Development of a Neuroergonomic Assessment for the Evaluation of Mental Workload in an Industrial Human–Robot Interaction Assembly Task: A Comparative Case Study

Abstract

:1. Introduction

2. Materials and Methods

2.1. Participants Selection

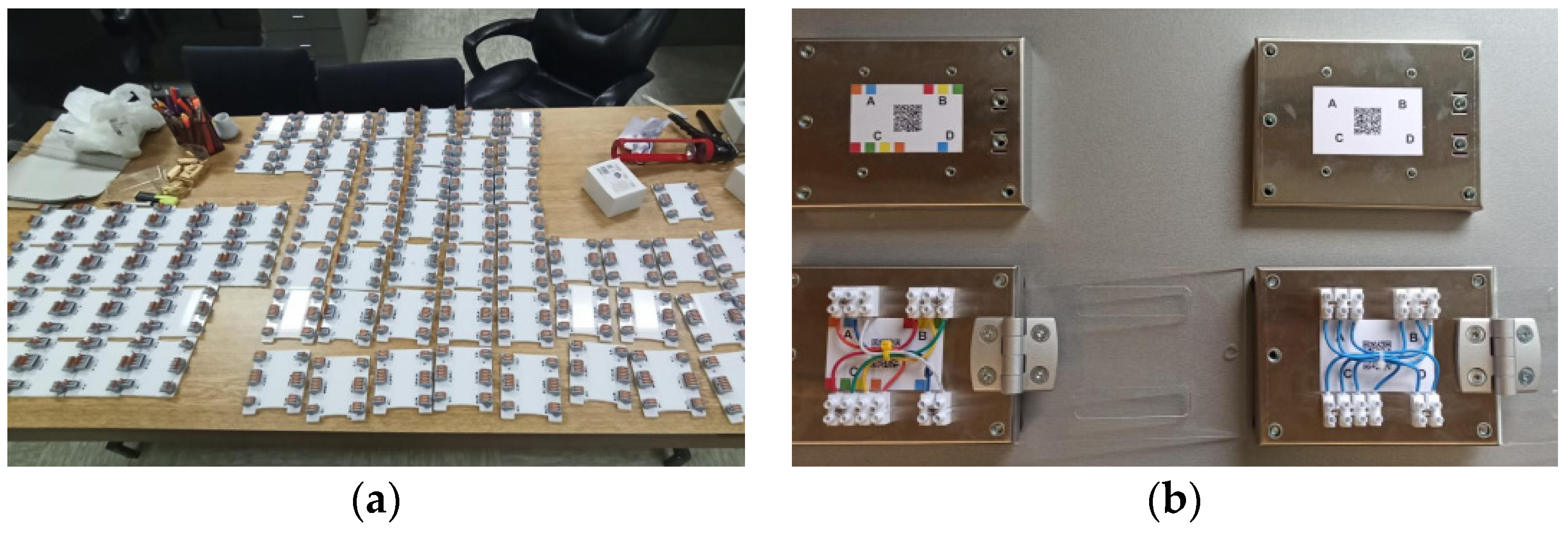

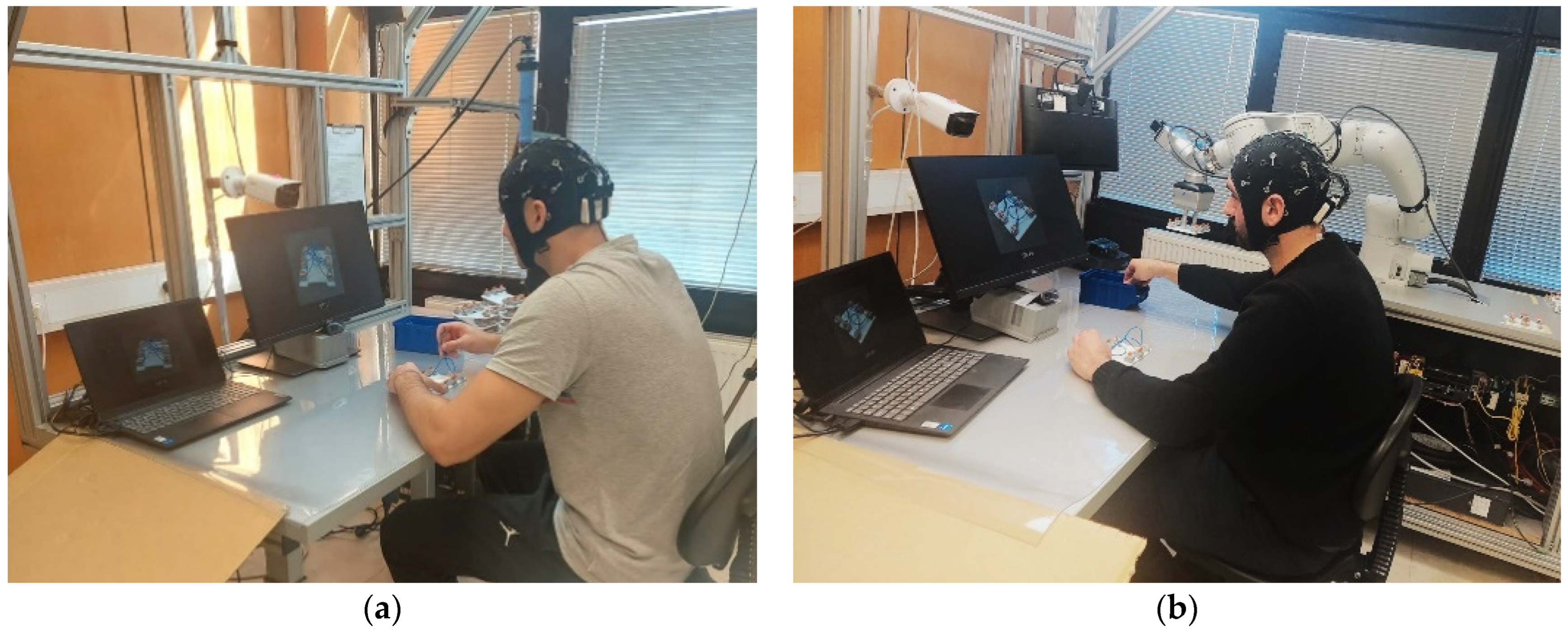

2.2. Experimental Design

- a touchscreen PC for task definition and stimulus application;

- lighting LED system to regulate the light and produce a soft shadow to put less strain on the eyes of the participant in the test;

- an audio 5.0 system to simulate the sounds of the industrial environment;

- an adjustable ergonomic work chair to let the participant sit during the tests.

- Take the plate located on the right side of the participant and set it on the work desk of the workstation [21].In the standard scenario, the plates are set in lots, and placed on the right side of the operator in the manual assembly desk area. On the other end, in the collaborative scenario, the cobot carried the plate to the operator on the right side, entering the manual assembly area and waiting for the participant to finish the task. The cobot positioned the plate to be taken by the participant. In this phase, ergonomic principles were considered to let the participant grasp the component without overextending the arm [62];

- Take seven wires from the container, one by one, set in the assembly area, and connect them to the plates.The connections were supported by the illustration from the installed PC touchscreen. The participant did not know which order scheme would appear on the monitor. The combination of the schemes’ connection was randomized in order not to affect the results.In the standard scenario, the participant performed the task without any external presence in the assembly area. On the other side, in the collaborative scenario, while the operator assembled the scheme, the robot moved back to pick and carry the other scheme to the position to be picked up by the participant;

- Set the plate on the slide located to the left side after having performed the task and touch the PC touchscreen to progress to the next scheme.

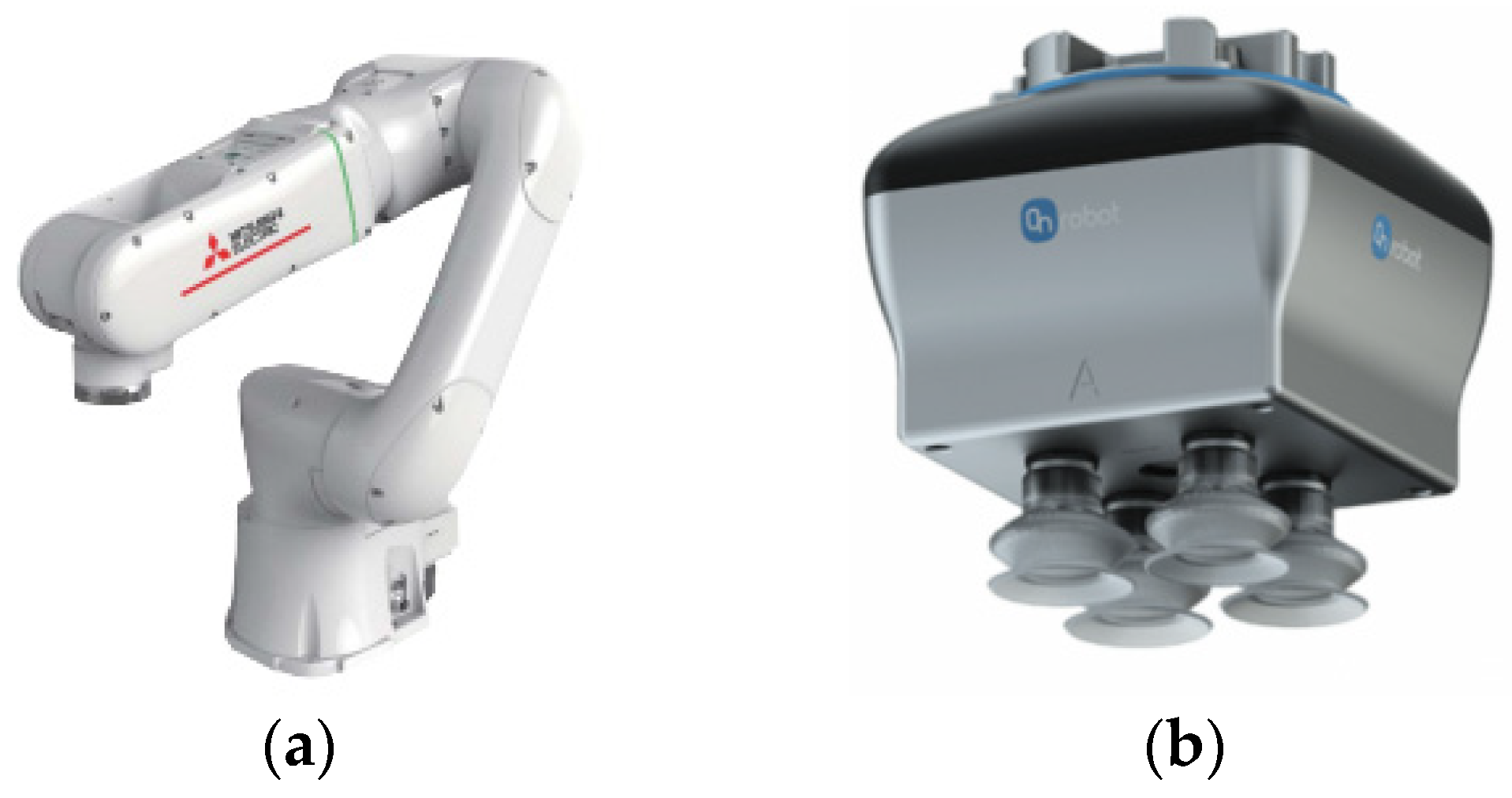

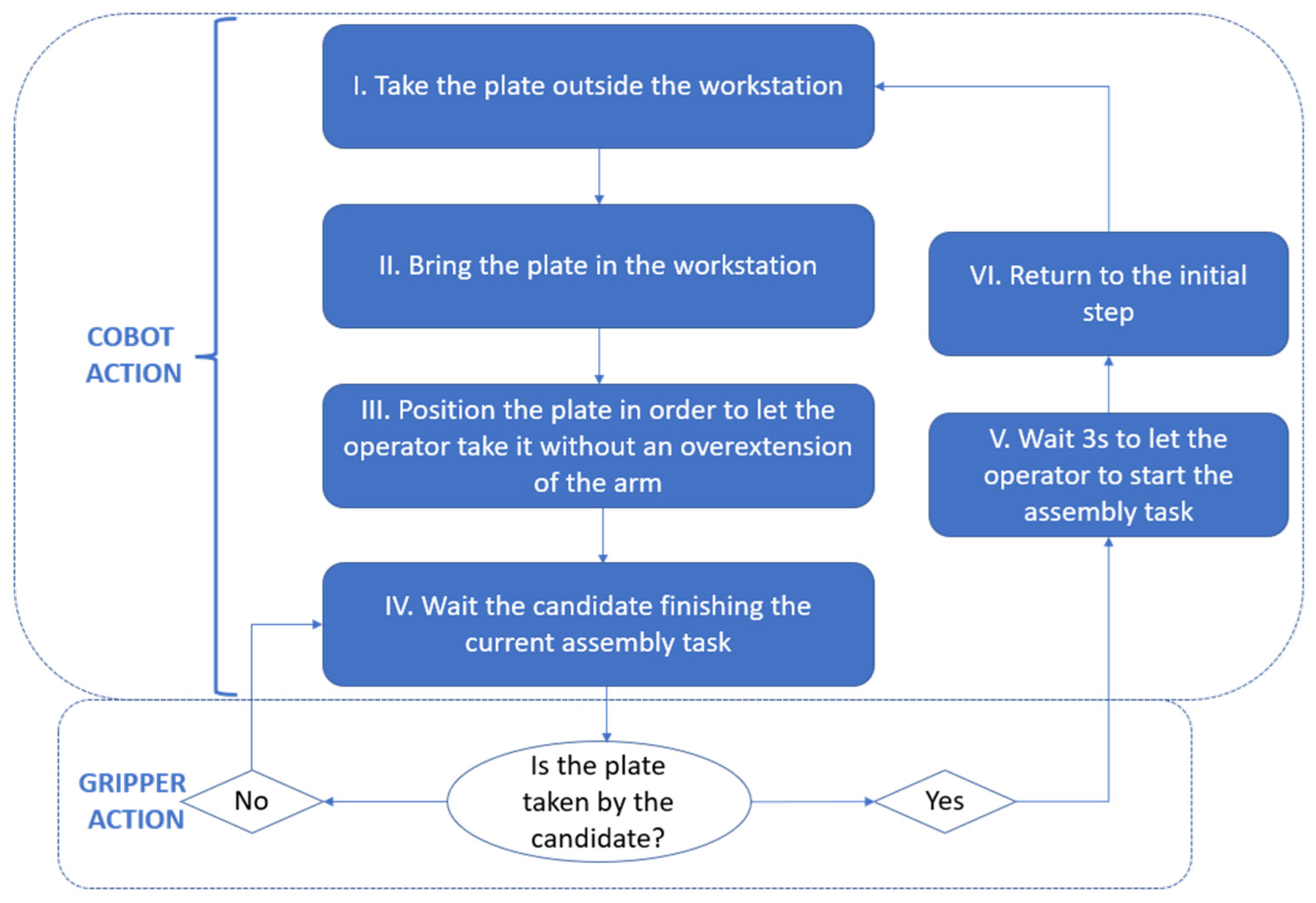

2.3. Collaborative Scenario

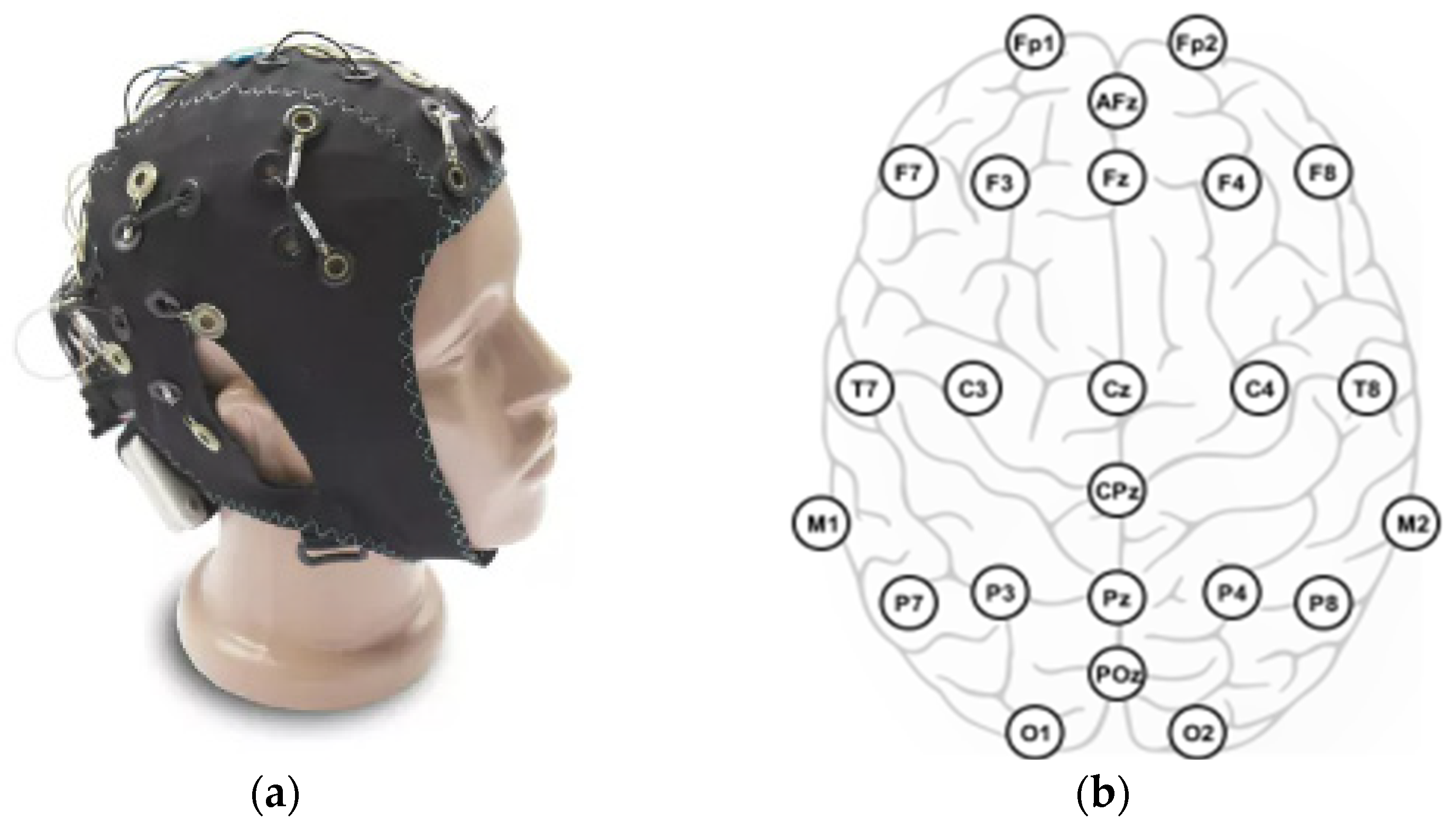

2.4. Neuroergonomic and Performance Assessment

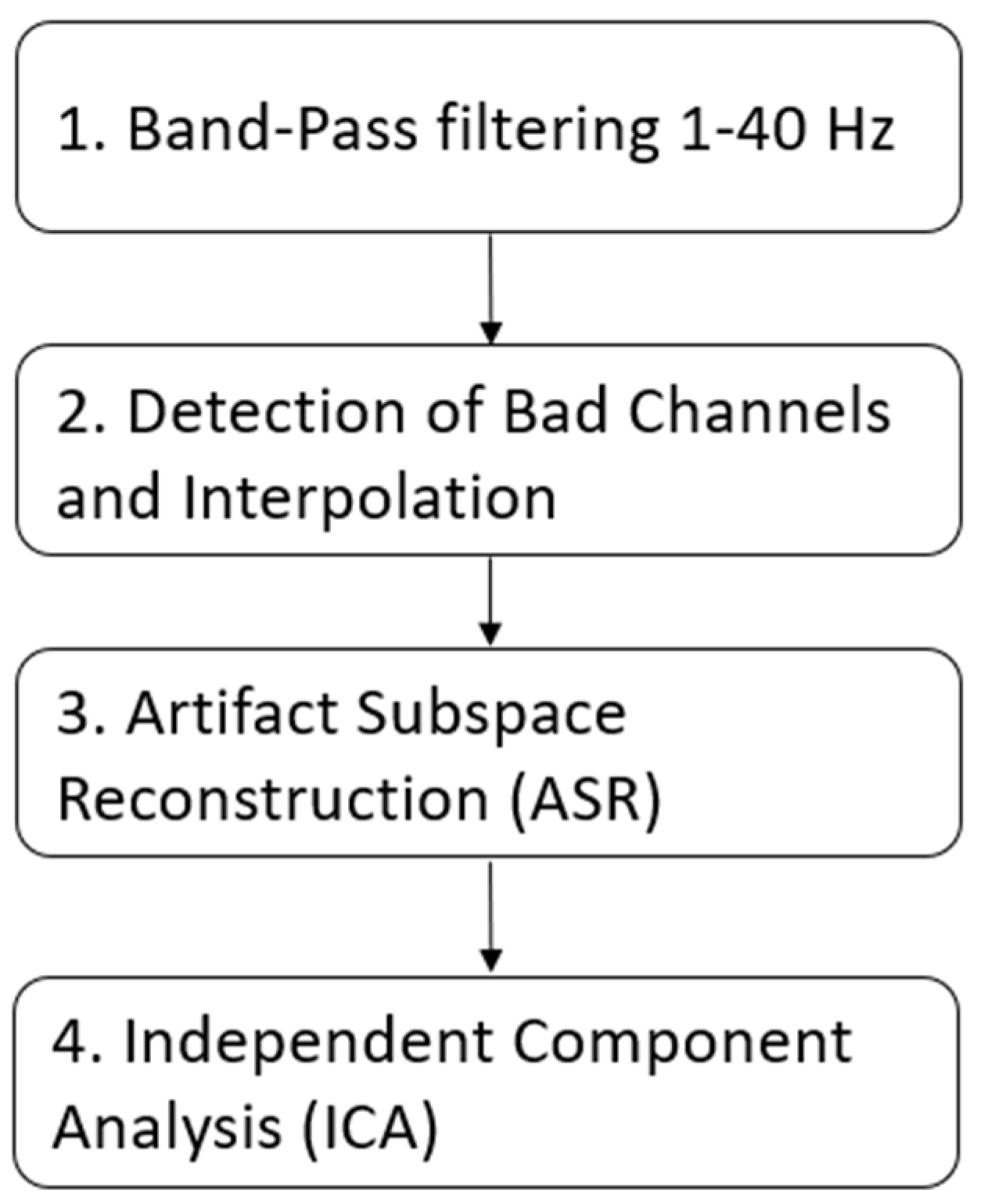

2.5. EEG Pre-Processing

- Delta (0.5–4 Hz): generated in a state of sleeping;

- Theta (4–8 Hz); generated in REM phase;

- Alpha (8–12 Hz): produced in an awake state while being concentrated and relaxed;

- Beta (13–29 Hz): generated while being in a state of stress and engagement;

- Gamma (25–45 Hz): produced in a state of processing information and making voluntary movements.

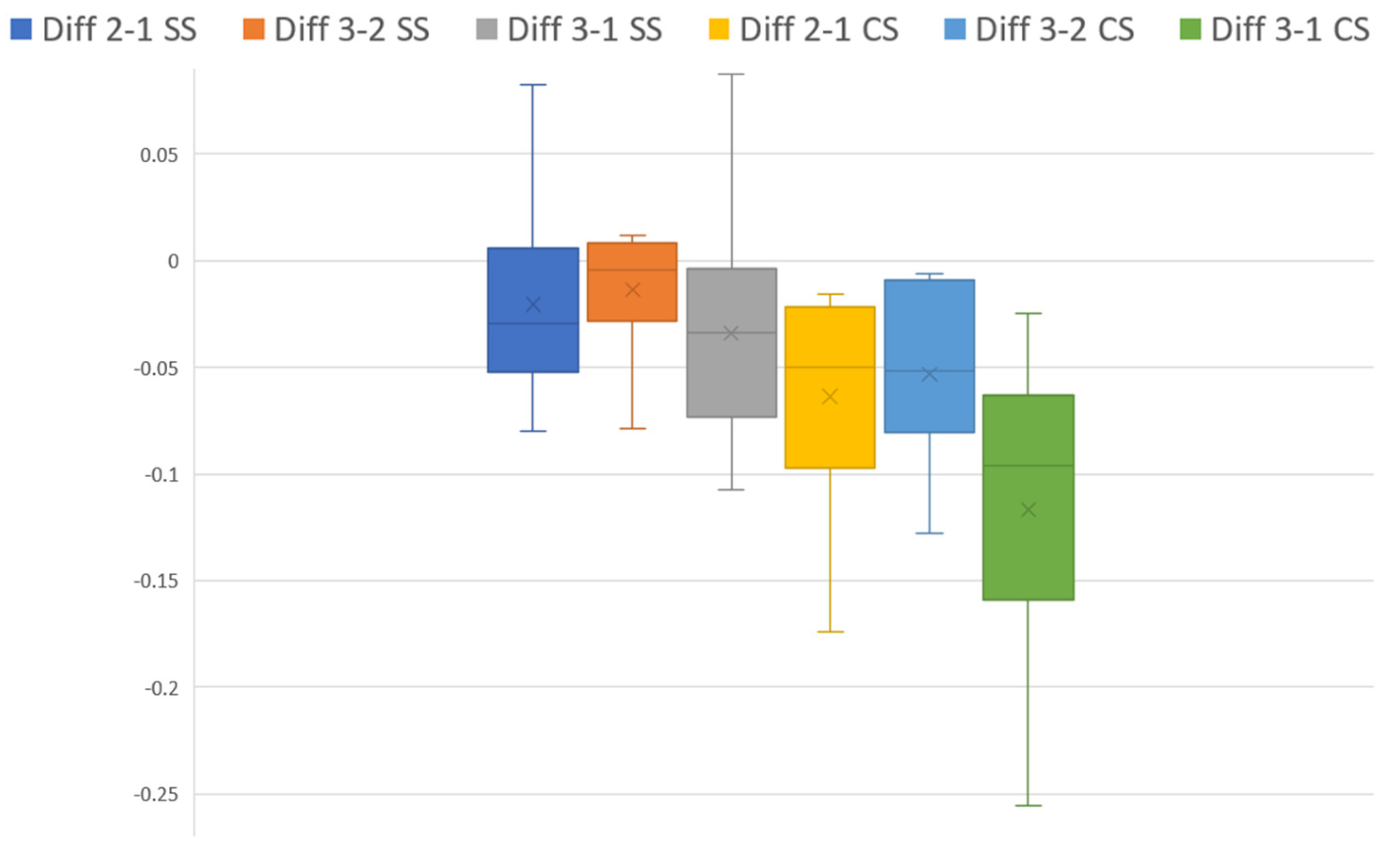

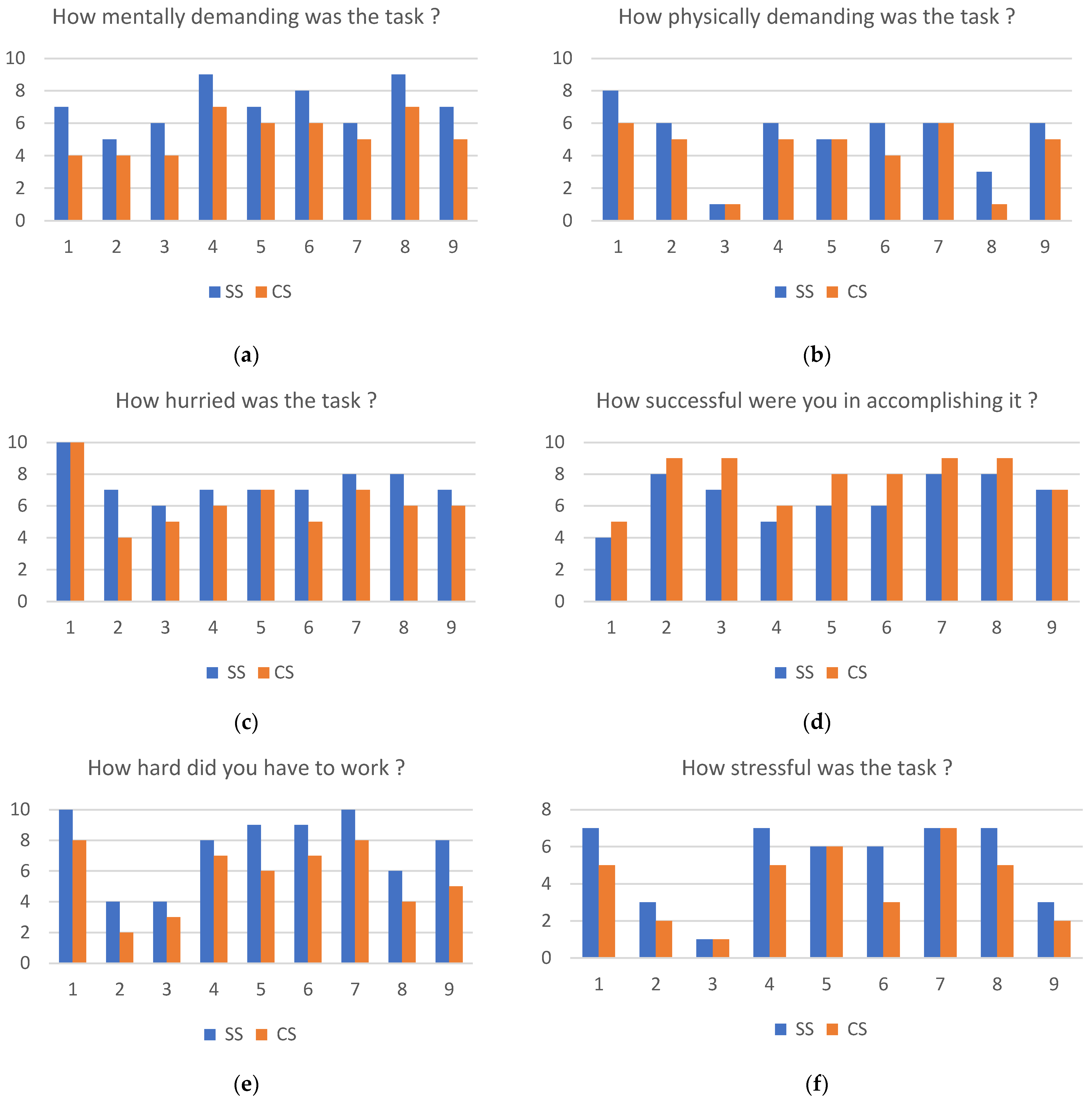

3. Results

4. Discussion

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Candidate Number | 1st Half SSS | 2nd Half SS | 3rd Half SS |

|---|---|---|---|

| 1 | 1.076603291 | 1.076561924 | 1.043664142 |

| 2 | 0.772474606 | 0.692860351 | 0.704460397 |

| 3 | 1.041756482 | 0.99235386 | 0.975106769 |

| 4 | 1.009762146 | 1.021124855 | 1.028503097 |

| 5 | 0.767191773 | 0.737818065 | 0.733678215 |

| 6 | 1.281920772 | 1.364712446 | 1.369240439 |

| 7 | 0.535837045 | 0.480604662 | 0.456824445 |

| 8 | 1.164515278 | 1.128745483 | 1.13843409 |

| 9 | 1.069157344 | 1.040192943 | 0.96160846 |

| Candidate Number | 1st Half CSS | 2nd Half CS | 3rd Half CS |

|---|---|---|---|

| 1 | 1.311318282 | 1.137371269 | 1.055976196 |

| 2 | 0.769286117 | 0.683612302 | 0.613492 |

| 3 | 0.693132066 | 0.677324776 | 0.5973241 |

| 4 | 1.061111957 | 1.045100041 | 1.036104363 |

| 5 | 0.720308583 | 0.692526322 | 0.650369239 |

| 6 | 1.289545341 | 1.259335851 | 1.131426059 |

| 7 | 0.47350241 | 0.408151724 | 0.399456098 |

| 8 | 1.213856242 | 1.163920243 | 1.15775252 |

| 9 | 1.111803357 | 1.003185084 | 0.95138055 |

| Candidate Number | Diff. 2-1 SSS | Diff 3-2 SS | Diff 3-1 SS |

|---|---|---|---|

| 1 | −4.13672 × 10−05 | −0.0329 | −0.03294 |

| 2 | −0.079614255 | 0.0116 | −0.06801 |

| 3 | −0.049402622 | −0.01725 | −0.06665 |

| 4 | 0.011362709 | 0.007378 | 0.018741 |

| 5 | −0.029373708 | −0.00414 | −0.03351 |

| 6 | 0.082791674 | 0.004528 | 0.08732 |

| 7 | −0.055232382 | −0.02378 | −0.07901 |

| 8 | −0.035769794 | 0.009689 | −0.02608 |

| 9 | −0.028964401 | −0.07858 | −0.10755 |

| Candidate Number | Diff. 2-1 CSS | Diff 3-2 CS | Diff 3-1 CS |

|---|---|---|---|

| 1 | −0.17395 | −0.0814 | −0.25534 |

| 2 | −0.08567 | −0.07012 | −0.15579 |

| 3 | −0.01581 | −0.08 | −0.09581 |

| 4 | −0.01601 | −0.009 | −0.02501 |

| 5 | −0.02778 | −0.04216 | −0.06994 |

| 6 | −0.03021 | −0.12791 | −0.15812 |

| 7 | −0.06535 | −0.0087 | −0.07405 |

| 8 | −0.04994 | −0.00617 | −0.0561 |

| 9 | −0.10862 | −0.0518 | −0.16042 |

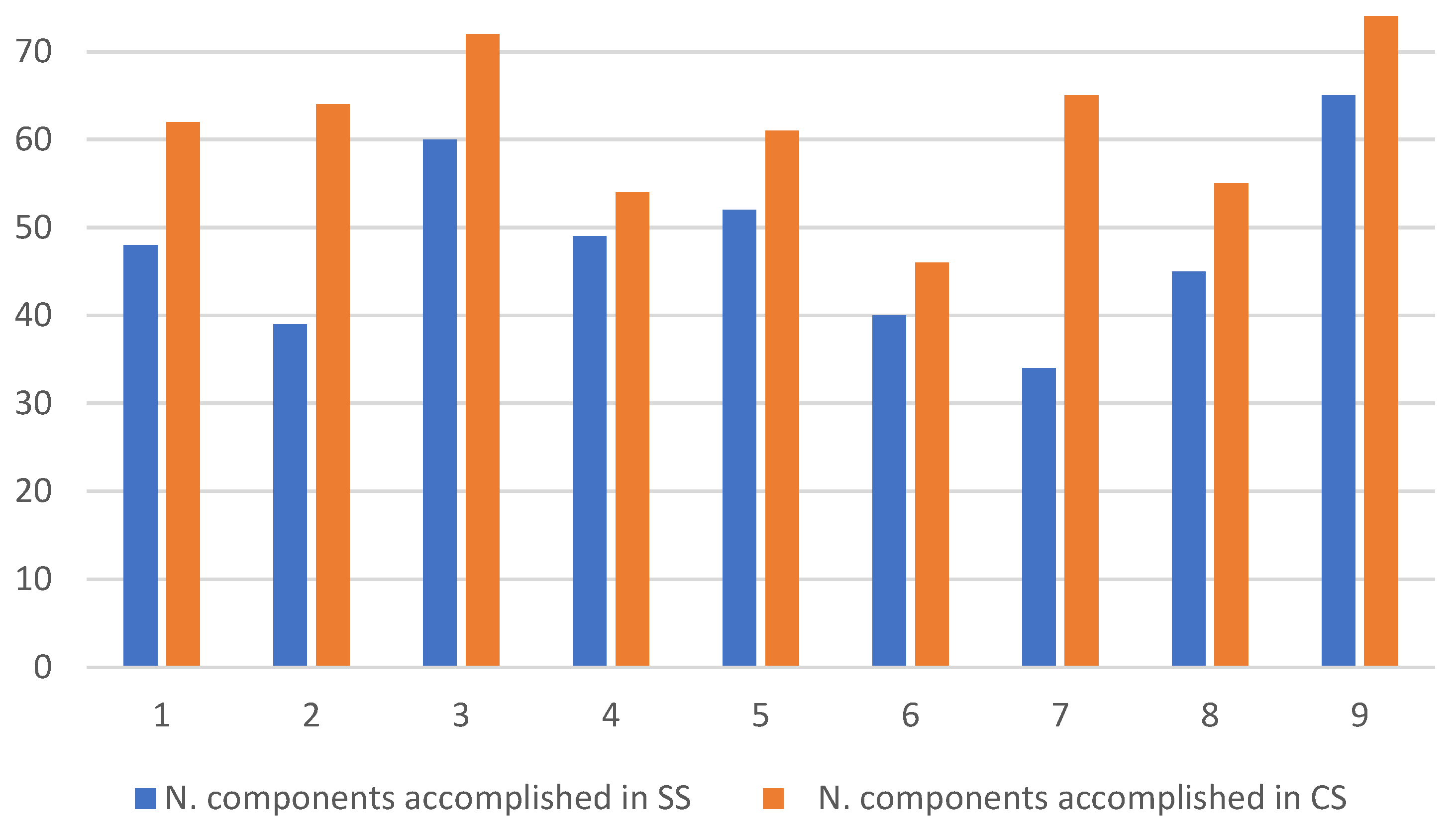

| Candidate Number | N. Components Achieved in SSS | N. Components Achieved in CS | Variation |

|---|---|---|---|

| 1 | 48 | 62 | +14 |

| 2 | 39 | 64 | +25 |

| 3 | 60 | 72 | +12 |

| 4 | 49 | 54 | +5 |

| 5 | 52 | 61 | +9 |

| 6 | 40 | 46 | +6 |

| 7 | 34 | 65 | +29 |

| 8 | 45 | 55 | +20 |

| 9 | 65 | 74 | +9 |

References

- Nahavandi, S. Industry 5.0—A Human-Centric Solution. Sustainability 2019, 11, 4371. [Google Scholar] [CrossRef]

- Tiwari, S.; Bahuguna, P.C.; Walker, J. Industry 5.0. In Handbook of Research on Innovative Management Using AI in Industry 5.0; IGI Global: Hershey, PA, USA, 2022. [Google Scholar]

- Javaid, M.; Haleem, A. Critical Components of Industry 5.0 towards a Successful Adoption in the Field of Manufacturing. J. Ind. Integr. Manag. 2020, 5, 327–348. [Google Scholar] [CrossRef]

- Demir, K.A.; Döven, G.; Sezen, B. Industry 5.0 and Human-Robot Co-working. Procedia Comput. Sci. 2019, 158, 688–695. [Google Scholar] [CrossRef]

- Mourtzis, D.; Angelopoulos, J.D.; Panopoulos, N. A Literature Review of the Challenges and Opportunities of the Transition from Industry 4.0 to Society 5.0. Energies 2022, 15, 6276. [Google Scholar] [CrossRef]

- Leva, M.C.; Demichela, M.; Albarrán Morillo, C.A.; Modaffari, F.; Comberti, L. Optimizing Human Performance to Enhance Safety: A Case Study in an Automotive Plant. Sustainability 2023, 15, 11097. [Google Scholar] [CrossRef]

- Peruzzini, M.; Carassai, S.; Pellicciari, M. The Benefits of Human-centred Design in Industrial Practices: Re-design of Workstations in Pipe Industry. Procedia Manuf. 2017, 11, 1247–1254. [Google Scholar] [CrossRef]

- Gualtieri, L.; Palomba, I.; Merati, F.A.; Rauch, E.; Vidoni, R. Design of Human-Centered Collaborative Assembly Workstations for the Improvement of Operators’ Physical Ergonomics and Production Efficiency: A Case Study. Sustainability 2020, 12, 3606. [Google Scholar] [CrossRef]

- Villani, V.; Ciaramidaro, A.; Iani, C.; Rubichi, S.; Sabattini, L. To collaborate or not to collaborate: Understanding human-robot collaboration. In Proceedings of the 2022 IEEE 18th International Conference on Automation Science and Engineering (CASE), Mexico City, Mexico, 22–26 August 2022; pp. 2441–2446. [Google Scholar]

- Iani, C.; Ciardo, F.; Panajoli, S.; Lugli, L.; Rubichi, S. The role of the co-actor’s response reachability in the joint Simon effect: Remapping of working space by tool use. Psychol. Res. 2019, 85, 521–532. [Google Scholar] [CrossRef] [PubMed]

- Hjorth, S.; Chrysostomou, D. Human-robot collaboration in industrial environments: A literature review on non-destructive disassembly. Robot. Comput. Integr. Manuf. 2022, 73, 102208. [Google Scholar] [CrossRef]

- Gualtieri, L.; Palomba, I.; Wehrle, E.; Vidoni, R. The Opportunities and Challenges of SME Manufacturing Automation: Safety and Ergonomics in Human–Robot Collaboration. In Industry 4.0 for SMEs; Palgrave Macmillan: London, UK, 2020. [Google Scholar]

- Liu, H.; Wang, F.; Zhang, D. Inspiring Real-Time Evaluation and Optimization of Human–Robot Interaction with Psychological Findings from Human–Human Interaction. Appl. Sci. 2023, 13, 676. [Google Scholar] [CrossRef]

- Gervasi, R.; Mastrogiacomo, L.; Maisano, D.A.; Antonelli, D.; Franceschini, F. A structured methodology to support human–robot collaboration configuration choice. Prod. Eng. 2021, 16, 435–451. [Google Scholar] [CrossRef]

- ISO/TS 15066:2016; Robots and Robotic Devices—Collaborative Robots. International Organization for Standardization: Geneva, Switzerland, 2016.

- EN ISO 10218-2:2011; Robots and Robotic Devices—Safety Requirements for Industrial Robots—Part 2: Robot Systems and Integration. International Organization for Standardization: Geneva, Switzerland, 2011.

- Liu, J. The State-of-the-art, Connotation and Developing Trends of the Products Assembly Technology. J. Mech. Eng. 2018, 54, 2. [Google Scholar] [CrossRef]

- Charalambous, G.; Fletcher, S.R.; Webb, P. Identifying the key organisational human factors for introducing human-robot collaboration in industry: An exploratory study. Int. J. Adv. Manuf. Technol. 2015, 81, 2143–2155. [Google Scholar] [CrossRef]

- Petrovic, M.R.; Vukicevic, A.M.; Djapan, M.; Peulić, A.; Jovičić, M.; Mijailovic, N.; Milovanović, P.; Grajic, M.; Savkovic, M.; Caiazzo, C.; et al. Experimental Analysis of Handcart Pushing and Pulling Safety in an Industrial Environment by Using IoT Force and EMG Sensors: Relationship with Operators’ Psychological Status and Pain Syndromes. Sensors 2022, 22, 7467. [Google Scholar] [CrossRef] [PubMed]

- Cardoso, A.; Colim, A.; Bicho, E.; Braga, A.C.; Menozzi, M.; Arezes, P.M. Ergonomics and Human Factors as a Requirement to Implement Safer Collaborative Robotic Workstations: A Literature Review. Safety 2021, 7, 71. [Google Scholar] [CrossRef]

- Savkovic, M.; Caiazzo, C.; Djapan, M.; Vukicevic, A.M.; Pušica, M.; Macuzic, I. Development of Modular and Adaptive Laboratory Set-Up for Neuroergonomic and Human-Robot Interaction Research. Front. Neurorobot. 2022, 16, 863637. [Google Scholar] [CrossRef]

- Schmidtler, J.; Hölzel, C.; Knott, V.C.; Bengler, K. Human Centered Assistance Applications for Production. Adv. Ergon. Manuf. Manag. Enterp. Future 2014, 13, 380–391. [Google Scholar]

- Colim, A.; Faria, C.; Cunha, J.; Oliveira, J.; Sousa, N.; Rocha, L.A. Physical Ergonomic Improvement and Safe Design of an Assembly Workstation through Collaborative Robotics. Safety 2021, 7, 14. [Google Scholar] [CrossRef]

- Ciccarelli, M.; Papetti, A.; Scoccia, C.; Menchi, G.; Mostarda, L.; Palmieri, G.; Germani, M. A system to improve the physical ergonomics in Human-Robot Collaboration. In Proceedings of the 2021 IEEE International Symposium on Multimedia, Naples, Italy, 29 November–1 December 2021. [Google Scholar]

- Simone, V.D.; Pasquale, V.D.; Giubileo, V.; Miranda, S. Human-Robot Collaboration: An analysis of worker’s performance. In Proceedings of the 2021 IEEE International Symposium on Multimedia, Naples, Italy, 29 November–1 December 2021. [Google Scholar]

- Bethel, C.L.; Salomon, K.; Murphy, R.R.; Burke, J.L. Survey of Psychophysiology Measurements Applied to Human-Robot Interaction. In Proceedings of the 16th IEEE International Symposium on Robot and Human Interactive Communication (RO-MAN 2007), Jeju, Republic of Korea, 26–29 August 2007; pp. 732–737. [Google Scholar]

- Hopko, S.; Mehta, R.K.; Pagilla, P.R. Physiological and perceptual consequences of trust in collaborative robots: An empirical investigation of human and robot factors. Appl. Ergon. 2022, 106, 103863. [Google Scholar] [CrossRef]

- Villani, V.; Gabbi, M.; Sabattini, L. Promoting operator’s wellbeing in Industry 5.0: Detecting mental and physical fatigue. In Proceedings of the 2022 IEEE International Conference on Systems, Man, and Cybernetics (SMC), Prague, Czech Republic, 9–12 October 2022; pp. 2030–2036. [Google Scholar]

- Scafà, M.; Papetti, A.; Brunzini, A.; Germani, M. How to improve worker’s well-being and company performance: A method to identify effective corrective actions. Procedia CIRP 2019, 81, 162–167. [Google Scholar] [CrossRef]

- Zakeri, Z.; Omurtag, A.; Breedon, P.; Hilliard, G.; Khalid, A. Studying Mental Stress Factor in Occupational Safety in the Context of the Smart Factory. In Proceedings of the 31st European Safety and Reliability Conference (ESREL 2021), Angers, France, 19–23 September 2021. [Google Scholar]

- Nenna, F.; Orso, V.; Zanardi, D.; Gamberini, L. The virtualization of human–robot interactions: A user-centric workload assessment. Virtual Real. 2022, 27, 553–571. [Google Scholar] [CrossRef]

- Dehais, F.; Lafont, A.; Roy, R.N.; Fairclough, S.H. A Neuroergonomics Approach to Mental Workload, Engagement and Human Performance. Front. Neurosci. 2020, 14, 268. [Google Scholar] [CrossRef] [PubMed]

- Lorenzini, M.; Lagomarsino, M.; Fortini, L.; Gholami, S.; Ajoudani, A. Ergonomic human-robot collaboration in industry: A review. Front. Robot. AI 2023, 9, 813907. [Google Scholar] [CrossRef] [PubMed]

- Paliga, M. The Relationships of Human-Cobot Interaction Fluency with Job Performance and Job Satisfaction among Cobot Operators—The Moderating Role of Workload. Int. J. Environ. Res. Public Health 2023, 20, 5111. [Google Scholar] [CrossRef]

- Fiorineschi, L.; Becattini, N.; Borgianni, Y.; Rotini, F. Testing a New Structured Tool for Supporting Requirements’ Formulation and Decomposition. Appl. Sci. 2020, 10, 3259. [Google Scholar] [CrossRef]

- Hopko, S.; Wang, J.; Mehta, R.K. Human Factors Considerations and Metrics in Shared Space Human-Robot Collaboration: A Systematic Review. Front. Robot. AI 2022, 9, 799522. [Google Scholar] [CrossRef]

- Berberian, B.; Somon, B.; Sahaï, A.; Gouraud, J. The out-of-the-loop Brain: A neuroergonomic approach of the human automation interaction. Annu. Rev. Control 2017, 44, 303–315. [Google Scholar] [CrossRef]

- Brunzini, A.; Grandi, F.; Peruzzini, M.; Pellicciari, M. Virtual training for assembly tasks: A framework for the analysis of the cognitive impact on operators. Procedia Manuf. 2021, 55, 527–534. [Google Scholar] [CrossRef]

- Yan, Y.; Jia, Y. A Review on Human Comfort Factors, Measurements, and Improvements in Human–Robot Collaboration. Sensors 2022, 22, 7431. [Google Scholar] [CrossRef]

- Nomura, T.; Suzuki, T.; Kanda, T.; Kato, K. Measurement of negative attitudes toward robots. Interact. Stud. Interact. Stud. Soc. Behav. Commun. Biol. Artif. Syst. 2006, 7, 437–454. [Google Scholar] [CrossRef]

- Panchetti, T.; Pietrantoni, L.; Puzzo, G.; Gualtieri, L.; Fraboni, F. Assessing the Relationship between Cognitive Workload, Workstation Design, User Acceptance and Trust in Collaborative Robots. Appl. Sci. 2023, 13, 1720. [Google Scholar] [CrossRef]

- Novak, D.; Beyeler, B.; Omlin, X.; Riener, R. Workload Estimation in Physical Human-Robot Interaction Using Physiological Measurements. Interact. Comput. 2015, 27, 616–629. [Google Scholar] [CrossRef]

- Upasani, S.; Srinivasan, D.; Zhu, Q.; Du, J.; Leonessa, A. Eye-Tracking in Physical Human-Robot Interaction: Mental Workload and Performance Prediction. Hum. Factors 2023. [Google Scholar] [CrossRef] [PubMed]

- Katmah, R.; Al-shargie, F.; Tariq, U.; Babiloni, F.; Al-Mughairbi, F.; Al-Nashash, H. A Review on Mental Stress Assessment Methods Using EEG Signals. Sensors 2021, 21, 5043. [Google Scholar] [CrossRef]

- So, W.K.; Wong, S.W.; Mak, J.N.; Chan, R.H. An evaluation of mental workload with frontal EEG. PLoS ONE 2017, 12, e0174949. [Google Scholar] [CrossRef]

- Zhou, Y.; Huang, S.; Xu, Z.; Wang, P.; Wu, X.; Zhang, D. Cognitive Workload Recognition Using EEG Signals and Machine Learning: A Review. IEEE Trans. Cogn. Dev. Syst. 2022, 14, 799–818. [Google Scholar] [CrossRef]

- Eoh, H.; Chung, M.K.; Kim, S. Electroencephalographic study of drowsiness in simulated driving with sleep deprivation. Int. J. Ind. Ergon. 2005, 35, 307–320. [Google Scholar] [CrossRef]

- Zhang, C.; Yu, X. Estimating mental fatigue based on electroencephalogram and heart rate variability. Pol. J. Med Phys. Eng. 2010, 16, 67–84. [Google Scholar] [CrossRef]

- Ismail, L.E.; Karwowski, W. Applications of EEG indices for the quantification of human cognitive performance: A systematic review and bibliometric analysis. PLoS ONE 2020, 15, e0242857. [Google Scholar] [CrossRef]

- Ryu, K.; Myung, R. Evaluation of mental workload with a combined measure based on physiological indices during a dual task of tracking and mental arithmetic. Int. J. Ind. Ergon. 2005, 35, 991–1009. [Google Scholar] [CrossRef]

- Fernández, T.; Harmony, T.; Rodriguez, M.; Bernal, J.; Silva, J.; Reyes, A.; Marosi, E. EEG activation patterns during the performance of tasks involving different components of mental calculation. Electroencephalogr. Clin. Neurophysiol. 1995, 94, 175–182. [Google Scholar] [CrossRef]

- Eyam, A.T.; Mohammed, W.M.; Lastra, J.L. Emotion-Driven Analysis and Control of Human-Robot Interactions in Collaborative Applications. Sensors 2021, 21, 4626. [Google Scholar]

- Chacón, A.; Ponsa, P.; Angulo, C. Cognitive Interaction Analysis in Human–Robot Collaboration Using an Assembly Task. Electronics 2021, 10, 1317. [Google Scholar] [CrossRef]

- Di Pasquale, V.; De Simone, V.; Giubileo, V.; Miranda, S. A taxonomy of factors influencing worker’s performance in human–robot collaboration. IET Collab. Intell. Manuf. 2022, 5, 12069. [Google Scholar] [CrossRef]

- Borges, G.D.; Reis, A.M.; Ariente Neto, R.; de Mattos, D.L.; Cardoso, A.; Gonçalves, H.; Merino, E.; Colim, A.; Carneiro, P.; Arezes, P.M. Decision-Making Framework for Implementing Safer Human–Robot Collaboration Workstations: System Dynamics Modeling. Safety 2021, 7, 75. [Google Scholar] [CrossRef]

- Chowdhury, A.; Ahtinen, A.; Pieters, R.; Väänänen, K. User Experience Goals for Designing Industrial Human-Cobot Collaboration: A Case Study of Franka Panda Robot. In Proceedings of the 11th Nordic Conference on Human-Computer Interaction: Shaping Experiences, Shaping Society, Tallinn, Estonia, 25–29 October 2020. [Google Scholar]

- Mühlemeyer, C. Assessment and Design of Employees-Cobot-Interaction. In Proceedings of the International Conference on Human Interaction and Emerging Technologies, Nice, France, 22–24 August 2019. [Google Scholar]

- Storm, F.A.; Chiappini, M.; Dei, C.; Piazza, C.; André, E.; Reißner, N.; Brdar, I.; Delle Fave, A.; Gebhard, P.; Malosio, M.; et al. Physical and mental well-being of cobot workers: A scoping review using the Software-Hardware-Environment-Liveware-Liveware-Organization model. Hum. Factors Ergon. Manuf. Serv. Ind. 2022, 32, 419–435. [Google Scholar] [CrossRef]

- Faccio, M.; Granata, I.; Menini, A.; Milanese, M.; Rossato, C.; Bottin, M.; Minto, R.; Pluchino, P.; Gamberini, L.; Boschetti, G.; et al. Human factors in cobot era: A review of modern production systems features. J. Intell. Manuf. 2022, 34, 85–106. [Google Scholar] [CrossRef]

- Navas-Reascos, G.E.; Romero, D.; Rodriguez, C.A.; Guedea, F.; Stahre, J. Wire Harness Assembly Process Supported by a Collaborative Robot: A Case Study Focus on Ergonomics. Robotics 2022, 11, 131. [Google Scholar] [CrossRef]

- Xiao-Ming, S.; Jie-Fang, Z. Agreement Dynamics of Memory-Based Naming Game with Forgetting Curve of Ebbinghaus. Chin. Phys. Lett. 2009, 26, 048901. [Google Scholar] [CrossRef]

- Stanton, N.A.; Salmon, P.M.; Rafferty, L.; Walker, G.H.; Baber, C. Human Factors Methods: A Practical Guide for Engineering and Design; CRC Press: Boca Raton, FL, USA, 2012. [Google Scholar]

- Mitsubishi Electric. Available online: https://dl.mitsubishielectric.com/dl/fa/document/manual/robot/bfp-a3727/bfp-a3727f.pdf (accessed on 2 August 2023).

- Arai, T.; Kato, R.; Fujita, M. Assessment of operator stress induced by robot collaboration in assembly. CIRP Ann. Manuf. Technol. 2010, 59, 5–8. [Google Scholar] [CrossRef]

- OnRobot. The VGC10 Electric Vacuum Gripper—Small, But Powerful. Available online: https://onrobot.com/en/products/vgc10 (accessed on 2 August 2023).

- mBrainTrain. Available online: https://mbraintrain.com/smartfones/ (accessed on 1 January 2020).

- Ives-Deliperi, V.; Butler, J.T. WITHDRAWN: The relationship between EEG electrode and functional cortex in the international 10-20 system. Clin. Neurophysiol. Pract. 2018, 35, 504–509. [Google Scholar] [CrossRef]

- Ochoa, J.B. EEG Signal Classification for Brain Computer Interface Applications; Ecole Polytechnique Federale de Lausanne: Lausanne, Switzerland, 2002. [Google Scholar]

- Tropschuh, B.; Niehues, S.; Reinhart, G. Measuring physical and mental strain during manual assembly tasks. Procedia CIRP 2021, 104, 968–974. [Google Scholar] [CrossRef]

- Gualtieri, L.; Fraboni, F.; De Marchi, M.; Rauch, E. Development and evaluation of design guidelines for cognitive ergonomics in human-robot collaborative assembly systems. Appl. Ergon. 2022, 104, 103807. [Google Scholar] [CrossRef] [PubMed]

- Fraboni, F.; Gualtieri, L.; Millo, F.; De Marchi, M.; Pietrantoni, L.; Rauch, E. Human-Robot Collaboration During Assembly Tasks: The Cognitive Effects of Collaborative Assembly Workstation Features. In Proceedings of the 21st Congress of the International Ergonomics Association (IEA 2021), Virtual, 13–18 June 2021. [Google Scholar]

- Gil-Vilda, F.; Sune, A.; Yagüe-Fabra, J.A.; Crespo, C.; Serrano, H. Integration of a collaborative robot in a U-shaped production line: A real case study. Procedia Manuf. 2017, 13, 109–115. [Google Scholar] [CrossRef]

- Valori, M.; Scibilia, A.; Fassi, I.; Saenz, J.F.; Behrens, R.; Herbster, S.; Bidard, C.; Lucet, E.; Magisson, A.; Schaake, L.; et al. Validating Safety in Human-Robot Collaboration: Standards and New Perspectives. Robotics 2021, 10, 65. [Google Scholar] [CrossRef]

- Aarts, S.; van den Akker, M.; Winkens, B. The importance of effect sizes. Eur. J. Gen. Pract. 2014, 20, 61–64. [Google Scholar] [CrossRef]

- Kang, H. Sample size determination and power analysis using the G*Power software. J. Educ. Eval. Health Prof. 2021, 18, 17. [Google Scholar] [CrossRef]

- Lin, C.; Shih, H.; Sher, P.J. Integrating technology readiness into technology acceptance: The TRAM model. Psychol. Mark. 2007, 24, 641–657. [Google Scholar] [CrossRef]

- Hertzum, M.; Holmegaard, K.D. Perceived Time as a Measure of Mental Workload: Effects of Time Constraints and Task Success. Int. J. Hum.–Comput. Interact. 2013, 29, 26–39. [Google Scholar] [CrossRef]

- Charles, R.; Nixon, J. Measuring mental workload using physiological measures: A systematic review. Appl. Ergon. 2019, 74, 221–232. [Google Scholar] [CrossRef]

| Candidate Number | Age | Body Weight (kg) | Height (cm) |

|---|---|---|---|

| 1 | 26 | 94 | 188 |

| 2 | 24 | 105 | 190 |

| 3 | 26 | 80 | 188 |

| 4 | 23 | 78 | 177 |

| 5 | 23 | 95 | 185 |

| 6 | 20 | 100 | 180 |

| 7 | 22 | 84 | 190 |

| 8 | 22 | 83 | 178 |

| 9 | 24 | 78 | 182 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Caiazzo, C.; Savkovic, M.; Pusica, M.; Milojevic, D.; Leva, M.C.; Djapan, M. Development of a Neuroergonomic Assessment for the Evaluation of Mental Workload in an Industrial Human–Robot Interaction Assembly Task: A Comparative Case Study. Machines 2023, 11, 995. https://doi.org/10.3390/machines11110995

Caiazzo C, Savkovic M, Pusica M, Milojevic D, Leva MC, Djapan M. Development of a Neuroergonomic Assessment for the Evaluation of Mental Workload in an Industrial Human–Robot Interaction Assembly Task: A Comparative Case Study. Machines. 2023; 11(11):995. https://doi.org/10.3390/machines11110995

Chicago/Turabian StyleCaiazzo, Carlo, Marija Savkovic, Milos Pusica, Djordje Milojevic, Maria Chiara Leva, and Marko Djapan. 2023. "Development of a Neuroergonomic Assessment for the Evaluation of Mental Workload in an Industrial Human–Robot Interaction Assembly Task: A Comparative Case Study" Machines 11, no. 11: 995. https://doi.org/10.3390/machines11110995

APA StyleCaiazzo, C., Savkovic, M., Pusica, M., Milojevic, D., Leva, M. C., & Djapan, M. (2023). Development of a Neuroergonomic Assessment for the Evaluation of Mental Workload in an Industrial Human–Robot Interaction Assembly Task: A Comparative Case Study. Machines, 11(11), 995. https://doi.org/10.3390/machines11110995