A New Direct and Inexpensive Method and the Associated Device for the Inspection of Spur Gears

Abstract

1. Introduction

1.1. Structural Solutions for Coupling Two Shafts with Crossed Axes

1.2. Structural Solutions for the Coupling of Two Shafts with Parallel Axes

1.3. Gears

2. Materials and Methods

2.1. Cylindrical Gear with Involute Teeth

2.1.1. The Involute Curve, Definition, and Properties

- The normals to the involute are tangent to the base circle;

- The current point of tangency T between the mobile straight line and the base circle is the curvature centre of the involute, and the curvature radius of the involute in the point M is .

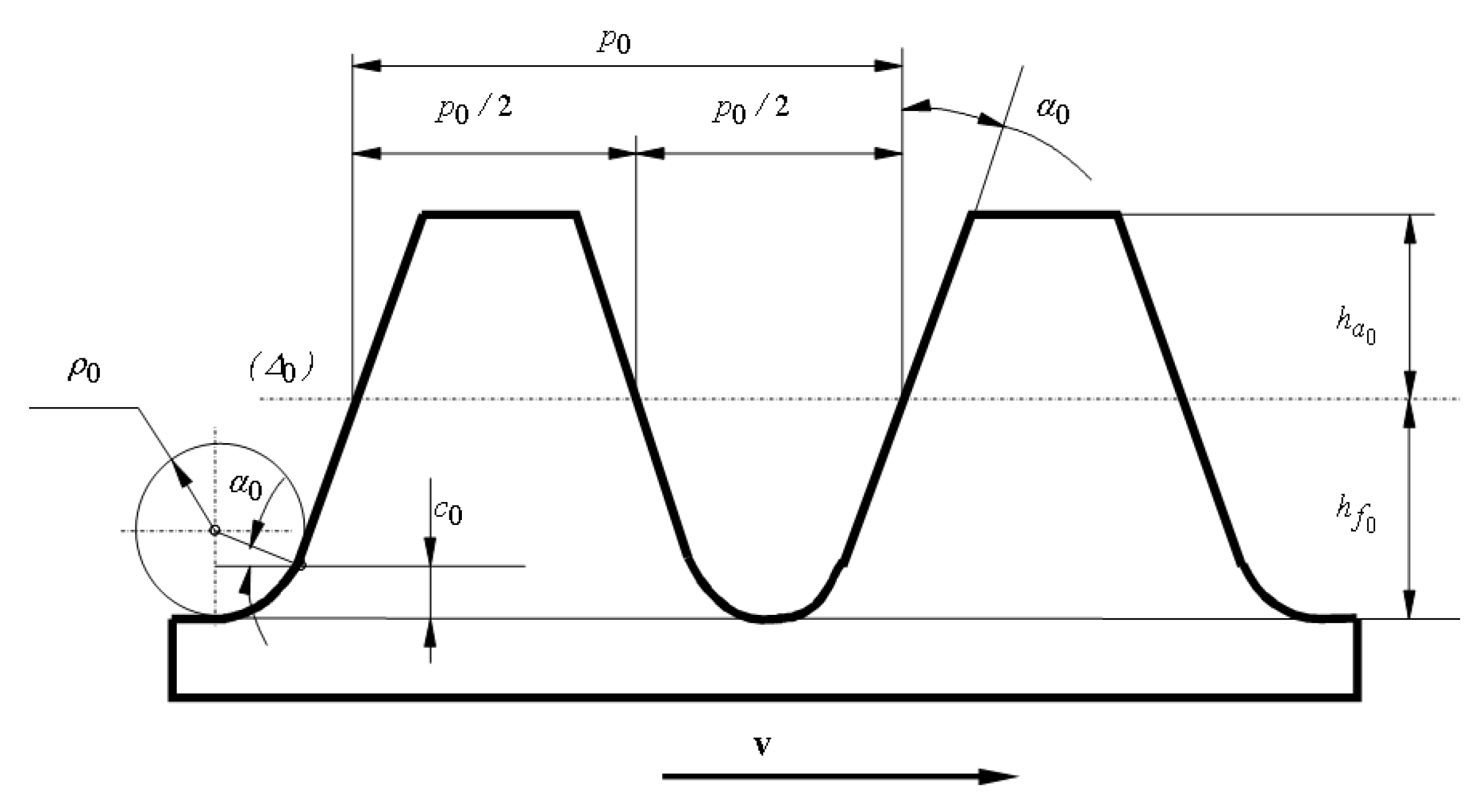

2.1.2. The Basic Rack for Spur Gear

- —the rack pitch;

- —the pressure angle corresponding to pitch circle (the angle of inclination of the profile with respect to the normal to reference line);

- —the addendum of the tooth;

- —the dedendum of the tooth;

- m—the module.

2.1.3. The Definition of the Cylindrical Gear Using the Standard Basic Rack for Spur Gear

- : the reference line and the pitch circle are tangent;

- : the reference line and the pitch circle are intersecting;

- : the reference line and the pitch circle have no common points.

- The number of teeth, z;

- The module, m;

- The coefficient of profile shift, x.

2.2. Inspection Dimensions for Spur Gears with External Teeth

2.2.1. The Surfaces Used in the Inspection of the Precision of the Teeth of Spur Gears

- The addendum (outside) cylinder ;

- The dedendum cylinder (root cylinder);

- Axial face ;

- Cylindrical hole for shaft assembly

- Keyway surface ;

- Involute flank surface

2.2.2. Inspection Dimensions for Spur Gears

- Span over teeth.

- 2.

- The dimension over pins.

2.3. Proposed New Method for Measuring the Dimension over Pins

2.3.1. Principle of the Method

2.3.2. The Algorithm for the Calculus of Module and the Coefficient of Flank Shift

- The change in the coefficient of flank shift does not significantly alter the geometry of the gear;

- The module of the gear must have a standard value.

- For the unshifted flank profile gear , Equation (42) becomes

- Next, the module mstd is adopted as the closest value from the standard STAS 822-82. This value is then introduced in relation (42), which becomes

3. Results and Discussions

3.1. The Experimental Test-Rig

- Positioning the gear 5 to be measured with the front face on the surface of the base plate 1.

- Two identical pins 4 are introduced in the spaces between teeth; afterwards, through gliding, the two pins are brought into contact with the active face of the fixed prism.

- Diametrically opposite to the first two pins, one or two other pins are introduced in the spaces between the teeth (as in Figure 18).

- The mobile prism 3 is translated along the rods 8 and the face of the mobile prism 3 is brought into contact with the pins; a firm contact must be achieved between all the pins and the mating prismatic parts.

- A calliper is used for measuring the distance between the active faces of the two prisms. A correct measurement requires symmetrical placement of the pins with respect to the measuring direction.

- The actual test-rig, assembled in the laboratory, is presented in Figure 19.

3.2. Example of Application of the New Method for Establishing the Characteristics of a Spur Gear

- The number of teeth of the wheel, z;

- The diameter of the pins dR;

- The polar angles of the centres of the wheels with respect to the measuring direction , ;

- The distance between the active faces of the prisms, D;

- The pressure angle of the basic rack is ;

- The diameter of the pins dR = 12 mm;

- The number of teeth z = 25,

3.3. Applying the New Method for Centre Distance

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Seherr-Thoss, H.C.; Schmelz, F.; Aucktor, E. Universal Joints and Driveshafts. Analysis, Design, Applications, 2nd ed.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 53–79, discussion 109–245. [Google Scholar]

- Luzi, L.; Sancisi, N.; Parenti-Castelli, V. The Potential of the 7R-R Closed Loop Mechanism to Transfer Motion between Two Shafts with Varying Angular Position. In Interdisciplinary Applications of Kinematics. Mechanisms and Machine Science; Kecskeméthy, A., Geu Flores, F., Carrera, E., Elias, D., Eds.; Springer: Cham, Switzerland, 2019; Volume 71, pp. 185–195. [Google Scholar]

- Angeles, J. Spatial Kinematic Chains: Analysis–Synthesis–Optimization; Springer: Berlin/Heidelberg, Germany, 1982; pp. 189–218. [Google Scholar]

- Hunt, K.H. Kinematic Geometry of Mechanisms; Oxford University Press: Oxford, UK, 1990; pp. 30–51. [Google Scholar]

- Uicker, J.J., Jr.; Pennock, G.R.; Shigley, J.E. Theory of Machines and Mechanisms, 4th ed.; Oxford University Press: New York, NY, USA, 2010; pp. 368–370. [Google Scholar]

- Gladwel, G.M.L. Contact Problems in the Classical Theory of Elasticity; Sijthoff & Noordhoff: Hague, The Netherlands, 1980; pp. 455–505. [Google Scholar]

- Hills, D.A.; Nowell, D.; Sackfield, A. Mechanics of Elastic Contacts; Elsevier Butterworth-Heinemann: Oxford, UK, 1993; pp. 198–226. [Google Scholar]

- Johnson, K.L. Contact Mechanics; Cambridge University Press: Cambridge, UK, 1985; pp. 84–106. [Google Scholar]

- Phillips, J. Freedom in Machinery; Cambridge University Press: New York, NY, USA, 2007; pp. 7–42. [Google Scholar]

- McCarthy, J.M.; Soh, G.S. Geometric Design of Linkages; Springer: Berlin/Heidelberg, Germany, 2010; pp. 253–279. [Google Scholar]

- McCarthy, J.M. Introduction in Theoretical Kinematics, 3rd ed.; MIT Press: Cambridge, MA, USA, 2018; pp. 103–108. [Google Scholar]

- Slocum, H. Kinematic couplings: A review of design principles and applications. Int. J. Mach. Tools Manuf. 2010, 50, 310–327. [Google Scholar] [CrossRef]

- Wittenburg, J. Kinematics. Theory and Applications; Springer: Berlin/Heidelberg, Germany, 2016; pp. 404–410. [Google Scholar]

- Bai, S.; Angeles, J. The design of spherical multilobe-cam mechanisms. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2009, 223, 473–482. [Google Scholar] [CrossRef]

- Gonzales-Palacios, M.A.; Angeles, J. Cam Synthesis; Springer: Dordrecht, The Netherlands, 1993; pp. 37–53. [Google Scholar]

- Rothbart, H.A. Cam Design Handbook; McGraw-Hill: New York, NY, USA, 2003; pp. 159–175. [Google Scholar] [CrossRef]

- Radzevich, S.P. Principal accomplishments in the scientific theory of gearing. MATEC Web Conf. Power Transm. 2019, 287, 01001. [Google Scholar] [CrossRef][Green Version]

- Radzevich, S.P. Theory of Gearing: Kinematics, Geometry, and Synthesis, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2018; pp. 76–133. [Google Scholar]

- Litvin, F.L.; Fuentes, A. Gear Geometry and Applied Theory; Cambridge University Press: Cambridge, UK, 2004; pp. 441–474. [Google Scholar]

- Phillips, J. General Spatial Involute Gearing, 2003rd ed.; Kindle Edition; Springer: Berlin/Heidelberg, Germany, 2013; pp. 41–61. [Google Scholar]

- Jelaska, D.T. Gears and Gear Drives, 1st ed.; Wiley Online Library: Hoboken, NJ, USA, 2012; pp. 29–155. [Google Scholar] [CrossRef]

- Ciornei, F.-C.; Alaci, S.; Doroftei, I. The conjugate profile of the circular teeth of a spur gear. Part I: Problem statement. IOP Conf. Ser. Mater. Sci. Eng. 2020, 997, 012067. [Google Scholar] [CrossRef]

- Alaci, S.; Ciornei, F.-C.; Doroftei, I. The conjugate profile of the circular teeth of a spur gear. Part II: Problem solution. IOP Conf. Ser. Mater. Sci. Eng. 2020, 997, 012068. [Google Scholar] [CrossRef]

- STAS 822-82; Gears, Range of Modules. IRS Tehnica: Bucuresti, Romania, 1984.

- Pueo, M.; Santolaria, J.; Acero, R.; Gracia, A. A review of tangential composite and radial composite gear inspection. Precis. Eng. 2017, 50, 522–537. [Google Scholar] [CrossRef]

- Moderow, R. Gear inspection and measurement. Gear Technol. 1992, 9, 44–49. [Google Scholar]

- Pillarz, M.; von Freyberg, A.; Fischer, A. Determination of the mean base circle radius of gears by optical multi-distance measurements. J. Sens. Sens. Syst. 2020, 9, 273–282. [Google Scholar] [CrossRef]

- Pillarz, M.; von Freyberg, A.; Fischer, A. Gear Shape Parameter Measurement Using a Model-Based Scanning Multi-Distance Measurement Approach. Sensors 2020, 20, 3910. [Google Scholar] [CrossRef] [PubMed]

- Auerswald, M.M.; von Freyberg, A.; Fischer, A. Laser line triangulation for fast 3D measurements on large gears. Int. J. Adv. Manuf. Technol. 2019, 100, 2423–2433. [Google Scholar] [CrossRef]

- Chen, Y.-C.; Chen, J.-Y. Optical Inspection System for Gear Tooth Surfaces Using a Projection Moiré Method. Sensors 2019, 19, 1450. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Zhou, Y.; Tang, J.; Tang, K.; Li, Z. Digital tooth contact analysis of face gear drives with an accurate measurement model of face gear tooth surface inspected by CMMs. Mech. Mach. Theory 2022, 167, 104498. [Google Scholar] [CrossRef]

- Lin, H.; Keller, F.; Stein, M. Influence and compensation of CMM geometric errors on 3D gear measurements. Measurement 2020, 151, 107110. [Google Scholar] [CrossRef]

- Alhadeff, L.L.; Slatter, T. A straightforward and low-cost pre-inspection measurement method for small gears. Manuf. Lett. 2020, 23, 23–28. [Google Scholar] [CrossRef]

- Boral, P.; Gołębski, R.; Stoić, A. Analysis of Outline Measurements Methods of Spur Gear Involute Profile. Tech. Gaz. 2021, 28, 1008–1011. [Google Scholar] [CrossRef]

- Alaci, S.; Muscă, I.; Pentiuc, Ș.-G. Study of the Rolling Friction Coefficient between Dissimilar Materials through the Motion of a Conical Pendulum. Materials 2020, 13, 5032. [Google Scholar] [CrossRef] [PubMed]

- Xu, H.; Anderson, N.E.; Maddock, D.G.; Kahraman, A. Prediction of mechanical efficiency of parallel-axis gear pairs. J. Mech. Des. 2006, 129, 58–68. [Google Scholar] [CrossRef]

- Verstrate, T.; Mathijssen, G.; Furnémon, R.; Vanderborght, B.; Lefeber, D. Modeling and design of geared DC motors for energy efficiency. Comparison between theory and experiments. Mechatronics 2015, 30, 198–213. [Google Scholar] [CrossRef]

- STAS 12222-84; External Involute Spur Gear Pair, Geometrical and Kinematic Calculator. IRS Tehnica: Bucuresti, Romania, 1986.

- Maxfield, B. Engineering with Mathcad; Butterworth-Heinemann Elsevier: Oxford, UK, 2006; pp. 287–289. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Alaci, S.; Ciornei, F.-C.; Romanu, I.-C.; Doroftei, I.; Bujoreanu, C.; Tamașag, I. A New Direct and Inexpensive Method and the Associated Device for the Inspection of Spur Gears. Machines 2023, 11, 1046. https://doi.org/10.3390/machines11121046

Alaci S, Ciornei F-C, Romanu I-C, Doroftei I, Bujoreanu C, Tamașag I. A New Direct and Inexpensive Method and the Associated Device for the Inspection of Spur Gears. Machines. 2023; 11(12):1046. https://doi.org/10.3390/machines11121046

Chicago/Turabian StyleAlaci, Stelian, Florina-Carmen Ciornei, Ionut-Cristian Romanu, Ioan Doroftei, Carmen Bujoreanu, and Ioan Tamașag. 2023. "A New Direct and Inexpensive Method and the Associated Device for the Inspection of Spur Gears" Machines 11, no. 12: 1046. https://doi.org/10.3390/machines11121046

APA StyleAlaci, S., Ciornei, F.-C., Romanu, I.-C., Doroftei, I., Bujoreanu, C., & Tamașag, I. (2023). A New Direct and Inexpensive Method and the Associated Device for the Inspection of Spur Gears. Machines, 11(12), 1046. https://doi.org/10.3390/machines11121046