Hyperbolic-Secant-Function-Based Fast Sliding Mode Control for Pantograph Robots

Abstract

:1. Introduction

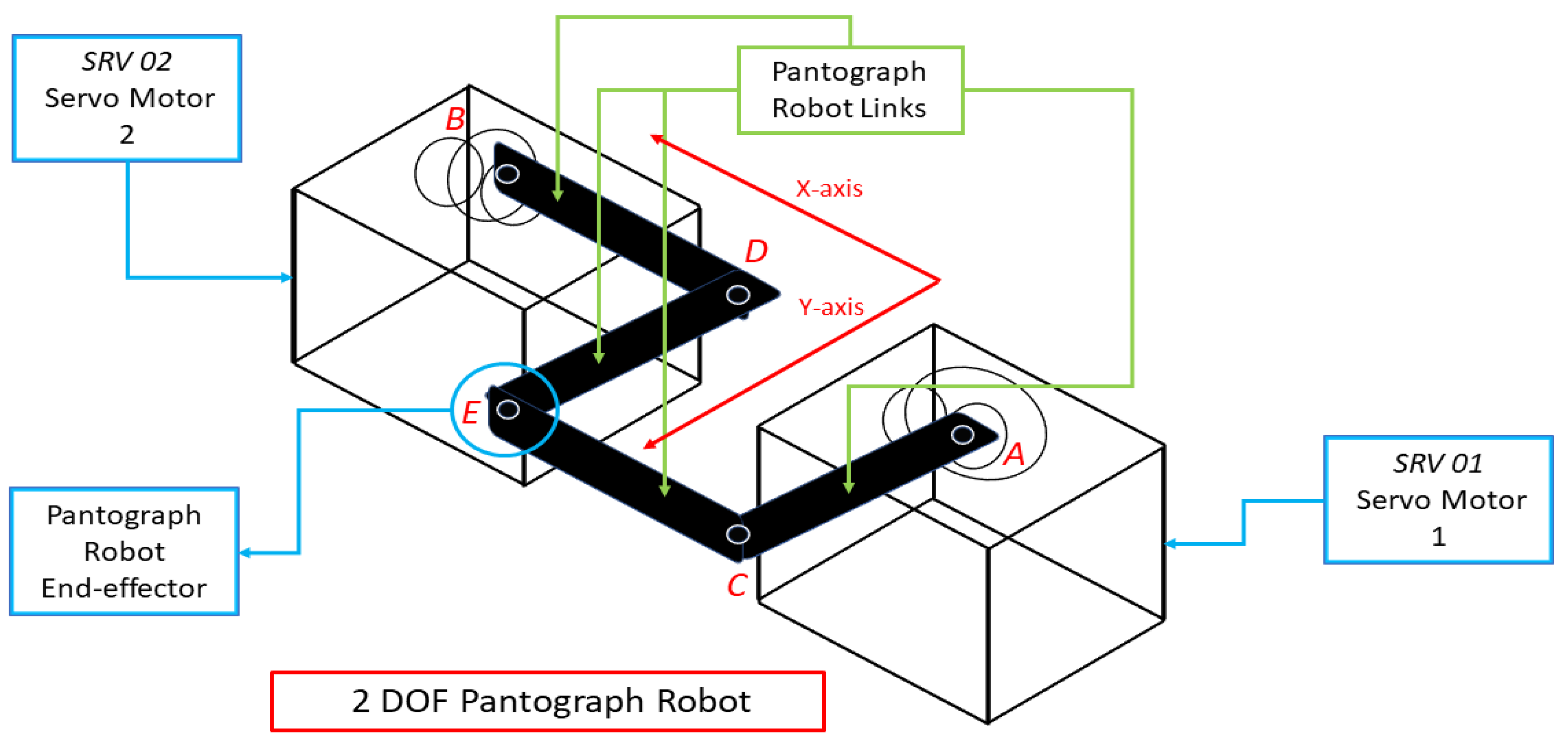

2. Mathematical Modeling of the Pantograph Robot

2.1. Servo Motor SRV01

2.2. Forward Kinematics

2.3. Inverse Kinematics

3. Design of the Proposed Control and Stability Analysis

3.1. The Proposed Control Structure of the PR

3.2. The Proposed Hyperbolic-Secant-Function-Based SMC

3.3. Stability Analysis

4. Comparative Simulation Analysis

4.1. Comparative Simulation with Same Parameters

4.2. Comparative Simulation with Optimal Tuning

5. Comparative Experimental Validation

6. Discussion

7. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Cheah, C.C.; Li, X.; Yan, X.; Sun, D.T. Simple PD control scheme for robotic manipulation of biological cell. IEEE Trans. Autom. Control 2014, 60, 1427–1432. [Google Scholar] [CrossRef]

- Awan, Z.S.; Ali, K.; Iqbal, J.; Mehmood, A. Adaptive backstepping based sensor and actuator fault tolerant control of a manipulator. J. Electr. Eng. Technol. 2019, 14, 2497–2504. [Google Scholar] [CrossRef]

- Al-Mahturi, A.; Wahid, H. Optimal tuning of linear quadratic regulator controller using a particle swarm optimization for two-rotor aerodynamical system. Int. J. Electron. Commun. Eng. 2017, 11, 184–190. [Google Scholar]

- Feng, H.; Yin, C.B.; Weng, W.W.; Ma, W.; Zhou, J.J.; Jia, W.H.; Zhang, Z.L. Robotic excavator trajectory control using an improved GA based PID controller. Mech. Syst. Signal Process. 2018, 105, 153–168. [Google Scholar] [CrossRef]

- Ali, N.; Ayaz, Y.; Iqbal, J. Collaborative position control of pantograph robot using particle swarm optimization. Int. J. Control Autom. Syst. 2022, 20, 198–207. [Google Scholar] [CrossRef]

- Saisudha, V.; Seeja, G.; Pillay, R.V.; Manikutty, G.; Bhavani, R.R. Analysis of speed control of DC motor using LQR method. Int. J. Control Theory Appl. 2016, 15, 7377–7385. [Google Scholar]

- Zheng, X.; Su, X. Sliding mode control of electro-hydraulic servo system based on optimization of quantum particle swarm algorithm. Machines 2021, 9, 283. [Google Scholar] [CrossRef]

- Young, K.D.; Utkin, V.I.; Ozguner, U. A control engineer’s guide to sliding mode control. IEEE Trans. Control Syst. Technol. 1999, 7, 328–342. [Google Scholar] [CrossRef]

- Šabanovic, A. Variable structure systems with sliding modes in motion control. Int. J. Control Theory Appl. 2011, 7, 212–223. [Google Scholar] [CrossRef]

- Utkin, V.; Guldner, J.; Shi, J. Sliding Mode Control in Electro-Mechanical Systems, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2017; pp. 154–503. [Google Scholar]

- Utkin, V.; Lee, H. Chattering problem in sliding mode control systems. IEEE Proc. Int. Workshop Var. Struct. Syst. 2006, 46, 346–350. [Google Scholar]

- Hassan, M.A.; Cao, Z.; Man, Z. End Effector Position Control of Pantograph Type Robot Using Sliding Mode Controller. In Proceedings of the Australian and New Zealand Control Conference, Gold Coast, Australia, 25 November 2022; pp. 156–160. [Google Scholar]

- Levant, A. Universal single-input-single-output (SISO) sliding-mode controllers with finite-time convergence. IEEE Trans. Autom. Control. 2001, 46, 1447–1451. [Google Scholar] [CrossRef]

- Utkin, V.; Poznyak, A.; Orlov, Y.; Polyakov, A. Conventional and high order sliding mode control. J. Frankl. Inst. 2020, 357, 10244–10261. [Google Scholar] [CrossRef]

- Bartolini, G.; Ferrara, A.; Usai, E.; Utkin, V.I. On multi-input chattering-free second-order sliding mode control. IEEE Trans. Autom. Control 2000, 45, 1711–1717. [Google Scholar] [CrossRef]

- Kawamura, A.; Itoh, H.; Sakamoto, K. Sakamoto, Chattering reduction of disturbance observer based sliding mode control. IEEE Trans. Ind. Appl. 1994, 30, 456–461. [Google Scholar] [CrossRef]

- Xu, W.; Jiang, Y.; Mu, C. Novel composite sliding mode control for PMSM drive system based on disturbance observer. IEEE Trans. Appl. Supercond. 2016, 26, 1–5. [Google Scholar] [CrossRef]

- Kachroo, P.; Tomizuka, M. Chattering reduction and error convergence in the sliding mode control of a class of nonlinear systems. IEEE Trans. Autom. Control 1996, 41, 1063–1068. [Google Scholar] [CrossRef]

- Gao, W.; Hung, J.C. Variable structure control of nonlinear systems: A new approach. IEEE Trans. Ind. Electron. 1993, 40, 45–55. [Google Scholar]

- Bartoszewicz, A. Discrete-time quasi-sliding-mode control strategies. IEEE Trans. Ind. Electron. 1998, 45, 633–637. [Google Scholar] [CrossRef]

- Bartoszewicz, A.; Leśniewski, P. New switching and nonswitching type reaching laws for SMC of discrete time systems. IEEE Trans. Control Syst. Technol. 2015, 24, 670–677. [Google Scholar] [CrossRef]

- Fallaha, C.; Saad, M.; Kanaan, H.; Al-Hadded, K. Sliding-mode control with exponential reaching law. IEEE Trans. Ind. Electron. 2011, 58, 600–610. [Google Scholar] [CrossRef]

- Bartoszewicz, A. A new reaching law for sliding mode control of continous time systems with constraints. Trans. Inst. Meas. Control 2014, 37, 515–521. [Google Scholar] [CrossRef]

- Zhai, J.; Li, Z. Fast-exponential sliding mode control of robotic manipulator with super-twisting method. IEEE Trans. Circuits Syst. II Express Briefs 2021, 69, 489–493. [Google Scholar] [CrossRef]

- Hou, H.; Yu, X.; Xu, L.; Rsetam, K.; Cao, Z. Finite-time continuous terminal sliding mode control of servo motor systems. IEEE Trans. Ind. Electron. 2019, 67, 5647–5656. [Google Scholar] [CrossRef]

- Mobayen, S.; Alattas, K.A.; Assawinchaichote, W. Adaptive continuous barrier function terminal sliding mode control technique for disturbed robotic manipulator. IEEE Trans. Circuits Syst. I Regul. Pap. 2021, 68, 4403–4412. [Google Scholar] [CrossRef]

- Yang, T.; Deng, Y.; Li, H.; Sun, Z.; Cao, H.; Wei, Z. Fast integral terminal sliding mode control with a novel disturbance observer based on iterative learning for speed control of PMSM. ISA Trans. 2023, 134, 460–471. [Google Scholar] [CrossRef] [PubMed]

- Nguyen, T.H.; Nguyen, T.T.; Nguyen, V.Q.; Le, K.M.; Tran, H.N.; Jeon, J.W. An adaptive sliding mode controller with a modified reduced-order PI observer for speed regulation of a permanent magnet synchronous motor. IEEE Trans. Ind. Electron. 2022, 69, 7181–7191. [Google Scholar] [CrossRef]

- Wang, H.; Liu, Z.; Han, Z.; Wu, Y.; Liu, D. Rapid Adaptation for Active Pantograph Control in High-Speed Railway via Deep Meta Reinforcement Learning. IEEE Trans. Cybern. 2023, 1–13. [Google Scholar] [CrossRef]

- Bahraini, M.S.; Mahmoodabadi, M.J.; Lohse, N. Robust Adaptive Fuzzy Fractional Control for Nonlinear Chaotic Systems with Uncertainties. Fractal Fract. 2023, 7, 484. [Google Scholar] [CrossRef]

- Dong, H.; Yang, X.; Gao, H.; Yu, X. Practical Terminal Sliding-Mode Control and Its Applications in Servo Systems. IEEE Trans. Ind. Electron. 2023, 70, 752–761. [Google Scholar] [CrossRef]

| Controller | Controller Parameters |

|---|---|

| SMC | (rad/sV), , (s), , (inch) |

| Proposed | (rad/sV), , (s), , (inch), |

| Controller | Controller Parameters |

|---|---|

| SMC | (rad/sV), , (s), , (inch). |

| ASMC | (rad/sV), (s), , (inch), , , . |

| Proposed | (rad/sV), , (s), , (inch), . |

| Cases | Index | Errors | Proposed | SMC |

|---|---|---|---|---|

| Case 1 | RMS() | 0.0177 | 0.0305 | |

| RMS() | 0.0032 | 0.0034 | ||

| Case 2 | RMS() | 0.0272 | 0.0472 | |

| RMS() | 0.0038 | 0.0039 | ||

| Case 3 | RMS() | 0.0272 | 0.0478 | |

| RMS() | 0.0047 | 0.0196 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hassan, M.A.; Cao, Z.; Man, Z. Hyperbolic-Secant-Function-Based Fast Sliding Mode Control for Pantograph Robots. Machines 2023, 11, 941. https://doi.org/10.3390/machines11100941

Hassan MA, Cao Z, Man Z. Hyperbolic-Secant-Function-Based Fast Sliding Mode Control for Pantograph Robots. Machines. 2023; 11(10):941. https://doi.org/10.3390/machines11100941

Chicago/Turabian StyleHassan, Muhammad Ali, Zhenwei Cao, and Zhihong Man. 2023. "Hyperbolic-Secant-Function-Based Fast Sliding Mode Control for Pantograph Robots" Machines 11, no. 10: 941. https://doi.org/10.3390/machines11100941