Numerical and Experimental Investigations of Axial Flow Fan with Bionic Forked Trailing Edge

Abstract

:1. Introduction

2. Geometric Model and Experimental Test

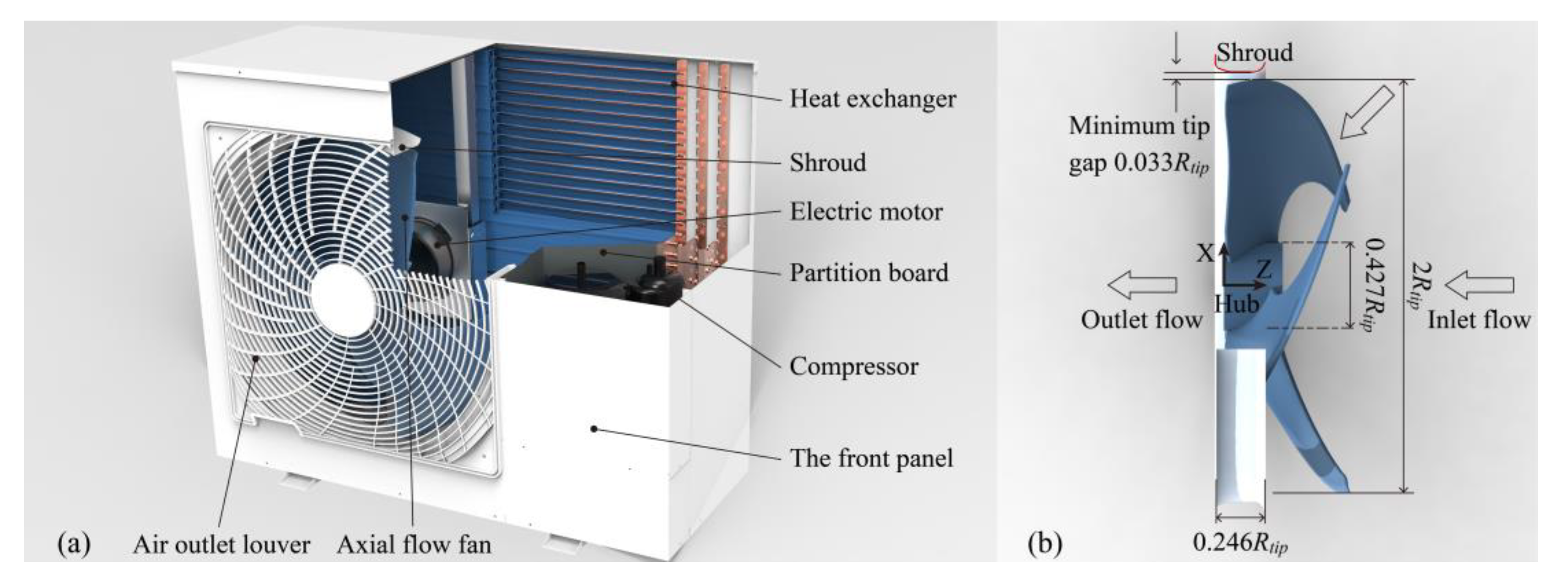

2.1. Axial Flow Fan Model

2.2. Bionic Forked Trailing Edge

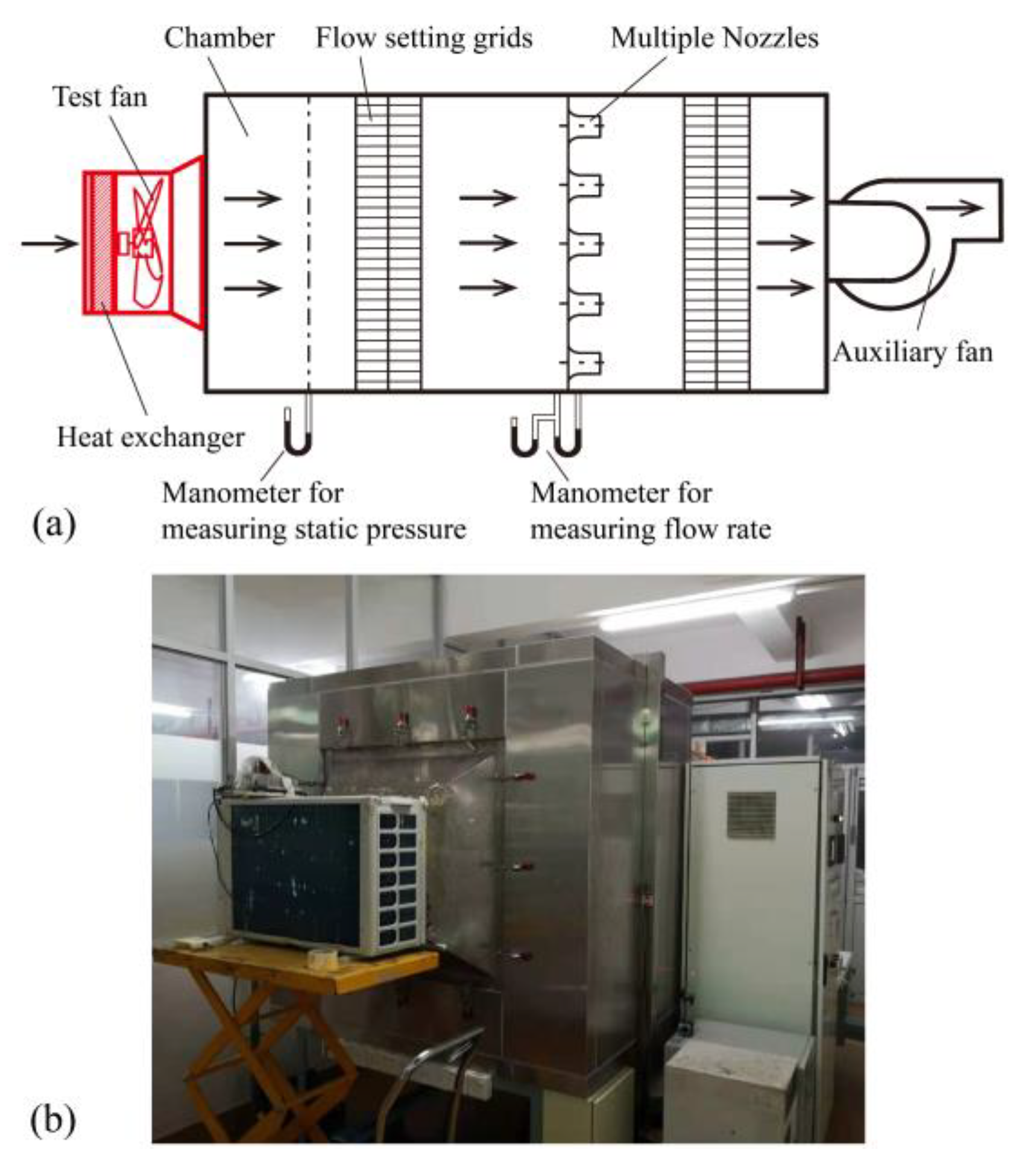

2.3. Experimental Setup

3. Numerical Method

3.1. Governing Equations and Turbulence Modeling

3.2. Porous Media

3.3. Mesh Sensitivity Study

4. Results and Discussions

4.1. Aerodynamic Performance

4.2. Effect of the Bionic Forked Trailing Edge on the Flow Field

4.3. Aeroacoustics

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Jiang, C.L.; Chen, J.P.; Chen, Z.J.; Tian, J.; Hua, O.Y.; Du, Z.H. Experimental and numerical study on aeroacoustic sound of axial flow fan in room air conditioner. Appl. Acoust. 2007, 68, 458–472. [Google Scholar] [CrossRef]

- Shiomi, N.; Kinoue, Y.; Jin, Y.Z.; Setoguchi, T.; Kaneko, K. Flow fields with vortex in a small semi-open axial fan. J. Therm. Sci. 2009, 18, 294–300. [Google Scholar] [CrossRef]

- Denton, J.D. Loss mechanisms in turbomachines. J. Turbomach. 1993, 115, 621–656. [Google Scholar] [CrossRef]

- Jang, C.M.; Furukawa, M.; Inoue, M. Analysis of vortical flow field in a propeller fan by LDV measurements and LES-Part II: Unsteady nature of vortical flow structures due to tip vortex breakdown. J. Fluids Eng. 2001, 123, 755–761. [Google Scholar] [CrossRef]

- Jang, C.M.; Furukawa, M.; Inoue, M. Analysis of vortical flow field in a propeller fan by LDV measurements and LES-Part I: Three-dimensional vortical flow structures. J. Fluids Eng. 2001, 123, 748–754. [Google Scholar] [CrossRef]

- Goodarzi, D.; Sookhak Lari, K.; Khavasi, E.; Abolfathi, S. Large eddy simulation of turbidity currents in a narrow channel with different obstacle configurations. Sci. Rep. 2020, 10, 12814. [Google Scholar] [CrossRef]

- Jung, J.H.; Joo, W.G. Effect of tip clearance, winglets, and shroud height on the tip leakage in axial flow fans. Int. J. Refrig. 2018, 93, 195–204. [Google Scholar] [CrossRef]

- Jung, J.H.; Joo, W.G. The effect of the entrance hub geometry on the efficiency in an axial flow fan. Int. J. Refrig. 2019, 101, 90–97. [Google Scholar] [CrossRef]

- Jiang, C.L.; Tian, J.; Ouyang, H.; Chen, J.P.; Chen, Z.J. Investigation of air-flow fields and aeroacoustic noise in outdoor unit for split-type air conditioner. Noise Control. Eng. J. 2006, 54, 146–156. [Google Scholar] [CrossRef]

- Jie, T.; Hua, O.; Wu, Y.; Du, Z.H.; Zheng, Z.M.; Sumio, S. Research of collateral axial flow fan system inside outdoor unit of air conditioner. In Proceedings of the 16th AIAA/CEAS Aeroacoustics Conference, Stockholm, Sweden, 7 June 2010. [Google Scholar]

- Nashimoto, A.; Fujisawa, N.; Akuto, T.; Nagase, Y. Measurements of aerodynamic noise and wake flow field in a cooling fan with winglets. J. Vis. 2004, 7, 85–92. [Google Scholar] [CrossRef]

- Lim, T.G.; Jung, J.H.; Jeon, W.H.; Joo, W.G.; Minorikawa, G. Investigation study on the flow-induced noise by winglet and shroud shape of an axial flow fan at an outdoor unit of air conditioner. J. Mech. Sci. Technol. 2020, 34, 2845–2853. [Google Scholar] [CrossRef]

- Zhou, S.Q.; Li, H.; Wang, J.; Wang, X.S.; Ye, J.J. Investigation acoustic effect of the convexity-preserving axial flow fan based on Bezier function. Comput. Fluids 2014, 102, 85–93. [Google Scholar] [CrossRef]

- Park, K.; Choi, H.S.; Sa, Y. Effect of a casing fence on the tip-leakage flow of an axial flow fan. Int. J. Heat Fluid Flow 2019, 77, 157–170. [Google Scholar] [CrossRef]

- Klan, S.; Bachmann, T.; Klaas, M.; Wagner, H.; Schroder, W. Experimental analysis of the flow field over a novel owl based airfoil. Exp. Fluids 2009, 46, 975–989. [Google Scholar] [CrossRef]

- Kondo, K.; Aono, H.; Nonomura, T.; Oyama, A.; Fujii, K.; Yamamoto, M. Large-eddy simulations of owl-like wing under low reynolds number conditions. In Proceedings of the Asme Fluids Engineering Division Summer Meeting, Incline Village, NV, USA, 7 July 2013. [Google Scholar]

- Gruber, M.; Joseph, P.F.; Chong, T. On the mechanisms of serrated airfoil trailing edge noise reduction. In Proceedings of the 17th AIAA/CEAS Aeroacoustics Conference, Portland, OR, USA, 5 June 2011. [Google Scholar]

- Chong, T.P.; Vathylakis, A.; Joseph, P.F.; Gruber, M. Self-noise produced by an airfoil with nonflat plate trailing-edge serrations. Aiaa J. 2013, 51, 2665–2677. [Google Scholar] [CrossRef] [Green Version]

- Dey, D.; Camci, C. Aerodynamic Tip Desensitization of an Axial Turbine Rotor Using Tip Platform Extensions. In Volume 1: Aircraft Engine; Marine; Turbomachinery; Microturbines and Small Turbomachinery, Proceedings of the ASME Turbo Expo 2001: Power for Land, Sea, and Air, New Orleans, LA, USA, 7 June 2001.

- Zhang, C.; Ji, L.C.; Zhou, L.; Sun, S.J. Effect of blended blade tip and winglet on aerodynamic and aeroacoustic performances of a diagonal fan. Aerosp. Sci. Technol. 2020, 98, 105688. [Google Scholar] [CrossRef]

- Lauder, G.V. Function of the caudal fin during locomotion in fishes: Kinematics, flow visualization, and evolutionary patterns. Am. Zool. 2000, 40, 101–122. [Google Scholar] [CrossRef] [Green Version]

- Lighthill, M.J. Note on the swimming of slender fish. J. Fluid Mech. 1960, 9, 305–317. [Google Scholar] [CrossRef]

- Lighthill, M.J. Aquatic animal propulsion of high hydromechanical efficiency. J. Fluid Mech. 1970, 44, 265–301. [Google Scholar] [CrossRef]

- Buren, T.V.; Floryan, D.; Brunner, D.; Senturk, U.; Smits, A.J. Impact of trailing edge shape on the wake and propulsive performance of pitching panels. Phys. Rev. Fluids 2017, 2, 1–10. [Google Scholar] [CrossRef]

- Li, G.J.; Luodin, Z.H.U.; Lu, X.Y. Numerical studies on locomotion perfromance of fish-like tail fins. J. Hydrodyn. 2012, 24, 488–495. [Google Scholar] [CrossRef]

- Matta, A.; Pendar, H.; Battaglia, F.; Bayandor, J. Impact of Caudal Fin Shape on Thrust Production of a Thunniform Swimmer. J. Bionic Eng. 2020, 17, 254–269. [Google Scholar] [CrossRef]

- Low, K.H.; Chong, C.W. Parametric study of the swimming performance of a fish robot propelled by a flexible caudal fin. Bioinspiration Biomim. 2010, 5, 046002. [Google Scholar] [CrossRef]

- Matta, A.; Bayandor, J.; Battaglia, F.; Pendar, H. Effects of fish caudal fin sweep angle and kinematics on thrust production during low-speed thunniform swimming. Biol. Open 2019, 8, bio040626. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Zhao, X.; Sun, J.; Zhi, Z. Numerical and experimental investigation of flow behaviour and aerodynamic noise in axial flow fan of airconditioner. In Volume 7: Turbomachinery, Parts A, B, and C, Proceedings of the ASME 2011 Turbo Expo: Turbine Technical Conference and Exposition, Vancouver, BC, Canada, 10 June 2011.

- Zhao, X.F.; Sun, J.J.; Zhang, Z. Prediction and measurement of axial flow fan aerodynamic and aeroacoustic performance in a split-type air-conditioner outdoor unit. Int. J. Refrig. 2013, 36, 1098–1108. [Google Scholar] [CrossRef]

- Zhang, W.J.; Yuan, J.P.; Zhou, B.L.; Li, H.; Yuan, Y. The influence of axial-flow fan trailing edge structure on internal flow. Adv. Mech. Eng. 2018, 10. [Google Scholar] [CrossRef] [Green Version]

- Davidson, L. Fluid Mechanics, Turbulent Flow and Turbulence Modeling. Chalmers University of Technology: Gothenburg, Sweden, 2010. [Google Scholar]

- Smagorinsky, J. General circulation experiments with the primitive equations. Mon. Weather. Rev. 1963, 91, 99–164. [Google Scholar] [CrossRef]

- Moin, P.; Kim, J. Numerical investigation of turbulent channel flow. J. Fluid Mech. 1982, 118, 341–377. [Google Scholar] [CrossRef] [Green Version]

- ANSYS FLUENT User’s Guide. Available online: https://ansyshelp.ansys.com/account/secured?returnurl=/Views/Secured/corp/v211/en/flu_ug/flu_ug.html (accessed on 23 November 2022).

- Haller, G. An objective definition of a vortex. J. Fluid Mech. 2005, 525, 1–26. [Google Scholar] [CrossRef] [Green Version]

- Wang, H.; Tian, J.; Ouyang, H.; Wu, Y.D.; Du, Z.H. Aerodynamic performance improvement of up-flow outdoor unit of air conditioner by redesigning the bell-mouth profile. Int. J. Refrig. 2014, 46, 173–184. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Number of blades | 3 |

| Blade tip radius, Rtip | 211mm |

| Rated operating condition, Qv,r | 2336 m3/h |

| Axial tip chord length, Cx/Rtip | 0.590 |

| Tip chord length, Ct/Rtip | 1.521 |

| Hub chord length, Ch/Rtip | 0.394 |

| Minimum tip celerance, tgap/Rtip | 0.033 |

| Hub-to-tip ratio, Rhub/Rtip Reynolds number, Re | 0.213 6.7 × 104 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liang, Z.; Wang, J.; Wang, W.; Jiang, B.; Ding, Y.; Qin, W. Numerical and Experimental Investigations of Axial Flow Fan with Bionic Forked Trailing Edge. Machines 2023, 11, 155. https://doi.org/10.3390/machines11020155

Liang Z, Wang J, Wang W, Jiang B, Ding Y, Qin W. Numerical and Experimental Investigations of Axial Flow Fan with Bionic Forked Trailing Edge. Machines. 2023; 11(2):155. https://doi.org/10.3390/machines11020155

Chicago/Turabian StyleLiang, Zhong, Jun Wang, Wei Wang, Boyan Jiang, Yanyan Ding, and Wanxiang Qin. 2023. "Numerical and Experimental Investigations of Axial Flow Fan with Bionic Forked Trailing Edge" Machines 11, no. 2: 155. https://doi.org/10.3390/machines11020155