5G on the Farm: Evaluating Wireless Network Capabilities and Needs for Agricultural Robotics

Abstract

:1. Introduction

- 5G has many desirable traits that can be leveraged by farmers that employ such technology, for example, high throughput, low latency and robust communications. Fifth-generation telecommunications can deal with the demands of real-time, in-field image recognition tasks. If farmers were to own their own private 5G, they could also have the opportunity to lease their wireless network capacity when their demand is low or they have unused bandwidth.

- WiFi6 is soon to become one of the new wireless network standards that will be widely used in appropriate settings (e.g., indoor locations, such as offices and greenhouses). It has impressively high throughput, low latency and more advanced reliability and quality-of-service features than today’s WiFi standard, i.e., WiFi5. The range of WiFi6 is smaller than that of 4G or 5G; hence, a number of mesh solutions have been proposed.

- 4G is currently available in over 85% of locations worldwide and is anticipated to cover 98% of the globe by 2028 [22]. Fourth-generation telecommunications can theoretically support high throughput and is known to be reliable, but not known to support low latency.

2. Related Work

3. Experiment Design

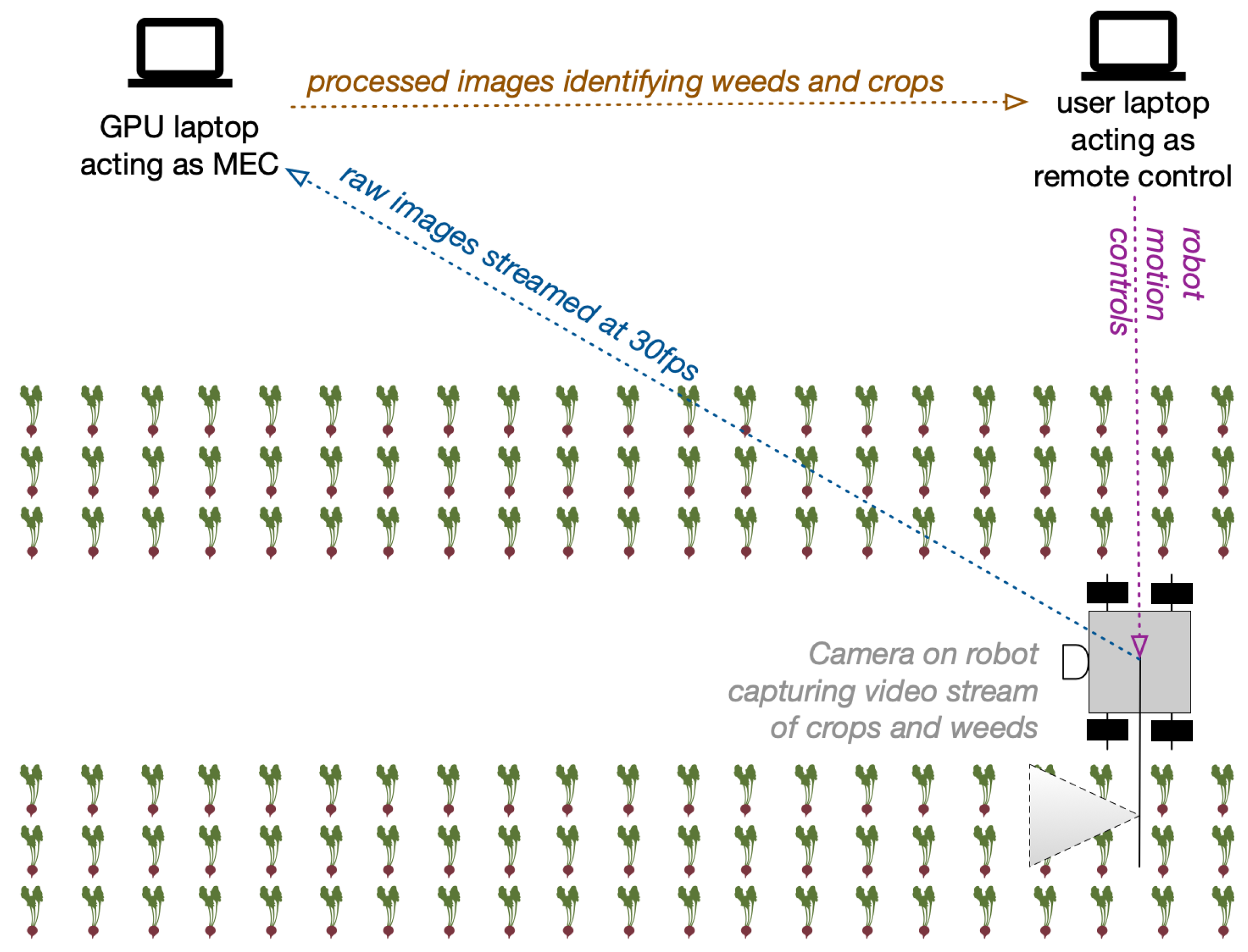

3.1. Agri-Robotics Use Case

3.2. Image Detection

- To detect weeds accurately using this model, images must be in focus and with a resolution of at least pixels (). The ML model benefits from higher resolution images as more detail is retained.

- To achieve “real-time” performance, the image-processing pipeline (including image capture and object detection) must be capable of running faster than a video stream of 30 frames per second (FPS) or higher (i.e., ≤ per frame). This is to enable video footage to run uninterrupted at 30FPS with overhead for missed frames.

- To provide practical utility for the spot-spraying task at hand, the model needs to achieve >80% accuracy in crop vs. weed detection.

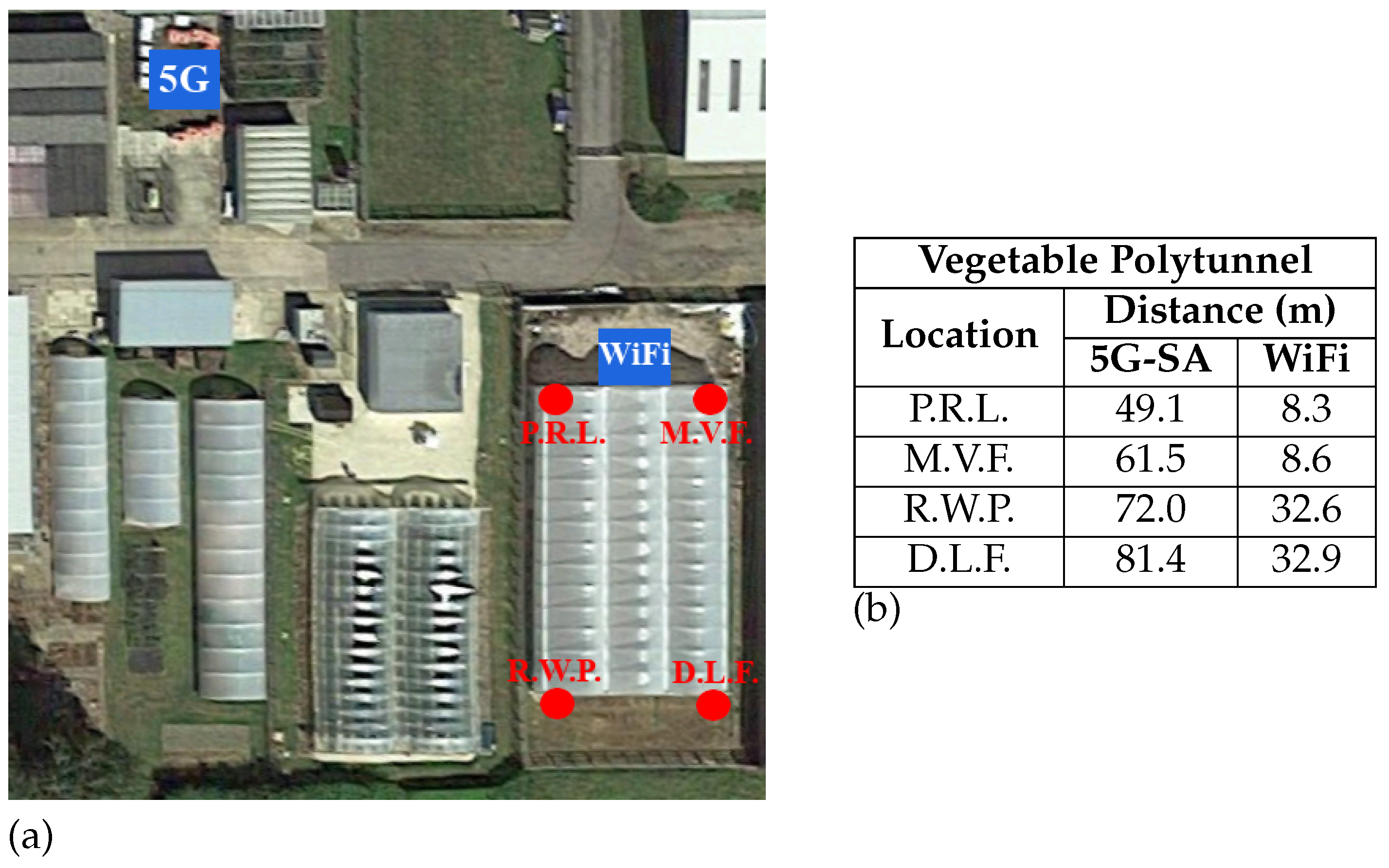

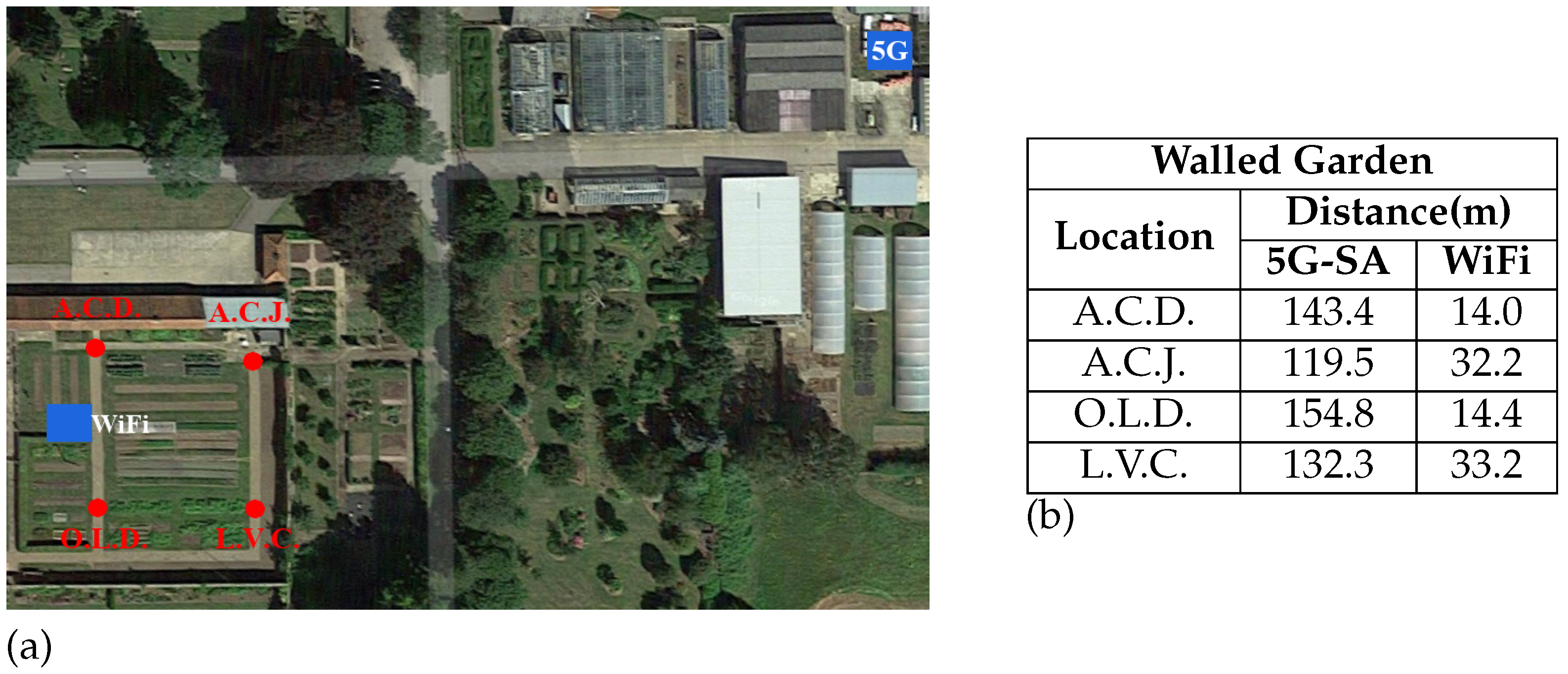

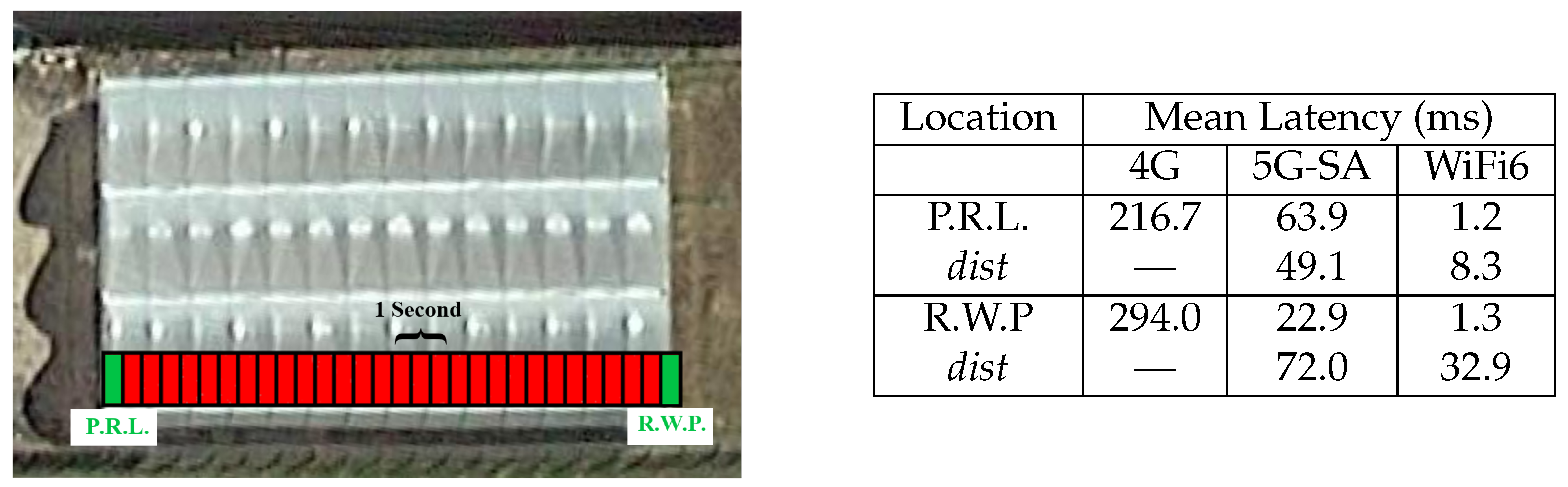

3.3. Experiment Locations

3.4. Apparatus

3.5. Wireless Networks

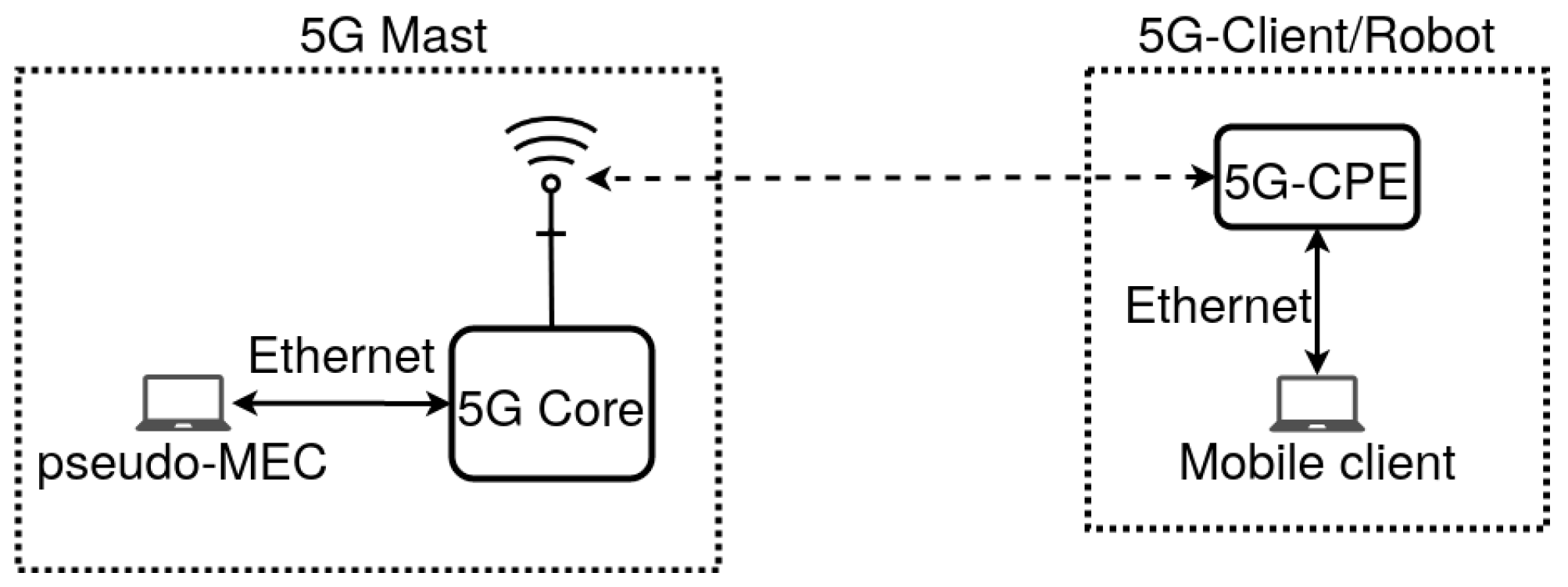

3.5.1. 5G-SA Network

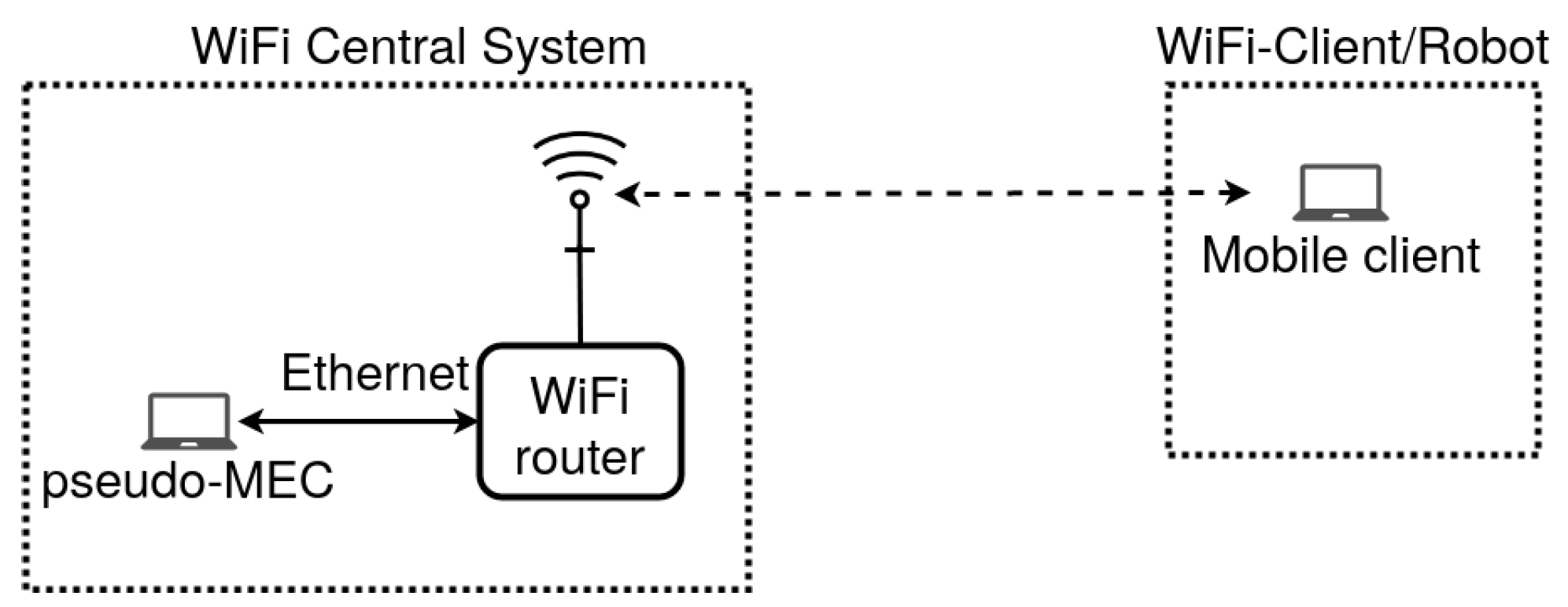

3.5.2. WiFi6 Network

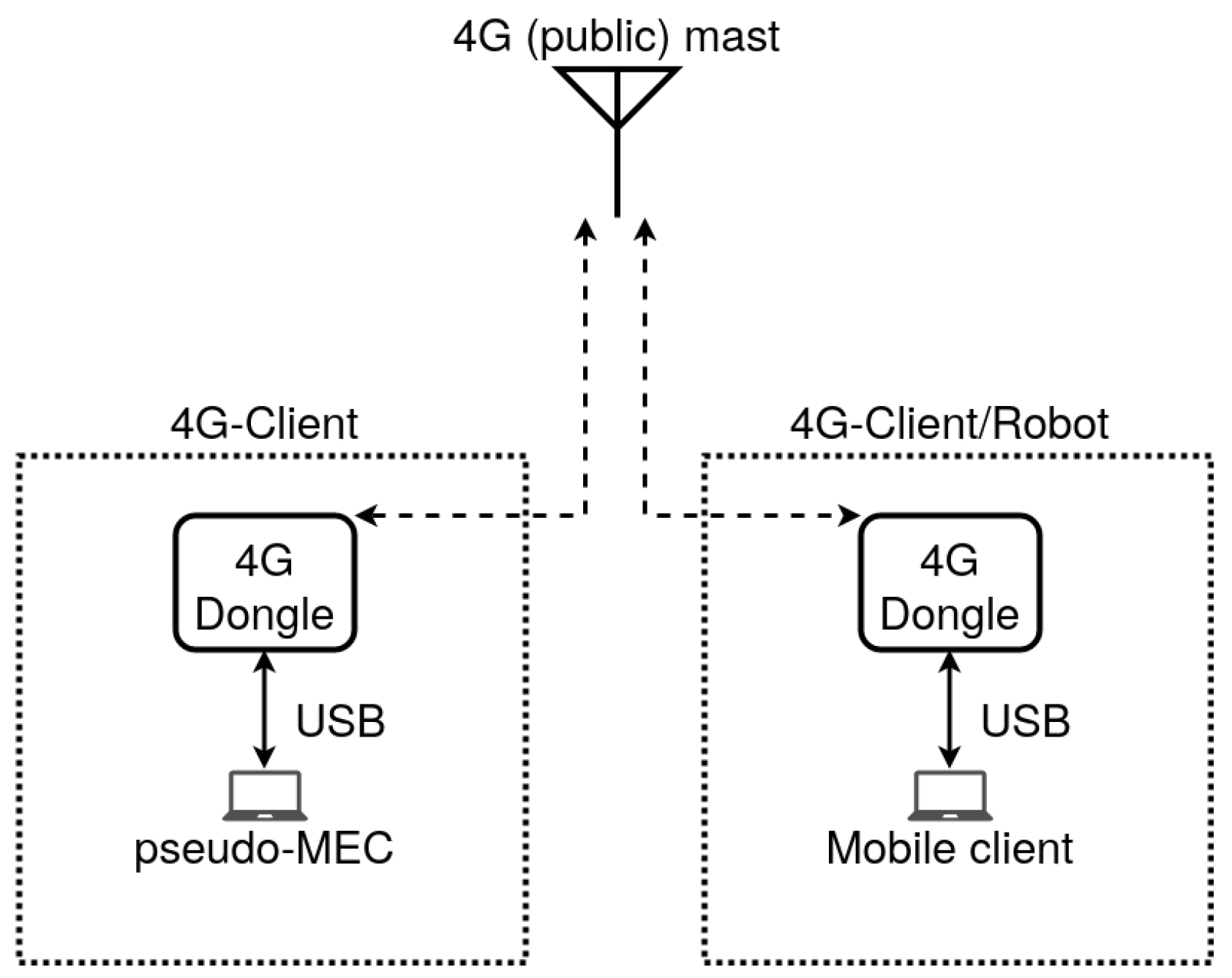

3.5.3. Fourth-Generation Network

3.6. Tunnelling in Wireless Communications

4. Physical Experiments: Network Throughput and Latency

4.1. Performance Metrics

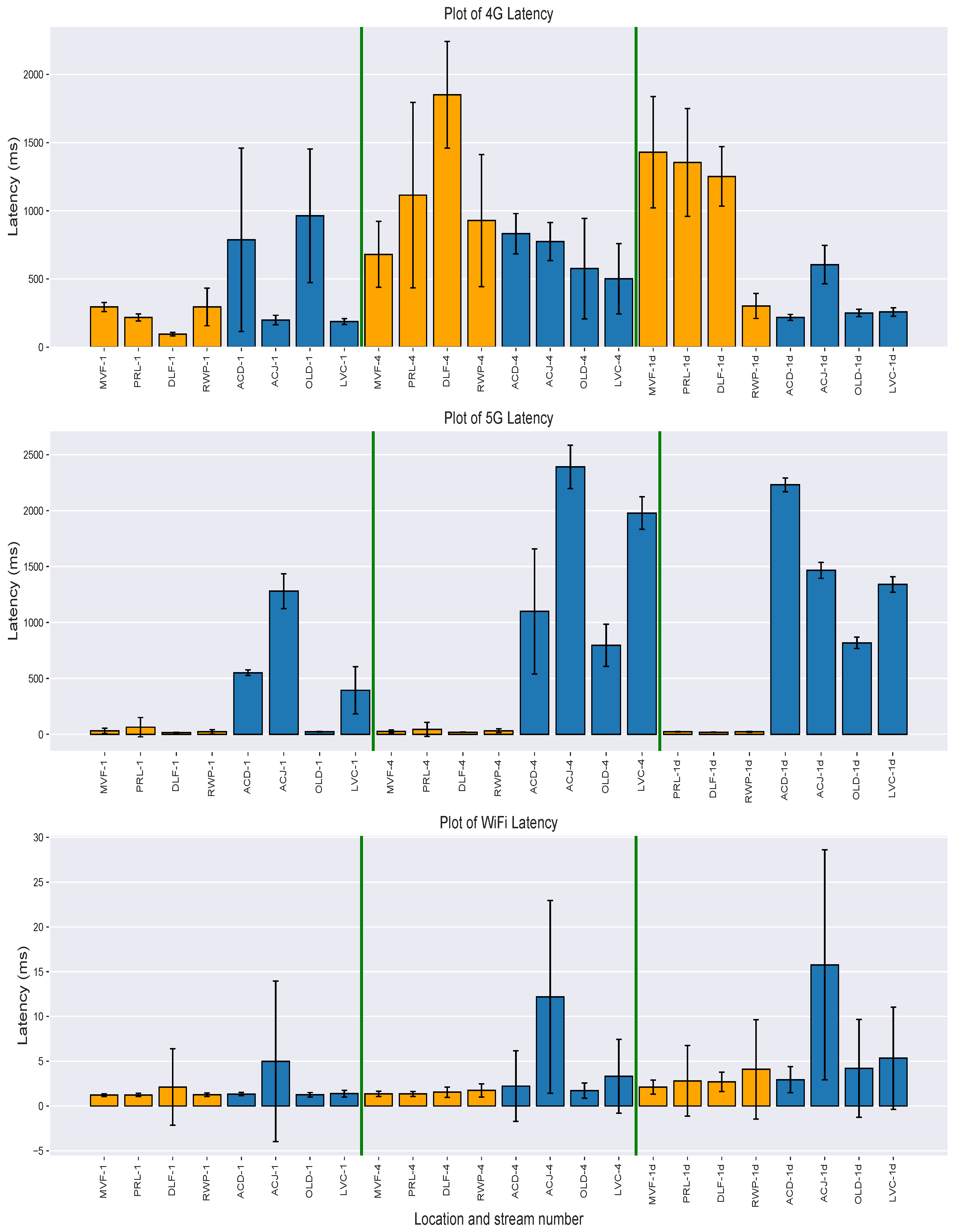

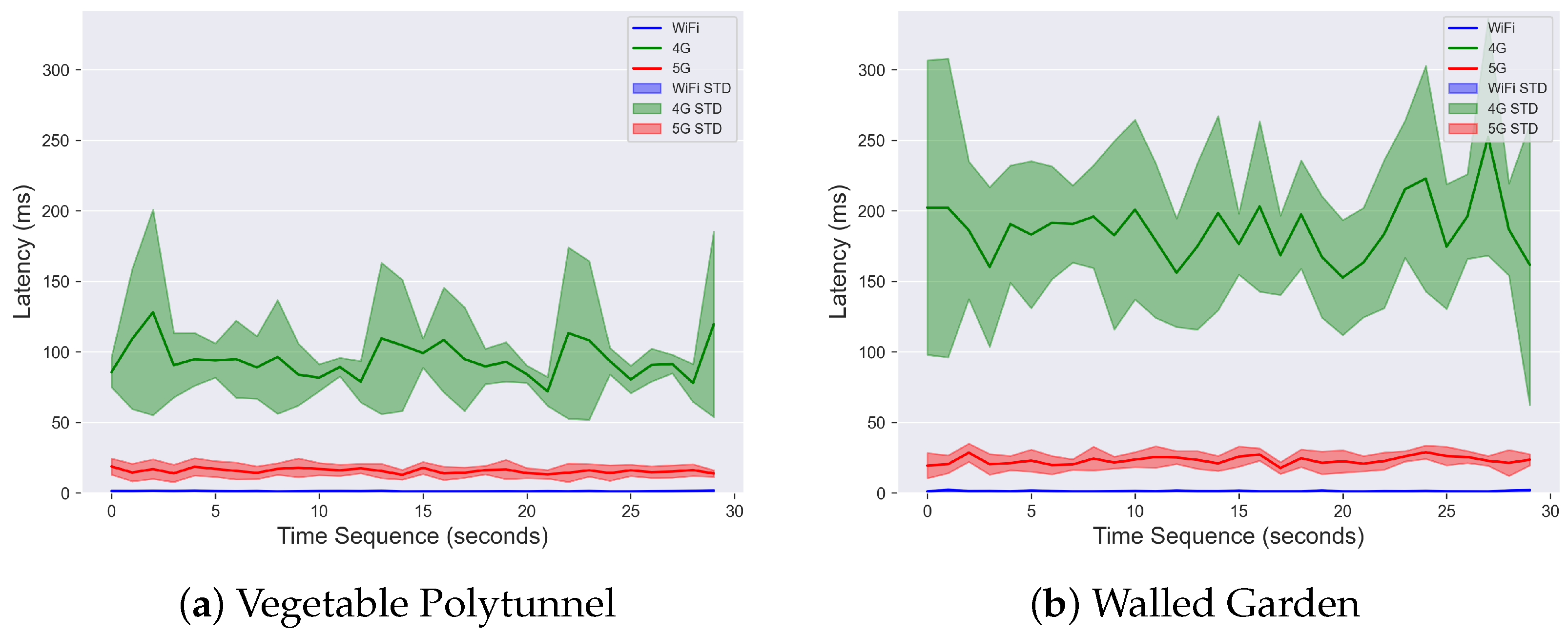

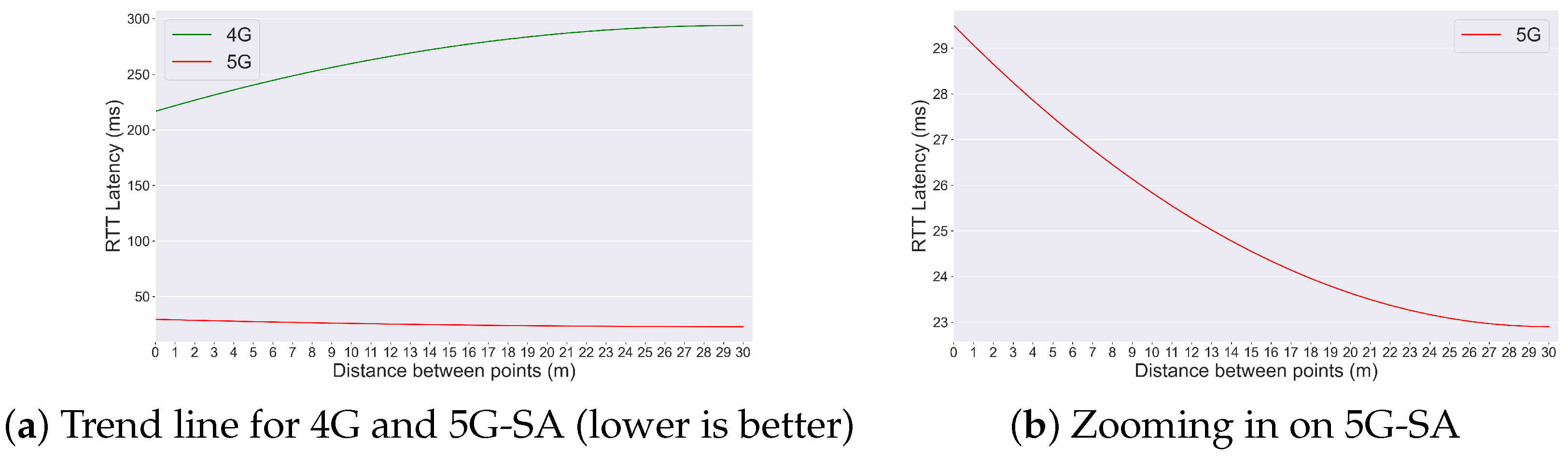

4.2. Results

4.3. Discussion

5. Simulated Experiment

5.1. Experiment Design

5.2. Results

5.3. Discussion

6. Conclusions

6.1. Summary

6.2. Considerations for Future Work

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Appendix A

| Latency | Throughput | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Location | Network | Stream | Mean | Std | Min | Max | Mean | Std | Min | Max |

| 4G | 1-RGB | 216.7 | 26.1 | 152.7 | 259.7 | 9.1 | 0.5 | 8.3 | 10.2 | |

| 5G-SA | 1-RGB | 63.9 | 86.4 | 14.4 | 374.3 | 17.4 | 2.1 | 12.8 | 21.1 | |

| WiFi6 | 1-RGB | 1.2 | 0.2 | 1.0 | 1.8 | 18.6 | 0.6 | 17.7 | 19.8 | |

| 4G | 4-RGB | 1115.0 | 681.0 | 0.0 | 2616.9 | 10.6 | 1.9 | 6.8 | 14.6 | |

| 5G-SA | 4-RGB | 44.2 | 62.3 | 22.6 | 359.5 | 51.9 | 3.6 | 42.3 | 61.0 | |

| WiFi6 | 4-RGB | 1.4 | 0.3 | 1.0 | 2.3 | 74.7 | 0.5 | 72.5 | 75.2 | |

| 4G | 1-RGBD | 1354.3 | 395.3 | 658.1 | 2179.6 | 8.0 | 1.6 | 5.5 | 11.4 | |

| 5G-SA | 1-RGBD | 22.6 | 2.9 | 17.2 | 27.4 | 57.1 | 5.8 | 48.7 | 65.1 | |

| WiFi6 | 1-RGBD | 2.8 | 3.9 | 1.1 | 23.1 | 144.2 | 0.2 | 143.6 | 144.6 | |

| 4G | 1-RGB | 293.8 | 33.4 | 235.8 | 364.5 | 10.5 | 0.9 | 8.5 | 12.5 | |

| 5G-SA | 1-RGB | 32.3 | 23.4 | 15.3 | 137.3 | 31.6 | 4.0 | 24.7 | 39.5 | |

| WiFi6 | 1-RGB | 1.2 | 0.2 | 1.0 | 1.6 | 16.8 | 0.5 | 16.1 | 17.4 | |

| 4G | 4-RGB | 680.5 | 242.6 | 333.3 | 1164.0 | 11.8 | 1.0 | 9.3 | 13.9 | |

| 5G-SA | 4-RGB | 26.2 | 12.1 | 14.3 | 83.6 | 41.4 | 0.4 | 40.4 | 42.3 | |

| WiFi6 | 4-RGB | 1.4 | 0.3 | 1.0 | 1.9 | 61.6 | 1.6 | 60.2 | 66.4 | |

| 4G | 1-RGBD | 1430.3 | 408.8 | 687.0 | 2356.1 | 9.2 | 1.6 | 6.4 | 12.3 | |

| 5G-SA | 1-RGBD | ** | ** | ** | ** | ** | ** | ** | ** | |

| WiFi6 | 1-RGBD | 2.1 | 0.8 | 1.1 | 4.2 | 144.2 | 0.2 | 143.7 | 145.0 | |

| 4G | 1-RGB | 294.0 | 137.9 | 130.3 | 574.5 | 9.7 | 0.9 | 8.3 | 11.2 | |

| 5G-SA | 1-RGB | 22.9 | 19.8 | 10.9 | 124.6 | 22.9 | 0.8 | 20.1 | 23.8 | |

| WiFi6 | 1-RGB | 1.3 | 0.2 | 1.0 | 1.8 | 13.7 | 0.5 | 12.8 | 14.7 | |

| 4G | 4-RGB | 928.4 | 484.7 | 231.9 | 1983.5 | 7.9 | 1.5 | 5.2 | 10.5 | |

| 5G-SA | 4-RGB | 31.7 | 16.9 | 20.1 | 110.8 | 38.2 | 1.4 | 34.7 | 41.8 | |

| WiFi6 | 4-RGB | 1.7 | 0.7 | 1.0 | 3.7 | 100.6 | 7.2 | 91.3 | 113.2 | |

| 4G | 1-RGBD | 301.6 | 91.7 | 182.4 | 637.9 | 8.8 | 0.8 | 7.3 | 10.6 | |

| 5G-SA | 1-RGBD | 22.3 | 3.7 | 15.8 | 33.0 | 47.5 | 4.4 | 38.8 | 55.0 | |

| WiFi6 | 1-RGBD | 4.1 | 5.6 | 1.1 | 24.5 | 144.2 | 0.3 | 142.8 | 144.5 | |

| 4G | 1-RGB | 94.9 | 13.0 | 72.0 | 128.0 | 10.4 | 0.0 | 10.3 | 10.4 | |

| 5G-SA | 1-RGB | 15.7 | 1.6 | 12.9 | 18.7 | 23.3 | 0.2 | 22.7 | 23.6 | |

| WiFi6 | 1-RGB | 2.1 | 4.3 | 1.0 | 24.3 | 18.3 | 0.6 | 17.1 | 19.0 | |

| 4G | 4-RGB | 1850.8 | 391.7 | 990.7 | 2398.8 | 12.5 | 1.6 | 9.2 | 16.5 | |

| 5G-SA | 4-RGB | 18.9 | 2.2 | 13.9 | 23.3 | 43.5 | 2.2 | 41.4 | 49.9 | |

| WiFi6 | 4-RGB | 1.5 | 0.6 | 1.0 | 2.9 | 66.4 | 0.8 | 65.5 | 68.4 | |

| 4G | 1-RGBD | 1252.2 | 218.3 | 896.7 | 1904.6 | 10.2 | 1.4 | 6.6 | 13.7 | |

| 5G-SA | 1-RGBD | 18.9 | 1.9 | 14.1 | 22.4 | 45.8 | 3.5 | 38.9 | 52.2 | |

| WiFi6 | 1-RGBD | 2.7 | 1.1 | 1.1 | 7.2 | 144.1 | 0.2 | 143.5 | 144.4 | |

| Latency | Throughput | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Location | Network | Stream | Mean | Std | Min | Max | Mean | Std | Min | Max |

| 4G | 1-RGB | 787.1 | 672.4 | 0.0 | 2327.8 | 2.8 | 0.6 | 1.7 | 4.2 | |

| 5G-SA | 1-RGB | 550.8 | 25.6 | 479.1 | 579.5 | 10.3 | 0.2 | 10.1 | 10.8 | |

| WiFi6 | 1-RGB | 1.3 | 0.2 | 1.0 | 1.7 | 16.9 | 1.1 | 16.2 | 20.3 | |

| 4G | 4-RGB | 831.5 | 148.0 | 362.0 | 1132.2 | 2.4 | 0.3 | 1.8 | 3.1 | |

| 5G-SA | 4-RGB | 1098.4 | 559.1 | 0.0 | 2155.9 | 8.7 | 1.2 | 6.6 | 12.4 | |

| WiFi6 | 4-RGB | 2.2 | 3.9 | 1.0 | 22.9 | 66.7 | 3.7 | 59.3 | 77.5 | |

| 4G | 1-RGBD | 217.6 | 22.3 | 182.8 | 262.3 | 11.6 | 0.6 | 10.4 | 12.8 | |

| 5G-SA | 1-RGBD | 2229.4 | 61.5 | 1929.4 | 2297.0 | 10.5 | 0.0 | 10.5 | 10.5 | |

| WiFi6 | 1-RGBD | 2.9 | 1.5 | 1.1 | 7.8 | 144.2 | 0.3 | 143.3 | 144.6 | |

| 4G | 1-RGB | 198.4 | 35.0 | 137.6 | 299.3 | 13.9 | 1.7 | 11.0 | 16.4 | |

| 5G-SA | 1-RGB | 1279.0 | 155.9 | 953.4 | 1442.5 | 11.7 | 0.2 | 11.2 | 12.2 | |

| WiFi6 | 1-RGB | 5.0 | 9.0 | 1.1 | 35.7 | 24.4 | 3.3 | 15.9 | 28.0 | |

| 4G | 4-RGB | 774.2 | 139.9 | 563.4 | 1102.6 | 15.4 | 1.1 | 13.5 | 17.8 | |

| 5G-SA | 4-RGB | 2390.4 | 193.8 | 1848.7 | 2697.0 | 14.7 | 1.0 | 12.8 | 16.9 | |

| WiFi6 | 4-RGB | 12.2 | 10.8 | 2.6 | 41.3 | 89.0 | 1.1 | 87.1 | 91.8 | |

| 4G | 1-RGBD | 604.6 | 140.9 | 372.2 | 1005.9 | 12.5 | 0.7 | 10.6 | 13.4 | |

| 5G-SA | 1-RGBD | 1464.9 | 70.8 | 1349.5 | 1628.8 | 19.3 | 1.7 | 16.8 | 21.0 | |

| WiFi6 | 1-RGBD | 15.8 | 12.8 | 2.7 | 48.0 | 143.8 | 2.6 | 137.4 | 149.5 | |

| 4G | 1-RGB | 963.7 | 489.7 | 235.8 | 2184.7 | 2.9 | 0.8 | 1.3 | 4.2 | |

| 5G-SA | 1-RGB | 23.1 | 2.8 | 17.7 | 28.9 | 12.7 | 0.1 | 12.5 | 13.2 | |

| WiFi6 | 1-RGB | 1.3 | 0.2 | 1.0 | 2.0 | 22.3 | 0.1 | 21.9 | 22.5 | |

| 4G | 4-RGB | 575.5 | 368.4 | 0.0 | 1157.8 | 2.7 | 1.0 | 0.6 | 4.9 | |

| 5G-SA | 4-RGB | 795.9 | 188.4 | 424.2 | 1391.5 | 31.0 | 1.5 | 26.2 | 33.8 | |

| WiFi6 | 4-RGB | 1.7 | 0.8 | 1.0 | 5.1 | 83.1 | 0.4 | 81.7 | 83.8 | |

| 4G | 1-RGBD | 249.6 | 26.9 | 200.3 | 324.1 | 8.1 | 0.5 | 7.2 | 9.4 | |

| 5G-SA | 1-RGBD | 817.7 | 51.6 | 726.7 | 952.1 | 26.8 | 2.1 | 22.5 | 30.7 | |

| WiFi6 | 1-RGBD | 4.2 | 5.5 | 1.3 | 25.2 | 144.2 | 0.4 | 142.7 | 145.1 | |

| 4G | 1-RGB | 187.2 | 21.2 | 152.7 | 252.3 | 10.5 | 0.9 | 8.7 | 12.1 | |

| 5G-SA | 1-RGB | 393.8 | 210.0 | 94.9 | 683.2 | 18.4 | 0.9 | 17.1 | 20.1 | |

| WiFi6 | 1-RGB | 1.4 | 0.4 | 1.0 | 2.2 | 22.1 | 0.1 | 21.9 | 22.5 | |

| 4G | 4-RGB | 500.3 | 258.2 | 200.4 | 1117.8 | 9.1 | 1.0 | 6.9 | 11.0 | |

| 5G-SA | 4-RGB | 1977.1 | 145.3 | 1715.5 | 2358.6 | 17.6 | 1.5 | 14.0 | 19.7 | |

| WiFi6 | 4-RGB | 3.3 | 4.1 | 1.1 | 24.0 | 85.1 | 0.4 | 84.5 | 86.0 | |

| 4G | 1-RGBD | 257.5 | 31.0 | 199.9 | 334.8 | 8.7 | 0.6 | 7.2 | 9.8 | |

| 5G-SA | 1-RGBD | 1339.2 | 68.3 | 1237.7 | 1553.9 | 10.5 | 0.0 | 10.5 | 10.5 | |

| WiFi6 | 1-RGBD | 5.3 | 5.7 | 1.2 | 25.3 | 144.2 | 0.3 | 143.7 | 145.2 | |

References

- Webb, P.; Benton, T.G.; Beddington, J.; Flynn, D.; Kelly, N.M.; Thomas, S.M. The urgency of food system transformation is now irrefutable. Nat. Food 2020, 1, 584–585. [Google Scholar] [CrossRef] [PubMed]

- Borsellino, V.; Schimmenti, E.; El Bilali, H. Agri-Food Markets towards Sustainable Patterns. Sustainability 2020, 12, 2193. [Google Scholar] [CrossRef]

- GOV.UK. Press Release: £25 Million Funding for High Tech Machinery on Farms. Available online: https://www.gov.uk/government/news/25-million-funding-for-high-tech-machinery-on-farms (accessed on 19 January 2022).

- DEFRA. Third Report of Session 2021–22: Tree Planting. Technical Report HC356, House of Commons, Environment, Food and Rural Affairs Committee. Available online: https://committees.parliament.uk/publications/9364/documents/160849/default/ (accessed on 8 March 2022).

- Duckett, T.; Pearson, S.; Blackmore, S.; Grieve, B.; Chen, W.H.; Cielniak, G.; Cleaversmith, J.; Dai, J.; Davis, S.; Fox, C.; et al. Agricultural Robotics: The Future of Robotic Agriculture. arXiv 2018, arXiv:1806.06762. [Google Scholar]

- Zhivkov, T.; Gomez, A.; Gao, J.; Sklar, E.; Parsons, S. The need for speed: How 5G communication can support AI in the field. In Proceedings of the UKRAS21 Conference: Robotics at Home, UK-RAS, Virtual, 2 June 2021. [Google Scholar] [CrossRef]

- Tang, Y.; Dananjayan, S.; Hou, C.; Guo, Q.; Luo, S.; He, Y. A survey on the 5G network and its impact on agriculture: Challenges and opportunities. Comput. Electron. Agric. 2021, 180, 105895. [Google Scholar] [CrossRef]

- Lang, T.; McKee, M. The reinvasion of Ukraine threatens global food supplies. BMJ 2022, 376, o676. [Google Scholar] [CrossRef] [PubMed]

- Rae, M. The Economic Impact of the Ukraine–Russia War. In SAGE Business Cases; SAGE Publications: Thousand Oaks, CA, USA, 2022. [Google Scholar]

- Partridge, J.; Partington, R. ‘The anxiety is off the scale’: UK farm sector worried by labour shortages. The Guardian, 25 August 2021. [Google Scholar]

- Washburn, K. In California farm country, growers struggle with labor shortage. USA Today, 4 April 2020. [Google Scholar]

- Naik, G. Global farming suffers from falling prices, labor shortages as virus spreads. S & P Global Market Intelligence, 2 April 2020. [Google Scholar]

- Raza, A.; Razzaq, A.; Mehmood, S.S.; Zou, X.; Zhang, X.; Lv, Y.; Xu, J. Impact of Climate Change on Crops Adaptation and Strategies to Tackle Its Outcome: A Review. Plants 2019, 8, 34. [Google Scholar] [CrossRef] [PubMed]

- Borrelli, P.; Robinson, D.A.; Panagos, P.; Lugato, E.; Yang, J.E.; Alewell, C.; Wuepper, D.; Montanarella, L.; Ballabio, C. Land use and climate change impacts on global soil erosion by water (2015–2070). Proc. Natl. Acad. Sci. USA 2020, 117, 21994–22001. [Google Scholar] [CrossRef]

- Shaheb, M.R.; Venkatesh, R.; Shearer, S.A. A Review on the Effect of Soil Compaction and its Management for Sustainable Crop Production. J. Biosyst. Eng. 2021, 46, 417–439. [Google Scholar] [CrossRef]

- Millard, A.G.; Ravikanna, R.; Groß, R.; Chesmore, D. Towards a Swarm Robotic System for Autonomous Cereal Harvesting. In Proceedings of the Towards Autonomous Robotic Systems, London, UK, 3–5 July 2019; Althoefer, K., Konstantinova, J., Zhang, K., Eds.; Springer International Publishing: Cham, Switzerland, 2019; pp. 458–461. [Google Scholar]

- Global Livestock Environmental Assessment Model (GLEAM), Food and Agriculture Organisation of the United Nations. 2022. Available online: https://www.fao.org/gleam/results/en (accessed on 23 July 2022).

- Stafford, J.V. Implementing Precision Agriculture in the 21st Century. J. Agric. Eng. Res. 2000, 76, 267–275. [Google Scholar] [CrossRef]

- Gebbers, R.; Adamchuk, V.I. Precision Agriculture and Food Security. Science 2010, 327, 828–831. [Google Scholar] [CrossRef]

- Durisi, G.; Koch, T.; Popovski, P. Toward Massive, Ultrareliable, and Low-Latency Wireless Communication with Short Packets. Proc. IEEE 2016, 104, 1711–1726. [Google Scholar] [CrossRef]

- Popovski, P.; Trillingsgaard, K.F.; Simeone, O.; Durisi, G. 5G wireless network slicing for eMBB, URLLC, and mMTC: A communication-theoretic view. IEEE Access 2018, 6, 55765–55779. [Google Scholar] [CrossRef]

- 5G Network Coverage Outlook. Available online: https://www.ericsson.com/en/reports-and-papers/mobility-report/dataforecasts/network-coverage (accessed on 1 July 2022).

- Rendon Schneir, J.; Xiong, Y. A cost study of fixed broadband access networks for rural areas. Telecommun. Policy 2016, 40, 755–773. [Google Scholar] [CrossRef]

- Adami, D.; Giordano, S.; Tamburello, M. A Monitoring Application for Animal Repelling Devices in Smart Agriculture. In Proceedings of the 2020 IEEE 25th International Workshop on Computer Aided Modeling and Design of Communication Links and Networks (CAMAD), Pisa, Italy, 14–16 September 2020; pp. 1–6. [Google Scholar] [CrossRef]

- Kagan, C.R.; Arnold, D.P.; Cappelleri, D.J.; Keske, C.M.; Turner, K.T. Special report: The Internet of Things for Precision Agriculture (IoT4Ag). Comput. Electron. Agric. 2022, 196, 106742. [Google Scholar] [CrossRef]

- Tao, W.; Zhao, L.; Wang, G.; Liang, R. Review of the internet of things communication technologies in smart agriculture and challenges. Comput. Electron. Agric. 2021, 189, 106352. [Google Scholar] [CrossRef]

- Karthikkumar, M.; Premchandran, V.; Sathish, E. An Agricultural Irrigatıon Management System Based on the Internet of Things With MQTT Protocol. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1084, 012118. [Google Scholar] [CrossRef]

- Bodunde, O.; Adie, U.; Ikumapayi, O.; Akinyoola, J.; Aderoba, A. Architectural design and performance evaluation of a ZigBee technology based adaptive sprinkler irrigation robot. Comput. Electron. Agric. 2019, 160, 168–178. [Google Scholar] [CrossRef]

- Tsipis, A.; Papamichail, A.; Koufoudakis, G.; Tsoumanis, G.; Polykalas, S.E.; Oikonomou, K. Latency-Adjustable Cloud/Fog Computing Architecture for Time-Sensitive Environmental Monitoring in Olive Groves. AgriEngineering 2020, 2, 175–205. [Google Scholar] [CrossRef]

- Maraveas, C.; Bartzanas, T. Application of Internet of Things (IoT) for Optimized Greenhouse Environments. AgriEngineering 2021, 3, 954–970. [Google Scholar] [CrossRef]

- Batte, M.T.; Ehsani, M.R. The economics of precision guidance with auto-boom control for farmer-owned agricultural sprayers. Comput. Electron. Agric. 2006, 53, 28–44. [Google Scholar] [CrossRef]

- Panfilov, I.; Mann, D.D. The importance of real-time visual information for the remote supervision of an autonomous agricultural machine. Can. Biosyst. Eng. 2018, 60, 2.11–2.18. [Google Scholar] [CrossRef]

- Gomez, A.S.; Aptoula, E.; Parsons, S.; Bosilj, P. Deep Regression Versus Detection for Counting in Robotic Phenotyping. IEEE Robot. Autom. Lett. 2021, 6, 2902–2907. [Google Scholar] [CrossRef]

- Choi, T.; Would, O.; Gomez, A.S.; Cielniak, G. Self-supervised Representation Learning for Reliable Robotic Monitoring of Fruit Anomalies. arXiv 2021, arXiv:2109.10135. [Google Scholar]

- Ponnambalam, V.R.; Fentanes, J.P.; Das, G.; Cielniak, G.; Gjevestad, J.G.O.; From, P.J. Agri-Cost-Maps-Integration of Environmental Constraints into Navigation Systems for Agricultural Robots. In Proceedings of the 2020 6th International Conference on Control, Automation and Robotics (ICCAR), Singapore, 20–23 April 2020; pp. 214–220. [Google Scholar] [CrossRef]

- Cox, J.; Tsagkopoulos, N.; Rozsypálek, Z.; Krajník, T.; Sklar, E.I.; Hanheide, M. Visual teach and generalise (VTAG)–Exploiting perceptual aliasing for scalable autonomous robotic navigation in horticultural environments. Comput. Electron. Agric. 2023, 212, 108054. [Google Scholar] [CrossRef]

- Salazar-Gomez, A.; Darbyshire, M.; Gao, J.; Sklar, E.I.; Parsons, S. Beyond mAP: Towards practical object detection for weed spraying in precision agriculture. In Proceedings of the IEEE/RSJ International Conference on Intelligent Robots and Systems (IROS), Kyoto, Japan, 23–27 October 2022. [Google Scholar]

- Available online: https://www.leorover.tech/ (accessed on 1 June 2023).

- Available online: https://www.intelrealsense.com/depth-camera-d435/ (accessed on 1 June 2023).

- Jocher, G.; Stoken, A.; Borovec, J.; NanoCode012; Chaurasia, A.; TaoXie; Changyu, L.; V, L.; Laughing; tkianai; et al. ultralytics/yolov5: v5.0—YOLOv5-P6 1280 models, AWS, Supervise.ly and YouTube integrations. Zenodo 2021. [Google Scholar] [CrossRef]

- Available online: https://www.asus.com/uk/Laptops/For-Gaming/TUF-Gaming/ (accessed on 1 June 2023).

- Available online: https://www.bt.com/ (accessed on 1 June 2023).

- Available online: https://www.nokia.com/ (accessed on 1 June 2023).

- Ofcom. Available online: https://www.ofcom.org.uk/home (accessed on 1 June 2023).

- Available online: https://static.tp-link.com/2021/202103/20210311/ArcherAX6000(EU&US)2.0_Datasheet.pdf (accessed on 1 June 2023).

- Available online: https://www.dlink.com/en/products/dwm-222-4g-lte-usb-adapter (accessed on 1 June 2023).

- Available online: https://ee.co.uk/ (accessed on 1 June 2023).

- Ofcom. Ofcom Publishes 4G and 3G Mobile Broadband Speeds Research. 2014. Available online: https://www.ofcom.org.uk/about-ofcom/latest/media/media-releases/2014/3g-4g-bb-speeds (accessed on 12 January 2022).

- D-Link. DWM-222 4G LTE USB Adapter. 2020. Available online: https://eu.dlink.com/uk/en/-/media/consumer_products/dwm/dwm-222/datasheet/dwm_222_a2_datasheet_en_eu.pdf (accessed on 17 November 2022).

- Available online: https://www.speedtest.net/ (accessed on 1 June 2023).

- Cisco. Tunneling. Available online: https://www.cisco.com/c/en/us/products/ios-nx-os-software/tunneling/index.html (accessed on 1 June 2023).

- Donenfeld, J.A. WireGuard: Next Generation Kernel Network Tunnel. 2020. Available online: https://www.wireguard.com/papers/wireguard.pdf (accessed on 1 June 2023).

- Available online: https://what3words.com (accessed on 1 June 2023).

- Fomon, J. The U.K. Is Ahead of European Trade Partners for 5G, Can’t Beat South Korea and China. 2021. Available online: https://www.ookla.com/articles/5g-united-kingdom-q1-q2-2021 (accessed on 1 June 2023).

- Lee, H.; O’Keefe, R.M.; Yun, K. The Growth of Broadband and Electronic Commerce in South Korea: Contributing Factors. Inf. Soc. 2003, 19, 81–93. [Google Scholar] [CrossRef]

- Massaro, M.; Kim, S. Why is South Korea at the forefront of 5G? Insights from technology systems theory. Telecommun. Policy 2022, 46, 102290. [Google Scholar] [CrossRef]

- Lavric, A.; Petrariu, A.I. LoRaWAN communication protocol: The new era of IoT. In Proceedings of the International Conference on Development and Application Systems (DAS), Suceava, Romania, 24–26 May 2018; pp. 74–77. [Google Scholar] [CrossRef]

| Specification | Description |

|---|---|

| 5G Frequency Band N77 | 3800–4100 MHz |

| Carrier Bandwidth | 100 MHz |

| Modulation | 256 (DL)/64 (UL) QAM |

| Transmit power | 5 W per Tx path (4Tx paths) |

| MIMO layers | 4 × 2 closed loop MIMO |

| TDD (UL:DL) ratio | 3/7 |

| Specification | Description |

|---|---|

| 5 GHz Frequency Band (802.11 ax) | 5160–5895 MHz |

| Carrier Bandwidth | 40–160 MHz |

| Modulation | (up to) 1024 (DL/UL) QAM |

| Transmit power | 1W |

| TDD (UL:DL) ratio | N/A |

| Specification | Description |

|---|---|

| LTE frequency band | 800–2600 MHz |

| Carrier bandwidth | 1–20 MHz |

| Modulation | 256 (DL)/64 (UL) QAM |

| Transmit power | 0.2 W |

| UL:DL (in Mbps) | 150:300 (theoretical) |

| 20:100 (real-world) |

| Vegetable Polytunnel | ||||||||

|---|---|---|---|---|---|---|---|---|

| Network | Latency (ms) | Throughput (Mbps) | ||||||

| Type | Mean | Min | Loc. | Dist. | Mean | Max | Loc. | Dist. |

| 4G | 94.9 | 72.0 | — | 12.5 | 16.5 | — | ||

| 5G-SA | 15.7 | 12.9 | 81.4 | 57.1 | 65.1 | 49.1 | ||

| WiFi6 | 1.2 | 1.0 | 8.6 | 144.2 | 145.2 | 33.2 | ||

| Walled Garden | ||||||||

| Network | Latency (ms) | Throughput (Mbps) | ||||||

| Type | Mean | Min | Loc. | Dist. | Mean | Max | Loc. | Dist. |

| 4G | 187.2 | 152.7 | — | 15.4 | 17.8 | — | ||

| 5G-SA | 23.1 | 17.7 | 132.3 | 31.0 | 33.8 | 132.3 | ||

| WiFi6 | 1.3 | 1.0 | 14.4 | 144.2 | 149.5 | 14.0 | ||

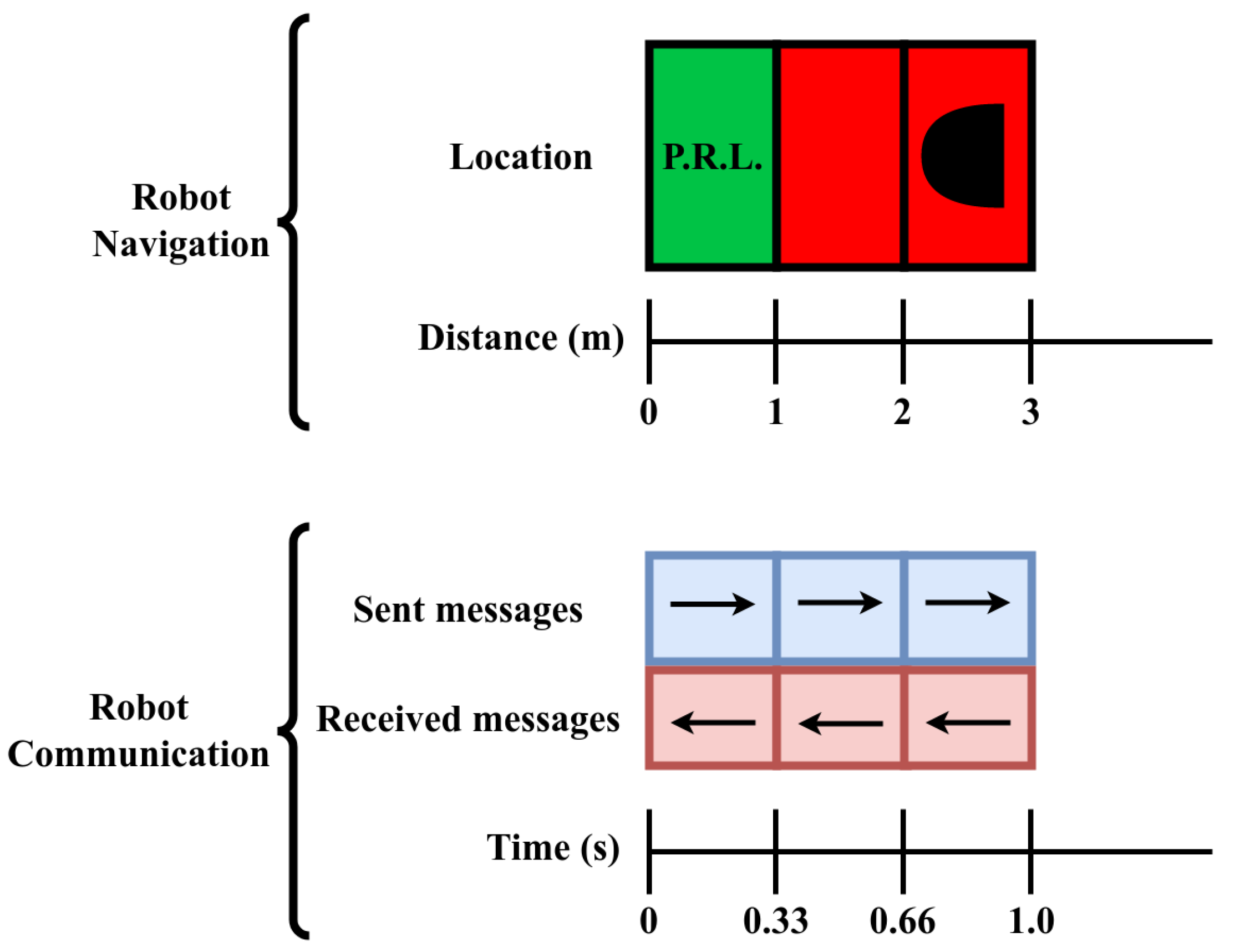

| Fixed robot velocity | 3 m/s |

| Location update time per meter | 0.333 s |

| Sent/received messages per second | 3 msg/s |

| Total messages per second | 6 msg/s |

| loc | Network | Sent rcv (ms) | Proc (ms) | msg Delay Time (ms) | Lag Time (ms) | Cumulative Delay over 30 Steps (ms) |

|---|---|---|---|---|---|---|

| 4G | 216.7 | 14.5 | 447.9 | 114.6 | 3436.9 | |

| 5G-SA | 63.9 | 14.5 | 142.3 | −191.0 | 0.0 | |

| WiFi6 | 1.2 | 14.5 | 17.0 | −316.3 | 0.0 | |

| 4G | 294.0 | 14.5 | 602.5 | 269.2 | 8075.4 | |

| 5G-SA | 22.9 | 14.5 | 60.4 | −272.9 | 0.0 | |

| WiFi6 | 1.3 | 14.5 | 17.0 | −316.3 | 0.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhivkov, T.; Sklar, E.I.; Botting, D.; Pearson, S. 5G on the Farm: Evaluating Wireless Network Capabilities and Needs for Agricultural Robotics. Machines 2023, 11, 1064. https://doi.org/10.3390/machines11121064

Zhivkov T, Sklar EI, Botting D, Pearson S. 5G on the Farm: Evaluating Wireless Network Capabilities and Needs for Agricultural Robotics. Machines. 2023; 11(12):1064. https://doi.org/10.3390/machines11121064

Chicago/Turabian StyleZhivkov, Tsvetan, Elizabeth I. Sklar, Duncan Botting, and Simon Pearson. 2023. "5G on the Farm: Evaluating Wireless Network Capabilities and Needs for Agricultural Robotics" Machines 11, no. 12: 1064. https://doi.org/10.3390/machines11121064

APA StyleZhivkov, T., Sklar, E. I., Botting, D., & Pearson, S. (2023). 5G on the Farm: Evaluating Wireless Network Capabilities and Needs for Agricultural Robotics. Machines, 11(12), 1064. https://doi.org/10.3390/machines11121064