1. Introduction

In recent years, there has been an exponential increase in agricultural automation due to advanced robotic technology [

1]. The automation of agricultural processes is vital for improving work efficiency, and results in higher yield with less labor [

2]. Many studies have been carried out by agricultural countries such as the United States, European Union, Australia, India, and others to develop more rational and adaptable autonomous vehicles to carry out agricultural operations effectively [

3]. The robotic vehicles so far developed in the world are primarily used for land preparation, harvesting, picking fruits, and crop monitoring [

4]. However, one of the emerging areas in agriculture is the automation in weed control.

Some of the prominent and conventional weed-killing techniques include flame, mechanical and chemical weeding [

5]. Chemical-based weed control is being widely adopted, among others. In this technique, chemicals are sprayed uniformly throughout the field, which has increased health risks, causing negative effects on humans, plants, soils and aquifers. Moreover, it makes the weed species immune to the herbicidal impact [

6]. Additionally, a large quantity of herbicides is wasted because weeds cover less area compared to the actual crop [

3].

Mechanical weed-killing methods are also unreliable due to damage caused by the equipment itself while moving across the field, compared to the in situ field condition. On the other hand, heavy weeding equipment has been reported to cause yield losses ranging from 11% to 14% [

7]. Manual weed control methods are the most reliable, but they require a lot of time and money [

8]. Furthermore, the manual weeding method requires constant human bending and, at times, exposure to infectious weed species [

9]. Manual methods are obsolete in developed countries due to health hazards [

2]. This situation demands for a cost-effective autonomous system that is less human intensive, chemical free, light-weight and effective in weed control [

10].

Weedbots are now in the spotlight, as precision agriculture has gained prominence with the use of robotic systems and electronic devices [

11]. Lately, researchers have begun to take a keen interest in developing a successful robot that precisely kills weeds. The robot would detect and kill weeds on the seed line between the crop plants (intra-row). It is currently a huge challenge, as it causes damage to the actual plant because weeds are grown alongside the crops [

12]. The robotic weed-killing mechanism should be precise and ensure the safety of the surroundings, i.e., ensure that the soil, crop and overall ecological environment are not affected during the weeding process. It should be able to work in a highly dynamic environment and must have the least possible impact while maximising efficiency [

13].

Several mechanical systems for intra-row weed control have been developed and modified without damaging the actual crop [

14]. Spring time harrows, finger, torsion, brush, and rotary weeders are examples of weeding machines. However, these methods require specialized protection to avoid any damages to the crop [

15]. For the development of a robust weed-killing system, researchers are primarily focused on crop-row detection, precise weeding and vehicle navigation using vision sensors [

12]. The autonomous navigation system is separated into three parts: image segmentation of crop-row, drive-able area extraction, and robot motion control. The image segmentation of the crop-row is where the crops and weeds are separated from the background (i.e., water, soil and stones) [

16]. The extraction of guidance lines generates a reference that allows the robot to follow the crop-row without damaging it. Thus, extraction of guidance lines is an important factor in allowing the robot to complete its job of precise weed control. Some of the existing solutions are discussed as following.

EcoRobotix is a solar powered, self-programmed robot weighing 130 kg [

17]. It detects weeds from the rows by using cameras and sensors mounted on it. According to the EcoRobotix team, it uses 20 times less herbicide than is typically used in standard treatments. It can be controlled and configured by a smartphone to operate on three hectares of land per day. It hosts two 15-litre herbicide containers, enough to carry out a day operation. However, the use of herbicides results in air pollution, which is preserved in about two hours after treatment [

17]. This makes the use of the EcoRobotix machine environmentally challenging.

Blue River Technology has created a robot for smart farming called the see and spray robot. The robot works on cotton farms for real-time weed detection using computer vision and artificial intelligence. It is attached to the tractor, which transports it throughout the field. This has obvious advantages over a smaller robot like the EcoRobotix, but it also has a few drawbacks. With the ability to spray a much larger area at once and without having to carry the sprayer to the weeds, it can operate faster. However, because a tractor is still needed to tow the sea spray robot, soil compaction is an issue. It is a step in the right direction, but it definitely does not solve all the problems associated with weeding.

The Variable Rate Application (VAR) flame weeding robot was designed by the University of Pisa [

18]. The machine used a mechanically installed flaming gun to selectively remove weeds. Flame weeding is carried out using prismatic burners that are fuelled by liquified petroleum gas and can treat soil surfaces up to 25 cm wide. The VAR machine was specifically designed to weed the maize crop, because of the relatively higher flaming impact on all other types of crops [

18]. This significantly affects the scope of this machine, while the flaming mechanism also damages the field fertility. Flame weeding is cheaper and fast compared to hand weeding. However, it is expensive compared to spraying or laser weeding [

19].

Rakmatulin et al. in 2020 developed a cheap laser-based prototype for the weeding. The testing of the weeding device was carried out on Elytrigia Repens (Couch Grass) intermixed with tomatoes [

20]. To carry out the investigation, three types of lasers were used—0.3 W, 1 W, and 5 W. The system was developed by training the neural network for the identification of the weed plants with the estimated coordinates through the laser guidance system. For the estimation of the energy required to kill a weed plant, an algorithm was developed based on the diameter and length of the plant. The decision model was also developed for device control. Through testing, it has been found that the 1W laser requires ample time to eliminate the weed plant, and hence the energy is not sufficient. Whereas, the laser considered that was 5 W was over-efficient because of the likelihood to be split up into two beams and, hence, resulting in crop damage. The challenges of exposure time minimization can be accommodated through the Gimbal Laser, which is the system based on the “2 degrees of freedom” with the “5 revolute rotational parallel manipulator” for the performance of the intra-row weeding operation [

21].

Pakistan is among the developing countries, where farmers can not afford expensive robots for weeding. Therefore, a laser-based low-cost solution is proposed in this study with the goal of simplifying the conventional weed control processes. The machine proposed in this study presents a laser based weed control robot. It is designed as a lightweight solution to minimize the soil compaction, whereas the use of the laser makes it highly precise, avoiding any impact on the field. It uses cameras and sensors to detect and remove weeds. Unlike the machines mentioned above, the robot has no impact on the field or environment but is relatively slow in speed. The weeding robot is currently powered by batteries, which are required to be charged before the weeding job. However, the inclusion of solar panels to charge the batteries will notably reduce the weeding time of the robot.

2. Materials and Methods

The design and development of the weeding robot includes the Computer-Aided Design (CAD) model and mechanical structure fabrication, along with the Robot Operating System (ROS) communication through distributed electronics. CAD is used to create a 3D model of the robot. Moreover, the ROS is made to communicate with the four-limbs via the decentralised electronic setup of the vehicle. Afterwards, the robot is tested for system accuracy with the following parameters in observation—power consumption and pulse width modulation (PWM). This is conducted in varied operating conditions with preliminary field evaluations at the agro living lab (ALL). ALL is a project initiated by the smart city lab that aims to facilitate research in real-time experimental setups. According to the field trials, the robot takes almost 34 h to weed a one acre (4046 m) plot at a linear velocity of 0.07 m/s, including the robot battery charging time of approximately 12 h. The primitive weeding methods, on the other hand, are extremely labor intensive, expensive and not environmental friendly. Based on the data presented here, the proposed system could be an excellent initiative, enabling higher food security and labor wages, as well as environmental sustainability. This section discusses the complete process of the robot development and is further divided in four subsections. The first two subsections discuss the key elements and features of the mechanical design and fabrication challenges; the third subsection explains the laser-based weeding mechanism; the fourth and final section sheds light on the electronics and communication setup.

2.1. Computer-Aided Mechanical Design

The Computer-Aided Design (CAD) basically refers to the use of computer systems to assist in developing, modifying and optimizing specialized engineering design functions. The latest CAD design is based on Integrated Computer Graphics (ICG) [

22]. It provides the basis for the assessment, visualization, and analysis of the design before practical implementation to avoid the iterative revision. Thus, CAD has played a crucial part in the development of multifaceted hardware. A top-down approach has been pursued to develop a framework for an actionable conclusion on the hardware design. The mechanical design of the robot was started by designing the metallic chassis. The chassis is designed to be 1.524 m in length, width and height. The frame design assembly consists of 12 parts in total: which includes 4 limbs for wheel mounting, 4 square cylinders to connect the limbs with the upper frame, 4 corners to house electronics and steering motors and 4 square cylinders to connect all the corners. The vehicle is made of square cylinders to ensure the efficient use of material, and it also makes the frame design very simple to assemble. The use of cheap material along with a very basic design of the decentralized limb assemblies make the vehicle chassis cost effective and easily replicable. After completing the chassis design and fabrication, other parts, including the chain sprocket, motor, wheel, etc., were incorporated onto the designed chassis. The mechanical model is designed such that it is capable of smooth travel across the rough agricultural fields. The square at the top of each limb signifies the electronic nodes and motor designated for the steering of the robot. The placement of these junctions is crucial, as they are responsible for the overall motion of the body, as shown in

Figure 1. Keeping in mind the application of the robot, the processed metal is considered to be the appropriate material for the construction of the robot, as it facilitates robustness to the weeding vehicle.

The model architecture is assembled in a manner that can be disassembled very easily. The robot is comprised of four limbs; each limb is the assembly of the brushed Direct Current (DC) motor and the wheel. It is further aided with a chain sprocket kit to provide effective mechanical commutation. This eventually makes the robot travel seamlessly. Moreover, a customized shock absorber (hydraulic device) is also designed to resolve the issue of maneuvering on the natural topography (relatively uneven agricultural fields). This device helps in controlling unwanted motion because of the spring-mounted vehicle. Additionally, an encoder disc is designed to measure the position of the wheel. The encoder disc is typically a circular disc with evenly spaced marking or lines on it, as shown in

Figure 2. These lines are also called the resolution; higher resolution encoder discs will have more lines, allowing for more accurate position measurement. As the disc rotates, the encoder sensor reads these markings to determine the position and/or speed of the rotation. In our case, we could not find the disc with requisite dimensions in our surroundings; hence, we designed and 3d-printed it. The encoder disc is 3d-printed in Acrylonitrile Butadiene Styrene (ABS) material to be robust and durable to withstand the rigors of continuous rotation and the environment in which it is used.

After design finalization, the system is introduced with its translational and rotational joints to carry out motion control commands. While generating a Unified Robotics Description Format (URDF), the definition of the robotics’ joints is required, as well as their axis of rotation through an extensible markup language (XML) specification and on Solidworks. There are two joints hoarded in each limb to ensure the effective translation of the vehicle. For all joints, the defined axis of rotation is the y-axis. This is because the drawing originates from the xz-plane.

2.2. Hardware Fabrication and Assembly

The choice of material has a vital importance when the hardware fabrication and assembly specifications are concerned [

23]. As discussed in earlier sections, processed metal is used for the fabrication of the vehicle. An assembly model requires the precise cutting of the metal so that all the parts are designed to integrate with the chassis fit-in with the least human effort. In line with this, purchased metal sheets are machined using a computer numeric control (CNC) machine. The slashed sheets are later welded and subsequently assembled to make a vehicle-like structure, as shown in

Figure 1.

For making a sophisticated robotic structure, chain sprockets and shock absorbers are integrated into the chassis. The chain sprocket is a very important element of our weeding vehicle, as it allows the chain to transmit power directly from the motor to the wheel, with the minimal loss of energy resulting in a very efficient drive system. Chain sprockets are gears with teeth that are used to drive a chain. They are typically made from steel or aluminum and can be found in vehicles with chain-driven systems. The number of teeth on the sprocket can affect the speed and torque of the drive system. The chain and sprockets are designed to withstand the rigors of continuous use and can last for many hours of operation, making them ideal for our application, where the weeding will continue for hours on rough agricultural fields. Another key component of a vehicle is the shock absorber, a hydraulic device to ensure a smooth and safe travel on rough fields. A shock absorber is used to dampen the movement of the wheel, and is typically made from metal. It contains a piston and fluid or gas that is used to dissipate the energy of the movement. As shown in

Figure 1, it is integrated into the chassis by attaching it to the frame and the wheels and is designed to withstand the forces of movement, while still providing a smooth ride. With its ability to dampen the movement of the wheels, it brings efficient handling and stability to the vehicle. It also contributes towards increasing the lifespan of a vehicle by reducing the stress applied on the vehicle equipment while moving on rough terrains.

The choice of wheel is made considering the problem of soil compaction. This is because soil compaction has a negative impact, as it lessens the air and water margin required to penetrate through the plant root. It also implicates an adverse effect on the aggregate structure, soil quality and crop production. These considerations help choose a wheel design with a minimal soil compaction on the crop field [

24]. Different studies have demonstrated that the tread pattern, wheel diameter and width are the important factors that require attention to avoid soil compaction and surface disturbances. For the appropriate selection of the wheel, the first step is to calculate the circumference (2

r or

d). In the current situation, the wheel diameter is 18 inches, based on which the circumference (distance traveled by the wheel in one rotation) is computed to be 56.54 inches. Therefore, a beach buggy wheel is used to entail the minimal impact on the compaction of the soil.

2.3. Laser-Based Weed Removal System

A very important part of the weeding robot is its weed-killing mechanism. The laser beam is identified to be the most efficient weed control method when compared to other applications because of its high accuracy and fewer environmental challenges. For an effective laser weeding operation, it is very necessary to determine the appropriate laser power for each crop type. Inappropriate laser power can cause a delay in the growth of the crop plant because it raises the temperature of the water in the plant cell. Therefore, a laser treatment mechanism was devised during the study to incorporate an effective weeding operation and minimize the impact on the crop plant.

The mechanical assembly consists of two aluminium rails, as shown in

Figure 3, with each attached to a stepper motor. These two rails are responsible for the positioning of the laser head. Hence, the laser is able to target weed plants in the proximity of 1 feet

. The stepper motors are controlled using an A4988 motor driving module for a far more accurate control of motors. The laser used in the aforementioned system is the same as that of the Laser Engraving Machine (VG-L7); it is designed for engraving and cutting purposes. The reason for using this laser type is its adjustable laser power, which helps in the engraving of different materials and hence different crops. The process of weed killing is similar to that of engraving, as it simply burns the targeted portion.

In the proposed weeding robot, a 20 watt laser is used to eliminate the weed plants. This highly precise weeding mechanism with the laser accuracy of 0.05 mm and focus distance of about 8 cm ensures that no useful crop plant is damaged in the close proximity of weed, which is the case with other weeding techniques. The laser module has a built-in interface for Arduino boards, that is why it did not require a separate controlling unit and was easily interfaced with a customized Arduino Uno board. However, the weeding system was first tested using its dedicated Computer Numeric Control software, known as VigoEngraverL. In order to automate the laser module, an instruction list from the software is extracted first, and later converted into an Arduino script.

2.4. Electronics and Communication Setup

Electronic and communication setup basically provides any robot or system with a network to operate effectively. This section only demonstrates the testing configuration of communication and electronics. However, ROS control is deployed by creating publisher and subscriber nodes. These nodes represent executable program files for the master and slave, respectively [

25]. The publisher nodes corresponding to the Raspberry Pi-master were programmed through python, whereas the subscriber nodes’ instruction file came through the arduino IDE. As shown in

Figure 4, there are two ways to control the vehicle, one of them is using a remote control, while the other is the laptop interface. The remote-based control of the vehicle is completely manual, allowing the pilot full control over the weeding pattern and the process speed, whereas the laptop-based control of the vehicle is semi-autonomous. In the case of laptop interface, the vehicle weeding pattern is defined, which is to treat each furrow line individually and subsequently move towards other furrows. However, this is not completely autonomous, as the speed of the vehicle is controlled manually and the laptop interface also allows a complete manual control when needed. The laptop interface is the default operating mode in which the vehicle is operating at any given time; however, the remote control mode is enabled by wiring up a transceiver with the Raspberry Pi master board.

In the communication setup, there is an RS485 protocol using MAX485 IC. It is a duplex communication system enabling the reception and transmission of data from both ends of a communication system at the same time [

26]. Four slave boards are connected with the master board via MAX485. The purpose of this IC was to translate Universal Asynchronous Receiver-Transmitter (UART) signals to the RS485 and vice versa. The overall setup consists of one master and four slaves, each slave controlling one limb through a signal from the Raspberry Pi master. The slave and master-printed circuit boards (PCBs) are customized circuit boards with everything on a single application-specific board, as shown in

Figure 5. The slave board is controlled via Arduino Uno, whereas a Raspberry Pi-3 commands the master board.

To make the system reliable in terms of computing, Raspberry Pi-3 is used as the master controlling unit. This is because it is a complete computer system, including a microprocessor, memory, wireless radios, and ports onto a single circuit board. Another key segment of the electronics setup is the power distribution system. The current measurements of the motor with load installed and without load are 50 and 18 watts, respectively [

27]. A 12 V lead acid dry battery is used with a max power capacity of 144 watts, although two batteries would have been enough to power all eight motors. However, each limb is powered using a dedicated battery, because the motors will require more power to travel across the rough agricultural fields.

The Robot Operating System (ROS)—an open-source and meta-operating system, is used to develop the Robot Communication Framework. It provides tools and libraries that give full access to write, build and run codes to other multiple computers [

28]. Meanwhile, most agricultural robots use the Controller Area Network (CAN) bus for communication between embedded devices because of its low cost, flexibility and built-in error detection system [

9]. It is not implemented in the proposed robot because of some major drawbacks, such as the limited number of nodes, as well as having a high cost for software development and maintenance [

29]. A robot with a computer brain needs many software tools, such as software drivers, simulation tools and third-party tools. ROS brings all these tools together and allows for the customized management of the code [

30]. In order to manually control the vehicle, ESP8266, a Wi-Fi microcontroller, is used as a wireless access point. It creates a dedicated local network to communicate remote commands for the manual control of the robot [

31].

The velocity commands are delivered to the base-link coordinate frame to control the velocity of the vehicle. In response to these commands, the robot is oriented in the coordinate frame with respect to the base-link. This makes the y-axis and z-axis of the base frame point in upward and forward directions, respectively. This eventually results in the robot translating in the x-z plane and steering around the y-axis. In order to translate the vehicle, the steering angles and wheel velocity are required to be in sync, such that all wheels point in the same direction. Any change in the steering angle would result in the robot going off the track. However, to steer the robot for inter-row travel, the center of the arc that results in the rotation of the limb is calculated; thus, wheel speeds and steering angles are adjusted accordingly.

The steering commands are passed through each slave, directing the respective spinning joints for intra-row translation. The motor installed in the steering box is electrically limited to 180 degrees for the safe operation of the steering mechanism in place. The steering system allows for the quick and safe rotation in the drive module, because we do not want to turn it any faster than necessary. A smooth operation is likely, with an offset in the desired steering angle of 180 degrees and reversing the wheel speed command. However, there is no limit applied on the drive module motors.

The robot velocity is estimated using odometry values. Each motor is equipped with encoders to the wheel speeds and position. The robot configuration file contains information about the motor positions in the base-link frame. Wheels are paired randomly to calculate the point of intersection between the lines normal to each wheel in the ground plane, which is conducted for a number of iterations. The average intersection point provides a reasonable estimate of the center of the arc, along which the robot is driving. It is combined with the wheels’ speed to estimate the robot’s movement. The wheel slip varies depending on the ground surface and the tires may have slightly different diameters or be inflated to slightly different pressures. As a result, the encoder-based odometry is insufficient for tracking the robot’s absolute position anywhere around us. Therefore, an additional Inertial Measurement Unit (IMU) is employed on each slave and master board. Its measurements will be used for robot mapping and localization. However, encoder-based odometry is still very useful, for example, it can be used as an input for SLAM algorithms or for keeping track of the robot between low-frequency GPS measurements. Therefore, it is critical that the robot is capable of providing accurate velocity estimates based on the encoder feedback [

32].

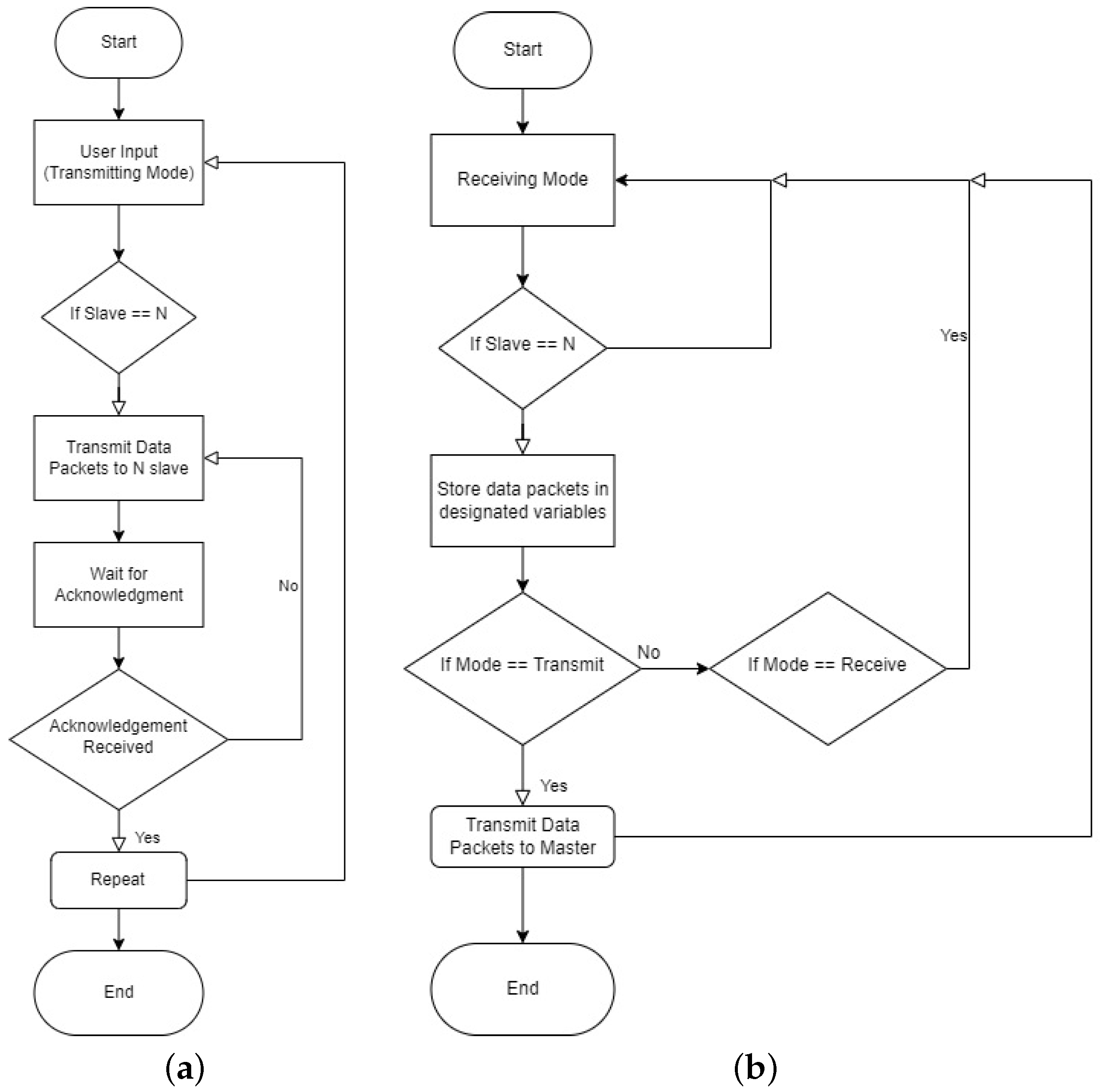

As shown in

Figure 6a, the robot is controlled through input from the user. The input was received using the ESP32 Wi-Fi microcontroller, which in our application is configured as a wireless access point. The slaves have to establish a connection with ESP32, and once the connection is established, the master shall wait for the input from the user. The user input comes through either a wireless remote or a laptop PC. When the master receives the input from user, it checks for the available slaves connected with the ESP32 wireless access point. The master then sends data packets to connected slaves and waits for acknowledgement from the slave. The master keeps transmitting data packets repeatedly, unless it receives acknowledgment in a defined waiting time. When an acknowledgment is received, it repeats this process and waits for user input again until the system is powered up.

The slave, on the other end, is in the receiving mode when powered up, as shown in

Figure 6b. Whenever a data packet is received, it checks whether the data are designated to itself or another slave. If the data are for some other slave, it discards the data and goes back to the receiving mode. However, when an N slave receives data designated to itself, it writes the received data on defined variables. These variables then control hardware output and read input through hardware pins. After storing data into variables, it checks for the communication mode. In the transmit mode, it sends an acknowledgment to the master and waits for further input in the receiving mode.

3. Theory/Calculation

In this section, the computation of the total time required by the robot to complete one acre of the area has been presented. In order to gather and interpret the field observations, the whole process is divided into four steps. During the testing of the robot, the data that have been collected helped in determining the hardware and software efficiency of the weeding vehicle.

Farmed land, also part of the agro living lab, a smart city lab venture in Gadap Town of Karachi city, was used to practically examine the weeding robot. One acre of land is considered as the study area, and was cultivated with the Okra crop. The method of irrigation, which has already been presented as the area of interest, is the furrow. The area is in the rectangular shape with a dimension of 201 × 20 m. Furthermore, the velocity of the robot is kept to remain constant during the testing phase and is 0.07 m/s. The cross-sectional view of the area is provided in

Figure 7. The considerations, which were made to carry out the testing of the robot, are presented in

Table 1.

In the first step, the linear velocity is calculated from the angular velocity; for that, Equation (

1) was used. The relationship of the linear velocity that was used is based on basic physics [

16]. Linear velocity is therefore computed using Equation (

1), and is 0.07 m/s.

In the second step, the time required to reach weed Plant 1 from weed Plant 2 was computed through the derived expression of Equation (

2). Here, the considered spacing between the weed plants is 1.7 m. Therefore, the time to maneuver in-between the furrows is computed as 24.2 s.

In the third step, the Equation (

3) is derived for the calculation of the time required by the robot to kill the weed on both sides of the furrow. Based on the derived equation, the time to kill the weeds on both sides of a furrow was computed to be 0.18 h.

In the last step, the total time required to kill the weeds from one acre was computed in Equation (

4), which is the product of the time required to kill weeds in one furrow on both sides and the number of furrows in one acre of the farm field. The computed result shows the total weeding time of 23.7 h for the considered area, which has 132 furrows in total.

V = velocity in m/s

r = radius of the wheel of the Robot

= Angular velocity in rotations/min or sec;

where, = Spacing between each weed plant in m;

V = Constant velocity of the robot in m/s;

T = time required to move between the weed plants.

where,

t = Time required in sec to kill weed on both sides of a furrow;

= First weed plant killing time in sec;

n = Number of sides in a furrow;

= Number of weed plants per side of the furrow;

T = time required to move between the weed plants;

= Time for killing weed plant.

= Time required to kill weed from one acre;

= Number of Furrows along length;

t = Time required to kill weed on both sides of a furrow.

After designing the field as per the global standards shown in

Figure 7, the robot size has been finalized, which is able to cover a furrow channel effectively. As shown in

Figure 8, the furrow irrigation is a primitive method of irrigation that is the water running down small trenches in an agricultural field. The model width was determined by adding the width of a furrow and a ridge. This was conducted to make sure that each plant is treated. However, as discussed and illustrated in

Section 2.1, the design is adjustable. Therefore, this calculation was set as the default size of the robot with one feet of adjustment. Thus, the robot is able to extend and shrink by 1 foot; in length, width and height.

6. Conclusions

The study is undertaken to design and develop a weed control robot in order to provide a cost effective solution that is compatible with the local field conditions. This work is the first attempt to provide a weeding vehicle in Pakistan that is cost effective and supersedes labor. The vehicle was tested on a rectangular-shaped field area of 201 × 20 m in Gadap Town (a locality in Karachi), which is approximately 4046 m. The aforementioned farmland is furrow-irrigated with 132 furrows in total and is a part of an agro living lab (an agriculture field dedicated for experimenting with organic and smart farming methods).

The field testing and computed results conclude that the time required for the weeding process is 35.7 h for the 4046 m plot area, which includes 5 s to kill a weed plant through the laser and battery charging time of 12 h. However, some unavoidable natural factors, such as climate, weed type and relatively rough farmland surfaces slightly affect the weeding time. The weeding vehicle has customized features such as: it is adjustable with respect to the field furrow, can be controlled via a remote or online server, and uses a precised laser killing mechanism with an adjustable laser power for the effective weeding of different crop types.

There are a few laser-based weeding machines already commercialized, which are being used in the market. Some of these robots are heavy, resulting in soil compaction that eventually affects land fertility, and some are designed to weed only a particular crop; meanwhile, others are very costly to purchase or be rented by common farmers [

33,

34]. This study proposes a weeding machine that is cost-effective, light in weight and easy to replicate for research groups in different parts of the world.