Adaptive Backlash Compensation for CNC Machining Applications

Abstract

:1. Introduction

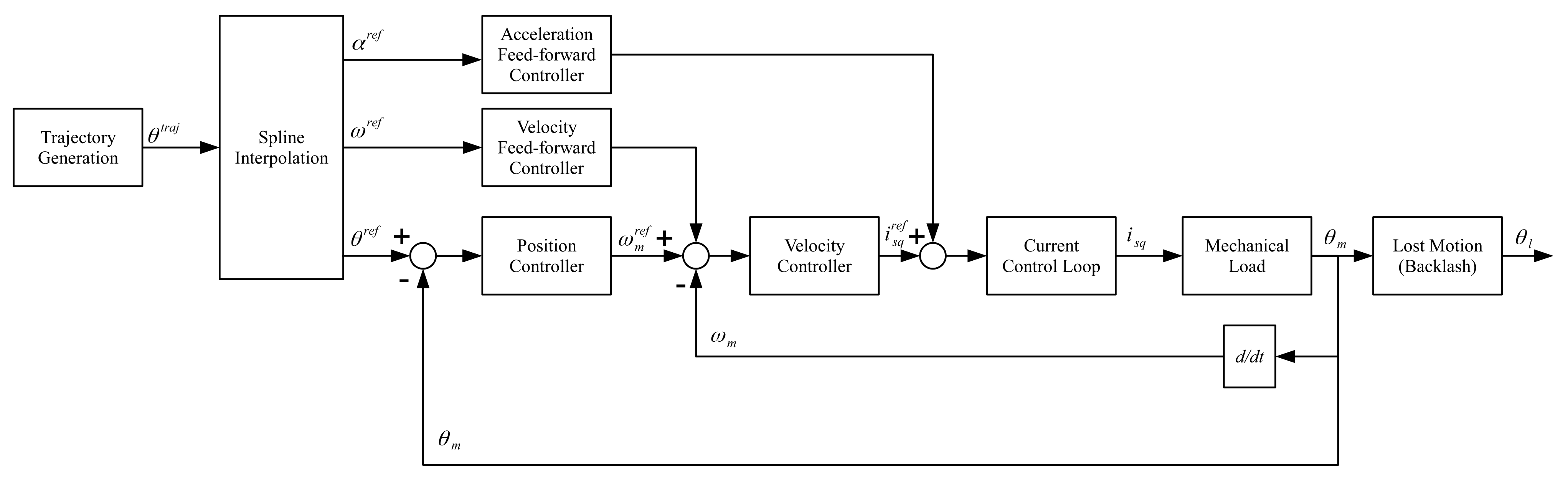

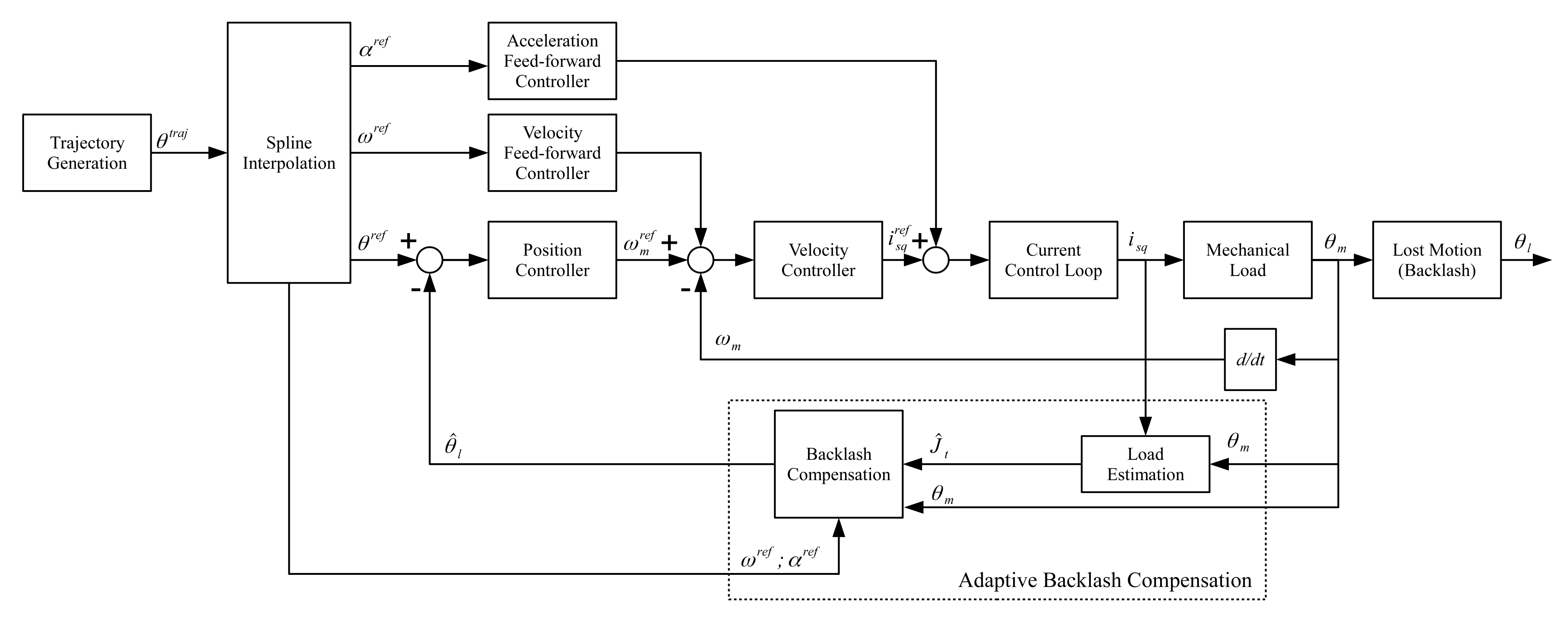

2. System Description

2.1. Overall Description

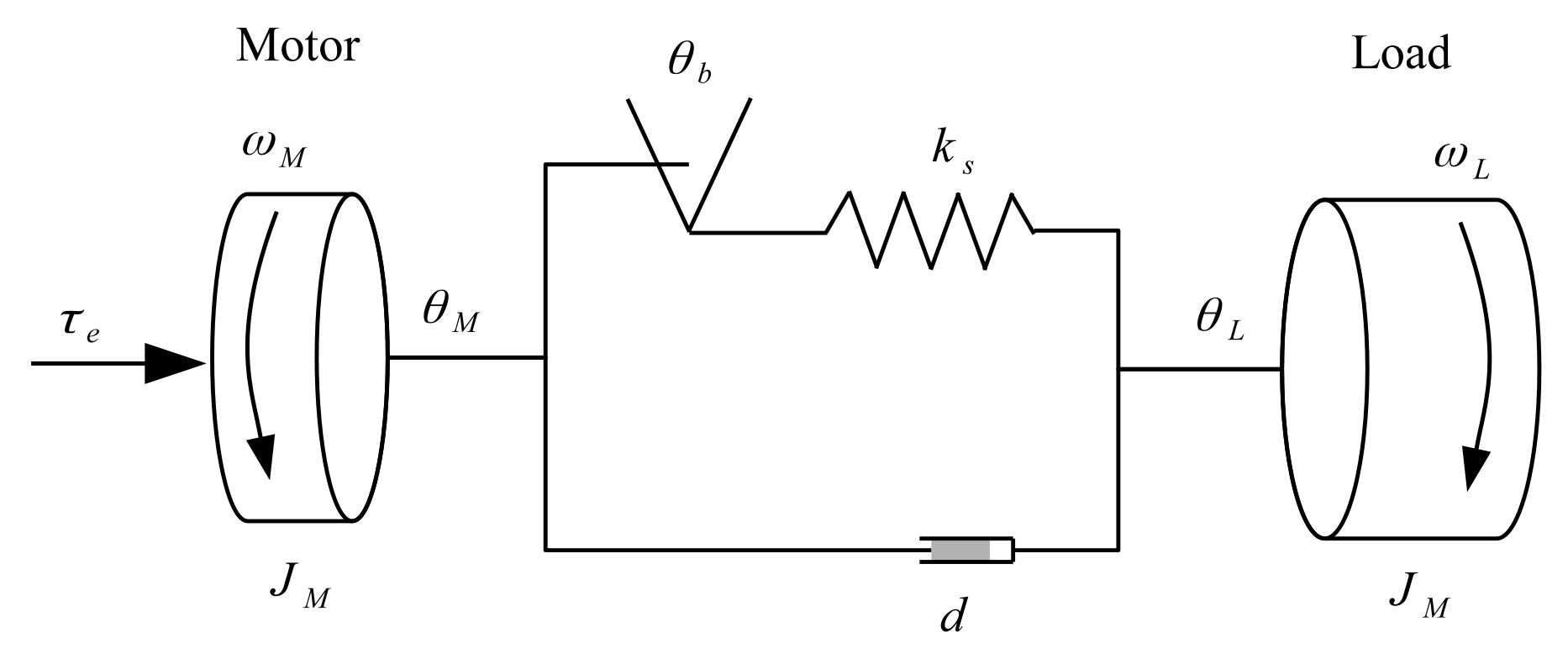

2.2. System Model

3. Proposed Compensation Method

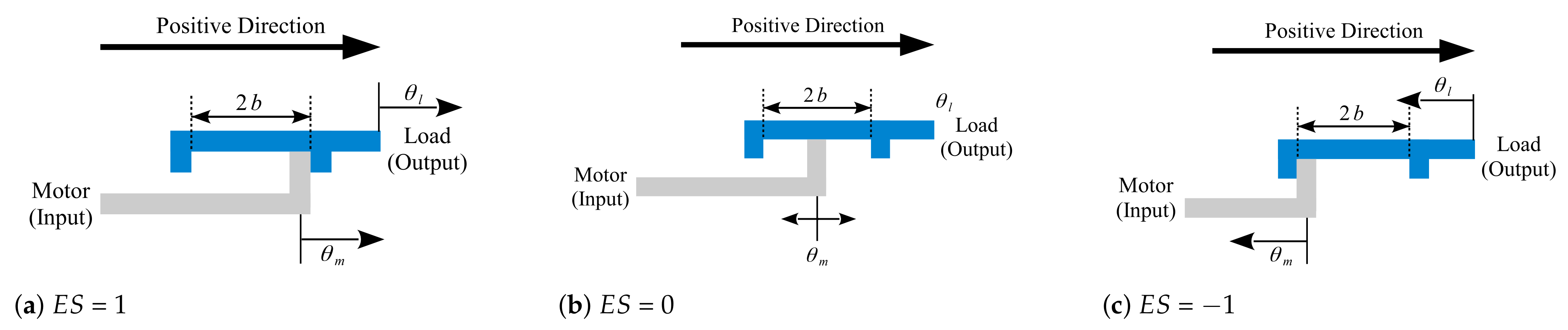

3.1. Mechanical Engagement Status

3.2. Recursive Least Square Regulation Estimation

- At the sampling instant k, we calculate the estimated parameter vector

- We update the covariance matrix usingTo accurately capture the abrupt parameter change, the recursive computation requires continuous excitation; hence, the matrix in the least square algorithm is reset to at the instance when the acceleration reference becomes a nonzero value. As a result, the computation of matrix becomes:where is the initial condition of the P matrix.

3.3. Adaptive Backlash Compensation

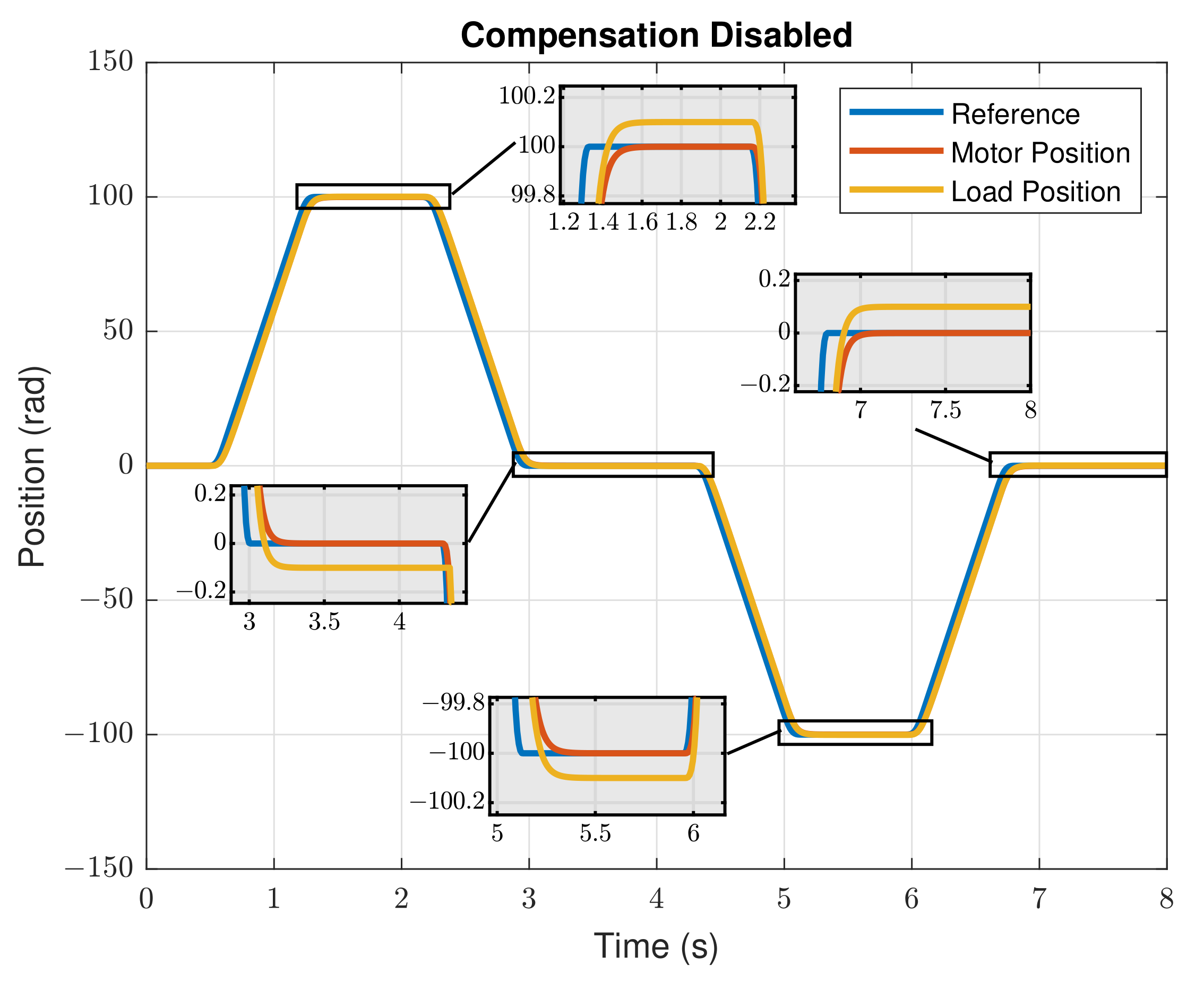

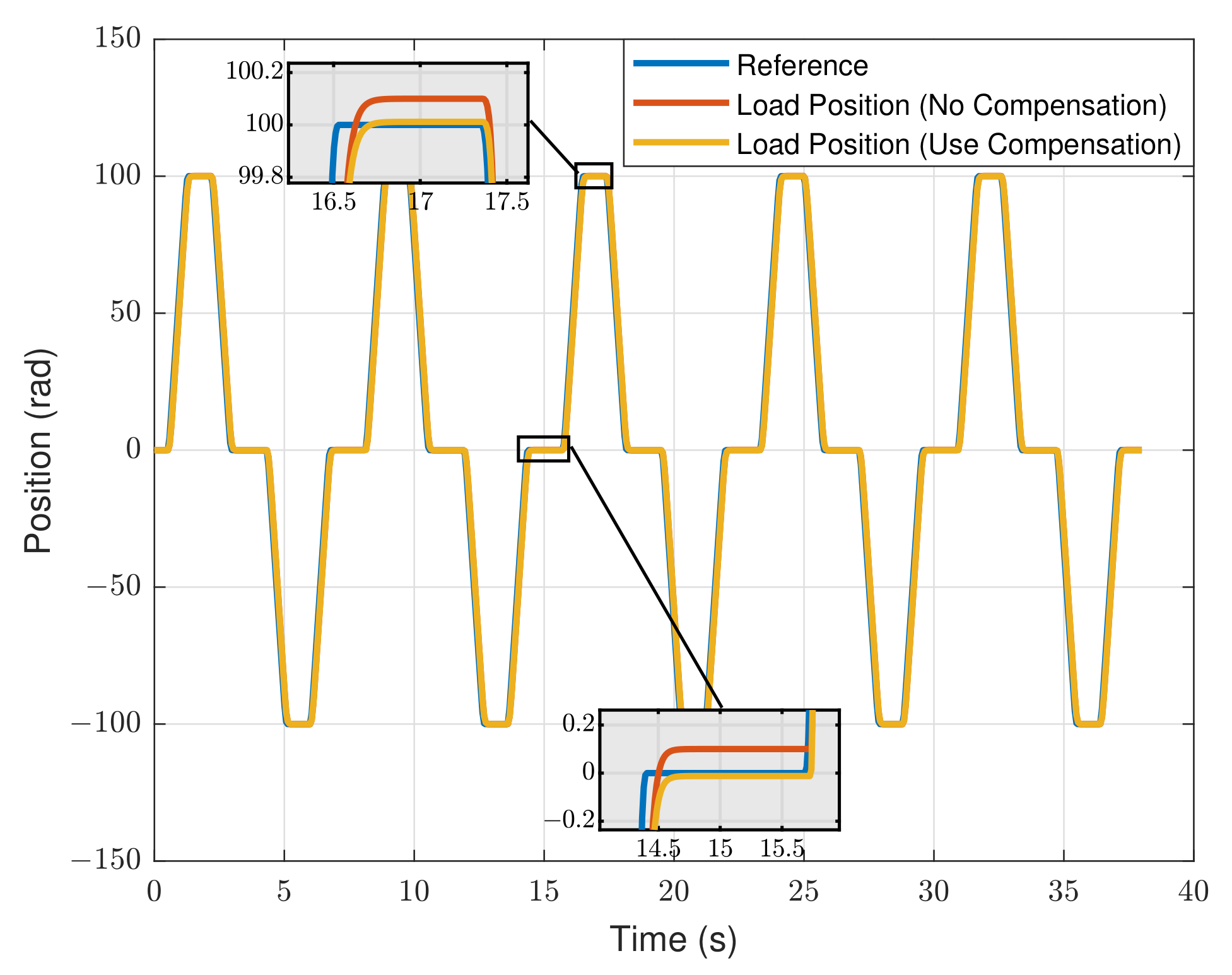

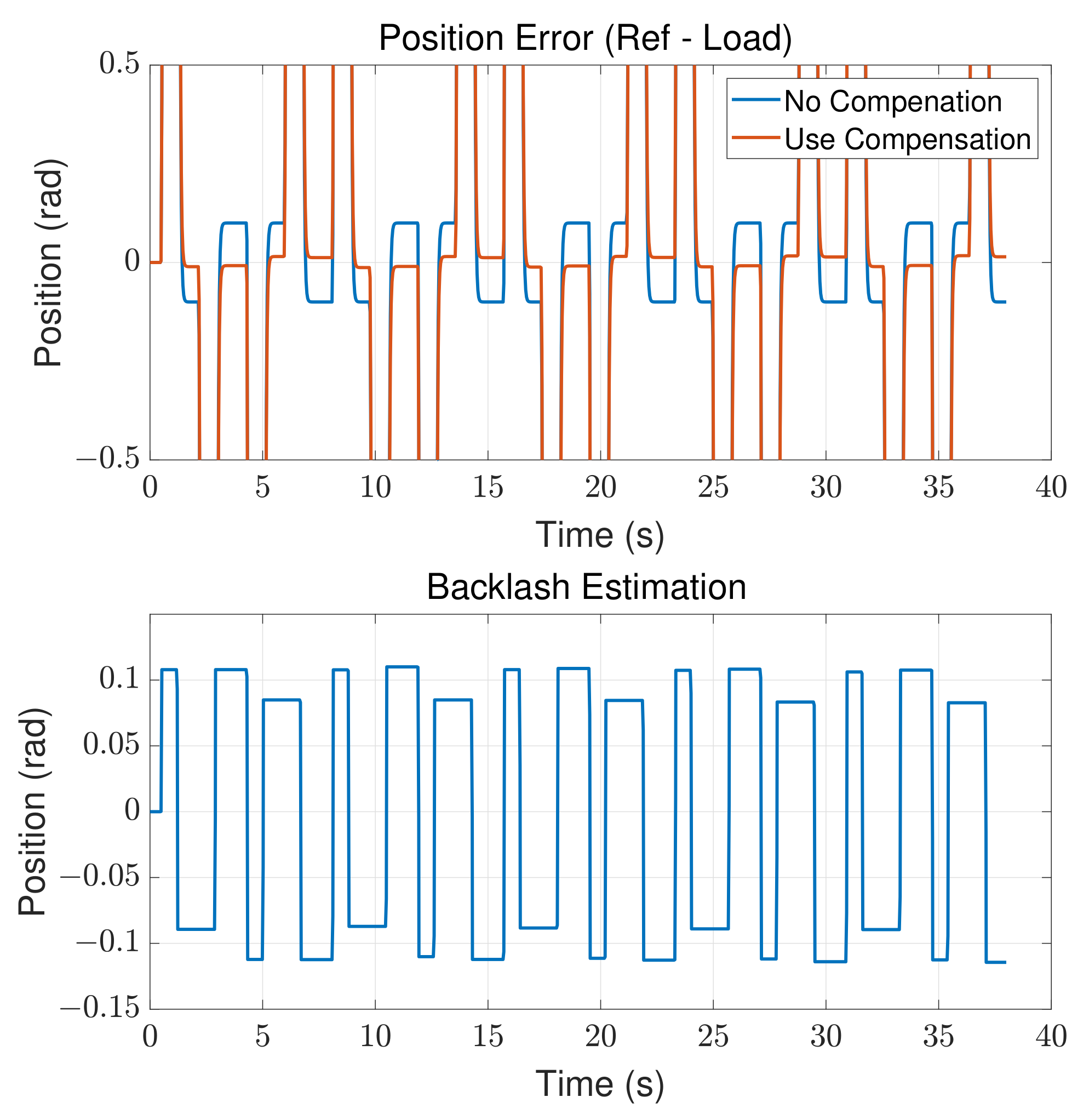

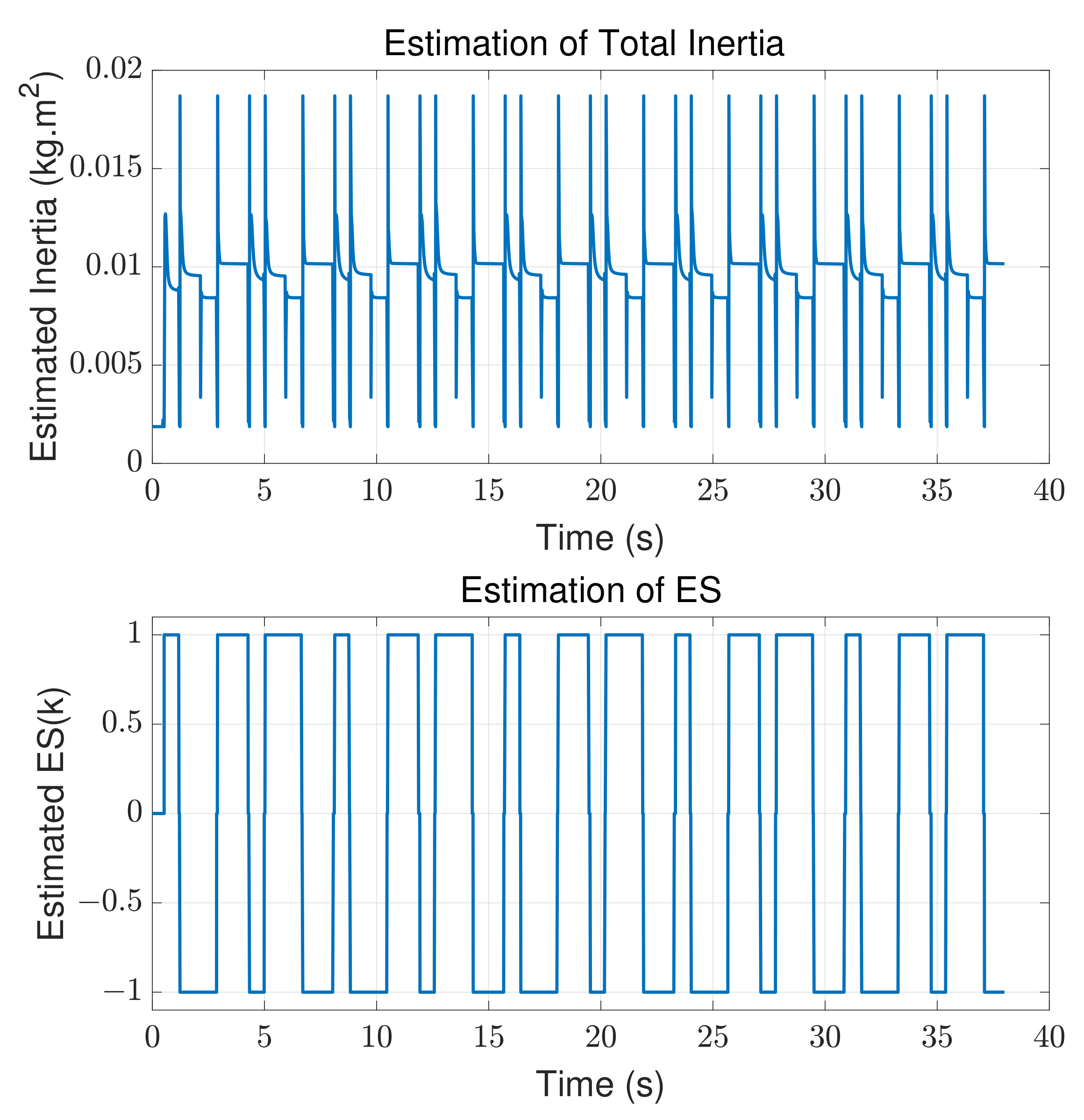

4. Simulation Results

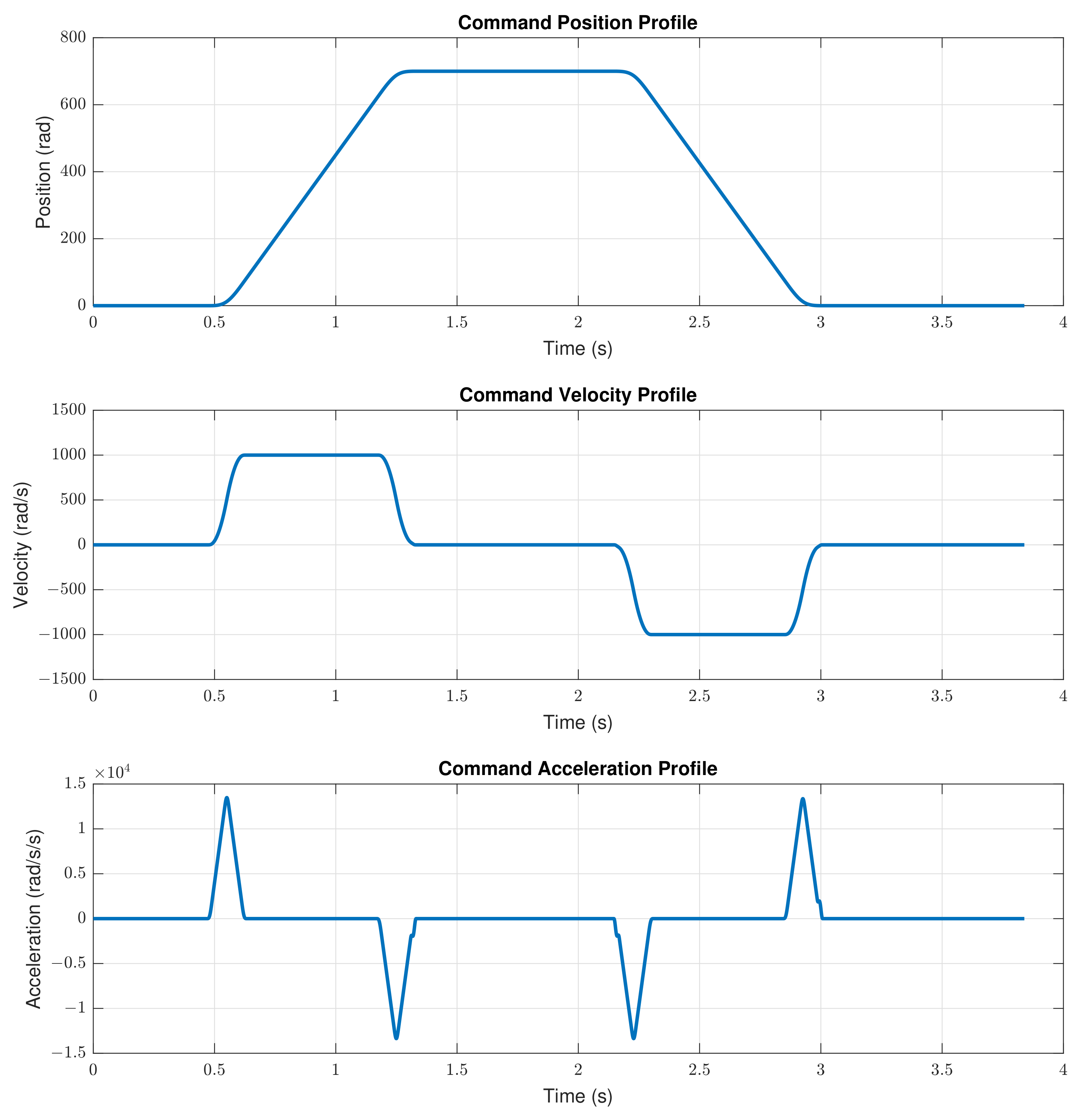

4.1. Simulation Setup

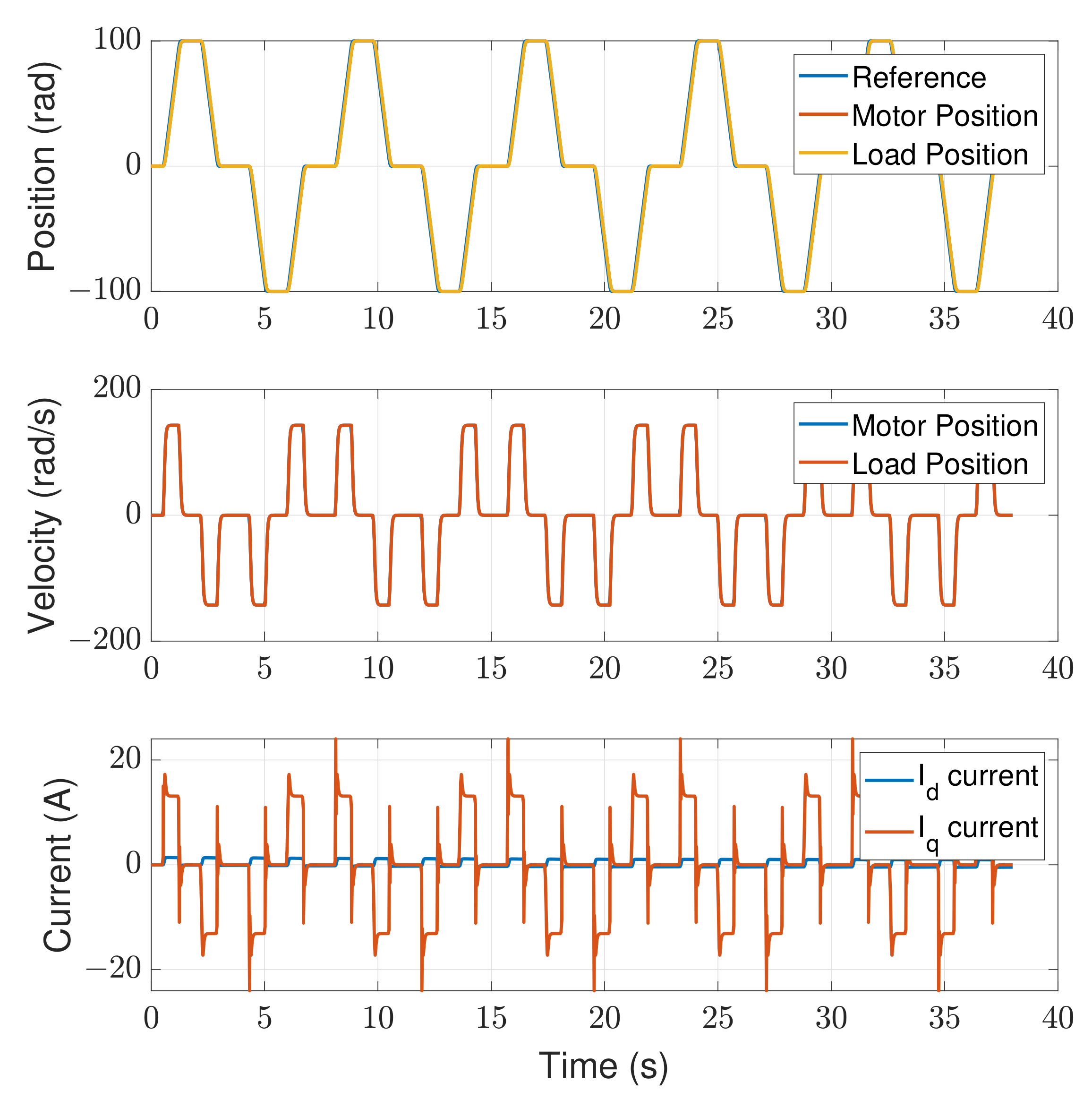

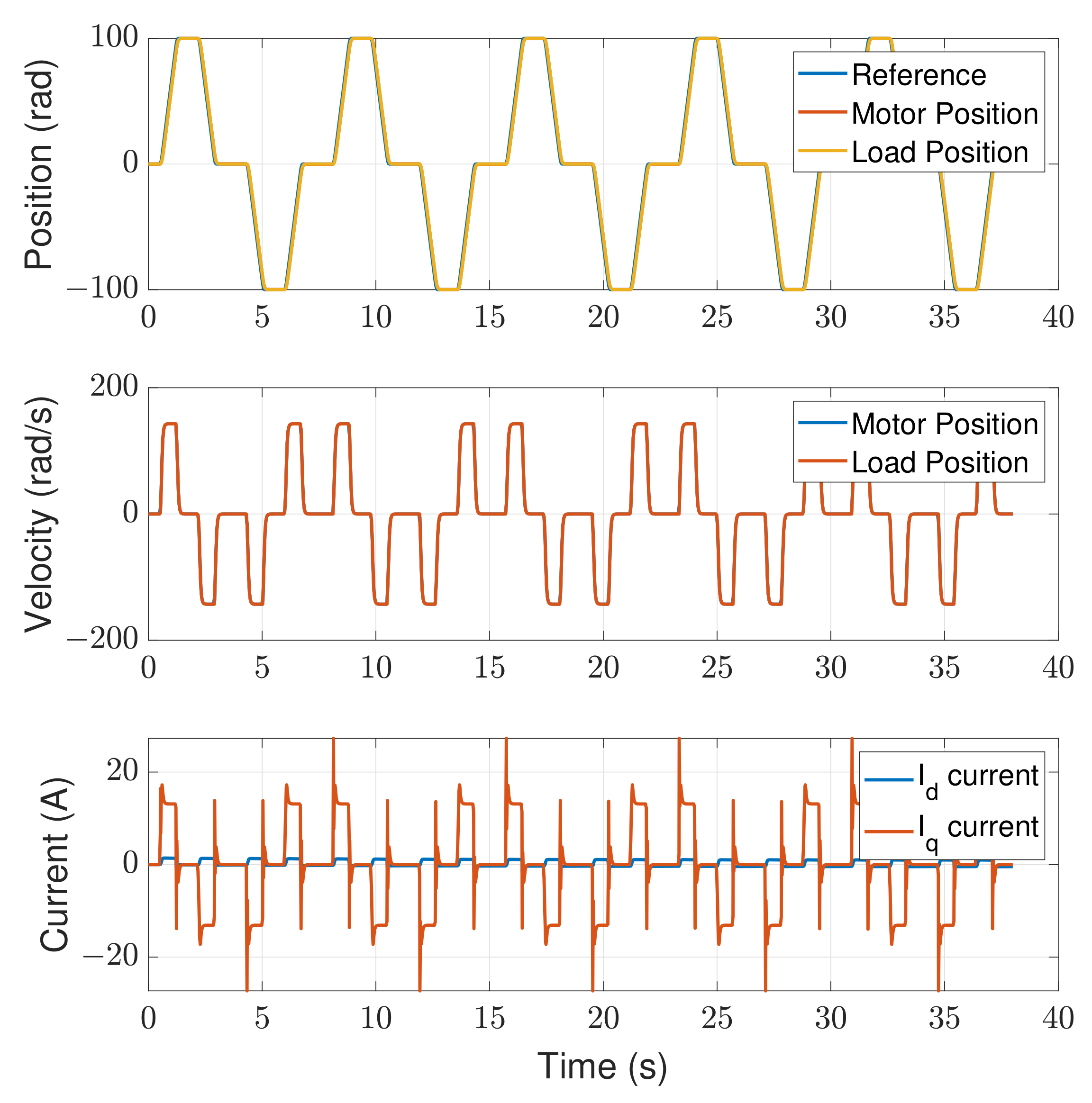

4.2. Result Analysis

5. Conclusions

- The proposed method will be validated with experimental devices. The experiment can start with a test bench of back-to-back motors, which has a coupler connecting the motor shafts with known stiffness and configurable backlash. Then, the experiment can be conducted on a single axis on a CNC machine, where the axis employs a mechanical transmission with a noticeable backlash that influences the contour performance. Finally, the experiment can be extended to the multiaxis contour control performance verification.

- Another extension of this work is to adaptively detect the stiffness and damping factor in the estimation, which will bring more variables into the picture; hence, it would be able to achieve more robust and accurate performance for these applications that require high precision. On the other hand, the real-time estimation of mechanical dynamics can also contribute to the study of deflection and deformation issues.

- Accumulating the knowledge from the works in the previous two points, the outcomes would potentially promote the proposed approach to applications other than CNC machines, such as robot joints.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Yeung, C.H.; Altintas, Y.; Erkorkmaz, K. Virtual CNC system. Part I. System architecture. Int. J. Mach. Tools Manuf. 2006, 46, 1107–1123. [Google Scholar] [CrossRef]

- Altintas, Y. Manufacturing Automation: Metal CuttingMechanics, Machine Tool Vibrations, and CNC Design; Cambridge University Press: Cambridge, UK, 2000. [Google Scholar]

- Heng, M. Smooth and Time-Optimal Trajectory Generation for High Speed Machine Tools. Master’s Thesis, University of Waterloo, Waterloo, ON, Canada, 2008. [Google Scholar]

- Erkorkmaz, K.; Yeung, C.H.; Altintas, Y. Virtual CNC system. Part II. High speed contouring application. Int. J. Mach. Tools Manuf. 2006, 46, 1124–1138. [Google Scholar] [CrossRef]

- Sencer, B. Smooth Trajectory Generation and Precision Control of 5-Axis CNC Machine Tools. Ph.D. Thesis, University of British Columbia, Vancouver, BC, Canada, 2009. [Google Scholar]

- Erkorkmaz, K.; Altintas, Y. High speed CNC system design. Part I: Jerk limited trajectory generation and quintic spline interpolation. Int. J. Mach. Tools Manuf. 2001, 41, 1323–1345. [Google Scholar] [CrossRef]

- Ackermann, J.; Müller, P. Dynamical Behaviour of Nonlinear Multibody Systems Due to Coulomb Friction and Backlash. In Proceedings of the IFAC/IFIP/IMACS Symposium on Theory of Robots, Vienna, Austria, 3–5 December 1986; Volume 19, pp. 193–198. [Google Scholar] [CrossRef]

- Erkorkmaz, K.; Altintas, Y. High speed CNC system design. Part III: High speed tracking and contouring control of feed drives. Int. J. Mach. Tools Manuf. 2001, 41, 1637–1658. [Google Scholar] [CrossRef]

- Kao, J.; Yeh, Z.; Tarng, Y.; Lin, Y. A study of backlash on the motion accuracy of CNC lathes. Int. J. Mach. Tools Manuf. 1996, 36, 539–550. [Google Scholar] [CrossRef]

- Tarng, Y.S.; Kao, J.Y.; Lin, Y.S. Identification of and compensation for backlash on the contouring accuracy of CNC machining centres. Int. J. Adv. Manuf. Technol. 1997, 13, 77–85. [Google Scholar] [CrossRef]

- Jukić, T.; Perić, N. A comparative study of backlash compensation methods. In Proceedings of the 2003 European Control Conference (ECC), Cambridge, UK, 1–4 September 2003; pp. 3261–3266. [Google Scholar] [CrossRef]

- Ravanbod-Shirazi, L.; Besançon-Voda, A. Backlash Identification: A Two Step Approach. In Proceedings of the 15th IFAC World Congress, Barcelona, Spain, 21–26 July 2002; Volume 35, pp. 85–90. [Google Scholar] [CrossRef]

- Moosavian, S.A.A.; MohammadiAsl, E. Backlash Detection in CNC Machines Based on Experimental Vibration Analysis. In Proceedings of the 2008 IEEE Conference on Robotics, Automation and Mechatronics, Chengdu, China, 21–24 September 2008; pp. 393–398. [Google Scholar] [CrossRef]

- Chen, C.; Liu, Z.; Zhang, Y.; Chen, C.L.P.; Xie, S. Actuator Backlash Compensation and Accurate Parameter Estimation for Active Vibration Isolation System. IEEE Trans. Ind. Electron. 2016, 63, 1643–1654. [Google Scholar] [CrossRef]

- Kang, M.J.; Park, J.H.; Kim, J.H.; Huh, U.Y. A disturbance observer design for backlash compensation. Int. J. Control. Autom. Syst. 2011, 9, 742. [Google Scholar] [CrossRef]

- Jung, B.J.; Kong, J.S.; Lee, B.H.; Ahn, S.M.; Kim, J.G. Backlash compensation for a humanoid robot using disturbance observer. In Proceedings of the 30th Annual Conference of IEEE Industrial Electronics Society, 2004. IECON 2004, Busan, Republic of Korea, 2–6 November 2004; Volume 3, pp. 2142–2147. [Google Scholar] [CrossRef]

- Yang, M.; Zheng, W.; Yang, K.; Xu, D. Suppression of mechanical resonance using torque disturbance observer for two-inertia system with backlash. In Proceedings of the 2015 9th International Conference on Power Electronics and ECCE Asia (ICPE-ECCE Asia), Seoul, Republic of Korea, 1–5 June 2015; pp. 1860–1866. [Google Scholar] [CrossRef]

- Zou, S.; Li, G.; Huang, Y. Transmission Backlash Compensation and Grasping Force Estimation of Surgical Instruments for the Laparoscopic Minimally Invasive Surgery Robot. Appl. Sci. 2022, 12, 12126. [Google Scholar] [CrossRef]

- Xu, H.; Li, Y.; Zhang, L. A New Control Method for Backlash Error Elimination of Pneumatic Control Valve. Processes 2021, 9, 1378. [Google Scholar] [CrossRef]

- Li, L.; Lin, Z.; Jiang, Y.; Yu, C.; Yao, J. Valve Deadzone/Backlash Compensation for Lifting Motion Control of Hydraulic Manipulators. Machines 2021, 9, 57. [Google Scholar] [CrossRef]

- Gomez-Acedo, E.; Olarra, A.; Orive, J.; Lopez de la Calle, L.N. Methodology for the design of a thermal distortion compensation for large machine tools based in state-space representation with Kalman filter. Int. J. Mach. Tools Manuf. 2013, 75, 100–108. [Google Scholar] [CrossRef]

- Díaz-Tena, E.; Ugalde, U.; López de Lacalle, L.N.; de la Iglesia, A.; Calleja, A.; Campa, F.J. Propagation of assembly errors in multitasking machines by the homogenous matrix method. Int. J. Adv. Manuf. Technol. 2013, 68, 149–164. [Google Scholar] [CrossRef]

- Salgado, M.; López de Lacalle, L.; Lamikiz, A.; Muñoa, J.; Sánchez, J. Evaluation of the stiffness chain on the deflection of end-mills under cutting forces. Int. J. Mach. Tools Manuf. 2005, 45, 727–739. [Google Scholar] [CrossRef]

- Barreiro, J.; Fernández-Abia, A.; González-Laguna, A.; Pereira, O. TCM system in contour milling of very thick-very large steel plates based on vibration and AE signals. J. Mater. Process. Technol. 2017, 246, 144–157. [Google Scholar] [CrossRef]

| Symbol | Name | SI Unit |

|---|---|---|

| Motor electromagetic torque | Nm | |

| Motor angular velocity | rad/s | |

| Load angular velocity | rad/s | |

| Motor inertia angle | rad | |

| Load inertia angular | rad | |

| Real-time backlash angle | rad | |

| b | Half of total backlash angle | rad |

| Motor inertia | ||

| Load inertia | ||

| Mechanical stiffness | Nm/rad | |

| d | Mechanical damping | Nm/(rad/s) |

| a PMSM Motor Parameters | ||

|---|---|---|

| Motor Parameters | Value | Unit |

| Line to line resistance | ||

| Line to line inductance | H | |

| Number of poles | 10 | |

| Rotor inertia | ||

| Torque constant | Nm | |

| Voltage constant | 296 | V/krpm |

| b Mechanical Load Parameters | ||

| Load Parameters | Value | Unit |

| Load inertia | ||

| Viscous friction coefficient | ||

| Spring damping factor | ||

| Spring stiffness coefficient | 2000 | Nm/rad |

| Gear ratio (In:Out) | 5:1 | |

| Total backlash distance | rad | |

| Controller Parameter | Value |

|---|---|

| Current proportional gain | 15 |

| Current integral time | |

| Velocity proportional gain | |

| Velocity integral time | |

| Position proportional gain | 25 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Gan, L.; Wang, L.; Huang, F. Adaptive Backlash Compensation for CNC Machining Applications. Machines 2023, 11, 193. https://doi.org/10.3390/machines11020193

Gan L, Wang L, Huang F. Adaptive Backlash Compensation for CNC Machining Applications. Machines. 2023; 11(2):193. https://doi.org/10.3390/machines11020193

Chicago/Turabian StyleGan, Lu, Liuping Wang, and Fei Huang. 2023. "Adaptive Backlash Compensation for CNC Machining Applications" Machines 11, no. 2: 193. https://doi.org/10.3390/machines11020193

APA StyleGan, L., Wang, L., & Huang, F. (2023). Adaptive Backlash Compensation for CNC Machining Applications. Machines, 11(2), 193. https://doi.org/10.3390/machines11020193