Effects of Mainstream Velocity and Turbulence Intensity on the Sweeping Jet and Film Composite Cooling

Abstract

:1. Introduction

2. Computational Method

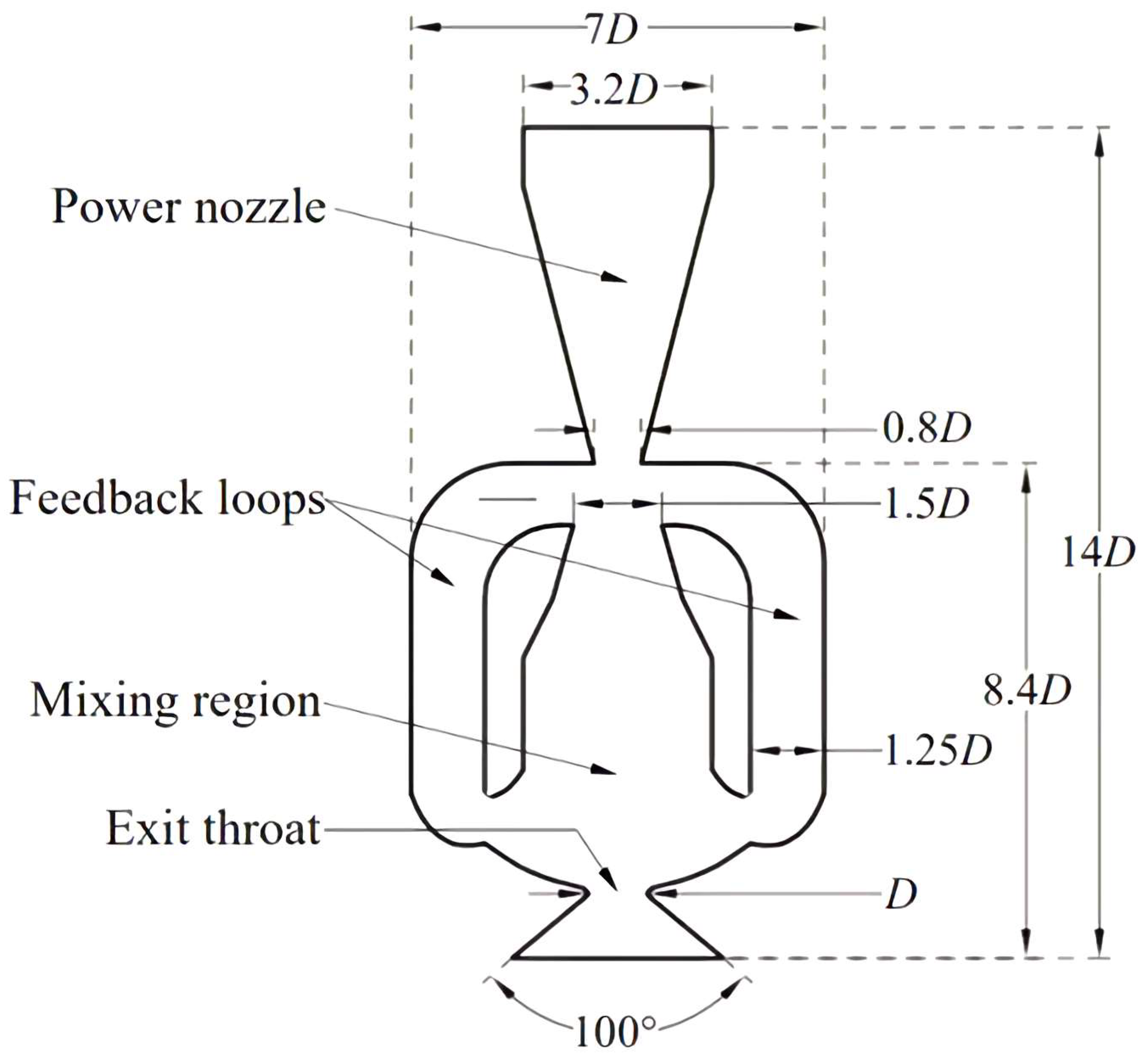

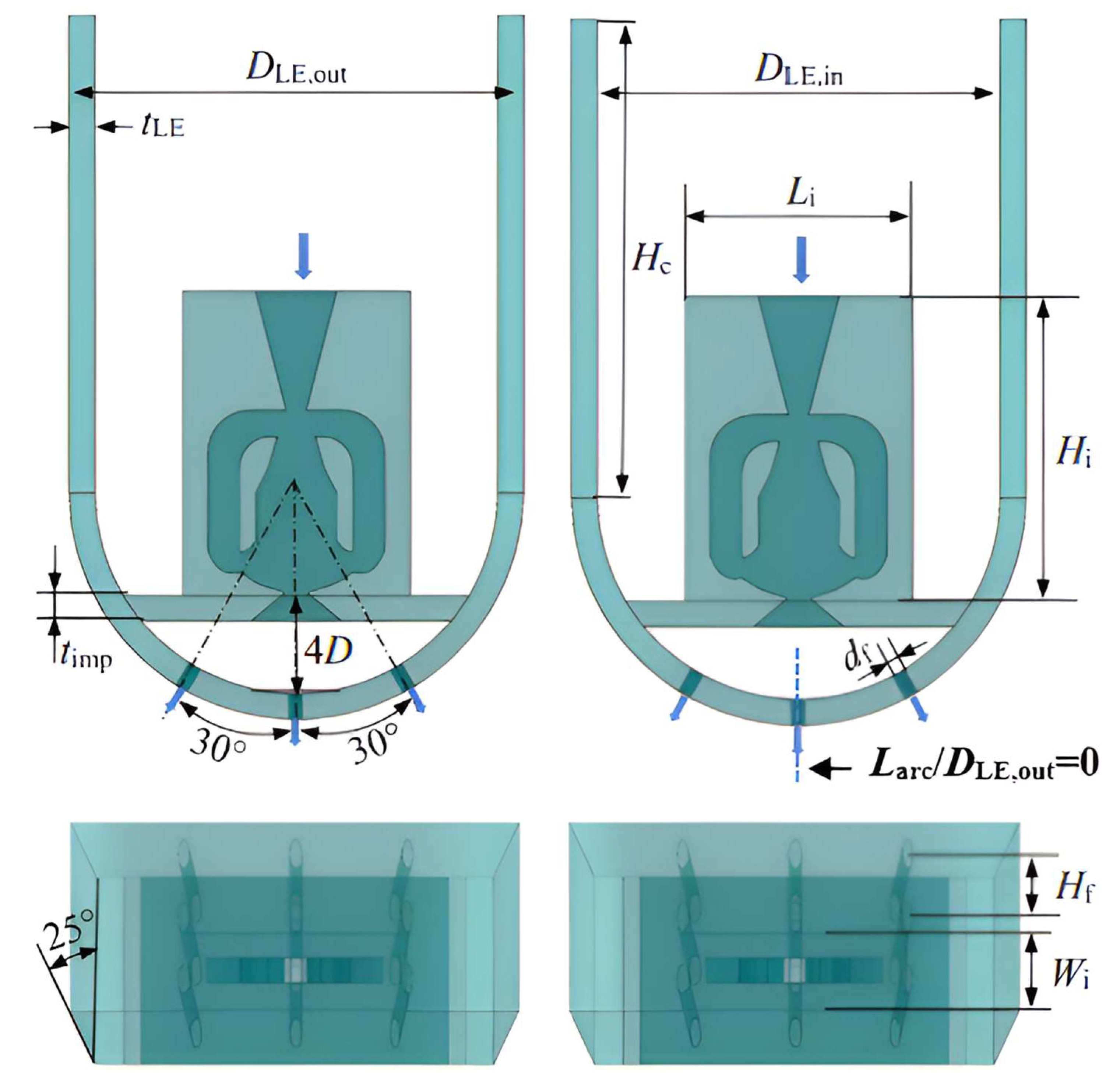

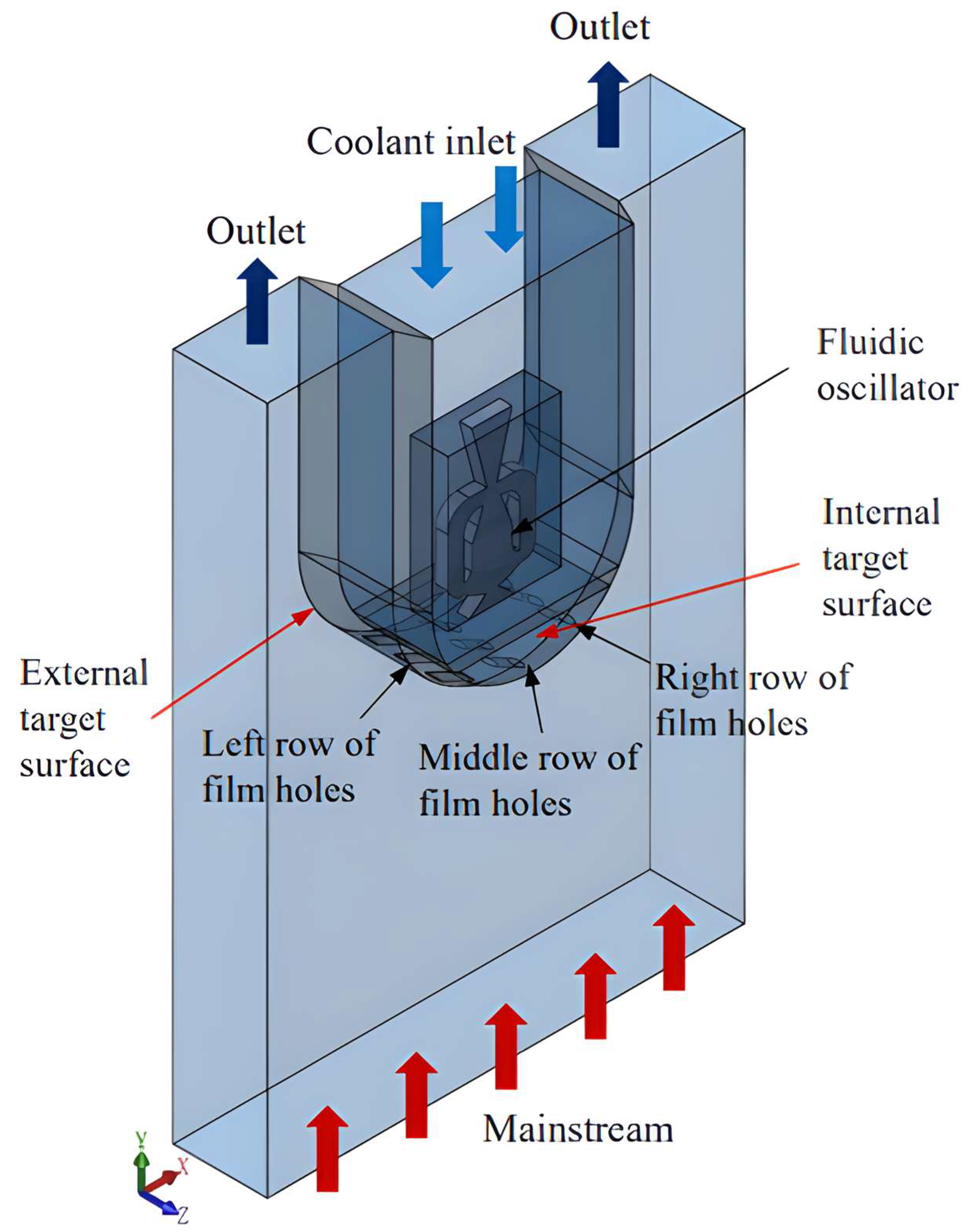

2.1. Physical Model of the SJF

2.2. Governing Equations

2.3. Boundary Conditions

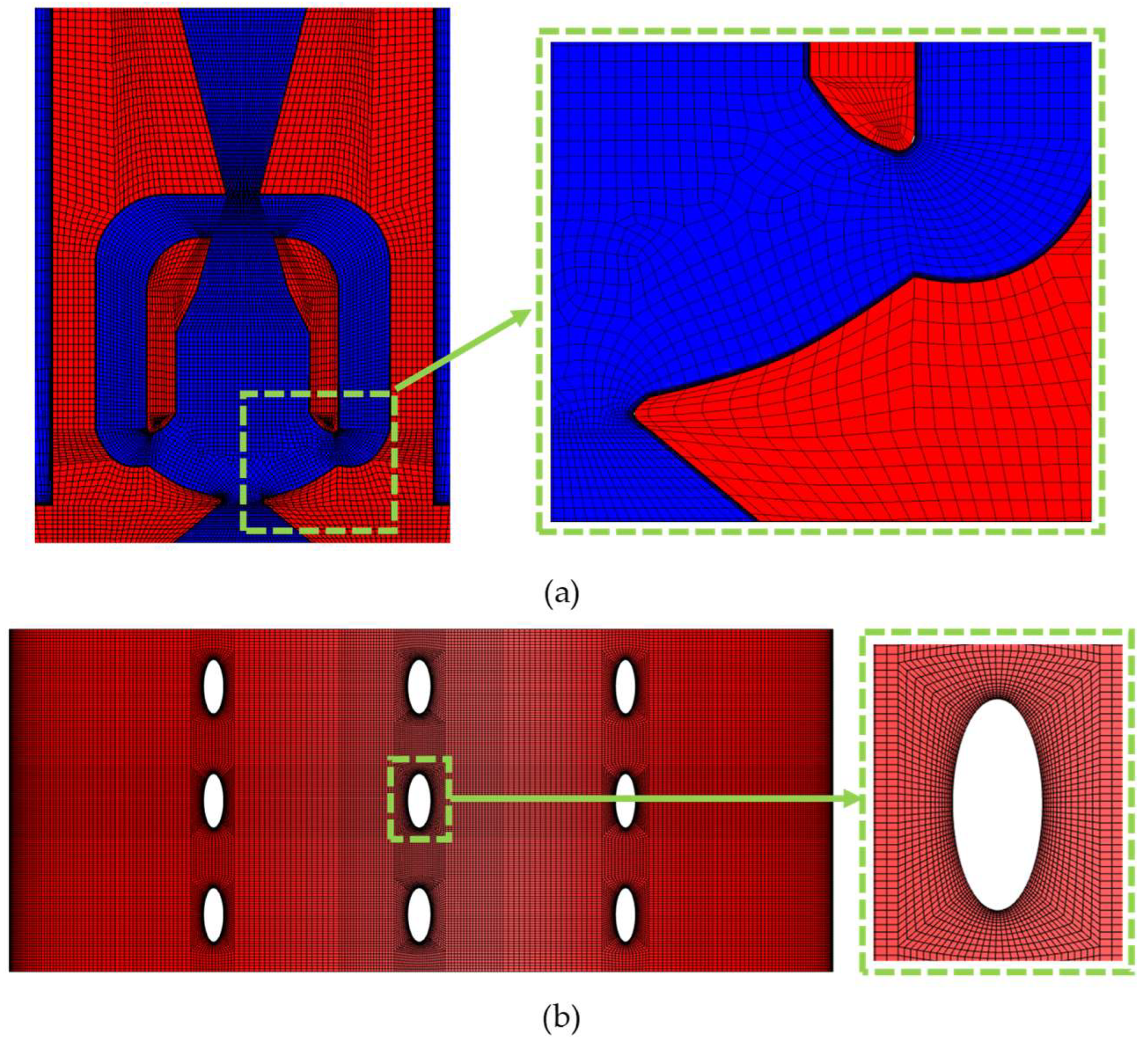

2.4. Grid and Independence Test

2.5. Parameter Definition

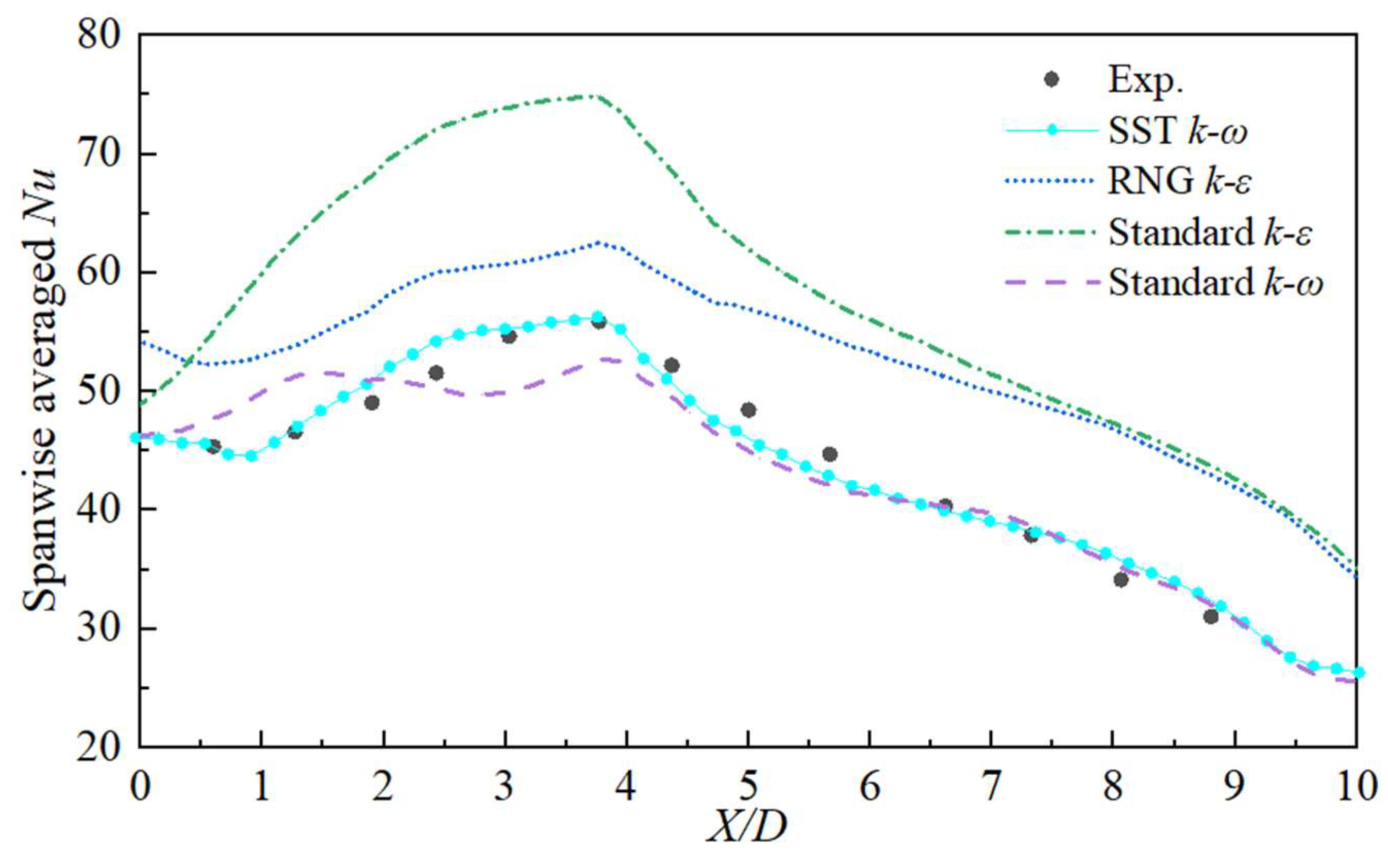

2.6. Turbulence Model Validation

3. Results

3.1. Aerodynamic Characteristics

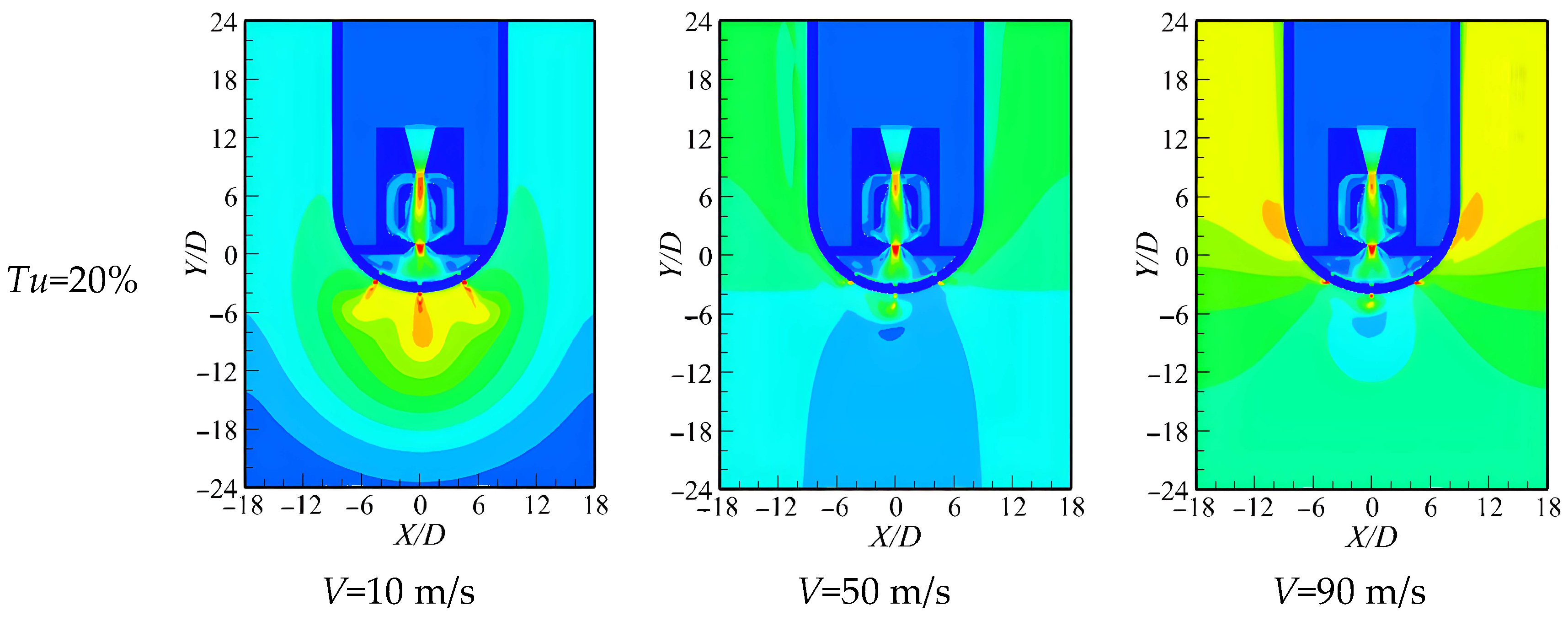

3.1.1. Velocity Contours of XY Section

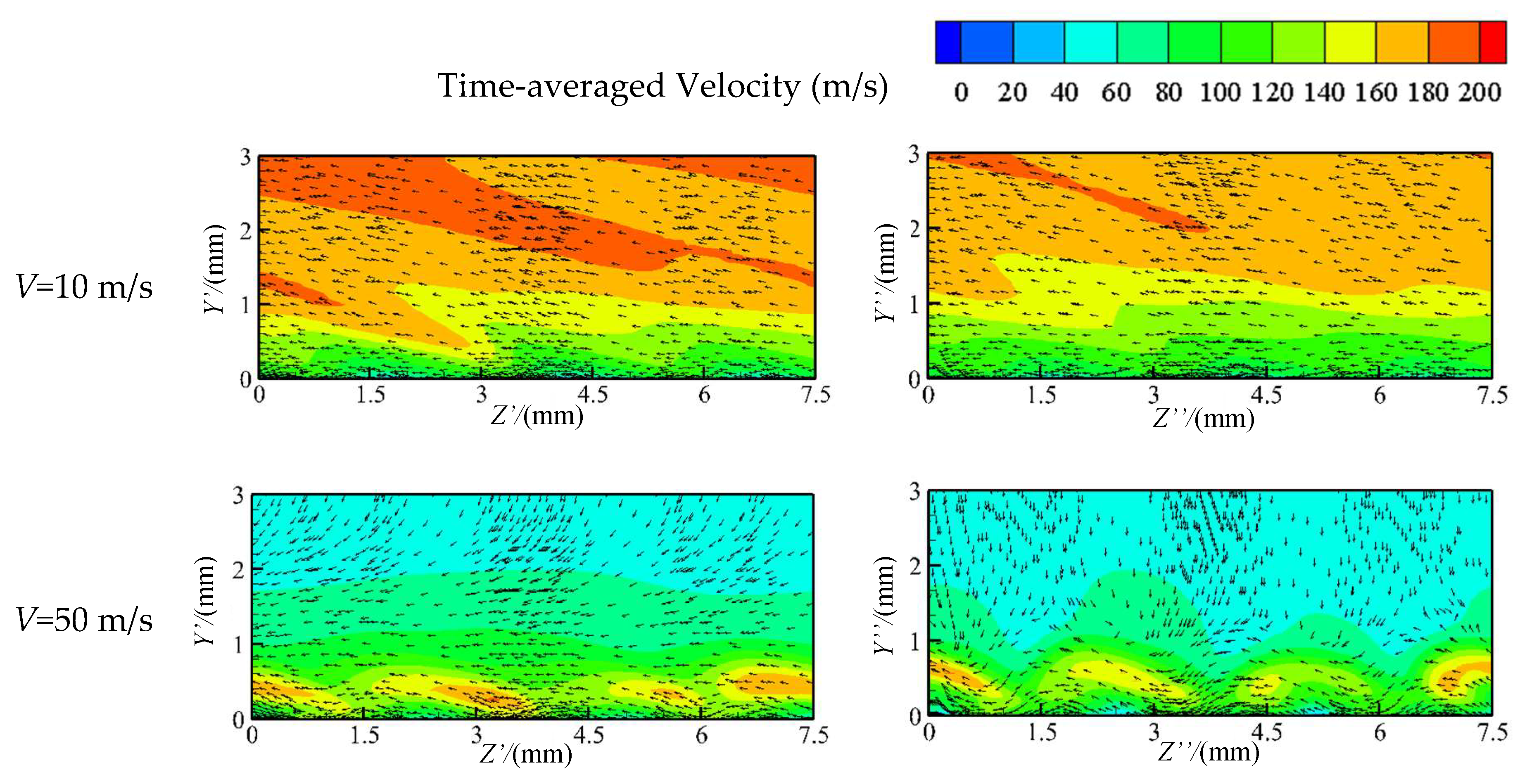

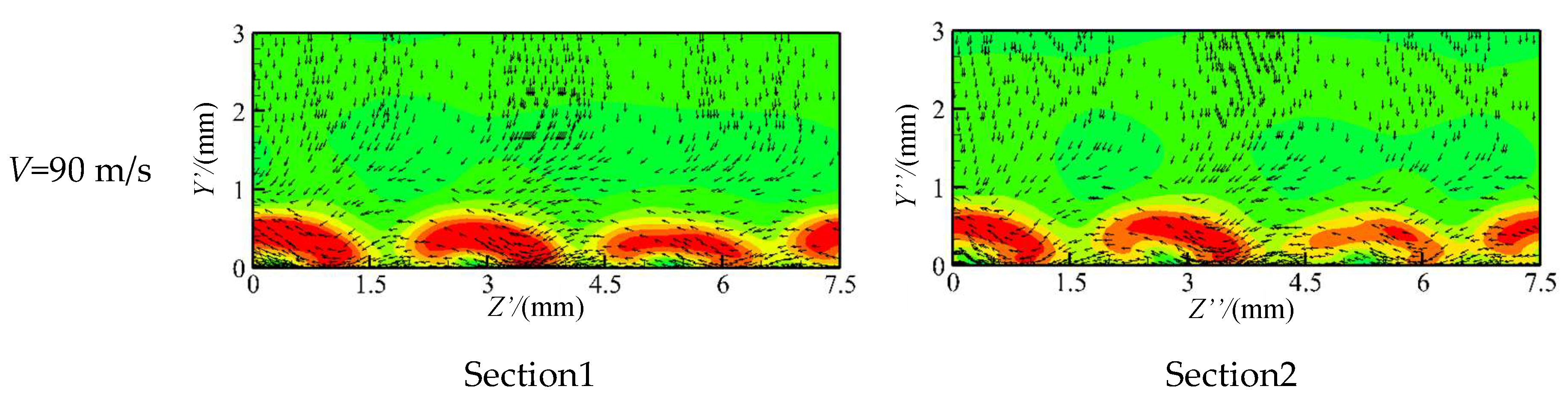

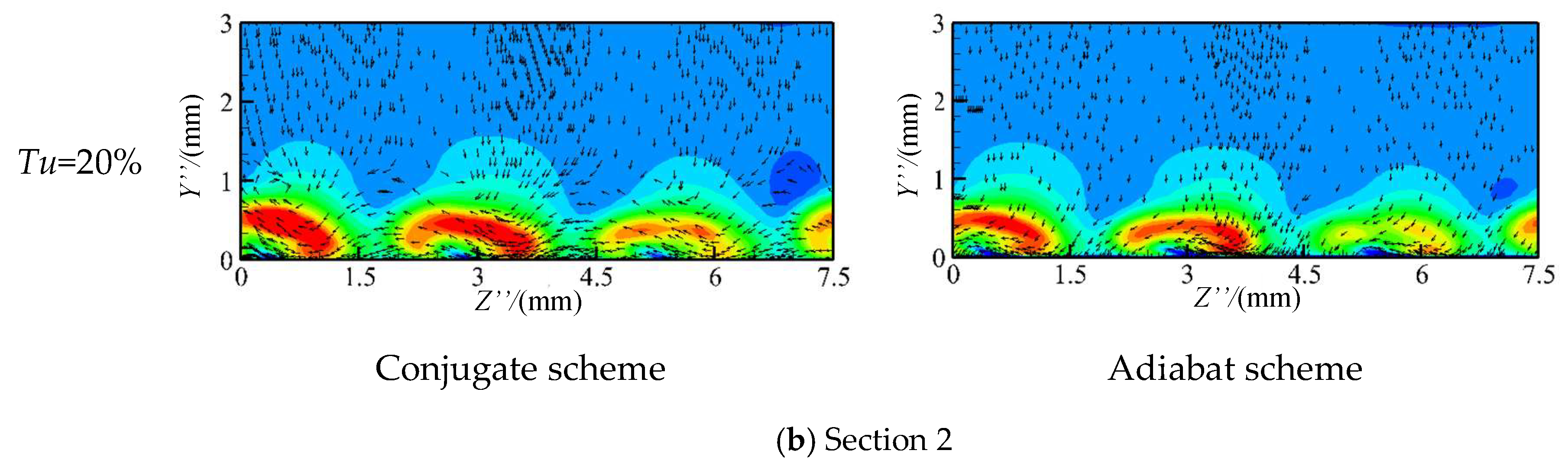

3.1.2. Flow Structure of Downstream of Left and Right Side Film Holes

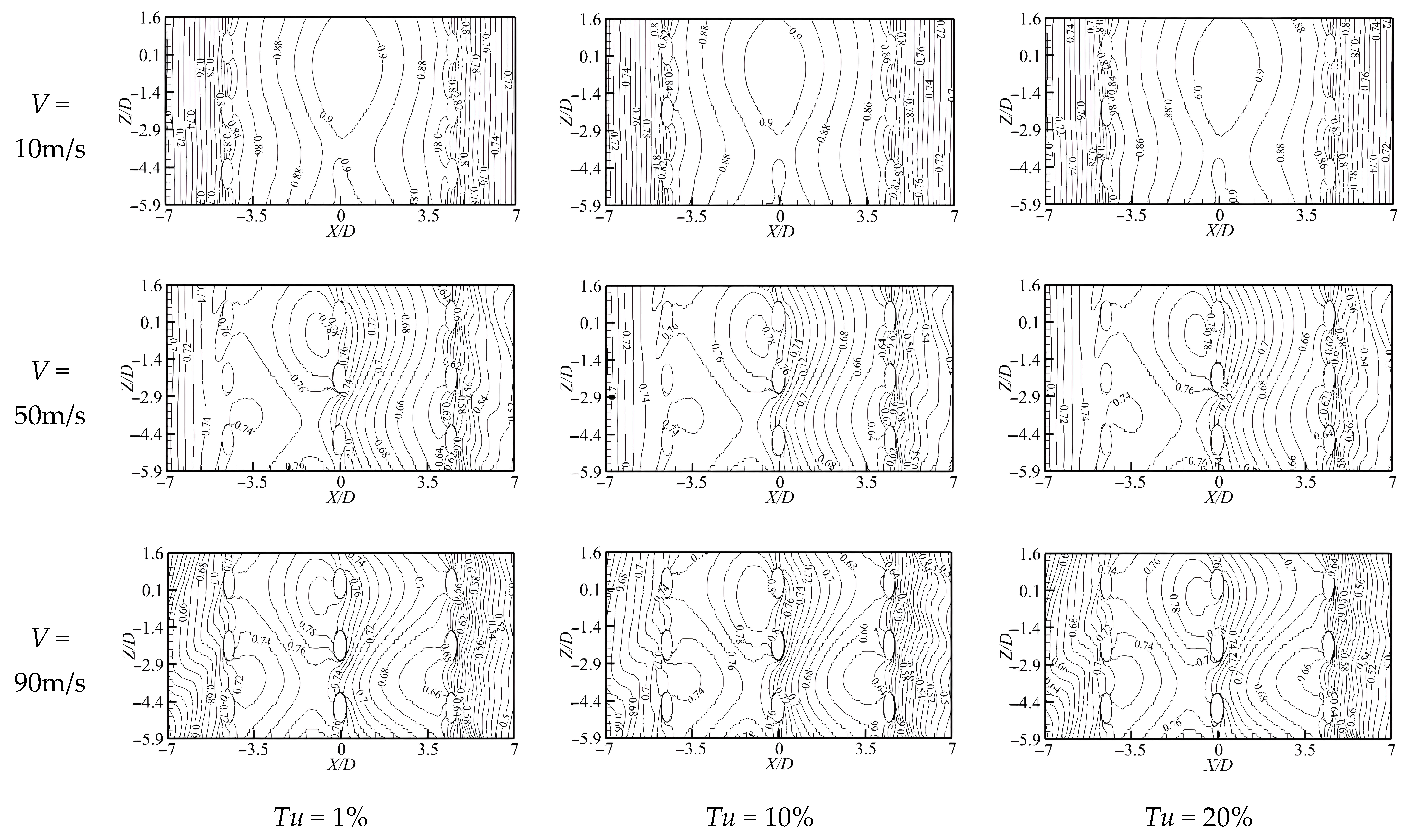

3.1.3. Total Pressure Loss Coefficient

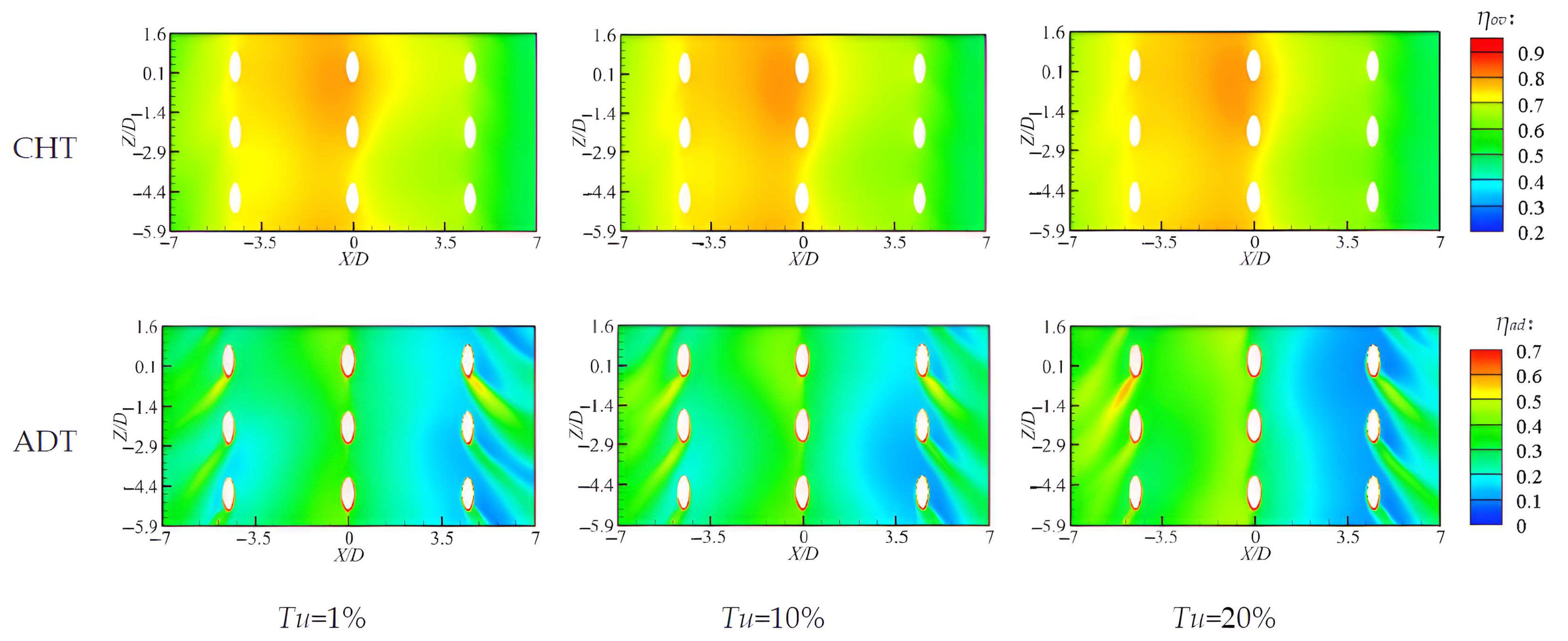

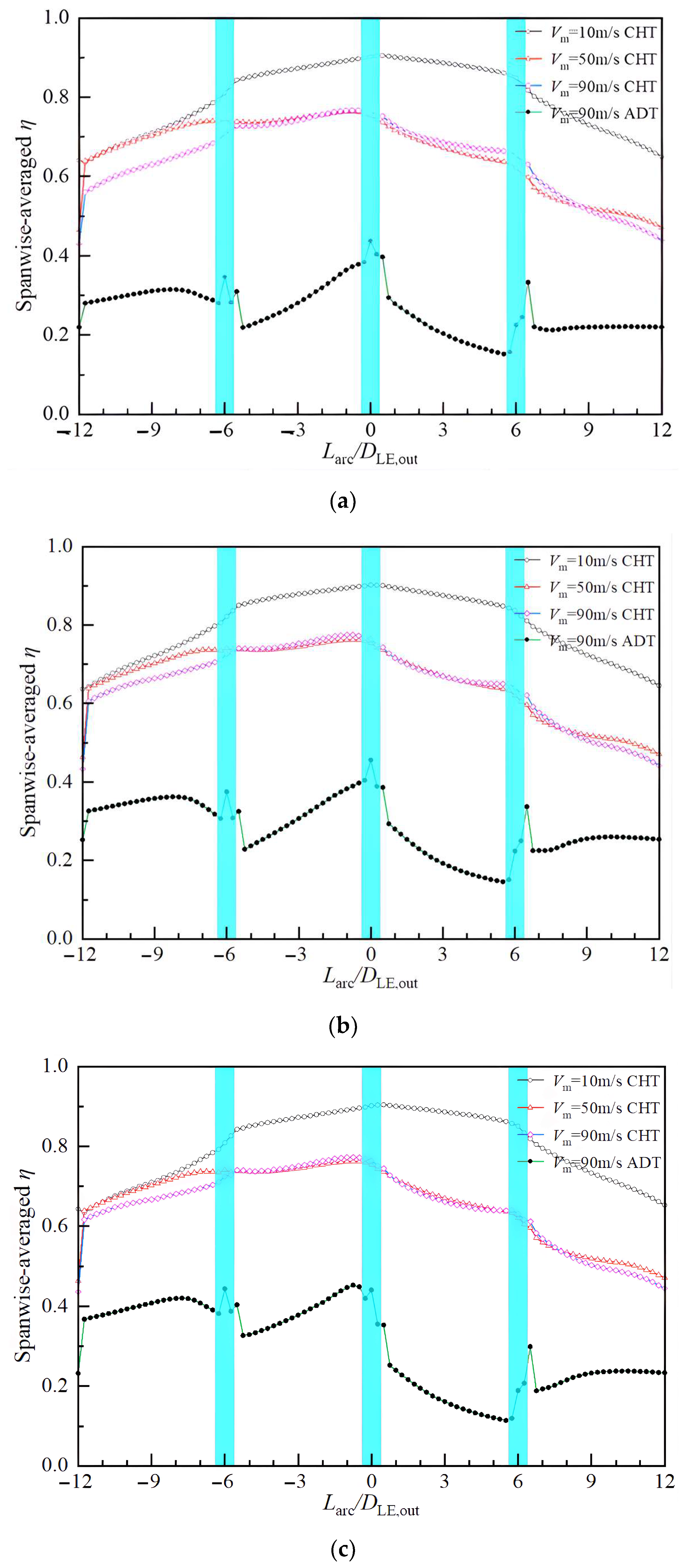

3.2. Heat Transfer Performance

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| ADT | Adiabatic scheme |

| CHT | Conjugate heat transfer scheme |

| Cp | Total pressure loss coefficient |

| df | Diameter of film hole, (mm) |

| D | Hydraulic diameter of the fluidic oscillator throat, (mm) |

| DLE,in | Internal diameter of semi-cylinder, (mm) |

| DLE,out | Outer diameter of semi-cylinder, (mm) |

| f | Sweep frequency, (HZ) |

| H | Nozzle-to-plate spacing, (mm) |

| Hc | Height of semi-cylinder, (mm) |

| Hf | Distance of film holes, (mm) |

| Hi | Height of the fluidic oscillator, (mm) |

| Larc | Length along semi-cylinder, (mm) |

| Li | Length of the fluidic oscillator, (mm) |

| MFH | Middle film holes |

| OCE | Overall cooling effectiveness |

| SJF | Sweeping jet and film composite cooling |

| timp | Height of impingement plate, (mm) |

| Tu | Turbulence intensity, (%) |

| Vm | Mainstream velocity, (m/s) |

| Wi | Weight of the fluidic oscillator, (mm) |

| X | Component X in global coordinate system, (mm) |

| Y | Component Y in global coordinate system, (mm) |

| Y′ | Component Y in local coordinate system, (mm) |

| Y+ | Non-dimensional distance = y·uτ/υ |

| Z | Component Z in global coordinate system, (mm) |

| Z′ | Component Z in local coordinate system, (mm) |

| ηov | Overall cooling effectiveness |

| ηad | Adiabat film cooling effectiveness |

| Φ | Phase angle, which represents a certain position of the sweeping jet in the whole sweep period, (°) |

References

- Zhang, M.; Wang, N.; Han, J.-C. Overall effectiveness of film-cooled leading edge model with normal and tangential impinging jets. Int. J. Heat Mass Transf. 2019, 139, 577–587. [Google Scholar] [CrossRef]

- Wang, J.; Li, L.; Li, J.; Wu, F.; Du, C. Numerical investigation on flow and heat transfer characteristics of vortex cooling in an actual film-cooled leading edge. Appl. Therm. Eng. 2021, 185, 115942. [Google Scholar] [CrossRef]

- Pourmahmoud, N.; Zadeh, A.; Moutaby, O.; Bramo, A. CFD analysis of helical nozzles effects on the energy separation in a vortex tube. Therm. Sci. 2013, 16, 151–166. [Google Scholar] [CrossRef]

- Stouffer, R.D. Oscillating spray device. U.S. Patent US4151955A, 1 May 1979. [Google Scholar]

- Cerretelli, C.; Kirtley, K. Boundary Layer Separation Control With Fluidic Oscillators. J. Turbomach. 2009, 131, 041001. [Google Scholar] [CrossRef]

- Raman, G.; Raghu, S. Miniature fluidic oscillators for flow and noise control-Transitioning from macro to micro fluidics. In Fluids 2000 Conference and Exhibit; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2000. [Google Scholar]

- Hossain, M.A.; Agricola, L.; Ameri, A.; Gregory, J.W.; Bons, J.P. Sweeping Jet Film Cooling on a Turbine Vane. J. Turbomach. 2019, 141, 031007. [Google Scholar] [CrossRef]

- Hossain, M.A.; Asar, M.E.; Gregory, J.W.; Bons, J.P. Experimental Investigation of Sweeping Jet Film Cooling in a Transonic Turbine Cascade. J. Turbomach. 2020, 142, 041009. [Google Scholar] [CrossRef]

- Hossain, M.A.; Prenter, R.; Lundgreen, R.K.; Ameri, A.; Gregory, J.W.; Bons, J.P. Experimental and Numerical Investigation of Sweeping Jet Film Cooling. J. Turbomach. 2017, 140, 031009. [Google Scholar] [CrossRef] [Green Version]

- Andrea, O.; Justin, H.; Husam, Z.; Erik, J.F.; Kapat, J.S. Impact of Sweeping Jet on Area-Averaged Impingement Heat Transfer. In Proceedings of the ASME Turbo Expo 2019: Turbomachinery Technical Conference and Exposition, Phoenix, AZ, USA, 17–21 June 2019. [Google Scholar]

- Park, T.; Kara, K.; Kim, D. Flow structure and heat transfer of a sweeping jet impinging on a flat wall. Int. J. Heat Mass Transf. 2018, 124, 920–928. [Google Scholar] [CrossRef]

- Kim, S.; Kim, H.D.; Kim, K. Measurement of two-dimensional heat transfer and flow characteristics of an impinging sweeping jet. Int. J. Heat Mass Transf. 2019, 136, 415–426. [Google Scholar] [CrossRef]

- Agricola, L.; Prenter, R.; Lundgreen, R.; Hossain, M.; Ameri, A.; Gregory, J.; Bons, J. Impinging Sweeping Jet Heat Transfer. In Proceedings of the 53rd AIAA/SAE/ASEE Joint Propulsion Conference, Atlanta, GA, USA, 10–12 July 2017. [Google Scholar]

- Hossain, M.A.; Agricola, L.; Ameri, A.; Gregory, J.W.; Bons, J.P. Effects of Exit Fan Angle on the Heat Transfer Performance of Sweeping Jet Impingement. In Proceedings of the 2018 International Energy Conversion Engineering Conference, Cincinnati, OH, USA, 9–11 July 2018. [Google Scholar]

- Kim, D.J.; Jeong, S.; Park, T.; Kim, D. Impinging sweeping jet and convective heat transfer on curved surfaces. Int. J. Heat Fluid Flow 2019, 79, 108458. [Google Scholar] [CrossRef]

- Hossain, M.A.; Agricola, L.; Ameri, A. Effects of curvature on the performance of sweeping jet impingement heat transfer. In Proceedings of the 2018 AIAA Aerospace Sciences Meeting, Kissimmee, FL, USA, 8–12 January 2018. [Google Scholar]

- Li, Y.; Liu, J.; Zhou, W.; Liu, Y.; Wen, X. Experimental investigation of flow dynamics of sweeping jets impinging upon confined concave surfaces. Int. J. Heat Mass Transf. 2019, 142, 118457. [Google Scholar] [CrossRef]

- Hossain, M.A.; Ameri, A.; Gregory, J.W.; Bons, J.P. Experimental Investigation of Innovative Cooling Schemes on an Additively Manufactured Engine Scale Turbine Nozzle Guide Vane. J. Turbomach. 2021, 143, 051004. [Google Scholar] [CrossRef]

- Pereira, O.; Rodríguez, A.; Barreiro, J.; Fernández-Abia, A.I.; de Lacalle, L.N.L. Nozzle design for combined use of MQL and cryogenic gas in machining. Int. J. Precis. Eng. Manuf. Green Technol. 2017, 4, 87–95. [Google Scholar] [CrossRef]

- Xu, K.; Wang, G.; Wang, L.; Yun, F.; Sun, W.; Wang, X.; Chen, X. CFD-Based Study of Nozzle Section Geometry Effects on the Performance of an Annular Multi-Nozzle Jet Pump. Processes 2020, 8, 133. [Google Scholar] [CrossRef] [Green Version]

- Pereira, O.; Rodríguez, A.; Calleja-Ochoa, A.; Celaya, A.; de Lacalle, L.N.L.; Fernández-Valdivielso, A.; González, H. Simulation of Cryo-cooling to Improve Super Alloys Cutting Tools. Int. J. Precis. Eng. Manuf. Green Technol. 2022, 9, 73–82. [Google Scholar] [CrossRef]

- Atmaca, M.; Çetin, B.; Ezgi, C.; Kosa, E. CFD analysis of jet flows ejected from different nozzles. Int. J. Low Carbon Technol. 2021, 16, 940–945. [Google Scholar] [CrossRef]

- Arts, T.; Lambert de Rouvroit, M. Aero-Thermal Performance of a Two-Dimensional Highly Loaded Transonic Turbine Nozzle Guide Vane: A Test Case for Inviscid and Viscous Flow Computations. J. Turbomach. 1992, 114, 147–154. [Google Scholar] [CrossRef]

- Kong, X.; Zhang, Y.; Li, G.; Lu, X.; Zhu, J.; Xu, J. Heat transfer and flow structure characteristics of film-cooled leading edge model with sweeping and normal jets. Int. Commun. Heat Mass Transf. 2022, 138, 106338. [Google Scholar] [CrossRef]

- Ismail, B.C.; Urmila, G.; Patrick, J.R.; Christopher, J.F.; Hugh, C.; Raad, P.E. Procedure for Estimation and Reporting of Uncertainty Due to Discretization in CFD Applications. J. Fluids Eng. 2008, 130, 078001. [Google Scholar]

- Liu, J.; Lin, X.; Zhang, X.; An, B. Investigation on cooling effectiveness and aerodynamic loss of a turbine cascade with film cooling. J. Therm. Sci. 2016, 25, 50–59. [Google Scholar] [CrossRef]

- Zhou, W.; Deng, Q.; He, W.; He, J.; Feng, Z. Conjugate heat transfer analysis for composite cooling structure using a decoupled method. Int. J. Heat Mass Transf. 2020, 149, 119200. [Google Scholar] [CrossRef]

- Liu, Z.; Ye, L.; Wang, C.; Feng, Z. Numerical simulation on impingement and film composite cooling of blade leading edge model for gas turbine. Appl. Therm. Eng. 2014, 73, 1432–1443. [Google Scholar] [CrossRef]

| Dimension (mm) | D | df | DLE,in | DLE,out | tLE | timp | Hi | Li | Wi | Hc | Hf |

|---|---|---|---|---|---|---|---|---|---|---|---|

| Value | 1.0 | 0.5 | 7.0 | 9.0 | 1.0 | 1.0 | 12.1 | 9.0 | 3.0 | 19.0 | 2.5 |

| Total temperature of mainstream inlet, Tm/(K) | 600 |

| Velocity of Mainstream inlet, Vin,m/(m/s) | 10, 50, 90 |

| Static pressure of outlet, Pout/(Pa) | 101,325 |

| Total temperature of coolant inlet, Tc/(K) | 300 |

| Total pressure of coolant inlet, Pt,c/(Pa) | 3.4 × 105 |

| Mainstream inlet turbulence, Tuin,m/(%) | 1, 10, 20 |

| Coolant inlet turbulence, Tuin,m/(%) | 5 |

| Element Number (Million) | Cp | Relative Error | ηov |

|---|---|---|---|

| 6.78 | 3.59 | 1.508% | 0.673 |

| 9.48 | 3.55 | 0.377% | 0.689 |

| 11.43 | 3.54 | 0.094% | 0.691 |

| Extrapolation | 3.53 | - | 0.692 |

| Models | f/Hz |

|---|---|

| Exp. [16] | 310 |

| SST k-ω | 315 |

| Standard k-ω | 353 |

| RNG k-ε | 270 |

| Standard k-ε | 254 |

| Tu = 1% | Tu = 10% | Tu = 20% | |||||||

|---|---|---|---|---|---|---|---|---|---|

| V = 10 m/s | V = 50 m/s | V = 90 m/s | V = 10 m/s | V = 50 m/s | V = 90 m/s | V = 10 m/s | V = 50 m/s | V = 90 m/s | |

| mm (g/s) | 1.6815 | 8.6017 | 16.6307 | 1.6806 | 8.6056 | 16.6218 | 1.6795 | 8.6027 | 16.7092 |

| Pt,m,in (MPa) | 1.0164 | 1.0455 | 1.1130 | 1.0166 | 1.0458 | 1.1446 | 1.0164 | 1.0458 | 1.1081 |

| Pt,c,in (MPa) | 3.6408 | 2.7622 | 3.6581 | 3.6561 | 2.8064 | 3.6538 | 3.6390 | 2.8064 | 3.6447 |

| Cp | 204.68 | 3.55 | 0.89 | 245.77 | 3.59 | 0.73 | 321.41 | 3.63 | 0.83 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kong, X.; Zhang, Y.; Li, G.; Lu, X.; Zhu, J.; Xu, J. Effects of Mainstream Velocity and Turbulence Intensity on the Sweeping Jet and Film Composite Cooling. Machines 2023, 11, 356. https://doi.org/10.3390/machines11030356

Kong X, Zhang Y, Li G, Lu X, Zhu J, Xu J. Effects of Mainstream Velocity and Turbulence Intensity on the Sweeping Jet and Film Composite Cooling. Machines. 2023; 11(3):356. https://doi.org/10.3390/machines11030356

Chicago/Turabian StyleKong, Xiangcan, Yanfeng Zhang, Guoqing Li, Xingen Lu, Junqiang Zhu, and Jinliang Xu. 2023. "Effects of Mainstream Velocity and Turbulence Intensity on the Sweeping Jet and Film Composite Cooling" Machines 11, no. 3: 356. https://doi.org/10.3390/machines11030356

APA StyleKong, X., Zhang, Y., Li, G., Lu, X., Zhu, J., & Xu, J. (2023). Effects of Mainstream Velocity and Turbulence Intensity on the Sweeping Jet and Film Composite Cooling. Machines, 11(3), 356. https://doi.org/10.3390/machines11030356