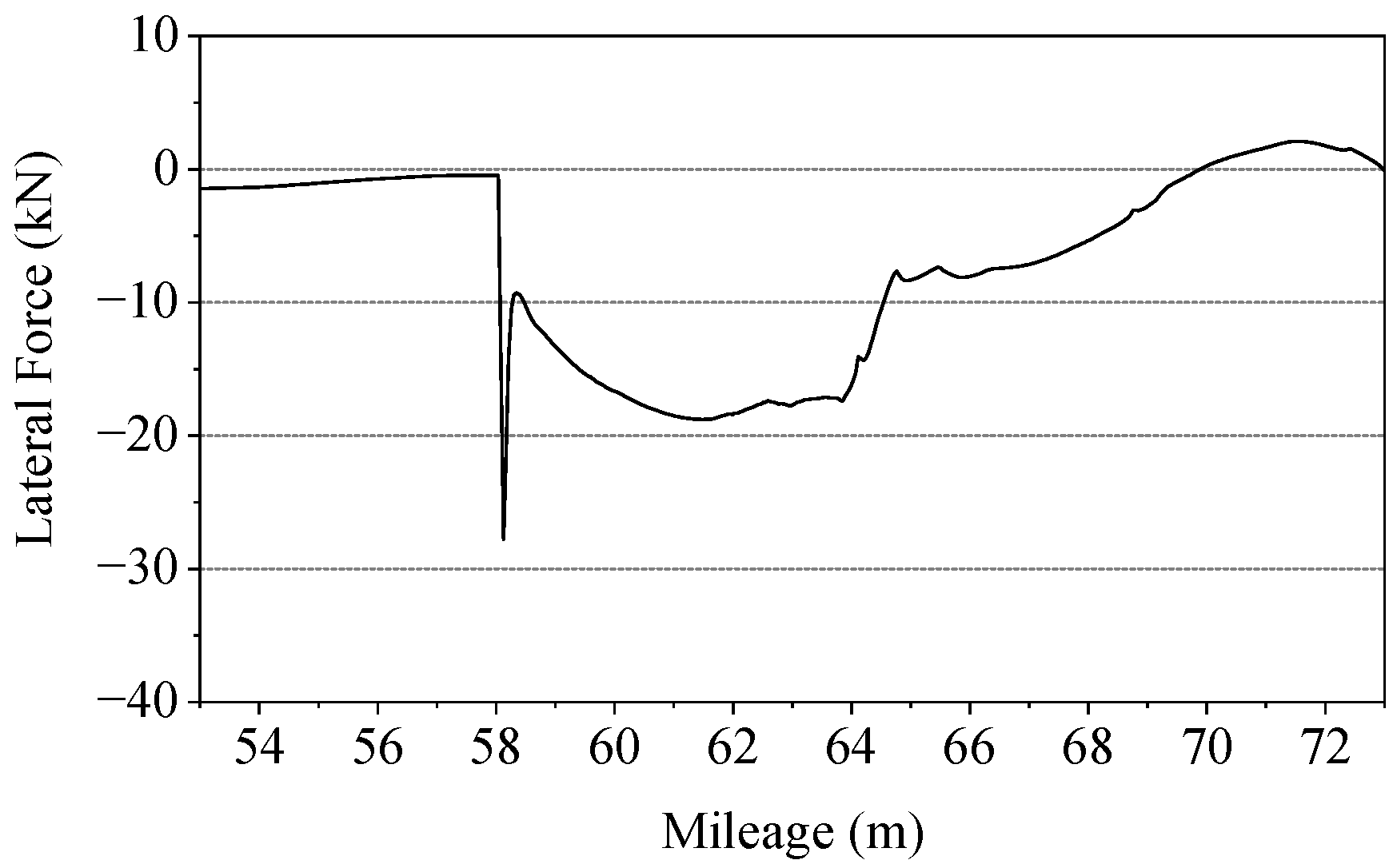

2. Modelling and Calculation

2.1. Vehicle–Track Dynamics Model

2.2. Calculation of Wheel–Rail Force

3. Analysis and Discussion

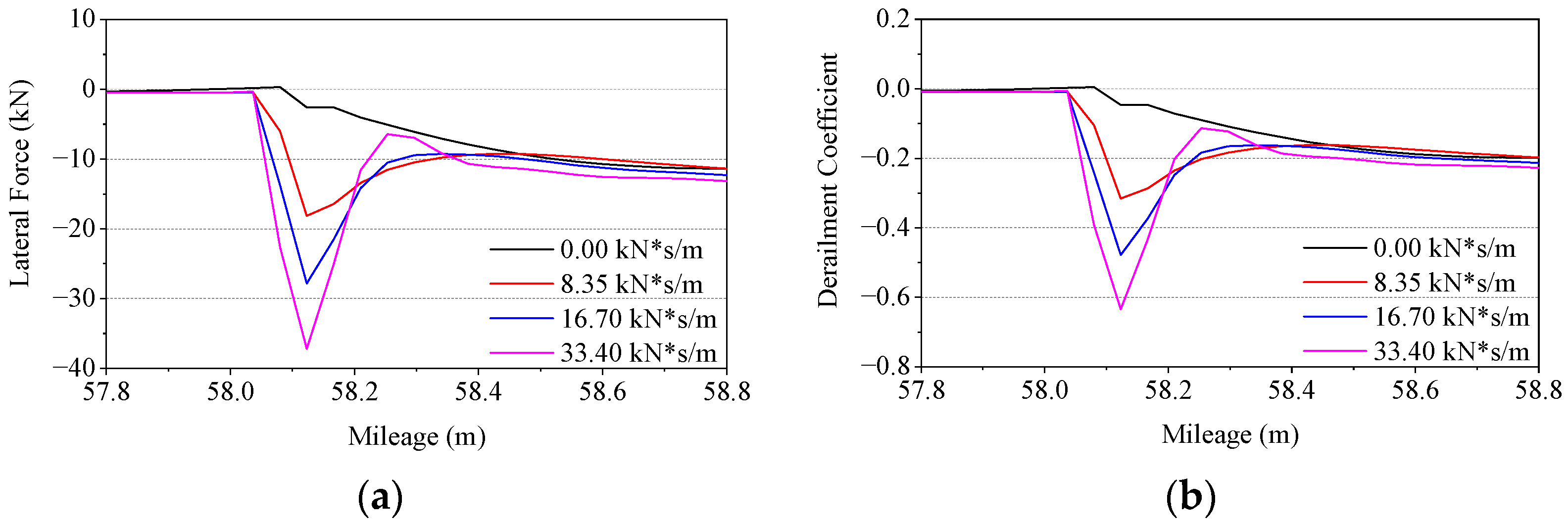

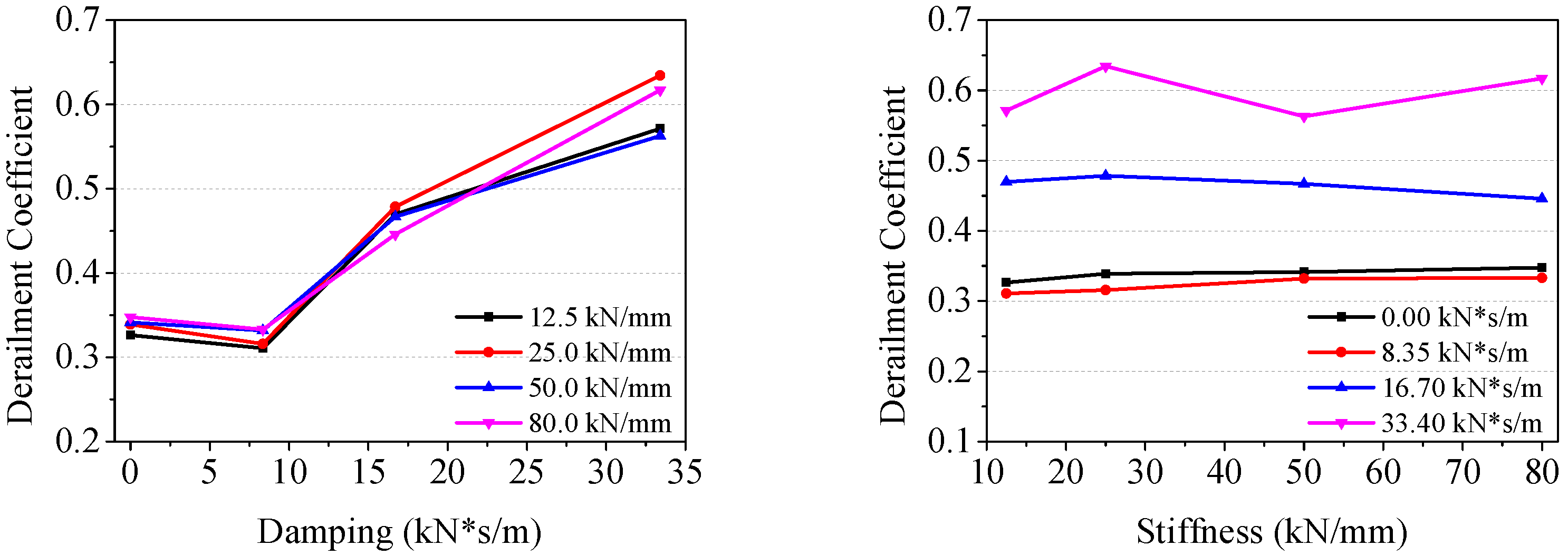

3.1. Influence of Lateral Damping and Stiffness

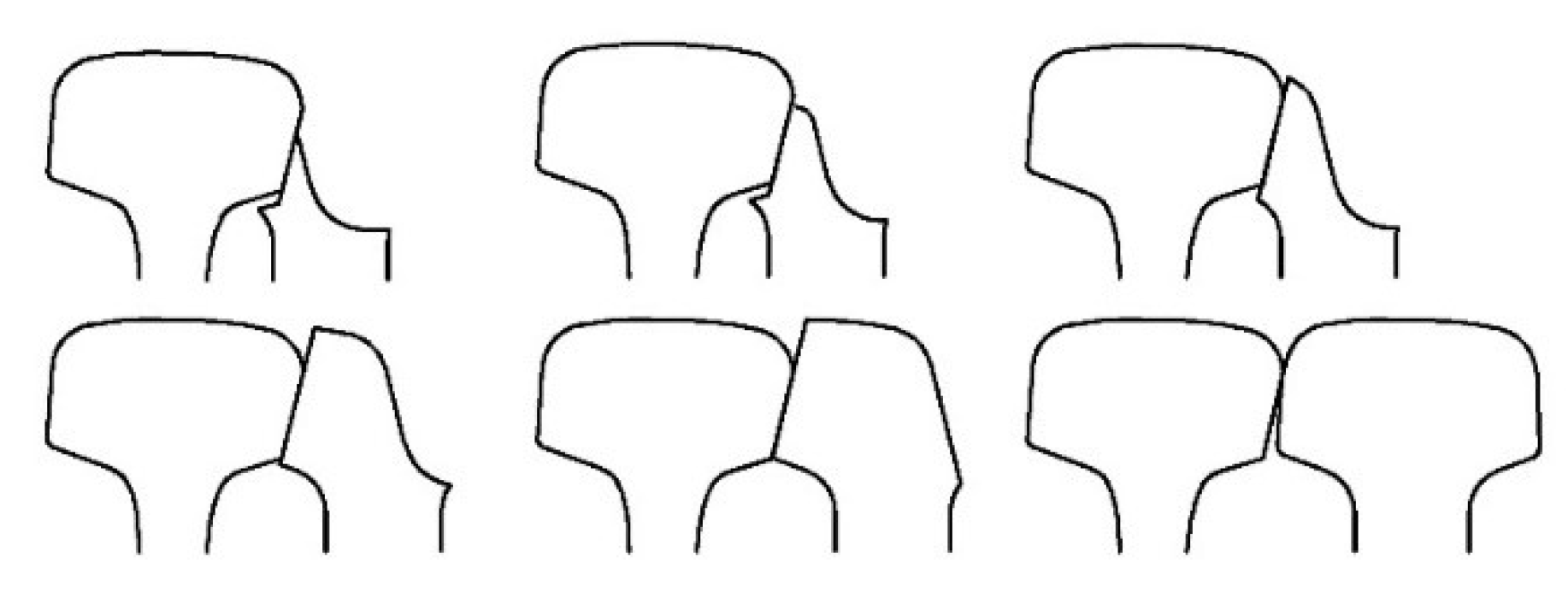

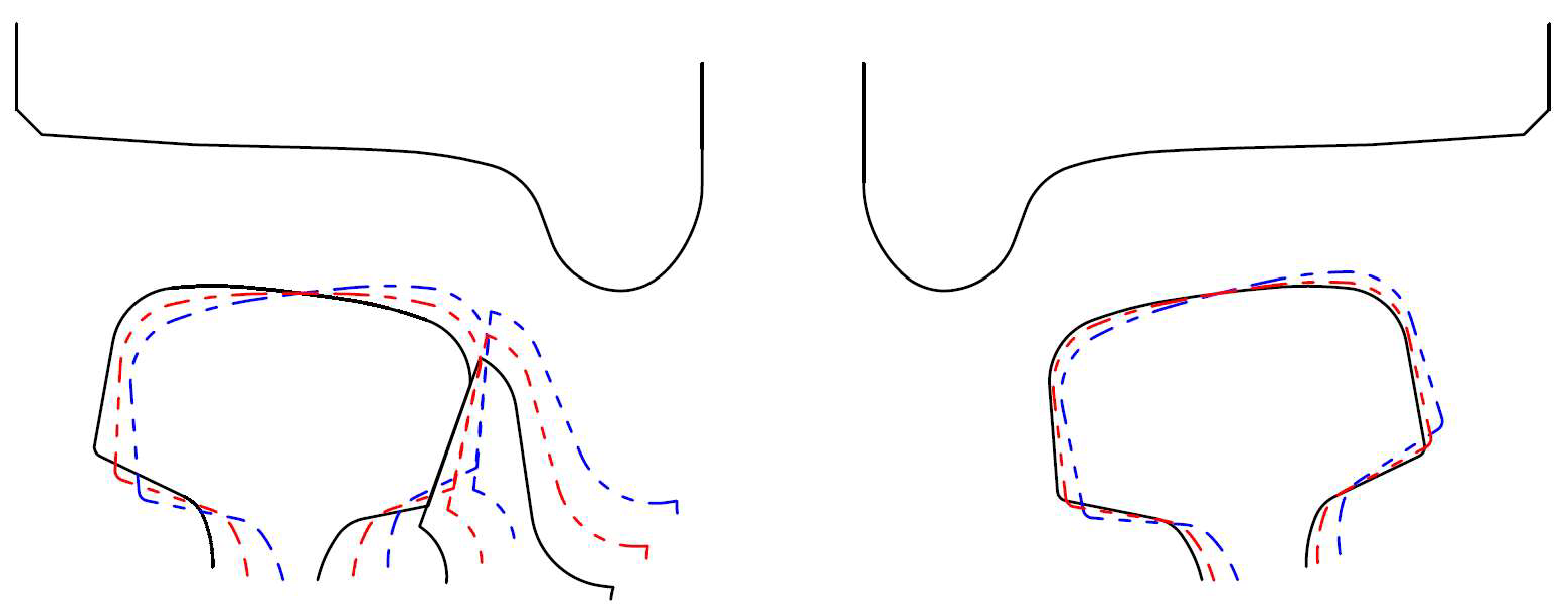

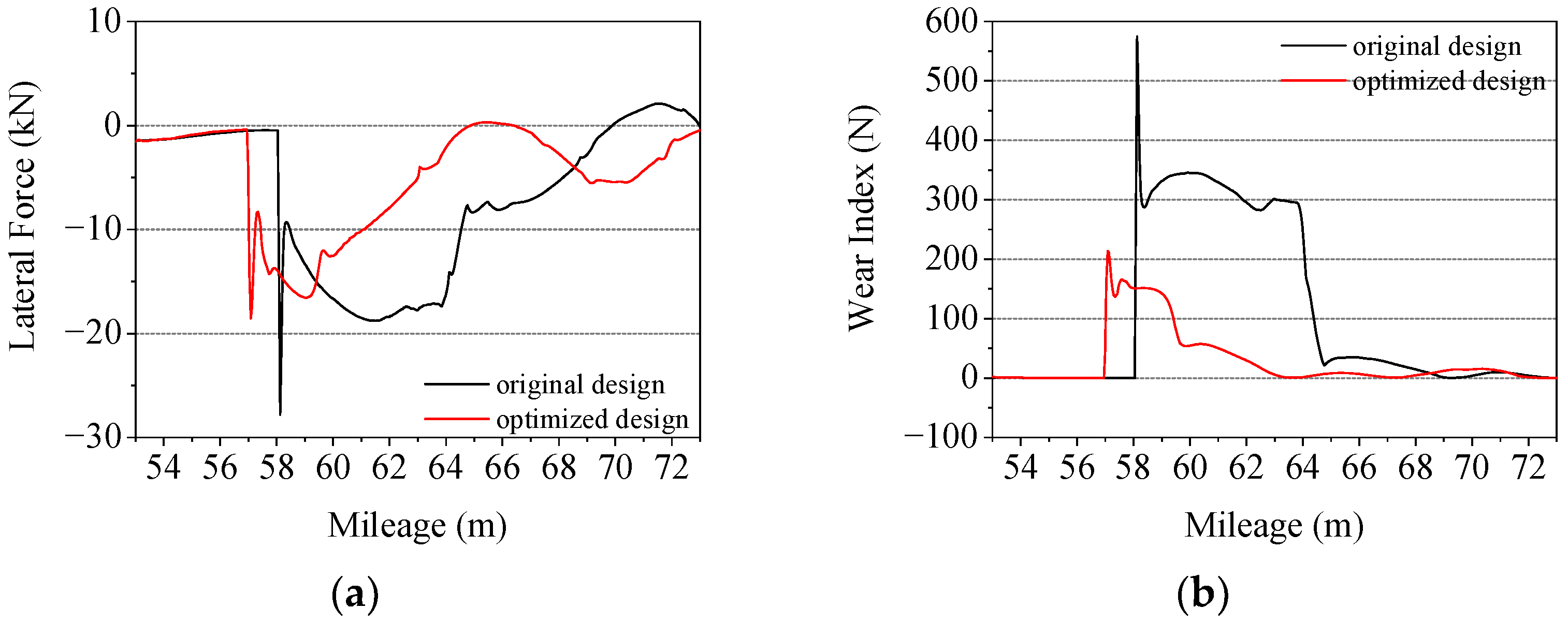

3.2. Influence of Rail Cant

3.3. Influence of the Reduced Value of Switch Rail

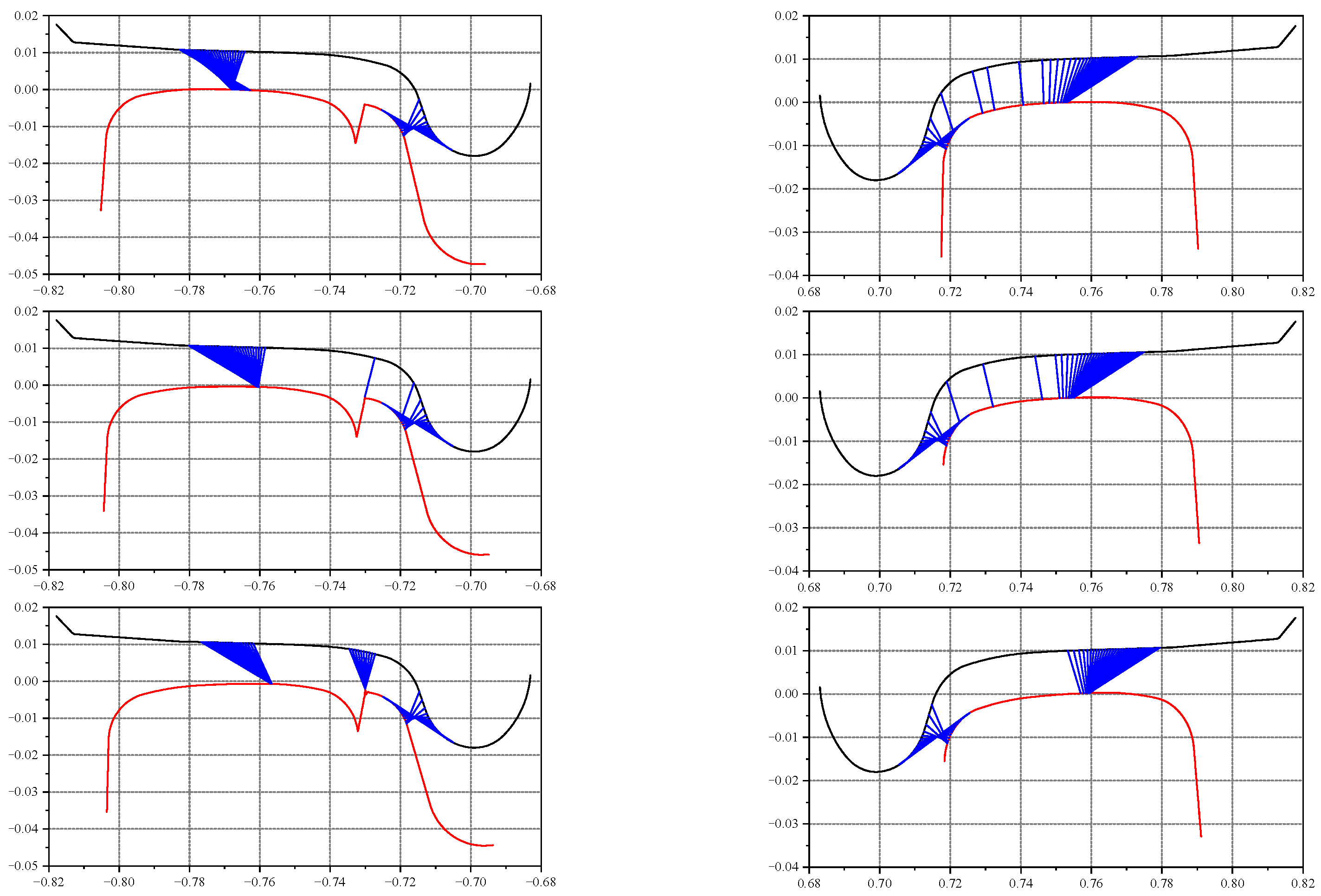

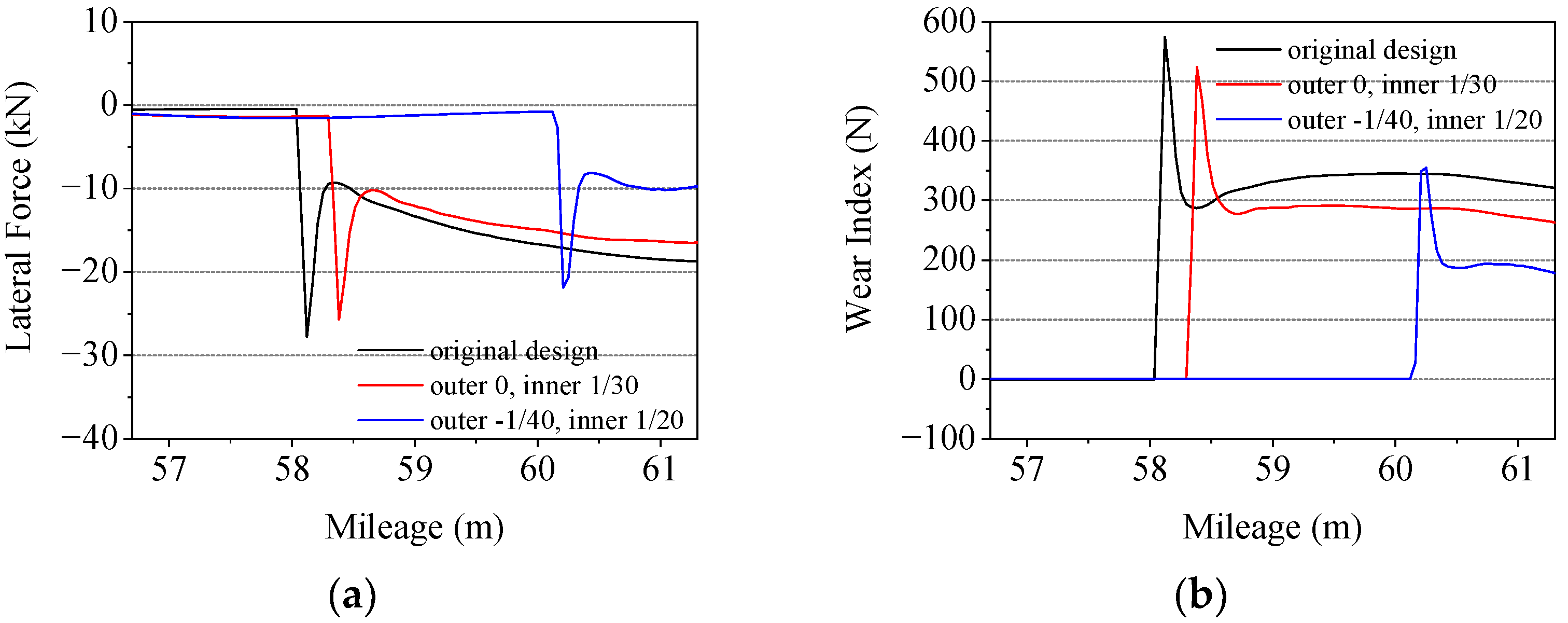

3.4. Other Factors

4. Conclusions

- (1)

- The decrease in lateral damping of the curved switch rail can effectively attenuate the wheel–rail impact, and then reduce the derailment coefficient in the corresponding section so as to improve the passing safety. The influence of the lateral damping is greater than that of the stiffness. Under different damping conditions, the intensity of the wheel–rail impact has different variation trends with respect to its lateral support stiffness.

- (2)

- (3)

- The change in rail cant has a notable influence on the wheel–rail lateral impact force of the forepart of the curved switch rail. Under the working condition in this paper, the decrease is about 21.3%.

- (4)

- By decreasing the height reduction of the switch rail, the wheel–rail lateral impact can be effectively reduced. On the basis of the calculation results of this paper, the wheel–rail lateral force can be reduced by 33.2%.

- (5)

- The wheel–rail impact angle and the speed of the train are positively correlated with the lateral wheel–rail impact force of the switch rail. Using a reasonable cutting mode for the switch blade will make a positive contribution to reducing the lateral wheel–rail impact force of the switch rail.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Sadeghi, J.; Masnabadi, A.; Mazraeh, A. Correlations among railway turnout geometry, safety and speeds. Proc. Inst. Civ. Eng. Transp. 2016, 169, 219–229. [Google Scholar] [CrossRef]

- Zhai, W.M.; Wang, K.Y. Safety assessment of trains passing through branch lines of turnouts. J. Tongji Univ. Nat. Sci. 2004, 32, 382–386. [Google Scholar]

- Hiensch, E.J.M.; Burgelman, N. Switch panel wear loading—A parametric study regarding governing train operational factors. Veh. Syst. Dyn. 2017, 55, 1384–1404. [Google Scholar] [CrossRef] [Green Version]

- Lau, A.; Hoff, I. Simulation of train-turnout coupled dynamics using a multibody simulation software. Model. Simul. Eng. 2018, 2018, 8578272. [Google Scholar] [CrossRef] [Green Version]

- Wang, L.; Ping, W.; Zhao, C.; Liu, D.; Ke, W. An experimental study on the characteristics of vibration source in urban rail transit turnouts. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2020, 234, 945–957. [Google Scholar] [CrossRef]

- de Miguel, A.; Jacobsen, F.; Lau, A.; Santos, I. Uncertainty analysis of track degradation at railway turnouts aided by a multi-body simulation software. J. Braz. Soc. Mech. Sci. Eng. 2019, 41, 544. [Google Scholar] [CrossRef]

- Li, M.; Gao, D.; Li, T.; Luo, S.; Ma, W.; Chen, X.; Tong, L. Dynamic interaction of medium–low-speed maglev train running on the turnout made of steel structures. Veh. Syst. Dyn. 2022, 1–22. [Google Scholar] [CrossRef]

- Wan, C.; Markine, V.; Shevtsov, I. Optimisation of the elastic track properties of turnout crossings. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2016, 230, 360–373. [Google Scholar] [CrossRef]

- Zhu, J.Y.; Dong, G.Y.; Li, L.; Luo, Y.Y. Comparison investigation on wheel/rail interaction by changing the lateral stiffness of the curved track. J. Railw. Eng. Soc. 2002, 4, 28–32. [Google Scholar]

- Blanco-Saura, A.E.; Velarte-González, J.L.; Ribes-Llario, F.; Real-Herráiz, J.I. Study of the dynamic vehicle-track interaction in a railway turnout. Multibody Syst. Dyn. 2018, 43, 21–36. [Google Scholar] [CrossRef]

- Kisilowski, J.; Kowalik, R. Mechanical wear contact between the wheel and rail on a turnout with variable stiffness. Energies 2021, 14, 7520. [Google Scholar] [CrossRef]

- Grossoni, I.; Hughes, P.; Bezin, Y.; Bevan, A.; Jaiswal, J. Observed failures at railway turnouts: Failure analysis, possible causes and links to current and future research. Eng. Fail. Anal. 2021, 119, 104987. [Google Scholar] [CrossRef]

- Jiang, B.; Ma, M.; Li, M.; Liu, W.; Li, T. Experimental study of the vibration characteristics of the floating slab track in metro turnout zones. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2019, 233, 1081–1096. [Google Scholar] [CrossRef]

- Chen, X.P.; Wang, P.; Zhang, Y. The reasonable stiffness of ballastless track turnout of 250 km/h passenger dedicated line. J. Railw. Eng. Soc. 2010, 27, 25–28. [Google Scholar]

- Wang, P.; Chen, R.; Xu, J.; Ma, X.; Wang, J. Theories and engineering practices of high-speed railway turnout system: Survey and review. J. Southwest Jiaotong Univ. 2016, 51, 357–372. [Google Scholar]

- Sun, J.; Chi, M.; Jin, X.; Liang, S.; Wang, J.; Li, W. Experimental and numerical study on carbody hunting of electric locomotive induced by low wheel–rail contact conicity. Veh. Syst. Dyn. 2021, 59, 203–223. [Google Scholar] [CrossRef]

- Li, W.; Guan, Q.; Chi, M.; Wen, Z.; Sun, J. An investigation into the influence of wheel–rail contact relationships on the carbody hunting stability of an electric locomotive. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit, 2022, in press. [CrossRef]

- Qian, Y.; Wang, P.; Su, Q.; An, B.Y.; Xu, J.M. Effect analysis of rail cant on the wheel-rail contact behavior of high-speed railway. J. Railw. Eng. Soc. 2018, 35, 18–25. [Google Scholar]

- Wang, S.; Qian, Y.U.; Feng, Q.; Luo, X.; Guo, F. Influence of rail cant on high rail side wear on sharp curve of urban transit. In Vehicle-Track Interaction, Proceedings of the 2019 Joint Rail Conference, Snowbird, UT, USA, 9–12 April 2019; ASME: New York, NY, USA, 2019. [Google Scholar]

- Ye, Y.; Sun, Y. Reducing wheel wear from the perspective of rail track layout optimization. Proc. Inst. Mech. Eng. Part K J. Multi-Body Dyn. 2021, 235, 217–234. [Google Scholar] [CrossRef]

- Wang, J.; Chen, X.; Li, X.; Wu, Y. Influence of heavy haul railway curve parameters on rail wear. Eng. Fail. Anal. 2015, 57, 511–520. [Google Scholar] [CrossRef]

- Wu, H.; Kerchof, B. Management of wheel/rail interface to prevent rail rollover derailments. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2014, 228, 673–686. [Google Scholar] [CrossRef]

- Ghosh, A.; Edwards, J.R.; Dersch, M.S. Effect of design rail cant on concrete crosstie rail seat pressure distribution. In Railroad Infrastructure Engineering, Proceedings of the 2016 Joint Rail Conference, Columbia, SC, USA, 12–15 April 2016; ASME: New York, NY, USA, 2016. [Google Scholar]

- Mojumder, S.; Su, H.; Qiu, C.; Mutton, P.; Singh, A.; Yan, W. The role of bending stress on the initiation of reverse transverse defects. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2021, 235, 61–72. [Google Scholar] [CrossRef]

- Wang, P.; Gao, L.; Hou, B.-W. Influence of rail cant on wheel-rail contact relationship and dynamic performance in curves for heavy haul railway. Appl. Mech. Mater. 2013, 365–366, 381–387. [Google Scholar] [CrossRef]

- Chang, W.; Cai, X.; Wang, P.; Wang, Q.; Sun, J. Optimizing reduced values of switch rails during the service time of high-speed railway turnouts. J. Transp. Eng. Part A Syst. 2022, 148, 04022031. [Google Scholar] [CrossRef]

- Ma, X.; Wang, P.; Wang, J.; Xu, J. Study on impact of over-limit reduced value of switch rail on dynamic characteristics of switch. J. China Railw. Soc. 2016, 38, 98–105. [Google Scholar]

- Wang, S.; Si, D.; Wang, M.; Ge, J. Influence of value reduced for switch rail of high speed railway on riding quality. China Railw. Sci. 2014, 35, 28–33. [Google Scholar]

- Ding, Z.; Ouyang, B. A Variable-length rational finite element based on the absolute nodal coordinate formulation. Machines 2022, 10, 174. [Google Scholar] [CrossRef]

- Yao, W.; Luo, J.J.; Xie, J.F.; Yuan, J.P. A novel Bezier method for continuous thrust maneuver orbit optimal design. J. Astronaut 2019, 40, 1274–1285. [Google Scholar]

- Zhai, W. Vehicle-Track Coupling Dynamics, 4th ed.; Science Press: Beijing, China, 2015. [Google Scholar]

- Du, L.; Liu, W.; Liu, W.; Ma, L. Study on dynamic characteristics of a curved track in 3 dimensions. China Civ. Eng. J. 2018, 51, 110–120. [Google Scholar]

- Kalker, J.J. Three-Dimensional Elastic Bodies in Rolling Contact; Springer: Dordrecht, The Netherlands, 1990. [Google Scholar]

- Kalker, J.J. A fast algorithm for the simplified theory of rolling contact. Veh. Syst. Dyn. 1982, 11, 1–13. [Google Scholar] [CrossRef]

- Huang, Y.; Wang, J.; Le, W.; Zhang, L.; Su, J. Study on mechanical behaviours of rail fasteners and effects on seismic performance of urban rail viaduct. Structures 2021, 33, 3822–3834. [Google Scholar] [CrossRef]

- Yang, G.; Zhao, F.; Li, Q.; Liang, Y.; Lin, G. Study of Influences of high-speed train wheel-rail contact geometric parameters on wheel-rail wear. J. China Railw. Soc. 2019, 41, 50–56. [Google Scholar]

- Wang, P.; Guo, Q.; Chen, J.; Yu, H.; Xu, J. Research on the effect of wheel-rail lubrication on curved switch rail wear in high-speed turnout. J. Railw. Eng. Soc. 2019, 36, 17–22. [Google Scholar]

- Wang, P. Chapter 2—Layout Design. In Design of High-Speed Railway Turnouts; Elsevier: Amsterdam, The Netherlands, 2015; pp. 37–75. [Google Scholar]

- Cao, Y.; Wang, P.; Deng, T. Analysis on cutting mode selection for switch blade based on wheel-rail system dynamics. J. China Railw. Soc. 2014, 36, 73–79. [Google Scholar]

- Hasan, N. Alignment tolerance of rail tracks. In Proceedings of the ASCE International Conference on Transportation and Development, Seattle, WA, USA, 26–29 May 2020; ASCE: Reston, VA, USA, 2020; pp. 114–124. [Google Scholar]

- de O Lima, A.; Edwards, J.R.; Chavez Quiroz, L.W.; Qian, Y.; Dersch, M.S. Load and response quantification of direct fixation fastening systems for heavy rail transit infrastructure. Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2021, 235, 1110–1121. [Google Scholar] [CrossRef]

- Fujimoto, H.; Tanifuji, K.; Miyamoto, M. Influence of track gauge variation on rail vehicle dynamics (an examination based on comparison between data from a test train running on track with irregularity artificially set and numerical simulation). Proc. Inst. Mech. Eng. Part F J. Rail Rapid Transit 2000, 214, 223–230. [Google Scholar] [CrossRef]

| Fastener Stiffness (kN/mm) | Fastener Damping (kN*s/m) | ||||

|---|---|---|---|---|---|

| Vertical | Lateral | Longitudinal | Vertical | Lateral | Longitudinal |

| 40 | 25 | 25 | 30 | 16.7 | 16.7 |

| Lateral damping (kN*s/m) | 0.00 | 8.35 | 16.70 | 33.40 |

| Location of extremum (m) | 61.3784 | 58.1231 | 58.1231 | 58.1231 |

| Derailment coefficient | 0.3390 | 0.3159 | 0.4785 | 0.6344 |

| Lateral displacement (mm) | 0.8041 | 0.04551 | 0.0525 | 0.0526 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liao, B.; Luo, Y. Study on the Factors Affecting the Wheel–Rail Lateral Impact of the Forepart of the Curved Switch Rail. Machines 2022, 10, 676. https://doi.org/10.3390/machines10080676

Liao B, Luo Y. Study on the Factors Affecting the Wheel–Rail Lateral Impact of the Forepart of the Curved Switch Rail. Machines. 2022; 10(8):676. https://doi.org/10.3390/machines10080676

Chicago/Turabian StyleLiao, Bo, and Yanyun Luo. 2022. "Study on the Factors Affecting the Wheel–Rail Lateral Impact of the Forepart of the Curved Switch Rail" Machines 10, no. 8: 676. https://doi.org/10.3390/machines10080676

APA StyleLiao, B., & Luo, Y. (2022). Study on the Factors Affecting the Wheel–Rail Lateral Impact of the Forepart of the Curved Switch Rail. Machines, 10(8), 676. https://doi.org/10.3390/machines10080676