Influence of Rotation Speed and Gas Content on the Transient Gas–Liquid Two-Phase Flow of an Electric Submersible Pump

Abstract

:1. Introduction

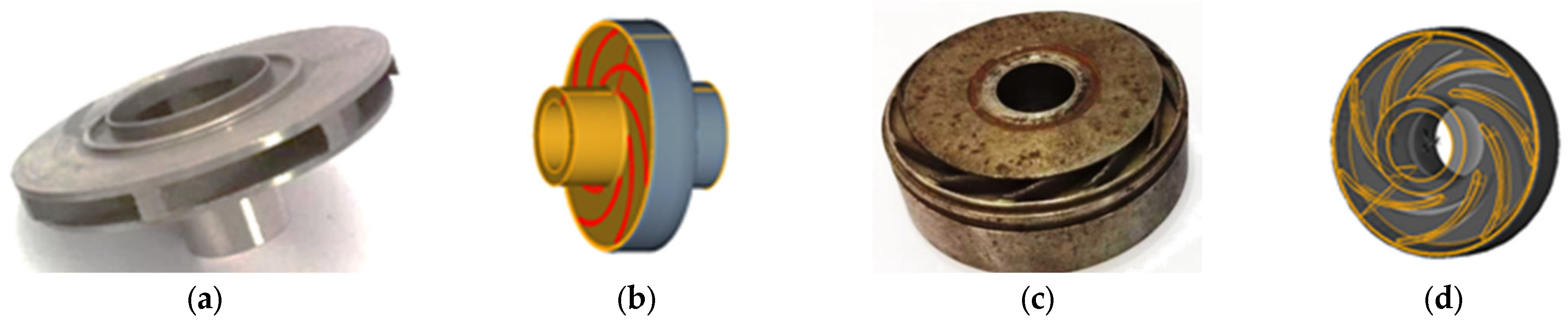

2. Structure Size and Grid Division of ESPs

3. Simulation Result Verification

4. CFD Calculation Method and Boundary Conditions

5. Calculation Results and Analysis of Variable Speed Two-Phase Flow of ESPs

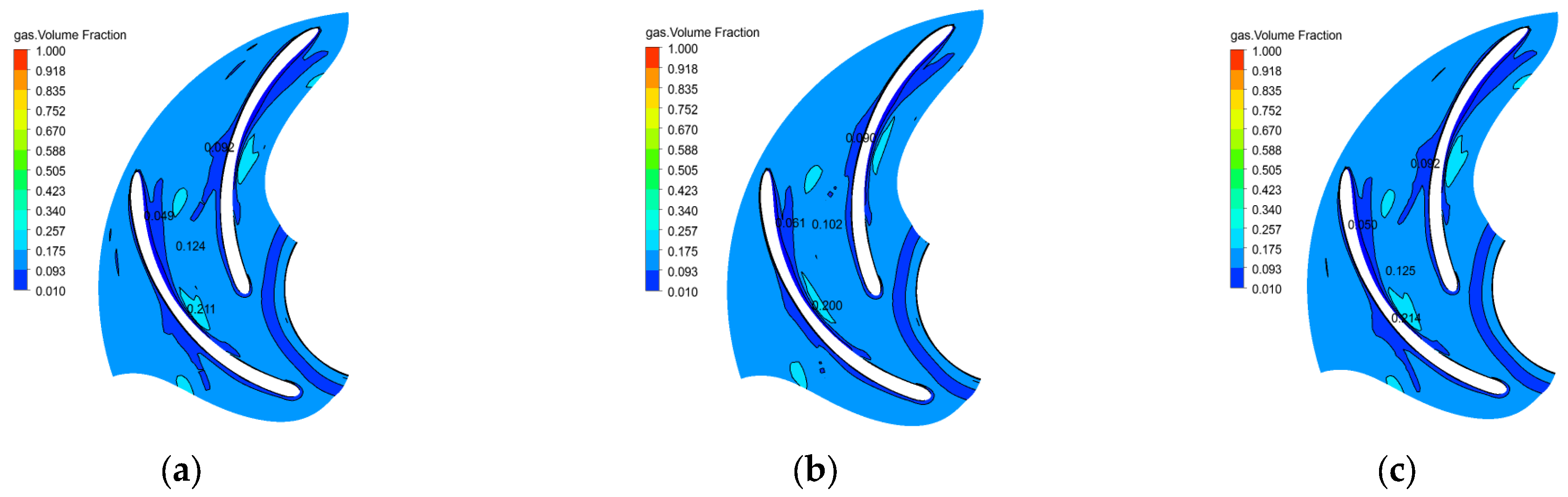

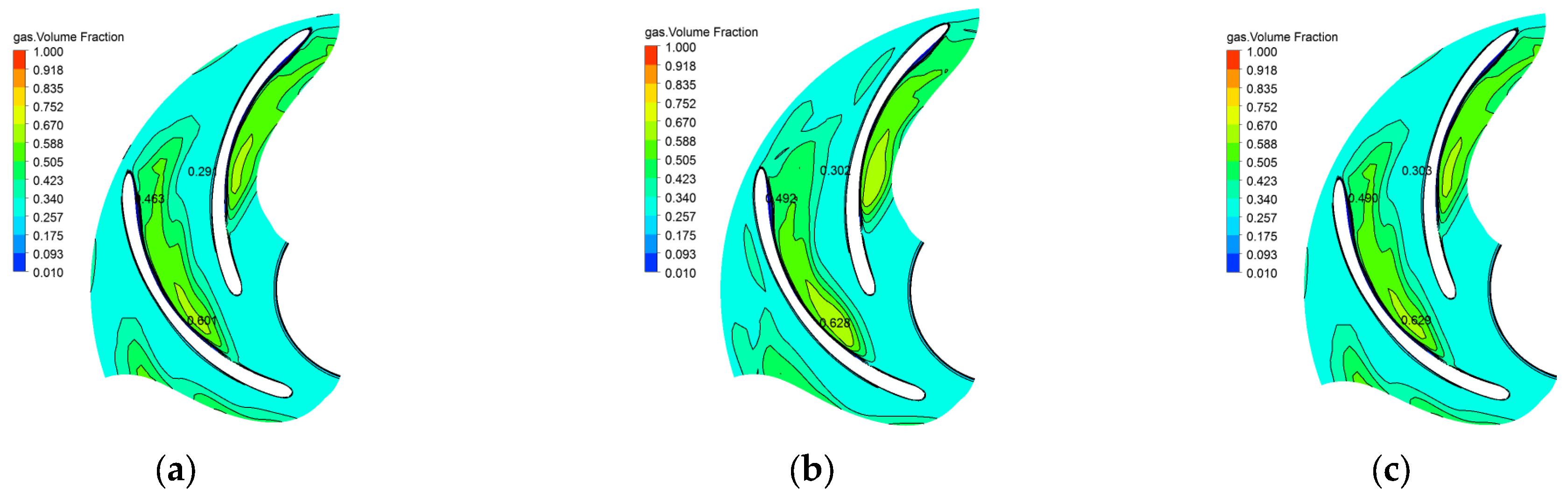

5.1. Transient Law of Gas Volume Fraction Distribution in the Pump

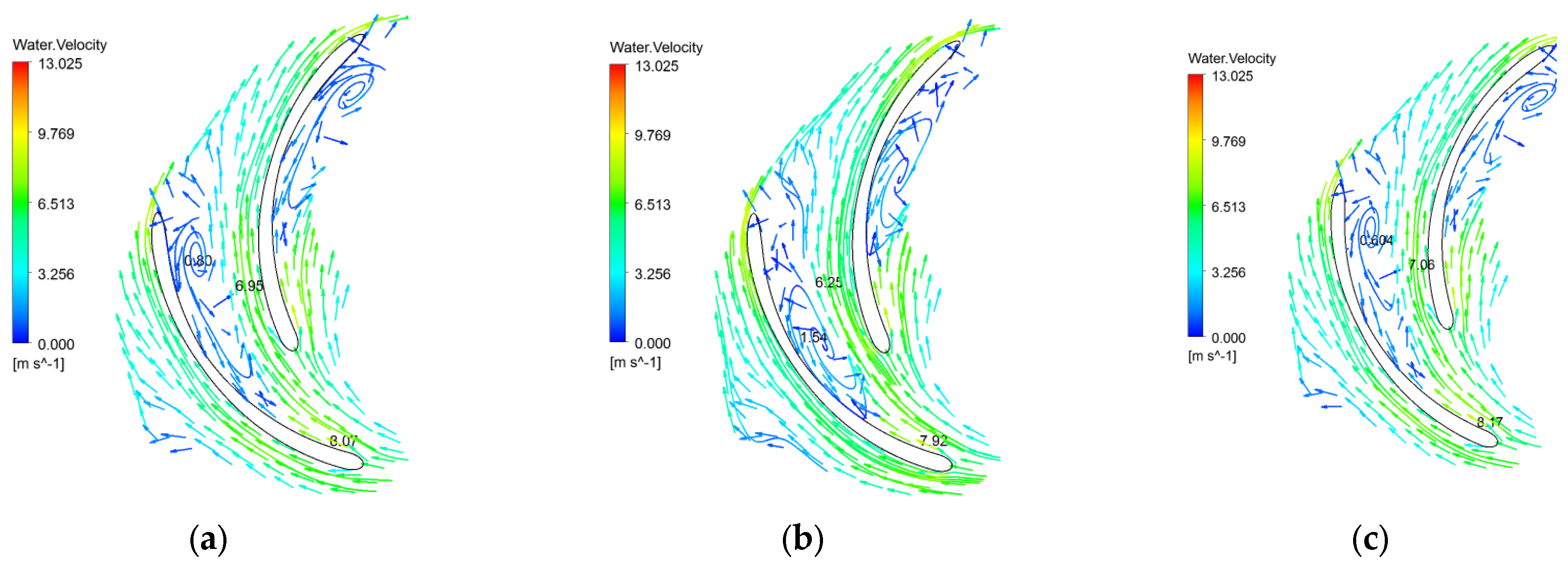

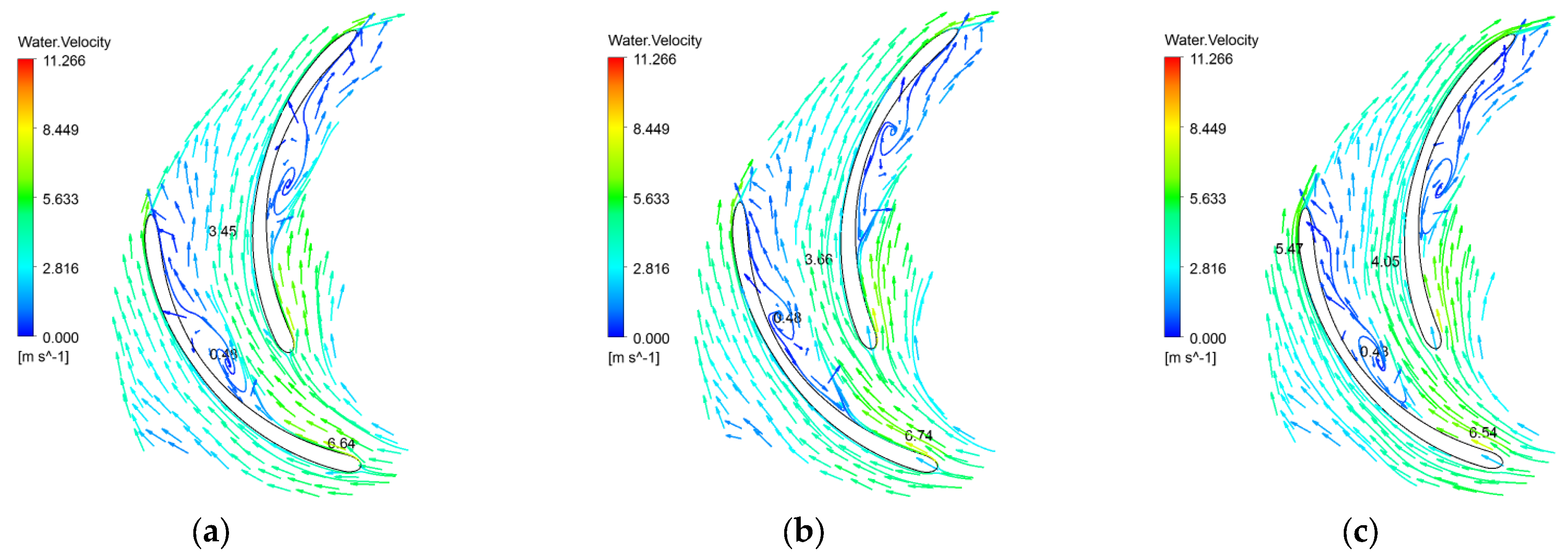

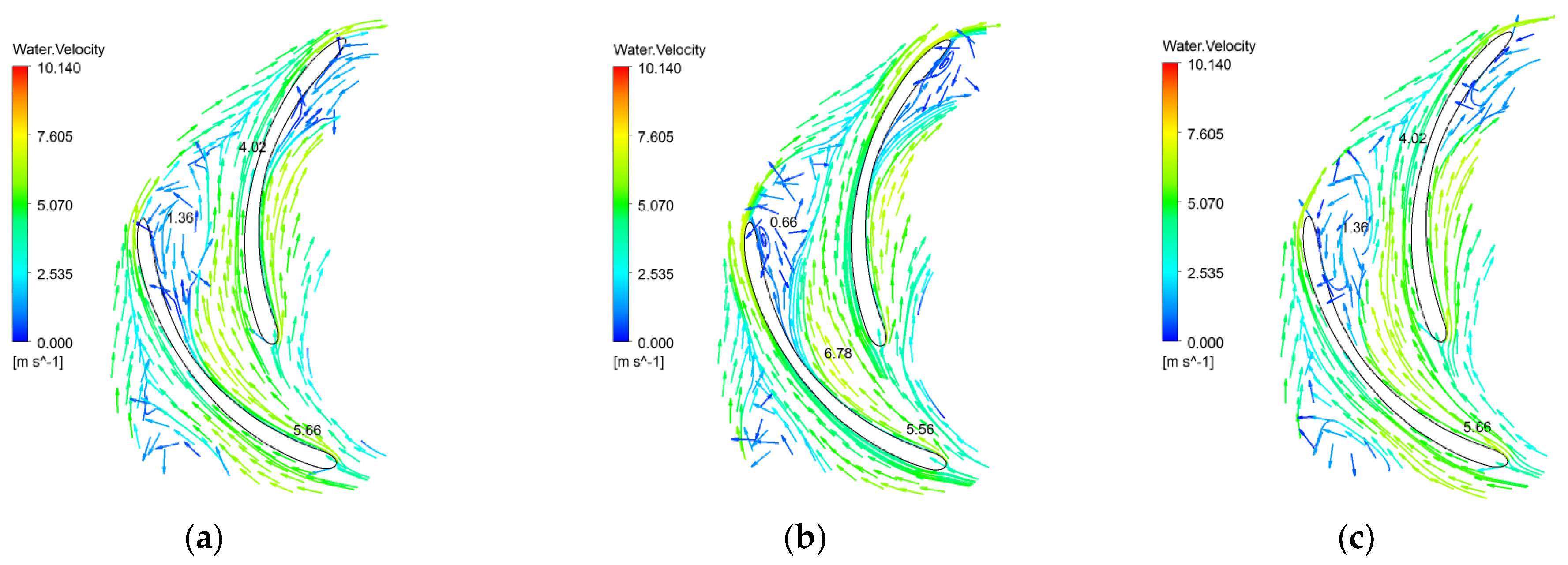

5.2. Transient Distribution of Velocity Field in the Pump

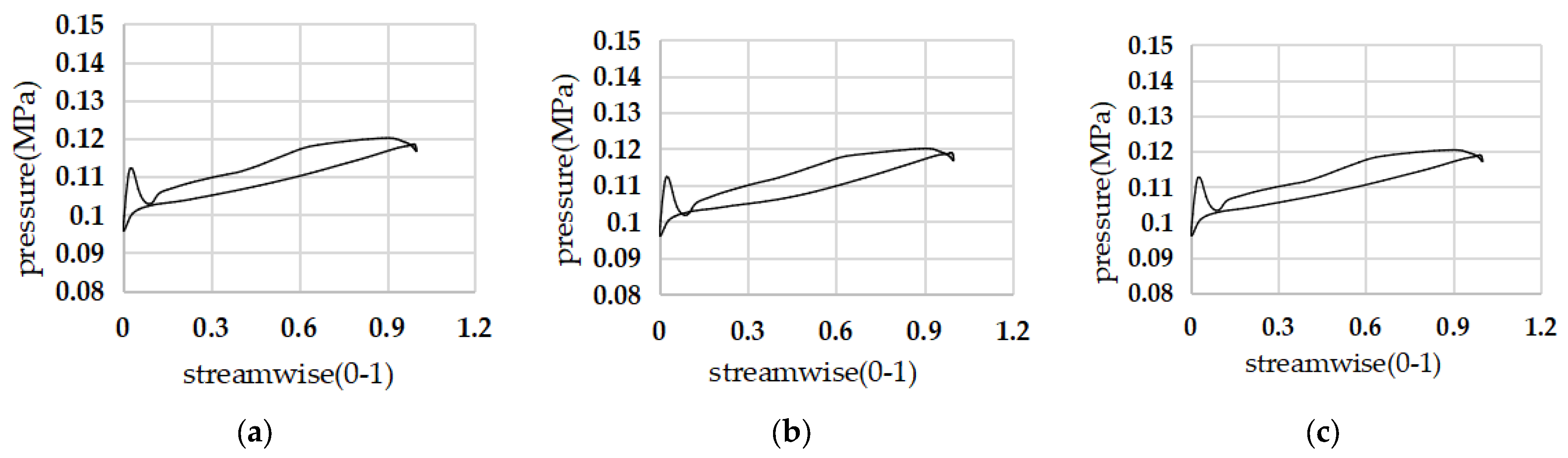

5.3. Transient Analysis of Blade Load under Variable Speed Conditions

6. Calculation Results and Analysis of Two-Phase Flow with Different Gas Content in ESPs

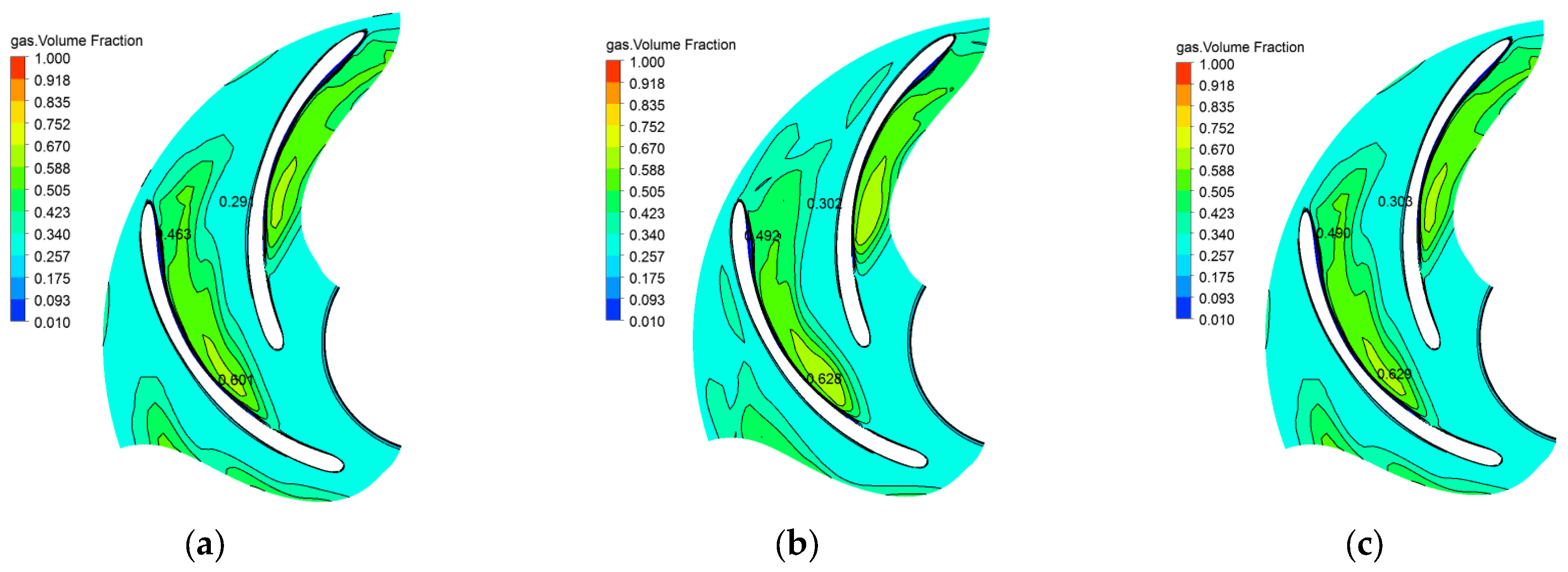

6.1. Transient Law of the Gas Volume Fraction Distribution in the Pump

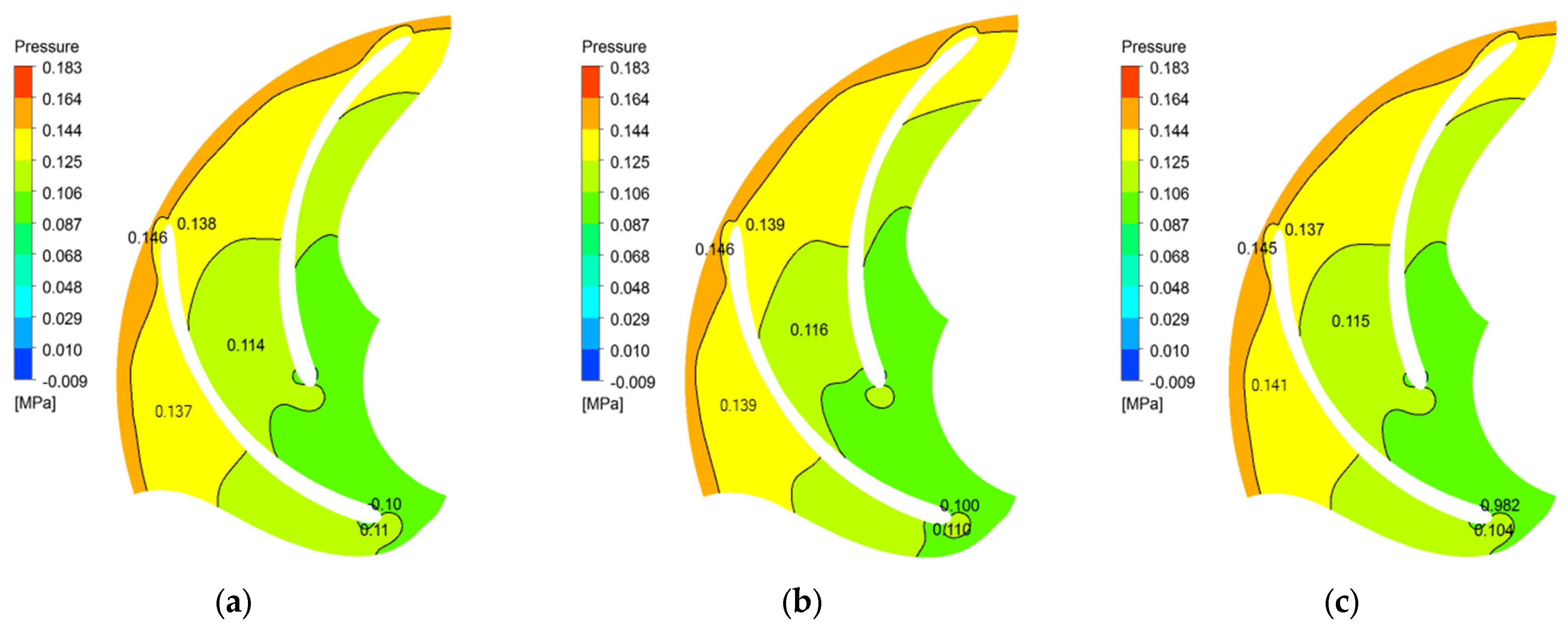

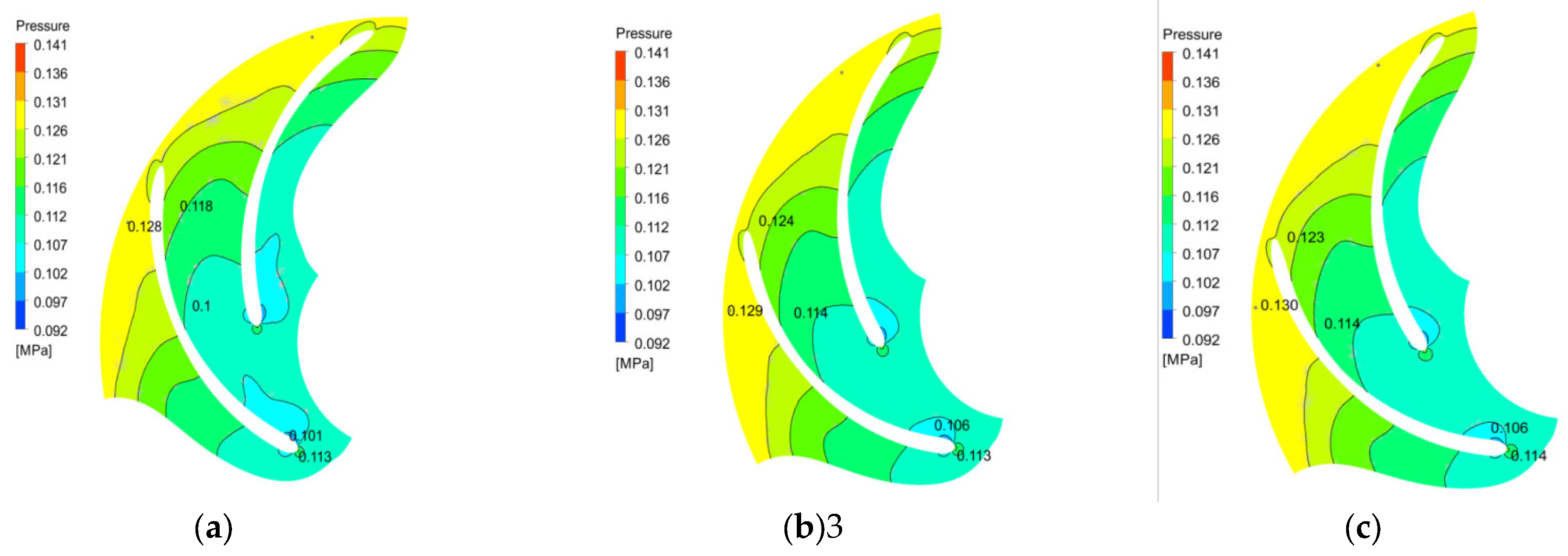

6.2. Transient Law of Pressure Feld in the Pump

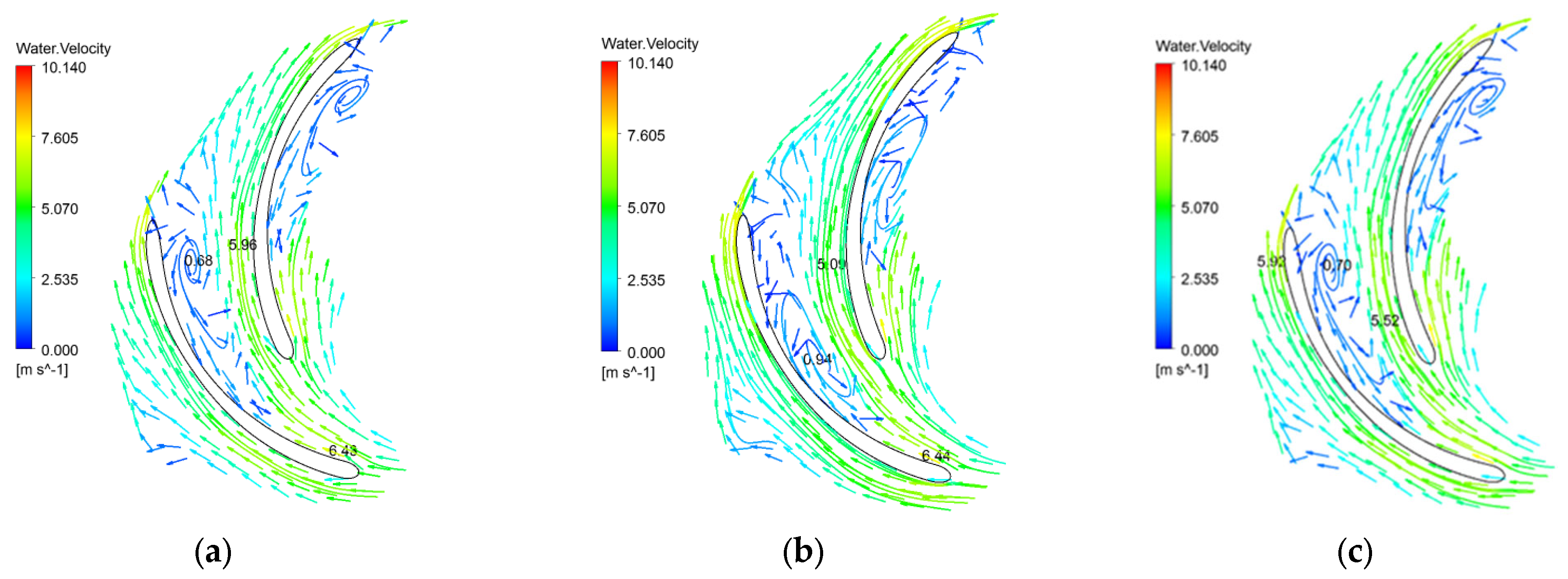

6.3. Transient Law of the Velocity Field in the Pump

7. Conclusions

- (1)

- In the gas–liquid two-phase flow, the gas phase is unevenly distributed in the flow channel. Along the axial direction, the range of gas phase accumulation in the impeller is shown as extending from the entrance of the front cover to the exit of the rear cover. The concentration of gas phase accumulation decreases from the entrance of the front cover to the exit of the flow channel.

- (2)

- The gas phase accumulation form in the channel is not affected, and the gas phase accumulation and the diffusion period are shortened; the gas phase accumulation concentration in the impeller decreases with the increase in speed.

- (3)

- Due to the regular and periodic accumulation and diffusion of gas in the flow channel, the load on both sides of the blade changes regularly, and the pressure difference on both sides of the blade fluctuates with a small amplitude during the change period. The increase in the impeller speed results in the increase in the pressure difference between the two sides of the blade, the increase in the load of the blade, and the increase in the pressure difference between the inlet and outlet.

- (4)

- Gas mixing has little effect on the pressure field in the pump, and the pressure value in the flow field increases slightly. The velocity value of the gas mixed into the flow channel increased slightly. The range of the vortex in the impeller expands to the pressure surface of the blade, and the center of the vortex corresponds to the position of the maximum concentration of gas phase. As the flow rate increases, the pressure in the two-phase flow field increases and the flow velocity increases.

- (5)

- When the gas content in the inlet increases, the gas phase distribution in the flow channel does not change significantly, and the gas phase is mainly concentrated on the back of the blades on the side of the front corner. With the increase in the gas content in the inlet, the maximum concentration of gas phase in the flow channel increases, the area of the flow channel occupied by the high concentration gas phase increases, the period of periodic accumulation and diffusion increases, and the range of the gas–liquid separation zone shrinks toward the front cover. The gas content in the inlet increases, the pressure in the pump increases slightly, the flow rate of the mainstream increases, and the range of vortex action increases.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Zhu, J.; Zhang, H.Q. Mechanistic modeling and numerical simulation of in-situ gas void fraction inside ESP impeller. J. Nat. Gas Sci. Eng. 2016, 36, 144–154. [Google Scholar] [CrossRef]

- Trevisan, F.E.; Prado, M.G. Experimental Investigation on the Viscous Effect on Two-Phase Flow Patterns and Hydraulic Performance of Electrical Submersible Pumps. J. Can. Pet. Technol. 2010, 50, 45–52. [Google Scholar] [CrossRef]

- Pessoa, R.; Mauricio, P. Experimental investigation of two-phase flow performance of electrical submersible pump stages. In Proceedings of the SPE Annual Technical Conference and Exhibition, New Orleans, LA, USA, 30 September 2001. [Google Scholar] [CrossRef]

- Barrios, L.; Prado, M.G. Experimental Visualization of Two-Phase Flow Inside an Electrical Submersible Pump Stage. J. Energy Resour. Technol. 2011, 133, 042901. [Google Scholar] [CrossRef]

- Pervaiz, S.S.; Hasan, A.; Dol, S.S.; Gadala, M.S. Numerical Investigation of Turbulence Production Under Two-Phase Flow in a Simulation of Electrical Submersible Pump Performance. ASME Open, J. Eng. 2022, 1, 011015. [Google Scholar] [CrossRef]

- Stel, H.; Sirino, T.; Ponce, F.J. Numerical investigation of the flow in a multistage electric submersible pump. J. Pet. Sci. Eng. 2015, 136, 41–54. [Google Scholar] [CrossRef]

- Pineda, H.; Biazussi, J.; López, F. Phase distribution analysis in an Electrical Submersible Pump (ESP) inlet handling water-air two-phase flow using Computational Fluid Dynamics (CFD). J. Pet. Sci. Eng. 2016, 139, 49–61. [Google Scholar] [CrossRef]

- Ali, A.; Yuan, J.; Deng, F.; Wang, B.; Liu, L.; Si, Q.; Buttar, N.A. Research Progress and Prospects of Multi-Stage Centrifugal Pump Capability for Handling Gas–Liquid Multiphase Flow: Comparison and Empirical Model Validation. Energies 2021, 14, 896. [Google Scholar] [CrossRef]

- Zhu, J.; Zhang, H.Q. Numerical study on electrical-submersible-pump two-phase performance and bubble-size modeling. SPE Prod. Oper. 2017, 32, 267–278. [Google Scholar] [CrossRef]

- Zhu, J.J.; Zhu, H.W.; Zhang, J.C. A numerical study on flow patterns inside an electrical submersible pump (ESP) and comparison with visualization experiments. J. Pet. Sci. Eng. 2019, 173, 339–350. [Google Scholar] [CrossRef]

- Li, X.; Chen, H.; Chen, B. Investigation of flow pattern and hydraulic performance of a centrifugal pump impeller through the PIV method. Renew. Energy 2020, 162, 561–574. [Google Scholar] [CrossRef]

- Dong, L.; Liu, J.; Liu, H.; Dai, C.; Gradov, D.V. Study on the internal two-phase flow of the inverted-umbrella aerator. Adv. Mech. Eng. 2019, 11, 1687814019871731. [Google Scholar] [CrossRef]

- Li, Y.J.; Yu, Z.Y.; Sun, W.H. Drag coefficient modification for turbulent gas-liquid two-phase flow in a rotodynamic pump. Chem. Eng. J. 2021, 417, 128570. [Google Scholar] [CrossRef]

- Lv, Y.T.; Ding, P.; Liu, J.S.; Ge, H.; Yang, F.; Tang, F. Numerical analysis of the internal flow and pressure pulsation characteristics of a submersible tubular electric pump device. Front. Energy Res. 2023, 10, 1104248. Available online: https://www.frontiersin.org/articles/10.3389/fenrg.2022.1104248 (accessed on 10 October 2023). [CrossRef]

- Guan, H.X.; Li, C.J.; Li, P. Research on Production Regulation Ability of ESPWells under Variable Frequency Conditions. China Pet. Mach. 2008, 36, 59–62. Available online: http://qikan.cqvip.com/Qikan/Article/Detail?id=26506756&from=Qikan_Search_Index (accessed on 10 May 2022).

- Li, W.; Liu, M.; Ji, L.; Li, S.; Song, R.; Wang, C.; Cao, W.; Agarwal, R.K. Study on the trajectory of tip leakage vortex and energy characteristics of mixed-flow pump under cavitation conditions. Ocean. Eng. 2023, 267, 113225. [Google Scholar] [CrossRef]

- Luo, C.; Liu, H.; Cheng, L.; Wang, C.; Jiao, W.; Zhang, D. Unsteady Flow Process in Mixed Waterjet PropulsionPumps with Nozzle Based on Computational Fluid Dynamics. Processes 2019, 7, 910. Available online: https://www.mdpi.com/2227-9717/7/12/910 (accessed on 11 May 2022). [CrossRef]

- Qian, J.; Zhang, J.; Wu, Z.; Sunden, B. Special Issue: Smart Flow Control in Micro Scale. Processes 2020, 8, 550. [Google Scholar] [CrossRef]

| Parameter | Numerical Value | Unit |

|---|---|---|

| Rate of flow (Q) | 100 | m3/d |

| Head of delivery (H) | 6.95 | m |

| Rated speed (ne) | 2900 | r/min |

| Impeller inlet diameter (D1) | 25.8 | mm |

| Outer diameter of impeller (D2) | 35.8 | mm |

| Impeller outlet width (b1) | 8 | mm |

| Outlet diameter of diffuser (b2) | 8 | mm |

| Number of impeller blades | 7 | |

| Number of diffuser blades | 10 |

| Impeller Grid Number | Number of Diffuser Grids | Head/m | Power/W | Efficiency |

|---|---|---|---|---|

| 56,900 | 48,900 | 4.71 | 114 | 0.465 |

| 118,232 | 127,242 | 4.8 | 115.5 | 0.475 |

| 153,560 | 137,677 | 4.92 | 116.2 | 0.49 |

| 195,854 | 173,160 | 4.91 | 116.1 | 0.485 |

| 202,889 | 189,663 | 4.92 | 116.2 | 0.484 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sun, D.; Xiao, Z.; Feng, Z.; Yuan, H.; Cui, W. Influence of Rotation Speed and Gas Content on the Transient Gas–Liquid Two-Phase Flow of an Electric Submersible Pump. Machines 2023, 11, 971. https://doi.org/10.3390/machines11100971

Sun D, Xiao Z, Feng Z, Yuan H, Cui W. Influence of Rotation Speed and Gas Content on the Transient Gas–Liquid Two-Phase Flow of an Electric Submersible Pump. Machines. 2023; 11(10):971. https://doi.org/10.3390/machines11100971

Chicago/Turabian StyleSun, Deqing, Zhongmin Xiao, Ziming Feng, Heng Yuan, and Wei Cui. 2023. "Influence of Rotation Speed and Gas Content on the Transient Gas–Liquid Two-Phase Flow of an Electric Submersible Pump" Machines 11, no. 10: 971. https://doi.org/10.3390/machines11100971

APA StyleSun, D., Xiao, Z., Feng, Z., Yuan, H., & Cui, W. (2023). Influence of Rotation Speed and Gas Content on the Transient Gas–Liquid Two-Phase Flow of an Electric Submersible Pump. Machines, 11(10), 971. https://doi.org/10.3390/machines11100971