Dynamics Modeling and Redundant Force Optimization of Modular Combination Parallel Manipulator

Abstract

:1. Introduction

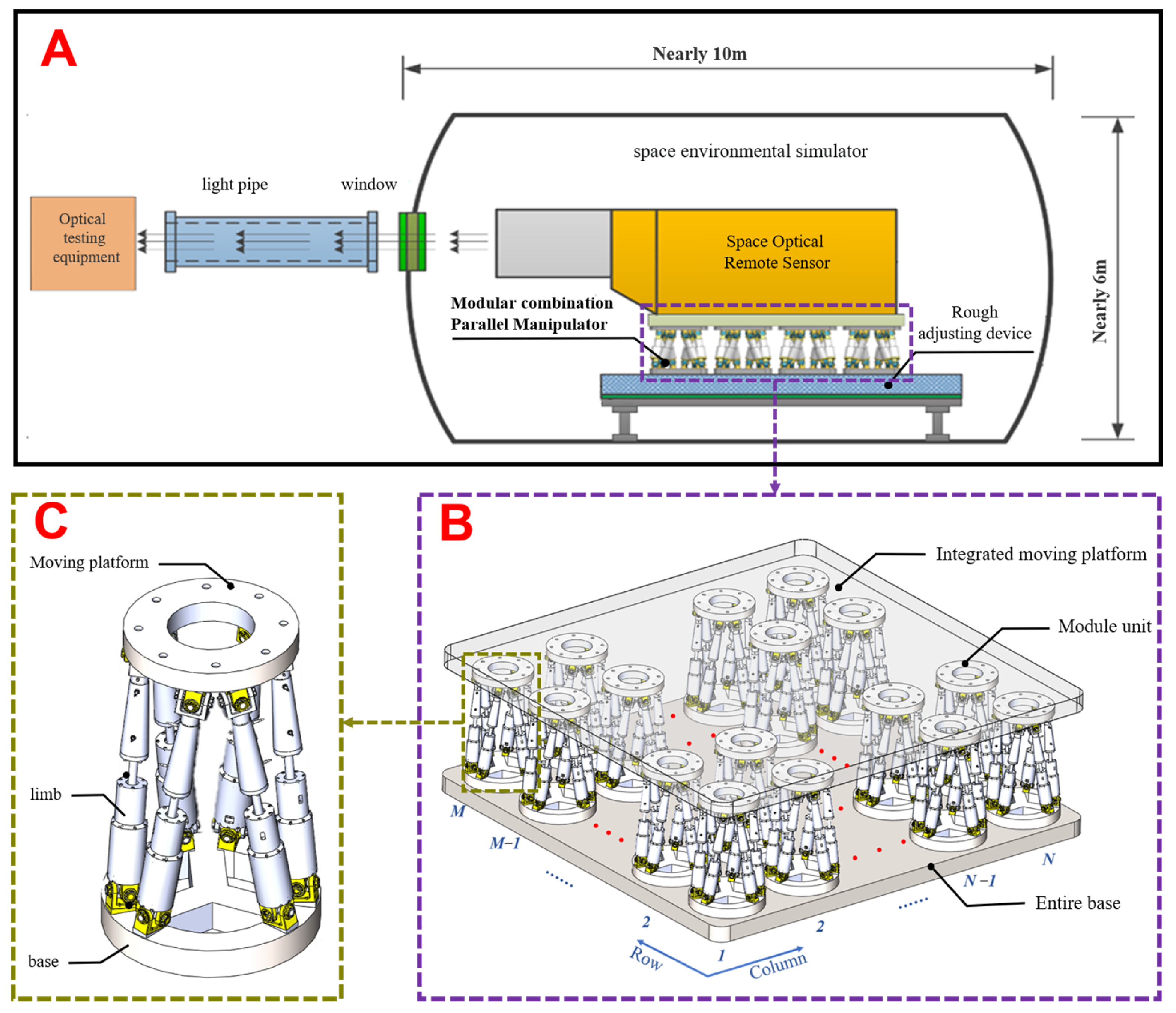

2. Structure Description and Inverse Kinematics

2.1. Structure Description

2.2. Inverse Kinematics

2.2.1. Kinematic Analysis between MCPM and Module Unit

2.2.2. Module Unit Inverse Kinematics

3. Inverse Dynamics

3.1. MCPM Applied and Inertia Force

3.2. Module Unit Applied and Inertia Force

3.3. Dynamics Equation

4. Redundant Driving Force Optimization

4.1. General Solution of Driving Force

4.2. Driving Force Optimization Method

5. Case Study

5.1. Inverse Kinematics and Dynamics Simulation

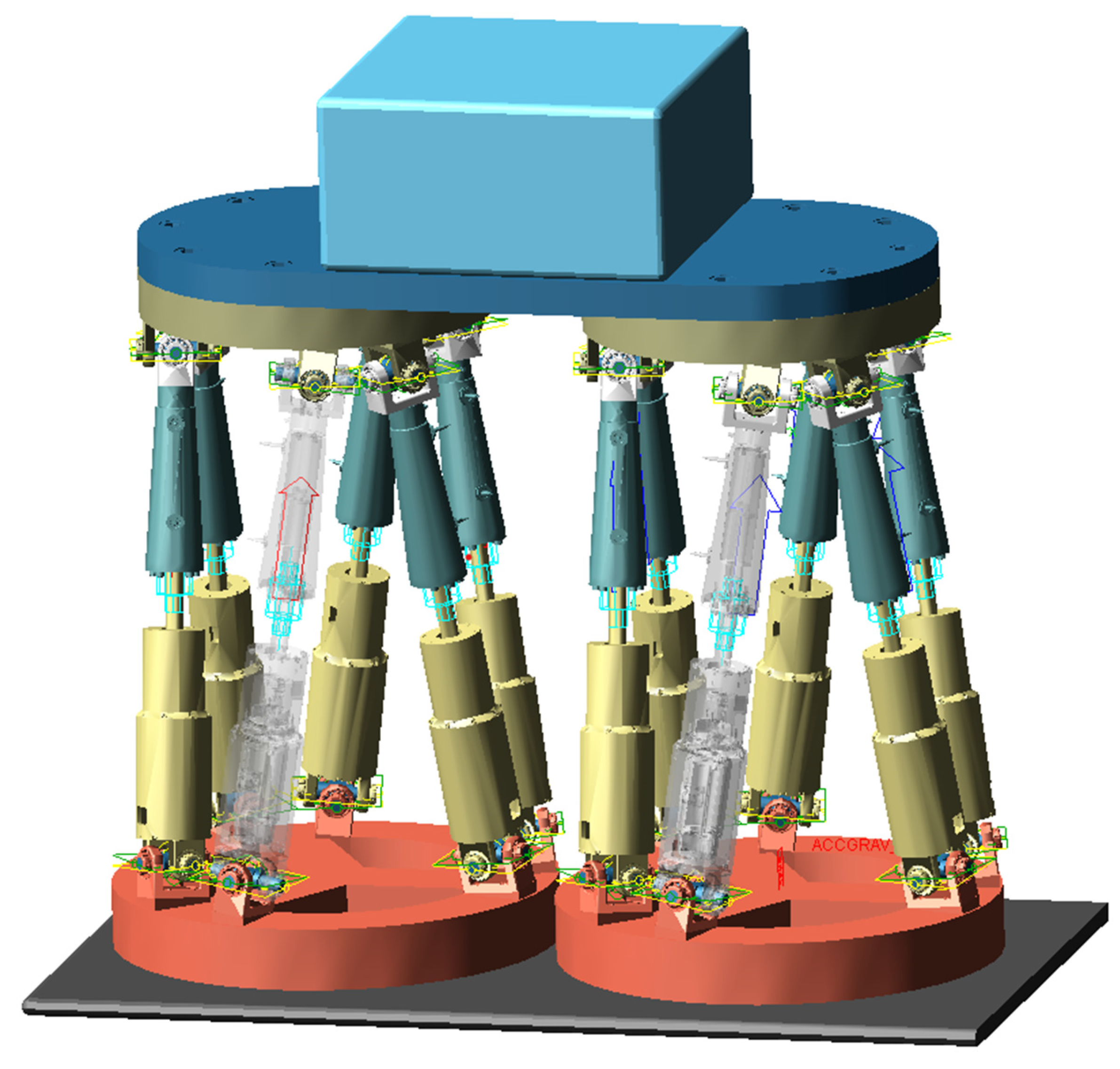

5.1.1. ADAMS Model

5.1.2. Co-Simulation

5.2. Redundant-Force-Optimization Method Simulation

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

References

- Tsai, L.-W. Solving the inverse dynamics of a Stewart-Gough manipulator by the principle of virtual work. J. Mech. Des. 2000, 122, 3–9. [Google Scholar] [CrossRef]

- Yang, C.; Ye, W.; Li, Q. Review of the performance optimization of parallel manipulators. Mech. Mach. Theory 2022, 170, 104725. [Google Scholar] [CrossRef]

- Wang, D.; Wang, L.; Wu, J. Physics-based mechatronics modeling and application of an industrial-grade parallel tool head. Mech. Syst. Signal Process. 2021, 148, 107158. [Google Scholar] [CrossRef]

- Bourbonnais, F.; Bigras, P. Minimum-time trajectory planning and control of a pick-and-place five-bar parallel robot. IEEE/ASME Trans. Mechatron. 2014, 20, 740–749. [Google Scholar] [CrossRef]

- Arrouk, K.A.; Bouzgarrou, B.C.; Gogu, G. CAD Based Techniques for Workspace Analysis and Representation of the 3CRS Parallel Manipulator. In Proceedings of the 19th International Workshop on Robotics in Alpe-Adria-Danube Region (RAAD 2010), Budapest, Hungary, 24–26 June 2010; pp. 155–160. [Google Scholar] [CrossRef]

- Tang, T.; Zhang, J. Conceptual design and kinetostatic analysis of a modular parallel kinematic machine-based hybrid machine tool for large aeronautic components. Robot. Comput. -Integr. Manuf. 2019, 57, 1–16. [Google Scholar] [CrossRef]

- Zhang, J.; Liu, C.; Liu, T.; Qi, K.; Niu, J.; Guo, S. Module combination based configuration synthesis and kinematic analysis of generalized spherical parallel mechanism for ankle rehabilitation. Mech. Mach. Theory 2021, 166, 104436. [Google Scholar] [CrossRef]

- Hao, G.; Kong, X. Design and Modeling of a Large-Range Modular XYZ Compliant Parallel Manipulator Using Identical Spatial Modules. J. Mech. Robot. 2012, 4, 021009. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; Wang, L. A comparison study of two planar 2-DOF parallel mechanisms: One with 2-RRR and the other with 3-RRR structures. Robotica 2010, 28, 937–942. [Google Scholar] [CrossRef]

- Qing, J.; Li, J.; Fang, B. Drive optimization of Tricept parallel mechanism with redundant actuation. J. Mech. Eng. 2010, 46, 8–14. [Google Scholar] [CrossRef]

- Yao, J.; Gu, W.; Feng, Z.; Chen, L.; Xu, Y.; Zhao, Y. Dynamic analysis and driving force optimization of a 5-DOF parallel manipulator with redundant actuation. Robot. Comput. -Integr. Manuf. 2017, 48, 51–58. [Google Scholar] [CrossRef]

- Zhao, Y.; Gao, F. Dynamic performance comparison of the 8PSS redundant parallel manipulator and its non-redundant counterpart—The 6PSS parallel manipulator. Mech. Mach. Theory 2009, 44, 991–1008. [Google Scholar] [CrossRef]

- Yan, P.; Huang, H.; Li, B.; Zhou, D. A 5-DOF redundantly actuated parallel mechanism for large tilting five-face machining. Mech. Mach. Theory 2022, 172, 104785. [Google Scholar] [CrossRef]

- Xu, Y.; Yao, J.; Zhao, Y. Inverse dynamics and internal forces of the redundantly actuated parallel manipulators. Mech. Mach. Theory 2012, 51, 172–184. [Google Scholar] [CrossRef]

- Xie, S.; Hu, K.; Liu, H.; Wan, Y. Dynamic modeling and performance analysis of a new redundant parallel rehabilitation robot. IEEE Access 2020, 8, 222211–222225. [Google Scholar] [CrossRef]

- Lee, G.; Sul, S.-K.; Kim, J. Energy-saving method of parallel mechanism by redundant actuation. Int. J. Precis. Eng. Manuf. -Green Technol. 2015, 2, 345–351. [Google Scholar] [CrossRef]

- Jiang, Y.; Li, T.-M.; Wang, L.-P. Dynamic modeling and redundant force optimization of a 2-DOF parallel kinematic machine with kinematic redundancy. Robot. Comput. -Integr. Manuf. 2015, 32, 1–10. [Google Scholar] [CrossRef]

- Hino, T.; Kawanishi, M.; Kanki, H.; Narikiyo, T. Control of parallel mechanism with redundant actuators and non-redundant actuators. In Proceedings of the ICMIT 2007: Mechatronics, MEMS, and Smart Materials, Gifu, Japan, 9 January 2008; pp. 639–644. [Google Scholar] [CrossRef]

- Wu, J.; Qiu, J.; Ye, H. Torque optimization method of a 3-DOF redundant parallel manipulator based on actuator torque range. J. Mech. Robot. 2022, 15, 021005. [Google Scholar] [CrossRef]

- Liu, W.; Xu, Y.; Yao, J.; Zhao, Y. The weighted Moore–Penrose generalized inverse and the force analysis of overconstrained parallel mechanisms. Multibody Syst. Dyn. 2016, 39, 363–383. [Google Scholar] [CrossRef]

- Notash, L. On the minimum 2-Norm positive tension for wire-actuated parallel manipulators. In Computational Kinematics; Springer: Berlin/Heidelberg, Germany, 2014; pp. 1–9. [Google Scholar]

- Ding, J.; Liu, X.; Wang, C. Repeatability Analysis of an Overconstrained Kinematic Coupling Using a Parallel- Mechanism-Equivalent Model. IEEE Access 2021, 9, 82455–82461. [Google Scholar] [CrossRef]

- Niu, X.-M.; Gao, G.-Q.; Liu, X.-J.; Bao, Z.-D. Dynamics and control of a novel 3-DOF parallel manipulator with actuation redundancy. Int. J. Autom. Comput. 2013, 10, 552–562. [Google Scholar] [CrossRef]

- Wu, J.; Wang, J.; Wang, L.; Li, T. Dynamics and control of a planar 3-DOF parallel manipulator with actuation redundancy. Mech. Mach. Theory 2009, 44, 835–849. [Google Scholar] [CrossRef]

- Gosselin, C.; Grenier, M. On the determination of the force distribution inoverconstrained cable-driven parallel mechanisms. Meccanica 2011, 46, 3–15. [Google Scholar] [CrossRef]

- Hassan, M.; Khajepour, A. Minimum-Norm Solution for the Actuator Forces in Cable-Based Parallel Manipulators Based on Convex Optimization. In Proceedings of the 2007 IEEE International Conference on Robotics and Automation, Rome, Italy, 10–14 April 2007; pp. 1498–1503. [Google Scholar] [CrossRef]

- Kucuk, S. Energy minimization for 3-RRR fully planar parallel manipulator using particle swarm optimization. Mech. Mach. Theory 2013, 62, 129–149. [Google Scholar] [CrossRef]

- Pasand, A.M.; Naderi, D. Energy optimization of a planar parallel manipulator with kinematically redundant degrees of freedom. In Proceedings of the 2013 First RSI/ISM International Conference on Robotics and Mechatronics (ICRoM), Tehran, Iran, 13–15 February 2013; pp. 362–367. [Google Scholar] [CrossRef]

- Wang, W.; Tang, X.; Shao, Z. Study on energy consumption and cable force optimization of cable-driven parallel mechanism in automated storage/retrieval system. In Proceedings of the 2015 Second International Conference on Soft Computing and Machine Intelligence (ISCMI), Hong Kong, China, 23–24 November 2015; pp. 144–150. [Google Scholar] [CrossRef]

- Wu, J.; Li, T.; Xu, B. Force optimization of planar 2-DOF parallel manipulators with actuation redundancy considering deformation. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 2013, 227, 1371–1377. [Google Scholar] [CrossRef]

- Zhang, L.; Jiang, Y.; Li, T. An articular force optimization method of parallel manipulator with actuation redundancy. In Proceedings of the 2014 International Conference on Mechanical Engineering, Automation and Control Systems (MEACS), Tomsk, Russia, 16–18 October 2014; pp. 1–6. [Google Scholar] [CrossRef]

- Kotlarski, J.; Abdellatif, H.; Heimann, B. Improving the pose accuracy of a planar 3RRR parallel manipulator using kinematic redundancy and optimized switching patterns. In Proceedings of the 2008 IEEE international conference on robotics and automation, Pasadena, CA, USA, 19–23 May 2008; pp. 3863–3868. [Google Scholar] [CrossRef]

- Kotlarski, J.; Do Thanh, T.; Heimann, B.; Ortmaier, T. Optimization strategies for additional actuators of kinematically redundant parallel kinematic machines. In Proceedings of the 2010 IEEE International Conference on Robotics and Automation, Anchorage, AK, USA, 3–7 May 2010; pp. 656–661. [Google Scholar] [CrossRef]

- Zhao, Y. Dynamic optimum design of a 3U P S-P RU parallel robot. Int. J. Adv. Robot. Syst. 2016, 13, 1–13. [Google Scholar] [CrossRef]

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| (−0.1488, −0.1416, 0.1) m | (−0.1530, 0.04837, 0.6651) m | ||

| (−0.04818, −0.1997, 0.1) m | (0.3463, −0.1567, 0.6651) m | ||

| (0.1970, −0.05810, 0.1) m | (0.1184, −0.1084, 0.6651) m | ||

| (0.1961, 0.05810, 0.1) m | (0.1184, 0.1084, 0.6651) m | ||

| (−0.04818, 0.1997, 0.1) m | (0.03463, 0.1567, 0.6651) m | ||

| (−0.1488, 0.1416, 0.1) m | (−0.1530, 0.04837, 0.6651) m | ||

| (0, 0, 0.7288) m | 30.68 kg | ||

| 0.1495 m | 3.089 kg | ||

| 0.1221 m | 1.825 kg | ||

| kg·m2 | kg·m2 | ||

| kg·m2 |

| Parameters | Value | Parameters | Value |

|---|---|---|---|

| 1000 kg | 103.5 kg | ||

| (0, 0, 0.9776) m | (0, 0, 0.7776) m | ||

| (0, 0, −10) N/kg | kg·m2 | ||

| 0.51 m | 0.51 m | ||

| kg·m2 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jiang, A.; Han, H.; Han, C.; He, S.; Xu, Z.; Wu, Q. Dynamics Modeling and Redundant Force Optimization of Modular Combination Parallel Manipulator. Machines 2023, 11, 247. https://doi.org/10.3390/machines11020247

Jiang A, Han H, Han C, He S, Xu Z, Wu Q. Dynamics Modeling and Redundant Force Optimization of Modular Combination Parallel Manipulator. Machines. 2023; 11(2):247. https://doi.org/10.3390/machines11020247

Chicago/Turabian StyleJiang, Aimin, Hasiaoqier Han, Chunyang Han, Shuai He, Zhenbang Xu, and Qingwen Wu. 2023. "Dynamics Modeling and Redundant Force Optimization of Modular Combination Parallel Manipulator" Machines 11, no. 2: 247. https://doi.org/10.3390/machines11020247