Experimental Study of Cavitation Damage to Marine Propellers Based on the Rotational Speed in the Coastal Waters

Abstract

1. Introduction

2. Experimental Methods

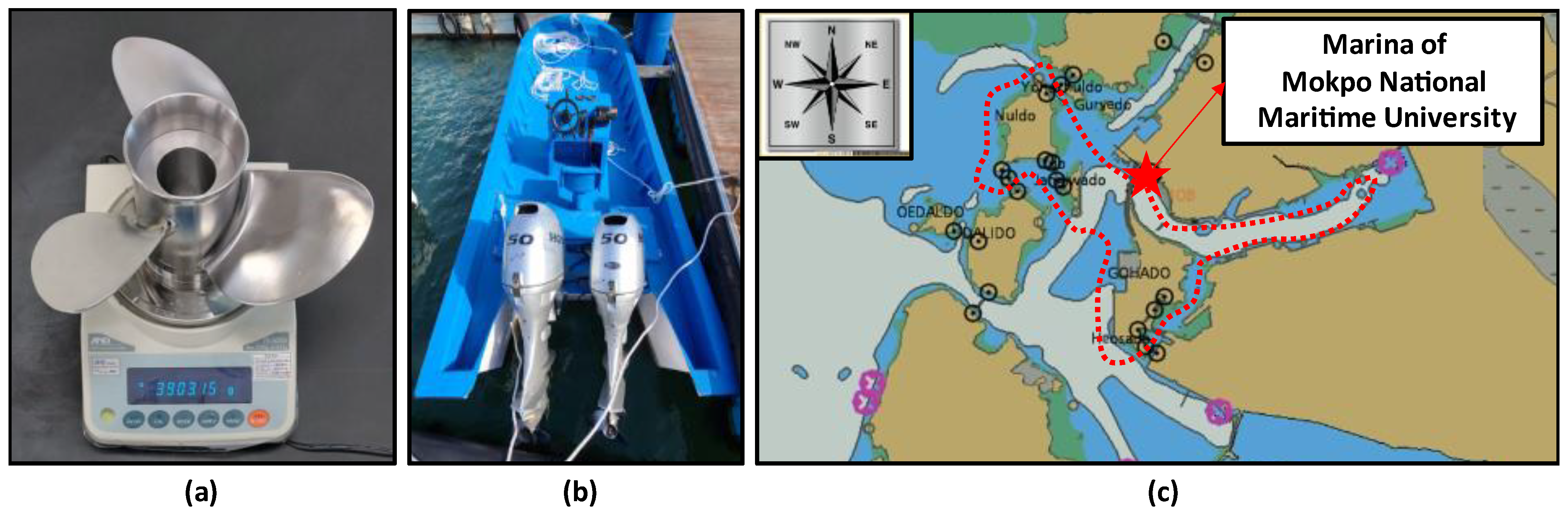

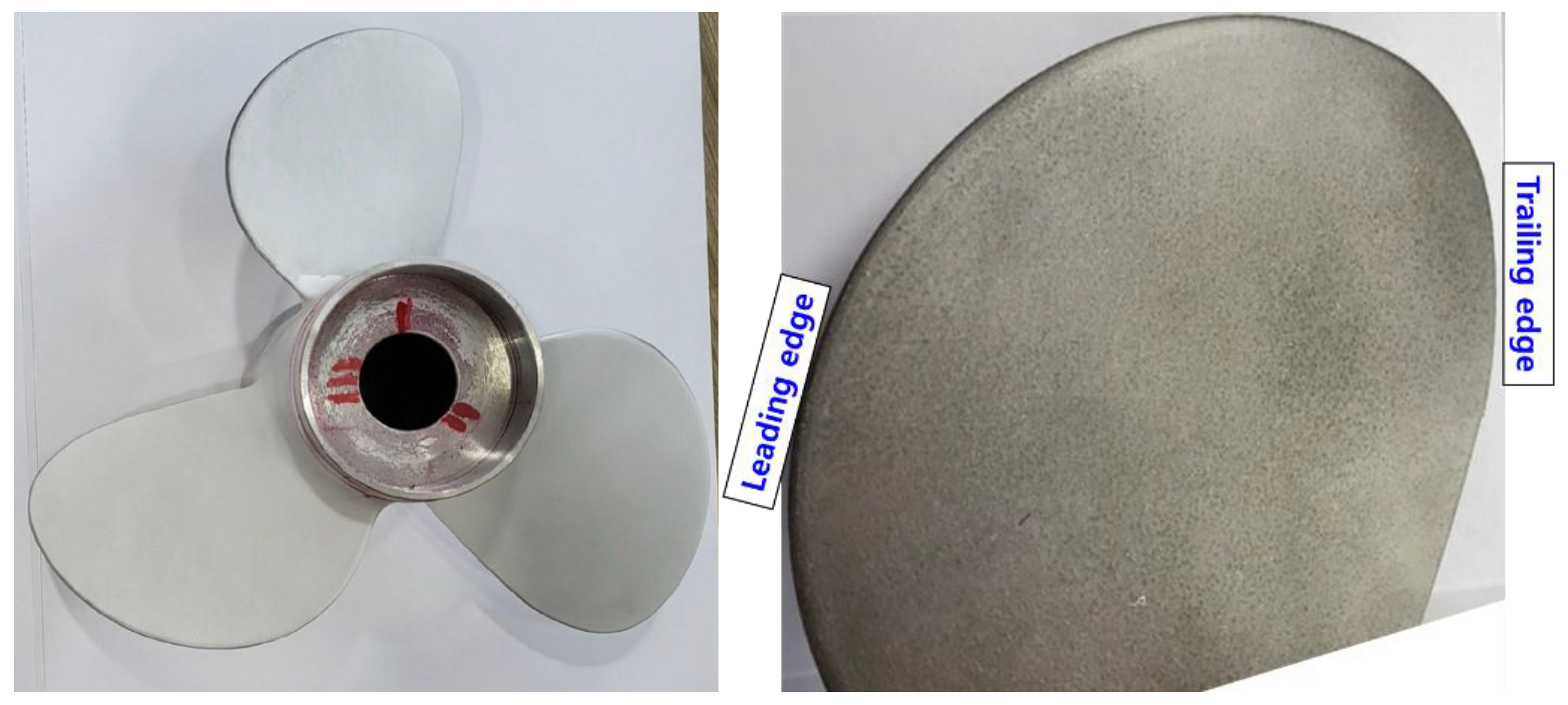

2.1. Propellers

2.2. Sea Trial in Coastal Waters

2.2.1. Weight Measurement of the Propeller

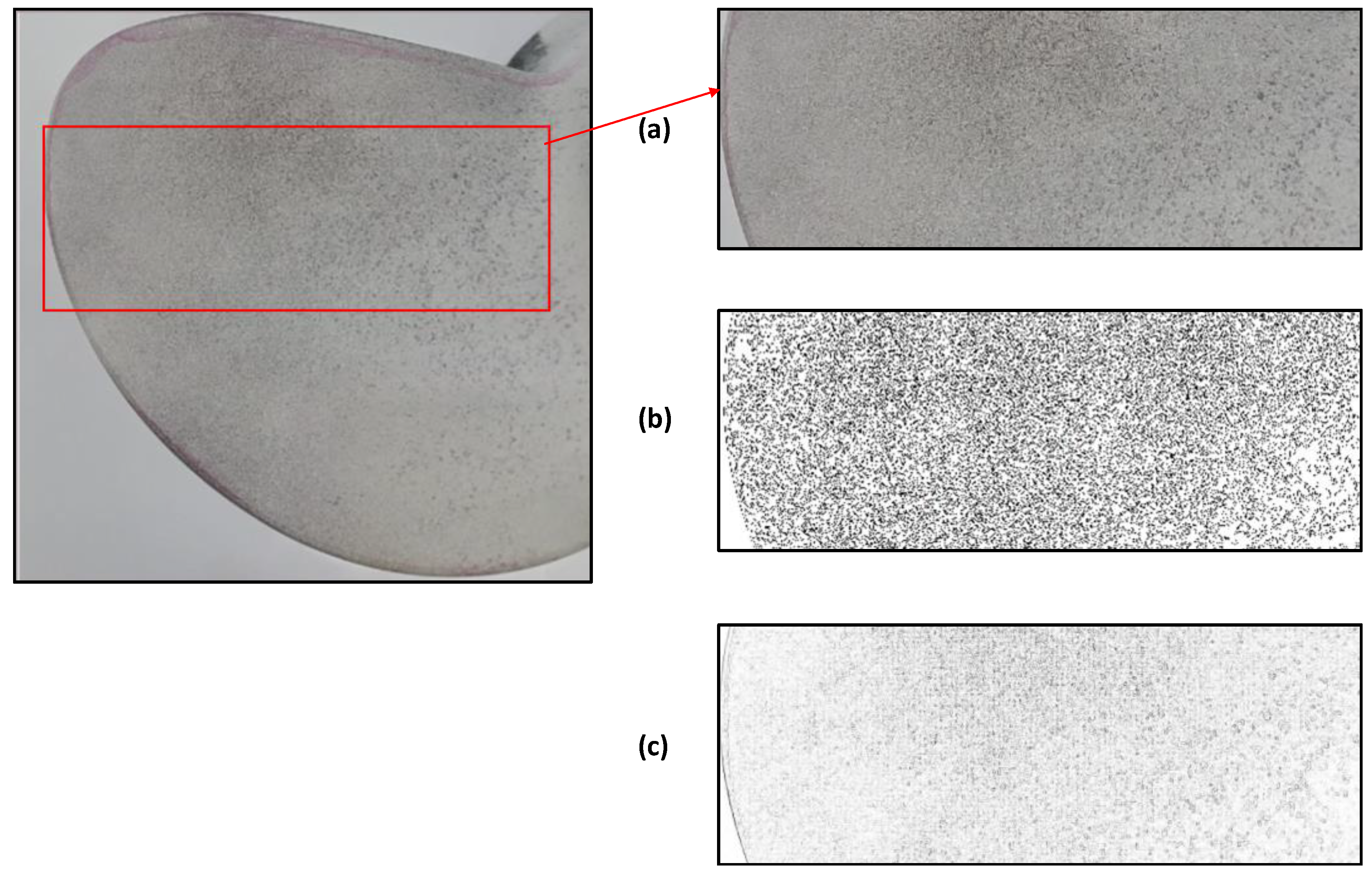

2.2.2. Nondestructive Testing (NDT)

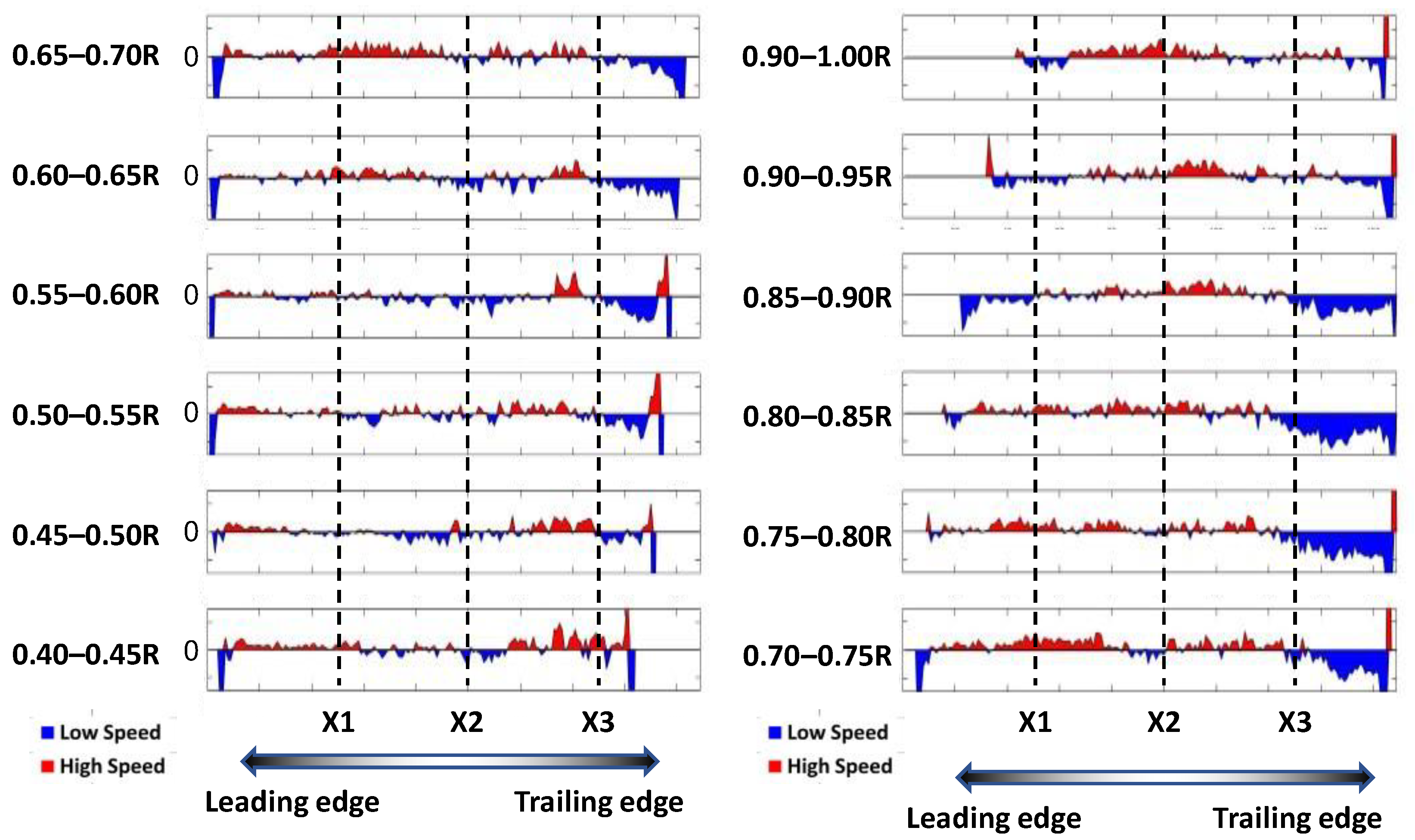

2.2.3. Image Processing

3. Results and Discussion

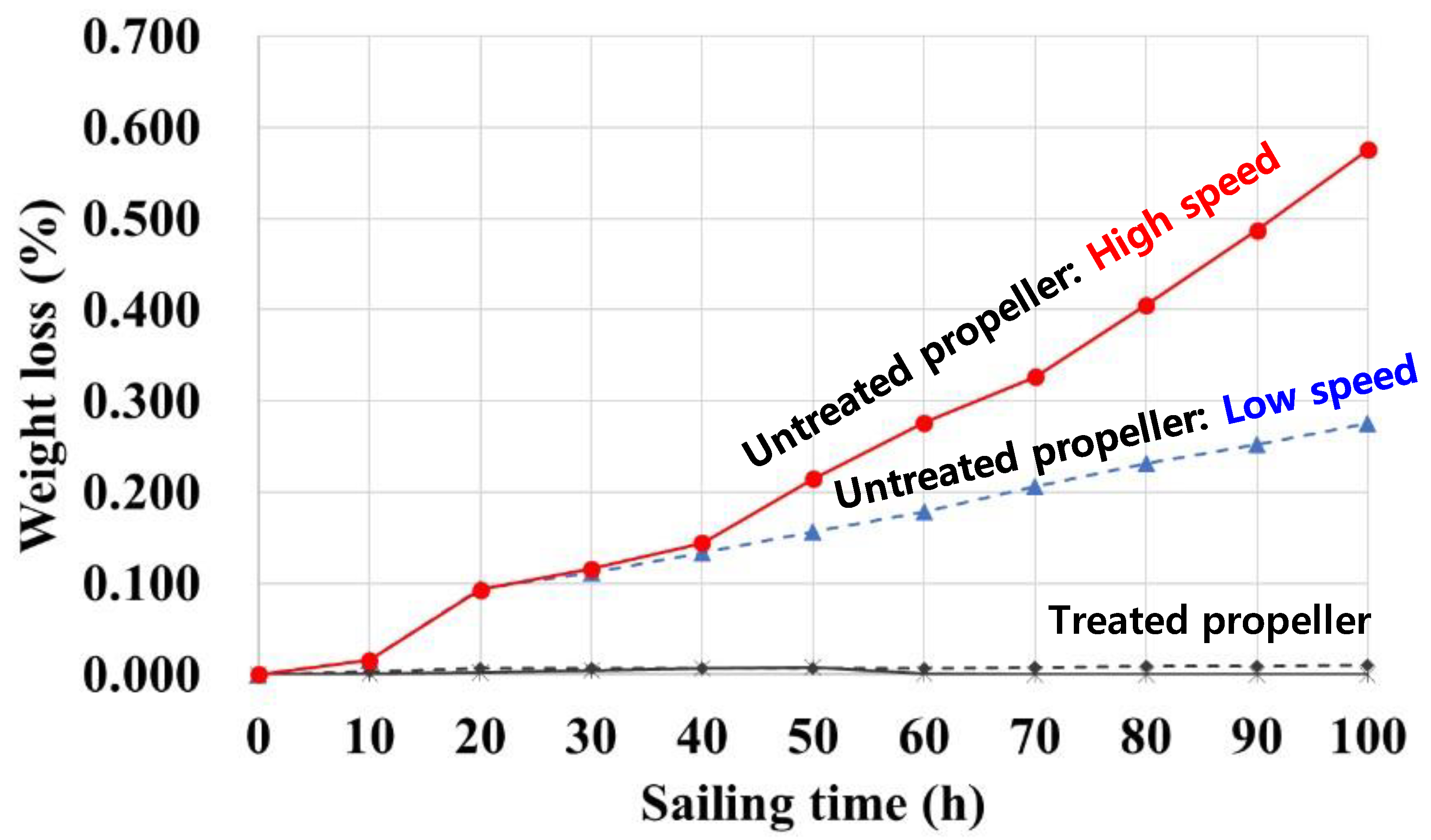

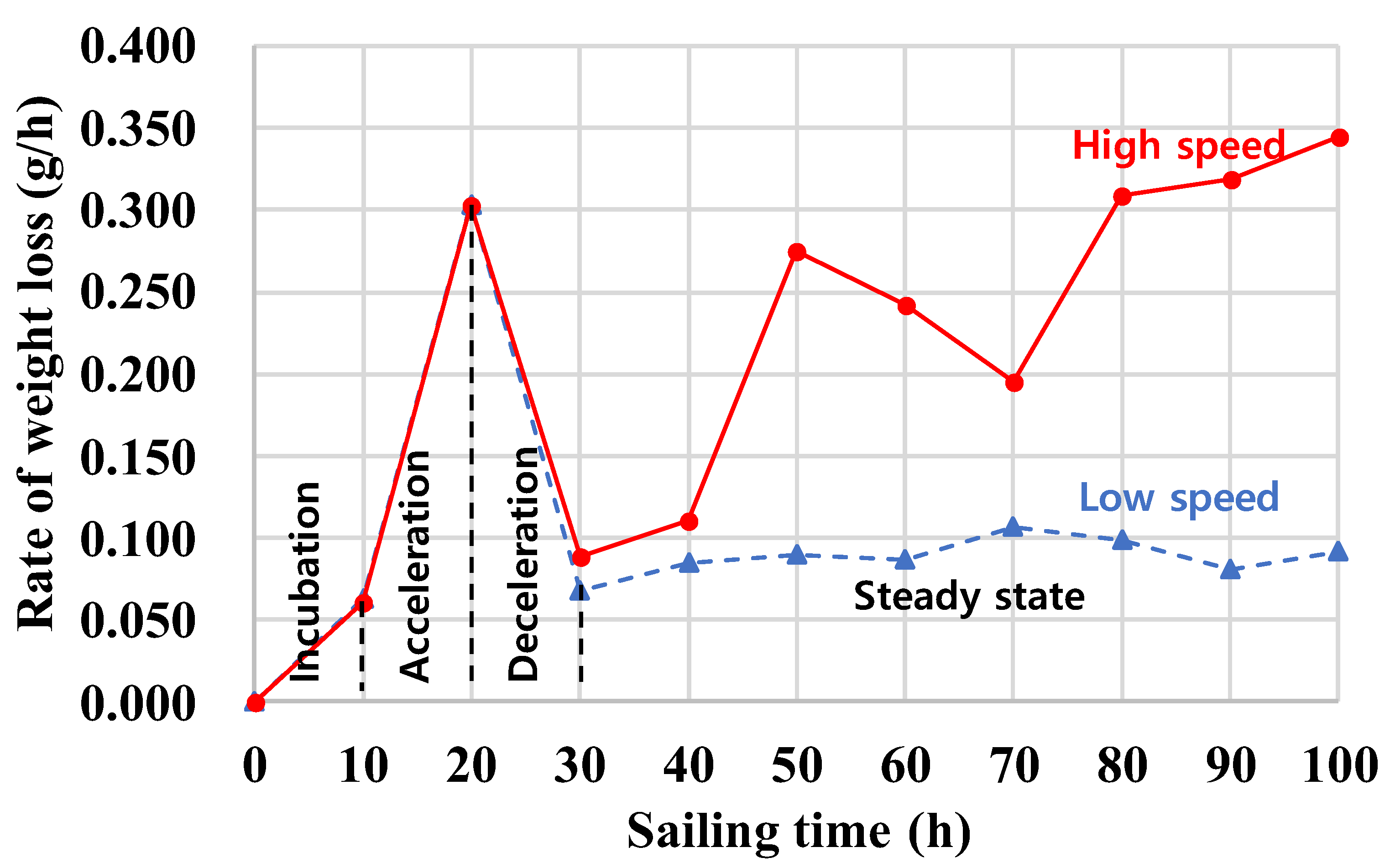

3.1. Weight Change of the Propeller

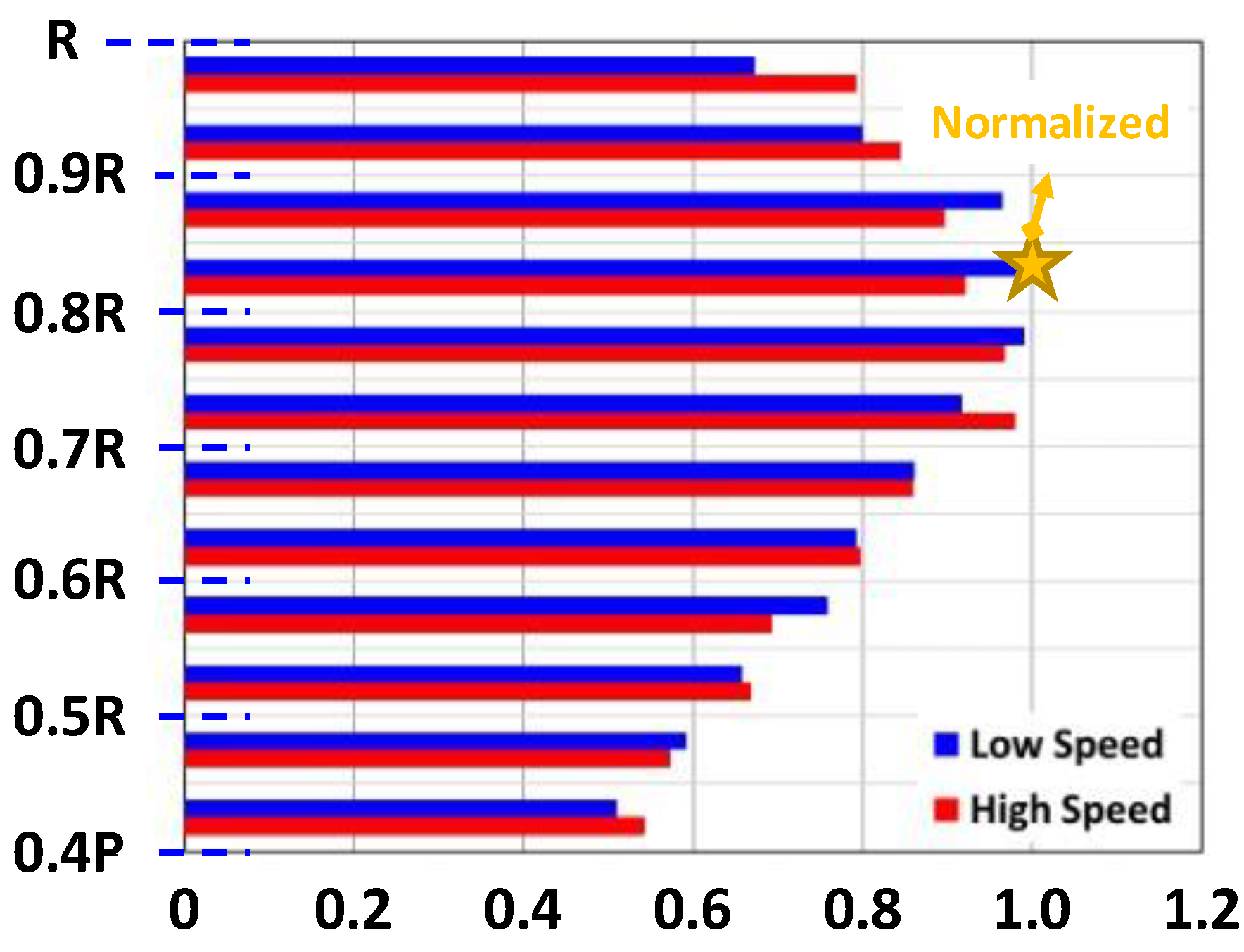

3.2. Erosion Pit Detection

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Guo, M.; Liu, C.; Yan, Q.; Wei, W.; Khoo, B.C. The Effect of Rotating Speeds on the Cavitation Characteristics in Hydraulic Torque Converter. Machines 2022, 10, 80. [Google Scholar] [CrossRef]

- Fivel, M.C.; Franc, J.P. Cavitation Erosion. In ASM Handbook, Volume 18: Friction, Lubrication, and Wear Technology; Totten, G.E., Ed.; ASM International: Novelty, OH, USA, 2018; pp. 290–301. Available online: https://hal.archives-ouvertes.fr/hal-01697361 (accessed on 12 August 2022).

- Helal, M.M.; Ahmed, T.M.; Banawan, A.A.; Kotb, M.A. Numerical prediction of sheet cavitation on marine propellers using CFD simulation with transition-sensitive turbulence model. Alex. Eng. J. 2018, 57, 3805–3815. [Google Scholar] [CrossRef]

- Carlton, J. Chapter 27—Propeller Maintenance and Repair. In Marine Propellers and Propulsion, 4th ed.; Butterworth-Heinemann: Oxford, UK, 2019. [Google Scholar]

- Lee, W.J.; Kim, M.C.; Chun, J.H.; Jang, J.Y.; Mun, W.J.; Lee, C.S. Study on Propeller Design for Fishing Vessel’s High Efficiency. J. Korean Soc. Mar. Environ. Energy 2011, 14, 73–80. [Google Scholar] [CrossRef]

- Karimi, A.; Martin, J.L. Cavitation erosion of materials. Int. Met. Rev. 1986, 31, 1986. [Google Scholar] [CrossRef]

- Koko, T.S.; Shahin, K.O.; Akpan, U.O.; Norwood, M.E. Review of Composite Propeller Developments and Strategy for Modeling Composite Propellers using PVAST. In DRDC Atlantic CR-2011-156; Defence R & D Canada: Ottawa, ON, Canada, 2012. [Google Scholar]

- Kim, J.-H.; Lee, H.; Kim, S.-H.; Choi, H.-Y.; Hah, Z.-H.; Seol, H.-S. Performance Prediction of Composite Marine Propeller in Non-Cavitating and Cavitating Flow. Appl. Sci. 2022, 12, 5170. [Google Scholar] [CrossRef]

- Islam, F.; Caldwell, R.; Phillips, A.W.; St John, N.A.; Prusty, B.G. A review of relevant impact behaviour for improved durability of marine composite propellers. Compos. Part C Open Access 2022, 8, 100251. [Google Scholar] [CrossRef]

- Young, Y.L. Analysis and Design of Advanced Marine Propulsors. In Proceedings of the ASME 2010 29th International Conference on Ocean, Offshore and Arctic Engineering, Shanghai, China, 6–11 June 2010. [Google Scholar]

- Hattori, S.; Ishikura, R. Revision of cavitation erosion database and analysis of stainless steel data. Wear 2010, 268, 109–116. [Google Scholar] [CrossRef]

- Hattori, S.; Ishikura, R.; Zhang, Q. Construction of database on cavitation erosion and analyses of carbon steel data. Wear 2004, 257, 1022–1029. [Google Scholar] [CrossRef]

- Basumatary, J.; Nie, M.; Wood, R.J.K. The synergistic effects of cavitation erosion—Corrosion in ship propeller materials. J Bio- Tribo-Corros. 2015, 1, 12. [Google Scholar] [CrossRef]

- Tomlinson, W.J.; Talks, M.G. Erosion and corrosion of cast iron under cavitation conditions. Tribol. Int. 1991, 24, 67–75. [Google Scholar] [CrossRef]

- Tian, Y.; Zhao, H.; Yang, R.; Liu, X.; Li, H.; Chen, X. Effects of Bacillus sp. adhesion on cavitation erosion behaviour of nickel aluminium bronze in artificial seawater. Wear 2022, 498, 204344. [Google Scholar] [CrossRef]

- Bertram, V. Chapter 2—Propellers. In Practical Ship Hydrodynamics; Elsevier: Amsterdam, The Netherlands, 2011. [Google Scholar] [CrossRef]

- Choi, G.H.; Chang, B.J.; Cho, D.S. Comparison of cavitation patterns between model scale observations using model and full-scale wakes and full scale observations for a propeller of crude oil carrier. J. Nav. Archit. Mar. Eng. 2011, 48, 15–22. [Google Scholar]

- Sampson, R.; Turkmen, S.; Aktas, B.; Shi, W.; Fitzsimmons, P.; Atlar, M. On the full scale and model scale cavitation comparisons of a Deep-V catamaran research vessel. In Proceedings of the Fourth International Symposium on Marine Propulsors SMP’15, Austin, TX, USA, 31 May–4 June 2015. [Google Scholar]

- Atlar, M.; Aktas, B.; Sampson, R.; Seo, K.C.; Viola, I.M.; Fitzsimmons, P.; Fetherstonhaug, C. A multi-purpose marine science and technology research vessel for full-scale observations and measurements. In Proceedings of the 3rd International Conference on Advanced Model Measurement Technologies for the Marine Industry, Gdansk, Poland, 17–18 September 2013. [Google Scholar]

- ITTC 2005. The specialist committee on cavitation erosion on propellers and appendages on high powered/high speed ships. In Proceedings of the 24th ITTC–Volume II, Edinburgh, UK, 11–13 April 2005. [Google Scholar]

- Bark, G.; Berchiche, N.; Grekula, M. Application of principles for observation and analysis of eroding cavitation. In The EROCAV Observation Handbook; Department of Shipping and Marine Technology, Chalmers University of Technology: Göteborg, Sweden, 2004. [Google Scholar]

- Aktas, B.; Ustab, O.; Atlar, M. Systematic investigation of coating application methods and soft paint types to detect cavitation erosion on marine propellers. Appl. Ocean. Res. 2020, 94, 101868. [Google Scholar] [CrossRef]

- Van Terwisga, T.J.C.; van Wijngaarden, H.C.J.; Bosschers, J.; Kuiper, G. Cavitation research on ship propellers—A review of achievements and challenges. In Proceedings of the Sixth International Symposium on Cavitation, CAV2006, Wageningen, The Netherlands, 11–15 September 2006. Report No. 1543-P. [Google Scholar]

- Kimmerl, J.; Mertes, P.; Abdel-Maksoud, M. Application of Large Eddy Simulation to Predict Underwater Noise of Marine Propulsors. Part 1: Cavitation Dynamics. J. Mar. Sci. Eng. 2021, 9, 792. [Google Scholar] [CrossRef]

- Köksal, Ç.S.; Usta, O.; Aktas, B.; Atlar, M.; Korkut, E. Numerical prediction of cavitation erosion to investigate the effect of wake on marine propellers. Ocean Eng. 2021, 239, 109820. [Google Scholar] [CrossRef]

- Kim, S.G.; Kim, S.W. The effect of activated nitrogen species for diffusion rate during a plasma nitriding process. J. Korean Soc. Heat Treat. 2010, 23, 150–155. [Google Scholar]

- Kim, S.G.; Yeo, K.H.; Lee, J.H.; Cho, Y.K.; Okumiya, M. Effect of Formation of Concentrated Stainless Steel Layer by Thermochemical Reaction and Addition of Hydrocarbon Gas on Sintered Part. Adv. Mater. Phys. Chem. 2018, 8, 227. [Google Scholar] [CrossRef][Green Version]

- ITTC Propulsion Committee. Model manufacture, propeller models terminology and nomenclature for propeller geometry. In Proceedings of the International Towing Tank Conference, Fukuoka, Japan,, 14–20 September 2008. [Google Scholar]

- Lin, C.; Zhao, Q.; Zhao, X.; Yang, Y. Cavitation Erosion of Metallic Materials. Int. J. Georesour. Environ. 2018, 4, 1–8. [Google Scholar] [CrossRef][Green Version]

- ASTM G1-03. Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens. ASTM: West Conshohocken, PA, USA, 2011.

- Korea Resister. Part 1—Classification and surveys. In Rules and Guidance for the Classification of Steel Ships; Bureau Veritas Marine & Offshore: Seoul, South Korea, 2020. [Google Scholar]

- ISO 3452:2021. Non-Destructive Testing—Penetrant Testing. ISO: Geneva, Switzerland, 2021.

- Korea Resister. Available online: https://www.krs.co.kr/kor/ (accessed on 12 August 2022).

- Rafael, C.G.; Richard, E.W.; Steven, L.E. Digital Image Processing using MATLAB; McGraw-Hill: New York, NY, USA, 2011; ISBN 978-0-07108-478-9. [Google Scholar]

- Gonzalez, R.; Woods, R. Digital Image Processing, 4th ed.; Pearson Education: New York, NY, USA, 2018; ISBN 978-1-29222-304-9. [Google Scholar]

- Jain, A.; Gupta, M.; Tazi, S.N.; Deepika. Comparison of edge detectors. In Proceedings of the International Conference on Medical Imaging, m-Health and Emerging Communication Systems (MedCom), Greater Noida, India, 7–8 November 2014; pp. 289–294. [Google Scholar] [CrossRef]

- Di Zenzo, S. A note on the gradient of a multi-image. Comput. Vis. Graph. Image Processing 1986, 33, 116–125. [Google Scholar] [CrossRef]

- Lee, I.; Park, S.; Seok, W.; Rhee, S.H. A study on the cavitation model for the cavitating flow analysis around the marine propeller. Math. Probl. Eng. 2021, 2021, 2423784. [Google Scholar] [CrossRef]

- Molland, A.F.; Turnock, S.R.; Hudson, D.A. Propeller Characteristics. In Ship Resistance and Propulsion; Cambridge University Press: Cambridge, UK, 2017; pp. 277–312. [Google Scholar] [CrossRef]

- Zakrzewska, D.E.; Krella, A.K. Cavitation erosion resistance influence of material properties. Adv. Mater. Sci. 2019, 19, 18–34. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2022 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ju, H.-j.; Choi, J.-s. Experimental Study of Cavitation Damage to Marine Propellers Based on the Rotational Speed in the Coastal Waters. Machines 2022, 10, 793. https://doi.org/10.3390/machines10090793

Ju H-j, Choi J-s. Experimental Study of Cavitation Damage to Marine Propellers Based on the Rotational Speed in the Coastal Waters. Machines. 2022; 10(9):793. https://doi.org/10.3390/machines10090793

Chicago/Turabian StyleJu, Hae-ji, and Jung-sik Choi. 2022. "Experimental Study of Cavitation Damage to Marine Propellers Based on the Rotational Speed in the Coastal Waters" Machines 10, no. 9: 793. https://doi.org/10.3390/machines10090793

APA StyleJu, H.-j., & Choi, J.-s. (2022). Experimental Study of Cavitation Damage to Marine Propellers Based on the Rotational Speed in the Coastal Waters. Machines, 10(9), 793. https://doi.org/10.3390/machines10090793