An LWPR-Based Method for Intelligent Lower-Limb Prosthesis Control by Learning the Dynamic Model in Real Time

Abstract

:1. Introduction

2. Materials and Methods

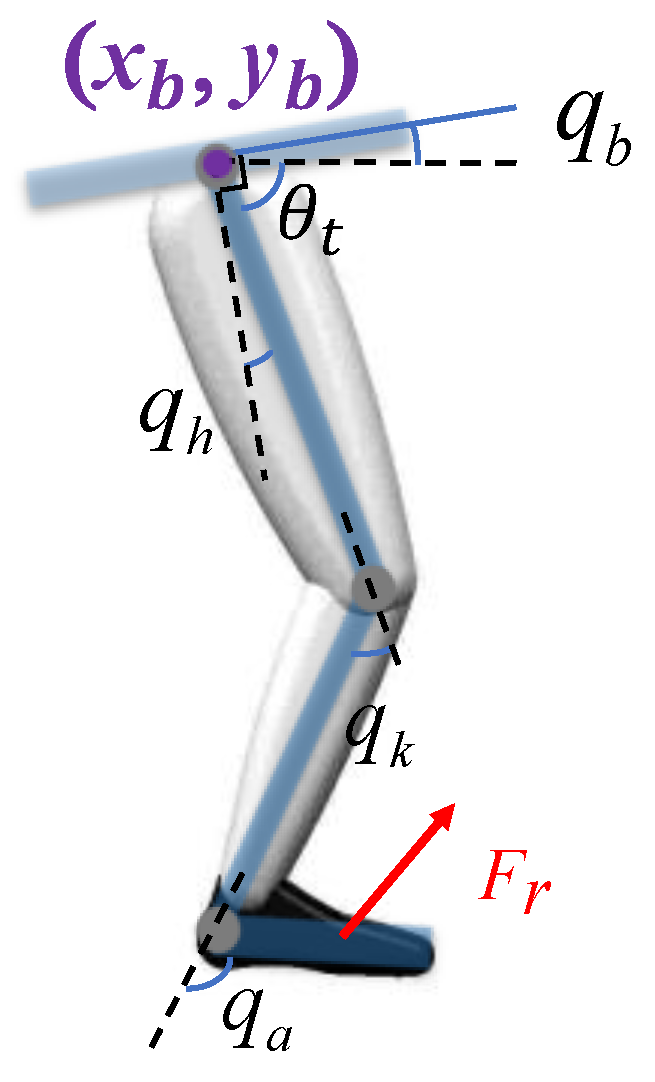

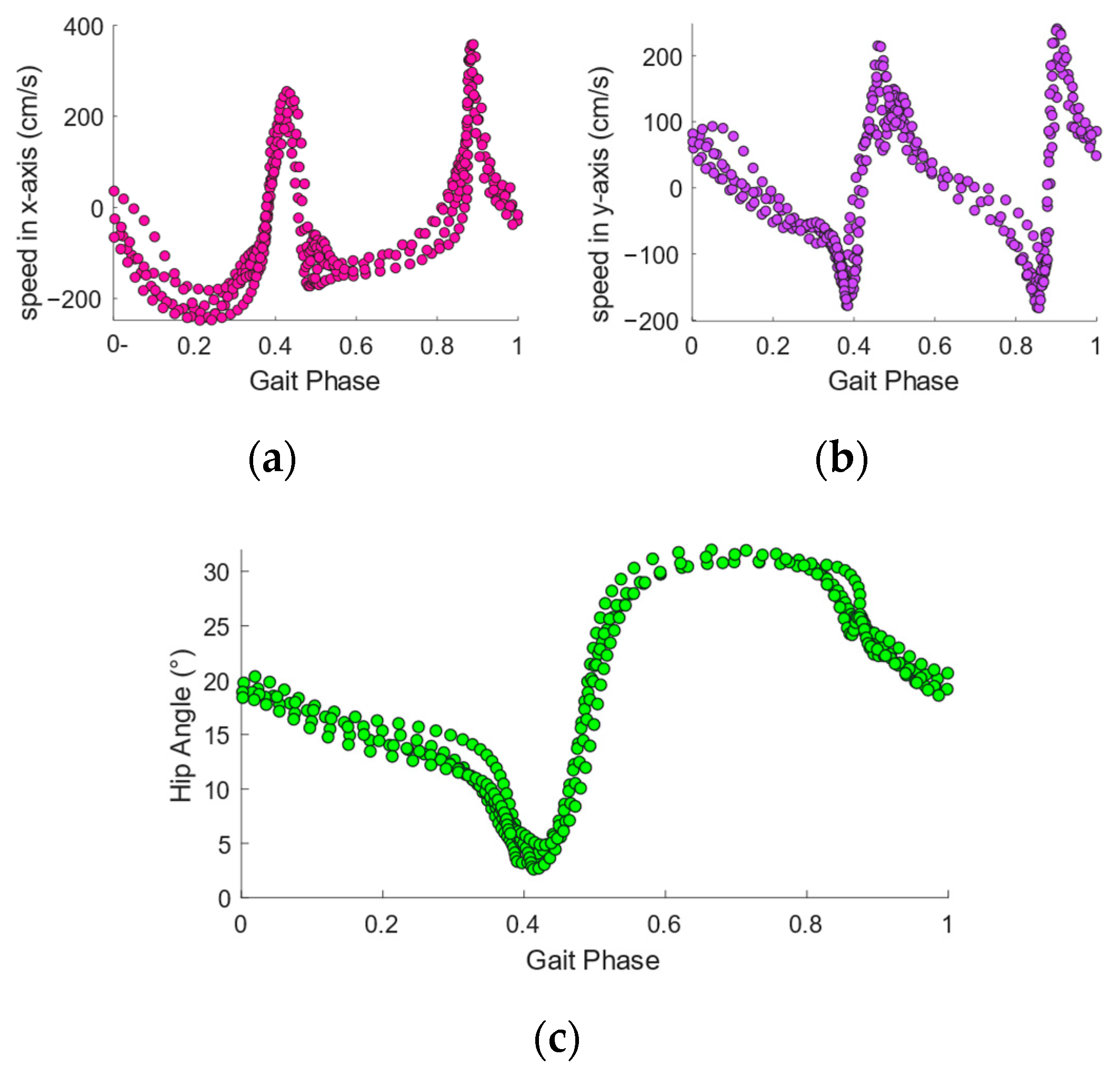

2.1. Phase Variable Selection

2.2. Motion Mode Recognizer

2.3. Reference Trajectory Generation

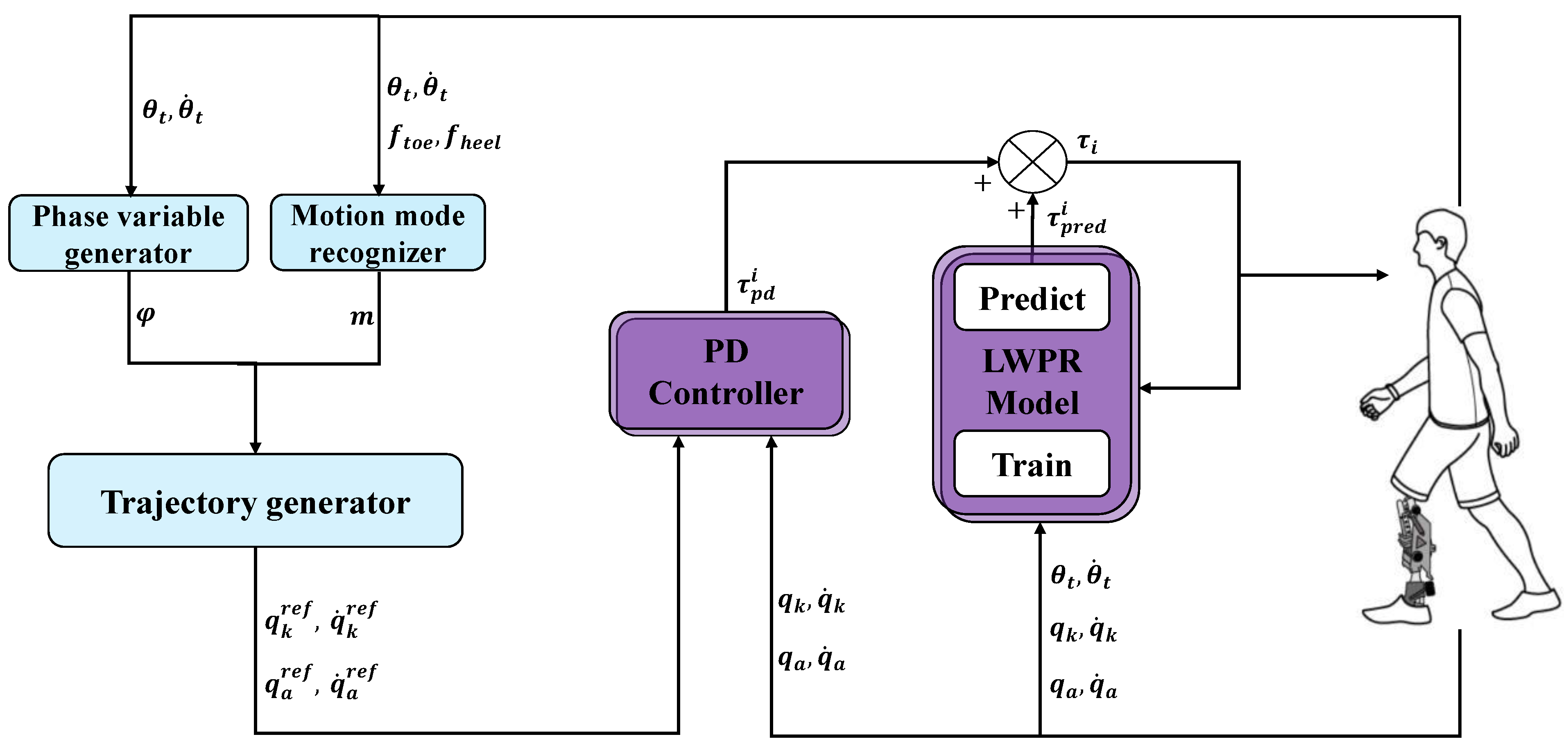

2.4. Controller Design

- (1)

- During swing phase

- (2)

- During stance phase

2.5. Learning Policy of LWPR Model

2.5.1. LWPR Model Configuration

2.5.2. Model Learning Policy

3. Results

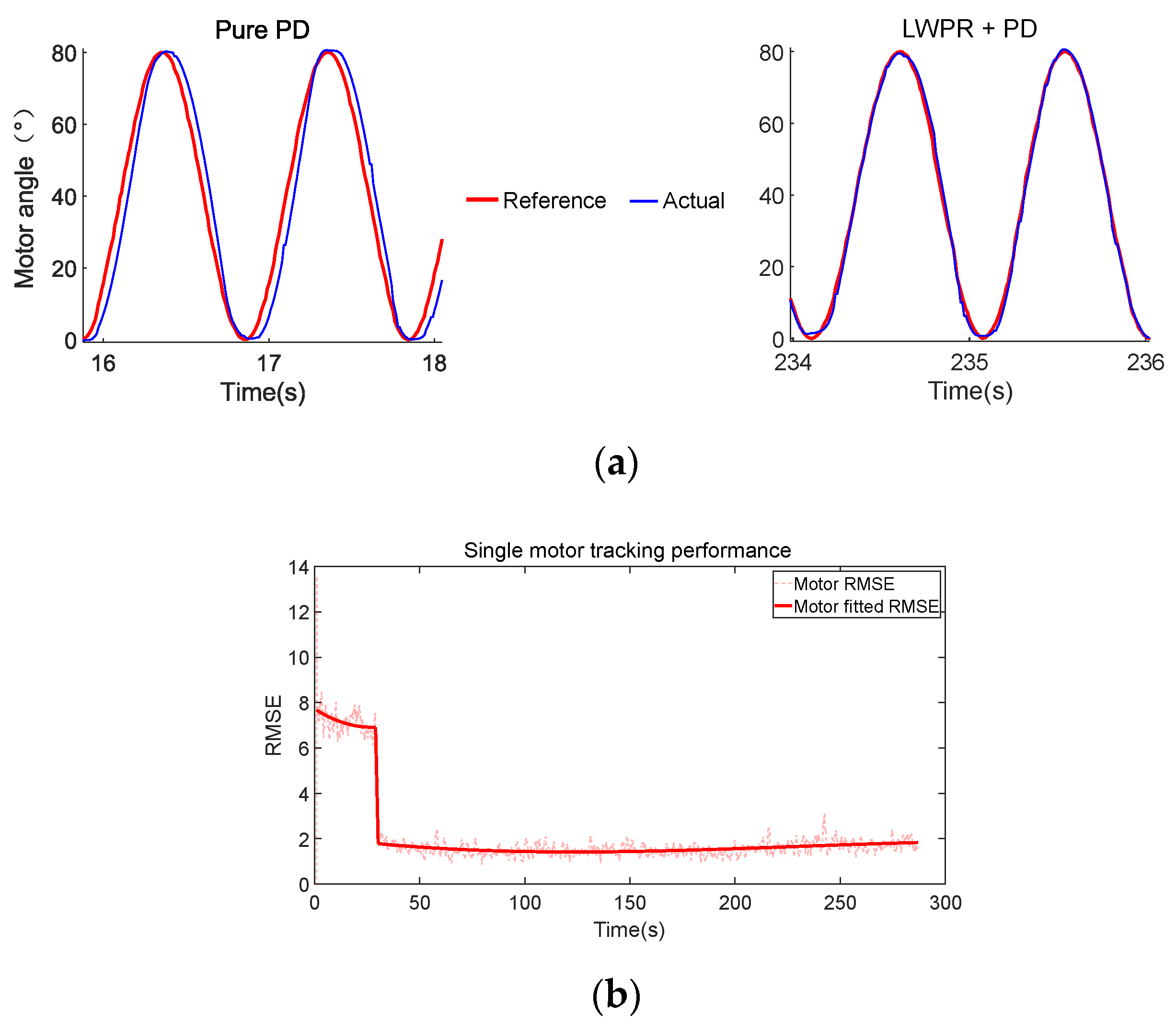

3.1. Single Motor Experiment

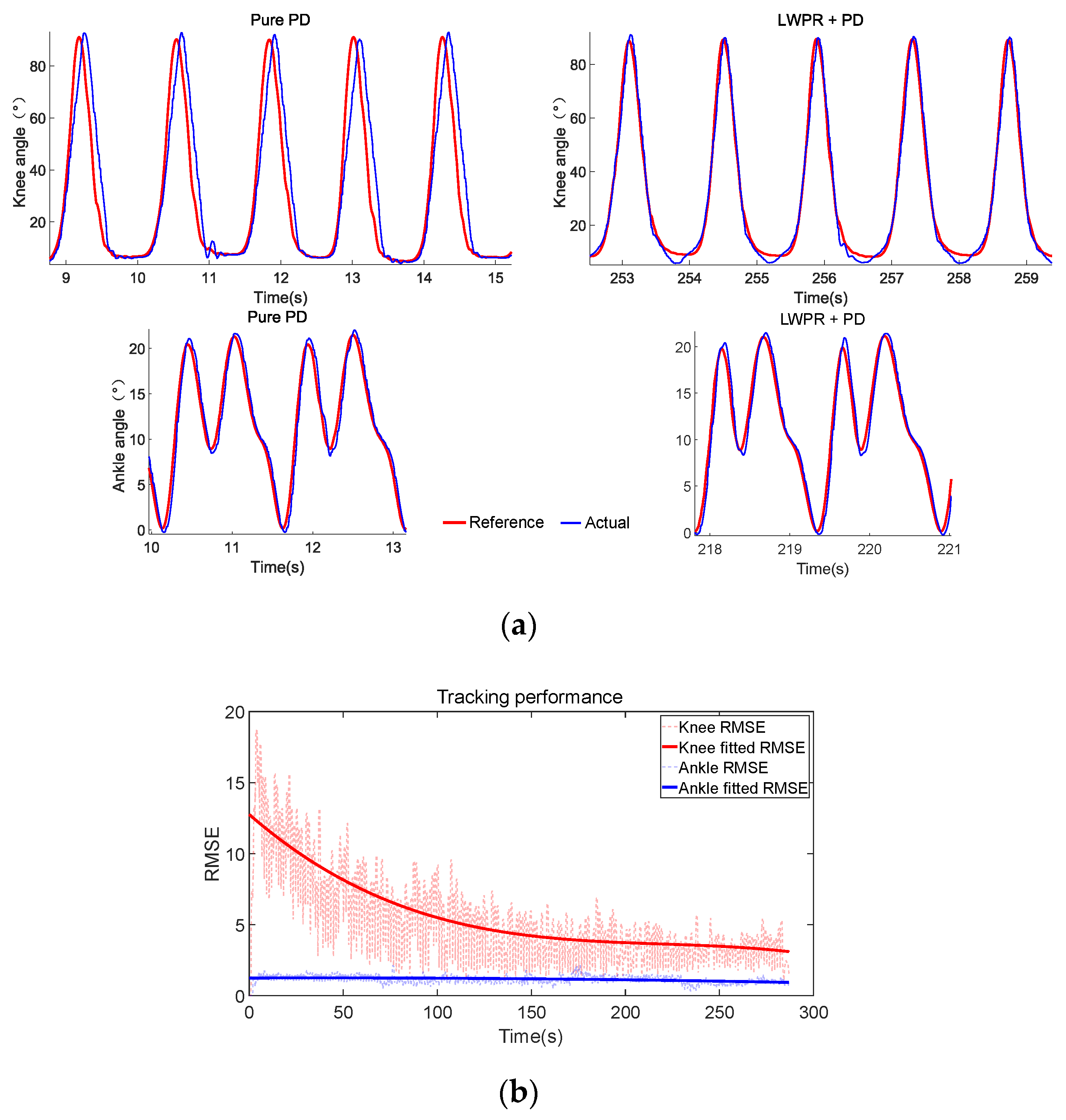

3.2. Hanging Up Experiment

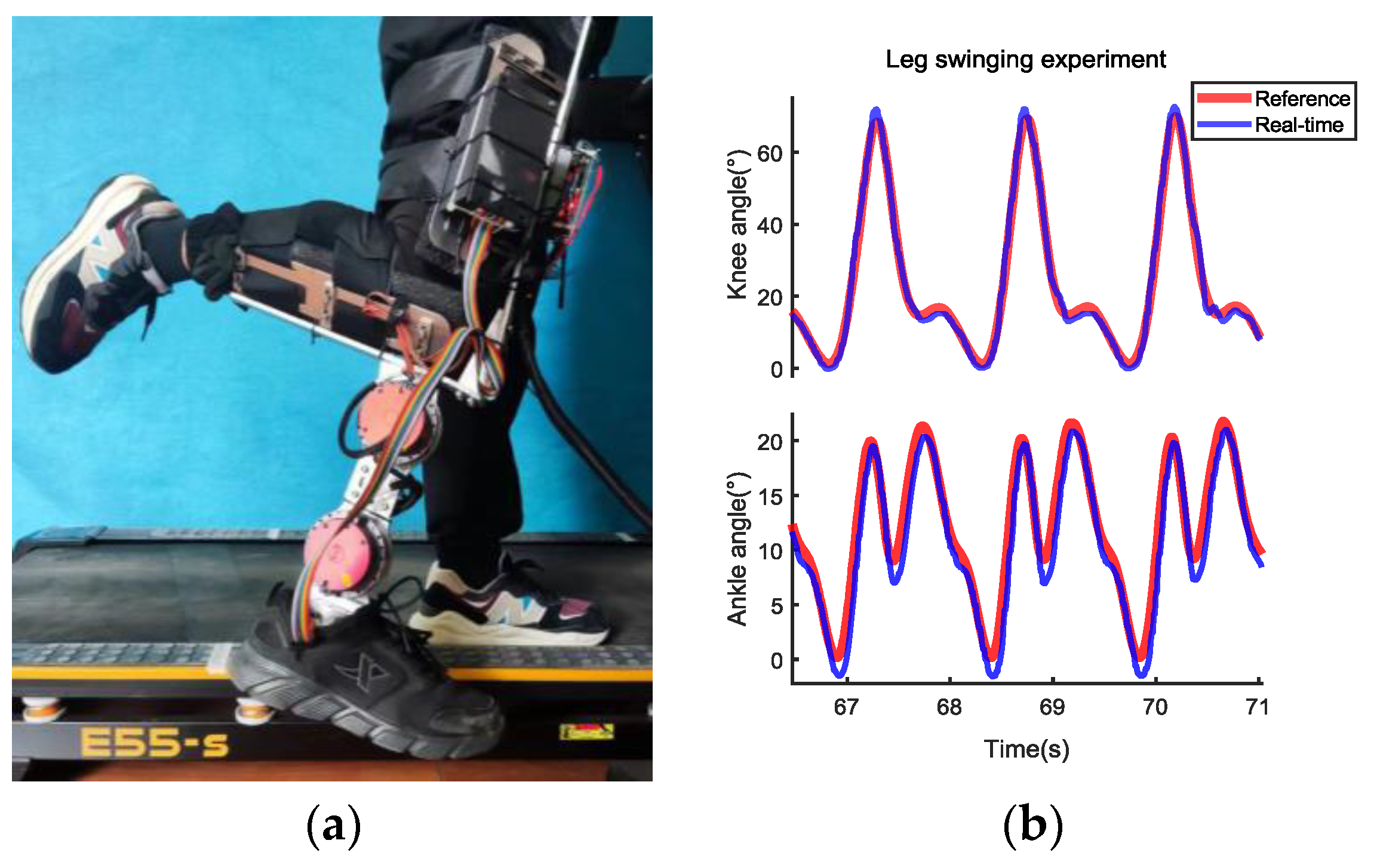

3.3. Leg Swinging Experiment

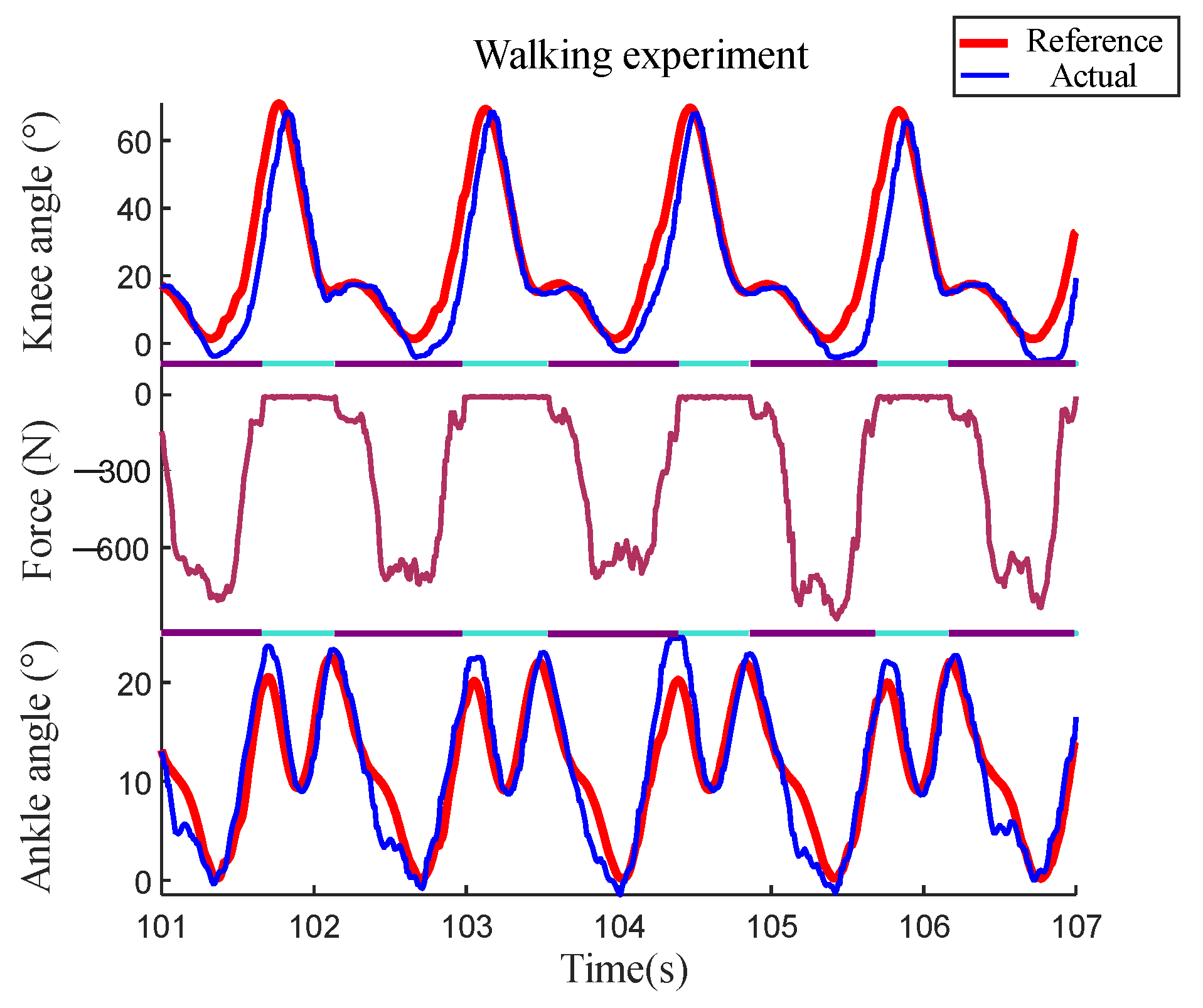

3.4. Walking Experiment

4. Discussion

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Parameters | Value |

|---|---|

| 0 | |

| 0 | |

| 0 | |

References

- Sagawa, Y.; Turcot, K.; Armand, S.; Thevenon, A.; Vuillerme, N.; Watelain, E. Biomechanics and physiological parameters during gait in lower-limb amputees: A systematic review. Gait Posture 2011, 33, 511–526. [Google Scholar] [CrossRef] [PubMed]

- Ettema, S.; Kal, E.; Han, H. Energy cost of walking in people after lower limb amputation: A systematic review and meta-analysis. Gait Posture 2020, 81, 89–90. [Google Scholar] [CrossRef]

- Robert, G.; Kerry, A.; Julie, C.; Jennifer, K.; Mariah, R. Review of secondary physical conditions associated with lower-limb amputation and long-term prosthesis use. J. Rehabil. Res. Dev. 2008, 45, 15–30. [Google Scholar]

- Tucker, M.R.; Olivier, J.; Pagel, A.; Bleuler, H.; Bouri, M.; Lambercy, O.; del R Millán, J.; Riener, R.; Vallery, H.; Gassert, R. Control strategies for active lower extremity prosthetics and orthotics: A review. J. NeuroEngineering Rehabil. 2015, 12, 1. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Pfeifer, S.; Allery, H.; List, R.J.; Perreault, E.J.; Riener, R. Finding Best Predictors for the Control of Transfemoral Prostheses. 2010. Available online: https://www.automed2010.ethz.ch/tagungsband/sitzung5_beitrag4_pfeifer.pdf (accessed on 26 January 2023).

- Wang, W.; Li, J.; Li, W.; Sun, L.N. An Echo-Based Gait Phase Determination Method of Lower Limb Prosthesis. Mechatron. Intell. Mater. III PTS 1-3 2013, 706, 629–634. [Google Scholar] [CrossRef]

- Lyu, Y.; Fang, H.; Xu, J.; Jianmin, M.; Qining, W.; Xiaoxu, Z. Dynamic Modeling and Analysis of the Lower Limb Prosthesis with Four-bar Linkage Prosthetic Knee. Chin. J. Theor. Appl. Mech. 2020, 52, 1157–1173. [Google Scholar]

- Thatte, N.; Geyer, H. Toward Balance Recovery with Leg Prostheses Using Neuromuscular Model Control. IEEE Trans. Biomed. Eng. 2016, 63, 904–913. [Google Scholar] [CrossRef] [PubMed]

- Gregg, R.D.; Sensinger, J.W. Towards Biomimetic Virtual Constraint Control of a Powered Prosthetic Leg. IEEE Trans. Control Syst. Technol. 2014, 22, 246–254. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gregg, R.D.; Lenzi, T.; Hargrove, L.J.; Sensinger, J.W. Virtual Constraint Control of a Powered Prosthetic Leg: From Simulation to Experiments with Transfemoral Amputees. IEEE Trans. Robot. 2014, 30, 1455–1471. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Quintero, D.; Lambert, D.J.; Villarreal, D.J.; Gregg, R.D.; Department of Mechanical Engineering. Real-Time continuous gait phase and speed estimation from a single sensor. In Proceedings of the Conference on Control Technology and Applications (CCTA), Maui, HI, USA, 27–30 August 2017. [Google Scholar]

- Quintero, D.; Villarreal, D.J.; Lambert, D.J.; Kapp, S.; Gregg, R.D. Continuous-Phase Control of a Powered Knee–Ankle Prosthesis: Amputee Experiments Across Speeds and Inclines. IEEE Trans. Robot. 2018, 34, 686–701. [Google Scholar] [CrossRef] [PubMed]

- Shultz, A.H.; Goldfarb, M. A Unified Controller for Walking on Even and Uneven Terrain with a Powered Ankle Prosthesis. IEEE Trans. Neural Syst. Rehabil. Eng. 2018, 26, 788–797. [Google Scholar] [CrossRef] [PubMed]

- Culver, S.; Bartlett, H.; Shultz, A.; Goldfarb, M. A Stair Ascent and Descent Controller for a Powered Ankle Prosthesis. IEEE Trans. Neural Syst. Rehabil. Eng. 2018, 26, 993–1002. [Google Scholar] [CrossRef] [PubMed]

- Ledoux, E.D.; Goldfarb, M. Control and Evaluation of a Powered Transfemoral Prosthesis for Stair Ascent. IEEE Trans. Neural Syst. Rehabil. Eng. 2017, 25, 917–924. [Google Scholar] [CrossRef] [PubMed]

- Wen, Y.; Si, J.; Brandt, A.; Gao, X.; Huang, H.H. Online Reinforcement Learning Control for the Personalization of a Robotic Knee Prosthesis. IEEE Trans. Cybern. 2019, 50, 2346–2356. [Google Scholar] [CrossRef] [PubMed]

- Heins, S.; Tolu, S.; Ronsse, R. Online Learning of the Dynamical Internal Model of Transfemoral Prosthesis for Enhancing Compliance. IEEE Robot. Autom. Lett. 2021, 6, 6156–6163. [Google Scholar] [CrossRef]

- Vijayakumar, S.; D’Souza, A.; Schaal, S. Incremental Online Learning in High Dimensions. Neural Comput. 2005, 17, 2602–2634. [Google Scholar] [CrossRef] [Green Version]

- Camargo, J.; Ramanathan, A.; Flanagan, W.; Young, A. A comprehensive, open-source dataset of lower limb biomechanics in multiple conditions of stairs, ramps, and level-ground ambulation and transitions. J. Biomech. 2021, 119, 110320. [Google Scholar] [CrossRef] [PubMed]

- Camargo, J.; Ramanathan, A.; Csomay-Shanklin, N.; Young, A. Automated gap-filling for marker-based biomechanical motion capture data. Comput. Methods Biomech. Biomed. Eng. 2020, 23, 1180–1189. [Google Scholar] [CrossRef] [PubMed]

- Klanke, S.; Vijayakumar, S.; Schaal, S. A Library for Locally Weighted Projection Regression. J. Mach. Learn. Res. 2008, 9, 623–626. [Google Scholar]

- Alejandro, G.Y.; Francisco, D.F.; Jesus, D.G.; Oscar, L. Effects of Discretization Methods on the Performance of Resonant Controllers. IEEE Trans. Power Electron. 2010, 25, 1692–1712. [Google Scholar]

| Parameters | Value (Knee) | Value (Knee) |

|---|---|---|

| init_D | 50 | 50 |

| w_gen | 0.2 | 0.2 |

| init_alpha | 250 | 150 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, Y.; An, H.; Ma, H.; Wei, Q. An LWPR-Based Method for Intelligent Lower-Limb Prosthesis Control by Learning the Dynamic Model in Real Time. Machines 2023, 11, 186. https://doi.org/10.3390/machines11020186

Liu Y, An H, Ma H, Wei Q. An LWPR-Based Method for Intelligent Lower-Limb Prosthesis Control by Learning the Dynamic Model in Real Time. Machines. 2023; 11(2):186. https://doi.org/10.3390/machines11020186

Chicago/Turabian StyleLiu, Yi, Honglei An, Hongxu Ma, and Qing Wei. 2023. "An LWPR-Based Method for Intelligent Lower-Limb Prosthesis Control by Learning the Dynamic Model in Real Time" Machines 11, no. 2: 186. https://doi.org/10.3390/machines11020186

APA StyleLiu, Y., An, H., Ma, H., & Wei, Q. (2023). An LWPR-Based Method for Intelligent Lower-Limb Prosthesis Control by Learning the Dynamic Model in Real Time. Machines, 11(2), 186. https://doi.org/10.3390/machines11020186